- Experimental Investigation on Room Temperature Vulcanised Silicone rubber and Epoxy resin coated porcelain outdoor insulators located at highly polluted environment

M. Ravindrana,*, S. Senthil Kumarb, N. Karuppiahc and M. Asokand

aAssociate Professor (S.G), Department of EEE, National Engineering College, Tamil Nadu, India

bAssistant Professor (S.G.), Department of EEE, National Engineering College, Tamil Nadu, India

cProfessor, Department of EEE, Vardhaman College of Engineering, Telangana, India

dPG Scholar, National Engineering College, Tamilnadu, India

Insulators flashover is one of

the major problem that confronts all around the world, particularly in austere

weather conditions and highly polluted areas. Any failure in the acceptable

performance of high voltage insulators result in intrerruption of electrical

power that leads to loss of capital. Flashover voltage (FOV) is directly

related to the severity of pollution on the surface of insulator. Generally,

anti-pollution flashover coating is considered as one of the most effective

means to prevent and reduce flashover. This paper investigates and compares the

results on application of Epoxy Resin and Room Temperature Vulcanized (RTV)

Silicone Rubber for improving the performance of outdoor (near coastal thermal

plant area) insulators of 12 KV rating. The flash over voltage of the

insulators is optimized for a polluted environment by applying the protective

coating and tested experimentally. The experimental results are compared with

simulated results using Artificial Neural Network.

Keywords: Artificial Neural Network, Epoxy Resin, Flashover voltage, Post Type Insulator

The rapid development of modern society and industries,

worldwide, made the power requirement to be more significant. The reliability

of the electrical network and its setup is essential for the satisfactory performance

of an electric power system [1, 2]. Insulators are one

among the significant apparatus in the high voltage transmission line and

switch yard, which are used for keeping apart the electrical

supply irregularities [3].

In general, electric power system has exploited the usage

of ceramic and non-ceramic insulators. In recently developed

transmission systems, polymer insulators which offer

several advantages over porcelain insulators are

used. Polymer insulators have excellent hydrophobic surface

property under wet conditions, eminent mechanical strength to

weight ratio, saving on labour due to less weight and bringing down maintenance

costs [4, 5]. Eventhough, polymer insulators have a number of advantages, it

suffers from a significant drawback i.e, these insulators are more prone to

chemical changes (weak bond compared to porcelain). Also, it suffers from

erosion and tracking their life expectancy is difficult. Porcelain Insulators

have some advantages over the polymer insulators as it is environmental

friendly, higher electrical strength (25 kV/mm), high thermal resistance,

stable against the effects of UV radiation and do not suffer

from defects in the ceramics-to-metal interface. Porcelain is a

sluggish and stable material and the surface does not easily degrade,

because dry band arcing withstand capacity is

high when compared to silicone rubber [6-8].

Pollution is a million dollar problem especially for

outdoor insulation systems. Pollution severity and the contamination present on

the surface of the insulators depend on the type of surface area of the

insulator (marine, industrial, ice and fog, chemical, desert, bird segregation

etc). There are several factors that are responsible for the flashover voltage

on the surface of the insulator [9]. They are surface resistance of a

material, surface condition and electric field intensity within the

conductor and insulator. Electric Arcing is an outside disruption on the

insulator surface. It is a cognitive process whose value is smaller

than the puncture voltage of the insulator. Sometimes it

exceeds the ceiling value and damages the insulator due to puncture which is

one of the worst cases that must be avoided. This paper investigates a 12 kV

Post type ceramic insulator which has been taken from near coastal coal based

power plant, which is situated in a nearest coastline within 1 km. The

combustion of coal at thermal power plants lets out carbon dioxide (CO2),

sulphur oxides (SOx), nitrogen oxides (NOx), CFCs particulates such as fly ash

and Suspended Particulate Matter (SPM) ranging from 0.5 to

100 micron in size. Because of these pollutants electrical

equipments of coal based power plant are extremely

affected [10, 11]. These coastal insulators often comes into

contact with dust and humidity (seashore area) and

thereby gets affected by the problem of corona. Generally

anti-pollution flashover coating is considered to be one of the most effective

means to prevent and reduce pollution flashover.The thickness of coating should

also be improved to withstand the voltage of the insulator. Silicone oil and

silicone grease are some of the existing coating methods that increases the

life of the insulator. Protective polymer coatings greatly bring down

the frequency of cleaning of insulators and periodic

re-application of greases besides their drawbacks such as poor mechanical

strength, thixotropic performance, tracking, erosion performance and flame

retardancy [12, 13].

In literature discussed above,

the strength of protective polymer

coating of Epoxy Resin and Silicon rubber are compared. In recent literatures,

the need for an optimization technique to

improve the new design of insulator is discussed [14-16]. COMSOL is one of the

advanced Finite Element methods and multi physics software package used to find

out the optimized effect of electric field

distribution of insulators. It is also used to minimize the electrical stress at the vicinity of the insulators [17, 18]. Also MATLAB is used in

simulation and mathematical modelling

of insulators. Critical flash over

voltages of insulators are obtained through MATLAB simulation and these simulated values are

compared with the experimental values.

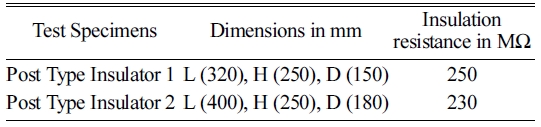

Post

insulator specimens

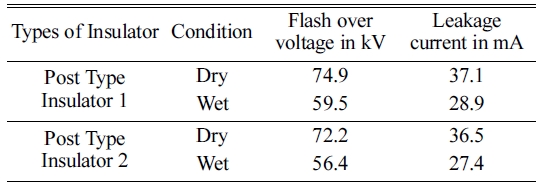

Two test specimen sets (12 kV Post Type Ceramic Insulator)

which are predominently used in high and extra high voltage substation switch

yards are taken. These specimen insulators are used for supporting electrical

equipment and bus conductors in switch yards. It is different from pin

insulator in such a way that it has metal support on both sides. Firstly, the

test specimens are measured in dimensions to find out the Insulation resistance

values. These measured values for the test specimens are shown in Table 1. In

this test, the insulators are cleaned and the measurement of

breakdown voltages and leakage current are

noted without pollution. The flasover voltages of the

specimen insulators are tested experimentally and these values are shown in

Table 2. Flash overvoltage test on insulator specimens should be

conducted only a few times orelse the insulator may destroy

permanently. The Insulator specimens should also be strong enough

to withstand over voltages during the operation.

