- The effects of particle sizes on crystal structure and diffusivity in 0.95(Na0.5K0.5)NbO3-0.05BaTiO3 ceramics

In-Ho Ima and Seung-Hwan Leeb,*

aDept. of Electrical Engineering, Shin Ansan University, Gyeonggi-do, Korea

bDept. of Battery Convergence Engineering, Kangwon National University, Gangwon State, KoreaThis article is an open access article distributed under the terms of the Creative Commons Attribution Non-Commercial License (http://creativecommons.org/licenses/by-nc/4.0) which permits unrestricted non-commercial use, distribution, and reproduction in any medium, provided the original work is properly cited.

We prepared powders with different particle sizes using various secondary milling times to fabricate 0.95(Na0.5K0.5)NbO3-0.05BaTiO3 (0.95NKN-0.05BT) by the conventional solid-state reaction. As secondary milling time of the powders was changed from 0 to 72 hours, the particle sizes of the powder with composition of 0.95NKN-0.05BT were significantly decreased from 14μm to submicron. As a results, the tetragonality (c/a) and the Curie temperatures (TC) was slightly increased. The diffusivities(γ) of 0.95NKN-0.05BT ceramics were sharply decreased when the particle sizes of powders with composition of 0.95NKN-0.05BT were decreased from 14μm to submicron. The phase transition characteristic of 0.95NKN-0.05BT ceramics shifted from relaxor-like ferroelectric to a normal ferroelectric as particle size of powder decreased from several micrometer to submicron in 0.95NKN-0.05BT ceramics.

Keywords: (NaK)NbO3-BaTiO3, Particle size, Diffusivity, Crystal structure.

Pb(ZrxTi1-x)O3 (PZT) piezoelectric ceramics, the most representative ferroelectric ceramics [1], have been widely used as actuators, sensor and other ferroelectric devices in various applications due to their superior piezoelectric properties for decade century. However Pb evaporation, which is occurred during sintering process of PZT green pellets, may cause various environmental problems and be harmful to human body. To solve these problems, many research groups have focused on development of Pb-free piezoelectric ceramics such as (BaCa)TiO3-Ba(ZrTi)O3 ceramics (BCT-BZT), (BiNa)TiO3 ceramics (BNT), and so on [2-5]. Among them, Saito’s group had developed and reported remarkable piezoelectric properties in (NaK)NbO3 (NKN) Pb-free ceramics [6], comparable to those of PZT piezoelectric ceramics. However, the NKN ceramic has difficulties for sintering in air. To solve the difficulties, many researchers have conducted studies on dielectric and piezoelectric properties of NKN Pb-free piezoelectric ceramics by adding additives [7-10], changing process parameters as sintering method [11-13] and sintering temperature [14, 15]. BaTiO3 (BT) ceramic had been studied and customized for electronic components due to high dielectric and piezoelectric properties for a long time. Among the studied NKN based ceramics, in particular, 0.95(Na0.5K0.5)NbO3-0.05BaTiO3 (0.95NKN-0.05BT) Pb-free piezoelectric ceramics has much attentions for academic and industrial fields, owing to good piezoelectric constant (d33) of above 200pC/N and electromechanical coupling factor (kp) of higher than 40%. Recently, our group studied and published papers on dielectric and piezoelectric properties of 0.95NKN-0.05BT Pb-free piezoelectric ceramics [15-17]. According to our research, the distribution of particle sizes of powder by variation of milling times was proved to have many effects on dielectric and piezoelectric properties in 0.95NKN-0.05BT Pb-free piezoelectric ceramics. Many researchers reported that NKN based ceramics have an orthorhombic phase at room temperature and shows a phase transition characteristic [18-21]. They reported that it comes from not only temperature dependent behaviors but also compositional dependent behaviors. In normal ferroelectric ABO3 piezoelectric ceramics, the change of dielectric constant with temperatures obeys the Curie-Weiss law, known as 1/ε = (T-TC)/C, and shows the sharp peak of dielectric constant at Curie temperature (TC) from tetragonal phase to cubic phase. However, dielectric constant in the complex ferroelectric (AA’)(BB’)O3 ceramics experiences a broadening property at a peak of dielectric constant. This ceramic is called as relaxor ferroelectrics which shows a diffused phase transition (DPT) [22]. It is well known that the DPT behavior in perovskite ABO3-type ferroelectrics is originated from multiple-ion occupation of A and/or B sites in the lattices and causes the deviation from Curie-Weiss Law [23]. These papers were mainly focused on characteristics by variation of compositions. However, there are few reports about the effects of particle sizes of powders on crystal structure and DPT behavior in NKN-BT Pb-free ceramics. In this paper, we investigated effects of particle sizes of powders on the crystal structure and diffused phase behavior in 0.95NKN-0.05BT ceramics.

