- Parametric studies in friction stir welding on Al-Mg alloy with (HCHCr) tool by Taguchi based desirability function analysis (DFA)

C. Chanakyana,* and S. Sivasankarb

aResearch Scholar, Department of Mechanical Engineering, Government College of Engineering, Thanjavur, Tamilnadu, India

bAssistant professor, Department of Mechanical Engineering, Government College of Engineering, Thanjavur, Tamilnadu, India

The present investigation is

to optimize the welding parameters designed for friction stir welding (FSW) of

aluminium magnesium alloy (AA5052). The authentic configuration of automated

linear friction stir welding machine used to weld the AA5052. The experiments

were conducted by selecting the different welding process parameters like tool

rotation speed (rpm), traverse speed (mm/min), and tool pin profiles. The pin

profile made with ceramic tool type (high carbon high chromium). Taguchi based

desirability function analysis engaged in establishing the optimal process

parameters with multi-objective function in order to maximize the tensile

strength and the nugget hardness. The welding parameter of optimum level was

attained by the highest composite desirability value. An optimal level of

welding parameters acquired the tool rotation speed at 1200 rpm, traverse speed

at 30 mm/min, and the pentagonal tool pin profile. Further, ANOVA (analysis of

variance) implemented to intimate the major impact of welding parameters on the

output responses (tensile strength and nugget hardness). An outcome perceived

that the tool pin profiles and tool rotational speed are the important

consequence factors to manipulate the mixed output responses. Contour plots and

mean effect show that the interaction of parameters of welding on the required

output response.

Keywords: DFA, HCHCr tool, FSW, Tensile, Microhardness, Microstructure

In the fusion welding process, the joining of aluminium

alloy was inflexible, and blemish joints occurred due to a low melting point

and high shrinkage. The welding institute introduced Friction stir welding

(FSW) to solve this issues in the fusion welding process. There are many

benefits in FSW such as, better mechanical properties, fine grain structure,

free porosity, and extending the enormous amount of production in the

automotive and marine sectors [1]. For setting the optimal level of welding

process parameters, it is indispensable to produce the exceptional quality of

the welding. There are different methods available to detect the optimal

parameters of welding in which Desirability function analysis (DFA) is found as

a precise method because it is less time consuming and materials for this

current investigation [2]. Periyasamy et al. [3] reported the multi-objective

optimization of FSW on the metal matrix composites by using the desirability

function. The optimum process parameters of welding were achieved by

desirability function to improve the responses of tensile strength, hardness,

and notch strength. Ambedkar et al. [4] examined the process parameters of FSW

multi-response by the approach of principal component analysis and artificial

neural network. They conducted the experiments on AA2024 aluminium alloy by

utilizing the friction stir welding. These approaches considered the control

factors as weld speed, tool rotation speed, and the tool dimensions ratio. They

determined 3 D/d ratio, 670 r/min spinning speed of tool, and 0.017 m/min weld

rate of optimal parameters by using principal component analysis. Devaiah et

al. [5] summarized the dissimilar FSW between the AA5083 and AA6061 to attain

the optimal welding parameters by utilizing the Taguchi. The most influencing

parameters of weld rate and spinning speed of tool was indicated by the ANOVA

outcomes and statistical model to create the correlation among the input

variable and the result responses. The Taguchi technique produced the optimal

parameters such as 1,120 rpm rotation speed of tool, 70 mm/min traverse

speed, and 20o tilt angle from the multi-objective optimization.

Devarasiddappa et al. [6] discussed the optimization of multi-objective in the

WEDM process of the material Inconel 825 which composed by

desirability function. The composite desirability produced the

pulse off time for significant impact compared to other parameters namely peak

current and pulse on time. The output responses namely surface roughness-SR and

material removal rate-MRR with percentage of 3.73, 1.22, and 4.46, respectively.

Jenarthanan et al. [7] studied the impact of friction stir dissimilar welding

between the AA2014 and AA6061 to develop the tensile strength coupled with

ANOVA and response surface methodology. They fabricated the high strength

welding by using the control parameters such as weld speed, tool spinning, and

the diameter of the tool pin. The CCD model validated by the ANOVA and also

examines the mechanical response. John et al. [8] investigated the friction

stir processing on AA2014 for developing the mechanical properties

by the optimization and manipulate of input parameters. By an approach

of desirability based response surface methodology to optimize the

parameters of welding. The main objective of this

examination was to find the optimal tool pin profile with an approach of

desirability function. Kumar et al. [9] predicted and developed the tensile

strength with the mathematical model for dissimilar FSW between the aluminium

alloy 6061 and 2024 by ANN and Taguchi. At the 2nd level of processing parameters,

the optimum value of the tensile strength of 189.1 MPa

was obtained. The model results confirmed with an

artificial neural network produce precise tensile strength compared to the

Taguchi method. The good welded joint between the aluminium alloy 6061 and 2024

was produced with significant control parameters like weld rate, tool spinning

rate, and axial load. Shashi Kumar et al. [10] identified the

optimal process parameters of FSW on the 316 L material for

maximizing the tensile strength by RSM based Box-Behnken

design. The regression model established the response of tensile

strength of the joint as an input factor such as spindle rate, weld rate, and

axial load of tool. Those input factors significantly proved by

the response surface method and desirability approach. Further, optimal

outcomes of tensile strength 604 MPa corresponding to optimum input process

parameters followed 597 rpm tool spindle speed, 74 mm/min tool weld speed, and

3 kN downward force. Kumar Naik et al. [11] proved that the optimization and

investigation of Hardox 400 plasma arc cutting by desirability analysis based

on the Taguchi method. To improve the quality of plasma arc cutting, Taguchi

based desirability analysis-TBDA is utilized to obtain the optimal condition of cutting

parameters. The plasma arc cutting efficiency was enhanced by setting optimal process parameters, which was verified by

the confirmation test. Muthu Krishnan et al. [12] investigated the statistical

modelling for the FSW of A319 and AA6063 using the ANN and response surface

method. They proved that the welding process

parameters like welding tool, tool spindle speed, axial force and traverse

speed play an influential function in

deciding the properties of the welded joints. The method ANN predicted the

tensile strength of AA6063 and A319 FSW. The ANN regression model found the error

in predicted values which was best technique in ANN compared to other ANN

techniques. Nwobi-Okoye et al. [13] compared the modeling between artificial

neural network and neuro-fuzzy system for multi-objective optimization of age hardening on A356 aluminium alloy. The

neuro-fuzzy system with a coefficient 99.8% was the predicted hardness values

which are finer than the artificial neural network having coefficient 99.2%. So

that outside experimental points of ANN, which were the fitness functions of

age hardening parameters using the

(GA) genetic algorithm. Banglong Fu

et al. [14] reported that the dissimilar friction stir welded joints between

the AZ31B and AA6061 alloy. The transitional combination of rate of tool

rotation 600rpm to 800rpm, the cross speed 30 mm/min to 60 mm/min and tool

offset 0.3mm to obtain the welding. The eutectic structure survived in the

nugget zone due to the intermetallics compounds of base metal. The tensile strength

of the dissimilar joint reached 70% of AZ31B base metal. The spindle torque

used to compute the heat-input between the base metal of AZ31B and AA6061

throughout the FSW process. The selected welding condition composed of the

proper heat input and material mixing, which was studied in this investigation. Arun Kumar Kadian et al. [15]

studied the material flow movement

between the dissimilar AA 6061 aluminium alloy and B370 copper alloy through

the friction stir welding. The material flow for the dissimilar FSW on the base

material has been projected and

located on the strain rate and temperature distribution. The temperature distributions were irregular in

the welded samples because of the enormous amount of heat transmitted in copper

material than the aluminium material. By maximizing the tool spinning speed,

the material movement in welded plates can be improved. During the corrosion

test, the volume of the fluid level was lower in the nugget region of the

copper alloy due to lesser fluidity at the higher welding temperature. Palani

K. et al. [16] conducted the dissimilar FSW on AA 8011 and AA 6061 al alloys.

The three different tool pin profiles, such as hexagonal, pentagonal, and

square, were played an essential role in promoting mechanical behavior during

the welding process. The 1,500 rpm spinning speed of the tool, 40 mm/min

traverse speed, and 2.5 mm depth of plunge with the hexagonal pin profile composed the excellent

mechanical properties of dissimilar welded joints. Next to

hexagonal pin profile, pentagonal pin

produced defect-free AA 8011 and AA 6061 al alloy welded joints. Prabhakar et

al. [17] investigated the FSP along with composite material of 5083 aluminium

alloy and its reinforcement of fly ash particles. The FSP was fabricated at tool

speeds 1,400 rpm, and varying weld

speed of 20 and 25 mm/min which was concluded as the optimal condition. The

maximum hardness attained in processed

composite specimens when compared with base metal 5083. The current density of corrosion was maximized with

processed 5083 aluminium alloy. The

Al 5083 composites of processed specimens accomplished the fine grain size due

to the presence of fly ash particles. Successfully, the researchers improved the performance of

mechanical characteristics of processed composite 5083 aluminium alloy. Gopi Krishnan et al. [18]

had undergone the stir casting method with aluminium oxide and silicon carbide

to produce the welded joints of AA7010. The working parameters, namely, axial force, traverse speed, and tool spinning speed, were varied. The

welding parameter was designed with

the L27 Taguchi technique. This

investigation focused on the development of welded tensile strength by using

regression analysis. The optimized parameters were done by the method of the

Genetic algorithm.

