- Experimental investigation and process parameters optimization for abrasive water jet machining using desirability function analysis

Balasubramaniam Vellaisamya,*, Murugan Kuppusamyb, Venugopal Thangamuthuc and Sivakumar Aburpa Avanacharid

aDepartment of Mechanical Engineering, Shivani Engineering College, Trichy, Tamilnadu, India

bDepartment of Mechanical Engineering, Mahendra Institute of Technology, Namakkal, Tamilnadu, India

cDepartment of Mechanical Engineering, KGISL Institute of Technology, Coimbatore, Tamilnadu, India

dDepartment of Mechanical Engineering, Varuvan Vadivelan Institute of Technology, Dharmapuri, Tamilnadu, IndiaThis article is an open access article distributed under the terms of the Creative Commons Attribution Non-Commercial License (http://creativecommons.org/licenses/by-nc/4.0) which permits unrestricted non-commercial use, distribution, and reproduction in any medium, provided the original work is properly cited.

Abrasive water jet cutting is a recent advanced machining process effectively used for machining several materials irrespective of hardness. MONEL K500 is hard to machine material used for various high temperature components like aircraft engine components, turbine blades, missiles, components for supercritical power plants etc. Non-traditional machining methods are more suitable for the machining of these kinds of hard alloys and abrasive water jet machining are highly preferred and found suitable for machining these materials in several industries. The multi-response process parameter optimization in abrasive water jet machining of MONEL K500 using composite desirability function analysis is carried out in this work. The significant process parameters are standoff distance, speed rate and abrasive flow rate. The responses considered in this work are surface roughness, material removal rate and kerf width. The individual desirability functions of all responses are considered and the weightages of each response are assigned to calculate the composite desirability. The higher composite desirability value provides the optimum process parameters and they are validated. ANOVA analysis and S/N plots for the responses and the composite desirability function are also carried out to predict the high influencing parameters while machining MONEL K500.

Keywords: MONEL K500, Composite desirability, ANOVA, Multi objective optimization.

Machining is dependent on four significant parameters namely mixing parameters, cutting parameters, abrasive parameters and hydraulic parameters [1]. The effect of nozzle diameter, stand off distance, speed rate, abrasive flow rate are predominant cutting process parameters in water jet machining. The depth of cut was observed to increase with rise in water jet pressure under various combinations of orifice and nozzle diameter. The orifice diameters of 0.25, 0.30 and 0.40 were experimentally investigated while 0.25 and 0.30 were said to produce higher depth of cut. The nozzle size to orifice size range of 3-4.5 was identified to be optimal for an orifice of 0.25 mm. Similarly, with increase in abrasive flow rate and waterjet pressure the material removal rate was also observed to be higher. The significance of orifice and nozzle diameter was not well pronounced in terms of surface roughness. The ANOVA analysis for wire cut EDM machining for optimizing the surface roughness, materials removal rate and tool wear are carried out [2]. The increase in water pressure provides better cutting efficiency by 20-30% and hence considered to be a significant parameter and an increase in water pressure resulted in a better surface finish [3]. As a result of increase in jet pressure, there occurs a tendency for the brittle abrasives to further break down. Reduction in abrasive size results in lower surface roughness. In addition, with increase in water pressure the kinetic energy of the particles increases thereby resulting in lower surface roughness. The findings indicate that in order to obtain surface with lower surface roughness, higher water pressure can be used during the process. Similar results were also observed while machining Grey cast iron and reported [4]. The influence of water jet pressure on depth of cut and kerf width while machining D2 Steel was experimentally investigated [5]. It was observed that at lower water pressure, the impact of abrasive water jet was not sufficient enough to remove more materials. This in turn results in lower depth of cut at lower water jet pressures. In addition to depth of cut, the kerf width was also observed to vary with respect to water jet pressure. At lower water jet pressures, the material removal was minimal and hence it was not possible to determine the bottom kerf width. Hence in order to obtain a thorough cut, it was essential to maintain a higher jet pressure of 216 to 240 MPa. Similarly, when the water jet is made to strike against the surface at higher pressure, the kinetic energy of the abrasive water jet while it strikes the surface is observed to be higher and decreases with increase in depth of penetration.

The surface characteristics while generating blind pockets on Ti-6Al-4V revealed that the depth of cut and material removal rate were observed to be significant process parameters while varying the water jet pressure [6]. This in turn was attributed to the kinetic energy of the abrasives. It was also observed that the surface morphology of the machined surface varied significantly with changes on water jet pressure. At higher water jet pressures, the kinetic energy of the abrasives were observed to be maximum and this has led to improved material removal from the target surface, workpiece [7]. Surface morphology observations revealed that there were minimal traces of striation marks across the surface at higher water jet pressures, improving the surface quality. An increase in surface quality by 33% was observed for a change in input pressure of 25% and a straightness of the cut and taper angle analysis of INCONEL 188 with the effective process parameter were analyzed [8]. Result shows that 80 mm/min of transverse speed and 200 g/min of abrasive flow rate determined MRR is increased but it decrease the surface roughness. H13 Hot Die Tool Steel by AWJM are optimized and shown that 76 mm/min of transverse speed and 30 g/min of abrasive flow rate was effective [9]. According to the analysis of variance, the main factor influencing responses like MRR and hole surface roughness is water pressure of 3000bar. The improvement in surface finish during multi objective genetic algorithm to optimize the machining parameters for carbon steel S235 with machining time of 7.266 sec/cm2 are studied [10]. The variables that have the greatest influences on the machining process are quality are traverse speed and pressure in abrasive water jet machining process [11]. The researchers have studied the performance of the process parameters for minimization of surface roughness in machining Titanium and Nickel alloy using abrasive water jet machining [12-14].

