- Experimental investigation and analysis of performance enhancement with improved condensate area in a modified single slope solar still

A. Gowrishankara,* and P.S.S. Srinivasanb

aDepartment of Mechanical Engineering, Mahendra Institute of Technology, Namakkal, India

bDepartment of Mechanical Engineering, Knowledge Institute of Technology, Salem, IndiaThis article is an open access article distributed under the terms of the Creative Commons Attribution Non-Commercial License (http://creativecommons.org/licenses/by-nc/4.0) which permits unrestricted non-commercial use, distribution, and reproduction in any medium, provided the original work is properly cited.

An experimental investigation and performance enhancement of modified single slope solar still has been conducted to study the effect variable sizes of external condensing units. The external condensing units are fabricated manually and attached to the two vertical (inclined) sides of the still. Experiments have been conducted for a period five days with five different condenser areas and compared with a conventional ceramic solar still. With the increase in external condenser area, distillate yield is found to increase. By providing 26% additional condensing area over the conventional solar still, the relative increase in daily average thermal efficiency of 58% is observed. The additional cost of adding an external condenser is 10%, whereas the addition of distillate yield is 58%, thus reducing the cost of distillate yield significantly.

Keywords: Solar still, Efficiency enhancement, Modified solar still, Thermal efficiency.

Clean drinking water requirements are keeps on increasing, and the production of clean water in an environmentally friendly way is a major challenge [1]. Use of single slope solar still is one of the best options for this purpose and it is simple, easy to fabricate and operate. However, the overall thermal efficiency of such solar stills are low [2, 3] and various studies have been carried out over past decades. The major parameters that affect the performance of single slope solar still and studies related to them are discussed by several researchers. Among the parameter studied, location, incident solar radiation levels, water depth, glass cover inclination are found to have significant effect on the performance of the still. Modifications like adding external condenser are found to have better effect on the solar still performance.

Numerous modifications have been carried out from the conventional single slope solar still and are reviewed [3, 4]. Among the various modifications, additions of external condenser are found to have considerable effect. External condenser with vacuum fan has been studied [5, 6]. It is observed that with these modifications, there is an increase in daily average efficiency of 5-30% [7, 8]. The higher side wall of the still is modified to accommodate external condensing surface [9, 10]. About 20% increase in efficiency is observed and it is indicated that addition of external condenser can have both positive as well as negative impact depending upon the external weather conditions [11]. The external water-cooled condenser is also used and reported that the daily average efficiency with condenser is 30% while that of the conventional solar still is 22%. A numerical and experimental study of solar still with integrated external condenser is studied and reported that increase in distillate yield of 40% is possible with such natural convection loop external condenser [12]. It is observed that use of external condenser can improve solar still performance. However, their impacts are not studied systematically. In the present work, a simple external condenser is considered, and its impact is studied experimentally. Production of clean water is highly important and it is produced by the solar stills. The solar still efficiency is improved by increased solar radiation, increased wind speed, decreased water depth, decreased ambient air temperature and improved geometric dimensions of the solar still. The effects of ceramic coated CI engine using bio-diesel bends with respect to the thermal efficiency and combustion characteristics are studied [13, 14].

