- Bio-concrete for the modern era: Paving the way for future construction

Abhishek Saxena, Amith Abraham and Byoung-In Sang*

Department of Chemical Engineering, Hanyang University, 222 Wangsimni-ro, Seongdong-gu, Seoul 04763, Republic of Korea

This article is an open access article distributed under the terms of the Creative Commons Attribution Non-Commercial License (http://creativecommons.org/licenses/by-nc/4.0) which permits unrestricted non-commercial use, distribution, and reproduction in any medium, provided the original work is properly cited.

Cement, a key component of concrete, significantly contributes to global carbon dioxide (CO2) emissions, ranking as the third-largest anthropogenic CO2 producer globally after transport and energy. It faces a reduced lifespan due to microbial attacks, leading to corrosion and structural damage from small fissures. Sealants and other conventional techniques are expensive, time-consuming, and non-sustainable. The negative environmental and health effects of cement-concrete manufacturing have led to the development of "Bio concrete," a self-healing alternative for eco-friendly and cost-effective construction for future generations. Bio-concrete utilizes microorganisms to make calcium carbonate (CaCO3), fostering crack healing and enhancing concrete qualities. This review explores recent advancements in bio-concrete technologies, the microorganisms and additives used in its production, and a cost-benefit analysis of its application. It also examines performance outcomes through algorithmic models, and case studies, aimed at fostering sustainable infrastructure using bio-concrete.

Keywords: Bio-concrete, Biomineralization, Microbial additives, Self-healing concrete, Sustainable infrastructure.

Since the 19th century, concrete, recognized for its affordability, durability, and versatility, has remained integral to construction [1]. The US Geological Survey reports a significant increase in cement production, from 4.1 billion metric tonnes (BMT) in 2019 to 4.4 BMT in 2021. This rise has contributed significantly to global CO2 emissions, which reached 1.6 billion metric tons and account for approximately 8% of total global greenhouse gas (GHG) emissions [2]. The International Energy Agency (IEA) predicts a 23% increase in global concrete production by 2050 due to urbanization and infrastructure development, with China's early 21st century output surpassing the US total output, reaching over 25.8 BT [3]. The continued demand for concrete is highlighted by projections that over the next 40 years, construction equal to the size of New York City will be built every month [4].

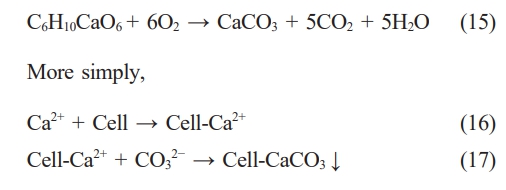

Despite its widespread use, concrete is highly susceptible to cracking, which allows water infiltration and accelerates steel reinforcement corrosion, thereby reducing the longevity of structures [5]. While concrete possesses excellent compressive strength, it has poor resistance to tensile forces, which can lead to the propagation of cracks, compromising the long-term integrity of infrastructure [6]. The repair of cracks is costly, with estimates reaching €130/m3, double the cost of producing concrete itself [7]. Various types of cracks, such as drying shrinkage, plastic shrinkage, and settlement cracks, can occur [8]. Encouraging concrete to self-heal offers a promising approach to improving durability, reducing maintenance costs, and lowering its carbon footprint [9]. Bio-concrete, also known as self-healing concrete, represents an innovative green construction solution aimed at addressing these issues. By incorporating specific microorganisms into the concrete mix, bio-concrete facilitates the natural repair of cracks through the production of carbonate/calcite/limestone (CaCO3), which fills in the gaps and restores the structure's integrity. This process, which mimics the way bones heal, occurs when Bacillus bacteria consume calcium lactate (C₆H₁₀CaO₆) and produce limestone [10-11]. The oxygen-consuming reaction also enhances the durability of steel-reinforced concrete, potentially reducing the need for costly maintenance [10, 12]. Research in this area began over a decade ago, with studies at Delft University focusing on bacteria that thrive in highly alkaline environments, such as alkali lakes and soda lakes. These bacteria were incorporated into concrete blocks, becoming active when cracks formed, and water penetrated the structure. The ideal nutrient source for these bacteria was found to be C6H10CaO6, which did not affect the concrete's setting time when dissolved during mixing [13]. Scientists of Far Eastern Federal University (FEFU) demonstrated that these bacteria could remain dormant for up to 200 years, becoming active when exposed to water and nutrients [14]. Laboratory tests have confirmed the effectiveness of self-healing agents encapsulated in clay pellets, which are activated by crack formation, with crack repair occurring within seven days under optimal conditions [13]. The present review paper explores the potential of bacteria, fungi, and microalgae in bio-concrete production and self-healing mechanisms in concrete. It evaluates advancements, challenges, and constraints in these groundbreaking methodologies, aiming to contribute to discussions on environment-friendly construction practices and align with global climate objectives, as outlined in the Paris Agreement [15].

Techniques for self-healing concrete

Autogenous (Natural) self-healing concrete

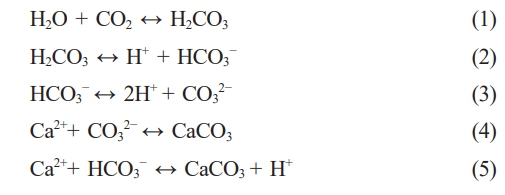

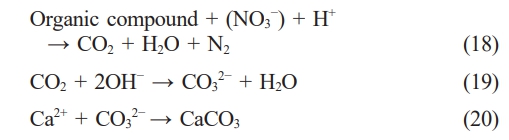

Autogenous self-healing concrete is the concrete's inherent ability to repair microcracks without external intervention. This process occurs through mechanisms like hydration of cement particles, precipitation of CaCO3 or calcium hydroxide (Ca (OH)2), secondary hydration products, water impurities blocking cracks, and expansion of calcium-silicate hydrate (CSH) gel. This helps maintain concrete's structural integrity and durability, extending its service life and reducing maintenance and repair needs (Fig. 1) [16]. The French Academy of Sciences first observed the autogenous healing process of concrete cracks in structures retained in water in 1836. The self-healing process involves the crystallization of CaCO3 in a cracked fracture surface, which is influenced by the amount of water added to the concrete mix. Anhydrate cement particles react with penetrated moisture, causing the crack to reclose [17]. The mechanism for the formation of CaCO3 and Ca (OH)2 for crack repair is shown below [18]:

The natural self-healing process in concrete, which fills cracks with CaCO3 crystals at pH levels above 8, is limited to smaller widths (0.1-0.2 mm), and methods like limiting crack widths, incorporating fiber reinforcements, and using superabsorbent polymers can enhance this process by promoting hydration and crystallization [19-20]. Researchers have explored using materials like fly ash and blast furnace slag for autogenous healing, but these may limit hydration. Crystalline additives and expansive agents like calcium sulphoaluminate can induce healing but may cause crack formation [21]. Factors such as concrete age, composition, aggregate type, hydration, and age play a significant role in its effectiveness. The clinker content, silicate additions, and consumption of Ca (OH)2 also influence the process. Water presence, temperature, and alkalinity also affect healing. Crack geometry and size also play a role, with narrower cracks and controlled expansion enhancing healing efficiency. Early crack age also influences healing effectiveness [18]. Researchers are exploring active methods to improve crack repair in concrete, addressing the limitations of natural self-healing. Bio-concrete and autogenous self-healing technologies are being developed to achieve sustainable, long-lasting infrastructure, addressing the insufficient capabilities of passive techniques.

Autonomous self-healing concrete

Autonomous self-healing concrete is a new technique that uses chemical or biological agents to repair fractures. These agents are released upon damage and react with stimuli like air, moisture, or heat. Compared to autogenous healing, autonomous healing can mend larger fractures, with bio-hydrogels and microencapsulated bacteria-based concrete repairing cracks up to 0.97 mm wide. The effectiveness of self-healing depends on factors like the agent's efficacy, encapsulation method, and triggering mechanism [20, 22].

Chemical method

Self-healing concrete uses chemical methods to release healing agents within the concrete matrix when cracks form. Microencapsulation is a prominent method, delivering agents directly to cracks for in-place repair. Designing encapsulated-based self-healing systems involves capsule creation, integration, mechanical characterization, triggering, and healing assessment, addressing various elements for effective repair [23].

Microencapsulation

Microencapsulated self-healing involves embedding a healing agent within a shell material and incorporating it into concrete. When cracks form, stress ruptures the microcapsules, releasing the agent, which reacts with the concrete's curing agent. This process can be triggered by external stimuli like mechanical stress, pH changes, temperature fluctuations, ions, and light. Chemical triggering involves breaking the shell material or controlling the release of healing agents [24]. For example, microcapsules made of hexadecane/poly (methyl methacrylate) have an ion-sensitive trigger activated by complex reactions between chloride ion and lead sulfate within the wall material [25], whereas other studies showed an intelligent release of self-healing microcapsules as pH decreases [26]. The physical triggering mode involves mechanical mechanisms, with microcapsules synthesized using phenol-formaldehyde resin as the shell material and dicyclopentadiene as the healing agent. The resin's mechanical tunability allows for easy dispersal and rupture during crack propagation [27]. Studies using ultrasound [28], microwave radiation [29], and electromagnetism [30] have successfully triggered microcapsule self-healing systems, making significant progress in addressing the challenge of microcapsule rupture in gelling materials. However, microencapsulation has limitations, such as low embedding rates and high energy consumption, while physical methods like spray drying and melting offer quick, easy processes, polycondensation requires specific material properties [31]. On the other hand, chemical methods offer high encapsulation rates but require specific object requirements. In situ polymerization ensures uniform shape but may incur high costs. Physicochemical methods like ionic gelation are efficient but can be costly and may cause porosity in some products. Thus, making it crucial to choose the most suitable approach based on desired outcomes and application constraints [31].

Biological method

The use of microorganisms in cementitious materials can enhance infrastructure resilience and sustainability. Microorganisms, such as bacteria, fungi, and microalgae, facilitate self-healing processes, reducing structural damage and minimizing the need for frequent repairs [32]. This reduces life cycle costs and extends service life, while also promoting eco-friendly practices and reducing the carbon footprint associated with conventional repair methods [33-34]. The biological self-healing concrete can be achieved by bacteria (most commonly), fungi, and microalgae.

Bacteria-mediated self-healing concrete

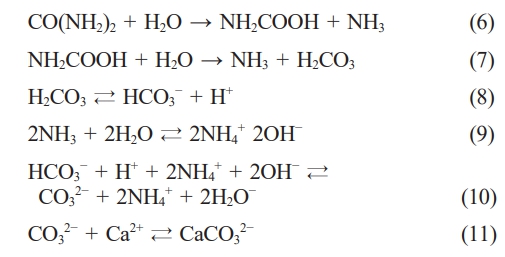

Viable bacteria can effectively seal cracks in concrete structures by converting precursor compounds into filler materials like CaCO3-based mineral precipitates. This process is essential for successful self-healing without affecting other properties. Alkali-resistant bacteria, capable of forming durable spores that remain viable for over 50 years even in dry conditions, show promise for concrete matrix incorporation [35-36]. Microbially induced calcium carbonate precipitation (MICP), or biocalcification, is a sustainable and eco-friendly method for sealing cracks in infrastructure materials was initially presented by Gollapudi and co-workers [37-38]. It uses natural bacterial activities to improve material qualities and solve engineering problems. MICP strengthens building materials, stabilizes soil [39] and bioremediates groundwater [40]. It can be caused by metabolic pathways like ureolysis [41], photosynthesis, methane oxidation, ammonification, denitrification, sulfate reduction [42], and iron reduction, respectively [43]. Ureolysis, also known as hydrolysis of urea [CO(NH2)2], is a highly effective method for producing calcite or CaCO3 quickly, making it ideal for engineering applications. It relies on a cementation medium, nutrients, and a suitable bacterium such as Bacillus sp. [44-49] to facilitate the MICP process [50]. Strains such as B. alkalinitrilicus [51], B. megaterium [52], B. mucilaginous [53], B. halodurans [54], B. subtilis [55], B. licheniformis [11], B. cohnii [56], B. sphaericus [57], B. pseudofirmus [58], B. cereus [59], and B. pasteurii [36] have been successfully employed in concrete at bacterial dosages ranging from 103 to 109 cfu/ml. Among them, B. cohnii has high mineralization activity, and pure calcite predominates in all the precipitations [56]. The urease enzyme breaks down urea, producing ammonia (NH3) and CO2, which increases the pH in calcium-rich environments, leading to calcite precipitation. Further hydrolysis results in the production of ammonium ions (NH4+) and carbonic acid (CO32-) [60]. The reaction mechanism involves the hydrolysis of 1 mol of CO(NH2)2 to generate 1 mol of NH3 and 1 mol of carbamic acid (NH2COOH). Microbial CO(NH2)2 enzymatic activity in the cell facilitates this process (Eq. 6). As NH2COOH and NH3 hydrolyze, they produce an additional 1 mol of NH3 and carbonic acid (H2CO3) (Eq. 7). After normalizing in water, these chemicals produce bicarbonate (HCO3–), two mol of NH4+, and hydroxide ions (OH–), which is reversible (Eq. 8 and 9). When OH– ions are released, the HCO3– equilibrium can be changed to produce carbonate ions (CO32–), raising the pH (Eq. 10). The local microbial community shows a rise in pH, which permeates the solution. Strongly negative bacteria's cell walls attract cations (Ca2+), which combine with CO32– ions to generate CaCO3. The increase in carbonate concentration due to supersaturation in cell walls, accompanied by heterogeneous nucleation and soluble Ca2+ ions, results in CaCO3 precipitation, as per Eq. (11) [43, 61-62].

