- Integrating artificial intelligence and generative engineering for constraint-aware ceramic jewelry design

Chen Guangming*

School of Arts and Media, Nanning College of Technology, Nanning, Guangxi, 530100, China

This article is an open access article distributed under the terms of the Creative Commons Attribution Non-Commercial License (http://creativecommons.org/licenses/by-nc/4.0) which permits unrestricted non-commercial use, distribution, and reproduction in any medium, provided the original work is properly cited.

This work explores the critical convergence of Artificial Intelligence (AI) and Additive Manufacturing to realize complex ceramic jewelry designs. The core challenge is overcoming the intrinsic conflict between the nearly unlimited geometric freedom offered by digital tools and the severe constraints of technical ceramics, namely brittleness, low tensile strength, and non-uniform volumetric shrinkage during high-temperature sintering .This work introduces a necessary computational framework that positions AI as a crucial tool for Design for Manufacturability, bridging creative exploration and physical viability. The conclusion is that AI acts as the essential connective tissue enabling the fabrication of complex ceramic components. The role of designer shifts towards a data curator and algorithm manager. Future commercial success relies on embracing a hybrid design practice that strategically frames AI as an amplifier of human creativity to preserve the narrative of skill and effort critical for consumer acceptance and market value.

Keywords: Jewelry design, Artificial Intelligence

Traditional jewelry creation methods, which rely on manual assembly, metal casting, and precision hand modeling, are being fundamentally transformed by the integration of computational tools. The craft of working with technical ceramics has historically been slow and unpredictable, requiring practitioners to adapt to the natural behavior of the material rather than exerting complete control. In contrast, computational approaches are typically positioned as mechanisms for dominating, automating, and accelerating workflows.

Artificial Intelligence (AI) has introduced a range of powerful generative tools that fundamentally alter the design landscape. AI generators enable rapid experimentation with diverse styles, materials, and techniques, significantly reducing the costs and prolonged timelines typically associated with traditional physical prototyping [1]. These systems can swiftly produce detailed variations in jewelry components, such as chains, beads, clasps, and shapes, based solely on text prompts or initial conceptual sketches [2]. The integration of AI with Additive Manufacturing - AM, or 3D printing, further enhances this transformation, offering unparalleled design freedom and structural complexity that transcend the limitations of conventional manufacturing methods, particularly in crafting intricate details and organic forms [3]. This novel workflow allows designers to explore a much broader array of aesthetic possibilities, conserving time and minimizing waste, thereby fostering ongoing creativity [4, 5].

Although AM has significantly transformed the creation of jewelry using metals and polymers, its application to ceramics presents distinct and crucial material limitations that require specialized computational solutions to address [6]. Ceramics are naturally characterized by high compressive strength but are notably weak in terms of tensile and flexural strength. This property renders ceramic structures highly susceptible to cracking during key stages, such as printing, handling (referred to as green part fragility), and rigorous post-processing [7]. The most formidable engineering challenge is the essential post-thermal sintering process needed to achieve complete material density, typically conducted at extremely high temperatures between 1200 and $1800. This high-temperature process results in significant material shrinkage and poses substantial difficulties in maintaining the dimensional accuracy [8]. Therefore, AI is not just a creative tool; it is a crucial engineering resource for Design for Manufacturability. Designers using AI often delve into highly intricate geometries, such as lattice structures, which inherently align with AM, as these shapes cannot be produced through traditional casting methods. As a result, advanced manufacturing techniques and generative AI must be viewed as an integrated unit to address the material’s inherent mechanical limitations and thermal instability [9].

The philosophical function of AI in design necessitates precise definition. Although commercial AI tools are typically geared towards automation and efficiency, recent studies propose that AI can be conceptualized as a reflective material [10]. In this framework, interacting with the AI model by adjusting its parameters and training data becomes a creative endeavor that encourages designers to pause and contemplate their work, akin to how a ceramicist works with clay. This method employs AI not only to create outputs but also to pose essential questions about design concepts and values [11]. This examination aims to connect these theoretical dualities. The computational framework utilizes AI for practical process optimization, specifically targeting the strict engineering limitations of ceramics, while also promoting reflective artistic exploration and the creation of new aesthetics. The incorporation of AI technology into ceramic production significantly enhances sustainability, as optimizing production processes, minimizing material waste, and striving for zero-defect manufacturing align economic efficiency objectives (cost savings, speed) with the necessity for responsible material usage [12].

