- Enhanced bio-concrete with integrated recycled glass and agricultural waste for sustainable infrastructure resilience in coastal environments

Fengxuan Suna,* and Jianhao Linb

aSchool of Urban Construction Engineering, Wenhua College, Wuhan 430074, Hubei, China

bInstitute of Architecture Engineering, Huanghuai University, Zhumadian, 463000, Henan, ChinaThis article is an open access article distributed under the terms of the Creative Commons Attribution Non-Commercial License (http://creativecommons.org/licenses/by-nc/4.0) which permits unrestricted non-commercial use, distribution, and reproduction in any medium, provided the original work is properly cited.

The construction industry faces growing challenges in developing sustainable and durable materials, particularly for infrastructure exposed to aggressive coastal environments. This study explores the potential of bio-concrete incorporating ceramic waste, recycled glass, and agricultural by-products to enhance mechanical strength and durability. Experimental results indicate significant improvements in flexural and tensile strength, increasing from 2.5 MPa to 6.0 MPa and 2.0 MPa to 4.6 MPa, respectively, over curing periods of 7, 28, and 56 days. Additionally, chloride ion penetration resistance and sulfate durability tests demonstrated enhanced performance, with minimal mass loss and strength reduction, reinforcing the material's suitability for sulfate-rich environments. The incorporation of these alternative materials positively influenced the concrete matrix, contributing to long-term structural integrity. This research highlights the feasibility of sustainable bio-concrete as an environmentally friendly alternative to conventional concrete, offering enhanced durability for coastal and marine infrastructure applications.

Keywords: Ceramic waste, Recycled glass.

The construction industry is undergoing a critical transformation to address sustainability challenges, reduce its environmental footprint, and enhance the longevity of infrastructure. Traditional concrete production heavily depends on natural aggregates and cement, both of which contribute to resource depletion and carbon emissions. In response, researchers have explored alternative materials such as ceramic waste, recycled glass, and agricultural by-products to develop environmentally friendly concrete mixtures [1, 2]. While these materials have shown promise in reducing waste and improving mechanical properties, their long-term durability and performance in aggressive environments remain areas of active investigation [3, 4].

Coastal regions, in particular, subject concrete structures to harsh conditions, including chloride ion ingress, sulfate attacks, and biological degradation caused by marine microorganisms. These factors significantly accelerate the corrosion of steel reinforcement and the deterioration of concrete, leading to costly repairs and reduced service life [5]. Despite growing interest in alternative materials and bio-concrete technologies, there is still a knowledge gap in understanding the synergistic effects of combining recycled materials with bio-agents in coastal infrastructure applications. The integration of ceramic waste, recycled glass, and agricultural residues in bio-concrete could offer a dual advantage by improving sustainability and enhancing durability. However, comprehensive evaluations of chloride ion penetration resistance, sulfate resistance, bio-durability, and mechanical properties are required to validate the feasibility of such mixtures [6].

This study aims to develop a novel bio-concrete incorporating ceramic waste, recycled glass, and agricultural by-products for enhanced performance. The research will focus on, (i) Chloride Ion Penetration Resistance: Assessing the ability of concrete to resist chloride ingress, a critical factor in protecting steel reinforcements from corrosion in coastal infrastructure, (ii) Sulfate Resistance: Evaluating the durability of the material against sulfate-induced deterioration, which is common in marine and industrial environments, and (iii) Mechanical Properties: examining key mechanical properties such as compressive strength, flexural strength, and tensile strength to ensure structural viability. By addressing these aspects, this research aims to bridge the gap between sustainable material innovation and practical application in coastal environments. The findings will contribute to the development of high-performance, eco-friendly bio-concrete with superior durability and resilience, ultimately supporting sustainable infrastructure development in marine and coastal regions.