Experimental setup

Fig. 1 shows the experimental setup in high voltage laboratory.

The setup has coupling capacitance and high voltage

transformer. The voltage rating of transformer is 2×0.22/100/0.22 kV, current

rating is 2×22.8/0.1A, with output rating as 10 kVA. The high voltage lab comprises of control panel with exact metering

facilities.

Pollution test without protective coating

Before conducting the tests on the insulators, they are

scavenged to get rid of dirt and greases. The type of pollutants which are

accumulated near coastal thermal plants are coal and fly ash. These are taken

at different ratios, and then mixed with distilled water and enforced over the

surface of the insulators test specimens by brushing method. The artificial

tests are carried out in high voltage laboratory and the test specimens are put

on slowly from zero voltage until consummate flashover

falls (occurring flashover as shown in Fig. 2) out on the insulator surface.

The average flashover voltage and leakage current is precipitated when the

quantity of dust is aroused. At flashover, the voltage and leakage current is

put down.

Pollution test with protective coating

To improve the performance of porcelain insulator under

polluted conditions, coatings are used to extenuate surface

leakage current, surface discharge and bring down flashover occurrence. This

practice is particularly desirable for insulators established at substations

with pollution severity. This analysis looks into the

performance of the proposed protective coating which increases the

property of leakage current suppression and flashover voltage performance of

the insulators in comparison with Epoxy Resin coatings and silicone rubber

(RTV) coatings.The epoxy

group, which is also addressed as the

glycidyl group, has higher molecular group to commute Epoxy resin to plastic

and this setting is called as a hardener. The hardener for the epoxy resins are

primarily diamines and polyamines and chemical compounds with various molecular weights. These have high

mechanical strength, chemical resistance, diffusion density, water tightness, electrical insulation capacity, shrinkage, Heat resistance etc., Silicone

rubber compounds have characteristics of both inorganic and organic

materials. Si-COAT 570 HVIC (High voltage

Insulator Coating) is a one-part; room temperature vulcanizing (RTV)

polysiloxane (silicone) coating. Its unique con- ceptualization furnishes a highly

