- Tuning τf of Li4Mg2SbO6F microwave dielectric ceramics through Li2SnO3 addition

Duanyuan Yanga, Luyi Wanga, Li Quana, Miao Chena, Yaming Zhanga, Weihong Liub, Cuijin Peia,

Guoguang Yaoa,*, Yansheng Wangc and Wei Zhanga,*aSchool of Science, Xi’an University of Posts and Telecommunications, Xi’an 710121, China

bSchool of Electronic Energineering, Xi’an University of Posts and Telecommunications, Xi’an 710121, China

cXi'an Chaofan Optoelectronic Equipment Co., LTD, Xi’an 710121, ChinaThis article is an open access article distributed under the terms of the Creative Commons Attribution Non-Commercial License (http://creativecommons.org/licenses/by-nc/4.0) which permits unrestricted non-commercial use, distribution, and reproduction in any medium, provided the original work is properly cited.

Microwave ceramics with low dielectric constant (εr<15), high quality factor (Q×f > 50,000 GHz) and near-zero temperature coefficient of resonance frequency (|τf|≤10 ppm/oC) are drawing tremendous attentions for basic study and 5G communication. To obtain above parameters, the (1-x)Li4Mg2SbO6F–xLi2SnO3 (x=0.65-0.85) composite ceramics were fabricated through a solid state reaction route at 825-900 oC. X-ray diffraction analysis showed two phase coexistence of cubic structural Li4Mg2SbO6F and monoclinic structural Li2SnO3. The microwave dielectric properties (MDPs) of Li4Mg2SbO6F-host counterpart is significantly improved with an amount of Li2SnO3 addition (x=0.75). For the x=0.75 composition, with increment of sintering temperature, its volume density and dielectric constant (εr) rose little by little, its quality factor (Q×f) rose first and then decreased, and its temperature coefficient of resonance frequency (τf) remained stable. Optimum MDPs with a εr of 12.9, Q×f of 60, 100 GHz and τf of -10.6 ppm/oC were achieved at x=0.75 composition sintered at 875 oC, this ceramics also exhibited good co-firing chemical compatibility with silver electrode.

Keywords: Diphase ceramics, Li4Mg2SbO6F oxyfluorides, Near-zero temperature coefficient.

Recently, Li-containing oxyfluoride ceramics are drawing tremendous attentions owing to their fascinating low sintering temperature as well as eminent MDPs [1-4]. Within the Sb2O5-LiF–Li2O–MgO system, a novel oxyfluoride namely, Li4Mg2SbO6F, was reported. We found that the 750 oC-sintered Li4Mg2SbO6F oxyfluoride ceramics possess eminent MDPs at 11.3 GHz (εr=12.6, Q × f = 59, 000 GHz, τf = -37 ppm/oC) [5]. However, its poor τf value (-37 ppm/oC) of Li4Mg2SbO6F oxyfluoride ceramics impedes its use in LTCC applications in a large measure [6]. There are two mainstream methods to modulate the MDPs, especially for τf, that is selecting two compounds with converse τf to construct diphase ceramics and ion replacement to construct a solid solution [7-10]. The solid solution LiIn1-xGaxO2 (x = 0.1, τf ≈ +10.1 ppm/oC) and (1-x)Mg(Zr0.05Ti0.95)O3–xSrTiO3 diphase ceramics (x = 0.04, τf ~ +10.1 ppm/oC) are the most suitable samples among the situations aforementioned [11, 12].

In this paper, the Li2SnO3 with positive τf (26.9 ppm/oC) was introduced to tune the MDPs of Li4Mg2SbO6F-basic ceramics [13, 14]. Thus, the (1-x)Li4Mg2SbO6F–xLi2SnO3 (x=0.65-0.85) diphase ceramics were designed and fabricated via a solid state reaction at 825-900 oC. The influence of Li2SnO3 addition on the phase assemble, sinterability, microstructures along with MDPs of 0.25Li4Mg2SbO6F–0.75Li2SnO3 sintered specimens was thoroughly investigated.

Through a solid-state process the (1-x)Li4Mg2SbO6F–xLi2SnO3 (x=0.65-0.85) (abbreviated as LMSOF-LSO) specimens were fabricated [15]. Based on stoichiometric Li4Mg2SbO6F and Li2SnO3, the initial materials of MgO, Li2CO3, LiF, Sb2O5, SnO2 (all purity >98.0%) were separately weighed, then were individually mixed via planetary milling for 9 h with anhydrous alcohol as medium. The dried Li4Mg2SbO6F and Li2SnO3 slurries were individually presintered under 550 oC/5 h and 950 oC/5 h. Subsequently, the LMSOF-LSO mixture powders were re-milled for 9 h. By adding 6 wt% PVA binder, the above mixture powders were granulated, and compacted into green discs with diameter of 10 mm and thickness around 4.5 mm. Finally, these discs were fired under 825 oC–900 oC for 5 h in air atmosphere.

The phase identification, structural investigation along with surface morphology of the LMSOF-LSO samples were examined via X-ray diffraction (XRD, Japan) and scanning electron microscopy (SEM, Czech). The volume densities of fired specimens were trialed employing Archimedes’ drainage approach [16]. With the help of resonant cavity method, the εr and Qxf values under microwave region about 10-11 GHz of the LMSOF-LSO ceramics were measured employing a vector network analyzer (Ceyer 3674D). The τf values were evaluated based on following expressions (1) [17].

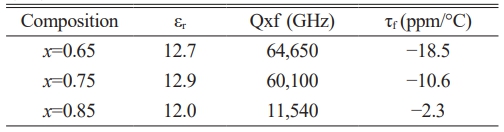

Table 1 summarizes the microwave dielectric properties of 875 °C-sintered LMSOF-LSO ceramics systems. As x rose from 0.65 to 0.85, the εr values first increased and then decreased, while the |τf| and Qxf values gradually decreased. The good comprehensive MDPs could be obtained for the composition of x=0.75. Therefore, the following research was focused on the x=0.75 composition ceramics.