Interestingly, biomineralizing involves unique chemistry, where microorganisms precipitate calcite minerals through ammonification, reducing nitrate, or hydrolyzing CO(NH2)2. Bacillus subtilis JC3 causes CO(NH2)2 hydrolysis or ammonification of amino acids, making it compatible with concrete matrix environments. This bio-CaCO3 precipitate is a promising candidate for crack repair. Biomineralizing involves complex biochemical reactions through ammonification, where amino acids liberated by microbes undergo deamination to produce NH3 [63]. This "ammonification" process, which is mediated by Bacillus subtilis JC3, usually takes place in an aerobic environment (oxidative deamination) and releases NH3 or NH4+ ions when dissolved in water [63] as shown in the Eq. below:

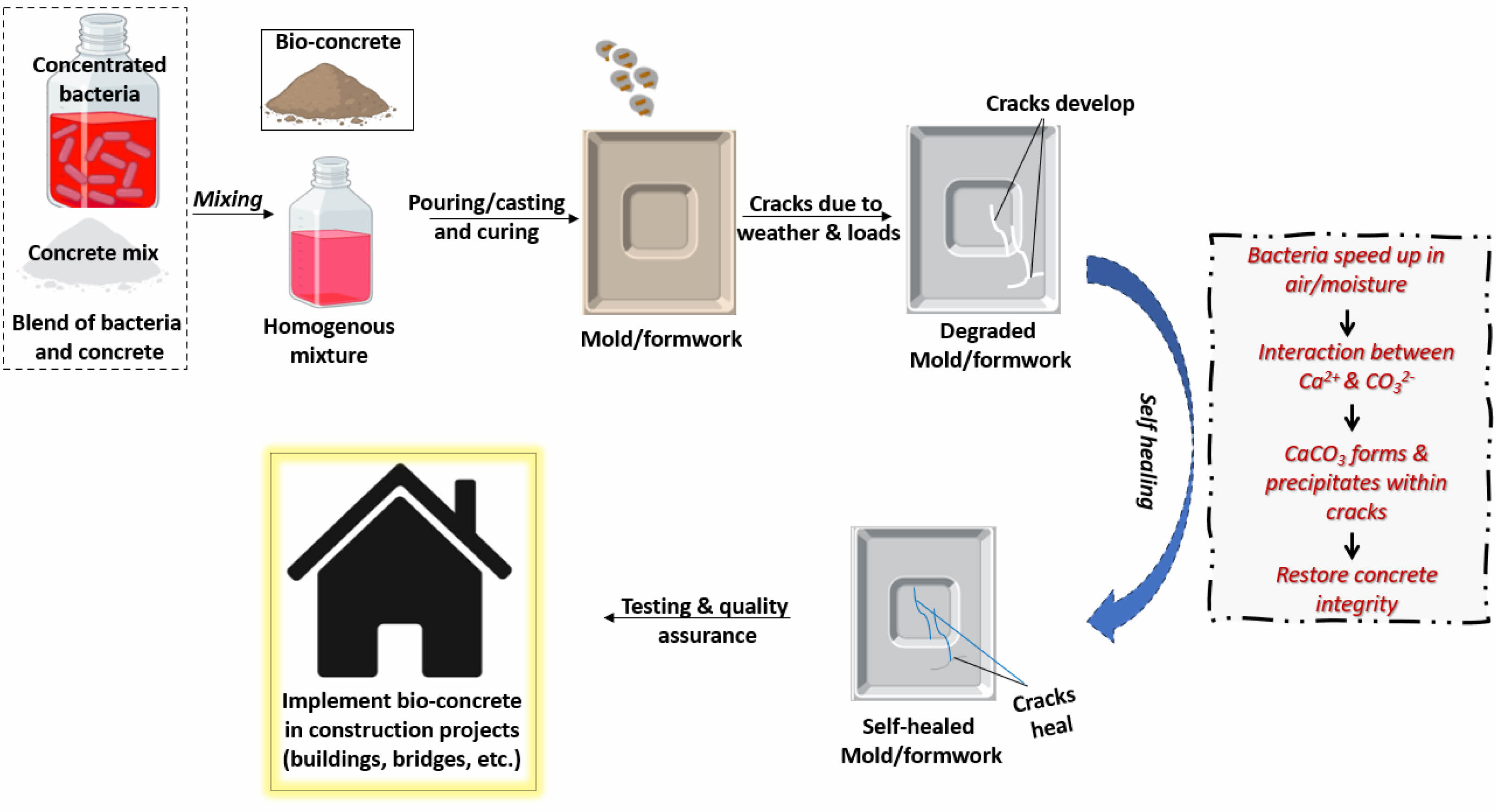

In a calcium-rich environment, the bacteria's cell walls due to their negative charge attract Ca²⁺ ions, facilitating CaCO3 formation on the cell surface, which strengthens the concrete by filling cracks and reducing permeability [49, 60, 64]. This microbial process, however, produces NH₃, which can increase the risk of corrosion in reinforcement structures [49]. To address this, Jonkers and colleagues developed a self-healing system that uses non-ureolytic bacteria and an organic calcium supply without releasing NH4+ ions. In an alkaline environment, organic substances break down into CO2 and H2O, transforming CO2 into CO32− ions and forming CaCO3 crystals in the presence of Ca2+ ions[33]as shown in the Eq. below:

The denitrification pathway is a crucial method but is often underutilized [64]. Denitrifying bacteria, such as Bacillus, Alcaligenes, Diaphorobacter, Pseudomonas, Spirillum, Paracoccus, Thiobacillus, and Achromobacter, are added to nutrient-rich media, nitrate (NO3−), calcium, and carbon sources [65]. Alkalinity converts CO2 into CO32− ions, producing N2 and CO2 gas, as well as CaCO3 precipitation in the presence of Ca2+ ions. This unique denitrification mechanism partially desaturates porous media, altering its hydromechanical behavior and elevating denitrification-mediated MICP, also known as microbially induced desaturation and precipitation (MIDP) [64, 66-67]. Most denitrifying bacteria initiate the denitrification process in the absence of oxygen or when it is scarce [68]. The denitrification reaction is as follows:

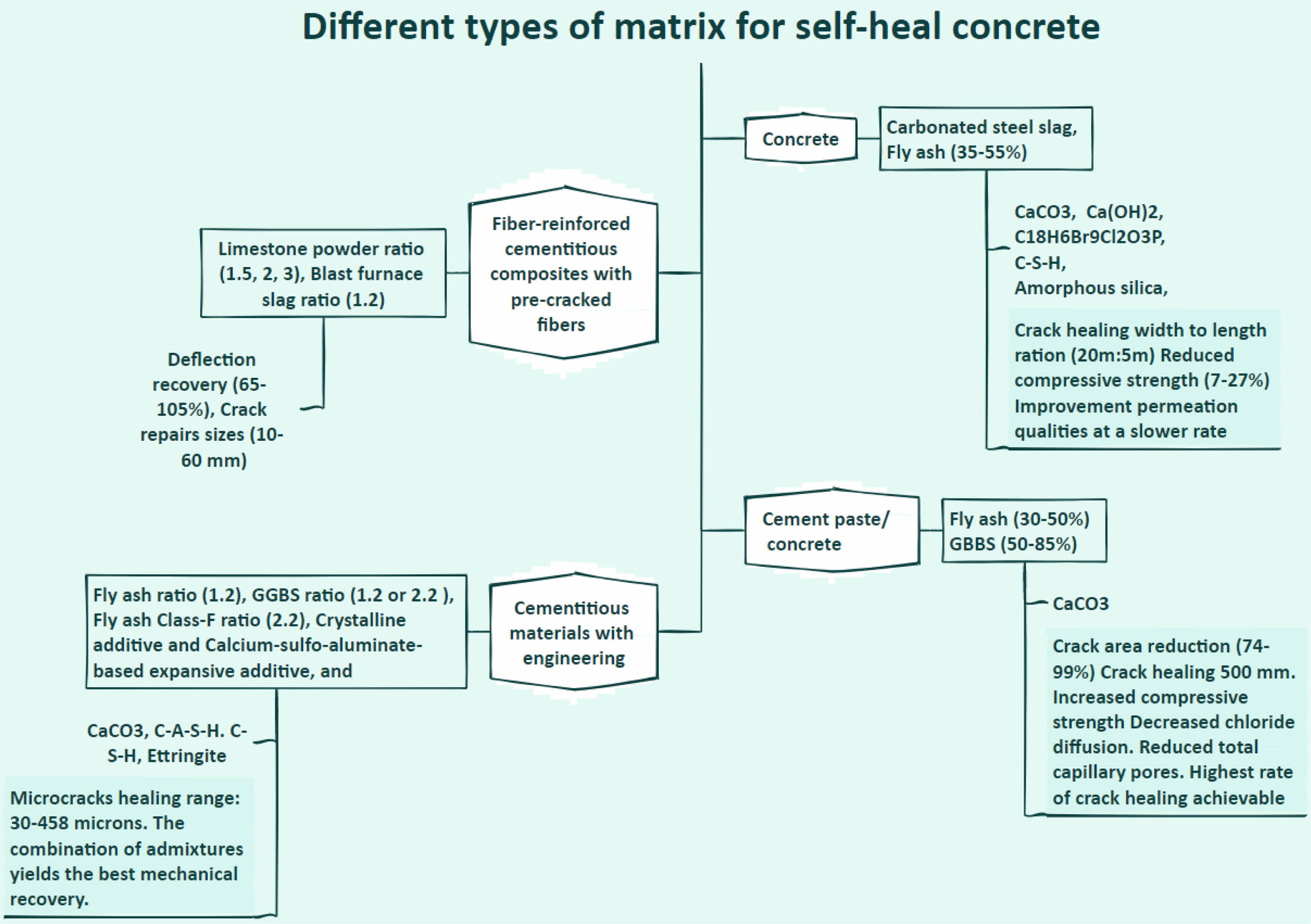

When a calcium supply is present, several mineralization pathways favor the precipitation of CaCO3, which is how bacteria-infused materials seal fissures or cracks (Table 1).