Inconel 718 is optimized using multi criteria decision making technique and other optimization techniques such as Taguchi technique, TOPSIS are also performed to determine the optimum process parameters [15-17]. The multi objective optimization is performed through several optimization techniques to determine the optimal process parameters for machining [18, 19]. From the literatures, it could be inferred that cutting process parameters associated to Abrasive water jet machining are primarily dependent on the material removal and surface finish. In addition, the process is primarily dependent on various other factors such as mixing parameters, abrasive parameters and cutting parameters. In specific, mixing parameters comprises of the focusing nozzle length and nozzle diameter. The parameters are abrasive mass flow rate, abrasive particle diameter, abrasive particle shape and abrasive material hardness. Significant cutting parameters that contribute to the process are traverse rate, number of passes, stand-off distance and jet impingement angle. In addition, the work piece properties play a major role in determining the efficiency of abrasive water jet machining process. ANN and RSM can able to build mathematical models and optimize the responses alone and provides a relationship between the input and output relationships. GRA provides multi response optimization by ranking closeness to an ideal solution. DFA combines the multi objective optimization problems into a single objective optimization problem. Several researchers used several optimization techniques to determine the optimal process parameters [20, 21].

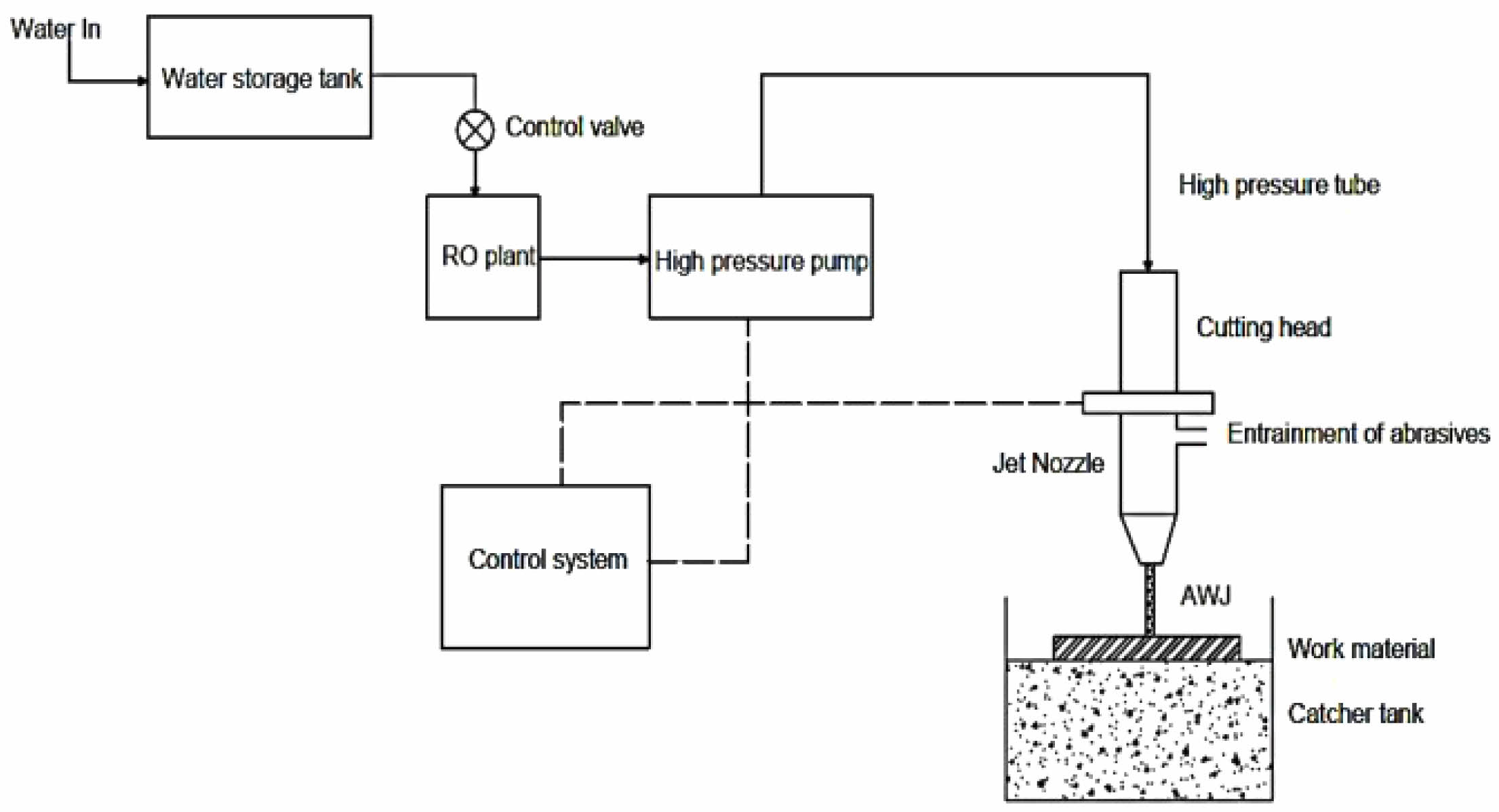

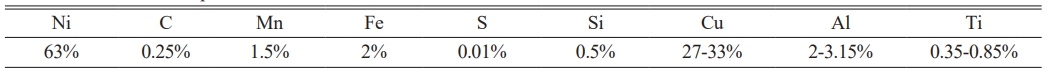

MONEL K500 is an age-hardenable Nickel-Copper alloy high strength corrosion fatigue and erosion resistance. Monel K500 finds applications in chains, cables, fasteners, springs, chemical processing, impellers, shafts, valves etc., This alloy is virtually non-magnetic at low temperatures and can be made slightly magnetic by leaving a nickel rich film on the outside of the material during heating. Low magnetic permeability, high strength and corrosion resistance are the prominent properties of MONEL K-500. Monel K-500 is often age-hardened and sensitive to thermal effects. AWJM’s reduces rework and preserves mechanical properties. Since the tool wear are highly controlled and tooling issues are reduced, AWJM is more feasible for industrial applications bringing economic production. There is no heat affected zone and no microstructural changes are found since AWJM is a cold cutting process. AWJM can produce high strength for intricate shapes with minimal machining. The material used in this experiment is Monel K-500 super alloy of dimension 100 mm×50 mm×15 mm. The chemical composition of MONEL K-500 is shown in Table 1. A typical schematic layout of abrasive water jet machining is given in Fig. 1.