Generative Modeling for Novel designs and Textures

In the early stages of concept development, generative AI models such as Generative Adversarial Networks (GANs) and Diffusion Models offer robust tools for exploring design possibilities. These technologies can swiftly create intricate design variations for jewelry components using abstract text prompts and uploaded images [13]. Designers can efficiently experiment with a wide range of styles, materials, shapes, and patterns without the usual expenses associated with extensive physical prototyping. These systems deliver high-quality outputs, such as realistic 3D visualizations and artistic renderings, enabling immediate feedback and refinement. Beyond static images, AI jewelry generators can also produce human AI models wearing the designed pieces directly from a photo, assisting designers in visualizing how intricate jewelry designs look on different styles and body types for marketing and display [14]. This front-end efficiency enhances creative workflows while ensuring the accuracy of preliminary designs. Machine learning algorithms process extensive datasets, including customer purchase histories, search behaviors, social media interactions, and trend reports to detect emerging patterns and consumer preferences [15]. These tools recommend suitable metals, motifs, and material combinations, helping designers remain competitive and align their products with market demands. This data-driven strategy enables true mass personalization of products. AI improves custom jewelry creation by translating descriptive client input (e.g., a preference for a specific engagement ring style) into precise technical designs, dynamically adjusting the size, shape, and material based on real-time feedback and preference prediction [16].

A significant obstacle to utilizing generative AI for ceramic jewelry design is the incorporation of physical constraints of the material during the conceptual phase. Although generative AI allows limitless design possibilities, the process of creating ceramics demands a fundamental “slowness” and adherence to limitations, such as drying periods and firing techniques. The most effective generative design systems for ceramics must not only produce visually innovative ideas but also be pre-screened for material feasibility, ensuring that the AI designs respect the material characteristics. For instance, prompt engineering strategies need to be developed to direct text-to-image systems to create designs that naturally address ceramic vulnerabilities, such as encouraging designs with rounded edges to minimize stress points and structures that can include internal lattices for added strength. This awareness of integrated constraints implies a significant shift in the traditional role of the jewelry designer. The designer's role has evolved from being a hands-on creator to a data curator and algorithm manager. Their expertise increasingly centers on providing effective design parameters and managing computational tool constraints, necessitating training that emphasizes feature engineering and algorithmic transparency over manual skills.

Limitations

For micro-scale jewelry, the specific fabrication requirements depend on the chosen AM technique. The main processes used for ceramics are vat photopolymerization (SLA/DLP) and binder jetting [17]. Importantly, the minimum feature resolution is determined by the limitations of the material. To ensure proper curing and avoid excessive brittleness, the minimum wall thickness is a crucial factor, ranging from approximately 0.5 mm in resin-based processes such as SLA/DLP to 1.5 mm or more for methods such as Selective Laser Melting [18]. Thin walls are preferred to minimize material usage, weight, and cost. However, the challenge with thin walls is that if they fall below a critical threshold, they can increase brittleness and the likelihood of part failure, particularly during the high-temperature sintering phase [19, 20].

Topology Optimization utilizes AI and machine learning (ML) algorithms to design geometries that are optimized for bearing loads while meeting specific structural constraints and objectives. This method is essential for ceramic jewelry to effectively manage its naturally low tensile strength. AI-powered generative design tools can quickly generate numerous design options optimized for factors such as cost, manufacturability, and performance. In ceramics, TO improves structures by integrating complex internal features, such as lattice frameworks, support ribs, and stress-relieving shapes, such as rounded corners. These components are designed to efficiently distribute stress, thereby enhancing strength and stability while minimizing material usage and weight by creating hollow or porous internal structures, such as Voronoi foams. The capability to produce these structures is inherently linked to AM technologies, as traditional methods cannot achieve this level of complexity [21].