In the present investigation, Taguchi based desirability

function analysis implemented to determine the optimal process parameters for

the Friction Stir Welded joints of AA5052, which was performed by ceramic tool

material. There are several strengthening tool materials, namely,

HSS, die steel, etc. Among these tool materials, high carbon

high chromium (HCHCr) is a ceramic tool that possesses

better strength for treating the surface of metals to

improve the metallic characteristics in aluminium alloy. Moreover, ANOVA

implemented to resolve the most critical impact of concerned

parameters for the multiple responses, namely, tensile strength and nugget

hardness. At last, the optimum process parameters confirmed by

performing the verification test.

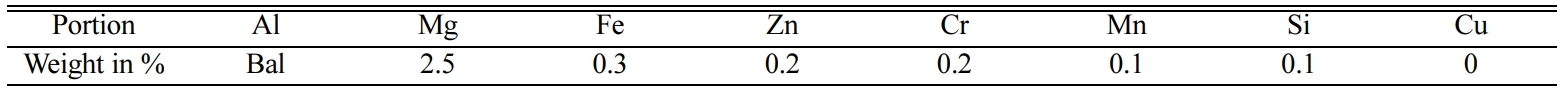

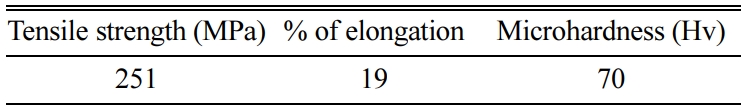

In this investigation, the friction stir welding of AA5052

was fabricated in FSW machine. AA5052 was good selection for integrated among

aluminium alloys due to fine weldability, wear resistance, better

corrosion, and superior hardness. Chemical composition and properties of the

AA5052 base showed in Tables 1 and 2, correspondingly. HCHCr (High Carbon High Chromium Die Steel) utilized to manufacture the

FSW tool. Fabricated tool pin profiles such as a Pentagonal pin cylinder (PC),

straight cylinder (SC), and fluted cylinder (FC) displayed in Fig. 1. Aluminium

alloy AA 5052 plates were having dimensions (100 mm ´ 50 mm ´ 6

mm), which are the required size of both specimen [19]. Square butt joint

designed with size of 100 mm ´

100 mm and equipped with welded joints. In the framework of single-pass

welding, the welded joint was created. The revolving direction was typical for

the welding direction with constant axial load of 5 kN was applied for all the

experimentation. Table 1, 2

Fig.

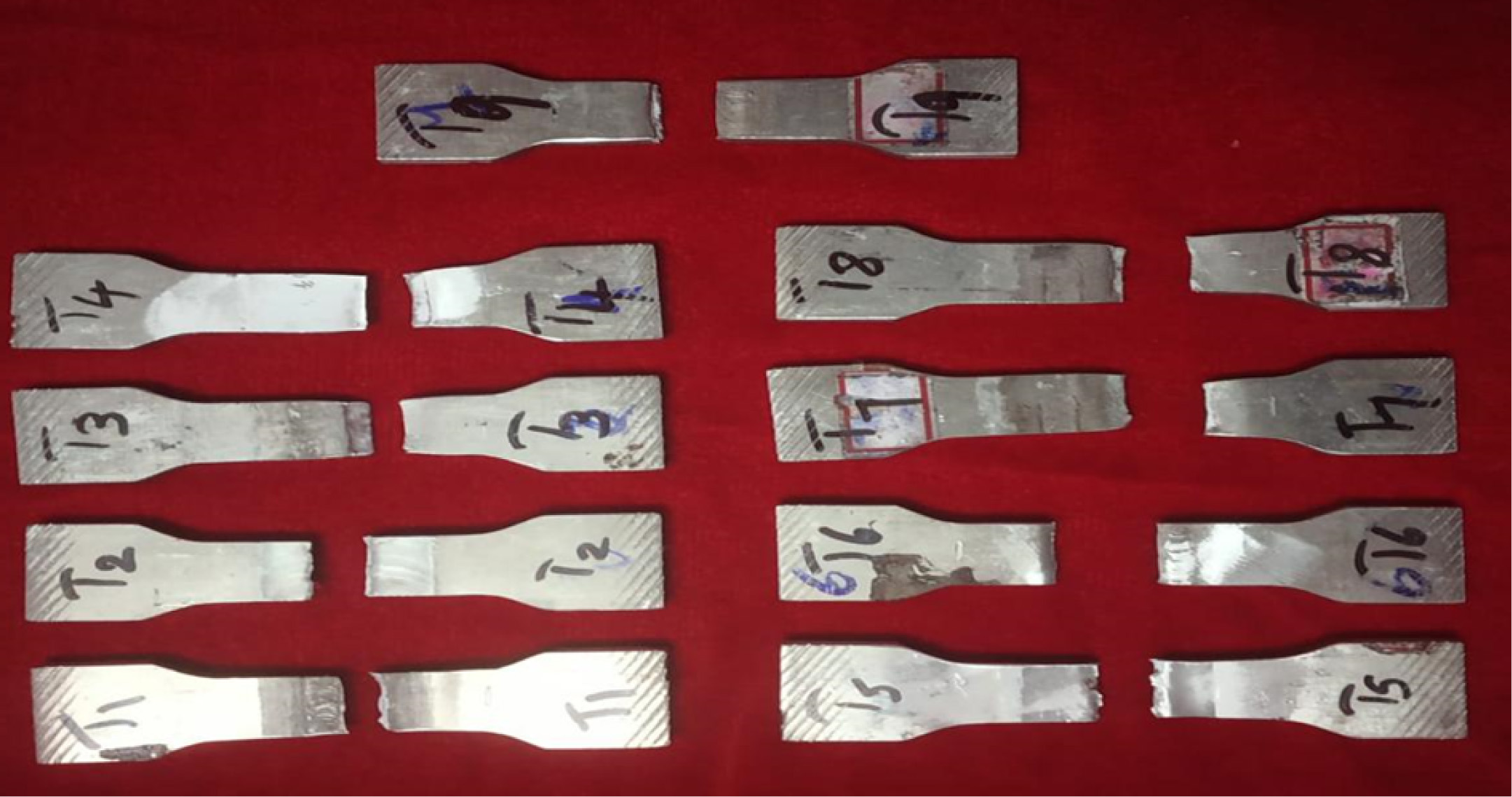

2 exhibits the photographic view of friction stir welded joints of AA5052.