0.95NKN-0.05BT ceramics were synthesized by using the raw materials such as K2CO3 (Junsei Chemical, Japan, 99%), Na2CO3 (Kanto Chemical, Japan, 99.5%), Nb2O5 (Junsei Chemical, Japan, 99.9%), BaCO3 (Kanto Chemical, Japan, 99%) and TiO2 (Hanawa Chemical, Japan, 99%) by the conventional mixed oxide method. The powders were mixed by ball milling in anhydrous ethanol with ZrO2 balls for 24 hr, followed by drying in oven at 100 oC for 24 hr. And then, the dried powders were calcined in furnace at 900 oC for 2 hr in air atmosphere. The calcined powders were remilled from 0 to 72 hrs to investigate effect of particle sizes on structure evolution of 0.95NKN-0.05BT ceramics. The powders with four kinds of secondary milled-powders, having different particle sizes, were mixed with 3 wt% polyvinyl alcohol (PVA) solution and then pressed into pellet with a size of 15.8 mm in diameter and 2 mm in thickness by applying 1.5ton pressure. After burning out PVA, the pellets covered with zirconia crucible were sintered at 1200 oC for 2 hr with a rising rate of 3 oC/min at atmospheric condition in electric furnace. The sintered pellets were polished up to 1 mm thickness. To investigate dielectric properties of 0.95NKN-0.05BT ceramics, the silver pastes were coated on both sides of the polished pallets and fired at 600 oC for 30min. And electric poling was performed at 100 oC in a silicone oil bath by applying a DC voltage of 3 kV/mm for 30 min. The particle size of the secondary milled powders with 4 different particles sizes was analyzed by using a particle size analyzer (Cilas 1190, France). X-ray diffraction (XRD, Rigaku, Japan) with Cu Kα radiation (step: 0.01º) was used to determine the crystal structure of four specimens. Also the dielectric constants of 0.95NKN-0.05BT ceramics were examined using a LCR meter (Ando AG-4303, Japan) in an electric furnace by measuring the capacitances in the range from room temperature to 480 ℃ at 1 kHz. The crystal structure evolution and the diffusivity in 0.95NKN-0.05BT ceramics were analyzed by using the results of XRD data and dielectric constant measurement.

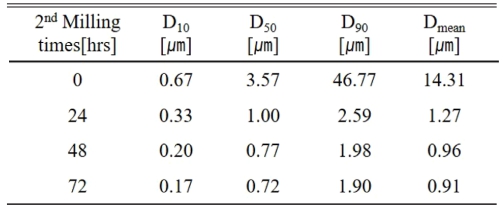

Table 1 shows the summary of particle sizes distributions of 0.95NKN-0.05BT composition powder as a function of secondary milling times. The four kinds of powders in 0.95NKN-0.05BT calcined powders exhibited different particle size distributions by varying secondary milling times from 0 to 72 hrs. As the milling time increases, the process energy and intensity of interaction between the particles, balls, and the surface of the particles increases during the milling process, thereby the probability of collision between the particles is increased and also surface area of particles is increased. Accordingly, the particles become smaller and the driving force of sintering increases as the surface energy increases due to the particle densification effect [24].