Geometric details

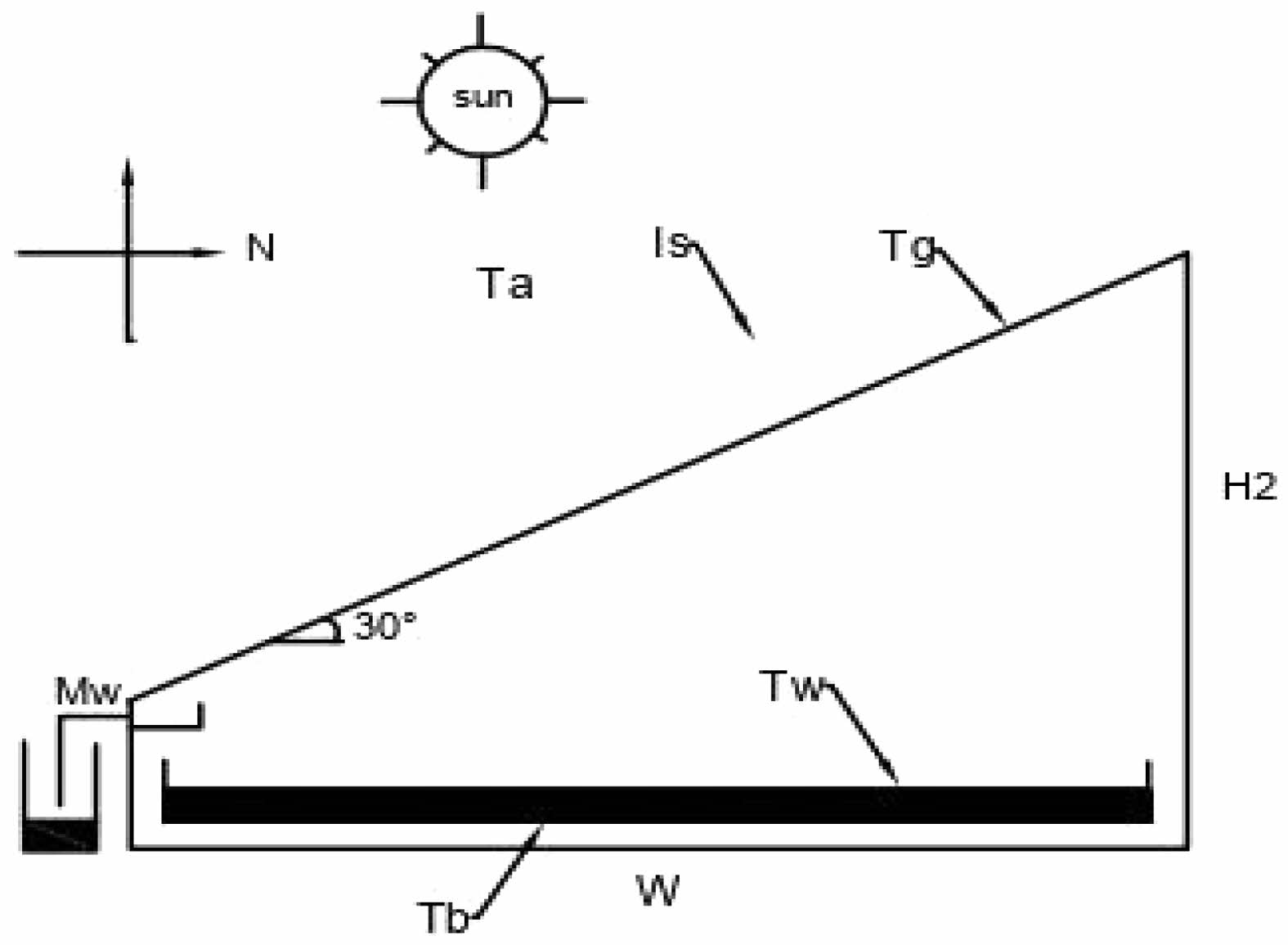

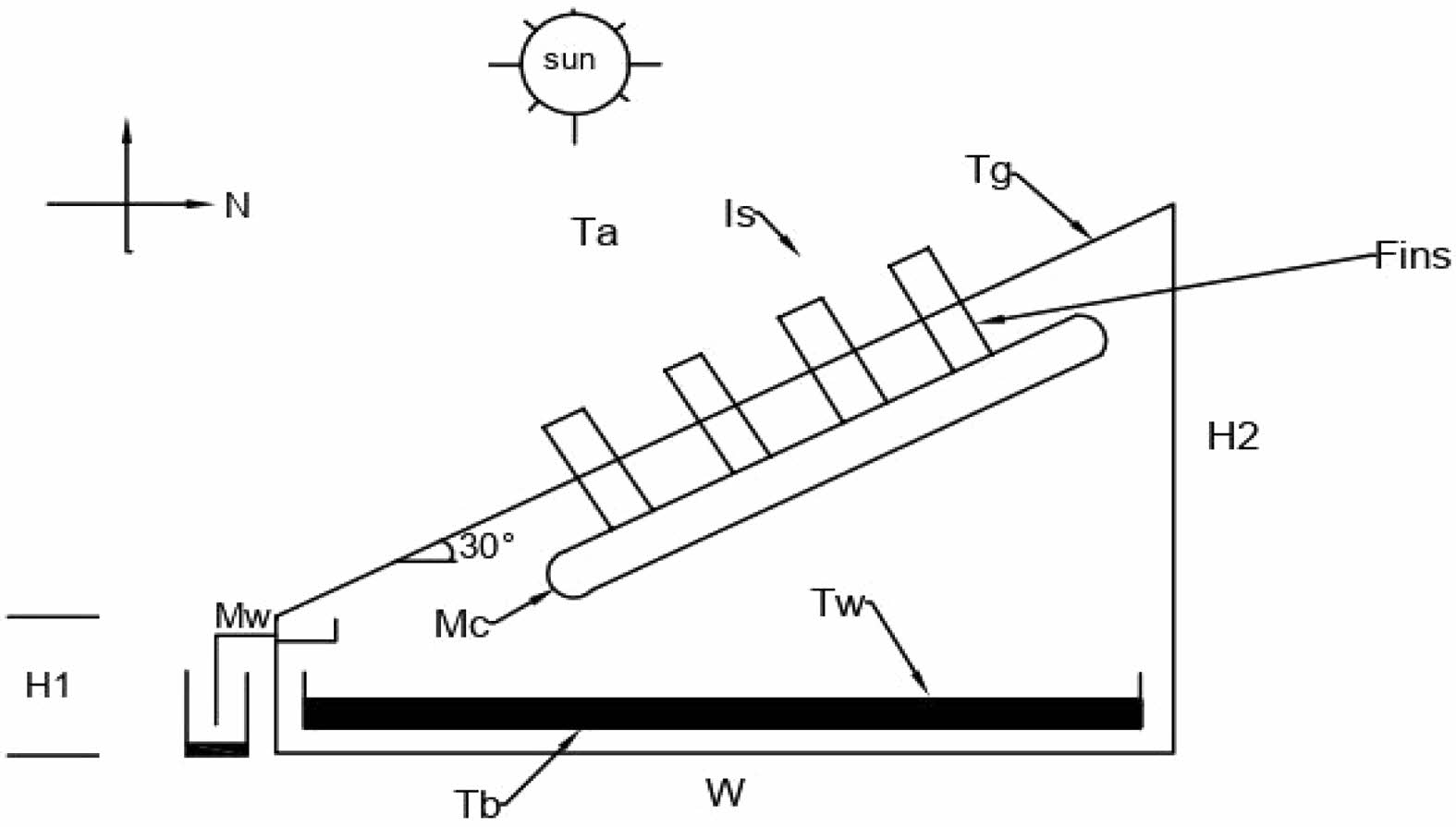

A conventional single slope solar still, is taken for investigation in this work. The line diagram of the conventional solar still and modified solar still are shown in Fig. 1. External condensers are added on both sides of the conventional solar still to get the modified solar still (MSS) as shown in Fig. 2. The line diagram of the modified solar still are shown in Fig. 3. When the external condenser is removed and the passages are blocked by dummy caps, the MSS becomes a conventional solar still (CSS). Ceramic coatings are done on the galvanized iron sheet to have a chemically bonded ceramic surface to improve durability and life of the still. Ceramic coating can create visually appealing color options to blend power and light fixtures into the environment. They are more stable and provide chemically bonded ceramic surface, that is durable and non-toxic. Solar stills are used to create fresh water from an impure water. Some of the applications of the solar stills are; Desalination, Groundwater purification, waste water treatment, life raft emergency kits and so on.

The dimensions of the conventional solar still basin is 1 m in length and 1 m in width in the upper side and the 0.1 m width in the lower side basin (H1) and slope of the glass is 30° with respect to the horizontal. Galvanized Iron sheet of 2 mm thickness is used to fabricate the still bottom and four vertical sides. During the experiments, a water depth of 4 cm is maintained in all the experiments. The effective height for water vapor to travel becomes 6 cm on the lower side and 54 cm on the higher side of the basin. Thus the effective height is 30 cm. The inner side of the basin is painted with dull black paint to have higher absorptivity. To reduce the heat loss from the bottom and four vertical sides, 25 mm thick thermocol insulation is used and Plywood of 6 mm thick is used over the insulation to fabricate the still. Condensing glass cover of 5 cm thickness is used. The vapour zone is made air tight using gaskets and silicone gel paste. The solar still is oriented due south, installed at roof top of the building.

Two side holes in the still and piping arraignment are made to attach the external condenser on both the side of the still. The condenser pipe is made of ceramic coated Galvanized Iron, with inner diameter of 25 mm and 2 mm wall thickness. The condenser has a main pipe of length 57 cm. On the main pipe, four auxiliary pipes of 25 mm inner diameter are vertically arranged. The surface area of the condenser is varied by varying the length of the four auxiliary pipes. The heights used are 5 cm (MSS1), 10 cm (MSS2), 15 cm (MSS3), 22.5 cm (MSS4), and 30 cm (MSS5). This arrangement is used on both the sides of the still. The surface area of the main pipes is 0.0455 m2. The total surface area of the external condenser is the sum of the surface area of two main pipes, and eight vertical auxiliary pipes. The total condensing area of MSS is sum of surface area of the main still (1 m2) and total surface area of external condenser. The total condensing area of CSS, MSS1, MSS2, MSS3, MSS4 and MSS5 are 1 m2, 1.16 m2, 1.19 m2, 1.22 m2, 1.27 m2, and 1.32 m2 respectively.

Operation of solar still

The incident solar radiation passes through the glass cover, air-water vapour mixture, water and finally falls on the absorber plate. The absorber plate absorbs the radiant heat energy and gets heated up. This heat is transferred to water by natural convention heat transfer. A negligible portion leaks through the bottom and sides by heat conduction across the walls. Due to the temperature difference between water surface (Tw) and glass cover (Tg), a natural convection heat transfer loop sets in. As Tw > Tg, due to the partial pressure difference of water vapour (Pw – Pg), water evaporates at the water surface and move towards glass cover through existing natural convection loop. As the atmospheric temperature (Ta) is lower than glass cover temperature (Tg), heat is lost from glass cover to atmosphere air by convection and radiation to the sky. This makes the water vapour to condense inside glass cover surface and condensate rolls along the inclined glass cover. The condensate is collected by the condensate collecting arrangement. In case of MSS, a portion of water vapour goes through the both of external condenser units, get condensed there. The condensate is collected at both the ends of the external condenser units.

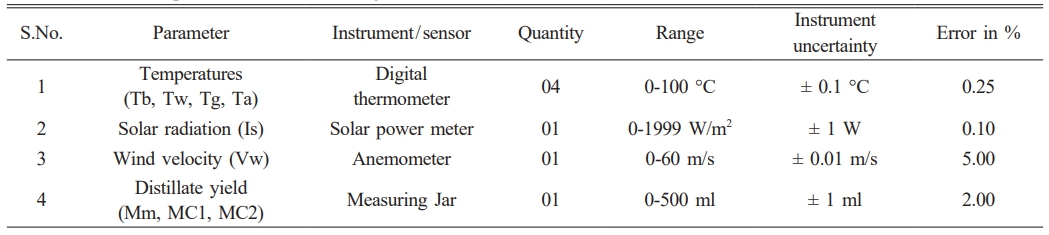

Measurement and instrumentation

The parameters measured are incident solar radiation on the top surface of the glass cover (Is, W/m2), temperature of the basin, (Tb, °C), temperature of water (Tw, °C), temperature of glass cover (Tg, °C) and atmosphere air temperature (Ta, °C), wind velocity (Vw, m/s), distillate collected at main solar still (Mm, ml/h) and at both sides of external condenser unit (MC1, ml/h and MC2, ml/h; Mc = MC1 + MC2). The measuring instruments used and their accuracy are listed in Table 1. The uncertainties in the calculated daily efficiency are calculated using procedure explained by Holman [B1] and are within ± 1%.

Experimental procedure

During all the days of experiments the saline water existing at the basin is removed and fresh saline water at 30 °C are filled at 8.00 am. The water depth of 4 cm is maintained, throughout the day by adding makeup water at each hour interval. The values of Is, Tb, Tw, Tg, Ta, Vw, Mm, MC1 and MC2 are measured at one hour interval from 08:00 hrs (08:00 am) to 18:00 hrs (6:00 pm). For each still, experiments are carried out on two clear sky days. Among the two days, one day reading are used for various calculations.