hydrophobic surface for its entire life. The coating is not impacted by UV

light, corona discharge, chemical contaminants, salt, extreme temperatures or

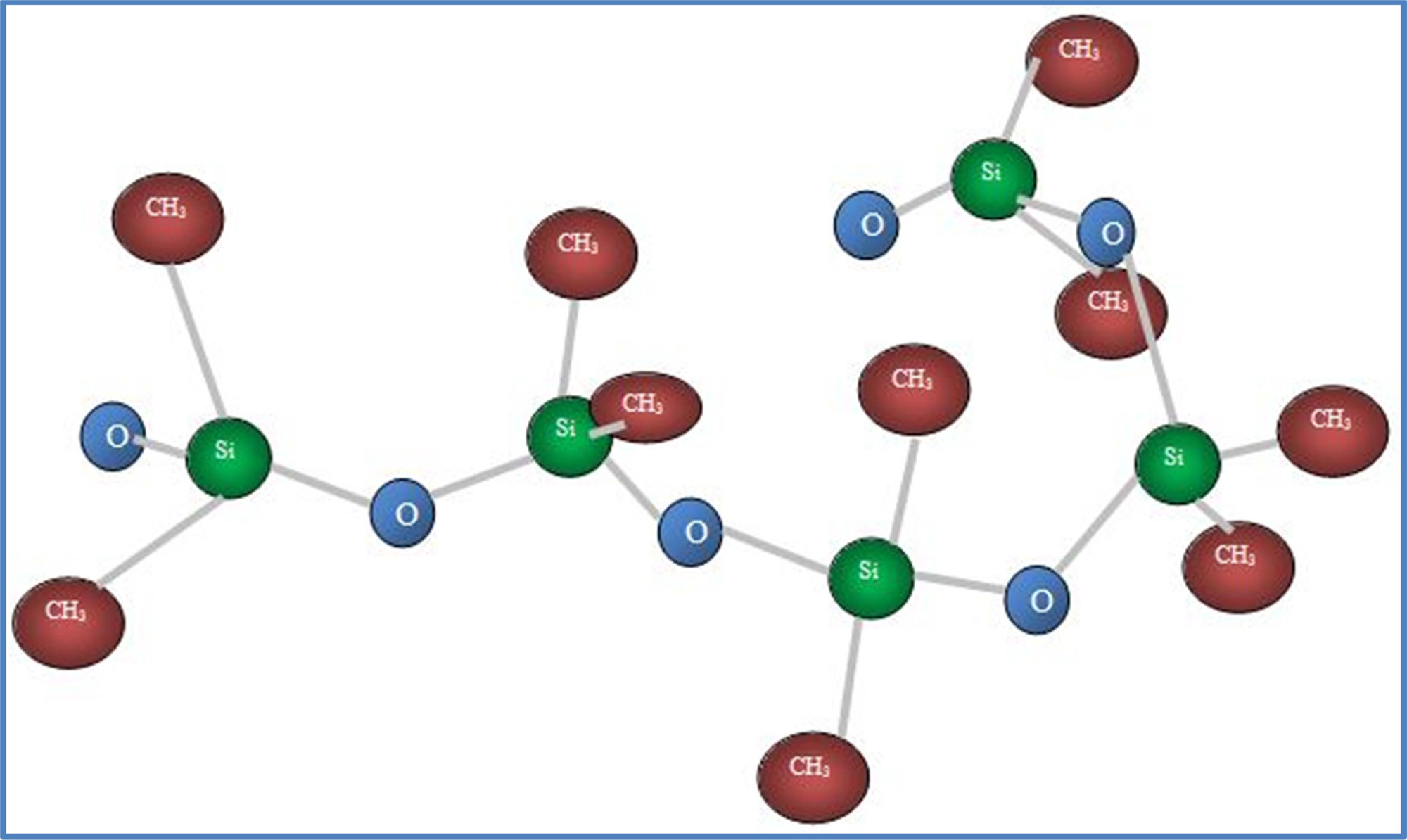

corrosive environments. Fig. 3 represents the structure of a RTV silicone

rubber [19].

Coating the porcelain post type insulators with RTV

coating is the only way to improve the water repellence of the surface. The

coating is enforced on the insulator surface by spraying the liquid polymer,

which then vulcanizes in presence of air into a flexible plastic layer and

Epoxy Resin coating applied by brushing method as shown in Fig. 4.