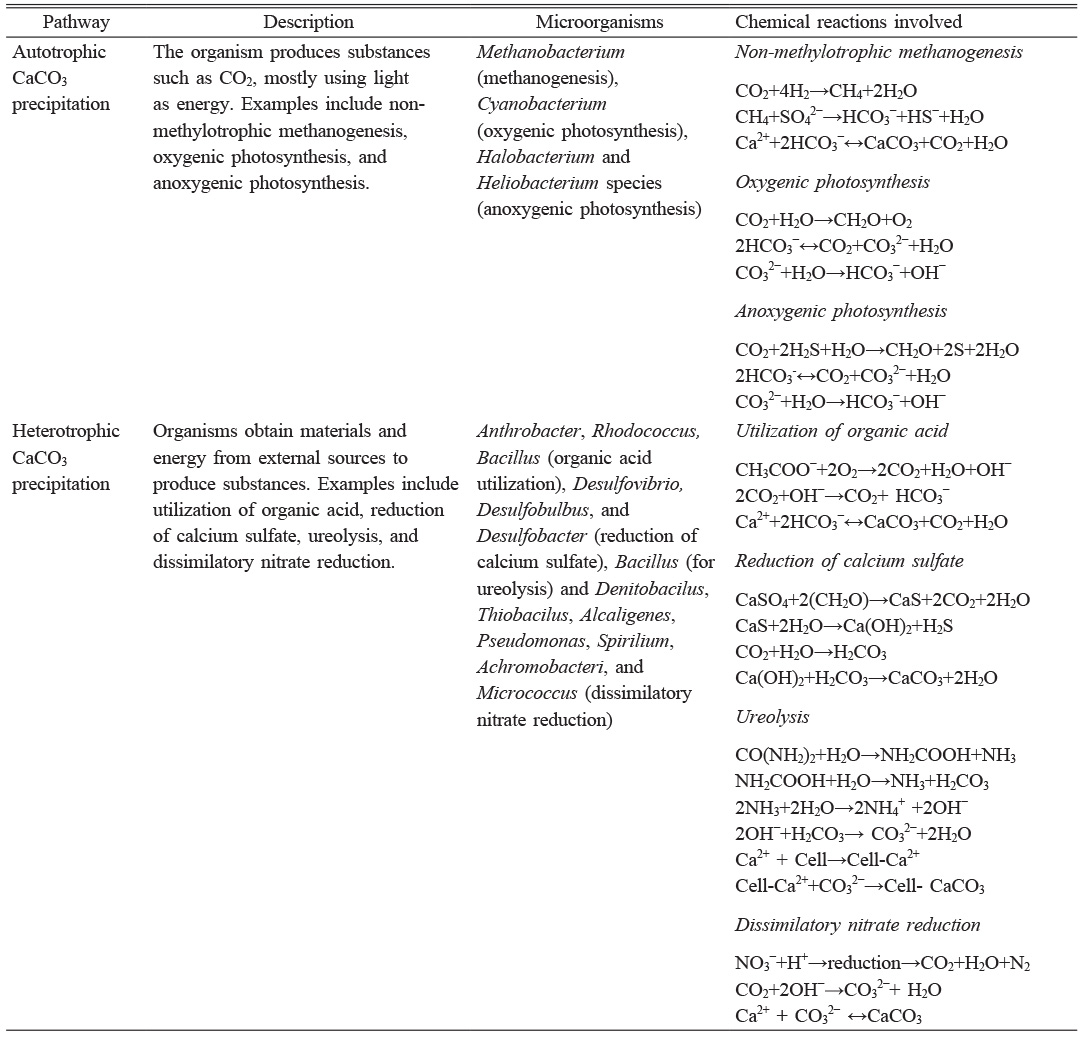

A study using artificial neural network (ANN) and adaptive neuro-fuzzy interface system (ANFIS) models was conducted to evaluate the mechanical properties of self-healing bio-concrete. The study found that the ANN model outperformed the ANFIS model, producing more accurate results with a regression value of 0.9865 and a mean square error of 3.07, indicating improved compressive strength and self-healing properties of bio-concrete. Both models belong to the field of civil engineering, with ANN used to predict compressive strength and ANFIS validating the findings. This suggests that bacterial species can be used in concrete designs for infrastructure development [69]. Durga and colleagues use Ultrasonic pulse velocity values to study bio-agents for crack sealing. They found that calcite precipitation enhances compressive strength, split tensile strength from EPS layer formation, and increased flexural strength due to urease enzyme action. CaCO3 formation reduces water absorption and water passage resistance, making this eco-friendly concrete effective [70]. The introduction of alkaliphilic spore-forming B. cohnii microbes into bio-concrete at different concentrations and nutrient levels has been found to seal nanopores, reduce total voids by 43-48% within 28 days, and increase compressive strength by 40-60% compared to reference concrete. The incorporation of B. cohnii does not negatively affect main cement hydration, indicating its potential for crack seal and successful healing [71]. Another study aims to improve bio-concrete production using MICP, a CO2 neutral alternative to conventional concrete. Key advancements include urease-active calcium carbonate powder, aggregate packing density optimization, and automated injection methods. These results in high-quality cementation, unprecedented compressive strength (52.5 MPa), and depth (140 mm), potentially replacing traditional concrete in prefabricated load-bearing building components [72]. Surprisingly, inclusion of B. subtilis in concrete results in higher compressive (40%) and split tensile strengths, with values 15% greater than those of control concrete, and 30% higher flexural strength. This enhanced strength allows the concrete to withstand larger strains without collapsing post-cracking, indicating significant improvement in resilience against earthquakes [73]. Significantly, a study used waste-activated sludge to create non-axenic sulfate-reducing bacterial (SRB) granules for bioconcrete, resulting in a compressive strength of 50 MPa and a 13% average volume of permeable voids. The bioconcrete also showed reduced water permeability (up to 70%) and decreased mass loss in sulfuric acid for specimens with surface calcite deposition after 120 days [74]. Vanjinathan et al. evaluated bio-concrete made from four microorganisms: B. subtilis, Brevibacillus sp., B. megaterium, and Microvirga sp., and found that B. subtilis bio-concrete had the highest compressive strength at 50.37 N/mm2, advancing bio-concrete design [75]. Mistri and co-investigators conducted the strengthening of recycled coarse aggregates (RCA) through cement slurry and bio-cement treatment. They developed a method for forming a single aggregate and assessed their micromechanical properties using nanoindentation. The results suggest that biocement treatment enables RCA to substitute natural aggregates without compromising performance [76]. Abo Sabah et al. optimized bio-concrete properties and durability by varying C₆H₁₀CaO₆ content and curing duration. The optimal conditions were found at 2.18 g/L C₆H₁₀CaO₆ content after 23.4 days, enhancing compressive, splitting tensile, and flexural strengths and reducing water absorption. The actual and predicted values closely matched, indicating potential for structure healing [77]. A study on developing bio-concrete for autonomous crack healing in marine environments found that C₆H₁₀CaO₆ was the optimal nutrient precursor, increasing overall healing by 16% and improving the aragonite/brucite ratio. The bio-concrete, incorporating Halobacillus halophilus bacteria, C₆H₁₀CaO₆, and expanded perlite aggregate, improved crack healing by 17% under submerged and tidal marine conditions [78]. A new microbial-based self-healing technology has been developed to seal micro-cracks in concrete by inducing Egyptian bacterial strains, B. subtilis and B. megaterium, at concentrations of 0.5% and 1% of cement weight. The technology has shown a 21.4% increase in compressive strength after 28 days and a 12.4% decrease in water absorption after 180 days. The bioconcrete exhibits ductile behavior and less deformation, potentially reducing inspection and maintenance costs [79]. A new bio-concrete design using wastewater-cultivated granular sludge shows significant corrosion resistance in sewer environments, thanks to sulfate-reducing bacteria that increase concrete surface pH and reverse corrosion products [80]. Ahmad and co-investigators conducted research to address compatibility issues between traditional binders like Portland cement (OPC) and bio-aggregates. They characterized OPC, geopolymer (GP), and magnesium phosphate cement (MPC) binders, identified optimized formulations, and evaluated pretreatments like hydrophobic treatment. MPC binders showed natural compatibility with bio-aggregates due to their low pH, eliminating the need for pretreatment. MPC-based bio-concrete demonstrated superior performance compared to OPC and GP variants [81]. Due to extensive research in bacteria-mediated self-healing concrete, the most significant studies are highlighted in Table 2.

Fungi-mediated self-healing concrete

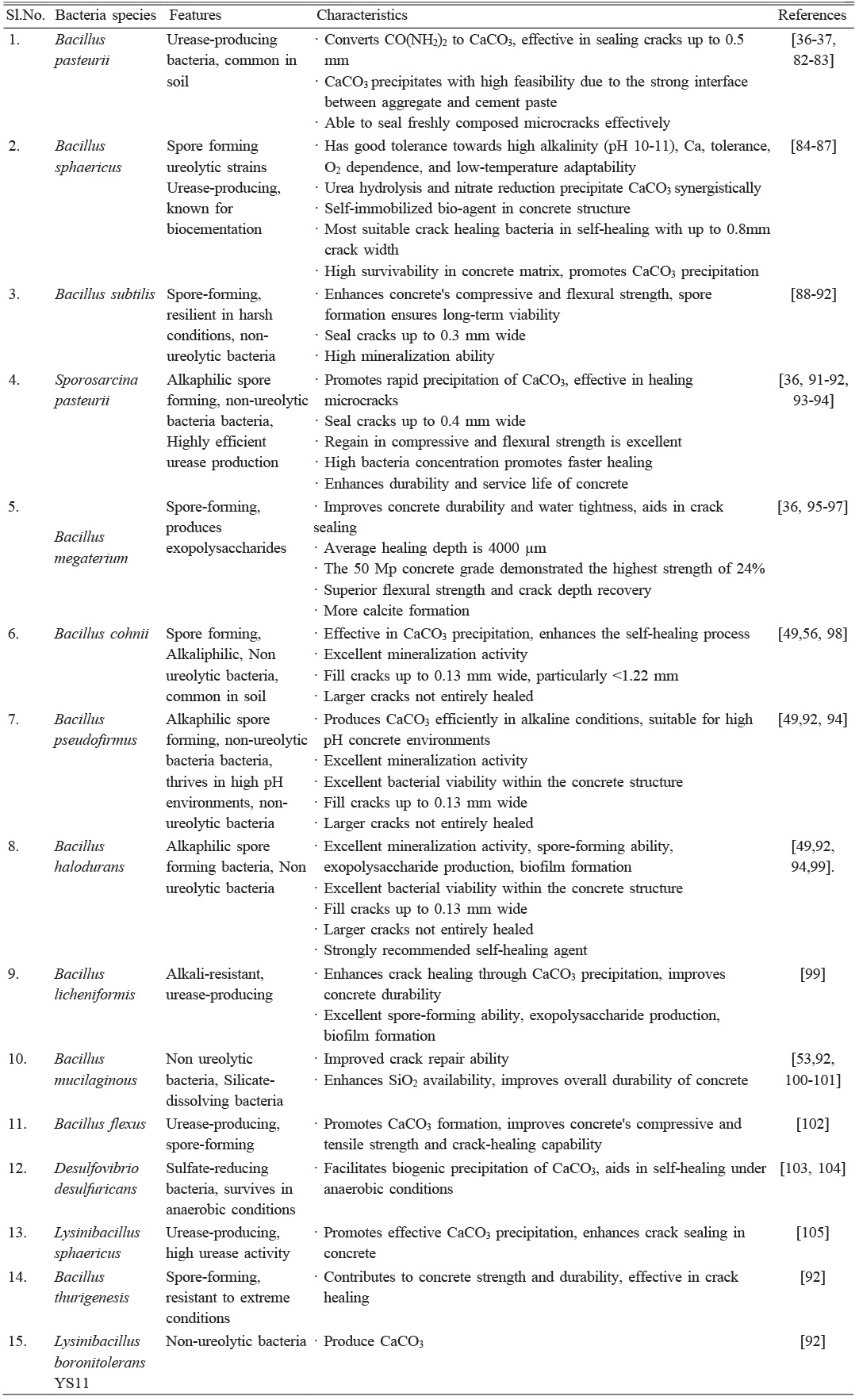

Fungi, a eukaryotic microorganism with a unique cell wall composed of mucopeptide and chitin (made of repeating units of N-acetylglucosamine), offers a promising approach in bio-concrete. Unlike bacteria, fungi reproduce via spores and thrive in various environments, including soil, aquatic habitats, and even oxygen-depleted areas. Their hyphal networks serve as nucleation sites for CaCO3 precipitation, facilitating mineralization through both biomineralization and organomineralization processes [32, 106, 107]. Biomineralization involves mechanisms such as calcium homeostasis, regulated by (i) active and passive transport of Ca2+ in/out of the cell (Ca2+pumped), (ii) sequestration of cytoplasmic Ca2+ into specific organelles (Ca2+sequestration in organelles), and (iii) binding to calmodulins (CaM) and calcineurins (Ca2+ binding proteins), which influence signaling pathways. Fungi increases carbonate alkalinity, creating conditions for CaCO3 precipitation. Organomineralization, on the other hand, utilizes chitin in fungal cell walls, offering a substrate for calcite nucleation and growth, allowing both active and inactive fungi to precipitate CaCO3 [107]. Several fungi have been studied for their role in CaCO3 biomineralization, including Aspergillus niger, Serpula himantioides, [106, 108], Cephalotrichum, Morchella sp., [32], Piloderma fallax [109], Beauveria caledonica [110], Neurospora crassa [111-112], Pseudophialophora magnispora [32], Myrothecium gramineum [32] and Colletotrichum [113] (Table 3). These fungi must withstand concrete's high alkalinity, thrive in nutrient-poor environments, non-pathogenic, sporulating, able to grow under crack-forming conditions and pose no health risks to researchers [107]. The selection of fungi for self-healing concrete is based on these characteristics, ensuring their suitability for lab and construction applications [114, 115].

Although research on fungi-mediated self-healing is limited but valuable, numerous studies are underway to explore its potential and emphasize the importance of fungi in construction. For example, Neurospora crassa, a urease-positive fungus, colonizes and protects porous infrastructure materials, causing calcite accumulation on concrete surfaces due to fungal-induced CaCO3 precipitation. This is achieved through CaCO3 pore clogging and biomass shielding, forming a biocrust that prevents water infiltration [112]. Recent research reveals that the fungus Mortierella is abundant in moonmilk, a speleothem found in limestone caves. Moonmilk is composed of minerals like calcite, aragonite, and gypsum (CaSO4·2H2O), with calcite being the most prevalent [116, 117]. The study by Menon et al. found that Aspergillus nidulans (MAD1445) can self-heal from CaCO3 precipitation in crack repair, despite pH changes caused by leaching Ca (OH)2. Other strains, such as A. nidulans (ATCC38163), A. nidulans (MAD0305), A. nidulans (MAD0306), R. oryzae (ATCC22961), P. chrysosporium (ATCC24725), A. terreus (ATCC1012), and A. oryzae (ATCC1011) couldn't survive in alkaline solutions caused by Ca (OH)2 leaching. This suggests that A. nidulans is typically harmless to healthy humans [118]. Luo and co-investigators studied six fungus strains, Trichoderma reesei, Aspergillus nidulans, Cadophora interclivum, Umbeliopsis dimorpha, Acidomelania panicicola, and Pseudophialophora magnispora, which showed robust growth on concrete plates, resulting in CaCO3 precipitation. This process, where CO2 dissolves and reacts with Ca (OH)2, is crucial for efficient crack repair through Ca mineralization. The study emphasizes the importance of finding fungi strains capable of surviving in concrete for effective crack healing [119]. Oligotrophic fungi, found in caves with low temperatures, humidity, and minimal organic matter, can thrive in concrete mixtures. Samples from a carbonate cave showed species like Plectosphaerella cucumerina, Clonostachys rosea, Cephalotrichum oligotriphicum, and C. guizhouense growing even on a carbon-free medium [120]. Fungal genera found in limestone rock substrates include Aspergillus, Aureobasidium, Cephalosporium, Fusarium, Monilla, and Penicillium [121] are the promising candidates for future investigations. Research on fungal concrete integration is limited, despite initial studies showing growth and CaCO3 formation. Methods for incorporating fungal spores into concrete mixes are not studied, raising questions about spore survival, nutrient addition, and impact on properties. Encapsulation methods and concrete compositions also pose challenges. The influence of fungi on concrete properties, crack healing capacity, and growth dynamics remains unexplored, highlighting the need for further research.

Microalgae-mediated self-healing concrete

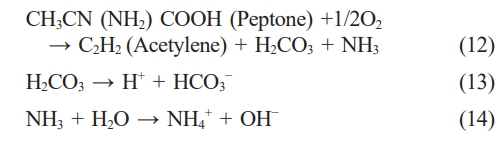

Microalgae are emerging as a promising method for promoting calcifications in bio-concretes [122]. Primarily autotrophic eukaryotes, which vary from unicellular to multicellular forms and thrive in diverse environments such as water and soil. While most belong to Plantae, cyanobacteria (blue-green algae) are prokaryotic but perform photosynthesis like many microalgae. These organisms induce mineral precipitation through biologically controlled or induced processes, with only a few species currently explored for microbial biomineralization [32]. Microalgae facilitate calcite formation through urease activity, utilizing CO(NH2)2 to supply carbonate ions essential for concrete strengthening and crack repair. This process strengthens concrete by filling cracks, consolidating sand, and restoring aggregates [122]. Unlike bacteria or fungi, microalgae achieve MICP through photosynthesis [12] as shown below:

There are two categories of microalgae i.e. calcifying and non-calcifying based on the ability to produce CaCO3. Calcifying microalgae, like coccolithophores such as Emiliania huxleyi [123] can secrete CaCO3, forming protective structures that play a vital role in the carbon cycle and contribute to oceanic sediments, making them potential candidates for biocement production. On the other hand, non-calcifying microalgae, such as green algae, diatoms, and cyanobacteria, do not produce CaCO3, while they don't contribute to carbonate sediments, they play crucial roles in ecosystems. Diatoms have silica cell walls and cyanobacteria aid in nitrogen fixation and oxygen production. Previous studies have shown that non-calcifying microalgae like Chlorella can precipitate CaCO3 [122].