The primary objective of this research work is improving the process parameters of abrasive water jet machining for machining MONEL K500. The experiments were conducted on OMEX 5555 jet machining centre. Three factors and three levels are chosen and the process parameters considered in this work are standoff distance (SOD), speed rate (SR) and abrasive flow rate (AFR). The parameters and its level are presented in Table 2. The responses such as surface roughness (SR), material removal rate (MRR) and kerf width are measured against these process parameters and recorded. This work applies to several industries since Monel K-500 is a high performance alloy and AWJM is a non-traditional machining process. High impact of this work is found in industries such as marine, oil & gas, Aerospace, Defence, Chemical industry, Power generation and so on.

Experimental Design

The primary objective of this research work is improving the process parameters of abrasive water jet machining for machining MONE K500. The experiments were conducted on OMEX 5555 jet machining centre. Three factors and three levels are chosen and the process parameters considered in this work are SOD, SR and AFR. The parameters and its level are presented in Table 2. In this work, stand off distance, speed rate and abrasive flow rate are considered as the process parameters for machining Monel K500 using abrasive water jet machining process. The other parameters which influence the machining of Monel K500 includes; tool material, depth of cut, feed rate, and so on. The stand-off distance, speed rate and abrasive flow rate are considered in this work. Since these responses are considered to the primary influencial parameter in AWJM process, they are selected in this work. These parameters will reduce experimental complexity and consistent with industrial applications. The other parameters such as water pressure, nozzle geometry, abrasive grit size are not considered because it provides less influence in the machining of Monel K-500.

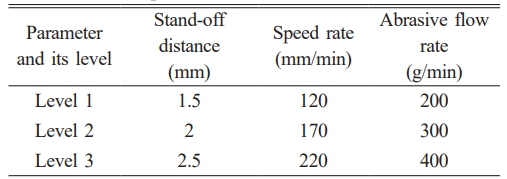

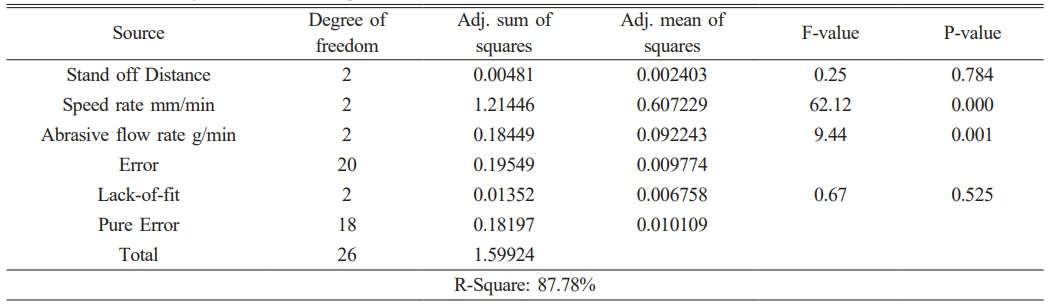

The responses such as surface roughness, material removal rate and kerf width are measured against these process parameters and recorded. Design of experiments is used to conduct the experiments with three process parameters and three levels, the L27 orthogonal array is selected to conduct the experiments at several combinations. Experiments are conducted and SR, MRR and kerf are measured at each experiment and recorded as presented in Table 3. The MRR is calculated by determining the weight difference of the material before and after machining. The Mitutoyo surface roughness tester is used to measure SR after machining the work material and three values are recorded and the average of this is recorded as the final surface roughness value after machining MONELK500.

|

Fig. 1 Abrasive water jet machining. |

DFA is preferable for multi- response optimization functions in industries, in which multi response characteristics is converted to single response characteristics function termed as composite desirability. The multi responses such as SR, MRR and Kerf are combined as composite desirability using desirability function analysis. To optimize multiple responses at the same time in an experiment, Desirability function analysis is performed. In this work, minimization of surface roughness, maximization of material removal rate and minimization of kerf width are considered. These multi responses are to be optimized simultaneously at the same time to evaluate the optimal machining process parameters for Abrasive water machining and hence desirability function analysis is performed. Optimization Steps using desirability function analysis in Taguchi method.

Step 1: Calculation of individual desirability index for the response

Step 2: Computation of the composite desirability

Step 3: Determination of optimal parameter and optimum levels. The higher the composite desirability it indicates better quality and this provides the optimum level of combinations.

Step 4: ANOVA analysis is carried out for the identification of the significant parameters.

The optimization process used in this work can be scaled up for industrial applications with larger part geometries. Also industries involving with continuous production requirement can use this optimization for effective selection of process parameters for machining Monel K-500 using AWJM. Process integration in the selection of optimum parameters and responses will provide higher efficiency of the machine.