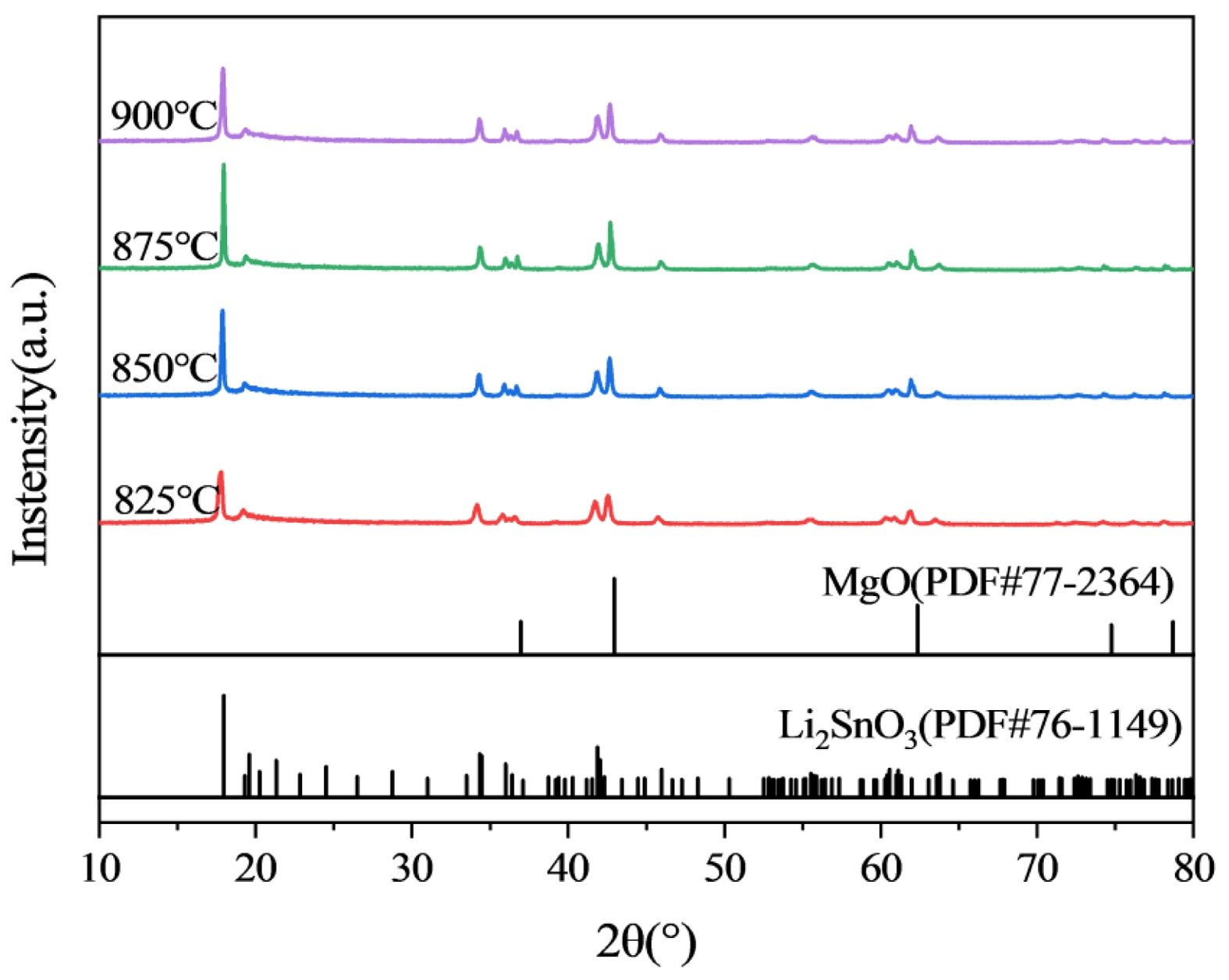

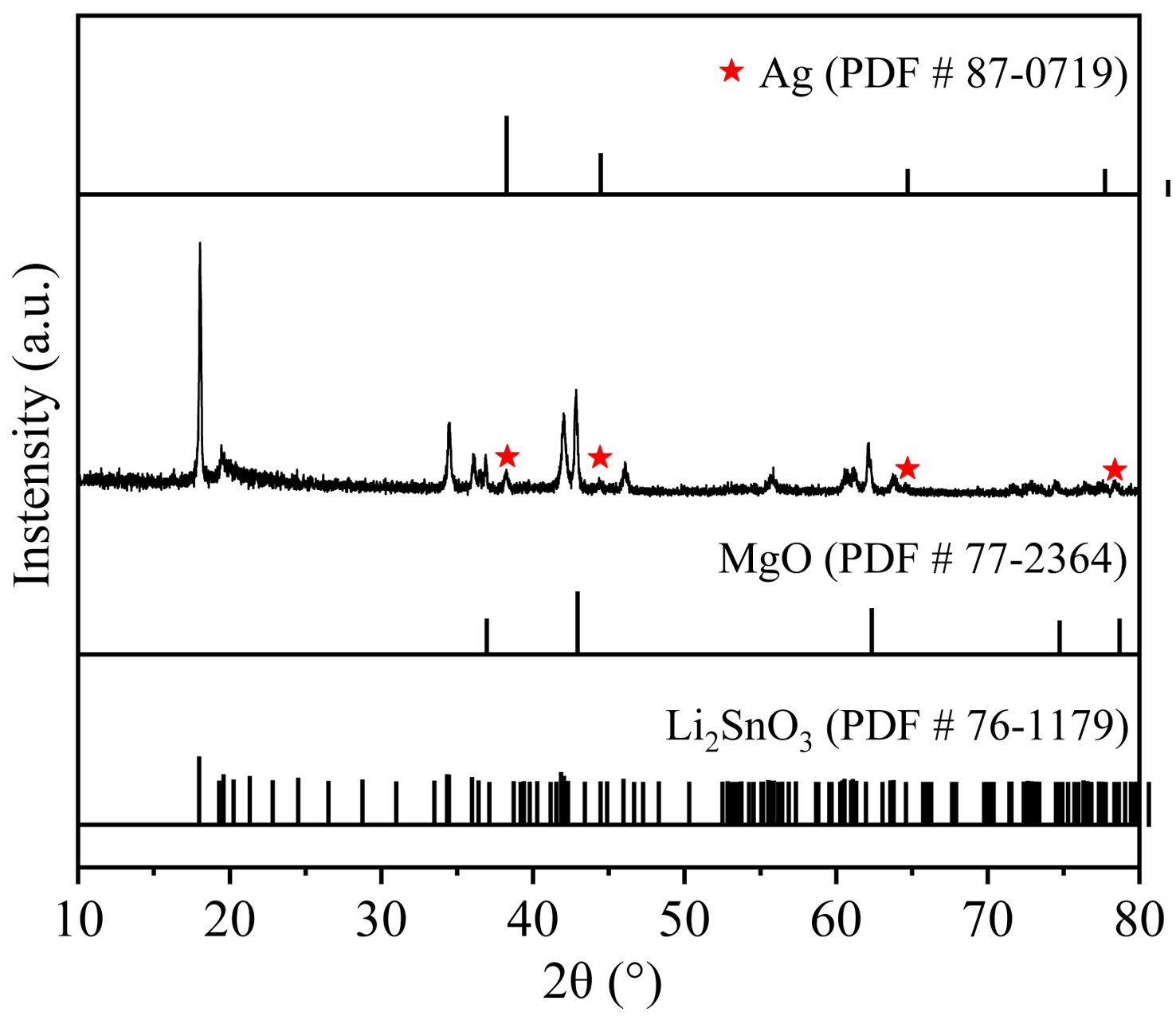

Fig. 1 gives the XRD plots of 0.25LMSOF-0.75LSO ceramics under diverse temperature sintering. All samples exhibited a similar phase assemble. All diffraction peaks match well with MgO-like (PDF #77-2364) cubic structural phase of Li4Mg2SbO6F and monoclinic structural phase of Li2SnO3 (PDF #76-1149). The achieved outcomes indicated the formation of a Li4Mg2SbO6F/Li2SnO3 diphase ceramics without noticeable secondary phases, which could attribute to their diverse crystal structure [18].