A study on eight microalgae evaluated their biomineralization potential in CaCO3 media. Synechocystis sp. ATCC 27178 showed the highest rate of calcium ion removal (0.70 mM/day) followed by Chlorella vulgaris (0.40 mM/day). Scanning electron microscope (SEM) and energy dispersive x-ray (EDX) analysis confirmed the morphology of CaCO3 crystals precipitated by these microalgae as calcite. Factors influencing biomineralization included pH, Ca2+ and HCO3− concentrations, and microalgae species. The ideal pH range for biomineralization was 8.5 to 10.2 [124]. Natsi and Koutsoukos found that CaCO3 precipitation on Acutodesmus obliquus results in a 75% increase in precipitation rate compared to its absence. Air-dried cultures at 25°C showed higher precipitation rates than active microalgae cultures, but at 70°C, nucleation and growth were inhibited due to microalgae molecular breakdown. CaCO3 precipitation rates on calcite from air-dried cultures were twice as high as rates from individual substrate components, indicating enhanced precipitation efficiency [125]. Interestingly, a study investigated carbonate precipitation through the co-cultivation of Chlorella sp. and Sporosaricina pasteurii under mixotrophic conditions. The optimal conditions included a 3:2 (v/v) algae-bacteria ratio, pH 9.0, and glucose concentration (1 g/L). Chlorella sp. biomass improved by 37.74%, with a 60.4% reduction in Ca2+ rates compared to monoculture. The calcification rate constant was 0.3514, and SEM observations confirmed mineral particle aggregation and microbial cell deposition, indicating the feasibility of MICP via the Chlorella-Sporosaricina co-culture [126]. A study aimed to optimize bio-cement production from cement kiln dust (CKD) using microalgae. The researchers varied reaction temperature, initial pH, and culture time intervals to maximize CaCO3 yield. They achieved a peak CaCO3 yield of 25.18 g at 23°C, pH 10.62, with 9 days of cultivation, using 96% of CKD for CaCO3 yield. Analytical tools confirmed bio-cement formation [127]. Thraustochytrium striatum demonstrates biocementation capability and produces urease, initiating CaCO3 precipitation in regolith columns, resulting in an average CaCO3 concentration of 12.21% ± 0.79% [128]. Microalgae, abundant in nature and capable of precipitating minerals, are yet to be fully explored for their application in bioconcrete. However, their adaptability, low-cost cultivation, and ability to induce calcite precipitation make them a promising avenue for future research in self-healing concrete, enhancing its durability and sustainability.

Stages of bio-concrete manufacturing

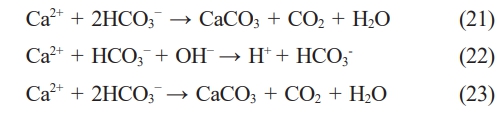

Bio-concrete is a material that incorporates bacterial agents and promotes crack healing through biomineralization. The process involves three major steps: bacteria cultivation, incorporation into concrete medium, and activation and biomineralization. Bacteria are grown in a suitable medium with optimal conditions and nutrients, such as beef extract, peptone, and CO(NH2)2 [144]. Once incorporated, spores and calcium lactate (C₆H₁₀CaO₆) are added to the concrete mixture [36], along with carrier media like water, [145], coarse aggregate [146], nano/microparticles encapsulation [147], or expanded clay [148]. The bacteria encapsulated in nano/microparticles form microcapsules that remain dormant until cracks form, activating the bacteria to initiate the healing process [147]. When cracks occur in the concrete, the bacteria become activated and metabolize calcium lactate (or another calcium source) in the presence of water and CO₂, leading to calcite (CaCO₃) precipitation, which helps seal cracks. This involves the bacteria metabolizing nutrients and producing calcite precipitation in response to environmental cues like moisture and calcium ions. The newly formed calcite crystals help seal cracks, enhancing the durability and longevity of the concrete structure (Fig. 2). The addition of bacteria and C₆H₁₀CaO₆ improves compaction and mechanical properties by filling micro-pores and reducing water and chemical ingress [11].

Factors affecting self-heal bio-concrete design

Bio-concrete is made from bacteria (Bacillus or Sporosarcina) and calcium-based agents (CaCO3 or C6H10CaO6), which remain dormant until cracks appear. Bacteria break down the calcium complex when they contact water, producing limestone that fills gaps and repairs concrete. However, the concentration of bacteria significantly influences the potency and efficacy of the self-healing process [5]. For example, healing capacity [149], crack width [150], strength integrity [151-152], optimization [153], and overall design are some of the considerations that require specific attention. Higher bacteria concentrations lead to greater healing capacity, allowing more calcium carbonate production to fill cracks effectively [149]. However, lower concentrations may require additional measures like fibers to bridge wider cracks [150]. Balancing these factors is crucial for maintaining structural integrity [151-152]. Optimal bacteria concentration requires extensive research and testing for specific applications. The overall design includes factors like healing agents, mix design, and curing conditions, all playing crucial roles in creating self-healing concrete [153].

Analysis and performance

Assessing concrete self-healing: Evaluation methods and strategies

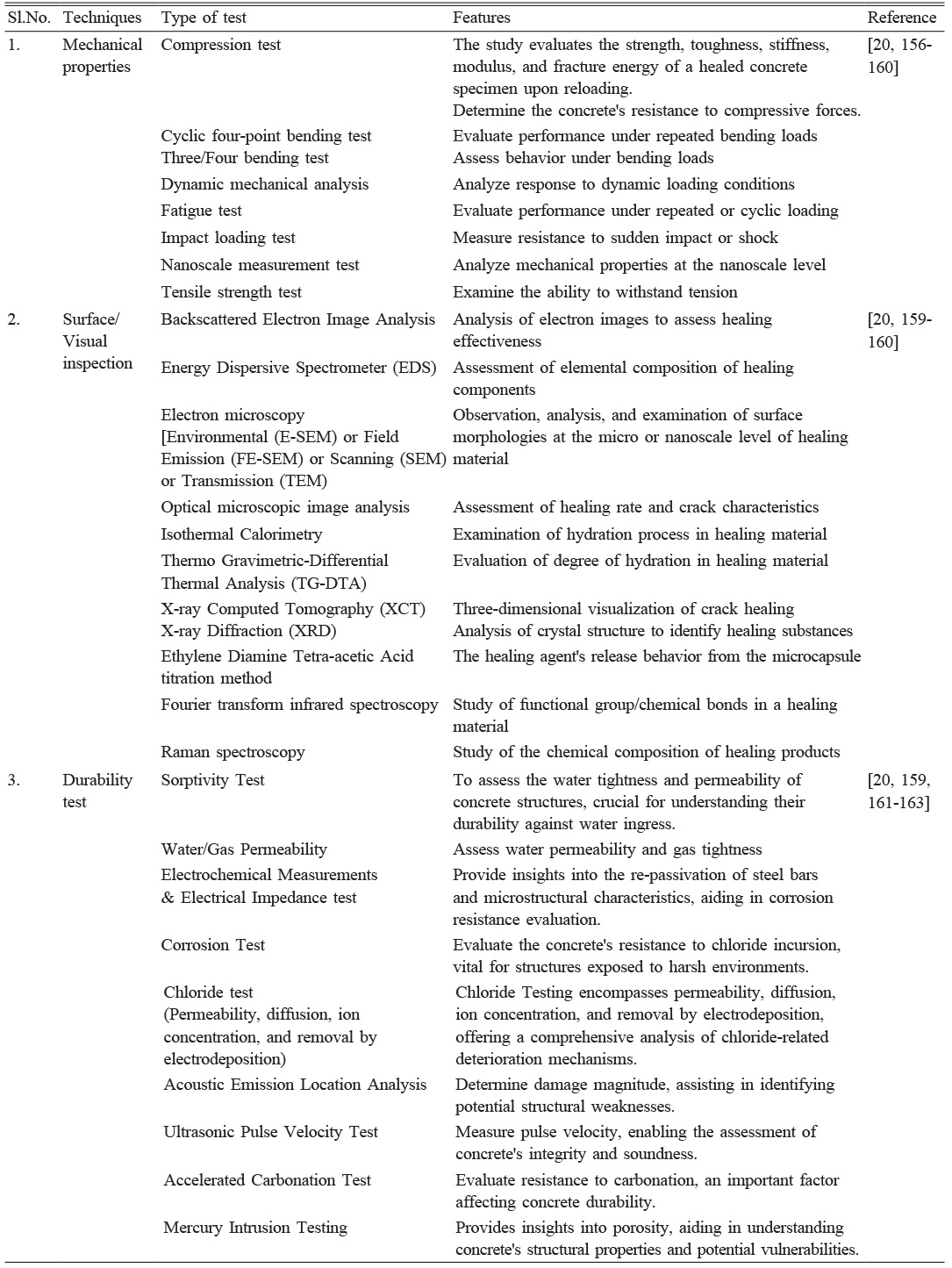

Concrete is widely used in construction due to its strength, affordability, and durability. However, its tendency to crack presents significant challenges, as it allows harmful substances to penetrate structures, leading to long-term damage [5]. According to a market study, cracking is a common problem in both new and old construction, particularly in bridges and underground structures. Older structures from the 1960s and 1970s exhibit susceptibility because of outdated design standards and construction practices [154]. Danish et al. identified various causes of concrete cracking, including plastic shrinkage, formwork movement, and detailing errors. Despite not immediately harmful can lead to significant repair cost. According to the American Society of Civil Engineers (ASCE), billions of dollars (approx. $20-22 billion) are spent globally on repairs, with many failing to extend the lifespan of structures, impacting the economy and environment [18]. In civil engineering, accurately identifying and quantifying cracks is critical for maintaining infrastructure, particularly in pavements, bridges, and tunnels. To build more eco-friendly and durable structures, research into self-healing concrete has become crucial [155]. Advances in technology have led to the development of various methods for measuring cracks, ranging from manual techniques to automated digital tools. Standards for assessing self-healing processes are evolving, focusing on improvements in mechanical properties like strength and fracture energy [155]. Digital image processing techniques, including edge detection algorithms, brightness modification, and analytical criteria including Fourier, Laplace, and wavelet transformations are employed to assess cracks in concrete, each approach offering various levels of precision and adaptability for calculating crack width [155]. Researchers quantify healing efficiency using different test methods, many of which are standard for concrete evaluation. Table 4 summarizes the applicability of various methods for self-healing analysis based on the literature study.