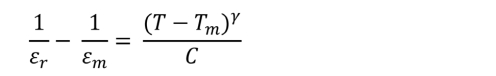

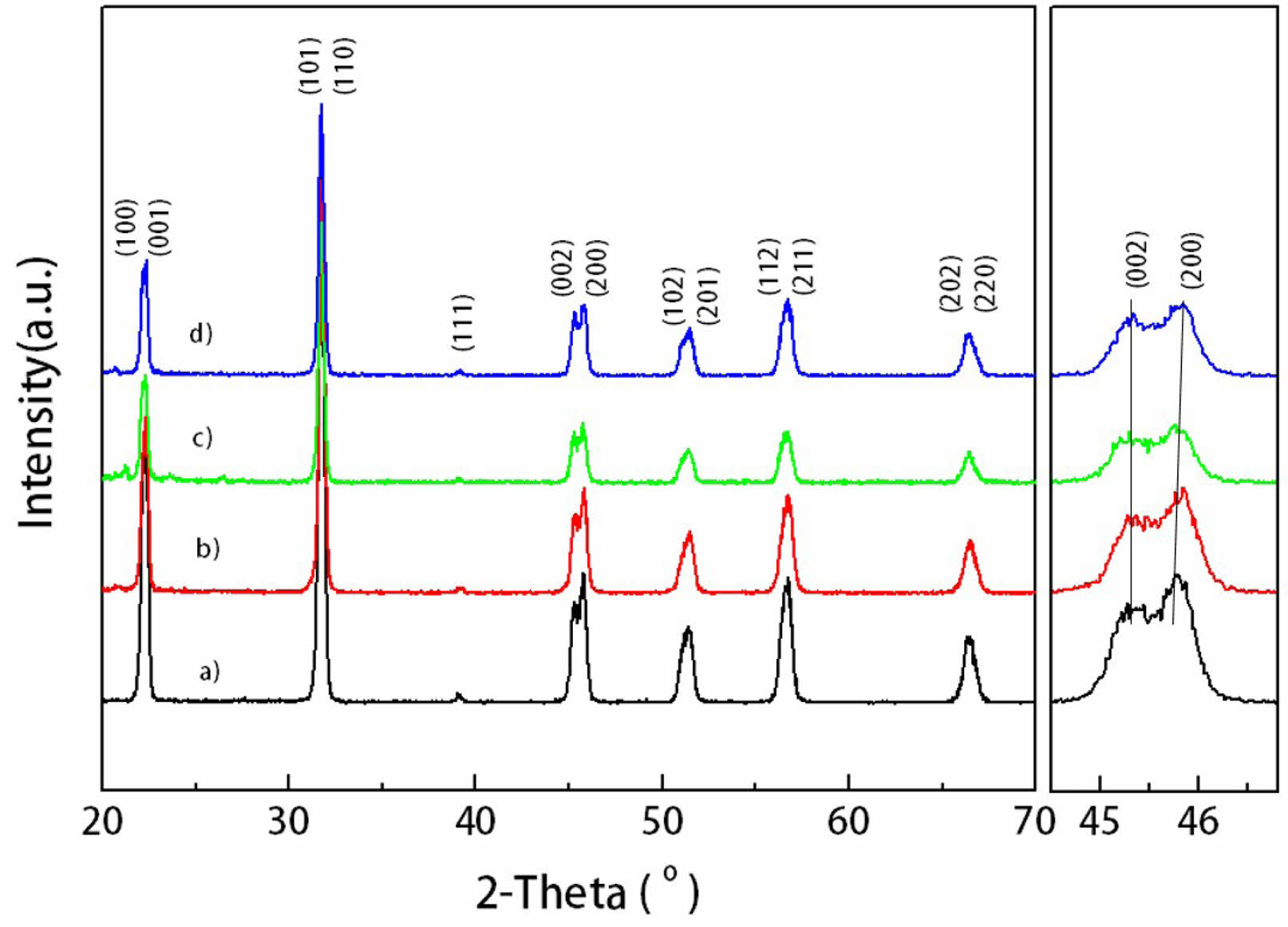

We can see that the particle sizes of the 0.95NKN-0.05BT powders were dramatically decreased from 14.31 μm to 0.91 μm by increasing secondary milling times from 0 to 72 hrs. In particular, the average particle sizes, Dmean, of the 0.95NKN-0.05BT powders with secondary milling above 48 hr had submicron size. The decrease of particle size in 0.95NKN-0.05BT ceramics brought about an increase of specific surface area, and lead a different distribution of grain structure in 0.95NKN-0.05BT ceramics. By earlier our paper [16], we reported the results about different distributions of grain structure, XRD result, dielectric and piezoelectric properties as a function of variation of particle size of powders in 0.95NKN-0.05BT ceramics. The distribution of particle size in 0.95NKN-0.05BT ceramics might affect the dielectric properties, especially the evolution of crystal structure and phase transition. Fig. 1 [16] shows XRD patterns of the 0.95NKN-0.05BT ceramics as particle sizes of powder decreased. All the 0.95NKN-0.05BT ceramics with different particle size of powder had a single phase with homogeneous phase without any secondary phases. From the right side of Fig. 1, we can see that the distance between (002) and (200) peaks was slightly increased as particle sizes of powder decreased. This phenomenon indicated that the crystal structure was changed by particle size of powders in 0.95NKN-0.05BT ceramics. Fig. 2 shows the lattice constant and the tetragonality of the 0.95NKN-0.05BT ceramics as particle sizes of powder decreased. It was found that the tetragonality(c/a) of 0.95NKN-0.05BT ceramics slightly increased as the particle size of powder decreased. It means that crystal structure of the 0.95NKN-0.05BT ceramics can be changed by not only the variation of composition but also that of particle size of powder. This should be attributed to the enlarged grain size with tetragonal phase owing to comparatively high solubility.