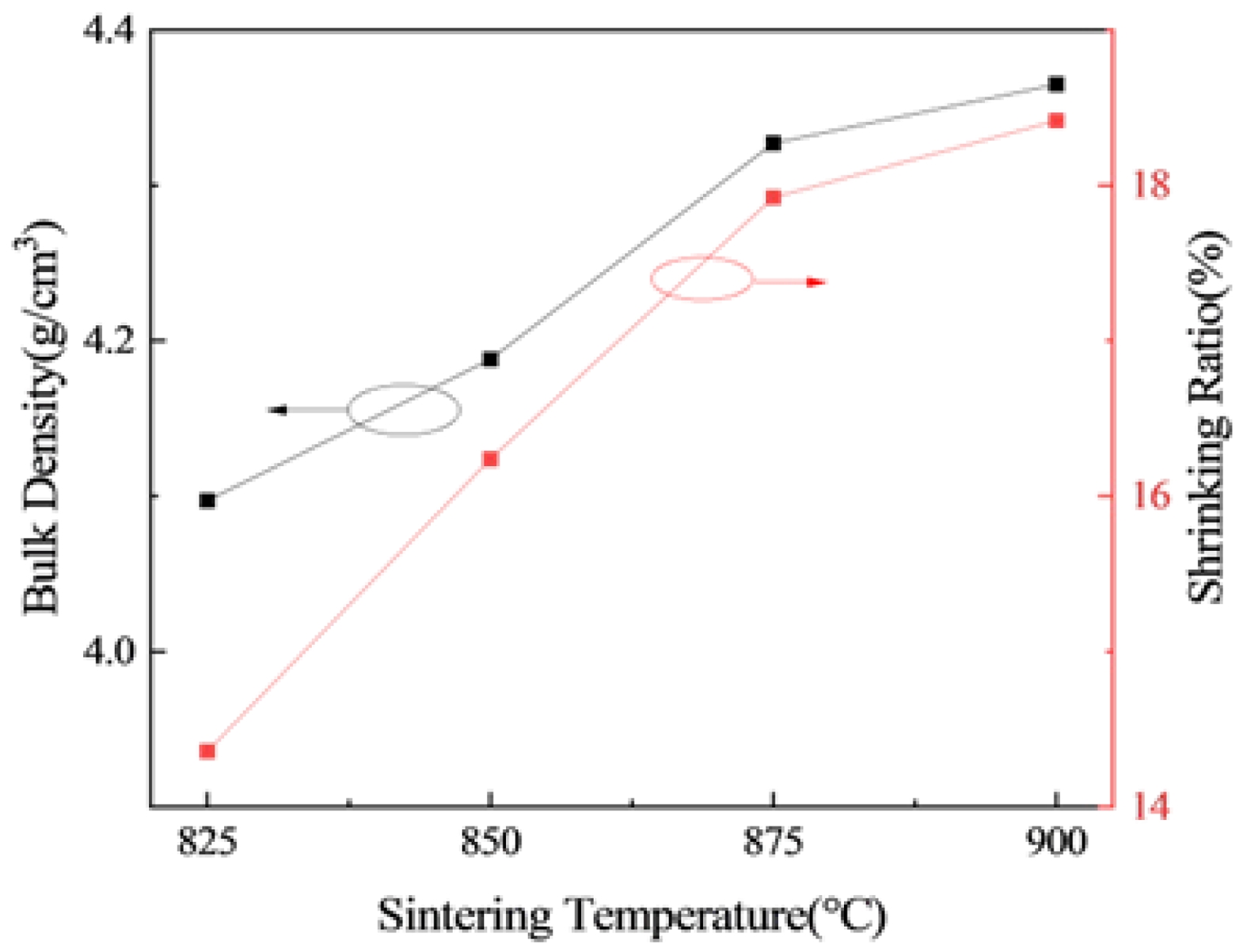

The density and shrinking ratio of 0.25LMSOF-0.75LSO under different temperature sintering are given in Fig. 2. The density and shrinking ratio showed a similar tendency, that is a whole enhancing tendency as the sintering temperature rose. This could attribute to that the gases from the pores within the ceramics flee with an increasement in firing temperature, the ceramics shrinks and thus results in its density increment [19, 20].