The materials used in this study were selected based on their potential to enhance the sustainability, mechanical properties, and durability of bio-concrete, particularly in coastal environments. The key components included recycled glass cullet (RGC), and agricultural waste-derived supplementary cementitious materials. Ordinary Portland Cement (OPC) was used as the primary binding material in all concrete mixtures. The fine and coarse aggregates were sourced from natural river sand and crushed stone, respectively. To enhance sustainability, recycled glass cullet (RGC) was used as a partial replacement for coarse aggregate at replacement levels of 5%, 10%, and 15% by weight. The RGC was crushed and sieved to match the particle size distribution of natural aggregates. Its pozzolanic properties and ability to mitigate alkali-silica reaction (ASR) were considered during the mix design. To reduce cement consumption and improve concrete durability, agricultural waste-derived materials such as rice husk ash (RHA) and coconut shell powder (CSP) were incorporated as partial cement replacements at levels of 5%, 10%, and 15% by weight. These materials were selected due to their high silica content, which contributes to pozzolanic reactions, improving long-term compressive strength, permeability reduction, and sulfate resistance. The RHA was obtained from controlled combustion of rice husks, while CSP was finely ground before mixing. Water was used for all concrete mixes to ensure consistency and hydration reactions. A superplasticizer was added to optimize workability and maintain uniform mixing, particularly in formulations with high RHA or CSP content.