Performance of the Solar Still

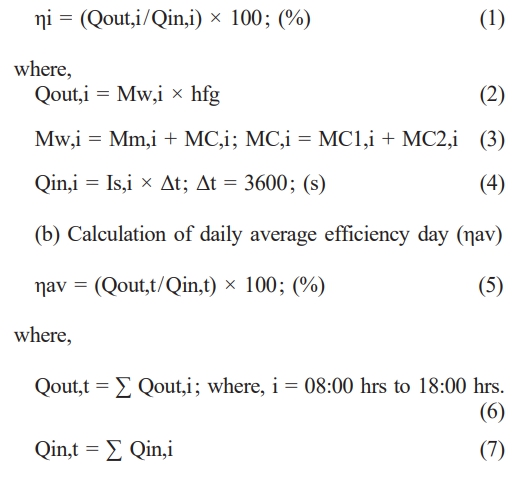

The performance is measured in terms of instantaneous thermal efficiency (ηi) over an hour and daily average thermal efficiency over the ten hours of the day (ηav), as given in Eqn. (1) and Eqn. (5).

(a) Calculation of instantaneous efficiency (ηi)

|

Fig. 1 Line diagram of the Conventional Solar Still (CSS). |

|

Fig. 2 Modified Solar Still (MSS). |

|

Fig. 3 Line diagram of the Modified Solar Still (MSS). |

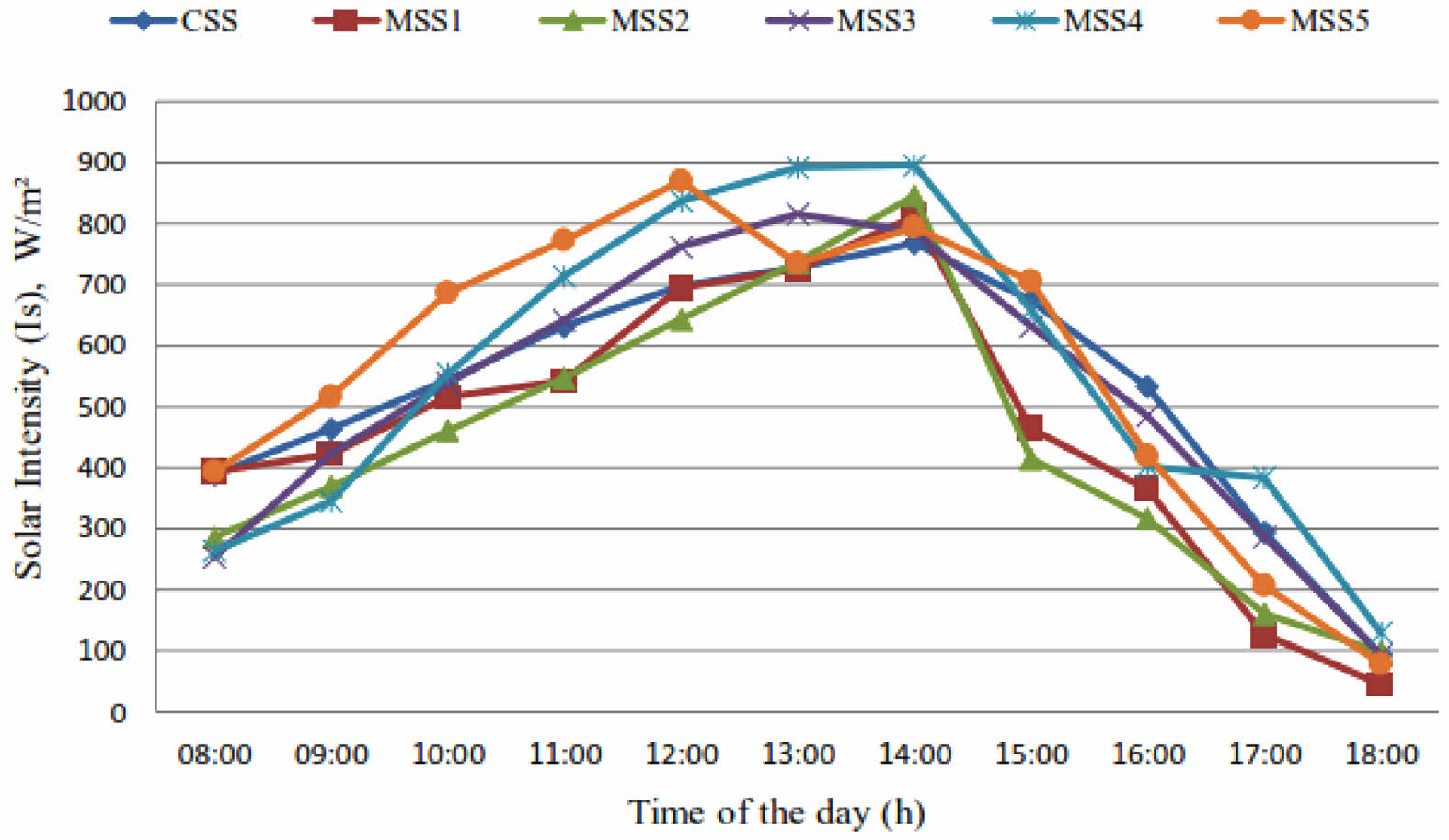

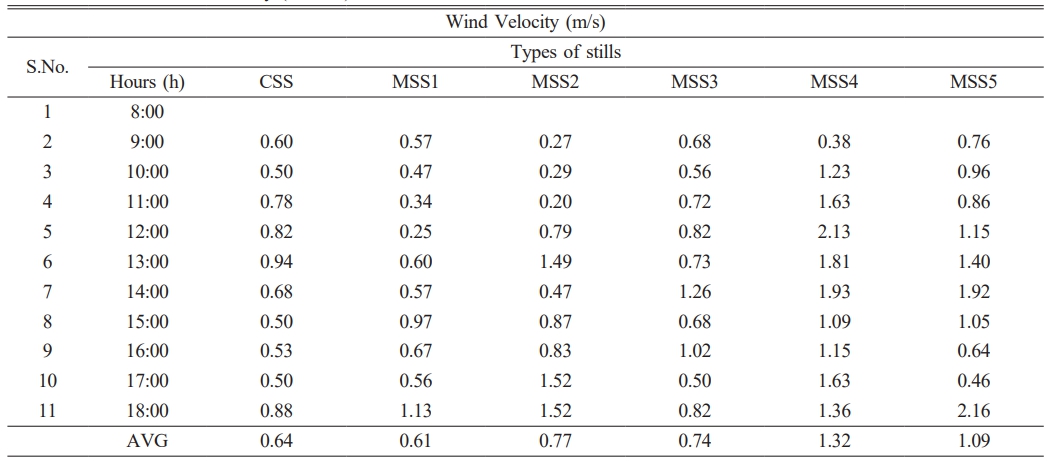

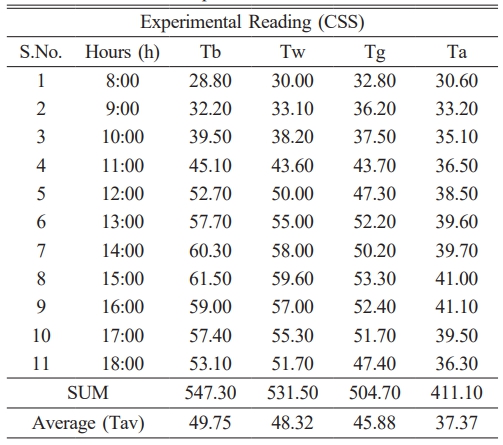

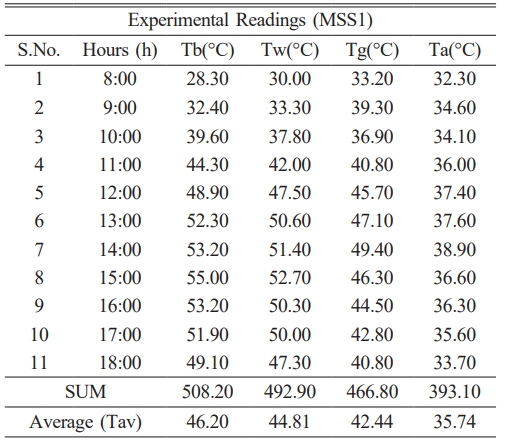

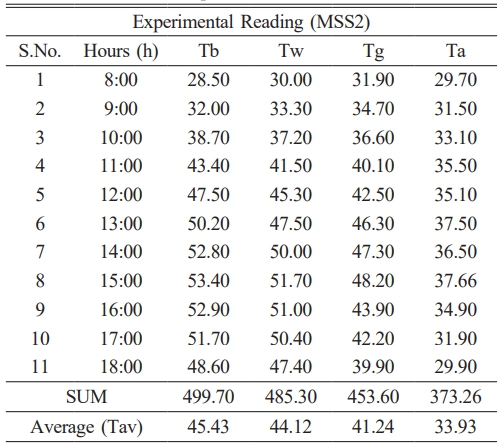

On the days of experiment, measured values of solar intensity and wind velocity are listed in Table 2 and Table 3, on hourly basis. The total radiation incidents and the average value of wind velocity over the ten hours period are calculated and presented. The Fig. 4 and Fig. 5 represents the comparison of the value of the solar intensity and wind velocity respectively. It is observed that, the solar radiation increases in the forenoon and reaches maximum around the noon and drops in the afternoon and also the wind velocity varies randomly over the day.