Constraint-Aware Design Systems

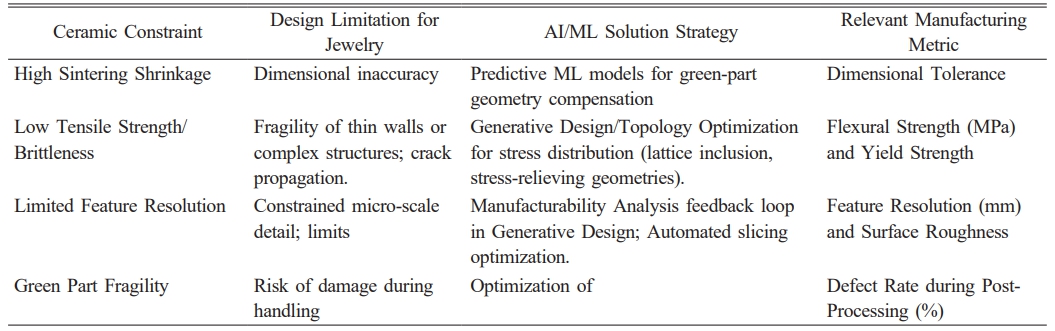

The incorporation of AI involves creating digital feedback mechanisms that guarantee that the designs are naturally suitable for manufacturing. AI tools play a role in automating routine modeling tasks, evaluating design options, and identifying potential manufacturability issues early in the process, which reduces development time and enhances product quality [22]. A significant application is the development of predictive machine learning models to address the substantial dimensional changes caused by sintering shrinkage before printing (precompensation modeling). This ensures that the final sintered product meets the required geometric accuracies [23]. To ensure this level of reliability, research must focus on the careful creation and validation of specialized datasets. These datasets should connect structural characteristics (such as curve radius, wall thickness, and lattice density) to the likelihood of mechanical failure in ceramic AM. The challenge of constructing reliable and generalizable ceramic AM datasets remains significant, often restricting the precision and applicability of machine learning models across various materials and processes. Table 1 outlines the strategic use of AI to tackle the main fabrication challenges associated with ceramics [24].

AI-Enhanced Material Processing and Quality Assurance

Beyond the initial design and structural engineering phases, AI and ML models play crucial roles in maintaining high aesthetic and material standards during the intricate chemical and thermal processing stages specific to ceramics. The firing stage is arguably the most pivotal phase, where thermal treatment and the composition of raw materials determine key final properties, such as water absorption and bending strength. Establishing these complex nonlinear relationships through traditional experimentation is extremely time-consuming. Advanced ensemble ML models, such as CatBoost and Gradient Boosting Regression, have shown excellent predictive capabilities in accurately forecasting these mechanical and functional properties based on input variables such as particle size, chemical composition, and firing temperature. The use of Explainable AI, particularly SHapley Additive exPlanations, has provided clarity into the process, revealing that for bending strength (BS), the firing temperature (35%) and Al2O3content (25%) are the most significant factors, enabling data-driven optimization. Similarly, K2O and sintering temperature positively impacted the bulk density, while negatively affecting the porosity and water absorption. This capability allows real-time process optimization and improved product consistency [25].

One of the major hurdles in ceramic art is the unpredictability of the final visual result, particularly concerning glazes and underglazes. The intricate chemical reactions of underglaze components during high-temperature firing can significantly influence the final color. This shift from relying on implicit knowledge and intuition is moving towards a more explicit, data-driven understanding through computational techniques. Deep learning methods are used to predict the final color outcome, measured in RGB, HSV, or CMYK color spaces, based on the complex mix of ingredients and specific firing conditions. This method transitions the ceramic process from a trial-and-error approach to a desired output workflow. A model trained on these correlations can take the target color as input and provide the necessary ingredient composition and ideal firing schedule, enabling the consistent and scalable reproduction of intricate aesthetic results. There is a crucial interdependence here: AI addresses two concurrent optimization challenges, enhancing mechanical properties (process optimization) and improving color precision (aesthetic optimization). A change in the firing temperature required to achieve the optimal flexural strength will also affect the final glaze color. Therefore, a comprehensive AI system must use multi-objective optimization, balancing quantitative mechanical performance metrics (such as bending strength) against perceptual aesthetic metrics (like Delta E color difference) [1].