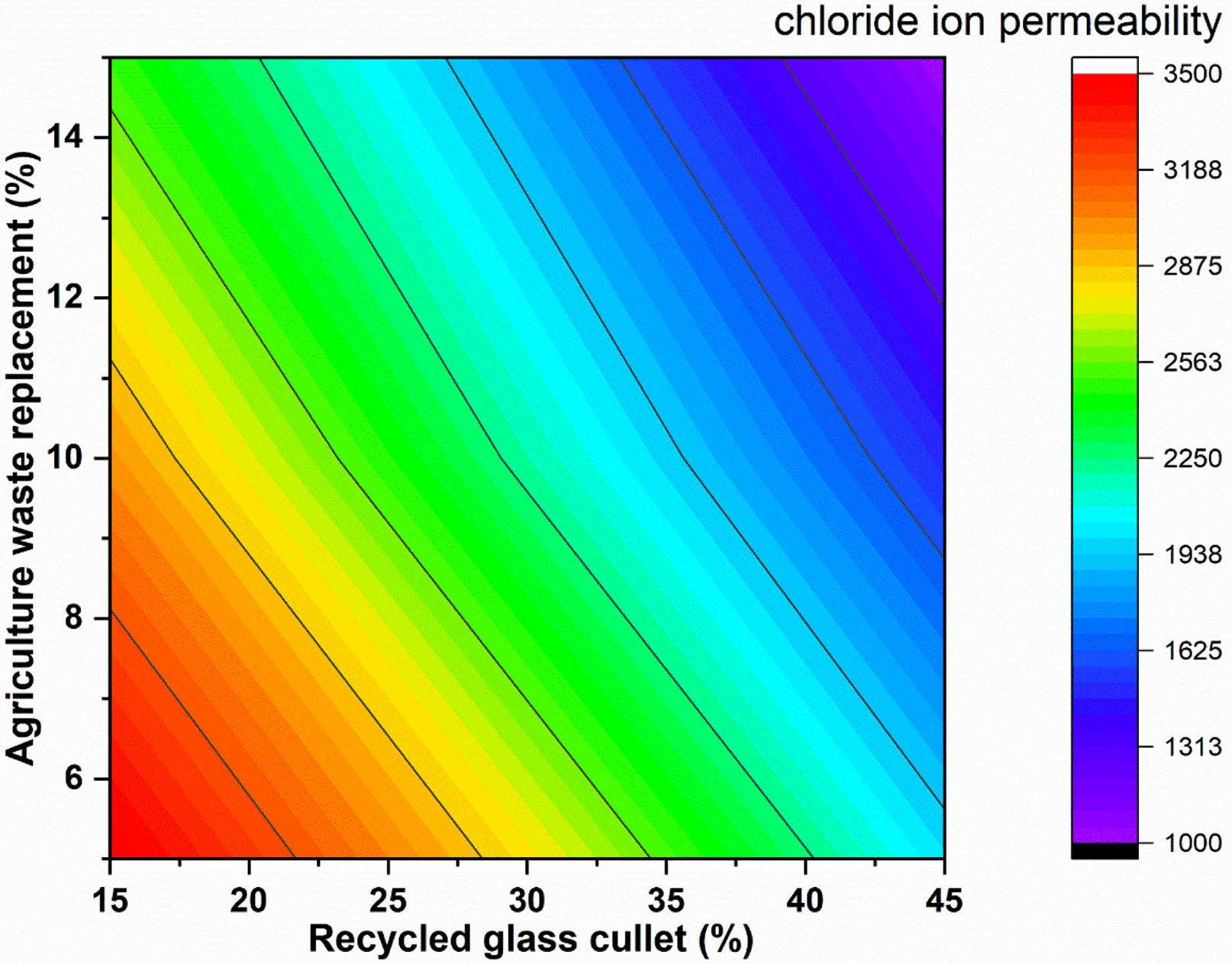

The heat map analysis of chloride ion permeability in bio-concrete mixtures clearly demonstrates the influence of Recycled Glass Cullet (RGC) and Agricultural Waste (RHA/CSP) replacement levels on concrete durability. A notable trend is observed where an increase in RGC content results in a significant reduction in chloride permeability. At 15% RGC replacement, permeability values range between 2500-3500 Coulombs, classifying the concrete as having moderate permeability according to ASTM C1202. As the RGC content increases to 30%, permeability values decrease to 1800-2800 Coulombs, shifting the classification to low permeability. The most substantial reduction is observed at 45% RGC replacement, where chloride permeability values fall between 1000-2000 Coulombs, indicating very low permeability. This improvement can be attributed to the pozzolanic activity of RGC, which refines the pore structure, enhances matrix densification, and minimizes pathways for chloride ingress. Fig. 1

Similarly, the incorporation of agricultural waste (RHA/CSP) as a partial cement replacement further enhances chloride resistance. At 5% RHA/CSP replacement, permeability values remain relatively high, ranging from 2800-3500 Coulombs, which still falls within the moderate permeability category. However, increasing the RHA/CSP content to 10% results in a marked decrease, with values ranging from 2200-3000 Coulombs, signifying improved durability. The lowest permeability is observed at 15% RHA/CSP replacement, where values range between 1000-2000 Coulombs, confirming a transition to the very low permeability category. The effectiveness of RHA/CSP is attributed to its high silica content, which contributes to additional calcium-silicate-hydrate (C-S-H) formation, reducing pore connectivity and enhancing long-term durability.

The synergy between RGC and RHA/CSP results in the optimal bio-concrete mix, where 45% RGC and 15% RHA/CSP replacement exhibit the lowest chloride permeability, approaching 1000 Coulombs. This demonstrates the potential of sustainable material integration in enhancing concrete durability, particularly in coastal environments where resistance to chloride-induced corrosion is critical. The findings suggest that incorporating RGC and RHA/CSP not only improves durability but also promotes sustainable construction practices by utilizing waste materials effectively [7].