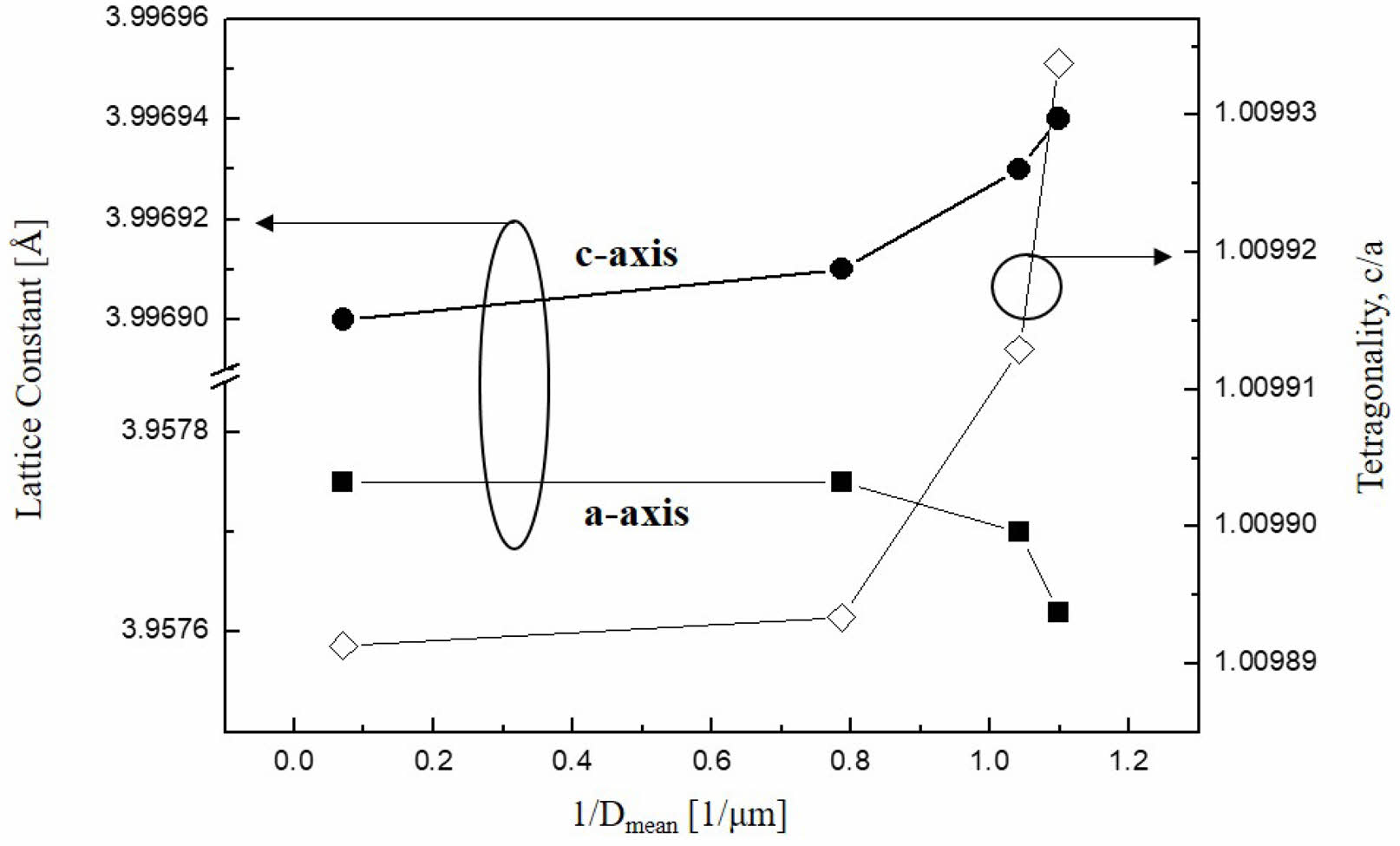

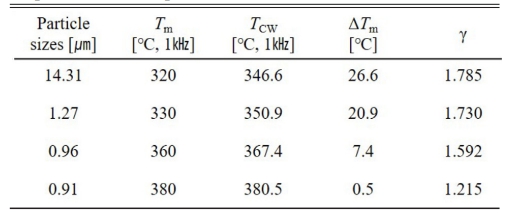

Fig. 3 shows the plot of reciprocal relative dielectric constant verse temperature of the 0.95NKN-0.05BT ceramics sintered with four different particle sizes of powder, which easily shows the diffused phase transition behavior of the peak of maximum dielectric constant. The Tm represent the temperature at which relative permitivity reaches the maximum and the TCW denotes the temperature from which relative permitivity starts to deviate from the Curie-Weiss law. The ΔTm, described by ΔTm = TCW - Tm), is used to define the degree of deviation from Curie-Weiss law. As you can see in the Fig. 3, Tm and TCW becomes increasingly closer as the particle size of the powder decreases, especially as it approaches submicron. We can see in this paper that ΔTm decreased when particle sizes of powder in 0.95NKN-0.05BT ceramics were decreased, which suggests the decreased dielectric diffuseness. This phenomenon indicated that 0.95NKN-0.05BT ceramics showed a transition from relaxor-like ferroelectric, ascribed by typical feature in NKN and BT ceramics, to a normal ferroelectric as the particle size of the powder approaches submicron. This phenomenon may be caused by various reasons. Guo et al reported that the relaxor property in NKN-based ceramics should attribute to cationic disorder induced by both A-site and B-site substitutions [25]. In the solid solution of 0.95NKN-0.05BT, Na, K and Ba ions occupy A-site and Nb and Ti ions occupy B-site of ABO3 perovskite structure. The ion disorder in NKN-BT perovskite might be one of the reason for the characteristics of relaxor-like ferroelectric as previously reported [26]. However, characteristics of relaxor-like ferroelectric in 0.95NKN-0.05BT ceramics were changed a normal ferroelectric when the particle size of the powder had submicron size. This can be explained by comparatively high solubility, as we mentioned previously, as particle size of powder approaches to submicron. This result shows that, in addition to the various reasons previously reported [25, 26], the crystal structure and phase transition property can be changed by changes in the particle size of powder.