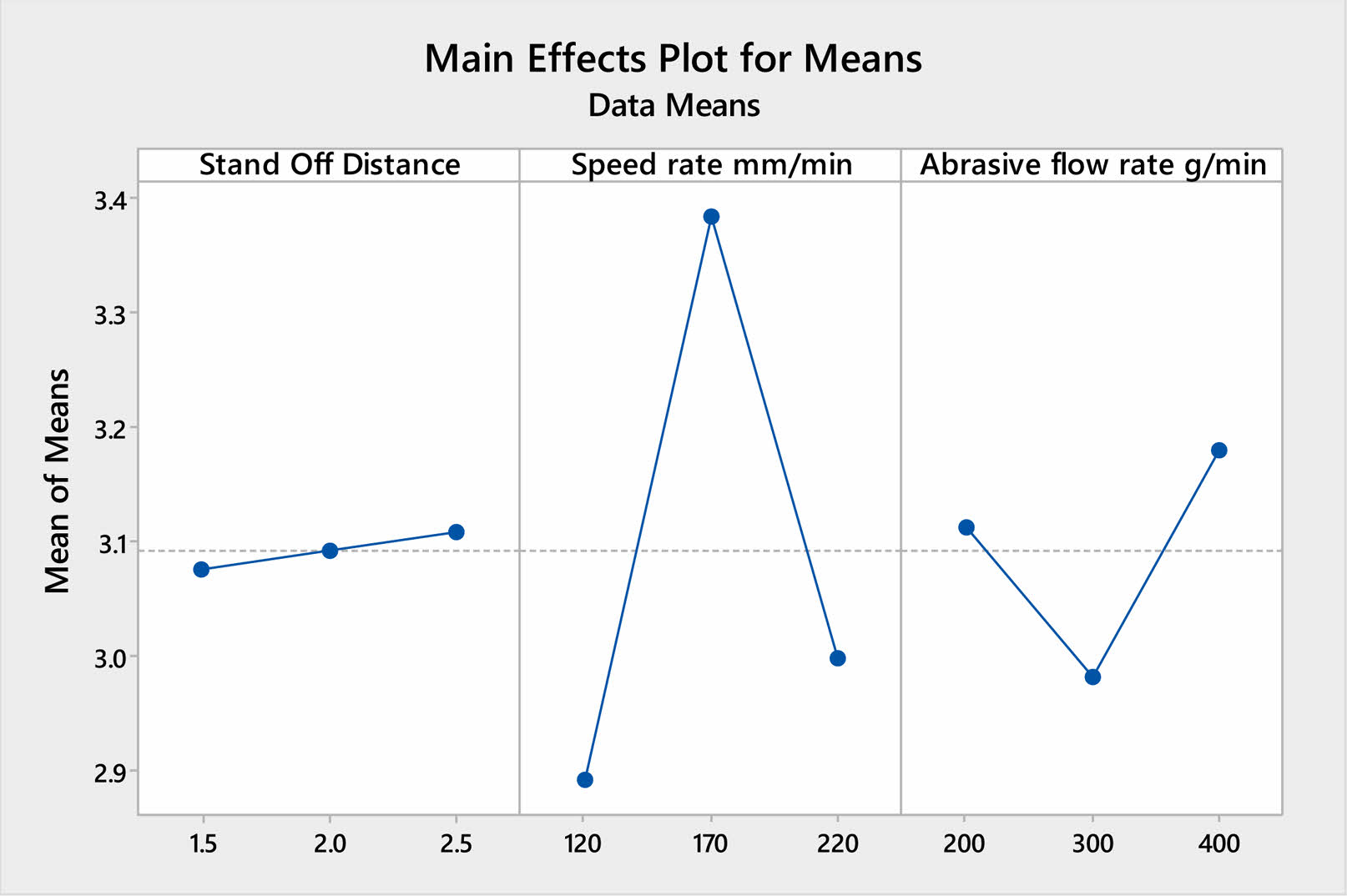

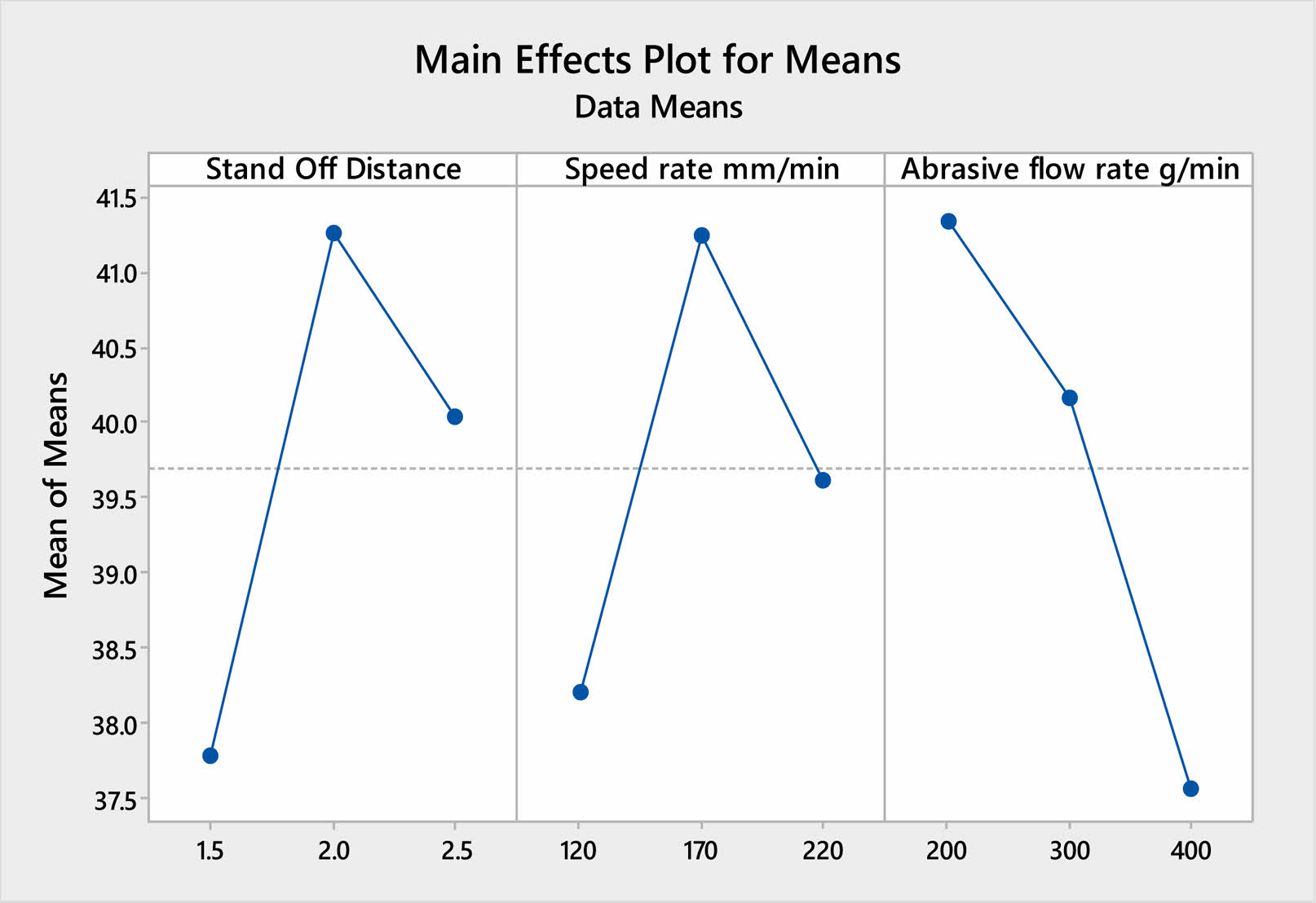

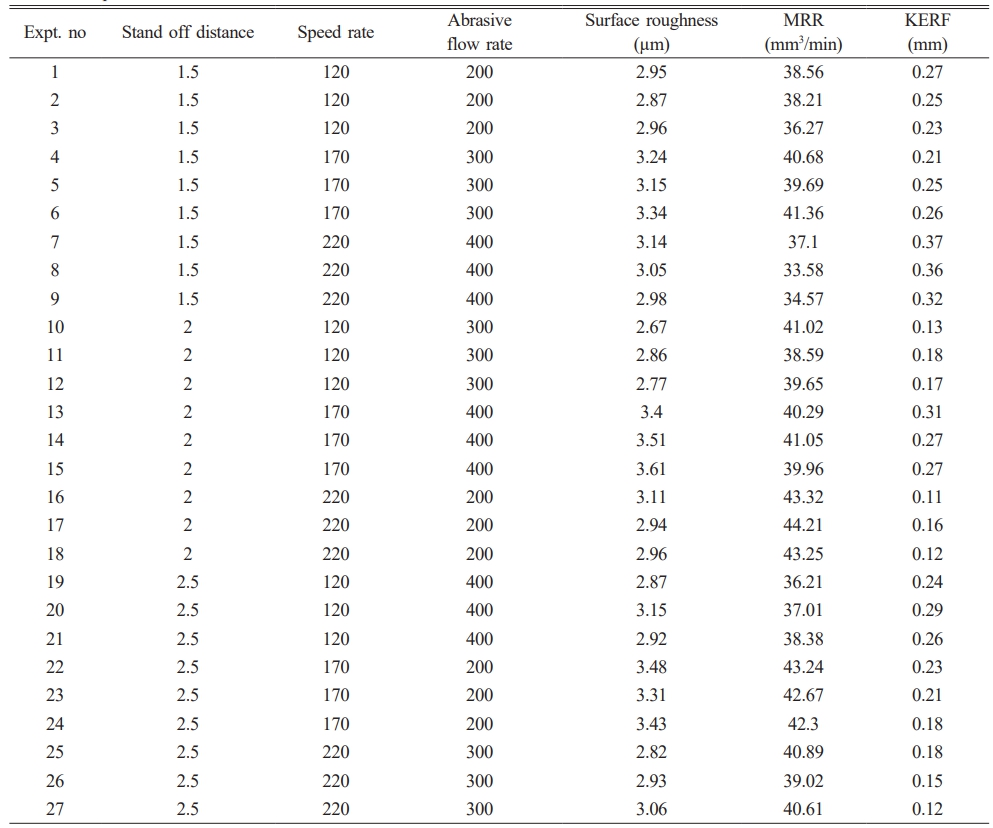

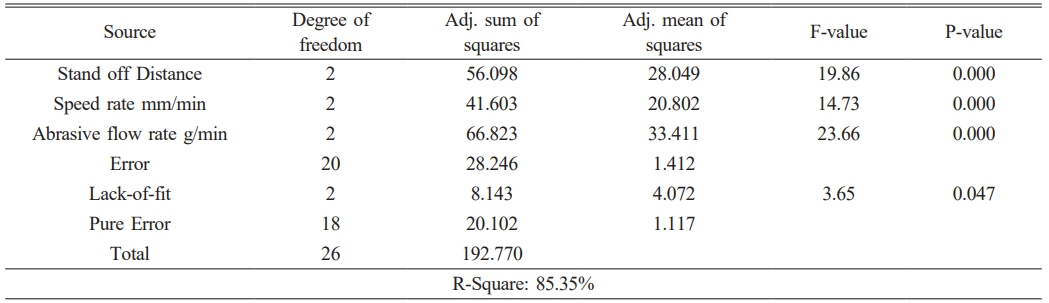

ANOVA analysis is useful in predicting the influence of the process parameters on the quality characteristics. F-value and p-value are used to study the significance of the process parameters on the response variables. In this work ANOVA analysis is carried out for all response to determine the dominant process parameters on machining of MONEL K500 using abrasive water jet machining. The ANOVA analysis for SR is carried out and it is observed that speed rate is the high influencing parameter in minimizing the surface roughness while machining MONEL K500 and it is followed with Abrasive flow rate and stand off distance. The R-square value of the ANOVA analysis is found to be 87.78% and it is highly acceptable. The ANOVA analysis for MRR is carried out and it is observed that stand-off distance, speed rate and abrasive flow rate are the high influencing parameter in maximizing the material removal rate for machining MONEL K500. The R-square value of the ANOVA analysis is found to be 85.35% and it is highly acceptable.