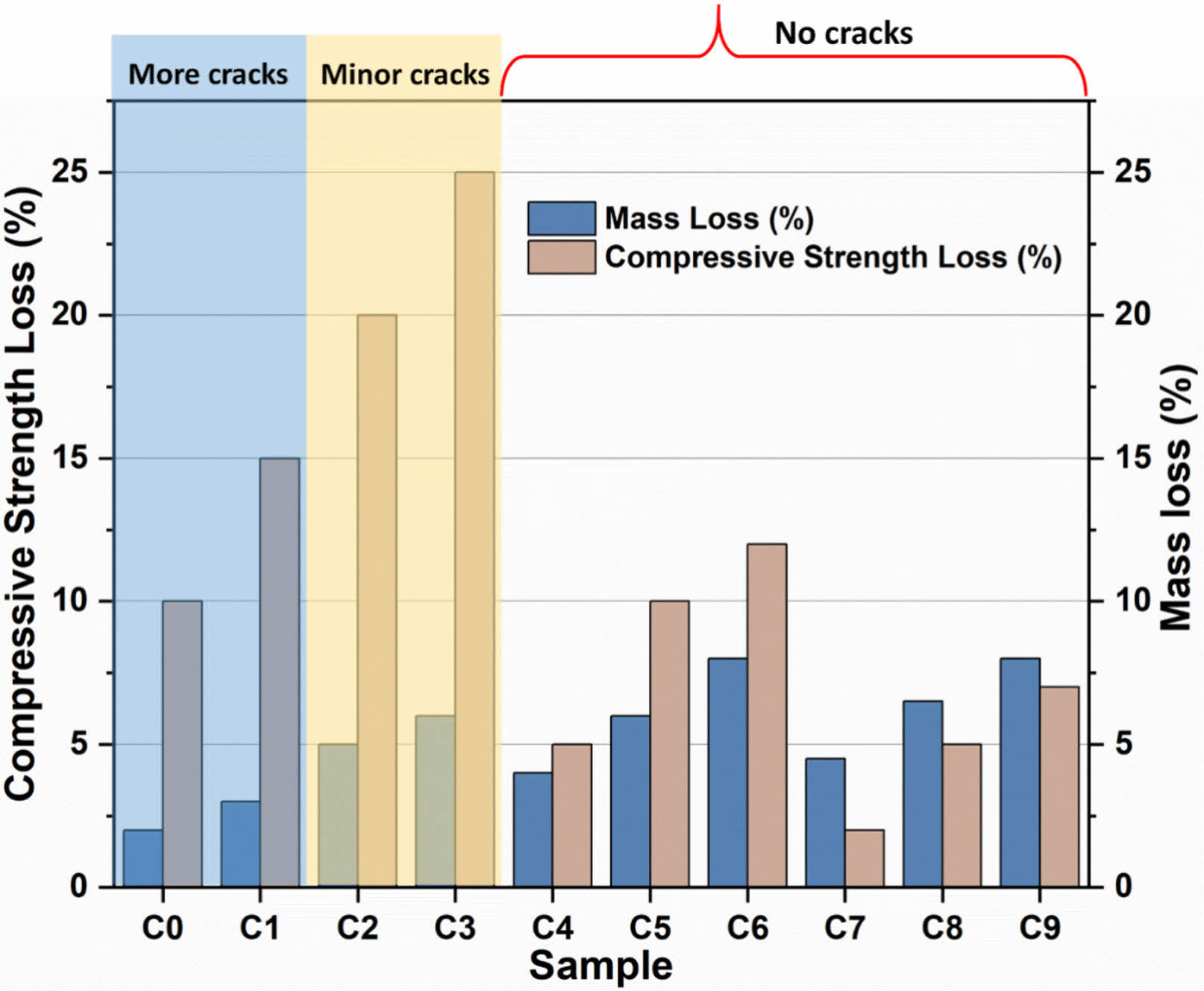

Figure 2 depicts the mass loss (%) and compressive strength loss (%) due to sulfate exposure. The results indicate that the inclusion of Recycled Glass Cullet (RGC) and Agricultural Waste (RHA/CSP) significantly influenced the concrete's durability in a 5% sodium sulfate solution over 28 days. The reference concrete (C0), which contained no RGC or RHA/CSP, exhibited a mass loss of 2.00% and a compressive strength loss of 10% after sulfate exposure. This served as the baseline for comparison. When 15% RGC was introduced (C1), the mass loss increased to 3.00%, and the compressive strength loss rose to 15%, indicating a slight decline in sulfate resistance. As the RHA/CSP content increased to 10% and 15% (C2, C3), the mass loss further increased to 5.00% and 6.00%, respectively, with strength loss reaching 20% and 25%. This trend suggests that lower RGC levels combined with higher RHA/CSP content led to reduced sulfate resistance, likely due to excessive cement replacement affecting the matrix integrity [8, 9].

However, at 30% RGC replacement (C4, C5, C6), a significant improvement in sulfate resistance was observed. The mass loss dropped to 4.00% for C4, while compressive strength loss decreased to just 5%. This indicates that an optimal RGC content helps in mitigating sulfate attack. Even at higher RHA/CSP levels (10% and 15%), the mass loss remained within 6.00%-8.00%, and the compressive strength loss was limited to 10%-12%, demonstrating enhanced durability compared to lower RGC mixes.