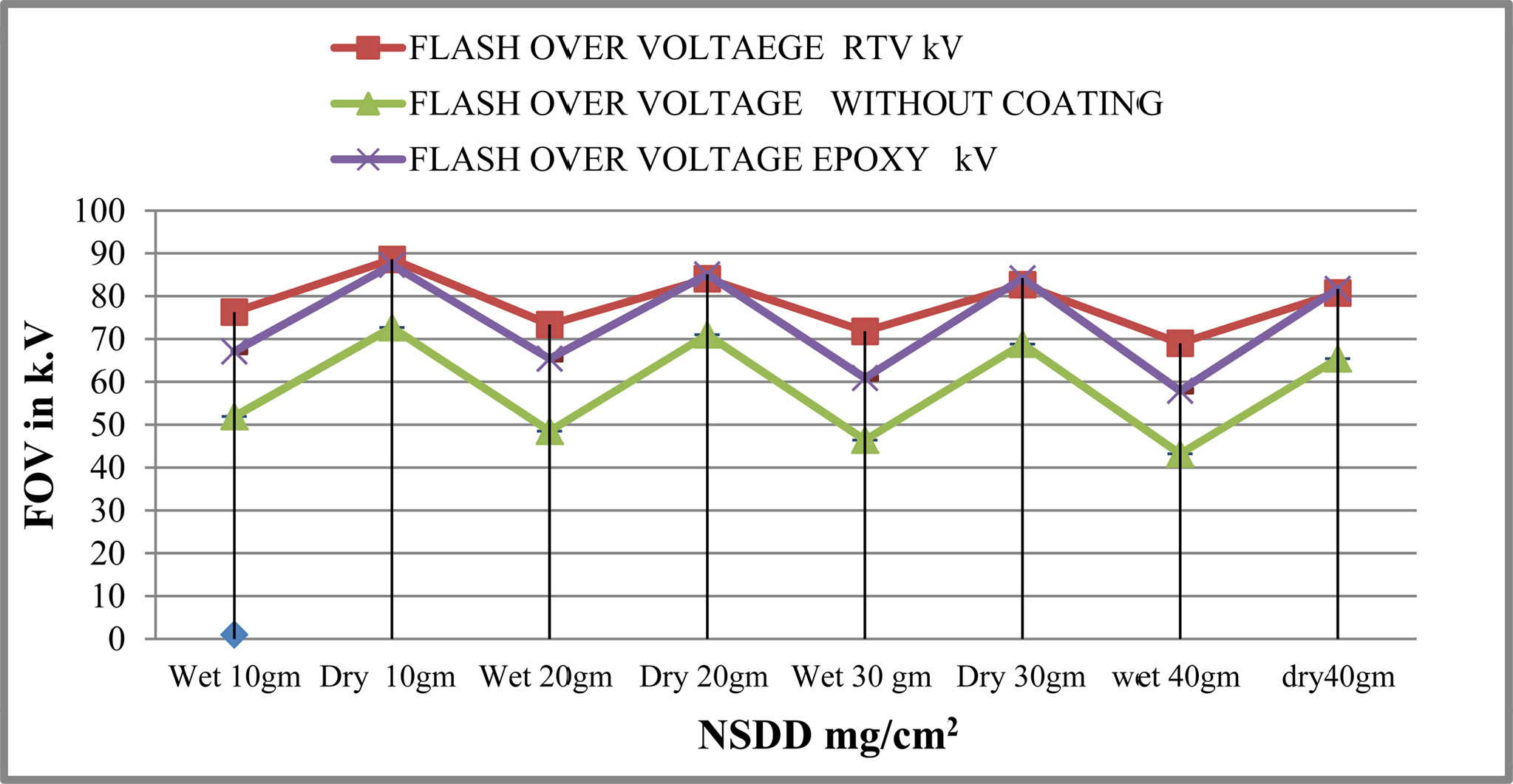

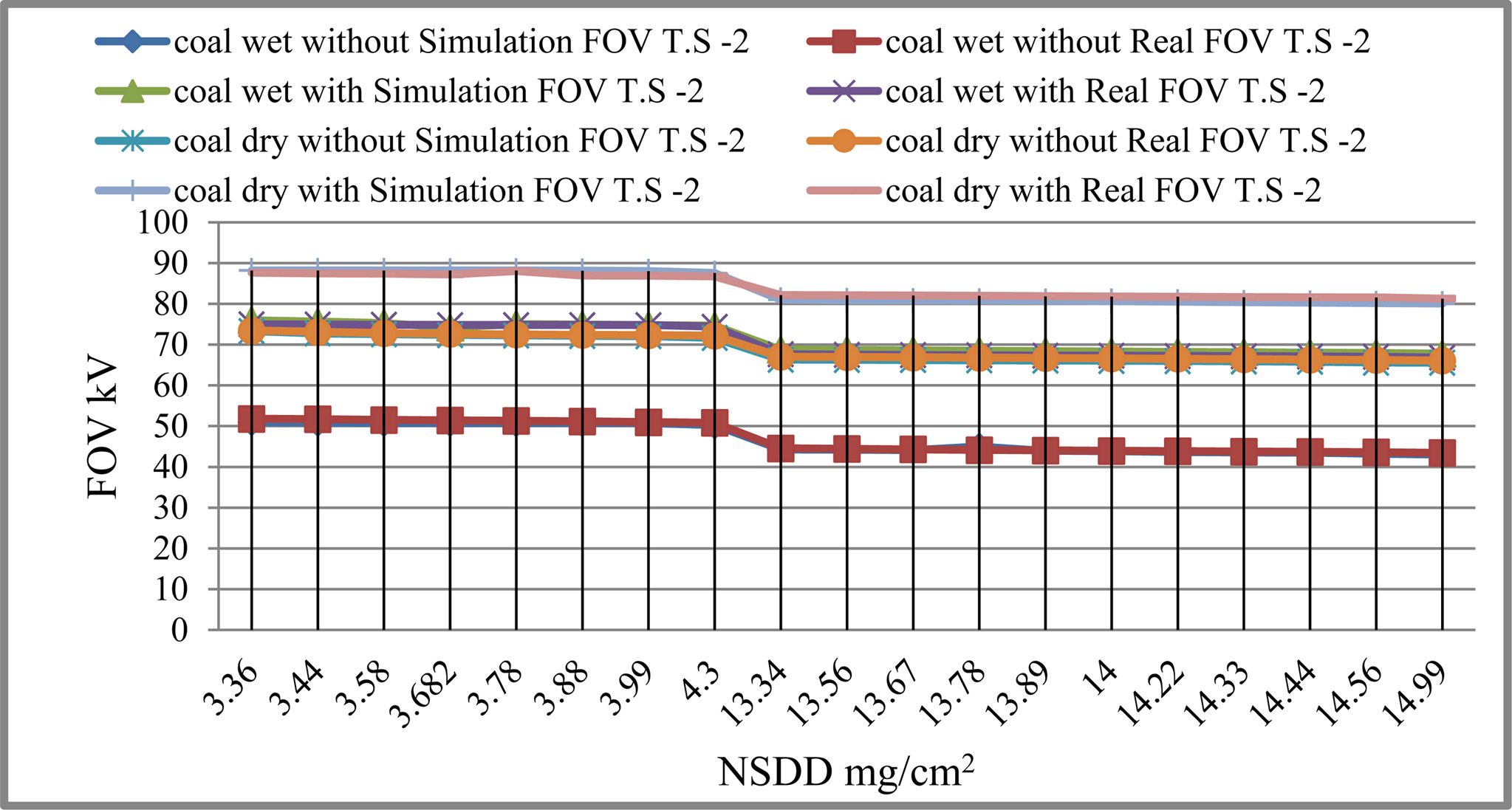

Flashover voltage vs Non Soluble Deposit Density value

(NSDD) are compared for the test specimens without pollution test (dry and wet

condition) and pollution test with RTV and Epoxy Resin coated 12 kV insulator

through high voltage testing. Fig. 5 represents graphically the flash over

voltage of insulator test specimens without pollution test and with pollution

test coated with different resins (Epoxy Resin and RTV).