Variation of temperature over the day

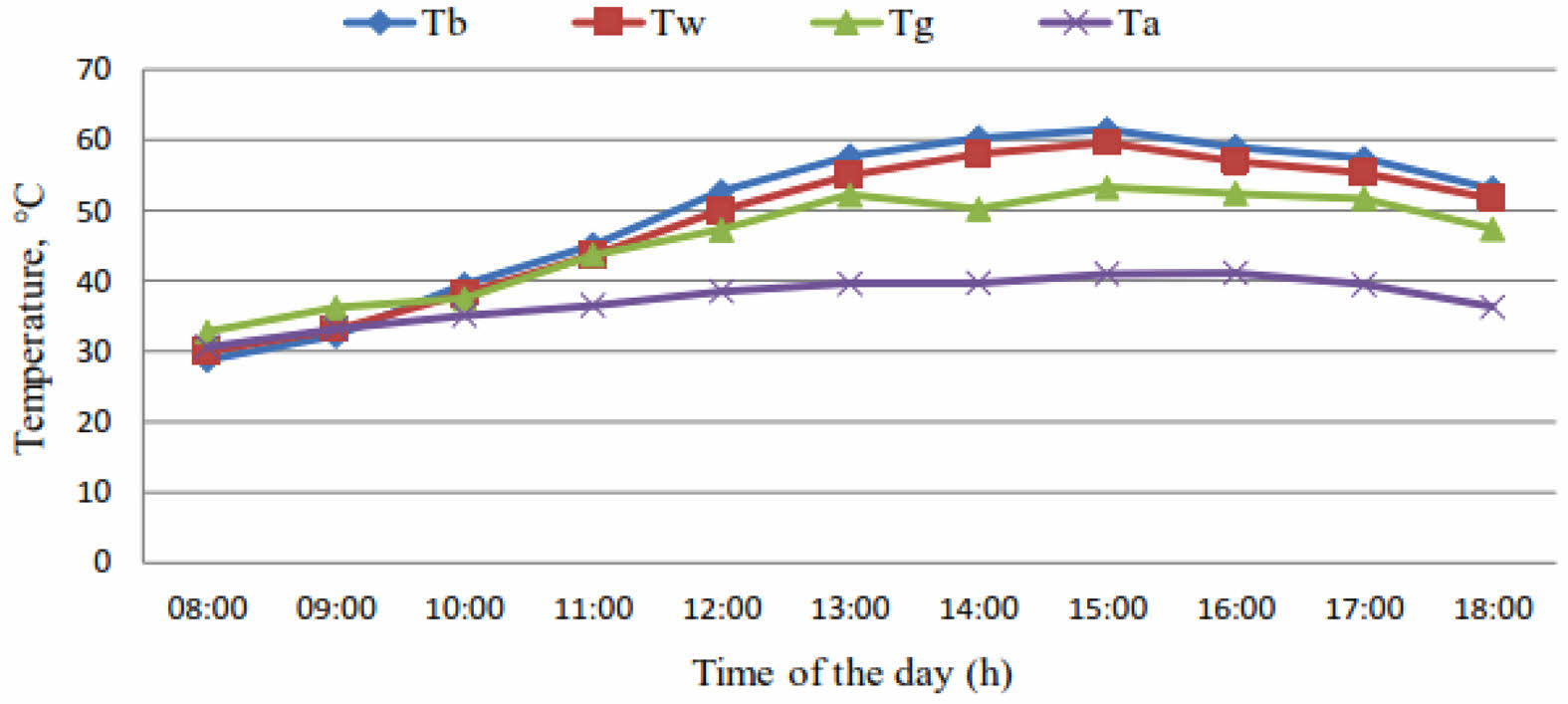

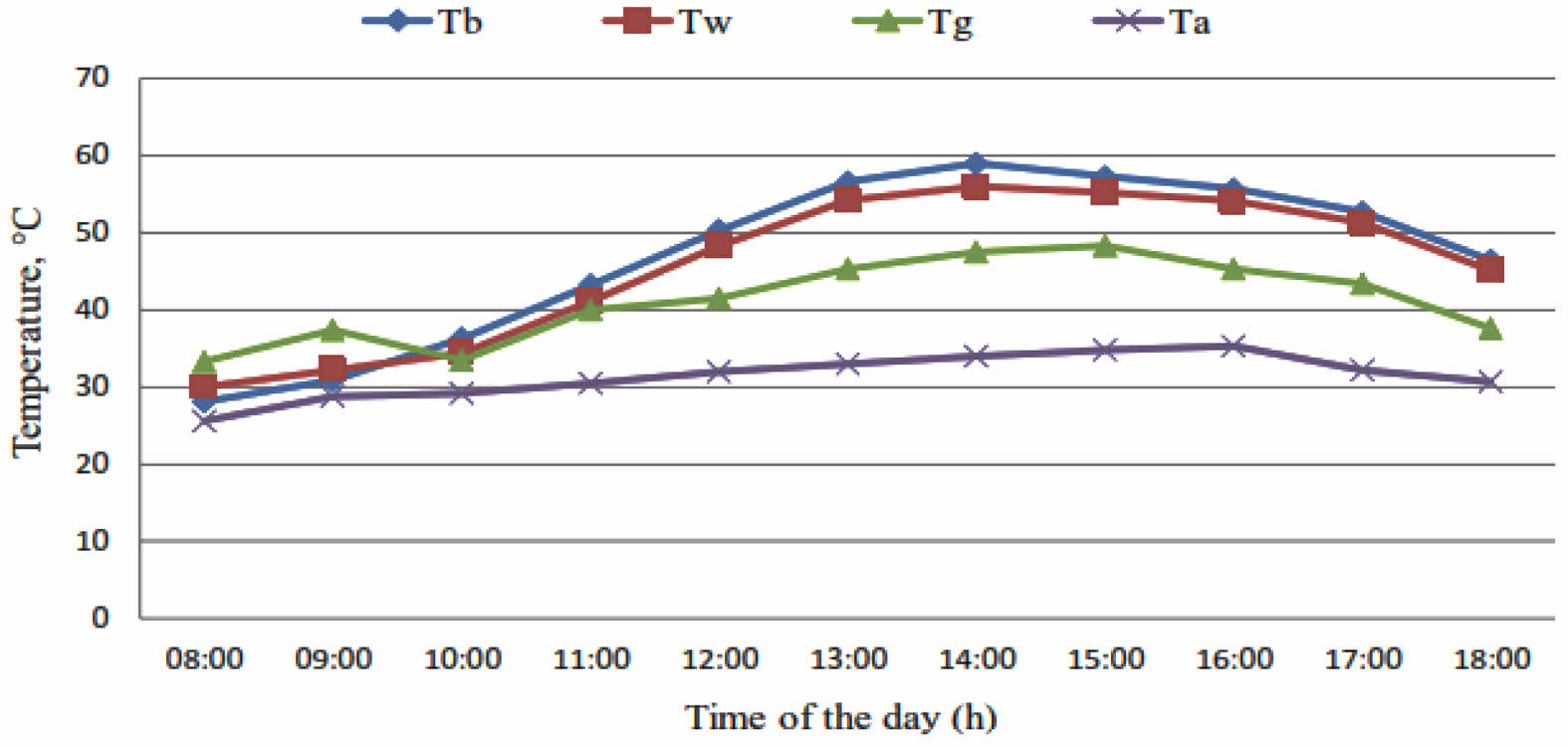

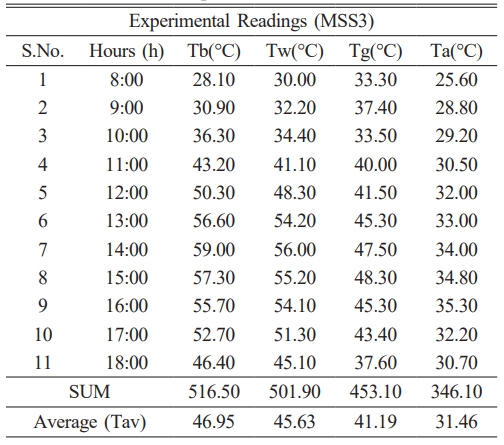

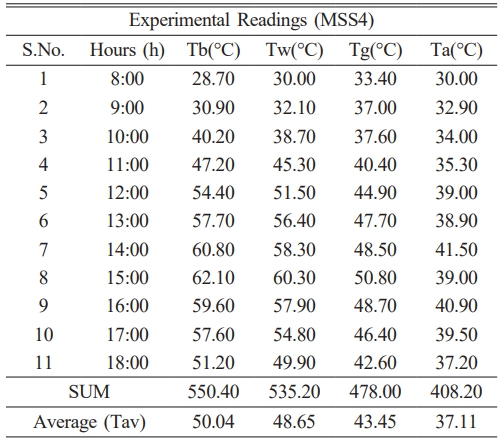

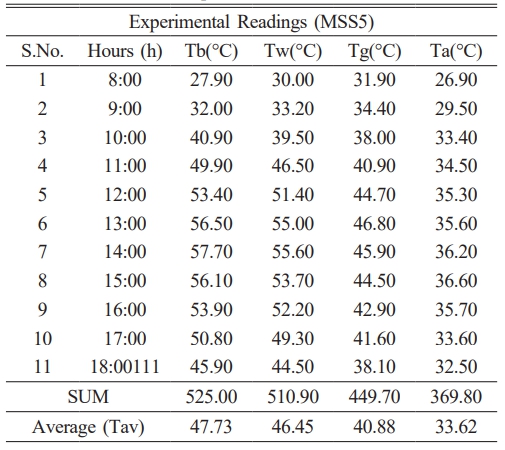

The measured temperature values for Tb, Tw, Tg, Ta are listed in the Table 4 to Table 9 for CSS, MSS1, MSS2, MSS3, MSS4 and MSS5 respectively. The daily average temperature (Tav) values, averaged over ten hours of the day are also for conventional solar still and modified solar still. The hourly variation of various temperature values of CSS and of MSS3 are shown in the Fig. 6 and Fig. 7 respectively. The values of all the temperature increases with time over the day up to 15:00 hrs and then decreases. In both the cases, at a given incident of time, Tb > Tw > Tg > Ta. Inline similar trends are reported in various earlier studies. Table 5 Table 6 Table 7 Table 8

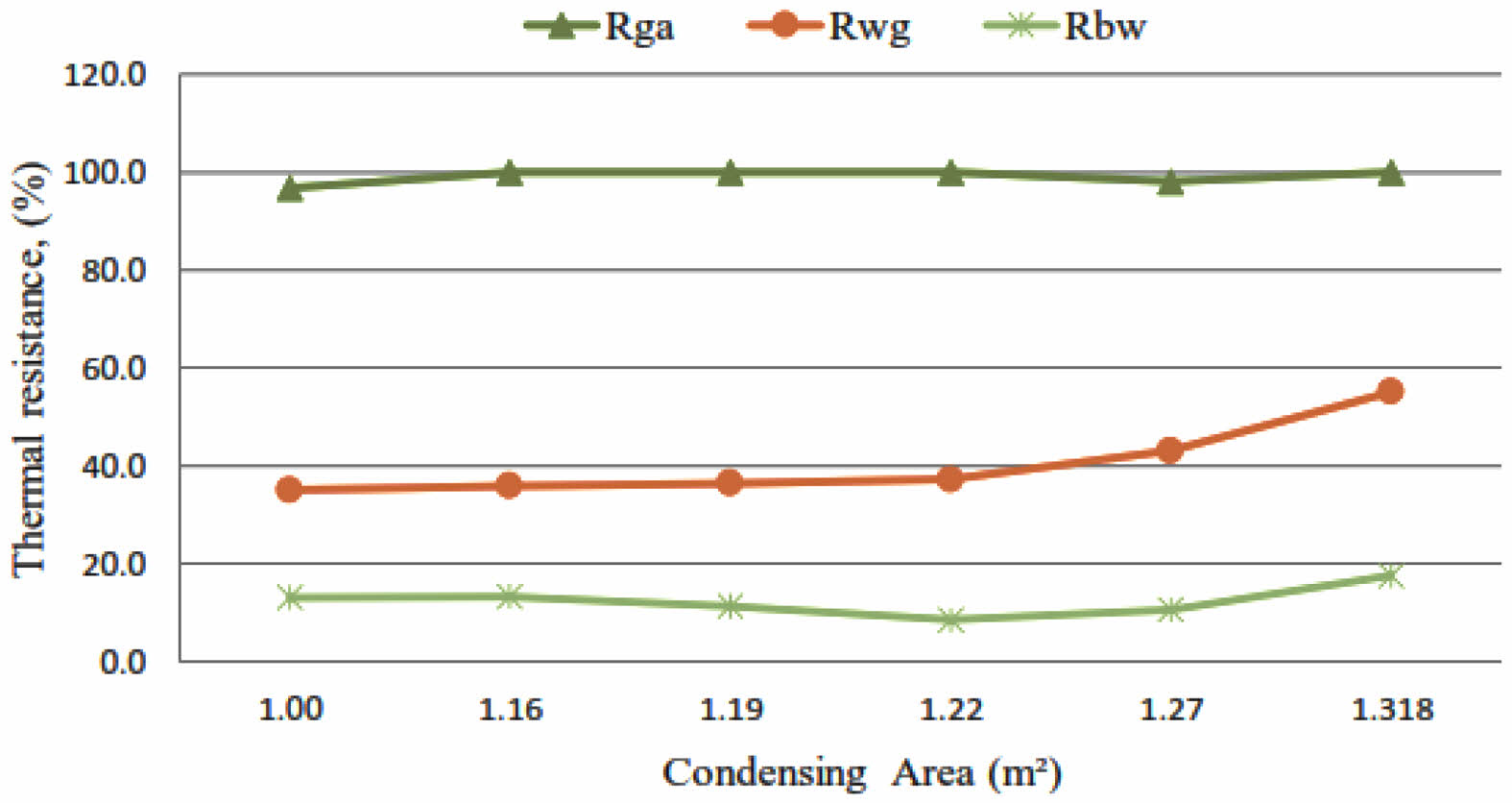

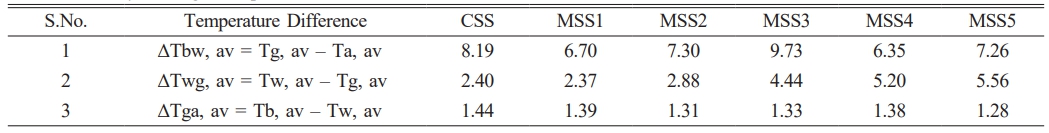

Variation of relative thermal resistance

The relative daily efficiency of solar still increases due to solar radiation. The efficiency is high during the daytime when the sun ray’s are the strongest and this increases the water temperature and evaporation rate. Wind speed reduces the glass plate temperature and increases the condensation on the inner surface thereby increasing the relative daily efficiency. Higher ambient temperature improves the temperature difference between the water basin and the condensing medium and increases the efficiency. The water depth, absorber shape and thickness of the glass plate are other parameter which influences the daily efficiency of the solar stills. The average temperature differences, that is responsible for the heat transfer (ΔTbw, av = Tb, av – Tw, av), (ΔTwg, av = Tw, av – Tg, av), and (ΔTga, av = Tg, av – Ta, av) are listed in Table 10. These values are shown in Fig. 8, The thermal resistance of each path are directly proportional to temperature difference (ΔTbw, av, ΔTwg, av, ΔTga, av) and that is expressed as % of total resistance in Fig. 9.