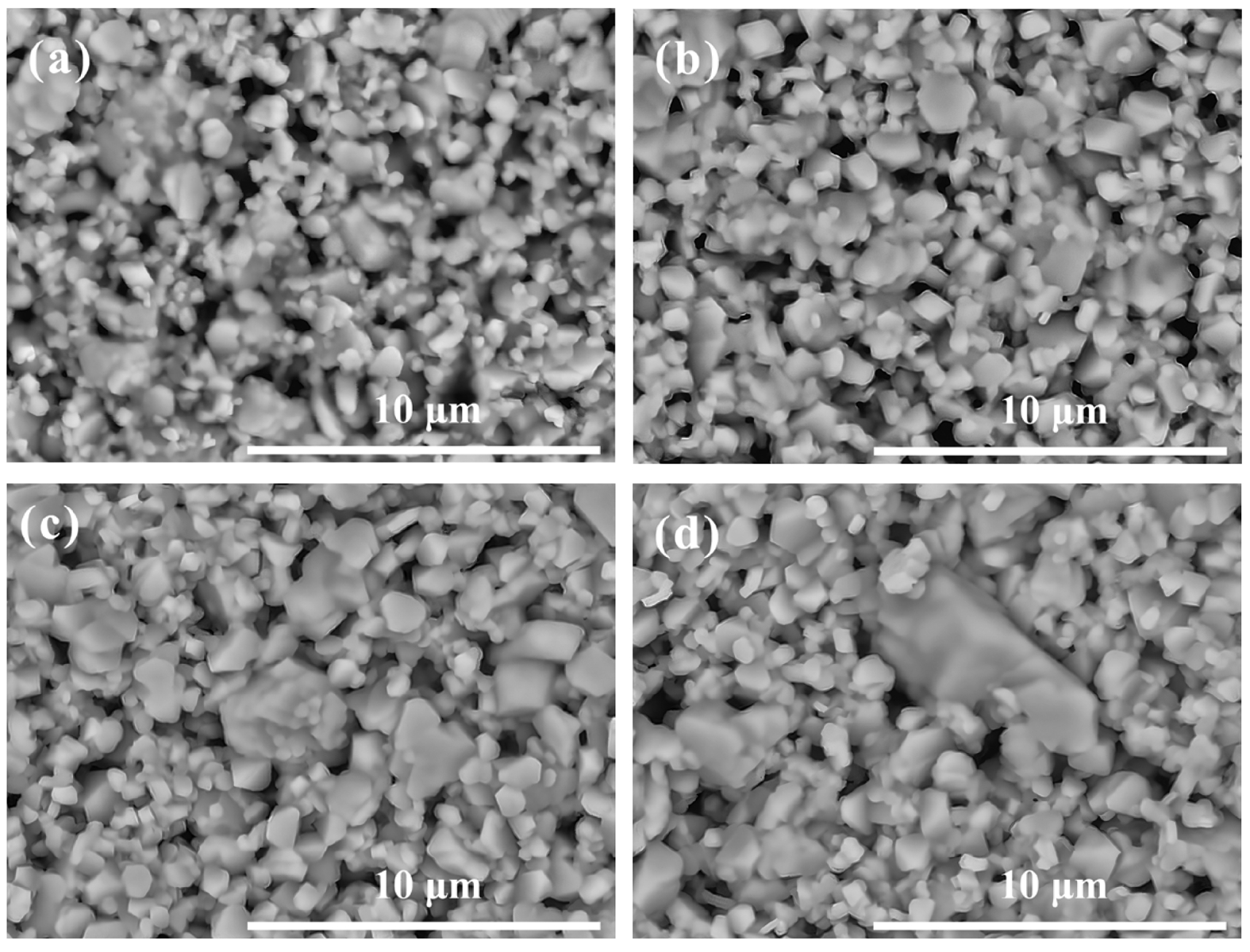

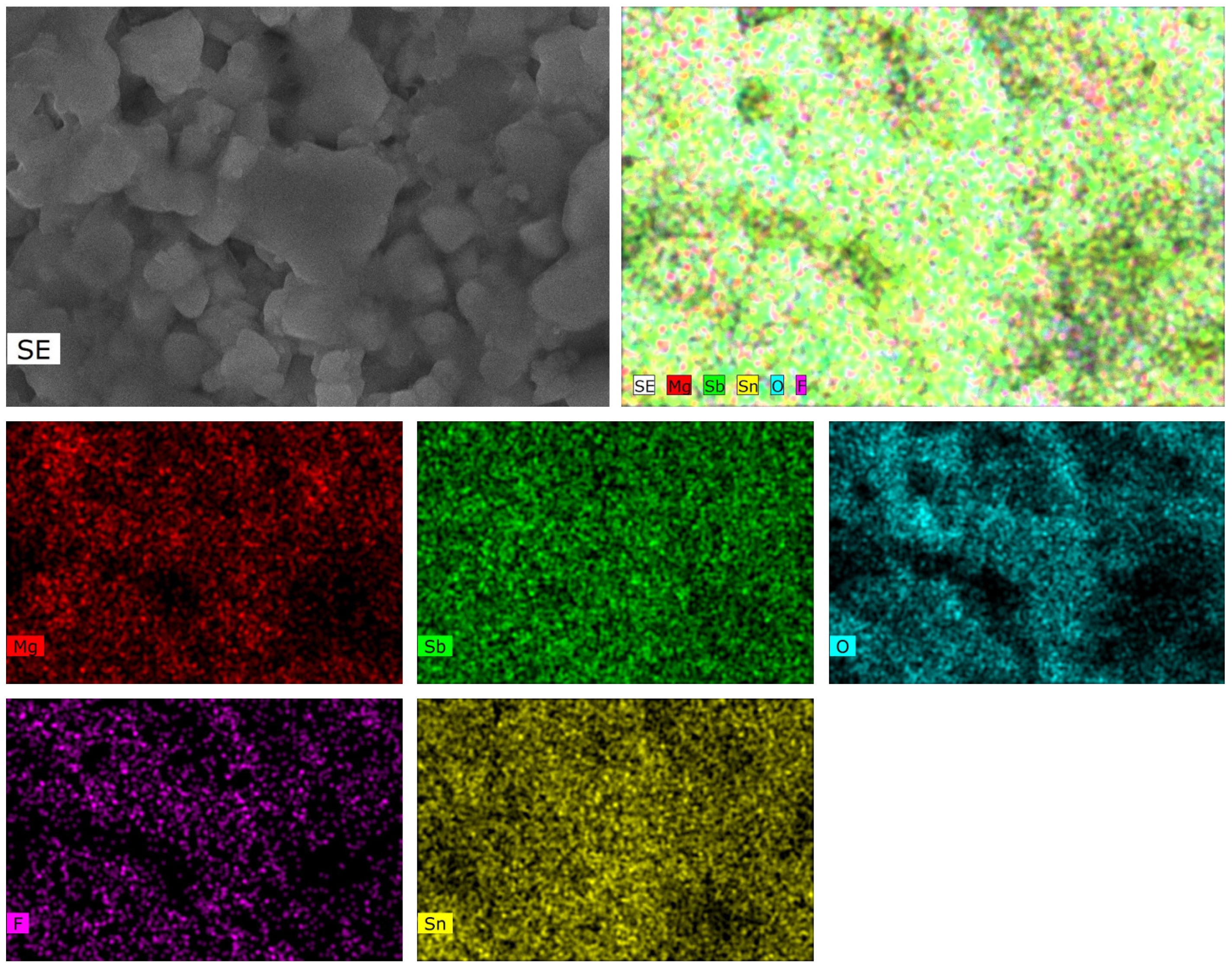

Fig. 3(a)-(e) display the typical SEM graphs of 0.25LMSOF-0.75LSO heated at 825-900 oC. All samples do not look very dense. When the samples were heated at 825 °C, numerous intergranular pores were observed, which tallied well with its poor density, as illustrated in Fig. 2 and Fig. 3(a). As the firing temperature rose, the amount of intergranular pores declined little by little, and a comparatively compact microstructure were gained for 875 oC-heated ceramics. Further increment the heating temperature to 900 oC, an abnormal grain growth emerged, as seen in Fig. 3(d). Moreover, all samples owned two distinct-colored grains (light and black) and similar grain shape, which tallied well with the aforementioned XRD results. To identify the phase composition of distinct-colored grains, the energy dispersive spectrometer was carried out on the 0.25LMSOF-0.75LSO ceramics sintered at 875 oC, as shown in Fig. 4. The elemental mappings results reveal local enrichment of Mg, Sb, and F elements, whereas the Sn element is distributed throughout the entire region, which is slightly different from the XRD results.