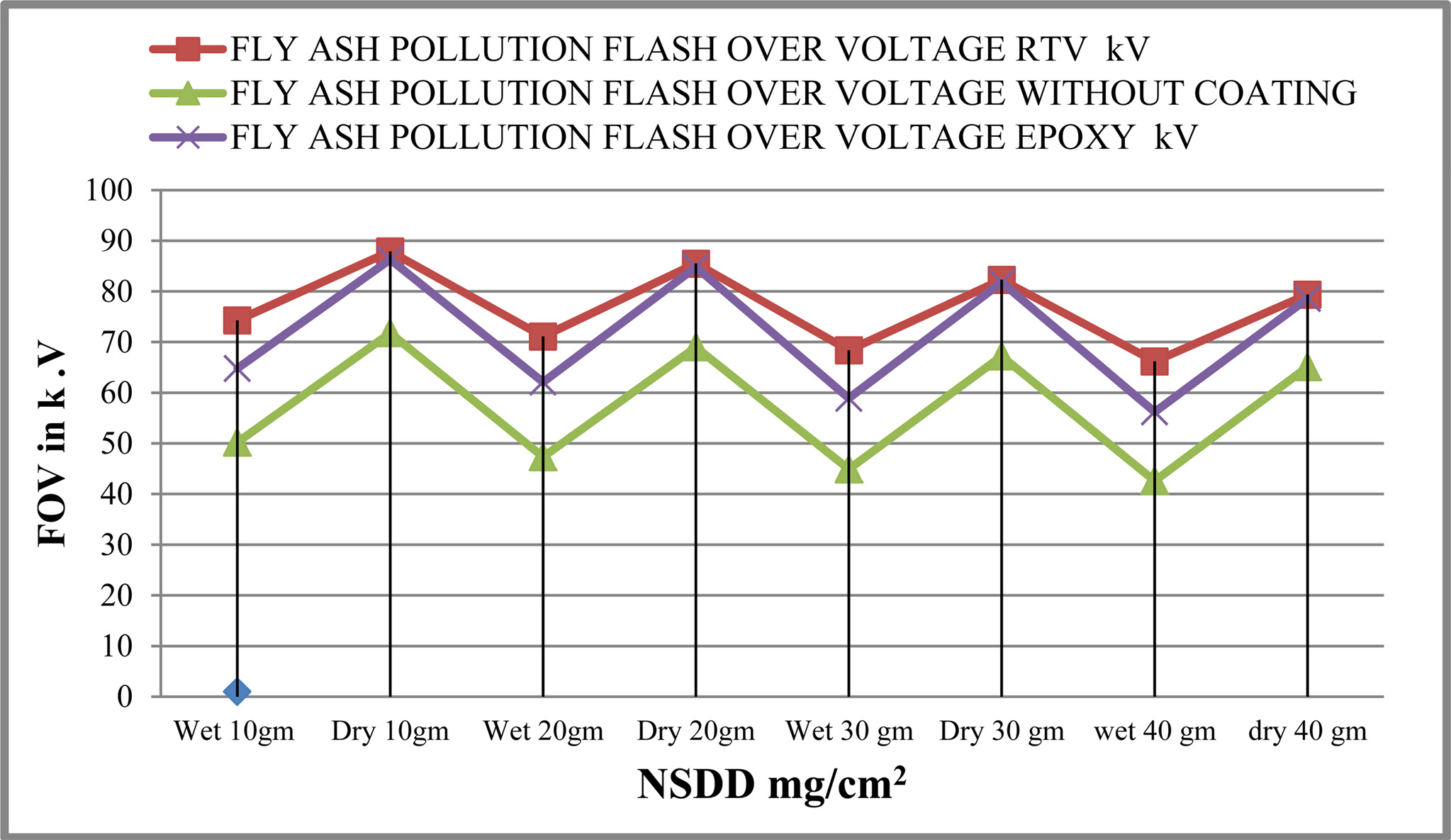

Fig. 6 represents the comparison of fly ash pollutants

with Epoxy Resin and RTV coating and without flyash pollutant. Tests are

conducted and flash over voltage is obtained in each case. In both the graphs

referred, it is clear that when the NSDD values are increased for every ratio

the flashover voltage has decreased. In wet conditions the flashover is

atrociously departed along with the increase of pollution

severity. In dry conditions the flash over voltage has slight

variations. In dry flash over, the performance comparison between epoxy resin

and silicone rubber are same, but in wet conditions silicone rubber coating has

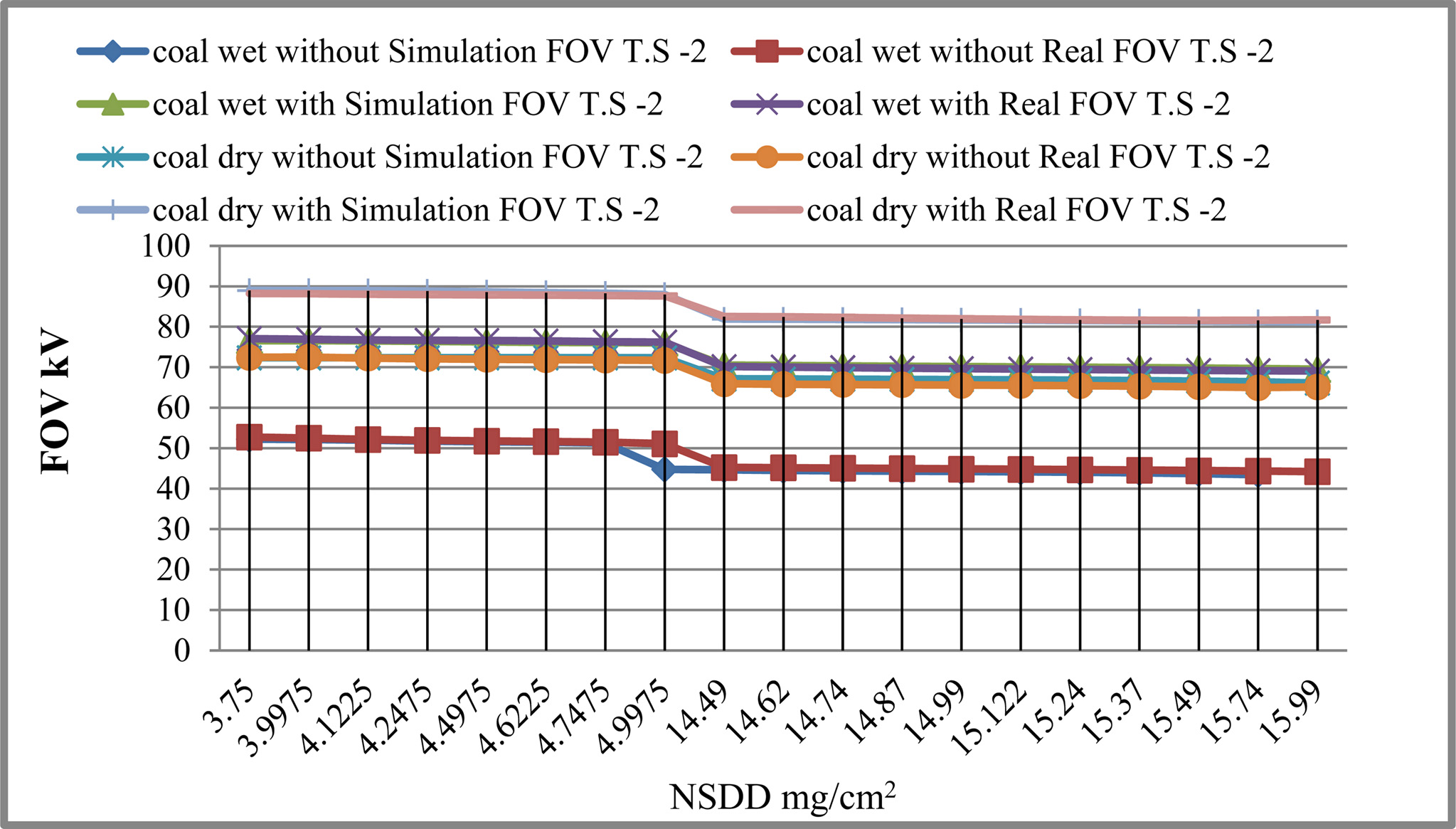

better performance when compared to epoxy resin. Fig. 7

|

Fig. 1 Experimental set up at High Voltage Research Laboratory in National Engineering College, Kovilpatti, Tamilnadu. |