This analysis illustrates that Artificial Intelligence serves as a crucial connection, enabling the development of complex ceramic jewelry designs and effectively harmonizing the extensive creative potential of digital tools with the stringent constraints of technical ceramics. The computational framework skillfully integrates Generative AI for ideation, Topology Optimization for structural design, and Machine Learning models for accurate material management and quality assurance. This approach not only streamlines product development but also ensures the physical viability and aesthetic consistency of ceramic pieces produced through Additive Manufacturing.

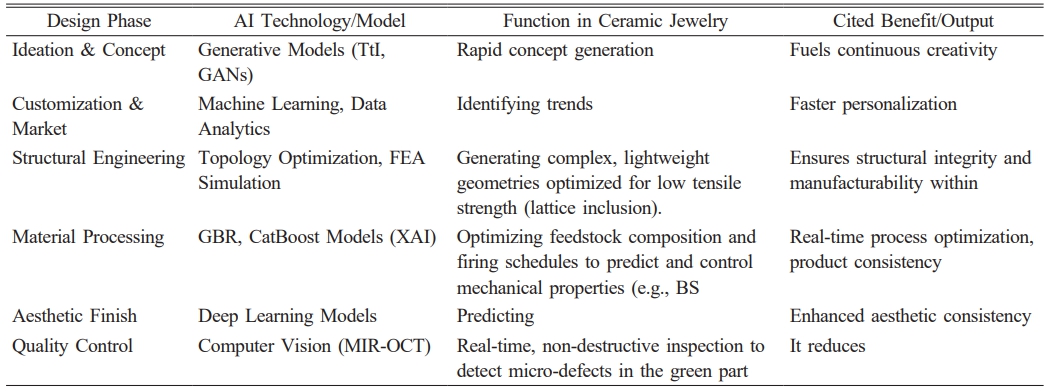

The following table summarizes the key AI technologies applied across the design lifecycle, confirming their specific utility in ceramic fabrication. Table 2

|

Table 1 Ceramic Additive Manufacturing Constraints and AI Integration Strategy. |

Despite the transformative potential of AI, several research challenges must be addressed to ensure robust and scalable deployment in ceramic jewelry manufacturing. There is a critical need to develop large, specialized, and generalizable ceramic-AM datasets. The accuracy and reliability of current ML models are often limited by data scarcity, particularly across diverse materials (e.g., jewelry-grade zirconia or alumina systems) and printer platforms. Future studies should prioritize standardized data collection methodologies. Evaluating the aesthetic success of AI-generated designs requires metrics beyond standard engineering measures such as R2 or Root Mean Squared Error (RMSE). Future research should develop and validate robust metrics, such as complexity scores, semantic coherence scores, or authenticity scales, to accurately evaluate the creativity of AI outputs within the context of computational craft.

The study was supported by the 2023 Ministry of Education Industry-Education Cooperation Collaborative Education Project: "Research on Jewelry Design and Craftsmanship Talent Cultivation from the Perspective of Intangible Cultural Heritage Inheritance” (230804213 290015).

- 1. N. Fatma, A. Haleem, S. Bahl, and M. Javaid, in Prospects of Jewelry Designing and Production by Additive Manufacturing2021 (Springer Singapore, 2021) p. 869-879.

-

- 2. Y. Lyu, M. Shi, Y. Zhang, and R. Lin, Sustainability 16[1] (2024) 65.

-

- 3. Y. Li, H. Zhao, H. Jiang, Y. Pan, Z. Liu, Z. Wu, P. Shu, J. Tian, T. Yang, S. Xu, Y. Lyu, P. Blenk, J. Pence, J. Rupram, E. Banu, N. Liu, L. Wang, W. Song, X. Zhai, K. Song, D. Zhu, B. Li, X. Wang, and T. Liu, arXiv:2410.21418 (2024).

-

- 4. T. Turchi, S. Carta, L. Ambrosini, and A. Malizia, in Human-AI Co-creation: Evaluating the Impact of Large-Scale Text-to-Image Generative Models on the Creative Process2023 (Springer Nature Switzerland, 2023) p. 35-51.