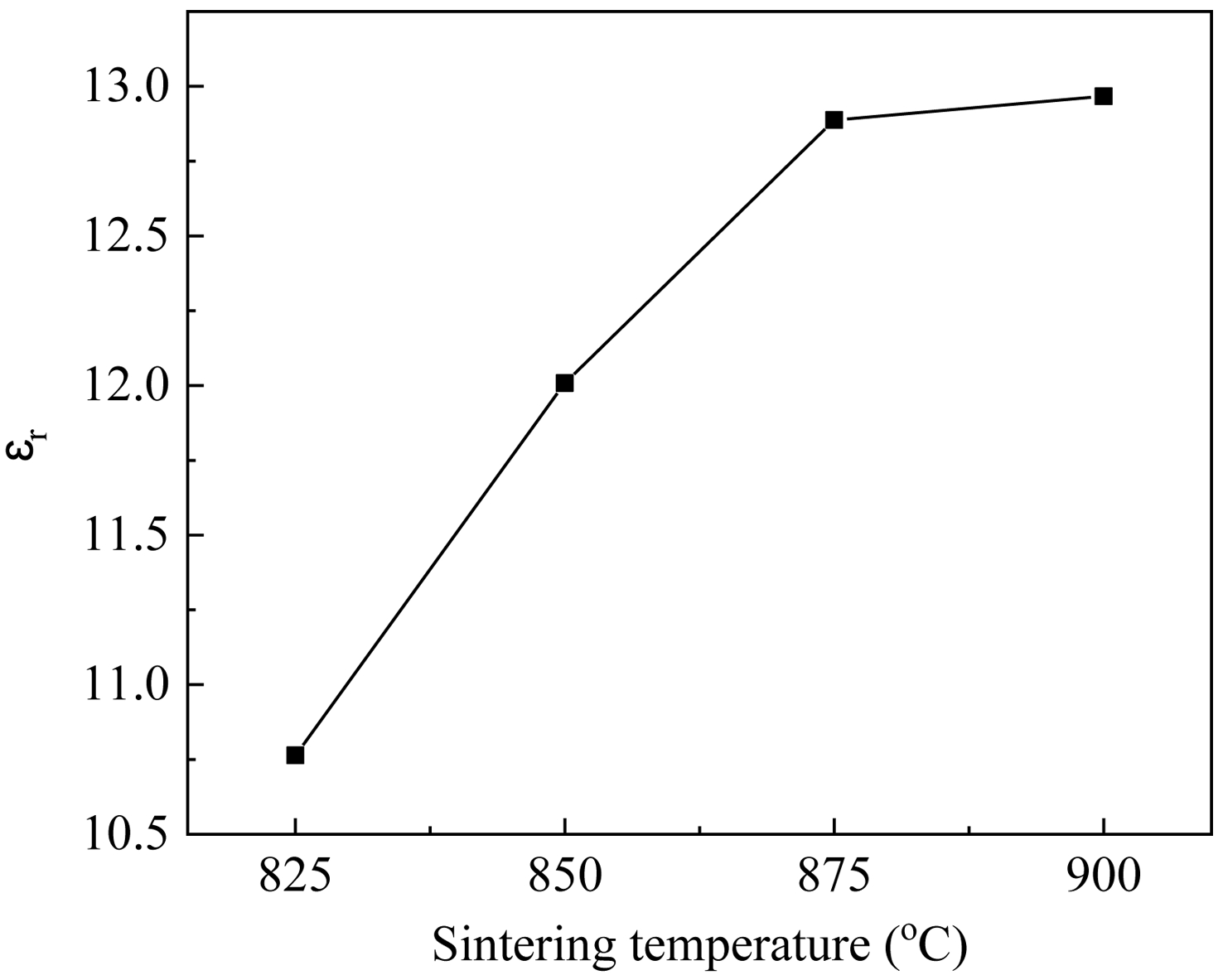

The dependence of εr over sintering temperature of the 0.25LMSOF-0.75LSO samples is exhibits in Fig. 5. The reliance of ɛr upon sintering temperature almost shows a similar inclination to that of densities (Fig. 2), since ɛr in microwave frequency is chiefly influenced by porosity for given composition [21]. The εr of present ceramics increased little by little from 10.7 to 13.0 upon enhancing sintering temperature, which is tightly connected with the reduce in porosity, considering the εr of pores is nearly equal to 1.