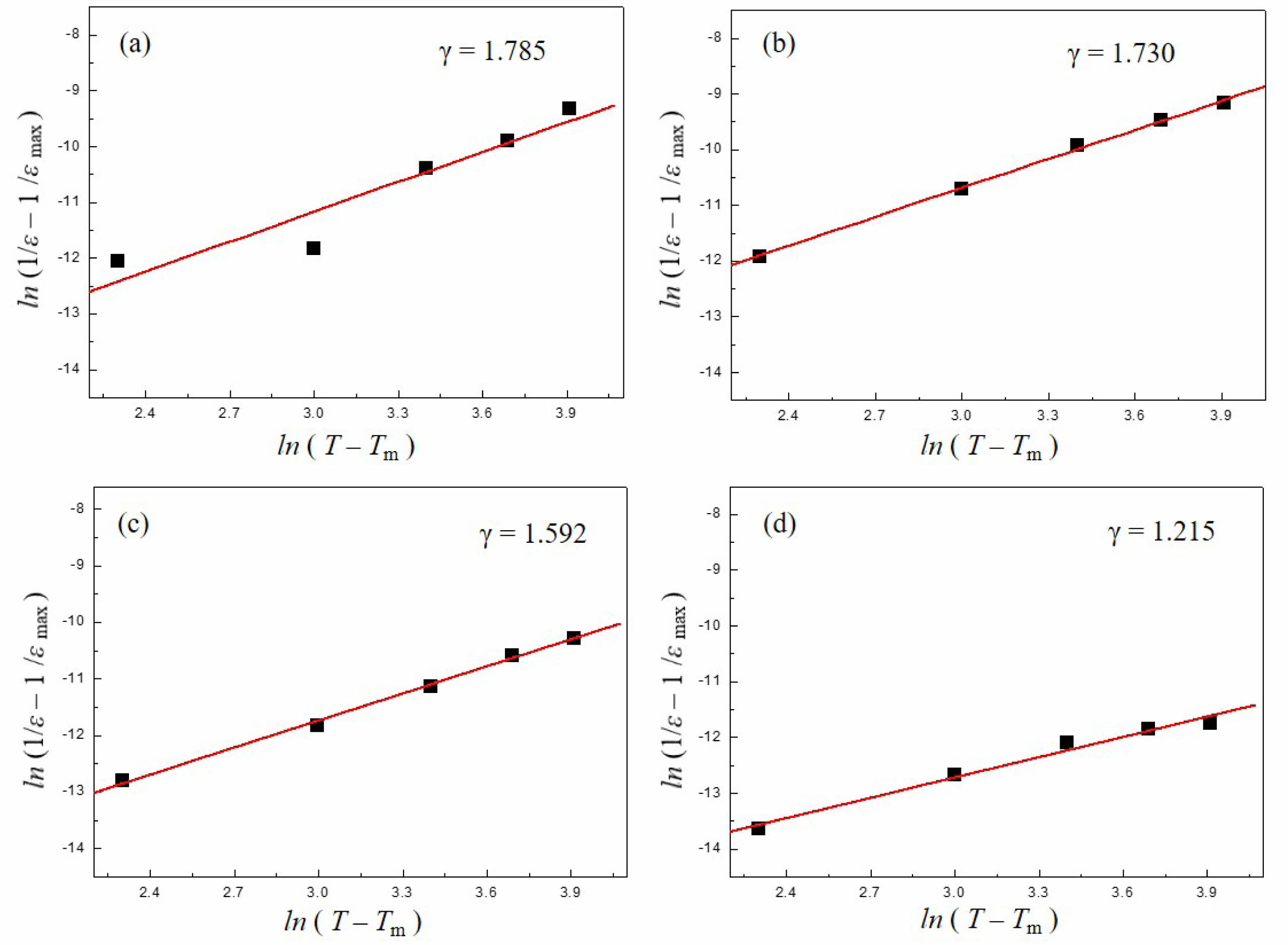

In order to study the characteristics of 0.95NKN-0.05BT ceramics as the particle size of the powder decreases, we investigated the diffusivity(γ) of 0.95NKN-0.05BT ceramics. In this paper, the diffuseness of the 0.95NKN-0.05BT ceramics by decreasing particle sizes can be determined from the modified Curie-Weiss law. The modified Curie-Weiss law is expressed as follow [27]:

Where εm is the maximum value of εr at the phase transition temperature Tm, γ is the degree of diffuseness, and C is Curie-Weiss constant. The parameter γ varies in the range from 1 for a normal ferroelectric, followed by Curie-Weiss behavior, to 2 for an ideal relaxor ferroelectrics. Zuo et al reported that the pure NKN ceramic has 1.03 of γ value [28]. Also BT ceramic is reported to have 1.25 of γ value [29]. As seen in Fig. 4, the 0.95NKN-0.05BT ceramics, sintered by using the particle sizes above 1 μm, showed high value γ of about 1.7, indicating that they have diffused phase transition property. However, the 0.95NKN-0.05BT ceramic sintered by using the particle sizes with submicron showed very low value γ of about 1.215. It can be interpreted that the solubility of 0.95NKN-0.05BT ceramics increase and crystal anisotropy increase as the particle size of the powder decreases to submicron. This result is consistent with XRD result, showing slightly increasing c/a tetragonality with decreasing particle sizes of powder.