The most promising sulfate resistance was observed in C7, C8, and C9, which contained 45% RGC. In C7, the mass loss was only 4.50%, and the compressive strength loss was just 2%, showcasing the highest sulfate resistance among all mixtures. Even when RHA/CSP content was increased to 10% and 15% (C8, C9), the mass loss remained below 8%, and strength loss did not exceed 7%, indicating significant improvement in sulfate durability. The higher RGC content contributed to a denser microstructure, reducing sulfate ingress, while the pozzolanic activity of RHA/CSP enhanced the formation of secondary C-S-H gel, improving sulfate resistance. Furthermore, crack formation observations aligned with the bar graph trends. While C0-C3 exhibited minor to small cracks due to sulfate expansion, C4-C9 showed no visible cracking, confirming that higher RGC content (30%-45%) combined with controlled RHA/CSP levels effectively mitigates sulfate-induced deterioration.

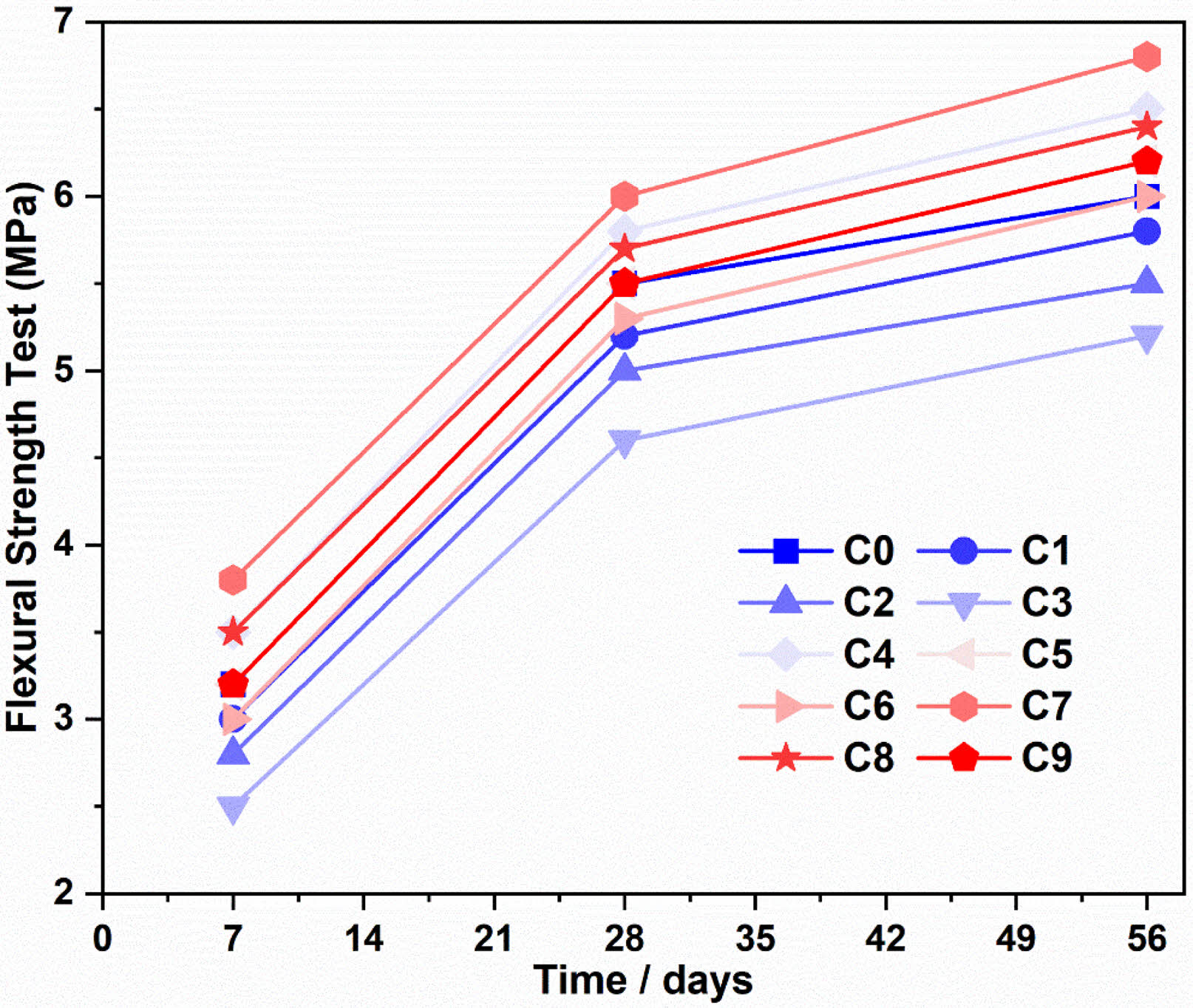

The flexural strength of the concrete mixes exhibited a progressive increase over time, demonstrating the continued hydration of cementitious materials and the pozzolanic activity of supplementary materials (Fig. 3). At 7 days, the flexural strength ranged from 2.5 MPa to 3.8 MPa, with Mix C3 recording the lowest value (2.5 MPa) and Mix C7 showing the highest (3.8 MPa). By 28 days, all mixes displayed a notable strength gain, ranging between 4.6 MPa and 6.0 MPa, where Mix C3 continued to have the lowest strength (4.6 MPa) and Mix C7 maintained the highest (6.0 MPa), indicating its superior long-term performance.

At 56 days, further improvements were observed, with flexural strength values increasing to 5.2 MPa-6.8 MPa. Mix C3 exhibited the least strength (5.2 MPa), while Mix C7 reached the highest (6.8 MPa), confirming the long-term benefits of the incorporated materials. The steady increase in flexural strength over time suggests enhanced bonding within the matrix due to prolonged hydration and the reaction of pozzolanic materials such as RHA or CSP, which contribute additional C-S-H gel formation. The presence of recycled glass aggregate did not significantly hinder strength gain, supporting its viability as a sustainable alternative in structural applications [10]. The results confirm that the incorporation of bio-concrete agents and sustainable materials does not compromise flexural strength. Instead, mixes with optimized material proportions, such as Mix C7, showed improved long-term strength development. This highlights the potential of such mixes for applications requiring high durability and flexural resistance, particularly in coastal environments where mechanical performance is crucial.