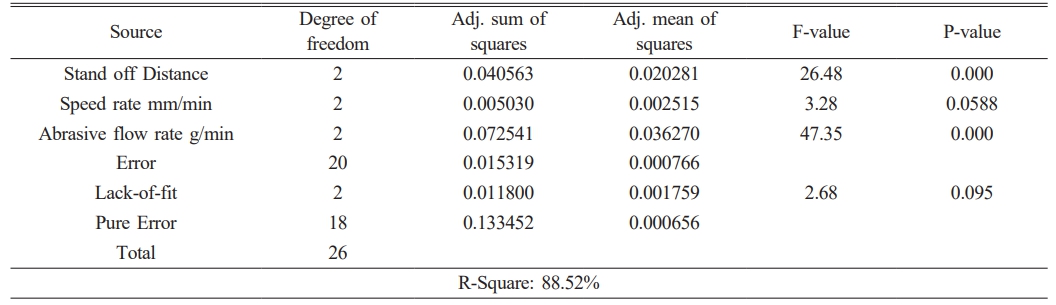

The ANOVA analysis for Kerf is carried out and it is observed that stand off distance and abrasive flow rate are the high influencing parameter in minimizing the kerf while machining MONEL K500 and it is followed speed rate. The R-square value of the ANOVA analysis is found to be 88.52% and it is highly acceptable. The ANOVA tables of surface roughness, material removal rate and Kerf are presented in Tables 4-6 respectively. R-square value represents the proportion of the response variability with respect to the factors and interaction of the factors considered as the process parameters in AWJM. 80-85% of R-square value denotes process variability can come from minor changes in the abrasive quality, environmental changes, measurement errors, vibration and so on. This value also depicts the model is highly significant and acceptable. The main effects plots for means for SR and MRR are shown in Fig. 2 and Fig. 3. respectively.