During the investigation, influence of tensile strength and nugget hardness of

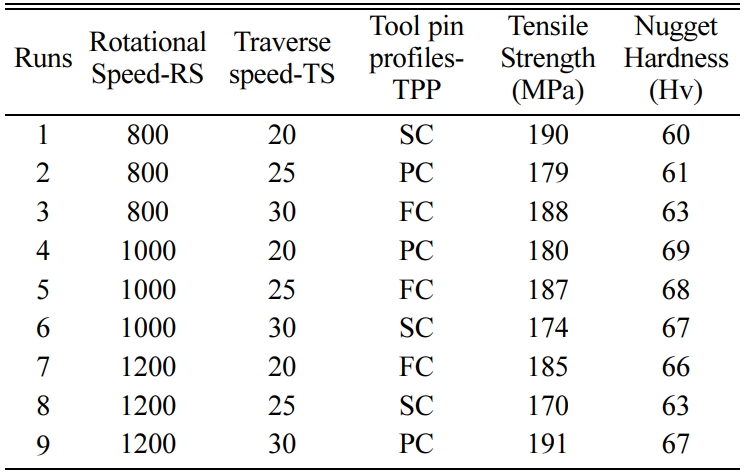

FSW on various welding parameters were examined. In present examination, the

impacts of process parameters of welding with 3-levels were chosen and it’s

given in Table 3. The L9 orthogonal array selected for

investigational outline of friction stir welding [20]. Tensile strength

verified by the UTM-universal testing machine

as per the standard of ASTM E9 used to prepare the tensile specimens. The

microhardness analyzer with 0.5 N loads used to calculate the nugget hardness

at three various spots for each nugget zone surface of welded specimen and the

nugget hardness average value was

measured. Investigational input process

parameters of FSW and the outputs were exhibited in Table 4. Similarly, the

photographic view of fractured tensile specimen displayed in Fig. 3.

|

Fig. 1 The fabricated FSW tool pin profiles |

|

Fig. 2 Friction stir welded joints of AA5052. |

|

Fig. 3 Fractured tensile specimen of FSWed AA5052. |

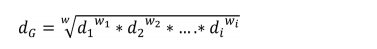

Desirability

Function Analysis (DFA)

Derringer and Suich proposed the Desirability function analysis

on optimizing multi-objective attributes conditions [21]. DFA utilized to

transform multiple-response attributes

interested in single response attributes among the composite desirability

inspection [22]. In present experimentation, the multiple responses namely

tensile strength and nugget hardness mixed as composite desirability method. The following steps of DFA

presented below:

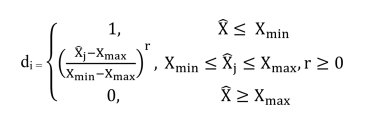

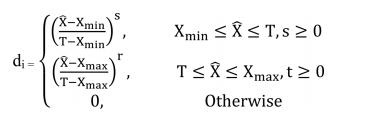

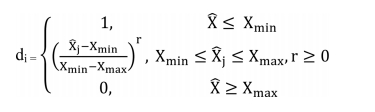

Step (1): For all results of responses should be

calculated by the individual desirability index (di). Three equations utilized

to determine the index of individual desirability [23].

Larger-the-better found to be the target for maximum

objective function by using the following equation.

Nominal-the-best found to be a goal for appropriate

objective function by using the following equation.

Smaller-the-better found to be a goal for minimum

objective function by using the following equation.

Here, Xmax is the greatest value of ‘X’, Xmin

is the lowest amount of ‘Y’. T- Signifies target values. The weight of the

responses results was denoted by s, t, r. In the current investigation, tensile

strength and nugget hardness were measured while the larger-the-better

attributes.

Step (2): The individual desirability index of all

responses are combined and used to determine the (dG) composite

desirability by subsequent equation.

Here, di denotes the individual

desirability index along with wi signifies weight of the output

response.

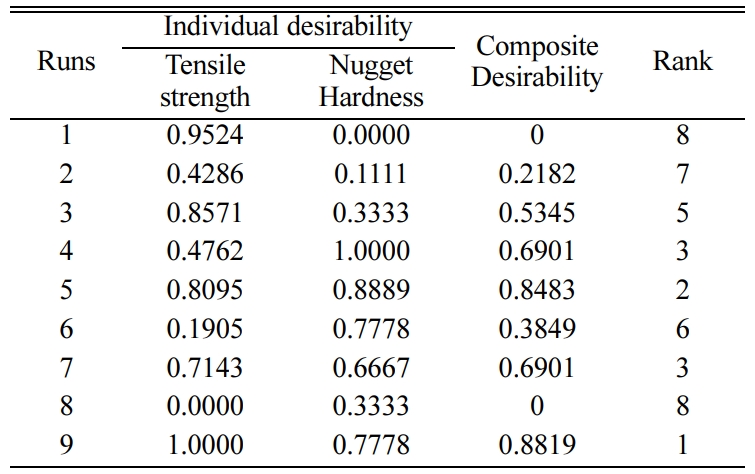

Step (3): Once obtaining the composite desirability

results, the optimal combination of the parameter level was measured. Commonly,

composite desirability maximum value

measured towards the optimum level of

process parameters. Manipulated composite desirability among rank order was presented in Table 5.

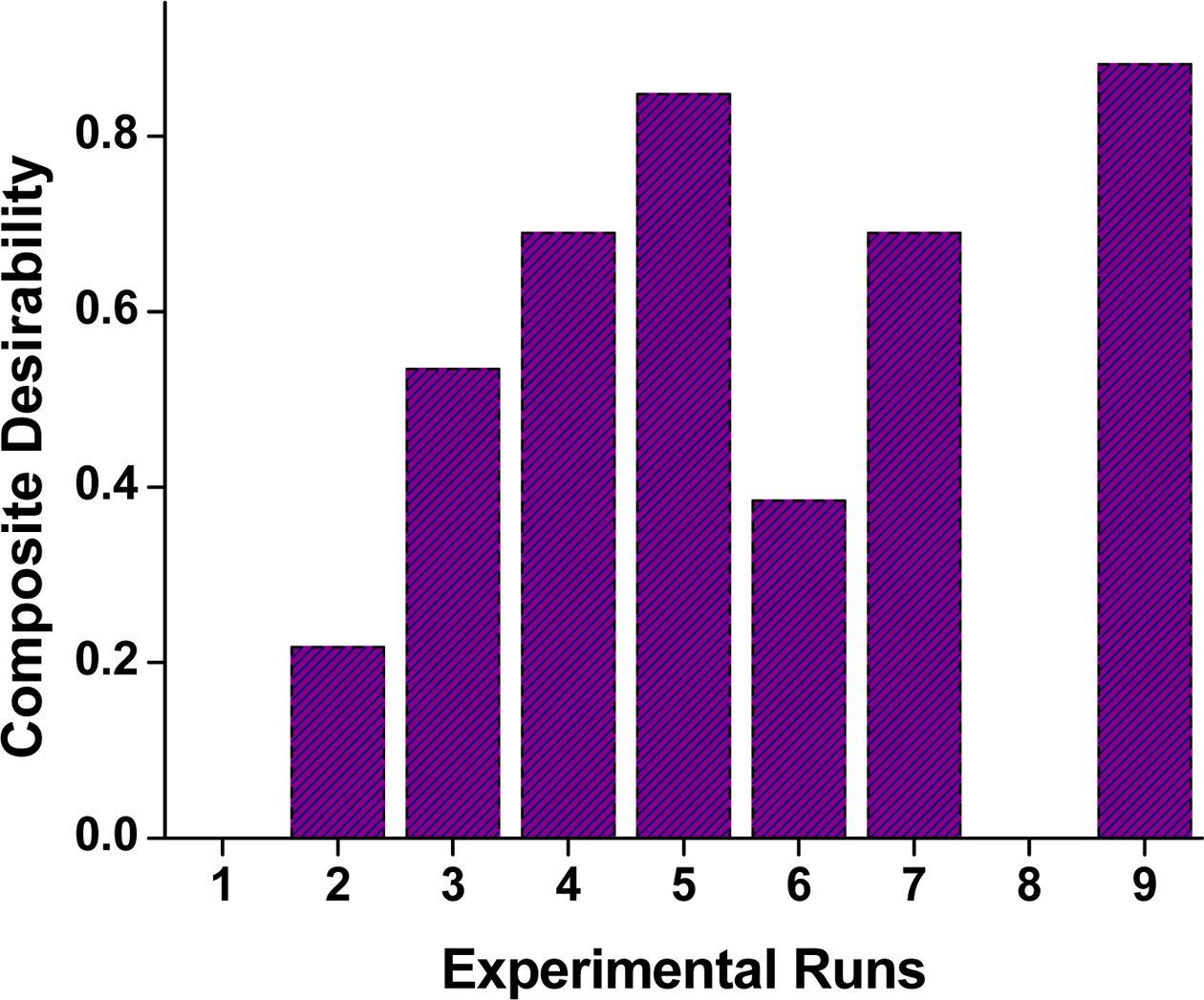

Fig. 4 exhibits the rank plots between the composite

desirability and the nine experimental runs. The Fig. 4 observed the 9th

experiments attains the maximum of composite desirability. In which the 9th

experiments intimates a superior combination of optimum level of welding

parameters tool rotation speed (1,200 rpm), tool traverse speed (30 mm/min),

and pentagonal pin profile. Multi-response attributes to maximize the tensile

strength and nugget hardness during the process of FSW on AA5052.