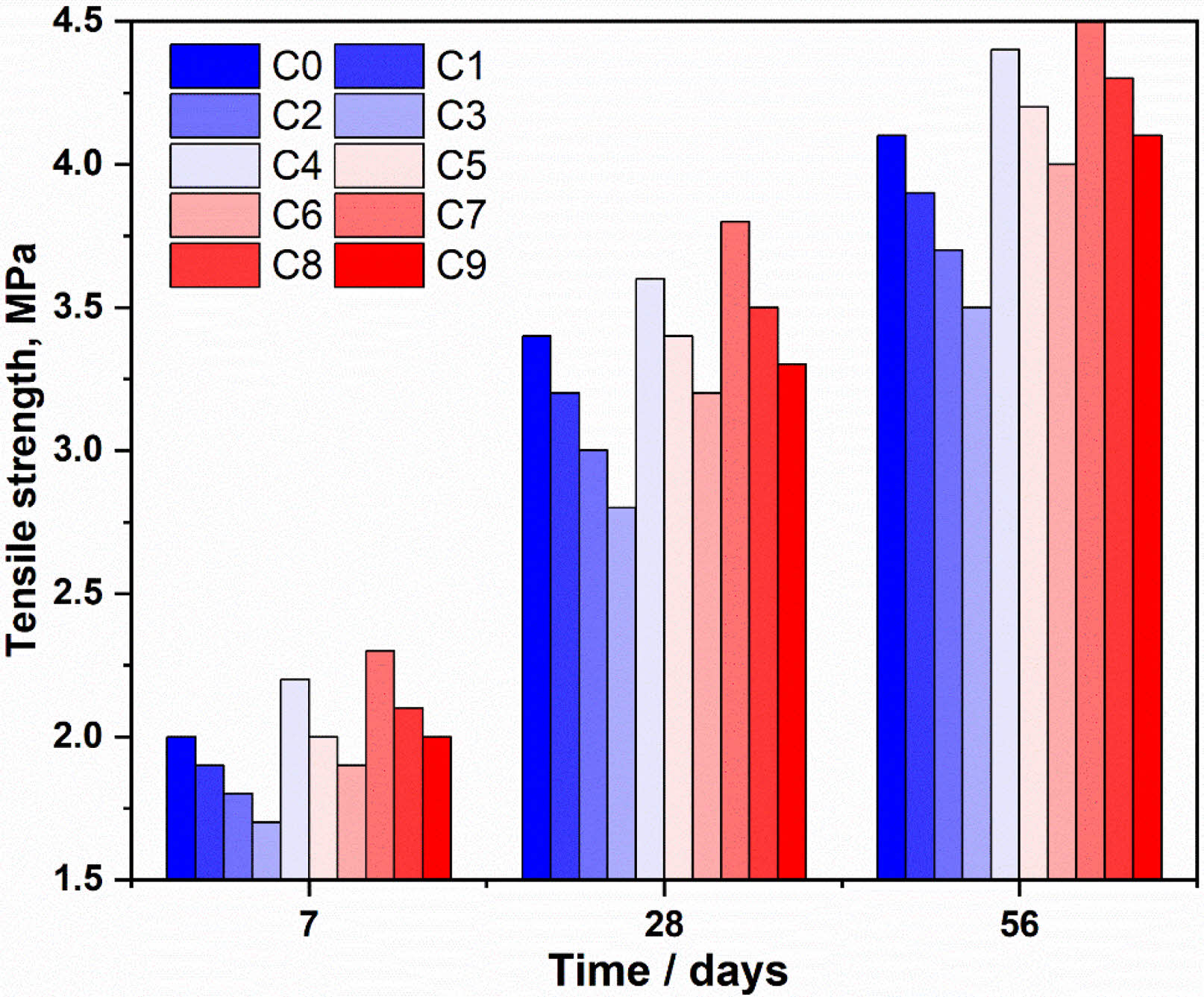

The tensile strength of the concrete mixes exhibited a consistent increase over time, highlighting the continued hydration process and the beneficial effects of supplementary materials (Fig. 4). At 7 days, the tensile strength ranged between 1.7 MPa and 2.3 MPa, with Mix C3 showing the lowest value (1.7 MPa) and Mix C7 achieving the highest (2.3 MPa). This early-stage strength development was influenced by the initial hydration of cement and the early pozzolanic reaction of the agricultural waste materials used as partial cement replacements [11]. By 28 days, a significant increase in tensile strength was observed across all mixes, ranging from 2.8 MPa to 3.8 MPa. Mix C3 continued to exhibit the lowest tensile strength (2.8 MPa), while Mix C7 reached the highest (3.8 MPa), suggesting that the optimized combination of recycled glass, and agricultural waste contributed to enhanced bonding and matrix densification. At 56 days, further improvements in tensile strength were recorded, with values ranging from 3.5 MPa to 4.6 MPa. The lowest strength remained with Mix C3 (3.5 MPa), whereas Mix C7 again displayed the highest (4.6 MPa), reinforcing the long-term benefits of the incorporated materials. The steady increase over time indicates that the presence of and pozzolanic materials enhanced durability without compromising mechanical performance [12]. These results confirm that sustainable concrete formulations incorporating recycled glass, and agricultural waste can achieve mechanical performance comparable to or even superior to conventional mixes, supporting their application in marine and industrial infrastructure [13].