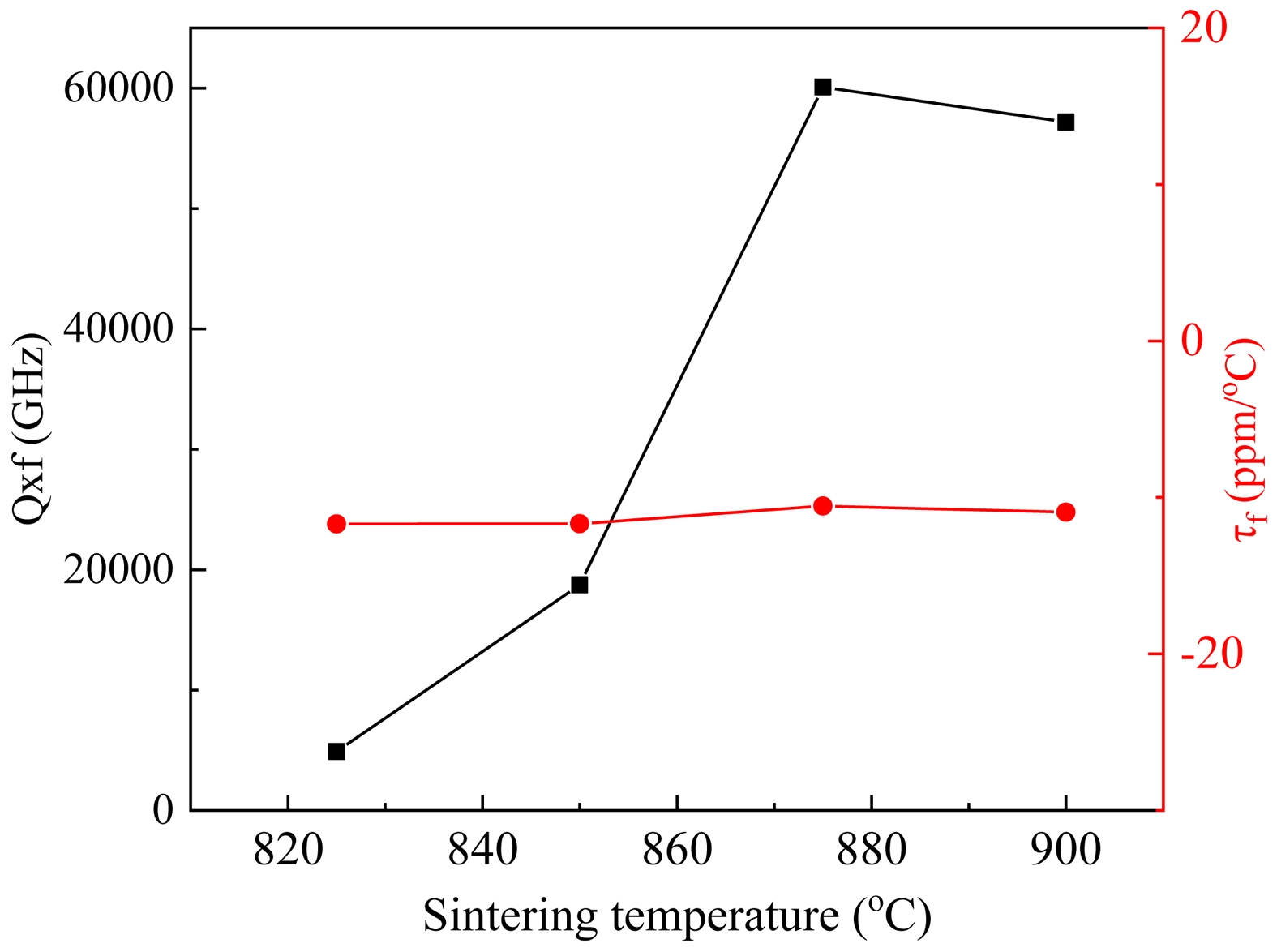

Fig. 6 exhibits the dependence of Q×f and τf of the 0.25LMSOF-0.75LSO samples on firing temperature. The change tendency of Q×f values over sintering temperature is not quite the same as that the variation in either density or ɛr values. It is notice that the change in Q×f value over sintering temperature is far more sophisticated compared to the one in either density or ɛr. The present ceramics displayed a stepwise increment in Q×f values with the wake of firing temperature, achieve a peak value of 60, 100 GHz at 875 °C, and slightly declined in the end with further increasing temperature. The increment in Q×f values is due to the increment in density (Fig. 2), whereas the reduced Q×f values at 900 °C is due to the observed an abnormal grain growth in Fig. 3(d). With regard to τf , as shown in Fig. 6, the τf values is irrelevant to sintering temperature and can remain relatively stable at approximately −10.6 ppm/°C. The τf value is well-known to be influenced by the composition, the additive and the second phase of the materials [22-24]. In current ceramics, the relatively stable τf can attribute to its unchanged phase assemble of Li₄Mg₂SbO₆F and Li₂SnO₃ (seen in Fig. 1), where Li₄Mg₂SbO₆F owns negative τf (-37 ppm/oC) and Li₂SnO₃ owns positive owns negative τf (26.9 ppm/oC) [5, 13].

To ensure the LTCC applicability of the present ceramic, good chemical compatibility with Ag electrode during sintering is necessary. Thus, the XRD was conducted to assess the compatibility of between 0.25LMSOF-0.75LSO composition and Ag electrode fired at 875 oC, and corresponding result is shown in Fig. 7. As the XRD pattern does not show the formation of any secondary phase except for Li4Mg2SbO6F, Li2SnO3 and Ag phases, suggesting well co-firing chemical compatibility of the 0.25LMSOF-0.75LSO ceramics with Ag electrode.

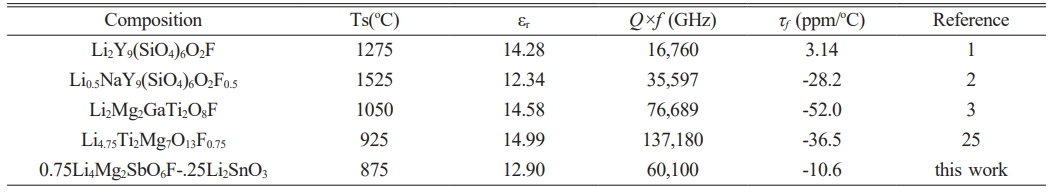