|

Fig. 2 Occurrence of flashover in Insulator test specimens |

|

Fig. 3 Chemical structure of a linear silicon polymer |

|

Fig. 4 RTV Silicone and Epoxy Resin Coating. |

|

Fig. 5 Comparison of flash over voltages of insulator test specimens with Epoxy Resin and RTV Coating with coal pollutant and without pollutant test. |

|

Fig. 6 Comparison of flash over voltages of insulator test specimens with Epoxy Resin and RTV Coating with fly ash pollutant and without pollutant test. |

|

Fig. 7 Insulator without and with coal and RTV Coating for wet and dry conditionds under simulation and real test (experiment) on test specimen. |

The experimwntal results of the test specimen is compared

with the simulation results and the outcomes are discussed.

Simulation

result analysis using artificial neural network

In electrical power systems, to avoid insulator failure,

flashover designing is one of the major constituents. ANN is an effective tool

through MATLAB, which is used for insulator flashover. Training process of ANN require

more values which are drew out by curve fitting method of

experimental data. The TRAINLM (Leven berg-Marquardt algorithm) function is

used in Feed-forward back propagation method. The Leven berg-Marquardt (LM)

algorithm is a reiterative proficiency that locates the minimum of a function

that is evinced as the sum of squares of nonlinear occasions and is

mathematically calculated using TANSIG method [20-23].

Test

results using ANN

In this experiment, test specimens without pollutants

(coal) and RTV coating and with pollutant (coal) and RTV coating are compared

using experiment setup and ANN. In ANN, it is trained with 80 inputs and

outputs. The following comparison graph is drawn considering 19

values from initial and final of experimental data and from ANN training data

sets. In coal with wet condition and without coating result in high

experimental values when compared with ANN simulation values.

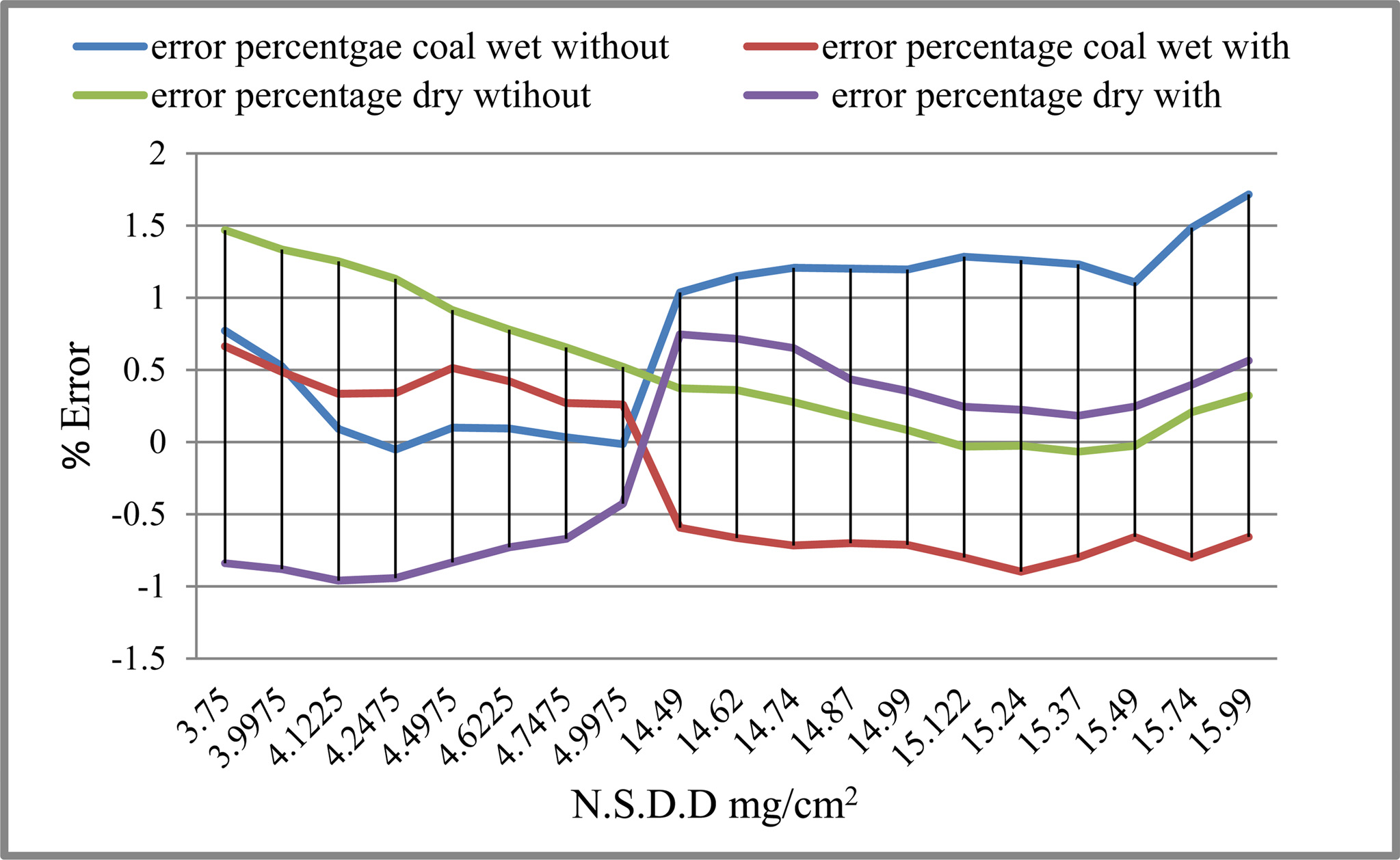

In above Fig. 8 graphical representation, coal with protective

coating under wet conditions have percentage error

values as oscillatory (both in positive and negative values). Coal without

protective coating under wet conditions have

an decreasing error percentage for starting values and increases upto 2

percentage. Coal with protective coating under dry conditions have percentage

error values as oscillatory (both in positive and negative values). But the

percentage error graph is opposite to

that in wet condition. Coal without protective coating under dry conditions have an decreasing error percentage.