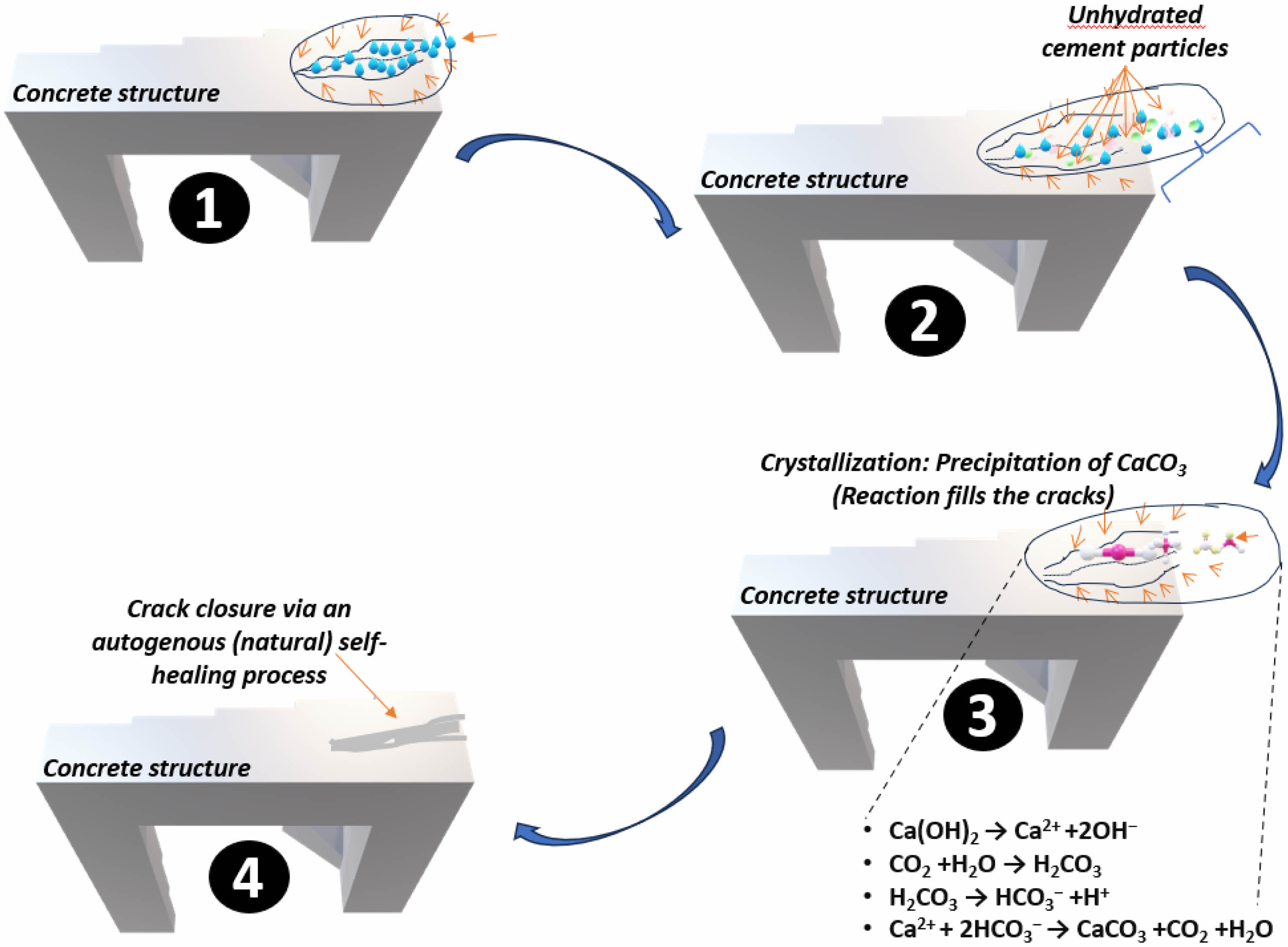

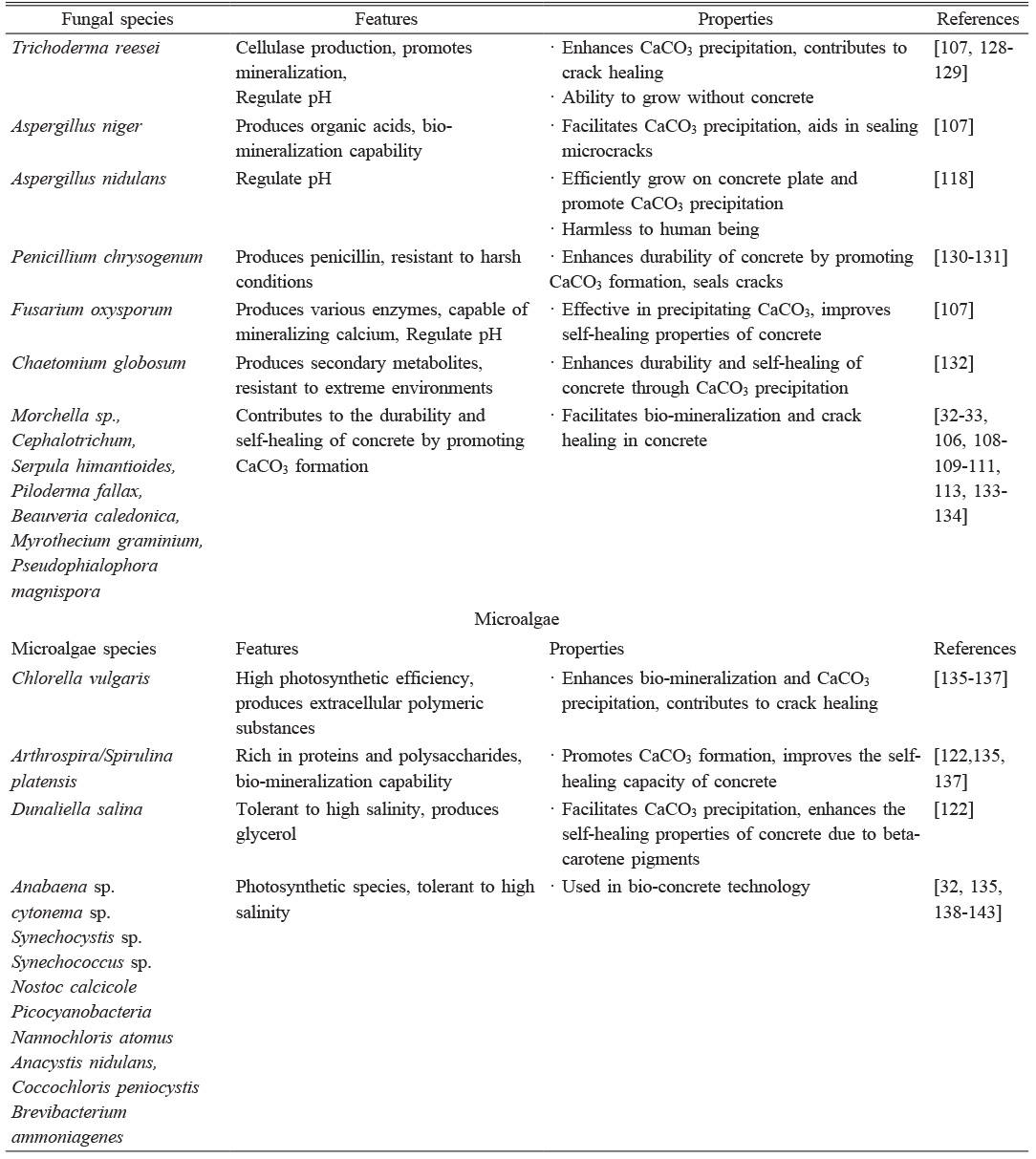

Concrete mixes are designed to create self-healing concrete, but the workability of fresh concrete can be impacted by specific materials due to their water absorption or swelling capabilities. Mineral admixtures are often used to partially replace cement to increase mechanical qualities while using less cement. The presence of capsules may have a minor impact on strength, so it is necessary to carefully determine the percentages of healing substances using scientific experimental approaches [20, 164-166]. A study found that using bacterially precipitated CaCO3 for crack healing is more environment friendly and compatible with concrete than using conventional polymeric materials. Diatomaceous earth (DE) was found to significantly boost ureolytic activity in concrete. Visual observation under light microscopy confirmed self-healing in cracked specimens [165]. Pre-cracked cementitious composites with local waste materials (Blast furnace slag and Limestone powder) showed 65-105% deflection capacity recovery and stiffness recovery. Field emission scanning electron microscope (FE-SEM) and EDX confirmed microcrack healing due to continuous hydration, which could reduce maintenance in civil infrastructure, particularly for applications needing high deformation capacity like bridge deck link slabs [167]. Additional studies on strain-hardening composites with crystalline and expanding additives, such as calcium sulfoaluminate, revealed healing products like ettringite (hydrous calcium aluminum sulfate mineral, forms during cement hydration), CSH, and CaCO3, highlighting the importance of material selection [168]. When combined with other additives such as fly ash, slag, and expansive agents, these materials significantly enhance self-healing capacity [169]. Notably, blast furnace slag is particularly effective in promoting self-healing due to its higher calcium oxide content, and Class-C fly ash performs better than Class-F fly ash, especially in freeze-thaw conditions [20,170]. A schematic overview of the matrix for self-heal concrete is presented in Fig. 3.

Technological advancement and innovations (predictive models)

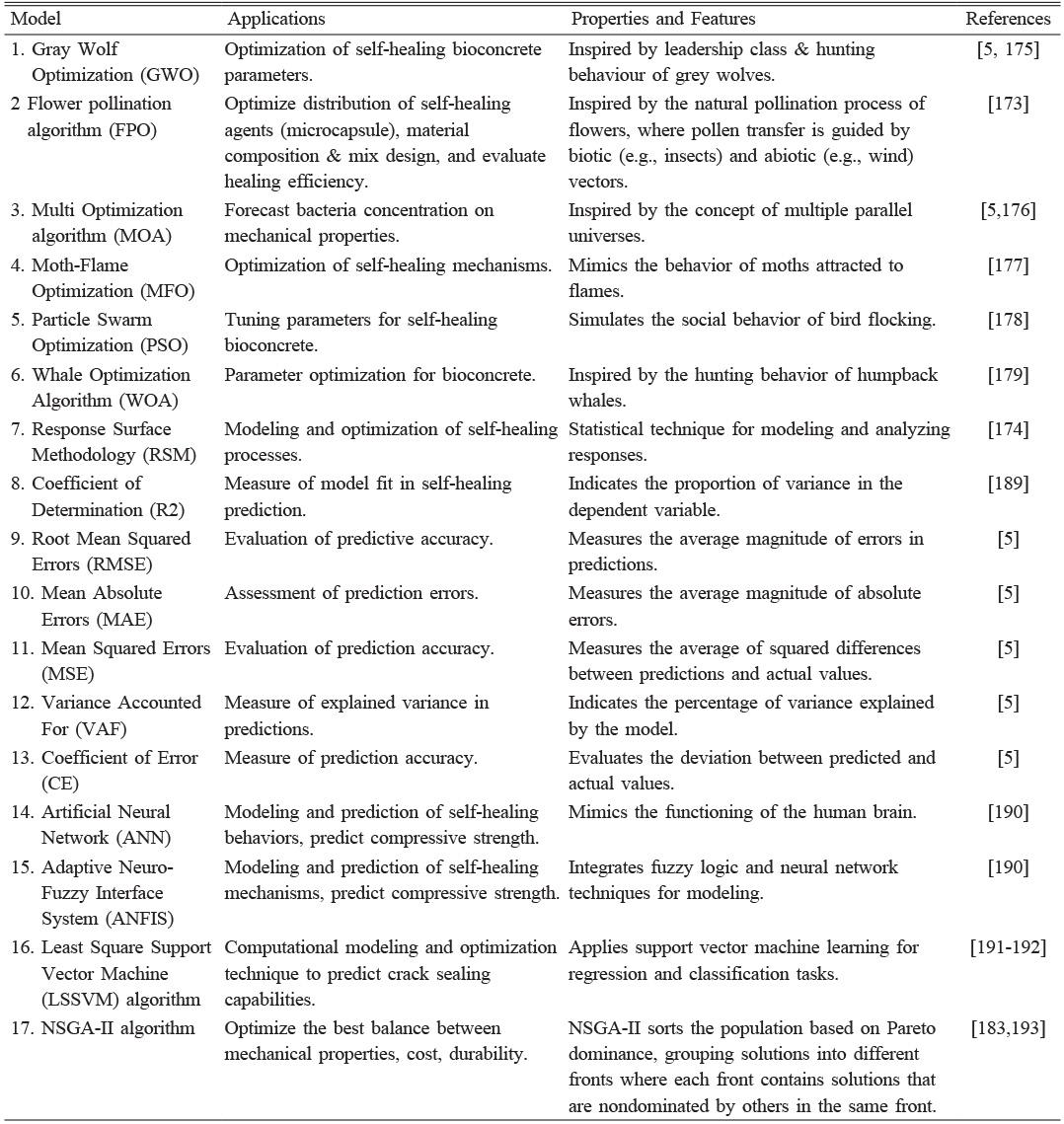

Self-healing concrete in construction reduces maintenance costs, improves project feasibility, and attracts developers. Durability and service life impact economic outcomes, and lifespan can influence global costs, sometimes surpassing environmental and financial considerations [171]. Research aims to extend the service life of reinforced concrete structures by incorporating self-healing properties. Life cycle costing (LCC) compares three material solutions in Turin, Northern Italy, using Global Cost calculation and the Factor Method, a recognized internationally accepted fundamental tool standardized using ISO 15686 part 1:2000. This helps select suitable alternatives from early design stages in the construction sector [172]. This indicates that predictive models' intelligent learning abilities are crucial for assessing mechanical properties, compressive strength, and bacteria concentration in concrete performance. They simplify and cost-effectively optimize mathematical relationships, allowing statistical assessment of effectiveness and accuracy before treatment. Metaheuristic techniques like Flower Pollination Algorithm (FPA), Linear multivariate regression (LMR), Response Surface Methodology (RSM), Gray Wolf Optimization (GWO), Multi-Verse Optimization (MVO), Moth-Flame Optimization (MFO), Particle Swarm Optimization (PSO), and Whale Optimization Algorithm (WOA) were used to optimize self-healing bio-concrete mechanical properties by forecasting bacterial concentration [5].

Yang et al. developed a flower pollination algorithm (FPA) that mimics plant evolution using abiotic and biotic approaches, optimizing global searches and local searches, and utilizing Lévy flights. This will accurately simulate pollinator travel, and self-pollination occurs when pollen falls on the same flower's stigma [173]. Linear multivariate regression (LMR) is a statistical technique used in fields like economics, finance, and social sciences to analyze and predict the relationship between multiple independent variables and a dependent variable. It is an extension of simple linear regression, aiming to estimate coefficients that best fit observed data by minimizing squared differences [5]. Response Surface Methodology (RSM) is a statistical and mathematical technique used in engineering, chemistry, and other physical sciences to analyze the relationship between controlled variables and a system's response. It involves conducting experiments to observe changes in system response and developing predictive models for performance optimization [5, 174]. Gray Wolf Optimization (GWO) is a metaheuristic optimization algorithm based on the leadership class and hunting behavior of grey wolves. It was proposed by Mirjalili and co-workers in 2014 which divides candidate solutions into four types: alpha, beta, delta, and omega. The algorithm updates the positions of these wolves iteratively, simulating a pack of wolves working together to find the best solution [175]. The Multi-Verse Optimization Algorithm (MOA) is a metaheuristic optimization algorithm that uses a population-based approach to represent potential solutions as universes. These universes evolve over iterations using physical phenomena. MOA aims to efficiently explore the solution space by allowing universes to explore different regions and exchange information. Its effectiveness depends on parameter settings, problem characteristics, and tuning strategies [5, 176]. Moth Flame Optimization (MFO) is a metaheuristic optimization algorithm that mimics moth behavior when attracted to a flame. It randomly initializes a moth population, attracts them to the brightest solution, adjusts their position, and encircles them to avoid premature convergence. The algorithm updates light intensity over iterations to simulate diminishing attractiveness. It stops when a termination condition is met. MFO's performance depends on parameter settings, problem characteristics, and tuning strategies [177]. Particle Swarm Optimization (PSO) is a widely used optimization technique developed by Dr. Eberhart and Dr. Kennedy in 1995. It treats potential solutions as swarms, with each particle adjusting its position based on its own experience and neighbor's. PSO is widely used in fields like engineering, computer science, finance, function optimization, neural network training, and feature selection [178]. The Whale Optimization Algorithm (WOA) is a 2016 algorithm that mimics humpback whales' social behavior during hunting. It updates candidate solutions' positions based on virtual whales' behavior, making it effective in engineering, data science, and other fields. Its ability to quickly converge to near-optimal solutions is a subject of interest for researchers [179]. The model's performance can also be evaluated using various metrics such as variance accounted for (VAF), coefficient of determination (R2), root mean squared errors (RMSE), mean absolute errors (MAE), and mean squared errors (MSE) [5].