Analysis

of FSW process parameters on composite desirability

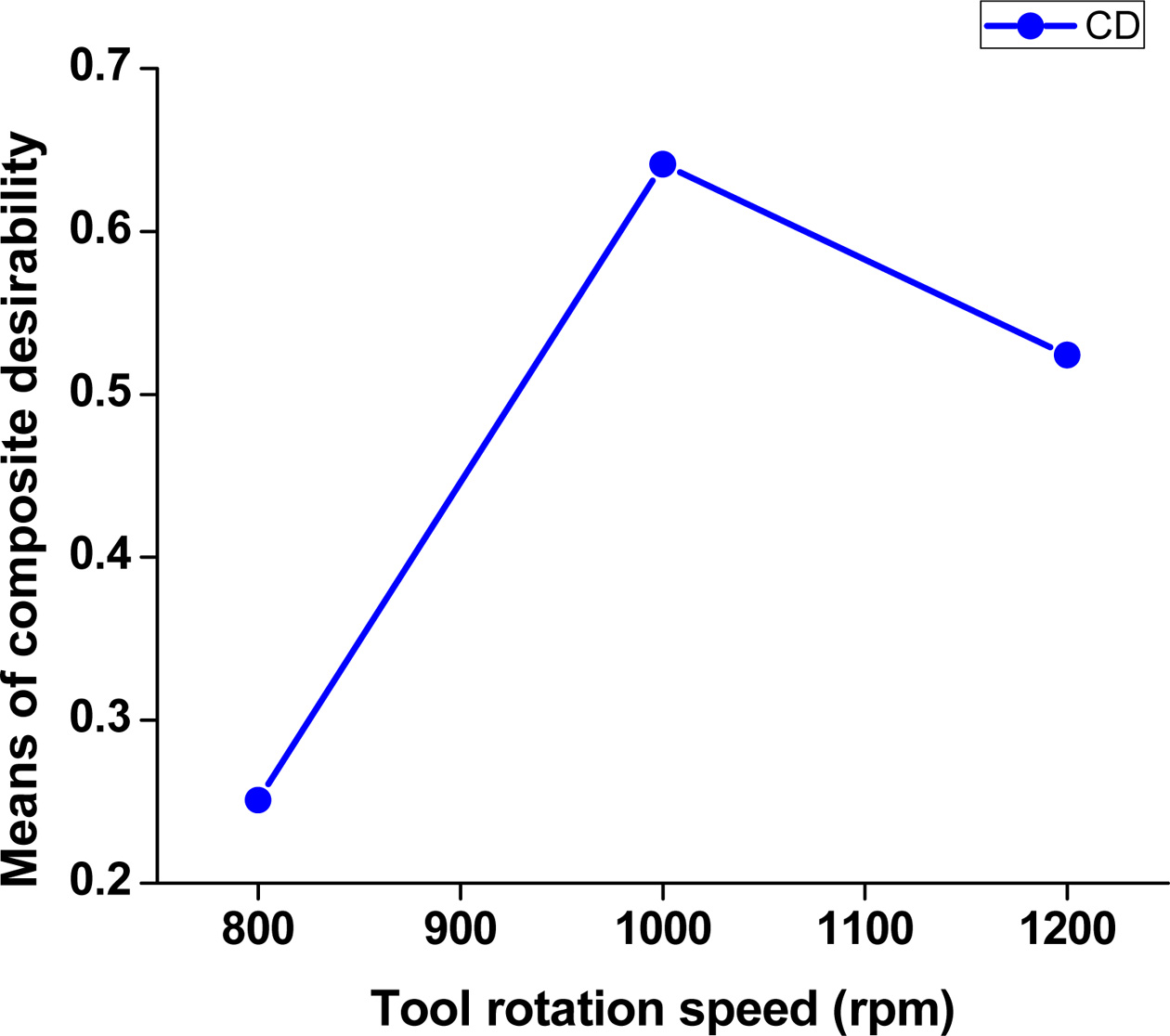

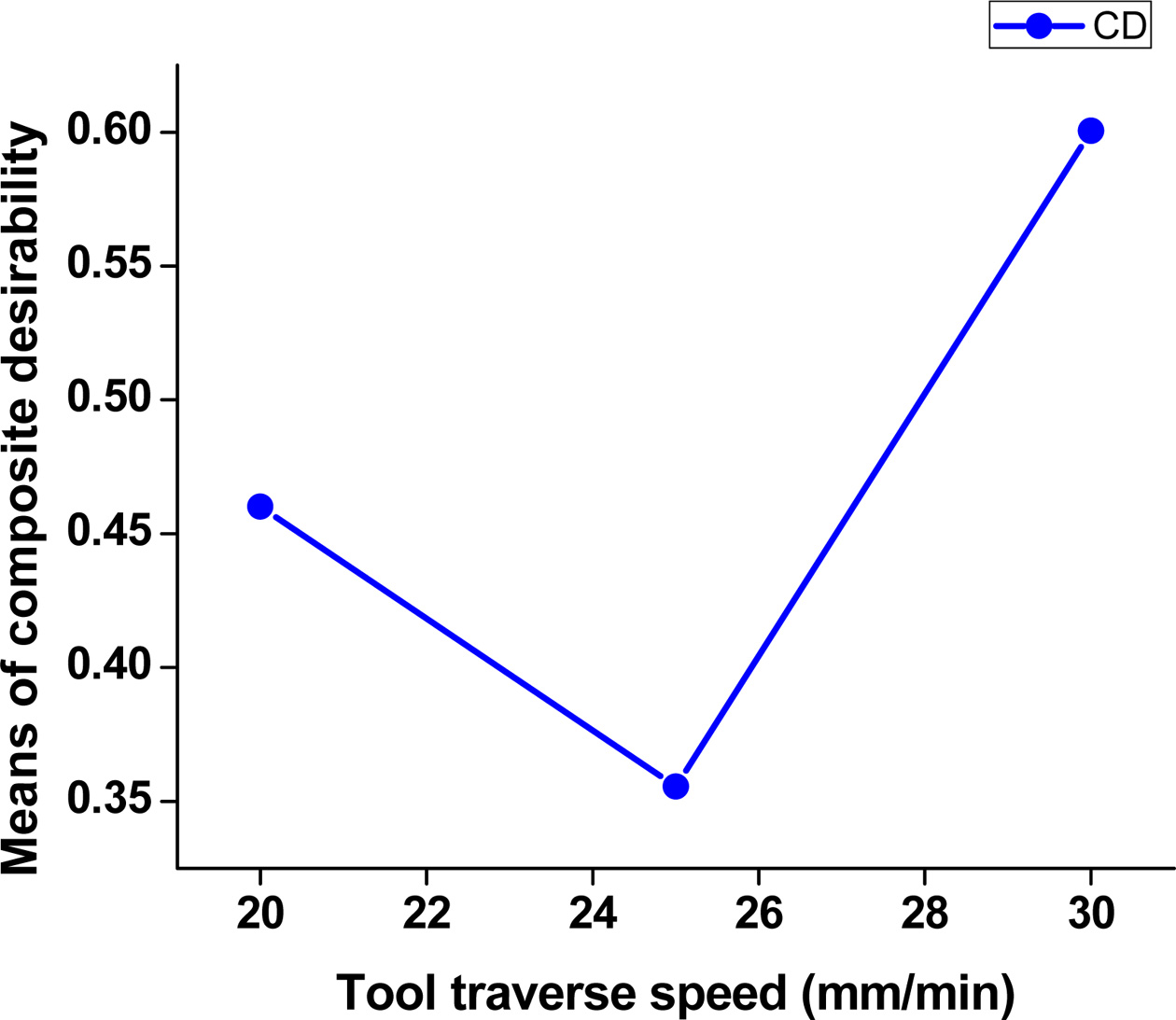

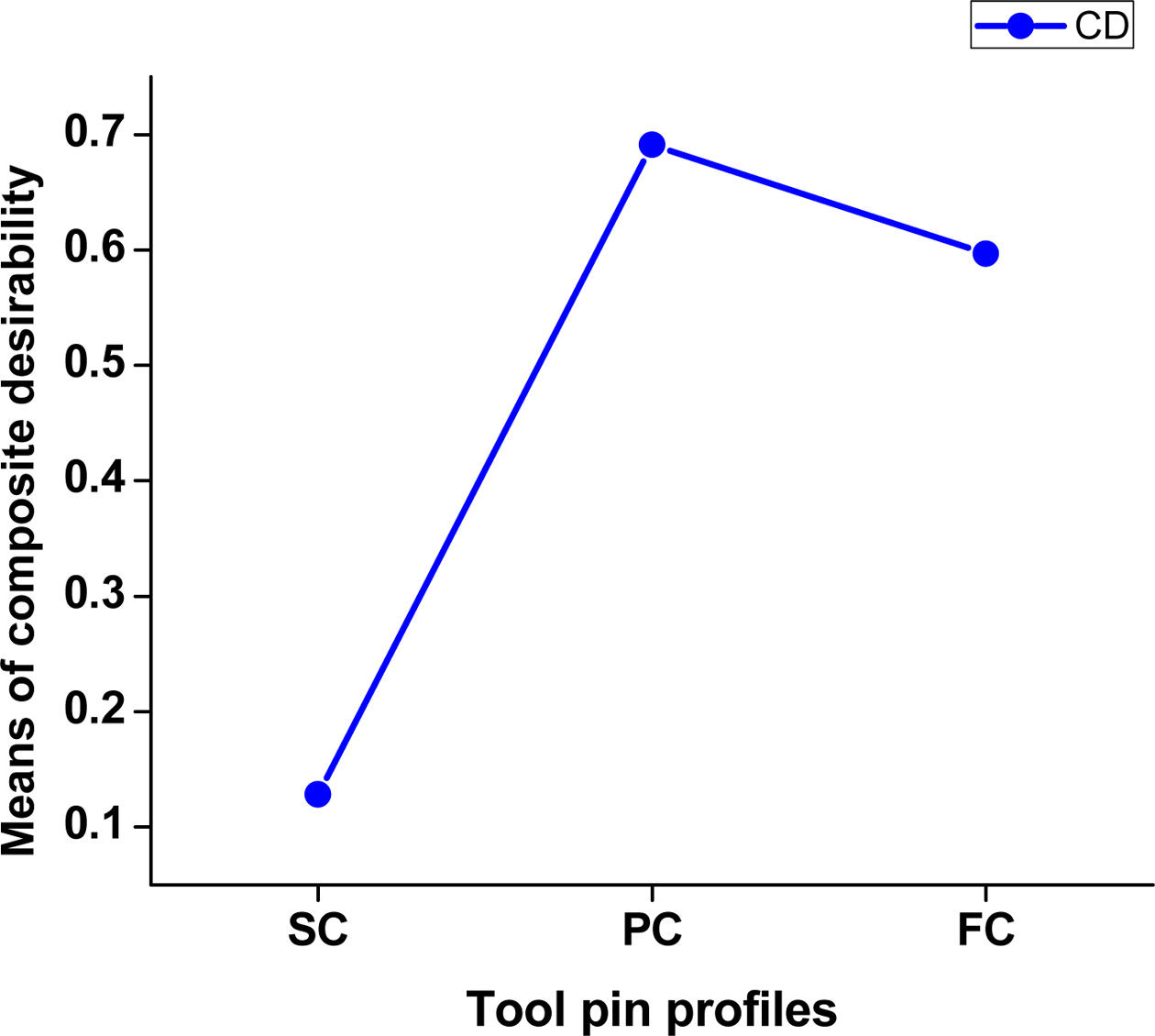

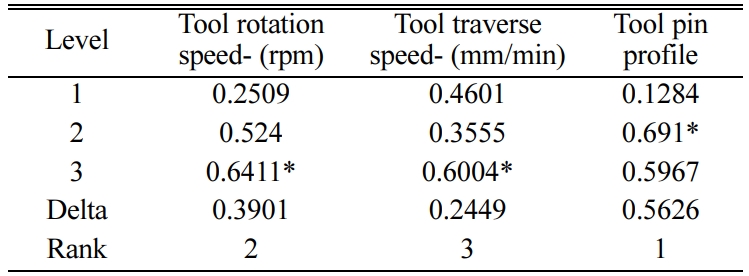

Fig. 5 to 7 6 presented means of composite desirability with

various FSW parameters. From the plots, the dotted line

signifies the mean value of composite desirability. It is observed that the

plots and the maximum value indicate the predicted

characteristics of multiple responses. It indeed that the optimal

level of FSW parameter arrangements obtained at the level A3B3C2,

which intimates that the tool rotation speed

(1,200 rpm) at level 3, tool traverse speed (30 mm/min) at level 3, and tool

pin profile (pentagonal cylinder) at level 2. Above the mentioned level of

welding process parameters enhances the multi-responses of tensile strength and

nugget hardness during the FSW process of AA5052 aluminium alloy. The mean and

the average composite desirability for every process parameters level was

displayed in Table 6. Therefore, table 6 clearly explains the order of control