Table 2 showcases the microwave dielectric properties of Li-based oxyfluorides ceramics. Compared to other ceramics except Li2Mg2GaTi2O8F, our 0.25LMSOF-0.75LSO ceramics has excellent comprehensive properties, including low εr, low sintering temperature dielectric, near-zero τf and high or comparable Q×f.

|

Fig. 1 The XRD plots of 0.25LMSOF-0.75LSO under different temperature sintering. |

|

Fig. 2 The density and shrinkage of 0.25LMSOF-0.75LSO under different temperature sintering. |

|

Fig. 3 The surface morphology of the 0.25LMSOF-0.75LSO samples under different temperature sintering: (a) 825 oC, (b) 850 oC, (c) 875 oC, (d) 900 oC. |

|

Fig. 4 Energy-dispersive spectroscopy elemental mapping results of 0.25LMSOF-0.75LSO ceramics sintered at 875 oC. |

|

Fig. 5 The εr of the 0.25LMSOF-0.75LSO samples under different sintering temperature. |

|

Fig. 6 The Q×f and τf of the 0.25LMSOF-0.75LSO samples under different sintering temperature. |

|

Fig. 7 The XRD pattern of the mixture of the 0.25LMSOF0.75LSO and Ag fired at 875 oC. |

|

Table 1 Microwave dielectric properties of 875 °C-sintered (1-x)LMSOF-xLSO ceramics. |

|

Table 2 Comparison of microwave dielectric properties of Li-based oxyfluorides ceramics. |

In this work, (1-x)Li4Mg2SbO6F–xLi2SnO3 (x=0.65-0.85) composite ceramics were fabricated through a solid state reaction route at 825-900 oC. The diphase ceramics of cubic structural Li4Mg2SbO6F and monoclinic structural Li2SnO3 could coexist harmoniously as confirmed by XRD analysis. The introduction of Li2SnO3 can not only significantly ameliorate the τf, but also improve the Q×f and εr of Li4Mg2SbO6F-host counterpart. For the x=0.75 composition, its εris chiefly influenced by density, its Q×f is chiefly influenced by density and overinflated grain coarsening, and its τf is chiefly influenced phase assemble. The excellent MDPs with a εr of 12.9, Q×f of 60,100 GHz and τf of -10.6 ppm/oC along with its well co-firing chemical compatibility with Ag electrode for x = 0.75 composition ceramics, make it a prospective material for LTCC applications.