-

- 5. M. Torricelli, M. Martino, A. Baronchelli, and L.M. Aiello, in "Proceedings of the 16th ACM Web Science Conference" (Association for Computing Machinery, 2024) pp. 235–240.

-

- 6. F. Cooper, Prog. Addit. Manuf. 1[1] (2016) 29-43.

-

- 7. M. Mayerhofer, W. Lepuschitz, T. Hoebert, M. Merdan, M. Schwentenwein, and T.I. Strasser, IEEE Open J. Ind. Electron. Soc. 2 (2021) 207-223.

-

- 8. M. Mohseni and S. Khodaygan, Rapid Prototyp. J. 30[7] (2024) 1411-1433.

-

- 9. Y. Zhai, D.A. Lados, and J.L. LaGoy, JOM 66[5] (2014) 808-816.

-

- 10. V.E. Ardeliya, J. Taylor, and J. Wolfson, International Journal of Cyber and IT Service Management (IJCITSM) 4[1] (2024) 40-46.

-

- 11. T. Chandrasekera, Z. Hosseini, and U. Perera, Int. J. Archit. Comput. 23[1](2025) 122-136.

-

- 12. M. Ghobakhloo, M. Fathi, M. Iranmanesh, M. Vilkas, A. Grybauskas, and A. Amran, J. Manuf. Technol. Manag. 35[9] (2024) 94-121.

-

- 13. A.S. Al-Busaidi, R. Raman, L. Hughes, M.A. Albashrawi, T. Malik, Y.K. Dwivedi, T. Al-Alawi, M. AlRizeiqi, G. Davies, M. Fenwick, P. Gupta, S. Gurpur, A. Hooda, P. Jurcys, D. Lim, N. Lucchi, T. Misra, R. Raman, A. Shirish, and P. Walton, J. Innov. Knowl. 9[4] (2024) 100630.

-

- 14. L.N. Fewella, Ain Shams Eng. J. 16[12] (2025) 103747.

-

- 15. T. Al-Mughanam and V. Tirth, J. Ceram. Process. Res. 24[2] (2023) 359-366.

-

- 16. J.M. Alcalde-Llergo, A. Ruiz-Mezcua, R. Ávila-Ramírez, A. Zingoni, J. Taborri, and E. Yeguas-Bolívar, Appl. Sci. 15[10] (2025) 5538.

-

- 17. M. Sugavaneswaran and G. Arumaikkannu, Mater. Des. 54 (2014) 779-785.

-

- 18. O.W. Saadi, A. Schiffer, and S. Kumar, Int. J. Adv. Manuf. Technol. 126[5] (2023) 1965-1978.

-

- 19. S. Cao, F. Xie, X. He, C. Zhang, and M. Wu, Adv. Mater. Sci. Eng. 2020[1] (2020) 3865752.

-

- 20. A. Ullah, M. Shah, Z. Ali, K. Asami, A. Ur Rehman, and C. Emmelmann, Int. J. Appl. Ceram. Technol. 22[3] (2025) e15087.

-

- 21. N. Hertlein, K. Vemaganti, and S. Anand, J. Mech. Des. 146[11] (2024).

-

- 22. A. Witkowski and A. Wodecki, Manag. Rev. Q.(2025).

-

- 23. W. Pan, Y. Yang, W.F. Lu, Y. Wang, M. Li, and H. Wu, Addit. Manuf. 79 (2024) 103919.

-

- 24. Y. Liang, X. Wei, Y. Peng, X. Wang, and X. Niu, Polym. Compos. 46[3] (2025) 1939-1960.

-

- 25. D. Soydaner and J. Wagemans, Br. J. Psychol. 12 (2024) 4716-4729.

-

This Article

This Article

-

2025; 26(6): 1099-1103

Published on Dec 31, 2025

- 10.36410/jcpr.2025.26.6.1099

- Received on Oct 29, 2025

- Revised on Dec 2, 2025

- Accepted on Dec 4, 2025

Services

Services

Shared

Correspondence to

Correspondence to

- Chen Guangming

-

School of Arts and Media, Nanning College of Technology, Nanning, Guangxi, 530100, China

- E-mail: chenguangmbest@163.com

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.