|

Fig. 1 Heat map showing chloride ion permeability of bioconcrete mixtures with varying RGC and RHA/CSP percentages, indicating the optimal mix for improved durability. |

|

Fig. 2 Sulfate resistance of concrete mixes based on mass loss and compressive strength loss. |

|

Fig. 3 Flexural strength development of concrete mixes over time. |

|

Fig. 4 Variation in tensile strength of concrete mixes at different curing times (7, 28, 56 days). |

This study demonstrates the potential of bio-concrete incorporating sustainable materials such as ceramic waste, recycled glass, and agricultural by-products to enhance concrete durability and mechanical properties in coastal environments. The findings reveal that the incorporation of these alternative materials significantly improves the resistance of concrete to aggressive environmental factors, such as chloride ion penetration and sulfate-induced deterioration. The concrete mixes exhibited notable improvements in both flexural and tensile strength, with values ranging from 2.5 MPa to 6.0 MPa for flexural strength and 2.0 MPa to 4.6 MPa for tensile strength over 7, 28, and 56 days of curing. This consistent strength development indicates the positive effects of the recycled materials on the matrix, enhancing its structural viability and long-term performance. Furthermore, sulfate resistance tests demonstrated minimal mass loss and strength reduction, reinforcing the durability of the material in sulfate-rich environments, which is essential for applications in coastal and marine settings. In conclusion, this research highlights the feasibility of using sustainable materials, such as ceramic waste, recycled glass, and agricultural by-products, to develop high-performance concrete. The results suggest that these bio-concrete mixtures offer a viable alternative to traditional concrete, providing both environmental and durability benefits for infrastructure exposed to harsh coastal conditions. This study contributes to the ongoing efforts to create more sustainable, durable, and resilient construction materials.

- 1. M. Saribiyik, A. Piskin, and A. Saribiyik, Constr. Build. Mater. 47 (2013) 840-844.

-

- 2. S. Abdallah and M. Fan, Int. J. Eng. Tech. Res. 2[6] (2014) 11-17.

- 3. T.C. Ling, C.S. Poon, and S.C. Kou, Cement Concr. Compos. 34[2] (2012) 265-272.

-

- 4. A. Saxena, A. Abraham, and B. Sang, J. Ceram. Process. Res. 25[6] (2024) 1122-1141.

-

- 5. P. Kara, J. Sustain. Archit. Civil. Eng. 6[1] (2014) 42-49.

-

- 6. S. A. Miller, P. R. Cunningham, and J. T. Harvey, Resour. Conserv. Recycl. 146 (2019) 416-430.

-

- 7. I. Y. Hakeem, M. Amin, I.S. Agwa, M.H. Abd-Elrahman, and M.F. Abdelmagied, Case Stud. Constr. Mater. 19 (2023) e02323.

-

- 8. A.A.J. Ghanim, M. Amin, A.M. Zeyad, B.A. Tayeh, and I.S. Agwa, Struct. Concr. 24 (2023) 6815-6832.

-

- 9. M.M. Alonso, C. Gascó, M.M. Morales, J.A. Suárez-Navarro, M. Zamorano, and F. Puertas, Cem. Concr. Compos. 104 (2019) 103384.

-

- 10. T. Ali, O. Zaid, and M.Z. Qureshi, Arab. J. Sci. Eng. 50 (2024) 1991-2007.

-

- 11. J. T. Ding and Z. Li, Mater. J. 99[4] (2002) 393-398.

- 12. G.C. Cordeiro and C.P. Sales, Cem. Concr. Compos. 73 (2016) 98-104.

-

- 13. M. Amin, A.M. Zeyad, I.S. Agwa, and A.M. Heniegal, J. Build. Eng. 89 (2024) 109208.

-

This Article

This Article

-

2025; 26(2): 295-298

Published on Apr 30, 2025

- 10.36410/jcpr.2025.26.2.295

- Received on Mar 22, 2025

- Revised on Apr 4, 2025

- Accepted on Apr 8, 2025

Services

Services

Shared

Correspondence to

Correspondence to

- Fengxuan Sun

-

School of Urban Construction Engineering, Wenhua College, Wuhan 430074, Hubei, China

Tel : 18971072860 Fax: 02787539668 - E-mail: fengxuan_sun@163.com

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.