process parameters verified by the delta result. The highest delta value

indicated as 1st rank, which denotes that, the control parameter

which are the significant impact of output response. From mean table, the tool

pin profile parameter was a significant aspect of the multiple performances of

the developed welding process

followed by the tool rotation speed.

Analysis

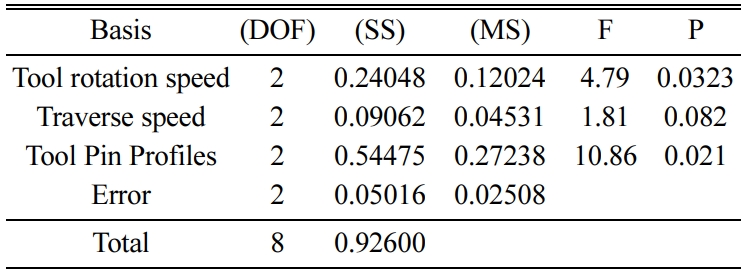

of composite desirability

ANOVA objective is to manipulate the FSW parameters with

contributions of integrated multi-response qualities [24].

Table 7 exhibited the ANOVA results of composite

desirability. ANOVA results proved that the tool pin profile was the most

influencing factor in which 62.1% contribution followed by tool rotation speed

contributes 27.4%. The lowest contribution of 10.3% occurred in tool traverse

speed. At a 95% confidence interval, the significant process parameters were

indicated by less than 0.05 of P-value. In this analysis, tool pin profiles (p

= 0.021) and tool rotation speed (p = 0.032) severely affecting the

process parameters on the output of multiple responses through the FSW of

AA5052 [25].