This work was funded by grants from National Natural Science Foundation of China (No. 52272122, No. 52002317), Service Local Special Plan Project of Shaanxi Province Education Department (No. 24JC082), Xi’an Sciences Plan Project (No. 24GXFW0084, No. 25GXKJRC00053), Undergraduate Innovation and Entrepreneurship Training Program in Shaanxi Province (No. S202511664075).

- 1. D.Y. Liang, T.T. Liao, F. Dong, B. Tang, and F. Si, J. Electron. Mater. 53 (2024) 3223-3230.

-

- 2. Z.X. Fang, H.F. Peng, D.Y. Liang, Y.X. Li, B. Tang, and M. Zhang. Ceram. Int. 50 (2024) 43513-43521.

-

- 3. Z.G. Hou, Y.X. Li, F. Wang, D.Y. Liang, B. Tang, and W. Liu, Ceram. Int. 50 (2024) 46542-46547.

-

- 4. P.S. Wu, C.J. Pei, M. Chen, X. Gao, W.H. Liu, G.G. Yao, and J. Liu, J. Ceram. Process. Res. 24[6] (2023) 977-982.

-

- 5. C.J. Pei, H.K. Liu, M. Chen, F. Shang, W.H. Liu, and G.G. Yao, Ceram. Int. 50 (2024) 51718-51723.

-

- 6. C.L. Huang,Y.Q. Guan, M. Huang, F.L. Wang, W. Li, H.J. Mao, Z.F. Liu, W.J. Zhang, and X.Y. Chen, Ceram. Int. 51 (2025) 13507-13513.

-

- 7. F.L. Liu, J. Li, Y.H. Sun, Y. Tang, and L. Fang, Ceram. Int. 51 (2025) 7370-7376.

-

- 8. G.G. Yao, J.J. Tan, J.X. Yan, M.Q. Liu, C.J. Pei, and Y.M. Jia, Ceram. Int. 47 (2021) 27406-27410.

-

- 9. A.R.H. Alzakree, C.H. Wan, and M. Shehbaz, J. Am. Ceram. Soc. 108 (2025) e20504.

-

- 10. C.H. Shen, C.H. Hu, J.Y. Chen, W.H. Chen, C.W. Tung, Y.H. Yang, and T.Y. Yang, J. Ceram. Process. Res. 25[5] (2024) 790-797.

-

- 11. J.W. Chen, J.J. An, J.Q. Chen, and L. Fang, J. Mater Sci: Mater. Electron. 36 (2025) 938.

-

- 12. T. Ahmed, J.H. Lee, M.Y. Kim, S.A. Khan, H.T. Kim, G.Y. Lee, D.H. Yeo, and S. Lee, J. Eur. Ceram. Soc. 44 (2024) 6987-6994.

-

- 13. X. Chu, L. Gan, J.Jiang, J.Z. Wang, and T.J. Zhang, Mater. Today Commun. 37 (2023) 107145.

-

- 14. L.X. Pang, and D. Zhou, J. Am. Ceram. Soc. 93 (2010) 3614-3617.

-

- 15. P.C. Chen, C.L. Pan, K.C. Lin, and C.H. Shen, J. Ceram. Process. Res. 25[2] (2024) 278-284.

-

- 16. J.H. Liu, Z. Lu, Y.G. Jung, Y. Li, Y.W. Zhou, H. Chen, J.H. Son, H.K. Choi, and J.S. Lee, J. Ceram. Process. Res. 26[3] (2025) 386-396.

-

- 17. H. Liu, L. Cao, and K. X. Song, J. Eur. Ceram. Soc. 45 (2025) 116957.

-

- 18. G.G. Yao, Z.Y. Ren, and P. Liu, J. Electroceram. 40 (2018) 144-149.

-

- 19. Y.J. Liu, G.Q. He, and H.F. Zhou, Ceram. Int. 50 (2024) 36440-36447.

-

- 20. Z.H. Huang, D.P. Wang, X.Y. Wu, W. Li, and W.T. Wang, J. Ceram. Process. Res. 26[1] (2025) 37-42.

-

- 21. X.H. Zhang, X.H. Zhang, S. Ma, X.Y. Qi, and Z.X. Yue, Ceram. Int. 50 (2024) 15831-15839.

-

- 22. X.S. Lv, L.X. Li, H. Sun, S. Li, and S. Zhang, Ceram. Int. 41 (2015) 15287-15291.

-

- 23. H.J. Wang and J.J. Bian, J. Eur. Ceram. Soc. 44 (2024) 2144-2149.

-

- 24. R.Z. Zuo, J. Zhang, J. Song, and Y.D. Xu, J. Am. Ceram. Soc. 101 (2018) 569-576.

-

- 25. R. Li, X.B. Zhou, S.M. Zhai, S.F. Hou, P. Shi, and P. Liu, Ceram. Int. 51 (2025) 8824-8831.

-

This Article

This Article

-

2025; 26(6): 1043-1047

Published on Dec 31, 2025

- 10.36410/jcpr.2025.26.6.1043

- Received on Aug 12, 2025

- Revised on Oct 29, 2025

- Accepted on Nov 21, 2025

Services

Services

- Abstract

introduction

experimental

results and discussion

conclusions

- Acknowledgements

- References

- Full Text PDF

Shared

Correspondence to

Correspondence to

- Guoguang Yao and Wei Zhang

-

School of Science, Xi’an University of Posts and Telecommunications, Xi’an 710121, China

Tel : +86 29 88166089 Fax: +86 29 88166333 - E-mail: yaoguoguang@xupt.edu.cn, zhangweio@xiyou.edu.cn

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.