From Fig. 7, it is observed that the values of ΔTbw, av, ΔTwg, av, and ΔTga, av are found to vary in the range 1.3-1.5 °C, 2.3-5.5 °C, and 6.3-8.2 °C. The thermal resistance (R) in each segment is directly proportional to the respective temperature difference (ΔTav) in that segment. The relative thermal resistance (the thermal resistance of the segment to the overall thermal resistance) is plotted in Fig. 8. With the addition of external condenser and increase in external condenser area, the relative resistance between water surface and glass cover (Rwg) is found to increase and correspondingly, the relative thermal variable between glass cover and atmospheric air decreases. It is because, a part of the vapour in the main still moves to external condenser and gets condensed there. The increase in the total condensing area will increase the rate of condensation and this will lead to increase in daily average thermal efficiency. This is observed in this work in all solar stills ranging from Conventional solar still to Modified Solar stills with varied combinations.

Thus, the vapour concentration in the main still get reduced, resulting in increased Tw – Tg, and hence the Rwg. As evaporation depends upon (Pw – Pg) and is proportional to (Tw – Tg), the overall evaporation increases. The additional vapour generated gets condensed in the external condenser, resulting in increase in the total distillate yield.

Condensate yield and still efficiency

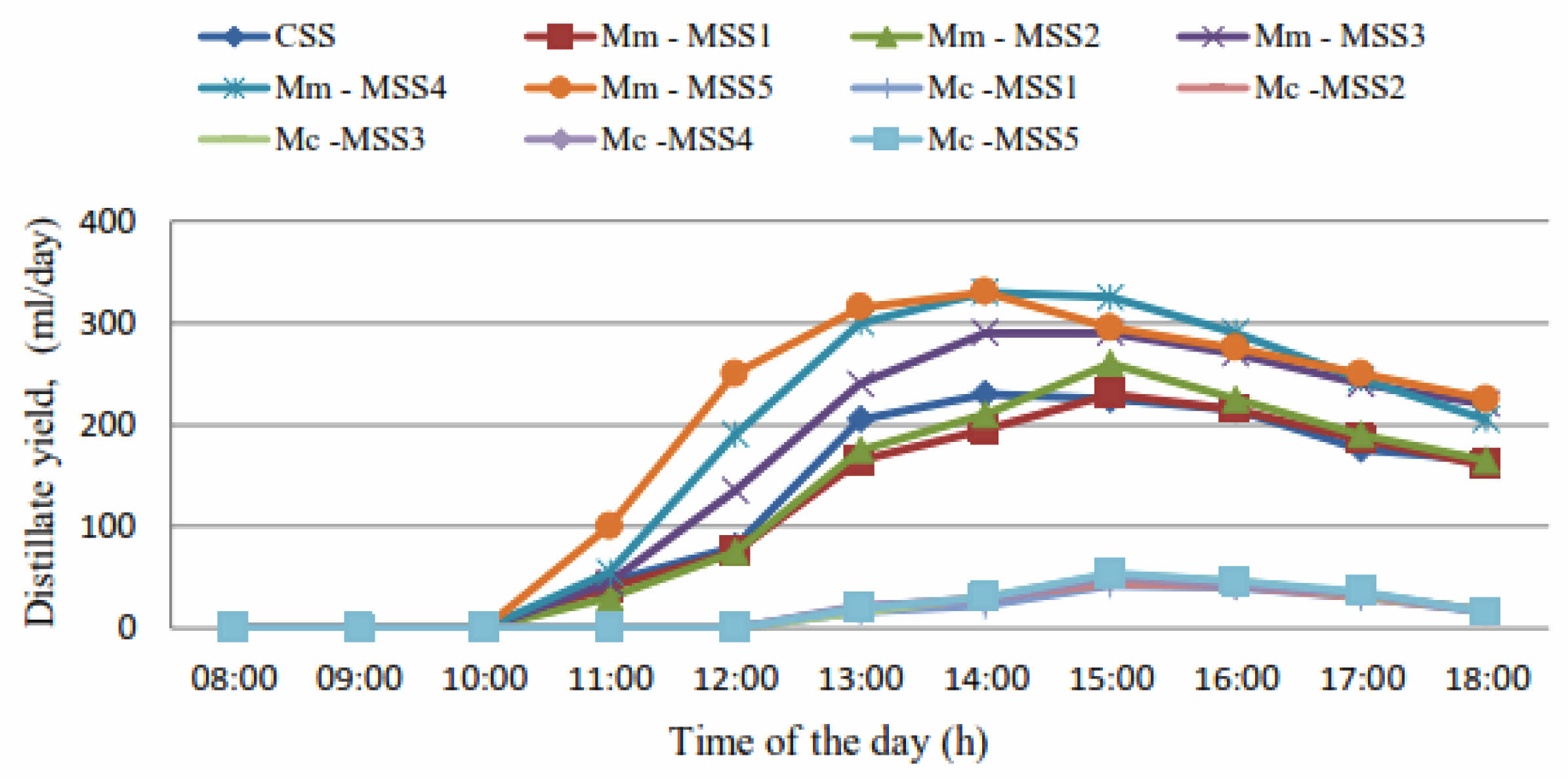

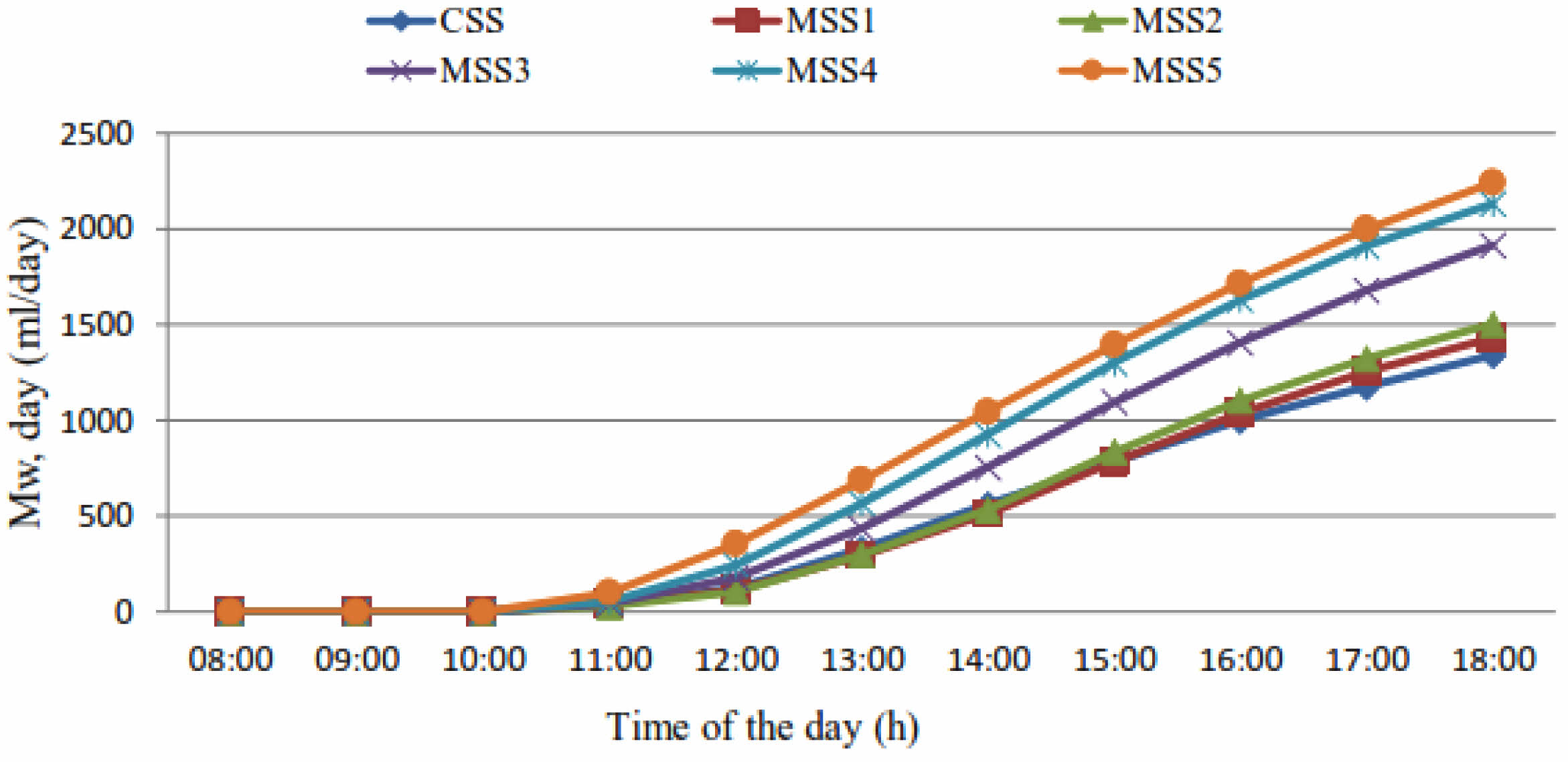

In case of CSS, distillate yield is from main still (Mm) only. In case of MSS, as distillate yields are from main still (Mm), and external condenser on each side (MC1 and MC2). The total distillate yield by external condenser is the sum of MC1 and MC2. The total condensate for the MSS is the sum of all the three (Mm + MC1 + MC2). The hourly values of distillate yield by various stills are shown in Fig. 10. The cumulative total distillate yield over the day is plotted in Fig. 11.