Implementation of Desirability function analysis

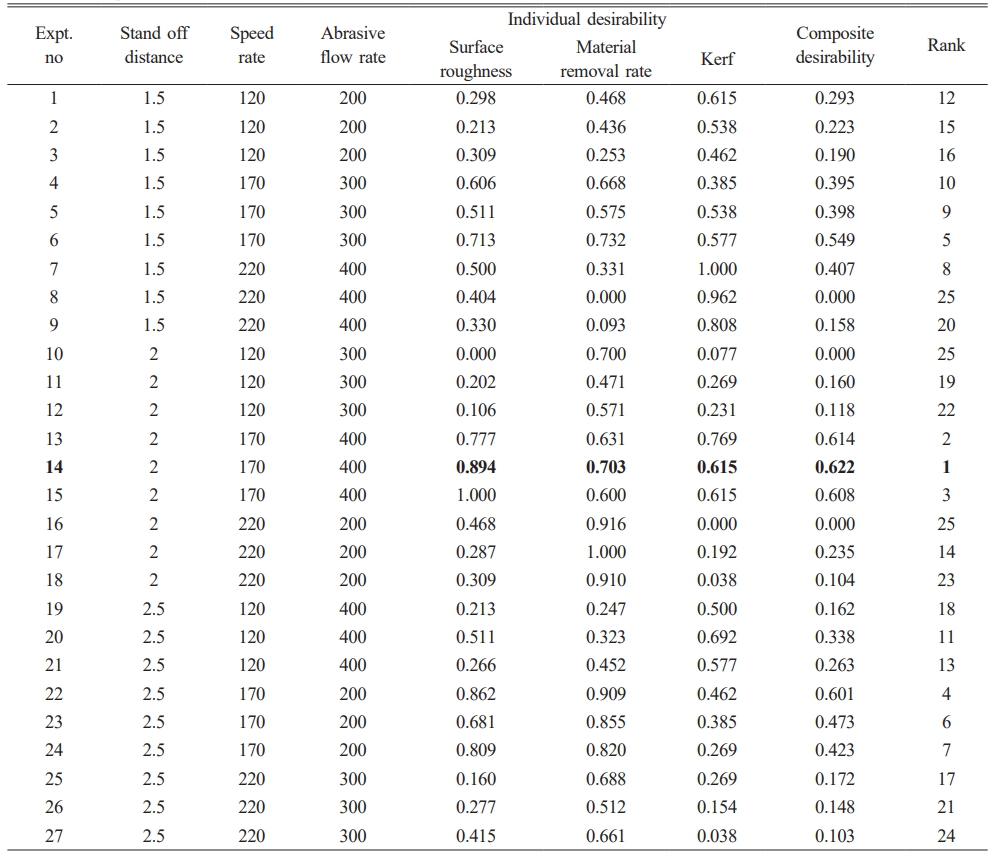

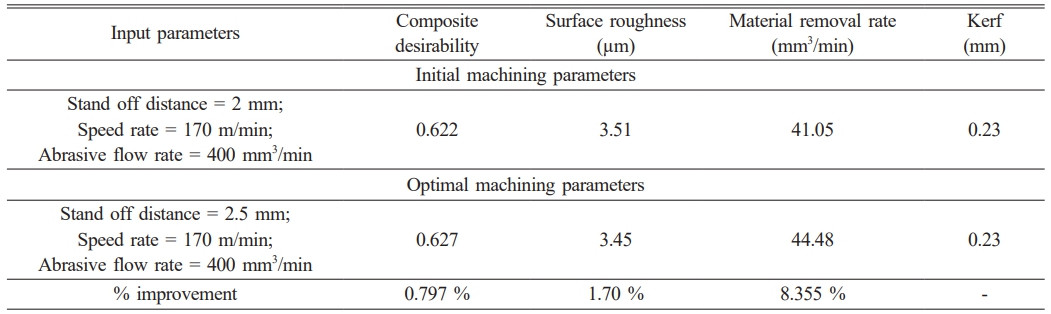

The individual desirability function for the SR, MRR and kerf are determined by assigning equal weightage to all the responses equally. Giving equal weightage to all the responses means, no single response is prioritized at the expense of the other. It provides a neutral optimization application allowing customization for all industrial applications. The composite desirability can be obtained without any bias by providing equal weights to all the responses. The composite desirability is computed and the optimum cutting parameters are determined. The higher the composite desirability, the better the quality conditions and it gives the optimal machining conditions. From Table 7, the higher composite desirability value is found to be 0.622 and the parameters against this value will provide the best optimum results. The values of composite desirability are ranked and higher the composite desirability, the value is ranked as ‘1’. The optimum input parameters for machining of MONEL K500 in abrasive water jet machining are computed as, standoff distance = 2 mm, speed rate = 170 mm/min and abrasive flow rate = 400 g/min. The composite desirability obtained for this combination is 0.622 and with these optimum levels, the surface roughness = 3.51 µm, material removal rate = 41.05 mm3/min and kerf = 0.23 mm. The validation of these parameters are performed and presented in Table 7.