Table 2 shows the variation of diffusivity of 0.95NKN-0.05BT ceramics as particle sizes of powder decreased. From the results on the basis of Curie-Weiss law and the parameters like TCW, Tm, ΔTm and γ, it can be interpreted that the degree of the diffuseness as the particle sizes of powder decreased, and a typical relaxor-like behavior significantly was suppressed when sintered with the submicron particle sizes of powder in 0.95NKN-0.05BT ceramics. Tang et al reported that another reason for high diffuseness might be the fine grain and large grain boundary volume [30]. Therefore, it can be concluded that the increase in grain size is responsibility for a transition from relaxor-like ferroelectric to a normal ferroelectric when sintered with submicron particle size of powder in 0.95NKN-0.05BT ceramics. Although the specific surface area was not measured in this paper, it was predicted that the specific surface area would increase as the powder size decreased [31]. Therefore, as the specific surface area increased, the driving force of sintering increased and the sintering characteristics improved, the temperature characteristics of ceramic became sharp, and the crystal structure also increased anisotropy. Based on these results, the diffusivity characteristics, which is the purpose of this paper, can be reduced.

|

Fig. 1 X-ray diffraction patterns [16] of the 0.95NKN-0.05BT ceramics as particle size of powders, Dmean, changed from a) 14.31 μm, b) 1.27 μm, c) 0.96 μm, and to d) 0.91 μm. |

|

Fig. 2 The dependence of particle sizes of powder on lattice constant and tetragonality in 0.95NKN-0.05BT. |

|

Fig. 3 (1/ε – 1/εmax) and linear fitting of paraelectric region for 0.95NKN-0.05BT ceramics as a function of particle sizes of powder, (a) 14.31 μm, (b) 1.27 μm, (c) 0.96 μm, and (d) 0.91 μm. |

|

Fig. 4 Plots of ln(1/ε – 1/εmax) vs ln(T – Tm) for 0.95NKN-0.05BT ceramics as a function of particle sizes of powder, (a) 14.31 μm, (b) 1.27 μm, (c) 0.96 μm, and (d) 0.91 μm. |

|

Table 1 Particle size distributions of 0.95NKN-0.05BT calcined powders with secondary milling times. |

|

Table 2 Various parameters of NKN-BT ceramics as a function of particle sizes of powder. |

We prepared the powders with four kinds of different particle sizes in order to investigate the variation of crystal structure and diffusivity in 0.95(Na0.5K0.5)NbO3-0.05BaTiO3 ceramics by conventional solid-state reaction. The crystal anisotropy (c/a) slightly increased from 1.00989 to 1.00993 and diffusivity (γ) significantly decreased from 1.785 to 1.215, when the particle sizes of powder were decreased from 14.31 μm to submicron in 0.95(Na0.5K0.5)NbO3-0.05BaTiO3 ceramics. Depending on the particle sizes of powder, crystal structure and diffusivity were changed from relaxor-like ferroelectric to a normal ferroelectric. This results revealed that crystal structure of the 0.95NKN-0.05BT ceramics can be changed by not only the variation of composition but also that of particle size of powder. Also it showed that the diffusivity can be decreased by particle size of powder in 0.95(Na0.5K0.5)NbO3-0.05BaTiO3 ceramics.

- 1. Z. He, J. Ma, and R. Zhang, Ceramics Int., 30 (2004) 1353.

-

- 2. C. Fujioka, R. Aoyama, H. Takeda, and S. Okamura, J. Eur. Ceram. Soc. 25 (2005) 2723.

-

- 3. W. Liu and X. Ren, Phys. Rev. Lett. 103 (2009) 257602.

-

- 4. A.B. Haugen, J.S. Forrester, D. Damjanovic, B. Li, K.J. Bowman, and J.L. Jones, J. Appl. Phys. 113 (2013) 014103.

-

- 5. I.H. Im and K.H. Chung, J. Nanosci. Nanotechnol. 14 (2014) 8920.

-

- 6. Y. Saito, H. Takao, T. Tani, T. Nonoyama, K. Takatori, T. Homma, T. Nagaya, and M. Nakamura, Nature 432 (2004) 84.

-

- 7. P. Agnihotri, R. Hawaldar, and R. Rai, Trans. Electr. Electron. Mater. 25[6] (2024) 745.