Contour

plot analysis for composite desirability

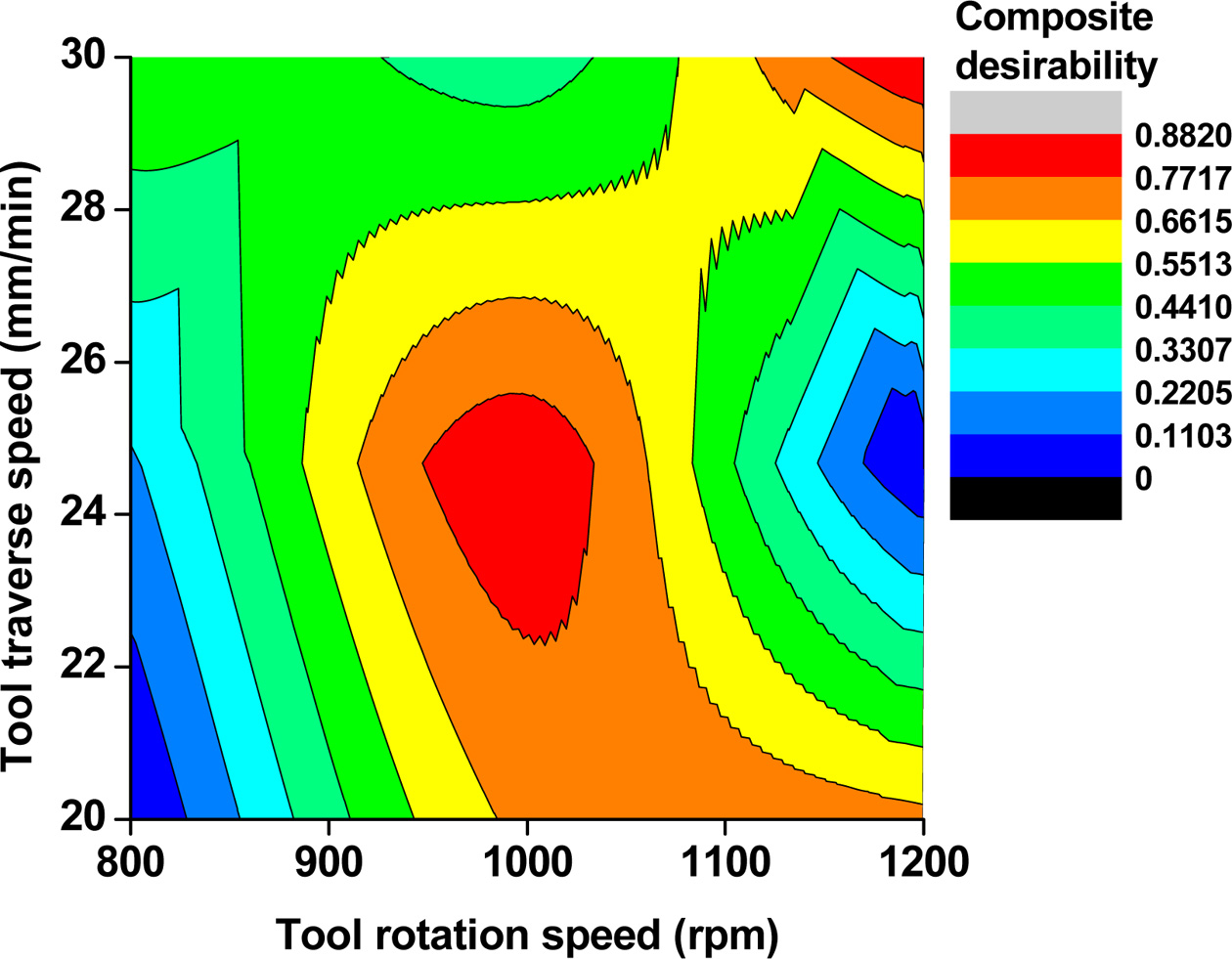

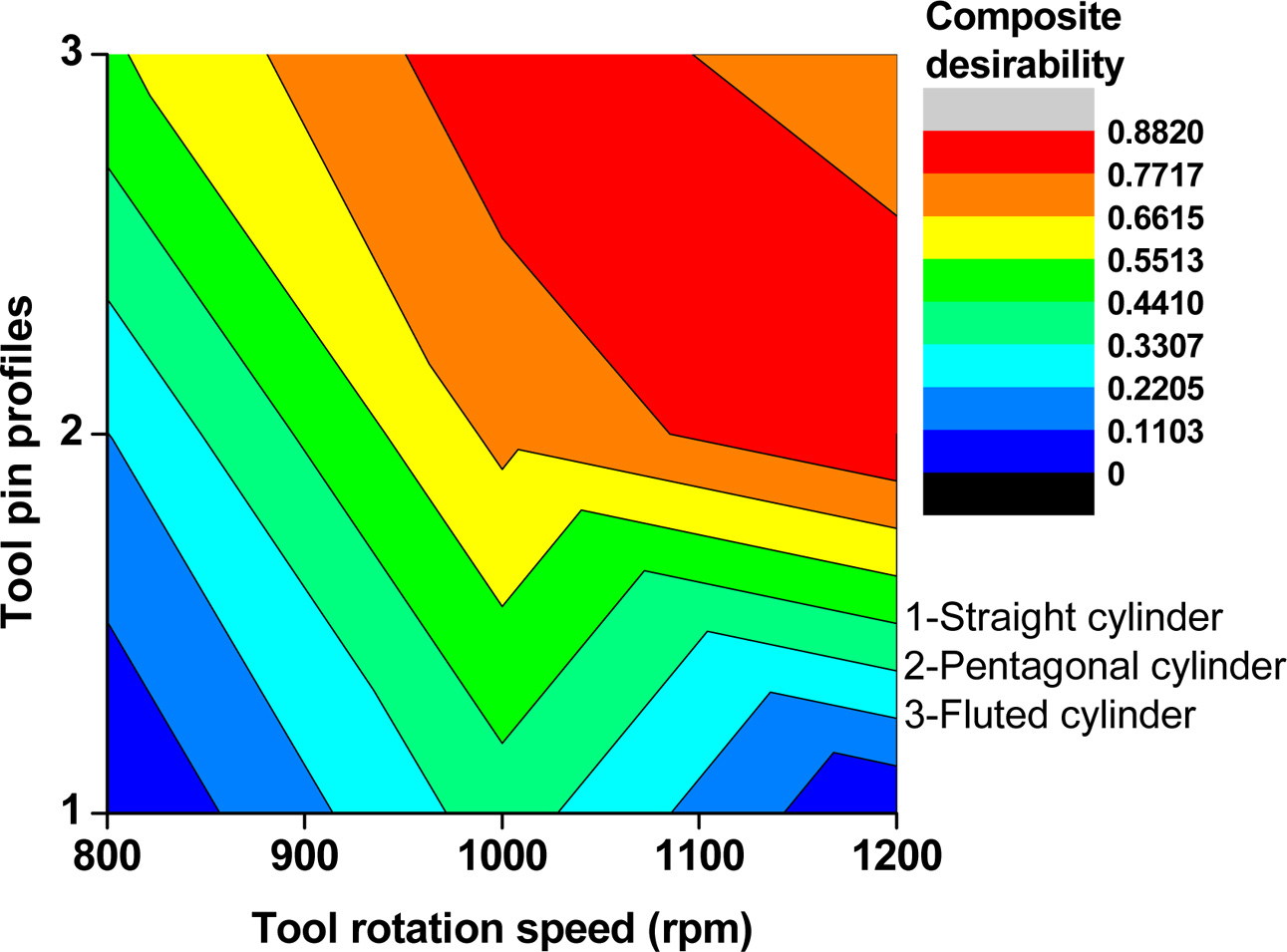

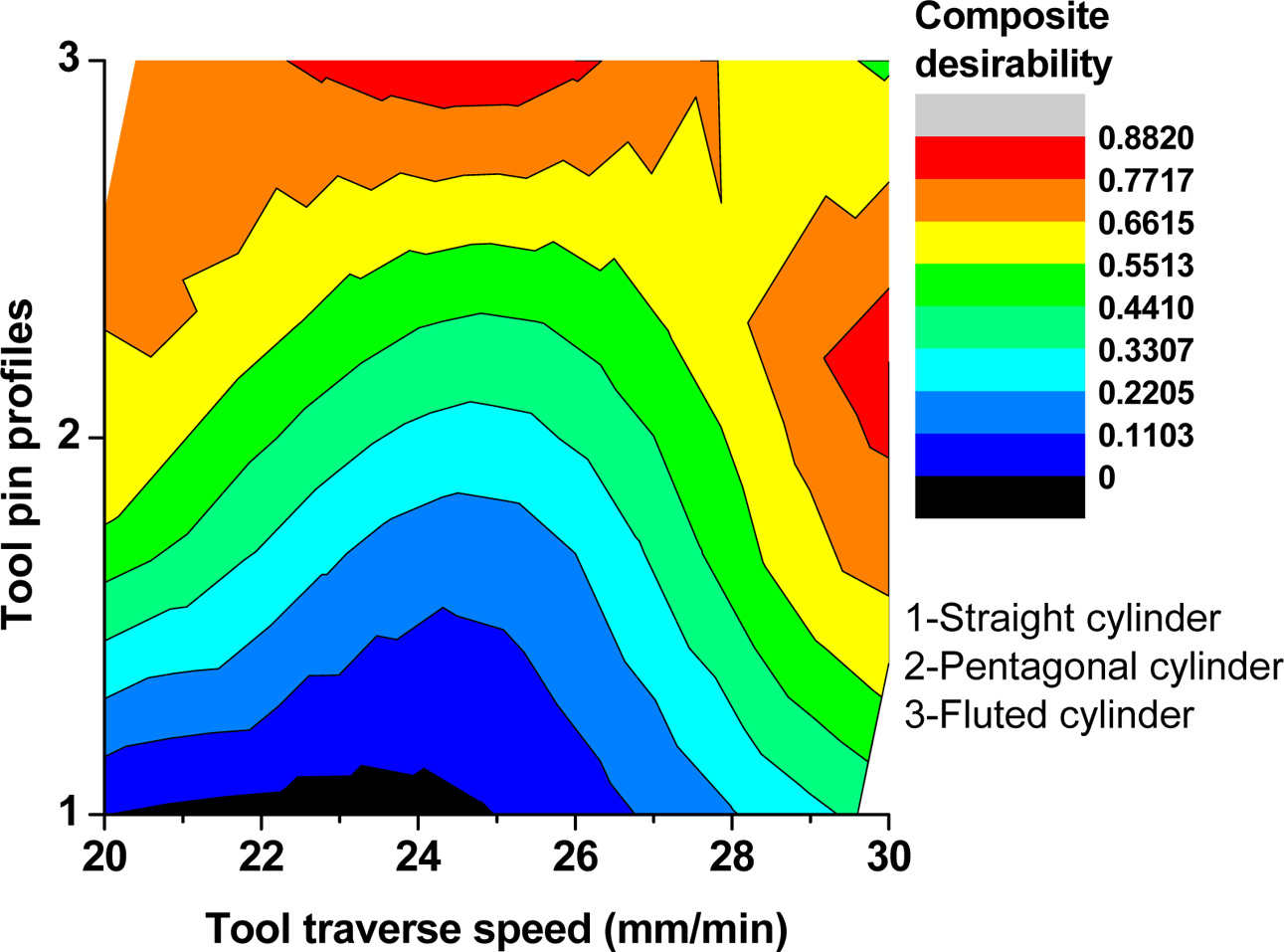

Fig. 8-10 exhibits the desirability contour plots with

processing parameters of welding at different levels. In Fig. 8 showed, the

impact of tool rate and tool traverse speed of composite desirability value. It

is perceived that the value of composite desirability was increased while

increasing the rate of tool rotation and weld speed. Maximum desirability value

of 0.8820 was occurred at the tool rotation speed (1,200 rpm) and tool traverse

speed (30 mm/min). In Fig. 9 showed that the effect of tool speed and three pin

profiles of composite desirability value. It revealed that the tool rotation

speed (1,200 rpm) and pentagon pin profile produces the highest composite

desirability value. Due to higher tool rotation produced higher friction