From Fig. 9, it can be observed that water at the still basin gets heated up during 08:00 – 10:00 hrs, and there is no condensation. In the main still, the condensation rate increases from 11:00 hrs to 15:00 hrs and then decreases. The increase is because of increase in solar radiation during the forenoon and the drop is due to decrease in solar radiation in the afternoon. The maximum distillate yield is around 15:00 hrs and values are in the range of 225 ml/h to 330 ml/h.

The condensation in the external condenser starts around 13:00 hrs and continuous up to 18:00 hrs. The maximum distillated yield in the external condenser is around 15:00 hrs, in the range of 40 ml/h to 55 ml/h. The cumulative total distillate yield is shown in the Fig. 10. With the increases in external condenser area, more vapour is condensed in the external condenser contribution to overall increase in total distillate yield. The total distillate yield over the day is 1341 ml/day with CSS and that of MSS1 to MSS2 are 1431, 1504, 1916, 2132 and 2242 ml/day. Addition of external condenser absorbs vapour from main condenser moves to external condenser and gets condensed there. It reduces the vapour concentration in the main still. It intern increase on Tw – Tg difference, leads to more evaporation and hence more distillate yield.

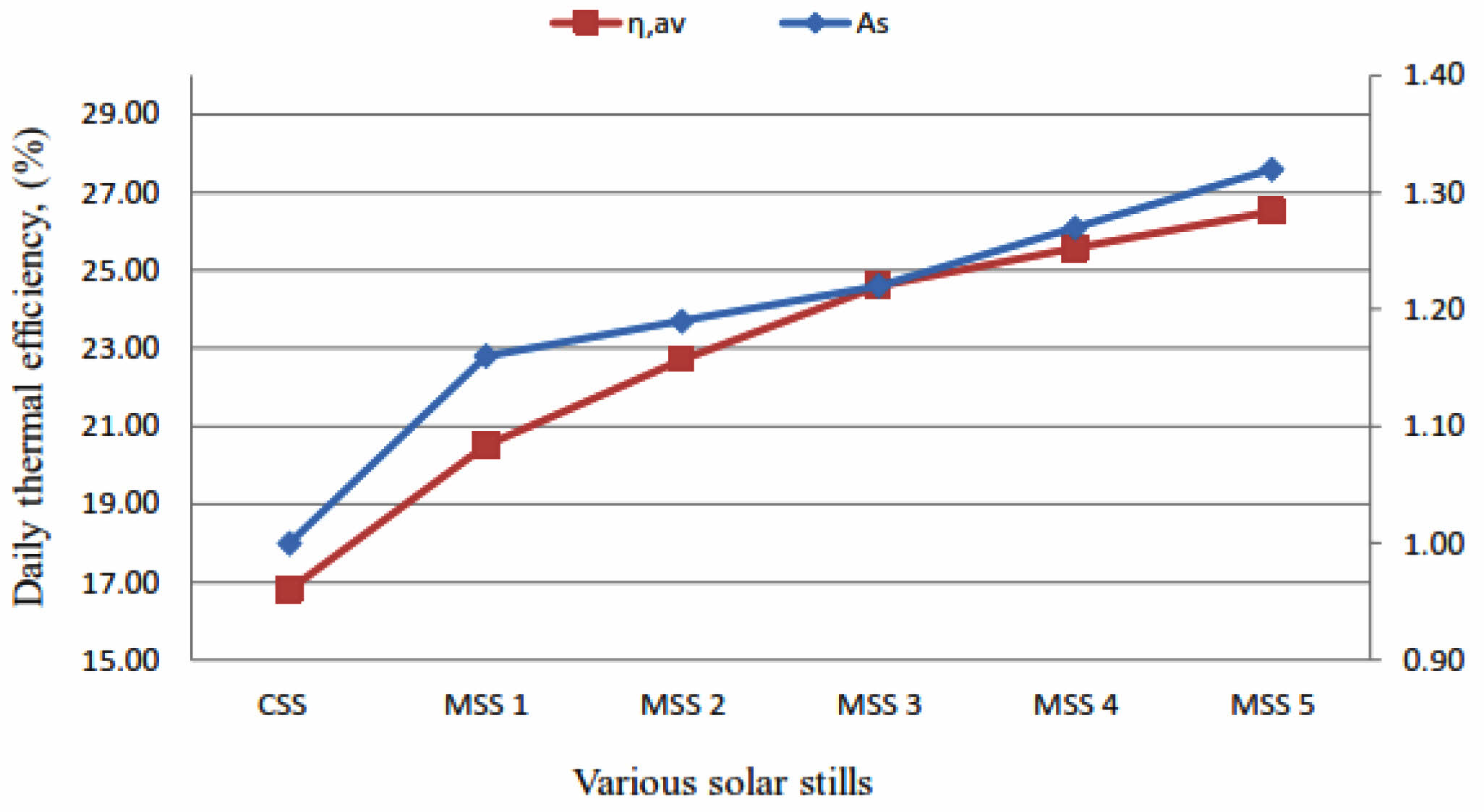

Effect of External condenser area on performance

The performance of the condenser area is measured by comparing the distilled output. This is influenced by the condenser surface, weather, circulation mode and solar still efficiency. The variation of total condensing area and the daily thermal efficiency are plotted in Fig. 12. The total condensing surface area is increased from 1.0 m2 to 1.26 m2. Correspondingly the daily thermal efficiency of the solar still increased from 16.81% to 26.51%.