Recent study on bioconcrete strength found that GWO, PSO, and MVO were the most effective in predicting concrete slump, flexural strength, and compressive strength. Bacterial concentration was found to be a significant parameter influencing self-healing concrete behavior. Overall, GWO, PSO, and MVO were considered superior, while RSM provided adequate precision in predicting mechanical properties. Sensitivity analysis revealed that bacterial concentration significantly influences self-healing concrete behavior [5]. A new metaheuristic method for neural network modeling for circular economy and disaster resilience, based on PSO, has been developed. The method predicts the final-age compressive strengths of sustainable concrete series using different aggregate types. The method outperformed classical machine learning algorithms, with a coefficient of determination of 0.999. This could significantly contribute to sustainable development and disaster risk reduction [180]. The study developed and validated three metaheuristic algorithms, WOA, GWO, and FPA, integrated with Xgboost, to predict the self-healing performance of ultra-high-performance concrete (UHPC). The dataset included experimental tests under sustained crack tensile stress and aggressive environments for up to six months, showcasing machine learning's potential in predicting self-healing [179]. Sun and co-investigators use meta-heuristic algorithms to assess the compressive strength of concrete specimens in laboratory experiments. The algorithms create relationships between parameters, determining their impact on compressive strength. The optimum conditions for compressive strength are presented, demonstrating the effectiveness of meta-heuristic algorithms as a substitute for empirical models [181]. A study compared six machine-learning approaches for predicting crack closure percentage in bacteria-based self-healing concrete, including Support Vector Regression, Decision Tree Regression, Gradient Boosting Regression, Artificial Neural Network, Bayesian Ridge Regression, and Kernel Ridge Regression, highlighting their potential in industrial engineering design [182]. A new method using nanofillers for self-healing concrete is proposed to enhance its durability in complex environments. The model uses PSO-LSSVM and an improved NSGA-II algorithm to determine the optimal mix ratio. Experimental research shows significant improvement in self-healing concrete's durability, with excellent generalization capability. The improved model is highly effective in predicting the optimal concrete mix proportion scheme [183]. A study explores the post-fire mechanical properties of natural zeolitic concrete (NZC) using an evolutionary-based machine learning model. The results show that the Meta-MARS model outperforms five other models, indicating the promising post-fire performance of NZC. This study highlights the climatic, environmental, and economic advantages of using natural pozzolans in cement-based materials. The model's robustness and uncertainty analysis are also applied [184]. The study developed a metaheuristic method to predict the creep strain of green concrete with ground granulated blast furnace slag using an ANN model, utilizing the firefly algorithm (FF) for weight optimization and comparing it to other optimization algorithms, revealing its more accurate and flexible results [185].

Renne et al. highlight the growing need for repair in the European construction industry due to aging infrastructure, highlighting environmental and economic concerns [186]. The Confederation of Construction's 2013-2014 report shows that 50% of Europe's construction budget is allocated to refurbishment and repair [187]. A study by Craeye et al. found that around 350 million euros are spent annually on maintaining roads and bridges in Flanders, Belgium, with concrete being a significant component [188]. A case study by Uguzzoni and his team developed microcapsules containing an expanding mineral powder to seal cracks in cement-based materials. The capsules were heated and coated with epoxy resin for waterproofing. After 28 days, the capsules showed 98.7% sealing efficiency, with a slight decrease in water flow. The mechanical property recovery in flexion was 10.6±4.5% [172]. A metasensor developed using a convolutional neural network accurately estimates crack width from high-resolution images and brightness profiles. This allows for repeated, semi-automated crack measurements at multiple locations, assessing self-healing progress. The study found differences in self-healing between exposed and deep-lying materials due to natural local porosity differentiation, supported by X-ray computed tomography and electron microscopy data [155]. Table 5 shows the list of various models employed in assessing self-healing concrete.

Limitations and challenges

Bio-concrete holds promise for enhancing infrastructure durability and reducing maintenance costs. However, its adoption requires significant adjustments to traditional design, mixing, and placement processes, which may encounter resistance from industry practitioners [194]. Training and transitioning to new techniques could add to the initial implementation costs. Additionally, the higher upfront cost of bio-concrete stems from advanced technologies, including encapsulated healing agents or specific bacterial strains, and the complexity of production [44]. This can deter widespread adoption, particularly in projects with tight budgets. Challenges also arise in fully repairing larger or deeper cracks and ensuring consistent performance under varying environmental conditions such as humidity, temperature, and chemical exposure. The activation of healing agents might be delayed in low-moisture environments, and their effectiveness can diminish over time due to deterioration [195]. Furthermore, scaling up for large infrastructure projects introduces variability in source materials and mixing techniques, leading to inconsistent self-healing results. These performance inconsistencies are further compounded by environmental conditions, making it difficult to guarantee consistent outcomes. Regulatory approval remains another significant hurdle, as new materials must undergo extensive testing to meet safety and performance standards. The process of certifying bio-concrete for widespread use can be lengthy and expensive. Long-term data on its performance in real-world conditions is still lacking, making it difficult to assess the material’s long-term feasibility and cost-effectiveness [196-198]. Overcoming these limitations will require continued research, collaboration between academia and industry, and advancements in material science to improve production processes and scalability. Establishing comprehensive testing protocols and fostering industry-wide awareness of the benefits will also be crucial for wider adoption.

Future prospects and conclusion

Bio-concrete, propelled by advancements in material science, biology, and engineering, presents a transformative future for infrastructure. Its ability to autonomously repair cracks not only reduces maintenance costs but also extends the lifespan of structures, leading to more sustainable construction practices by minimizing the carbon footprint associated with concrete production and repairs. Though the initial costs may be higher due to the advanced materials and technologies involved, the long-term savings from reduced upkeep make bio-concrete especially well-suited for large-scale projects such as high-rise buildings, bridges, and tunnels [199]. Future advancements in bio-concrete are likely to be driven by innovations such as the integration of smart infrastructure technologies, including Internet of Things (IoT) devices and sensors. These technologies can enable real-time monitoring and automated maintenance of concrete structures, ensuring timely interventions, especially in harsh environments like maritime or coastal settings [200-202]. Moreover, genetic engineering of bacteria or microorganisms used in self-healing processes, along with the addition of nanomaterials like nanosilica, nanoclay, and carbon nanotubes, offers the potential for even more efficient micro- and nanoscale healing mechanisms [203]. To facilitate the widespread adoption of bio-concrete

|

Fig. 1 Schematic overview of Autogenous (natural) self-healing mechanism in the concrete structure. |

|

Fig. 2 An overview showing different stages of bio-concrete manufacturing. |

|

Fig. 3 Structural overview of self-repairing concrete matrix. |

|

Table 1 Pathways of CaCO3 precipitation in bacterial concrete, their description, and chemical reaction involved. |

|

Table 2 Summary of various bacterial species studied in the design of bio-concrete, highlighting significant features and results. |

|

Table 3 Tabulated presentation of most probable fungi and microalgae species participates in bio-concrete design.Fungi |

|

Table 4 Tabulated overview depicting various techniques for assessing the self-healing performance of concrete. |

|

Table 5 Tabulated presentation of various predictive models, their applications, properties and features. |

This work was supported by Korea Environment Industry & Technology Institute (KEITI) through Development of Demonstration Technology for energy conversion using waste resources Program, funded by Korea Ministry of Environment (MOE) (2022003480001).

The authors announce no conflict of interest.

- 1. M. Bagga, C. Hamley-Bennett, A. Alex, B.L. Freeman, I. Justo-Reinoso, I.C. Mihai, S. Gebhard, K. Paine, A.D. Jefferson, E. Masoero, and I.D. Ofiţeru, Constr. Build. Mater. 358 (2022) 129412.

-

- 2. F. Pacheco, H.Z. Ehrenbring, R. Christ, R.P. de Souza, R.C.E Modolo, V.H Valiatio, B.F. Tutikian, and Z. Wu, Sustainability 16[24] (2024) 10829.

- 3. International Energy Agency (IEA), Technology Roadmap: Low-Carbon Transition in the Cement Industry, Paris, France, 2018.

-

- 4. B. Gates, in "How to Avoid a Climate Disaster: The Solutions We Have and the Breakthroughs We Need" (Alfred A. Knopf, 2021) p. 257.

-

- 5. K.C. Onyelowe, A.F. Adam, N. Ulloa, C. Garcia, A.I. Andrade Valle, M.G. Zúñiga Rodríguez, A.N. Zarate Villacres, J. Shakeri, L. Anyaogu, M. Alimoradijazi, and N. Ganasen, Sci. Rep. 14 (2024) 8414.

-

- 6. J. Weerhejim, in “Understanding the Tensile Properties of Concrete” (Elsevier, 2024) p. 17-48.

-

- 7. F.B. Silva, N. Boon, N.D. Belie, and W. Verstraete, J. Commer. Biotechnol. 21[1] (2015) 31-38.

-

- 8. H. Pan and L. Pi, IOP Conf. Ser. Earth Environ. Sci. 189 [2] (2018) 022078.

-

- 9. Y. Javeed, Y. Goh, K.H. Mo, S.P. Yap, and B.F. Leo, J. Mater. Res. Technol. 29 (2024) 2376-2395.

-

- 10. S. Sangadji and E. Schlangen, J. Adv. Concr. Technol. 10[5] (2012) 185-194.

-

- 11. M. Nodehi, T. Ozbakkaloglu, and A. Gholampour, J. Build. Eng. 49 (2022) 104038.

-

- 12. A.V. Handore, S.R. Khandelwal, R. Karmakar, A.S. Jagtap, and D.V. Handore, in "Ecological and Health Effects of Building Materials" (Springer, 2022) p 567-584.

-

- 13. Ingenia, Self-Healing Concrete (2011) 46. [Online]. Available: https://www.ingenia.org.uk/articles/self-healing-concrete.

- 14. H.M. Jonkers, A. Thijssen, G. Muyzer, O. Copuroglu, and E. Schlangen, Ecol. Eng. 36[2] (2010) 230-235.

- 15. A.N. Craik and W.C.G. Burns, Envtl. L. Rep. News & Analysis, 49 (2019) 11113.

- 16. M. Rajczakowska, K. Habermehl-Cwirzen, H. Hedlund, and A. Cwirzen, J. Mater. Civ. Eng. 31[9] (2019) 03119001.

-

- 17. I.H. Abd Elzahra and M.H. Al-Sherrawi, in IOP Conf. Ser.: Mater. Sci. Eng. 1117 (2021) 012026.

-

- 18. A. Danish, M.A. Mosaberpanah, and M.U. Salim, J. Mater. Res. Technol. 9 (2020) 6883-6699.

-

- 19. K. Van Tittelboom and N. De Belie, Materials 6[6] (2013) 2182-2217.

-

- 20. M.M. Meraz, N.J. Mim, M.T. Mehedi, B. Bhattacharya, M.R. Aftab, M.M. Billah, and M.M. Meraz, Alex. Eng. J. 73 (2023) 665-694.

-

- 21. G. Souradeep and H.W. Kua, J. Mater. Civ. Eng. 28[12] (2016) 04016165.

-

- 22. S. Gupta, S. Dai Pang, and H.W. Kua, Constr. Build. Mater. 146 (2017) 419-428.

-

- 23. N. De Belie, E. Gruyaert, A. Al-Tabbaa, P. Antonaci, C. Baera, D. Bajare, A. Darquennes, R. Davies, L. Ferrara, T. Jefferson, and C. Litina, Adv. Mater. Interfaces 5[17] (2018) 1800074.

-

- 24. K. Han, J.W. Ju, X. Chen, L.Y. Lv, S. Zhou, G. Wei, Z. Zhang, and H. Cui, Int. J. Damage Mech. 0[0] (2024) 1-23.

-

- 25. Y.X. He, G.M. Zhu, Z.P. Wu, and Y.M. Zhou, Gongneng Cailiao/J. Funct. Mater. 46 (2015) 02144-02147.

- 26. B. Dong, Y. Wang, G. Fang, N. Han, F. Xing, and Y. Lu, Cem. Concr. Compos. 56 (2015) 46-50.

-

- 27. L. Lv, Z. Yang, G. Chen, G. Zhu, N. Han, E. Schlangen, and F. Xing, Constr. Build. Mater. 105 (2016) 487-495.

-

- 28. N. Xu, Z. Song, M.Z. Guo, L. Jiang, H. Chu, C. Pei, P. Yu, Q. Liu, and Z. Li, Cem. Concr. Compos. 118 (2021) 103951.

-

- 29. Y. Li, J. Yu, Z. Cao, P. He, Q. Liu, X. Han, and Y. Wan, Constr. Build. Mater. 304 (2021) 124616.

-

- 30. Y. Li, J. Yu, Z. Cao, W. Du, Y. Zhang, and Y. Zou, Constr. Build. Mater. 265 (2020) 120703.

-

- 31. L. Zhang, M. Zheng, D. Zhao, and Y. Feng, J. Build. Eng. 89 (2024)109331.

-

- 32. M.R. Bhina, A.H. Wibowo, K.Y. Liu, W. Khan, and M. Salim, Preprints (2021) doi: 10.20944/preprints 202104.0019.v1.

-

- 33. H.M. Jonkers, A. Thijssen, G. Muyzer, O. Copuroglu, and E. Schlangen, Ecol. Eng. 36[2] (2010) 230-235.

-

- 34. K. Van Tittelboom, N. De Belie, W. De Muynck, and W. Verstraete, Cem. Concr. Res. 40[1] (2010) 157-166.

-

- 35. H.M. Jonkers, Heron 56 (2011) 1-12.

-

- 36. K. Vijay, M. Murmu, and S.V. Deo, Constr. Build. Mater. 152 (2017) 1008-1014.

-

- 37. D. Sarda, H.S. Choonia, D.D. Sarode, and S.S. Lele, J. Ind. Microbiol. Biotechnol. 36[8] (2009) 1111-1115.

-

- 38. U.K. Gollapudi, C.L. Knutson, S.S. Bang, and M.R. Islam, Chemosphere 30[4] (1995) 695-705.

-

- 39. M. Naeimi, J. Chu, M. Khosroshahi, and L.K. Zenouzi, Geoderma 429 (2023) 116183.

-

- 40. W. Mwandira, K. Nakashima, and S. Kawasaki, Ecol. Eng. 109 (2017) 57-64.

-

- 41. J.A. Ohan, S. Saneiyan, J. Lee, A.W. Bartlow, D. Ntarlagiannis, S.E. Burns, and F.S. Colwell, Front. Microbiol. 11 (2020) 1327.

-

- 42. H. Zúñiga-Barra, C. Ostojic, Á. Torres-Aravena, M. Rivas, C. Vílchez, and D. Jeison, Algal Res. (2024) 103499.

-

- 43. V. Wiktor and H.M. Jonkers, Cement Concr. Compos. 33[7] (2011) 763-770.

-

- 44. N. De Belie and J. Wang, J. Sustain. Cement-Based Mater. 5[1-2] (2016) 35-56.

-

- 45. T.K. Sharma, M. Alazhari, A. Heath, K. Paine, and R.M. Cooper, J. Appl. Microbiol. 122[5] (2017) 1233-1244.

-

- 46. N. Schwantes-Cezario, M.F. Porto, G.F. Sandoval, G.F. Nogueira, A.F. Couto, and B.M. Toralles, Rev. IBRACON Estrut. Mater. 12 (2019) 31-38.