between the base metal and the tool, thus the outcomes improved the tensile

strength and nugget hardness. In Fig. 10 represents the

response of tool traverse speed and tool pin profiles of the

desirability values, the maximum value of composite desirability

attained at the 30 mm/min tool traverse speed and pentagonal tool pin profile

parameters.

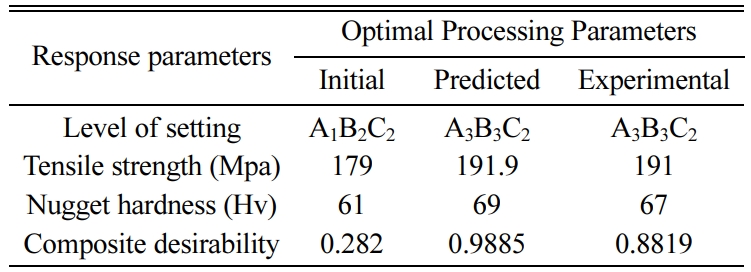

Confirmation

analysis of composite desirability

The verification test engaged to verify the

investigational outcomes. An optimal level of FSW

parameters utilized to validate the multi-response

qualities during the process on AA5052. By

using below the equation, the predicted value of

composite desirability was determined.

The composite desirability of

average value and the mean value indicated by hm and hi by the optimum level of process parameters. K-denotes

the number of FSW parameters. Predicted,

experimental and improved percentage on composite desirability value was presented in Table 8.