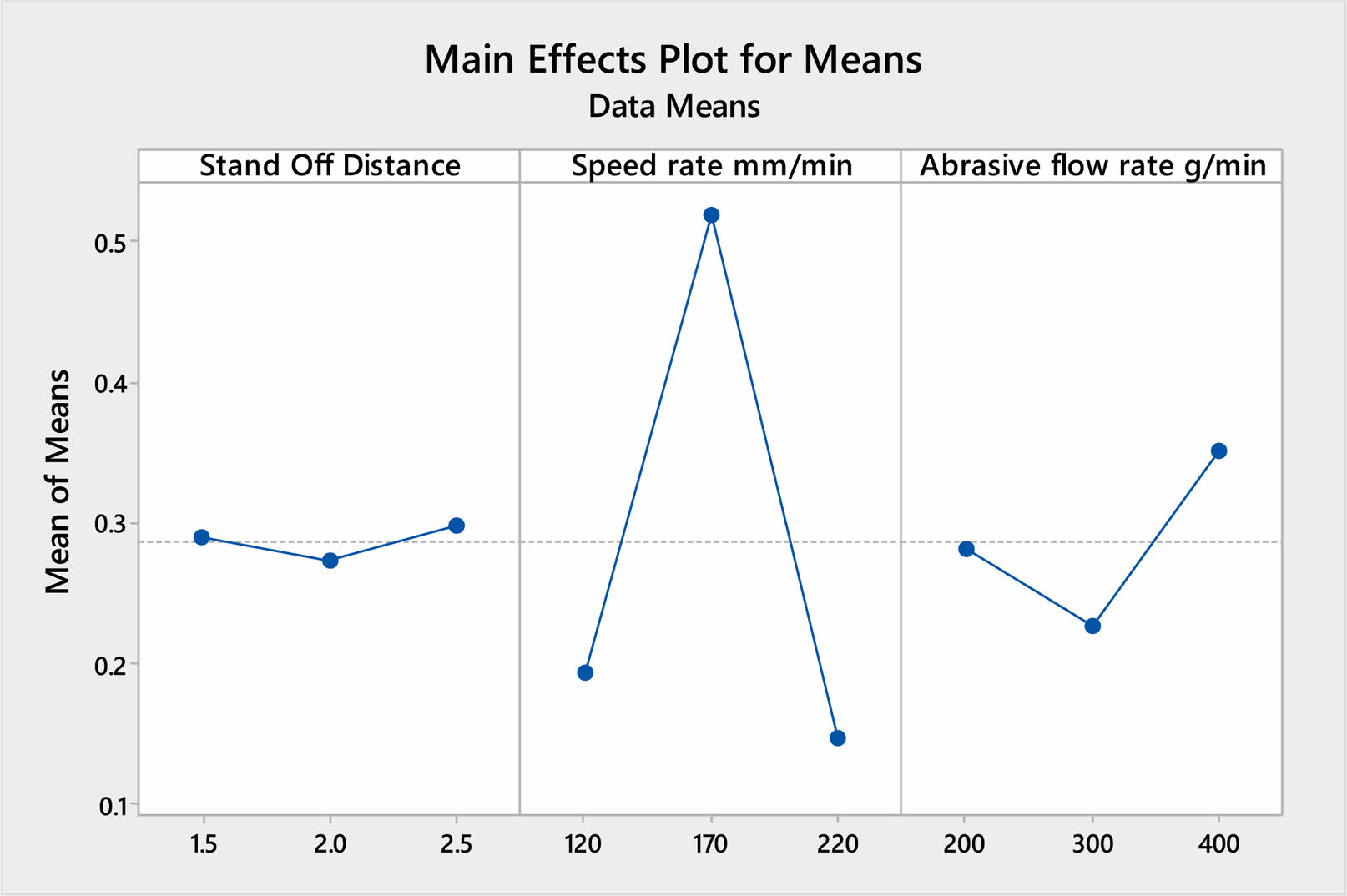

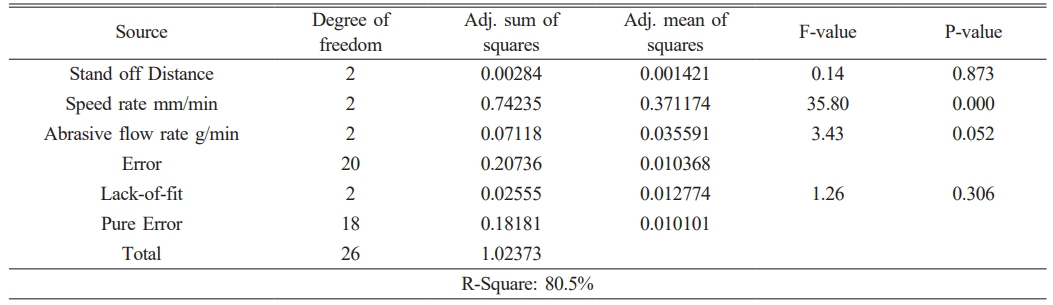

The ANOVA analysis for composite Desirability is carried out and shown in Table 8 and it is observed that speed rate and abrasive flow rate are the high influencing parameter in maximizing the composite desirability for machining MONEL K500 and it is followed by standoff distance. The R-square value of the ANOVA analysis is found to be 80.5% and it is highly acceptable. The main effects plot for mean for composite desirability is shown in Fig. 4. The response table and main effect plots for means for composite desirability are determined and it is observed form the mean plots that the optimum values for standoff distance = 2.5 mm, speed rate = 170 m/min and abrasive flow rate 400 mm3/min.

|

Fig. 2 Main effects plots for Means for Surface Roughness |

|

Fig. 3 Main effects plots for Means for Material removal rate. |

|

Fig. 4 Main effects plots for means for Composite Desirability. |

The process parameter optimization of SR, MRR and kerf are carried out using desirability function analysis. Experiments are conducted as per Taguchi L27 orthogonal array with three levels for each parameter. The ANOVA analysis for each response is carried out and composite desirability for the multi objective optimization is calculated and found to be 0.622. Validation experiment is conducted for these optimum parameters and values are recorded as shown in Table 9.

It is found that the percentage of improvement in composite desirability is 0.79%, minimizing surface roughness is 1.70% and maximizing MRR is 8.32% and no significant change is observed in Kerf.

- 1. A. Anu kuttan, R. Rajesh, and M. Dev Anand, J. Braz. Soc. Mech. Sci. & Eng. 43 (2021) 1-14.

-

- 2. K. Radhakrishnan and R. Kesavalu, Matéria (Rio de Janeiro.), 30 (2024) e20240797

-

- 3. M. Chithirai Pon Selvan, N. Mohana Sundara Raju, and H.K. Sachidananda, Front. Mech. Eng. 7 (2012) 439-444.

-

- 4. M. Chithirai Pon Selvan, and N. Mohana Sundara Raju, Int. J. Sci. Environ. Tech. 1[3] (2012) 174-182.

- 5. D. Deepak, D.V. Akash, and D. Anjaiah, Int. Journal of Research in Engineering and Technology 4[9] (2015) 344-347.

- 6. V.K. Pal and S.K. Choudhury, Procedia Mater. Sci. 5 (20114) 1584-1592.

-

- 7. M. Naresh Babu and N. Muthukrishnan, Mater. Manuf. Processes 29 (2014) 1422-1428.

-

- 8. Ajay D Kumbhar and Manavendra Chatterjee, Int. J. Tech. Res. Eng. 4[9] (2017) 1548-1553.

- 9. Naidu Naresh Kumar, G. Sharath Kumar, and M. Shiva Shankar Durga, Int. J. Modern St. Mech Eng. 5[1] (2019) 41-47.

- 10. Miroslav Radovanovic, Procedia Manufacturing 47 (2020) 781-787.

-

- 11. A. Dumbhare, P. Dubey, and S.V. Deshpande, J. Braz. Soc. Mech. Sci. Eng. 40[5] (2018) 259.

- 12. Y.I. Mogul, I. Nasir, and P. Myler, Mater. Today Proc. 28 (2020) 604-610.

- 13. M. Soori and B. Arezoo, Proc. Inst. Mech. Eng., Part E: J. Process Mech. Eng. 238[4] (2023) 1613-1625.

-

- 14. A. Kumar, H. Singh, and V. Kumar, Mater. Manuf. Processes 33[13] (2018) 1483-1490.

-

- 15. R. Thirumalai, J.S. Senthilkumaar, P. Selvarani, and S. Ramesh, Proc. Inst. Mech. Eng., Part C: J. Mech. Eng. Sci. 227[9] (2013) 1889-1897.

-

- 16. R. Thirumalai, M. Seenivasan, and K. Pannerselvam, Mater. Today Proc. 45 (2021) 467-472.

-

- 17. R. Thirumalai and J.S. Senthil Kumar, J. Mech. Sci. Tech. 27 (2013) 1109-1116.

-

- 18. A. Srinivasan, R. Prabu, and S. Ramesh, J. Ceram Process Res. 23[6] (2022) 783-793.

-

- 19. N. Ravikumar, R. Vijayan, and R. Viswanathan, J. Ceram Process Res. 24[1] (2023) 142-152.

-

- 20. K.M. Senthilkumar N. Kathiravan, L. Girisha, and M. Sivaperumal, J. Ceram. Process. Res. 23[4] (2022) 541-545.

-

- 21. N. Manoj Krishna, M. Selvaraj, Arul Kulandaivel, and S. Lakshmana Kumar, J. Ceram Process Res. 23[5] (2022) 656-665.

-

This Article

This Article

-

2025; 26(5): 779-786

Published on Oct 31, 2025

- 10.36410/jcpr.2025.26.5.779

- Received on Jul 24, 2025

- Revised on Aug 9, 2025

- Accepted on Sep 2, 2025

Services

Services

- Abstract

introduction

materials and methods

desirability function analysis

results and discussion

conclusion

- References

- Full Text PDF

Shared

Correspondence to

Correspondence to

- Balasubramaniam Vellaisamy

-

Department of Mechanical Engineering, Shivani Engineering College, Trichy, Tamilnadu, India

Tel : +919486646392 - E-mail: vbalu9356@gmail.com

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.