-

- 47. N. Schwantes-Cezario, G.S. Camargo, A.F. do Couto, M.F. Porto, L.V. Cremasco, A.C. Andrello, and B.M. Toralles, J. Build. Eng. 30 (2020) 101235.

-

- 48. M.G. Sohail, Z. Al Disi, N. Zouari, N. Al Nuaimi, R. Kahraman, B. Gencturk, D.F. Rodrigues, and Y. Yildirim, Constr. Build. Mater. 328 (2022) 126943.

-

- 49. A. Ivaškė, V. Gribniak, R. Jakubovskis, and J. Urbonavičius, Microorganisms 11[10] (2023) 2402.

- 50. C.A. Spencer, H. Sass, and L. van Paassen, Geotechnics 3[4] (2023) 1047-1068.

- 51. A.N. Beskopylny, E.M. Shcherban’, S.A. Stel’makh, A.A. Shilov, A. Chernil’nik, D. El’shaeva, and V.A. Chistyakov, Materials 17[18] (2024) 4508.

- 52. V. Achal, X. Pan, and N. Özyurt, Ecol. Eng. 37[4] (2011) 554-559.

-

- 53. H. Chen, C. Qian, and H. Huang, Constr. Build. Mater. 126 (2016) 297-303.

-

- 54. R. Siddique and A. Rajor, Constr. Build. Mater. 52 (2014) 42-51.

-

- 55. T.H. Nguyen, E. Ghorbel, H. Fares, and A. Cousture, Cement Concr. Compos. 104 (2019) 103340.

-

- 56. L. Jiang, G. Jia, Y. Wang, and Z. Li, ACS Appl. Mater. Interfaces 12[9] (2020) 10938-10948.

-

- 57. J. Wang, K. Van Tittelboom, N. De Belie, and W. Verstraete, Construct. Build. Mater. 26 (2012) 532-540.

-

- 58. A. González, A. Parraguez, L. Corvalán, N. Correa, J. Castro, C. Stuckrath, and M. González, Construct. Build. Mater. 257 (2020) 1-11.

-

- 59. M. Wu, X. Hu, Q. Zhang, D. Xue, and Y. Zhao, Construct. Build. Mater. 209 (2019) 631-643.

-

- 60. P.S. Nair, R. Gupta, V. Agrawal, and B.S. Thomas, Mater. Today Proc. 65 (2022) 1410-1417.

-

- 61. F. Hammes, A. Seka, S. de Knijf, and W. Verstraete, Water Res. 37[3] (2003) 699-704.

-

- 62. P. Anbu, C.H. Kang, Y.J. Shin, and J.S. So, Springer plus 5 (2016) 250.

-

- 63. M.S. Rao, V.S. Reddy, and C. Sasikala, J. Inst. Eng. India Ser. A 98 (2017) 501-510.

-

- 64. W. Lin, W. Lin, X. Cheng, G. Chen, and Y.C. Ersan, Appl. Sci. 11[17] (2021) 7842.

- 65. W.G. Zumft, in “The denitrifying prokaryotes. The Prokaryotes” (Springer. 1992) p.1.

-

- 66. S.T. O’Donnell, N. Hamdan, B.E. Rittmann, and E. Kavazanjian Jr., in “A stoichiometric model for biogeotechnical soil improvement” (Geotech Spl. Publ, 2016) p. 7-16.

-

- 67. V.P. Pham, in Bio-based ground improvement through Microbial Induced Desaturation and Precipitation (MIDP), Doctoral thesis, Delft University of Technology, 2017.

- 68. Y.C. Ersan, in “Overlooked strategies in exploitation of microorganisms in the field of building materials” (Springer, 2019) p.19-45.

-

- 69. K.S. Sri, R.R. Nayaka, and M.S. Kumar, J. Build. Pathol. Rehabil. 8[2] (2023) 99.

-

- 70. C.S. Durga, N. Ruben, M.S. Chand, and C. Venkatesh, Mater. Today Proc. 27 (2020) 158-162.

-

- 71. M. Sarkar, M. Maiti, S. Xu, and S. Mandal, J. Build. Eng. 74 (2023) 106888.

-

- 72. M. Smirnova, C. Nething, A. Stolz, J.A. Gröning, D.P. Funaro, E. Eppinger, M. Reichert, J. Frick, and L. Blandini, npj Mater. Sustain. 1[1] (2023) 4.

-

- 73. S. Udhaya, V.V. Devi, J. Philips, and R.L. Lija, Mater. Today Proc. (2023). https://doi.org/10.1016/j.matpr.2023.03.676

-

- 74. K. Chetty, U. Garbe, Z. Wang, S. Zhang, T. McCarthy, F. Hai, and G. Jiang, J. Sustain. Cem. Based Mater. 12[9] (2023) 1049-1060.

-

- 75. J. Vanjinathan, V. Sampathkumar, N. Pannirselvam, R. Krishnan, M. Sivasubramanian, S. Kandasamy, S.A. Selvasofia, and M. Kavisri, Biomass Convers. Biorefin. 14 (2024) 29941-29947.

- 76. A. Mistri, N. Dhami, S.K. Bhattacharyya, S.V. Barai, and A. Mukherjee, Constr. Build. Mater. 369 (2023) 130509.

-

- 77. S.H. Abo Sabah, L.H. Anneza, M.I. Juki, H. Alabduljabbar, N. Othman, A.A. Al-Gheethi, and A.F. Al-Shalif, Sustainability 13[16] (2021) 9269.

-

- 78. M.B. Khan, L. Shen, and D. Dias-da-Costa, Constr. Build. Mater. 277 (2021) 122332.

-

- 79. S.O. Ahmed, A.A. Nasser, R.N. Abbas, M.M. Kamal, M.A. Zahran, and N.M. Sorour, 3 Biotech 11[5] (2021a) 231.

-

- 80. Y. Song, K. Chetty, U. Garbe, J. Wei, H. Bu, L. O'moore, X. Li, Z. Yuan, T. McCarthy, and G. Jiang, Sci. Total Environ. 791 (2021) 148270.

-

- 81. M.R. Ahmad, B. Chen, and S.F. Shah, Constr. Build. Mater. 281 (2021b) 122533.

-

- 82. S. Luhar and S. Gourav, J. Civ. Eng. Res. 5[3] (2015) 53-58.

-

- 83. H.J. Chen, C.F. Peng, C.W. Tang, and Y.T. Chen, Materials 12[24] (2019) 4099.

-

- 84. F.B. Da Silva, N. De Belie, N. Boon, and W. Verstraete, Constr. Build. Mater. 93 (2015) 1034-1041.

-

- 85. J. Wang, H.M. Jonkers, N. Boon, and N. De Belie, Appl. Microbiol. Biotechnol. 101[12] (2017) 5101-5114.

-

- 86. M. Rauf, W. Khaliq, R.A. Khushnood, and I. Ahmed, Constr. Build. Mater. 258 (2020) 119578.

-

- 87. X. Zhu, A. Mignon, S.D. Nielsen, S.E. Zieger, K. Koren, N. Boon, and N. De Belie, Cem. Concr. Compos. 119 (2021) 104006.

-

- 88. N.N. Huynh, N.M. Phuong, N.P. Toan, and N.K. Son, Procedia Eng. 171 (2017) 598-605.

-

- 89. N.N. Huynh, K.I. Imamoto, and C. Kiyohara, J. Adv. Concr. Technol. 17[12] (2019) 700-714.

-

- 90. J. Feng, B. Chen, W. Sun, and Y. Wang, Constr. Build. Mater. 280 (2021) 122460.

-

- 91. Q. Fu, Y. Wu, S. Liu, L. Lu, and J. Wang, Constr. Build. Mater. 332 (2022) 127371.

-

- 92. I. Justo-Reinoso, A. Heath, S. Gebhard, and K. Paine, J. Build. Eng. 42 (2021) 102834.

-

- 93. B. Chen, W. Sun, X. Sun, C. Cui, J. Lai, Y. Wang, and J. Feng, Process Biochem. 107 (2021) 100-111.

-

- 94. H.M. Jonkers and E. Schlangen, in Proceedings of Fracture Mechanics of Concrete and Concrete Structures (FRACOS6, 2007) p.1821-1826.

- 95. Y. Su, T. Zheng, and C. Qian, Constr. Build. Mater. 273 (2021) 121740.

-

- 96. S. Bifathima and B.N. Matcha, Civ. Environ. Eng. 16[1] (2020) 184-197.

-

- 97. S.U. Islam and S.A. Waseem, Constr. Build. Mater. 404 (2023) 133331.

-

- 98. P.S. Nair, R. Gupta, and V. Agrawal, Mater. Today Proc. 65 (2022) 1410-1417.

-

- 99. C.S. Durga, N. Ruben, M.S. Chand, M. Indira, and C. Venkatesh, Materialia 15 (2021) 101051.

-

- 100. Z. Li, A. Liu, C. Sun, H. Li, Z. Kong, and H. Zhai, Appl. Biochem. Biotechnol. 196 (2023) 1896-1920.

-

- 101. W. Liu, X. Xu, X. Wu, Q. Yang, Y. Luo, and P. Christie, Environ. Geochem. Health 28[2] (2006) 133-140.

-

- 102. H.H. Mahmoud, M.H. Kalaba, G.M. El-Sherbiny, A.E. Mostafa, M.E. Ouf, and W.M. Tawhed, J. Sustain. Cem. Based Mater. 11[6] (2022) 465-478.

-

- 103. J. Xiang, L. Qu, X. Fei, J. Qiu, and X. Kong, J. Build. Eng. 84 (2024) 108485.

-

- 104. O.M. Munyao, J.K. Thiong'o, J.M. Wachira, D.K. Mutitu, M. Romano, and G. Murithi, J. Chem. Rev. 1[4] (2019) 287-299.

- 105. S. Shivanshi, G. Chakraborti, K.S. Upadhyaya, and N. Kannan, Mater. Today: Proc. (2023).

-

- 106. M.M. Gharieb, J.A. Sayer, and G.M. Gadd, Mycol. Res. 102[7] (1998) 825-830.

-

- 107. A. Van Wylick, A.V. Monclaro, E. Elsacker, S. Vandelook, H. Rahier, L. De Laet, D. Cannella, and E. Peeters, Fungal Biol. Biotechnol. 8[1] (2021) 16.

-

- 108. E.P. Burford, S. Hillier, and G.M. Gadd, Geomicrobiol. J. 23[8] (2006) 599-611.

-

- 109. M.M.S. Tuason and J.M. Arocena, Appl. Environ. Microbiol. 75 (2009) 7079-708.

-

- 110. M. Fomina, S. Hillier, J.M. Charnock, K. Melville, I.J. Alexander, and G.M. Gadd, Appl. Environ. Microbiol. 71 (2005) 371-381.

-

- 111. Q. Li, L. Csetenyi, and G.M. Gadd, Environ. Sci. Technol. 48[24] (2014) 14409-14416.

-

- 112. J. Zhao, T. Dyer, L. Csetenyi, R. Jones, and G.M. Gadd, J. Clean. Prod. 330 (2022) 129793.

-

- 113. T. Li, Y.L. Hu, and B. Zhang, Front. Microbiol. 9 (2018) 1884.

-

- 114. C. Martuscelli, C. Soares, A. Camões, and N. Lima, Procedia Manuf. 46 (2020) 180-185.

-

- 115. S. Bindschedler, G. Cailleau, and E. Verrecchia, Minerals 6[2] (2016) 1-19.

-

- 116. W.B. White, in “Encyclopedia of Caves, 3rd ed.” (Academic Press, 2019) p. 1006-1017.

-

- 117. S. Park, Y.J. Cho, D. Jung, K. Jo, E.J. Lee, and J.S. Lee, Front. Microbiol. 11 (2020) 613.

-

- 118. R.R. Menon, J. Luo, X. Chen, H. Zhou, Z. Liu, G. Zhou, N. Zhang, and C. Jin, Sci. Rep. 9[1] (2019) 2075.

-

- 119. J. Luo, X. Chen, J. Crump, H. Zhou, D.G. Davies, G. Zhou, N. Zhang, and C. Jin, Constr. Build. Mater. 164 (2018) 275-285.

-

- 120. J.R. Jiang, L. Cai, and F. Liu, Mycology 8[3] (2017) 164-177.

-

- 121. E.P. Burford, M. Kierans, and G.M. Gadd, Mycologist 17[3] (2003) 98-107.

-

- 122. M.M. Nur and R.N. Dewi, Biocatal. Agric. Biotechnol. [56] (2024) 103048.

-

- 123. E. Paasche and S. Brubak, Phycologia 33[5] (1994) 324-330.

-

- 124. K. Arumugam, R. Mohamad, S.E. Ashari, J.S. Tan, and M.S. Mohamed, Asia Pac. J. Chem. Eng. 17[3] (2022) e2767

-

- 125. P.D. Natsi and P.G. Koutsoukos, Biomimetics 7[4] (2022) 140.

-

- 126. P. Xu, H. Fan, L. Leng, L. Fan, S. Liu, P. Chen, and W. Zhou, Algal Res. 47 (2020) 101831.

-

- 127. M.F. Irfan, S.M.Z. Hossain, H. Khalid, F. Sadaf, S. Al-Thawadi, A. Alshater, M.M. Hossain, and S.A. Razzak, Biotechnol. Rep. 23 (2019) e00356.

-

- 128. J. Gleaton, in Biocementation of Simulant Martian Regolith, Clemson University, Master’s Thesis, Clemson University, 2018.

- 129. P.C. Chiadighikaobi, M. Hematibahar, M. Kharun, N.A. Stashevskaya, and K. Camara, Cogent Eng. 11[1] (2024) 2307193.

-

- 130. R.A. Khushnood, A.M. Ali, M.F. Bhatti, and H.A. Khan, J. Build. Eng. 50 (2022) 104155.

-

- 131. N. Khan, H.A. Khan, R.A. Khushnood, M.F. Bhatti, and D.I. Baig, Constr. Build. Mater. 392 (2023) 131910.