|

Fig. 4 The composite desirability vs the nine experimental runs. |

|

Fig. 5 Means of composite desirability vs Tool rotation speed. |

|

Fig. 6 Means of composite desirability vs Tool traverse speed. |

|

Fig. 7 Means of composite desirability vs Tool pin profiles |

|

Fig. 8 Contour plot of composite desirability for Tool traverse

speed vs Tool rotation speed. |

|

Fig. 9 Contour plot of composite desirability for Tool pin

profiles vs Tool rotation speed. |

|

Fig. 10 Contour plot of composite desirability for Tool pin

profiles vs Tool traverse speed. |

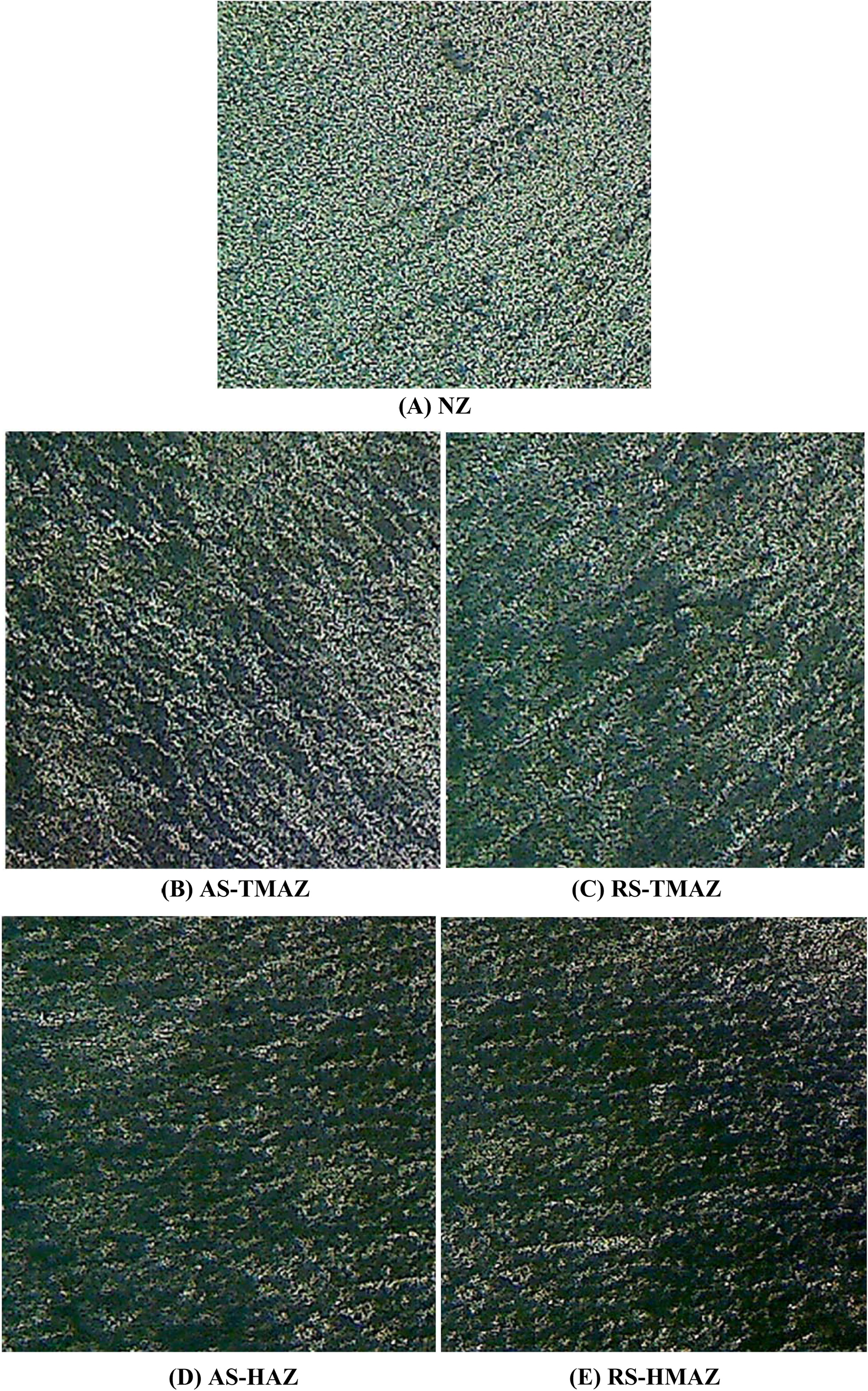

The optical microscopy investigation was conducted on the

microstructure analysis of the entire AA5052 welded region with the influence

of various welding parameters. The micrographs of stirred zone of joints were

observed to dynamic recrystallization appeared during the welding. Also

mentioned variations in grain size and homogeneity were determined in the

welding technique [26]. The grain size was measured at three deformation

zones, namely the nugget zone (NZ), thermo-mechanically

affected zone (TMAZ), and heat-affected zone (HAZ). Heyn’s line intercept

technique applied to determine the (AGD- Average Grain Diameter) of stirred

zone on welded specimens. The granular grains of the base metal modified to

fine grains in the nugget zone. The microstructure of fabricated FSW joints

utilizing the optimum parameters were shown in Fig. 11. Mentioned

figure shows the grain structure of friction stir welded

at different zones with magnification of 100 ´

and 100 μm. In all the welded specimens, the nugget zone grain size is much

smaller than the TMAZ and HAZ. The advancing and retreating side of the TMAZ

grain size is finer than that of the HAZ. The welded joints thermo mechanically

affected zoneadvancing side (TMAZ-AS) fabricated by the indicated process

parameters exhibits coarse and elongated of deformed grains at the welded

interface. The welded joints thermomechanically

affected zone - retreating side (TMAZ-RS) shows the elongated

oriented grains due to the deformation of the welded interface

was slowly reduced. The heat affected zone on advancing side (AS) and

retreating side (RS) micrographs show the coarsening of grain

occurred in HAZ due to mechanically influenced deformation

not occurred [27-29]. Fig. 11 presents the microstructures

of various zones at the optimum process parameters

with tool rotation speed (1,200 rpm), traverse speed (30

mm/min), and the pentagonal cylinder tool pin profile. The nugget zone grain

size is much smaller than the TMAZ and HAZ. The advancing

and retreating side of the TMAZ grain size is finer than that of

the HAZ. The average grain diameter at the nugget zone is 1.59 μm.

|

Fig. 11 Microstructure of different zones at the optimum process parameters 1,200 rpm, 30 mm/min and pentagonal cylinder tool . |

1. The FSW of AA5052 aluminium alloy was

effectively fabricated throughout this welding process and the optimal

process parameters of FSW was investigated.

2. Taguchi based desirability function analysis

was successfully employed to verify the optimum level of welding parameters

during welding process.

3. The optimal level of process parameters are

tool rotation speed (1,200 rpm),

tool traverse speed (30 mm/min) and the pentagonal pin profile achieved maximum

tensile strength and nugget hardness.

4. ANOVA outcomes showed, the tool pin profiles

was the most significant factor for output responses with contribution of

62.1%. Subsequently, tool spinning rate and weld speed contributes the 27.4%

and 10.3%.

5. The confirmation analysis of composite

desirability utilized to validate the optimum level of process parameters

so as to improve the composite desirability with

68.02%.

The authors express their genuine gratefulness to

Coimbatore institute of technology (CIT), Coimbatore providing the amenities

for conduct of the research.

- 1. T.A. Barnes and I.R. Pashby, J. Mate. Proc. Tech. 99[1-3] (2000) 62-71.

-

- 2. S.V. Alagarsamy, M. Ravichandran, S. Dinesh Kumar, S. Sakthivelu, M. Meignanamoorthy, and C. Chanakyan, Mate. Today. Proc. 27[2] (2020) 853-858.

-

- 3. P. Periyasamy, B. Mohan, V. Balasubramanian, S. Rajakumar, and S. Venugopal, Tran. Nonf. Meta. Soci. Chin. 23[4] (2013) 942-955.

-

- 4. M. Ambekar and J. Kittur, Mate. Today. Proc. 27[1] (2019) 363-368.

-

- 5. D. Devaiah, K. Kishore, and P. Laxminarayana, Mate. Today. Proc. 5[2] (2018) 4607-4614.

-

- 6. D. Devarasiddappa, M. Chandrasekaran, and M.T. Sambandam, Mate. Today. Proc. 5[5] (2018) 11531-11547.

-

- 7. M.P. Jenarthanan, C. Varun Varma, and V. Krishna Manohar, Mate. Today. Proceedings 5[6] (2018) 14384-14391.

-

- 8. J. John, S.P Shanmuganatan, and M.B Kiran, Mate. Today. Proc. 5[11] (2018) 25458-25467.

-

- 9. A. Kumar, M.K. Khurana, and G. Singh, Mate. Toda Proc. 5[11] (2018) 25440-25449.

-

- 10. S. Shashi Kumar, N. Murugan, and K.K. Ramachandran, Measurement. 137 (2019) 257-271.

-

- 11. D.K. Naik and K.P. Maity, Mate. Today. Proc. 5[5] (2018) 13157-13165.

-

- 12. M. Muthu Krishnan, J. Maniraj, R. Deepak, and K. Anganan, Mate. Today. Proc. 5[1] (2018) 716-723.

-

- 13. C.C. Nwobi-Okoye, B.Q. Ochieze, and S. Okiy, J. Mate. Rese. Tech. 8[3] (2019) 3054-3075.

-

- 14. B. Fu, G. Qin, F. Li, X. Meng, J. Zhang, and C. Wu, J. Mate. Proc. Tech. 218 (2015) 38-47.

-

- 15. A.K. Kadian and P. Biswas. J. Manuf. Proc. 34 (2018) 96-105.

-

- 16. K. Palani, C. Elanchezhian, B. Vijaya Ramnath, G.B. Bhaskar, and E. Naveen, Mate. Today. Proc. 5[11] (2018) 24515-24524.

-

- 17. Prabhakar, N. Ravi Kumar, and B. Ratna Sunil, Mate. Today. Proc. 5[2] (2018) 8391-8397.

-

- 18. P. Gopi Krishnan, B. Suresh Babu, and K. Siva, J. Ceram. Process. Res. 21[2] (2020) 157-163.

- 19. C. Chanakyan and S. Sivasankar, Inte. J. Rapi. Manu. 8[1/2] (2019) 147-160.

-

- 20. C. Chanakyan and S. Sivasankar, M. Meignanamoorthy, M. Ravichandran, and T. Muralidharan, Mate. Toda. Proc. 21 (2020) 231-236.

-

- 21. B. Singaravel and T. Selvaraj, J. Adva. Manu. Syst. 15[1] (2016) 1-11.

-

- 22. M. P. Jenarthanan and R. Jeyapaul, Inte. J. Scie. Tech. 5[4] (2013) 23-36.

-

- 23. P. Sengottuvel, S. Satishkuma, and D. Dinakaran, Proc. Engi. 64 (2013) 1069-1078.

-

- 24. S.V. Alagarsamy and M. Ravichandran, Indu. Lubr. Trib. 71[9] (2019) 1064-1071.

-

- 25. R. Bobbili, V. Madhu, and A.K. Gogia, Engi. Scie. Tech. Inter. J. 18[4] (2015) 720-726.

-

- 26. G. Ugrasen, G. Bharath, G. Kishor Kumar, R. Sagar, P.R. Shivu, and R. Keshavamurthy, Mate. Toda. Proc. 5[1] (2018) 3027-3035.

-

- 27. K. Meena, A. Kumar, and S.N. Pandya, Mate. Toda. Proc. 4[2] (2017) 1978-1987.

-

- 28. H, Fujii, L. Cui, M. Maeda, and K. Nogi, Mate. Scie. Engi. A. 419[1-2] (2006) 25-31.

-

- 29. P. Thread Gill, Science and Technology of Welding and Joining 12[4] (2007) 357-360.

-

This Article

This Article

-

2020; 21(6): 647-655

Published on Dec 31, 2020

- 10.36410/jcpr.2020.21.6.647

- Received on May 15, 2020

- Revised on Aug 15, 2020

- Accepted on Sep 4, 2020

Services

Services

- Abstract

introduction

materials and methods

result and discussion

microstructure

conclusion

- Acknowledgements

- References

- Full Text PDF

Shared

Correspondence to

Correspondence to

- C. Chanakyan

-

Research Scholar, Department of Mechanical Engineering, Government College of Engineering, Thanjavur, Tamilnadu, India

Tel : +91 9786964398 - E-mail: chanmech89@gmail.com

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.