-

- 8. Z. Yang, Y. Chang, and L. Wei, Appl. Phys. Lett. 90 (2007) 042911.

-

- 9. S.H. Lee, S.P. Nam, S.C. Lee, S.G. Lee, and Y.H. Lee, J. Ceram. Pro. Res. 12 (2011) 195.

-

- 10. C.H. Wang, J. Ceram. Pro. Res. 14 (2013) 163.

-

- 11. X. Pang, J. Qiu, K. Zhu, and J. Du, Ceramics Int. 38 (2012) 2521.

-

- 12. H. Du, Z. Li, F. Tang, S. Qu, Z. Pei, and W. Zhou, Mater. Sci. Eng. B 131 (2006) 83.

-

- 13. R.Z. Zuo, X.S. Fang, and C. Ye, Appl. Phys. Lett. 90 (2007) 092904.

-

- 14. J.H. Yeo, S.G. Lee, T.H. Lee, and H.R. Jung, J. Ceram. Pro. Res. 14 (2013) 648.

-

- 15. I.H. Im, S.H. Lee, H.K. Kim, D.H. Lee, S.H. Kim, Y.S. Yun, Y.K. Choi, and S.P. Nam, J. Ceram. Pro. Res. 15 (2014) 26.

-

- 16. S.G. Bae, H.Y. Shin, E.Y. Sohn, and I.H. Im, Trans. Electr. Electron. Mater. 14[2] (2013) 78.

-

- 17. S.G. Bae, H.Y. Shin, K.H. Chung, J.H. Yoo and I.H. Im, Trans. Electr. Electron. Mater. 16[4] (2015) 179.

-

- 18. Dunmin Lin, K.W. Kwon, and H.W.L. Chan, Appl. Phys. Lett. 91 (2007) 143513.

- 19. W. Zuo, R. Zuo, and W. Zhao, Ceramics Int. 39 (2013) 725.

-

- 20. J.S. Park, J.K. Lee, and K.S. Hong, J. Appl. Phys. 101 (2007) 114101.

-

- 21. H.J. Trodahl, N. Klein, D. Damjanvic, N. Setter, B. Ludbrook, D. Rytz, and M. Kuball, Appl. Phys. Lett. 93 (2008) 262901.

-

- 22. L.E. Cross, Ferroelectrics 76 (1987) 241.

-

- 23. K. Uchino and S. Nomura, Integr. Ferroelectric 44 (1982) 55.

-

- 24. L.B. Kong, W. Zhu, and O.K. Tan, Mater. Lett. 42 (2000) 232.

-

- 25. Y. Guo, K. Kakimoto, and H. Ohsato, J. Phys. Chem. Solids 65 (2004) 1831.

-

- 26. H.Y. Park, C.W. Ahn, H.C. Song, J.H. Lee, S. Nham, K. Uchino, H.G. Lee, and H.J. Lee, Appl. Phys. Lett. 89 (2006) 062906.

-

- 27. D. Viehland, S.J. Jang, L.E. Cross, and M. Wuttig, Phys. Rev. B 46 (1992) 8003.

-

- 28. J. Fu, R. Zuo, X. Wang, and L. Li, Journal of Alloy and Compound. 486 (2009) 790.

-

- 29. M. Arshad, D. Huiling, J.M. Sufyan, A. Maqsood, I. Ashraf, S. Hussain, W. Ma, and H. Ran, Ceramics Int. 46 (2020) 2238.

-

- 30. X.G. Tang, J. Wang, X.X. Wang, and W. Chen, Solid State Commun. 131 (2004) 163.

-

- 31. M.L. Panchula and J.Y. Ying, J. Am. Ceram. Soc. 86[7] (2003) 1121.

-

This Article

This Article

-

2025; 26(1): 157-161

Published on Feb 28, 2025

- 10.36410/jcpr.2025.26.1.157

- Received on Aug 21, 2024

- Revised on Jan 8, 2025

- Accepted on Jan 10, 2025

Services

Services

Shared

Correspondence to

Correspondence to

- Seung-Hwan Lee

-

Dept. of Battery Convergence Engineering, Kangwon National University, Gangwon State, Korea

Tel : +82-33-250-6265 - E-mail: shlee@kangwon.ac.kr

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.