-

- 132. E. Loukou, N.F. Jensen, L. Rohde, and B. Andersen, J. Fungi 10[2] (2024) 108.

-

- 133. K. Kolo, E. Keppens, A. Preat, and P. Claeys, J. Geophys. Res. Biogeosci. 112[G1] (2007) G01007.

-

- 134. Q. Li, L. Csetenyi, G.I. Paton, and G.M. Gadd, Environ. Microbiol. 17[8] (2015) 3082-3097.

-

- 135. R. Ramanan, K. Kannan, A. Deshkar, R. Yadav, and T. Chakrabarti, Bioresour. Technol. 101[8] (2010) 2616-2622.

-

- 136. A. Khafhafera, in Production of Multi-Purpose Bio-Solid Feedstock for Oxidation in Cement Calciner using Microalgae, Master’s Thesis, Queen’s University, Kingston, ON, 2017.

- 137. U.J. Alengaram, S. Ibrahim, S.M. Phang, V. Vello, H.K. Jun, and A.M. Alnahhal, J. Build. Eng. 44 (2021) 102958.

-

- 138. A.G. Miller and B. Colman, Plant Physiol. 65[2] (1980) 397-402.

-

- 139. H.A. Hasan, Commun. Soil Sci. Plant Anal. 31[15-16] (2000) 2565-2589.

-

- 140. M. Dittrich, P. Kurz, and B. Wehrli, Geomicrobiol. J. 21[1] (2004) 45-53.

-

- 141. T. Zhu and M. Dittrich, Front. Bioeng. Biotechnol. 4 (2016) 4.

-

- 142. K. Kumar, C.N. Dasgupta, B. Nayak, P. Lindblad, and D. Das, Bioresour. Technol. 102[8] (2011) 4945-4953.

-

- 143. S. Parmar and D. Marjadi, World J. Res. Rev. 4[3] (2017) 262839.

- 144. A.M. Grabiec, J. Klama, D. Zawal, and D. Krupa, Constr. Build. Mater. 34 (2012) 145-150.

-

- 145. N. Shaheen, R.A. Khushnood, W. Khaliq, H. Murtaza, R. Iqbal, and M.H. Khan, Constr. Build. Mater. 226 (2019) 492-506.

-

- 146. C. Liu, Z. Lv, J. Xiao, X. Xu, X. Nong, and H. Liu, Cem. Concr. Compos. 124 (2021) 104232.

-

- 147. M. Seifan, A.K. Sarmah, A.K. Samani, A. Ebrahiminezhad, Y. Ghasemi, and A. Berenjian, Appl. Microbiol. Biotechnol. 102 (2018) 4489-4498.

-

- 148. S. Han, E.K. Choi, W. Park, C. Yi, and N. Chung, Appl. Biol. Chem. 62 (2019) 1-5.

-

- 149. C. M. Aldea, W. J. Song, J.S. Ppovics, and S.P. Shah, J. Mater. Civ. Eng. 12 (2000) 92-96.

-

- 150. J.-S. Ryu, Mater. Struct. 34 (2001) 433-437.

-

- 151. M. de Rooij, K. V. Tittelboom, N. De Belie, and E. Schlangen in “Self-Healing Phenomena in Cement-Based Materials” (Springer, 2013) p.1

-

- 152. M. Rajczakowska, K. Habermehl-Cwirzen, H. Hedlund, and A. Cwirzen, J. Mater. Civ. Eng. 31[9] (2019) 03119001.

-

- 153. D. Snoeck and N. De Belie, J. Mater. Civ. Eng. 28[1] (2016) 4015086.

-

- 154. D. Gardner, R. Lark, T. Jefferson, and R. Davies, Case Stud. Constr. Mater. 8 (2018) 238-247.

-

- 155. J. Jakubowski and K. Tomczak, Constr. Build. Mater. 422 (2024) 135768

-

- 156. B. Dong, Y. Wang, G. Fang, N. Han, F. Xing, and Y. Lu, Cem. Concr. Compos. 56 (2015) 46-50.

-

- 157. H. Siad, M. Lachemi, M. Sahmaran, H.A. Mesbah, and K.A. Hossain, Constr. Build. Mater. 176 (2018) 313-322.

-

- 158. B. Hilloulin, D. Hilloulin, F. Grondin, A. Loukili, and N. De Belie, Cem. Concr. Res. 80 (2016) 21-32.

-

- 159. W. Zhang, Q. Zheng, A. Ashour, and B. Han, Compos. Part B Eng. 189 (2020) 107892.

-

- 160. B.F. Yip, M.R. Haniffah, E.H. Kasiman, and A.R. Abidin, J. Technol. 84[3] (2022) 25-45.

-

- 161. P. Minnebo, G. Thierens, G. De Valck, K. Van Tittelboom, N. De Belie, D. Van Hemelrijck, and E. Tsangouri, Materials 10[1] (2017) 49.

-

- 162. S. Kashif Ur Rehman, F. Mahmood, M. Jameel, N. Riaz, M.F. Javed, A. Salmi, and Y.A. Awad, Crystals 12[9] (2022) 1222.

- 163. G. Uildmen, A.H. Khiavi, S. Yeşilmen, and M. Şahmaran, Cem. Concr. Compos. 87 (2018) 172-186.

-

- 164. C. Joseph, A.D. Jefferson, B. Isaacs, R. Lark, and D. Gardner, Mag. Concr. Res. 62[11] (2010) 831-843.

-

- 165. J.Y. Wang, N. De Belie, and W. Verstraete, J. Ind. Microbiol. Biotechnol. 39[4] (2012) 567-577.

-

- 166. J.S. Ryu, Mag. Concr. Res. 55[1] (2003) 35-40.

-

- 167. S. Qian, J. Zhou, M.R. De Rooij, E. Schlangen, G. Ye, and K. Van Breugel, Cem. Concr. Compos. 31[9] (2009) 613-621.

-

- 168. K. Sisomphon, O. Copuroglu, and E.A. Koenders, Constr. Build. Mater. 42 (2013) 217-224.

-

- 169. Z. Jiang and W. Li, Z. Yuan, Cem. Concr. Compos. 57 (2015) 116-127.

-

- 170. M. Sahmaran, G. Yildirim, and T.K. Erdem, Cem. Concr. Compos. 35[1] (2013) 89-101.

-

- 171. E. Fregonara and D.G. Ferrando, Sustainability 10[10] (2018) 3642.

-

- 172. A.M. Uguzzoni, G. Anglani, P. Antonaci, and J.M. Tulliani, in New self-healing system for cracks repairing (MATEC Web of Conferences) 378 (2023) p.02014.

-

- 173. X.S. Yang, in International Conference on Unconventional Computing and Natural Computation, September 2012 (Springer, 2012) p. 240-249.

-

- 174. M.F. Md Jaafar, N.O. Ghazali, K.A. Shahid, R.O. Zailan, K.H. Muthusamy, and F.M. Yahaya, Key Eng. Mater. 943 (2023) 213-223.

-

- 175. S. Mirjalili, S.M. Mirjalili, and A. Lewis, Adv. Eng. Softw. 69 (2014) 46-61.

-

- 176. H. Safayenikoo, M. Khajehzadeh, and M.L. Nehdi, Sustainability 14[9] (2022) 4934.

-

- 177. J. Zhao, T. Wu, J. Li, and L. Shi, Multiscale Multidiscip. Model. Exp. Des. 7 (2024) 69-82.

-

- 178. H. Mashhadban, S.S. Kutanaei, and M.A. Sayarinejad, Constr. Build. Mater. 119 (2016) 277-287.

-

- 179. B. Xi, Z. Huang, S. Al-Obaidi, and L. Ferrara, Constr. Build. Mater. 381 (2023) 131261.

-

- 180. M. Ulucan, E. Gunduzalp, G. Yildirim, B. Alatas, and K.E. Alyamac, Struct. Concr. (2024) Apr 10.

-

- 181. L. Sun, M. Koopialipoor, D. Jahed Armaghani, R. Tarinejad, and M.M. Tahir, Eng. with Comput. 37 (2021) 1133-1145.

-

- 182. X. Zhuang and S. Zhou, Comput. Mater. Continua. 59 (2019) 57-77.

-

- 183. Y. Xue, W. Gao, and Y. Zhao, Adv. Civil Eng. 2023 (2023) 1-13.

-

- 184. A. Ashrafian, A.A. Shahmansouri, H. Akbarzadeh Bengar, and A. Behnood, Arch. Civ. Mech. Eng. 22 (2022) 101.

-

- 185. Ł. Sadowski, M. Nikoo, M. Shariq, E. Joker, and S. Czarnecki, Materials 12[2] (2019) 293.

-

- 186. N. Renne, P. Kara De Maeijer, B. Craeye, M. Buyle, and A. Audenaert, Infrastructures 7[10] (2022) 128.

-

- 187. Confederation of Construction, in Annual Report: Construction and Europe Dutch (2014).

- 188. B. Craeye, G. Cockaerts, and P. Kara De Maeijer, Infrastructures 3[1] (2018) 4.

-

- 189. F. Althoey, M.N. Amin, K. Khan, M.M. Usman, M.A. Khan, M.F. Javed, M.M. Sabri, R. Alrowais, and A.M. Maglad, Case Stud. Constr. Mater. 17 (2022) e01610.

-

- 190. H.A. Algaifi, S.A. Bakar, R. Alyousef, A.R. Sam, A.S. Alqarni, M. Ibrahim, S. Shahidan, M. Ibrahim, and B.A. Salami, Smart Struct. Syst. 28[4] (2021) 535-551.

-

- 191. B.G. Aiyer, D. Kim, N. Karingattikkal, P. Samui, and P.R. Rao, KSCE J. Civil Eng. 18 (2014) 1753-1758.

-

- 192. F. Asgharpour and M. Hosseini, Alfa journal of engineering and applied sciences 1 (2024) 33-48.

- 193. S. Chatterjee, S. Sarkar, N. Dey, A.S. Ashour, and S. Sen, in “Hybrid non-dominated sorting genetic algorithm: II-neural network approach” (IGI global publishing, 2018) p. 264-286.

-

- 194. M. Luo, C.X. Qian, and R.Y. Li, Constr. Build. Mater. 87 (2015) 1-7.

- 195. Y.S. Lee and W. Park, Appl. Biochem. Biotechnol. 102 (2018) 3059-3070.

-

- 196. L.B. Barros, M. Knockaert, and R. Tenório, in Analysis of the commercialization barriers of self-healing concrete (MATEC Web of Conferences 378, 2023) p. 10001.

-

- 197. S. Inozemtcev and E. Korolev, in Review of road materials self-healing: problems and perspective (IOP Conference Series: Mater. Sci. Eng. 855, 2020) p. 012010.

-

- 198. I. Justo-Reinoso, N. Arena, B.J. Reeksting, S. Gebhard, and K. Paine, DIBE 16 (2023) 100244.

-

- 199. G. Tyagi, M. Lahoti, A. Srivastava, D. Patil, U.U. Jadhav, and A.S. Purekar, Appl. Biochem. Biotechnol. 196 (2024) 2901-2927.

-

- 200. D. Albuhairi and L. Di Sarno, Buildings 12 (2022) 1196.

-

- 201. S. Arroyave, E. Asensio, J.E. Perilla, P.C. Narváez-Rincón, A. Cadavid, and A. Guerrero, Mater. Today Proceed. (2023) doi.org/10.1016/j.matpr.2023.03.673.

-

- 202. A.K. Das, D.K. Mishra, J. Yu, and C.K. Leung, Adv. Civil Eng. Mater. 8 (2019) 554-578.

-

- 203. R. Goyal, V.K. Verma, and N.B. Singh, Mater. Today Proceed. (2023). https://doi.org/10.1016/j.matpr.2023.03.553

-

- 204. L.B. Barros, M. Knockaert, and J.R. Tenório Filho, Constr. Build. Mater. 403 (2023) 133094.

-

- 205. S.H. Jakhrani, A. Qudoos, A. Rehman, H.G. Kim, I.K. Jeon, and J.S. Ryou, J. Ceram. Process. Res. 20 [special 1] (2019) 1-18.

-

- 206. K.B. Shim, T. Kishi, C.-S. Choi, and T.-H, Ahn, J. Ceram. Process. Res. 16 [special 1] (2015) 1-13.

-

- 207. T.-H. Ahn and T. Kishi, J. Ceram. Process. Res. 16[1] (2015) 117-123.

-

- 208. J.S. Lee, A. Qudoos, A.U. Rehman, H.G. Kim, S.H. Jakhrani, and J.-S. Ryou, J. Ceram. Process. Res. 20[4] (2019) 314-320.

-

- 209. J.H. Kim, Y.-S. Lee, A. Qudoos, H.G. Kim, T.H. Ahn, and J.-S. Ryou, J. Ceram. Process. Res. 20 [special 1] (2019) 70-76.

-

- 210. M.G.S. Beltran and H.M. Jonkers, J. Ceram. Process. Res. 16 [special 1] (2015) 33-39.

-

- 211. H. He, G. Li, J. Zhang, J. Zhang, M. Luo, W. Hu, Y. Lin, Z. Deng, Z. Liu, W. Chen, and X. Deng. J. Ceram. Process. Res. 20[5] (2019) 470-478.

-

- 212. M. Seifan, A.K. Samani, and A. Berenjian, Appl. Microbiol. Biotechnol. 100 (2016) 2591-2602.

-

- 213. M. Amran, A.M. Onaizi, R. Fediuk, N.I. Vatin, R.S. Muhammad Rashid, H. Abdelgader, and T. Ozbakkaloglu, Materials 15 (2022) 3214.

-

This Article

This Article

-

2024; 25(6): 1122-1141

Published on Dec 31, 2024

- 10.36410/jcpr.2024.25.6.1122

- Received on Nov 1, 2024

- Revised on Nov 30, 2024

- Accepted on Dec 5, 2024

Services

Services

Shared

Correspondence to

Correspondence to

- Byoung-In Sang

-

Department of Chemical Engineering, Hanyang University, 222 Wangsimni-ro, Seongdong-gu, Seoul 04763, Republic of Korea

Tel : +82-2-2220-2328 - E-mail: biosang@hanyang.ac.kr

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.