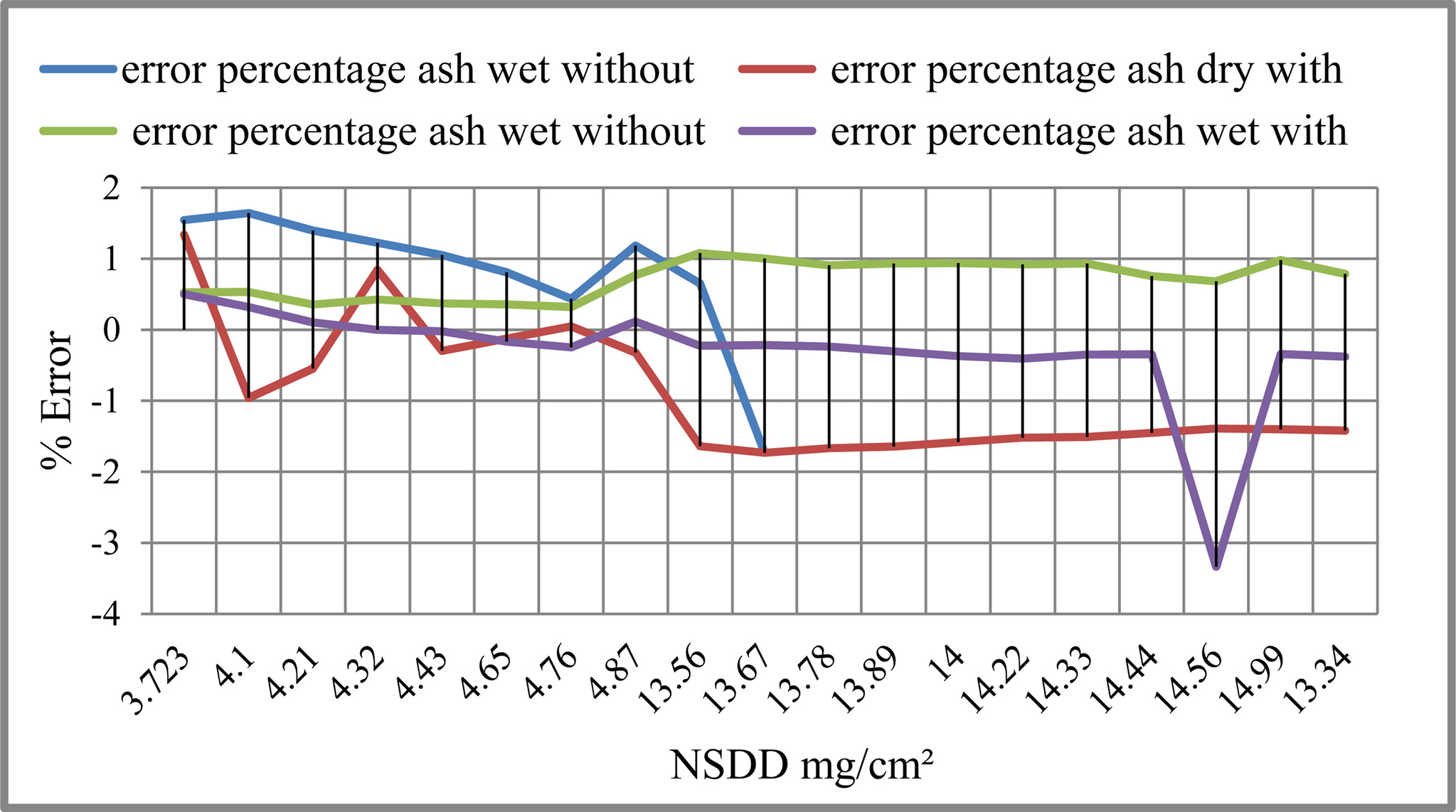

Secondly, comparison of graphical representation for Fly

ash pollution under wet and dry conditions using ANN and experimental set up is

shown in Fig. 9. The graph shows that the values are same even if the

conditions are varied.

In dry condition the percentage error without coating and

flyash carried out using simulation and experimental values are oscillatory

between positive and negative values. In dry

condition the percentage error with coating and

flyash carried out using simulation and experimental values

is constant. In wet condition the percentage error without coating and flyash carried out using

simulation and experimental values

are oscillatory between positive and

negative values in the beginning and settles down at a constant negative value.

In wet condition the percentage error with coating and flyash carried out using

simulation and experimental values are negative mostly with a steep negative

surge at the end.

In Fig. 10 graphical representations for all error values are

oscillatory in positive and negative value except wet without

coating. Its function is to estimate the model relationship

between critical flashover voltage, creepage distance

and Non Soluble Deposit Density for predicting the

flashover voltage of non-soluble polluted insulator. Simulation results are

foretelling and basically logical and agree with the experimental results.

|

Fig. 8 Percentage error of test specimen with and without Coal and coating under wet and dry conditions. |

|

Fig. 9 Insulator without and with Fly ash and RTV Coating for wet and dry conditions under simulation and real value (experimental) comparison on test specimen. |

|

Fig. 10 Percentage error values for test specimen with and without Fly ash and coating under wet and dry condition. |

This paper analyses the comparison

in high voltage Post Type insulators. The artificial pollution

testing insulator flashover voltage performance is directly proportional to the

quantity of pollution severity. Non-soluble Deposit Density (NSDD) values in

coal is little higher when compared with NSDD of fly ash and combination of

coal and ash. These results indicate that Silicone

Rubber-RTV coating increases the performance of ceramic

outdoor insulator to overcome pollution effect. The coated insulator maintains

it hydrophobicity under various polluted conditions. The flashover

voltage is approximately increased up to 25% after coated with

Silicone Rubber coating. When comparing with Epoxy resin and silicone rubber

coating, RTV coated insulator has high flashover voltage at wet and dry

conditions. Silicone rubber coated insulator is suitable for seashore and

tropical climate.