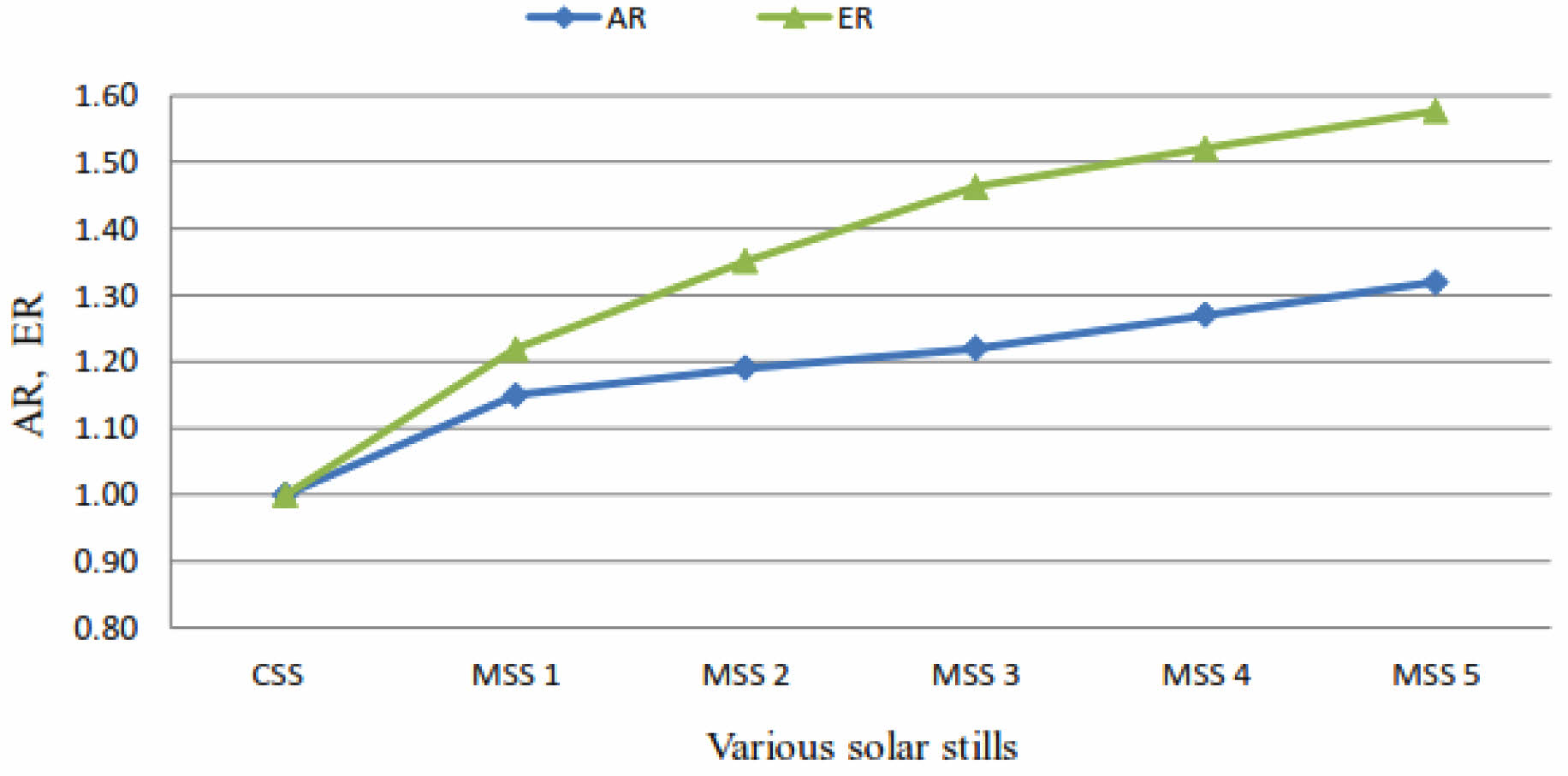

To understand the effect of external condenser area on the performance of solar still, relative increase in daily average thermal efficiency (ER) and relative increase in total condensing area are plotted in Fig. 13.

Relative increases in surface area (AR) is defined the ratio of total condensing area of the solar still to that of the main still. Similarly, relative increase in daily thermal efficiency is the ratio of daily total thermal efficiency of the solar still to that main condenser. It can be observed from Fig. 13. that the relative increases in condensing surface area is 26%. whereas relative increases in daily distillate yield and daily thermal efficiency is 58%. The cost of main still (includes material cost and fabrication cost, excluding cost instruments and measurement) is about INR 14750 (USD 180) and that of external condenser is INR 1480 (USD 18). The increase in cost is 10%. However the increase in distillate yield is 58%. Thus the type of external condenser is economically viable. Moreover, these are simple and easy to fabricate.

|

Fig. 4 Solar radiation data on various days. |

|

Fig. 5 Wind velocity data on various days. |

|

Fig. 6 Hourly variation of temperatures for CSS. |

|

Fig. 7 Hourly variation of temperatures for MSS3. |

|

Fig. 8 Variation of mean temperature difference with condensing area. |

|

Fig. 9 Variation of thermal resistance with condensing area. |

|

Fig. 10 Hourly variation of distillate yield for various stills. |

|

Fig. 11 Cumulative total distillate yield for various stills. |

|

Fig. 12 Daily thermal efficiency and total condensing area for various stills. |

|

Fig. 13 Variation of Area ratio and Relative daily efficiency for various stills. |

Conventional single slope solar still (CSS) is simple and easy to fabricate. Effect of various parameters on the performance (Daily condensate yield, Daily average efficiency) has been widely studied. The uses of external condenser are found to improve the performance of CSS. In the present investigation, the effect of external condenser area on performance of the CSS is studied. CSS has condensation area of 1m2. External condensers with additional of area 0.155 m2, 0.188 m2, 0.122 m2, 0.269 m2 and 0.318 m2 are added, and referred as modified solar stills. The performance of CSS and five configurations of modified solar still (MSS1, MSS2, MSS3, MSS4 and MSS5) are experimentally investigated.

From the investigation, the following conclusions are arrived.

(i) The trends in performance of conventional solar still (CSS) are in line with the earlier studies.

(ii) With the addition of external condensers more distillate yield are obtained.

(iii) Addition of external condenser removes a part of vapour generated in the main still, thus vapour loading in the main still is reduced. It is increases water to glass temperature difference, resulting in increase the evaporation rate.

(iv) With the addition of external condenser, the relative increases in total condensing area is 26%; however, the relative increases in distillate yield and daily thermal efficiency are 58%.

(v) Additional cost due to additional of external condenser is about 10%; but, the additional distillate yield is 56%.

It is thus inferred that the proposed external condenser is simple in design, easy to fabricate, easy to operate, and cost effective.

- 1. H. Panchal, D. Mevada, and K.K. Sadasivuni, Heat Transfer 49[6] (2020) 3758-3778.

-

- 2. A.E. Kabeel, Z.M. Omara, F.A. Essa, and A.S. Abdullah, Renewable Sustainable Energy Rev. 59[C] (2016) 839-857.

-

- 3. L.D. Jathar, S. Ganesan, K. Shahapurkar, M.E.M. Soudagar, M.A. Mujtaba, A.E. Anqi, and M.R. Safaei, J. Therm. Anal. Calorim 147[7] (2022) 4491-4522.

-

- 4. M. Bhargva, and A. Yadav, Environ. Sci. Pollut. Res. 28[39] (2021) 54383-54402.

-

- 5. A. Rahmani, F. Khemmar, and Z. Saadi, Desalination 501 (2021) 114914.

-

- 6. A.G. Ibrahim and S.E. Elshamarka, Sol. Energy 118 (2015) 397-409.

-

- 7. R.A. Kumar, G. Esakkimuthu, and K.K. Murugavel, Desalination 399 (2016) 198-202.

-

- 8. A.E. Kabeel, Z.M. Omara, and F.A. Essa, J. Taiwan Inst. Chem. Eng. 75 (2017) 77-86.

-

- 9. A. Rahmani and A. Boutriaa, Int. J. Hydrogen Energy 42[48] (2017) 29047-29055.

-

- 10. K. Rabhi, R. Nciri, F. Nasri, C. Ali, and H.B. Bacha, Desalination 416 (2017) 86-93.

-

- 11. H. Hassan and S. Abo-Elfadl, Desalination 417 (2017) 60-68.

-

- 12. A.J.N. Khalifa, Energy Convers. Manage. 52[1] (2017) 431-436.

-

- 13. G. Usmansha, K. Senthil Kumar, and R. Thirumalai, J. Ceram. Process. Res. 24[1] (2023) 205-209.

-

- 14. K. Murugan and R. Thirumalai, Mater. Technol. 55[1] (2021) 121-126.

-

This Article

This Article

-

2025; 26(1): 109-116

Published on Feb 28, 2025

- 10.36410/jcpr.2025.26.1.109

- Received on Nov 4, 2024

- Revised on Dec 12, 2024

- Accepted on Jan 6, 2025

Services

Services

Shared

Correspondence to

Correspondence to

- A. Gowrishankar

-

Department of Mechanical Engineering, Mahendra Institute of Technology, Namakkal, India

Tel : +91 9965740661 - E-mail: gowrimech2727@gmail.com

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.