Pollution performance model of investigating samples

under artificial pollution condition has been done using Artificial Neural

Network. Its function is to estimate the model relationship between

critical flashover voltage, creepage distance and Non-soluble

Deposit Density for predicting the flashover voltage of non-soluble polluted

insulator. Simulation results are promising and are basically consistent with

the experimental results.

- 1. M.G. Sugirtha, P. Latha, N. Karuppiah, and J. Shanmugapriyan, in Proceedings of the International Conference on Computing Methodologies and Communication (IEEE 2018), 926-930.

-

- 2. N. Karuppiah and V. Malathi, Technical Gazette 23[1] (2016) 221-228.

-

- 3. T. Alshaketheep, K. Murakami, and N. Sekimura, Journal of Nuclear Science and Technology, Taylor & Francis Online 53[9] (2016) 1366-1370.

-

- 4. B.S. Reddy and A.R. Verma, Applied Energy 185[2] (2017) 1724-1731.

- 5. M. Majid Hussian, S. Farokhi, S. G. Mc Meekin, and M. Farzaneh, IEEE Transactions on Dielectrics and Electrical Insulation 24[2] (2017) 1068-1076.

-

- 6. D. Pylarinos, K. Siderakis, and E. Thalassinakis, IEEE Electrical Insulation Magazine 31[2] (2015) 23-29.

-

- 7. G.K. Artun, N. Polat, O.D. Yay, Ö.Ö. Üzmez, A. Arı, G.T. Tuygun, T. Elbir, H. Altuğ, Y. Dumanoğlu, T. Döğeroğlu, A. Dawood, M. Odabasi, and E.O. Gaga, Atmospheric Environment 150 (2017) 331-345.

- 8. E.A. Cherney, M. Marzinotto, R.S. Gorur, I. Ramirez, S. Li, A. El-Hag, and A. Tzimas, IEEE Transactions on Dielectrics and Electrical Insulation 21[1] (2014) 253-261.

-

- 9. P. Balagurusamy, R.V. Maheswari, B. Vigneshwaran, and M. Willjuice Iruthayarajan, IEEE International Conference on Circuit, Power and Computing Technologies, 2014.

-

- 10. F. Gerdinand I, M. Budde I, and M. Kurrat, in Proceedings of the International Conference on Solid Dielecrics, Toulouse (2004) 320-323.

- 11. C. Chen, Z. Jia, H. Lu, Z. Yang, and T. Li, IEEE Transactions on Dielectrics and Electrical Insulation 21[6] (2014) 2458-2465.

-

- 12. B. Zegnini, D. Mahi, and A. Chaker, Acta Electrotechnica et Informatica 9[4] (2009) 17-23.

- 13. L. Wei and Y. Wu, Journal of Ceramic Processing and Research 20[3] (2019) 216-222.

- 14. Agus Edy Pramonoa, Muhammad Zaki Nuraa, Johny Wahyuadi M. Soedarsonob, and Nanik Indayaningsihc, Journal of Ceramic Processinng and Research 20[1] (2019) 1-7.

- 15. F.O. Aramide, O.D. Adepoju, and A.P. Popoola, Journal of Ceramic Processing and Research 19[6] (2018) 483-491.

- 16. Y.-D. Li, J.-M. Chen, and Y.-C. Lee, Journal of Ceramic Processing and Research 19[6] (2018) 461-466.

- 17. S. Gowthama Kannan, L. Kalaivani, M. Willjuice Iruthayarajan, and M. Bakrutheen, IEEE International Conference on Circuit, Power and Computing Technologies, ICCPCT-2014, Nagercoil, pp. 345-349.

-

- 18. S. Gowthama Kannan, L. Kalaivani, M. Willjuice Iruthayarajan, M. Bakrutheen, IEEE International Conference on Circuit, Power and Computing Technologies, ICCPCT-2014, Nagercoil, pp. 345-349.

-

- 19. W. Xiaofeng, W. Jincheng, and Z. Yi, Journal of Experimental Nanoscience 11[13] (2016) 1058-1073.

-

- 20. W. Xiaofeng, W. Jincheng, and Z. Yi, Journal of Experimental Nanoscience 11[13] (2016) 1058-1073.

-

- 21. S. Tamilselvi, N. Karuppiah, and B. Rajagopal Reddy, 1st International Conference on Sustainable Energy and Future Electric Transportation (SeFet 2019), 87, 01026, pp. 1-8.

-

- 22. S.A. Ryder, Q. He, J. Si, and D.J. Tylavsky, IEEE Transactions on Power Delivery. 16[4] (2001) pp.825-826

-

- 23. N. Karuppiah, V. Malathi, and G. Selvalakshmi, International Conference on Swarm, Evolutionary, and Memetic Computing, 8947, pp. 292-303, 2014.

This Article

This Article

-

2020; 21(1): 14-20

Published on Feb 28, 2020

- 10.36410/jcpr.2020.21.1.14

- Received on May 15, 2019

- Revised on Oct 6, 2019

- Accepted on Oct 20, 2019

Services

Services

Shared

Correspondence to

Correspondence to

- M. Ravindran

-

Associate Professor (S.G), Department of EEE, National Engineering College, Tamil Nadu, India

Tel : +9194870 80584 - E-mail: ravinec99@gmail.com

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.