- Color stability of graphene oxide reinforced monolithic zirconia after hydrothermal aging

Nazmiye Şen*

Associate Professor, Department of Prosthodontics, Faculty of Dentistry, University of Istanbul, Istanbul, Turkey

This article is an open access article distributed under the terms of the Creative Commons Attribution Non-Commercial License (http://creativecommons.org/licenses/by-nc/4.0) which permits unrestricted non-commercial use, distribution, and reproduction in any medium, provided the original work is properly cited.

The purpose of the study was to investigate the influence of graphene oxide (GO) and hydrothermal aging on the color stability of monolithic zirconia with different yttria concentrations. Disc shaped specimens (N=60) with a diameter of 15.0mm and a thickness of 1.0 mm were prepared from zirconia blocks having different yttria concentrations (HT, ST, and XT). Half of the specimens were immersed in 0.2 wt% GO-water dispersion (HTG, STG, and XTG). Color parameters were assessed using a reflection spectrophotometer before and after 5 and 10 hours of hydrothermal aging. Color differences (∆E00) were calculated and compared to perceptibility and acceptability visual thresholds. Data were statistically analyzed with 2-way ANOVA followed by post-hoc comparisons (α=.05). Regardless of the aging time applied, ΔE00 values below PT were found in the groups of HT, ST, and XT. Hydrothermal aging significantly increased ΔE00 values in the groups of HTG, STG, and XTG that presented values above AT (p<.001). Immersion in GO-water dispersion significantly increased ΔE00 values of zirconia discs (P<.001). Color stability of zirconia ceramics with graphene oxide reinforcement was affected by hydrothermal aging.

Keywords: Color stability, Monolithic zirconia, Graphene oxide, CIEDE2000.

Yttria-stabilized tetragonal zirconia polycrystal (Y-TZP) characterized by outstanding mechanical properties such as high strength, fracture toughness, corrosion resistance, low thermal conductivity, and wear resistance is used for a wide range of applications in dentistry [1-3]. However, its predisposition to hydrothermal aging known as low temperature degradation (LTD) is considered to be an important disadvantage of the material [2, 4-6]. LTD leads to progressive deterioration of mechanical strength and decreased long-term stability due to the spontaneous transformation of tetragonal (t) grains into monoclinic (m) symmetry when exposed to humid environment [2, 4, 6]. Several methods have been investigated to overcome the negative effects of LTD for creating reliable and successful restorations in the long-term. Increasing yttria content and changing sintering parameters are reported to be effective on both mechanical and optical properties of yttria-stabilized zirconia (YZP) [1, 3]. Nevertheless, the stability of zirconia restorations in the oral cavity due to hydrothermal aging is still crucial [2, 4, 6, 7]. Not only LTD, another critical disadvantage of Y-TZP is low translucency and high opacity that limits the clinical use especially in anterior region [1, 3, 8]. To increase the optical performance of material, several variants of YZP have been introduced by adding different amounts of yttria (Y2O3) [1, 3, 5]. The Y2O3 content was increased to improve light transmission properties by increasing the amount of nonbirefringent cubic phase [1, 5, 9]. However, fabrication of natural looking restorations requires not only matching in optical properties but also color matching (value, hue, and chroma) and color stability [5, 9-11]. For the long-term clinical success of zirconia restorations, color stability has a vital importance to ensure reliable restorations [5, 10, 11].

Recently, graphene and graphene-based nanostructures such as graphene oxide (GO) and reduced graphene oxide (rGO) have attracted considerable scientific interest due to their remarkable intrinsic mechanical properties and extreme strengthening effect [12-15]. Graphene has high potential for use as reinforcing material for different ceramic matrix systems due to its large surface area, high light transmittance,biocompatibility, and chemical stability [12-16]. These properties make the material suitable and influential for the design and manufacture of new ceramic systems to overcome problems associated with the performance of traditional all ceramics [17-19]. Especially, the long-term stability of GO reinforced ceramic systems is crucial and have been reported to be affected by several factors such as processing route, concentration, particle size, shape, and surface characteristics of graphene that might have significant influence on the color properties of final material [12-19]. However, there is limited research available regarding the influence of graphene oxide on long-term stability of zirconia ceramics, which has paramount importance for safe and reliable clinical application of these composites. Therefore, the efficiency of graphene-based nanostructures for the reinforcement of zirconia ceramics needs to be investigated.

The color stability of zirconia ceramics is a concern when the restorations are exposed to different intraoral conditions [10, 11, 20]. Hydrothermal aging is one of the most common approaches used to simulate intraoral aging of zirconia ceramics [9-11]. For this purpose, steam autoclaves providing humidity and varying temperatures under pressure have been used to simulate accelerated aging as indicated by The International Organization for Standardization (ISO) 13356-2015 [21]. The effect of aging obtained via steam autoclaves is reported to be affected by a variety of factors including type of zirconia material, aging time, and temperature that may lead to changes in the color properties, eventually [4, 5, 9, 10].

The influence of GO on the color stability of monolithic zirconia with different yttria concentrations after hydrothermal aging have not been thoroughly investigated. Therefore, the aim of the present study was to reveal the influence of GO on the color stability of monolithic zirconia after hydrothermal aging. The null hypothesis was that color coordinates of monolithic zirconia would not be affected by graphene oxide reinforcement and hydrothermal aging.

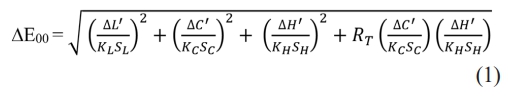

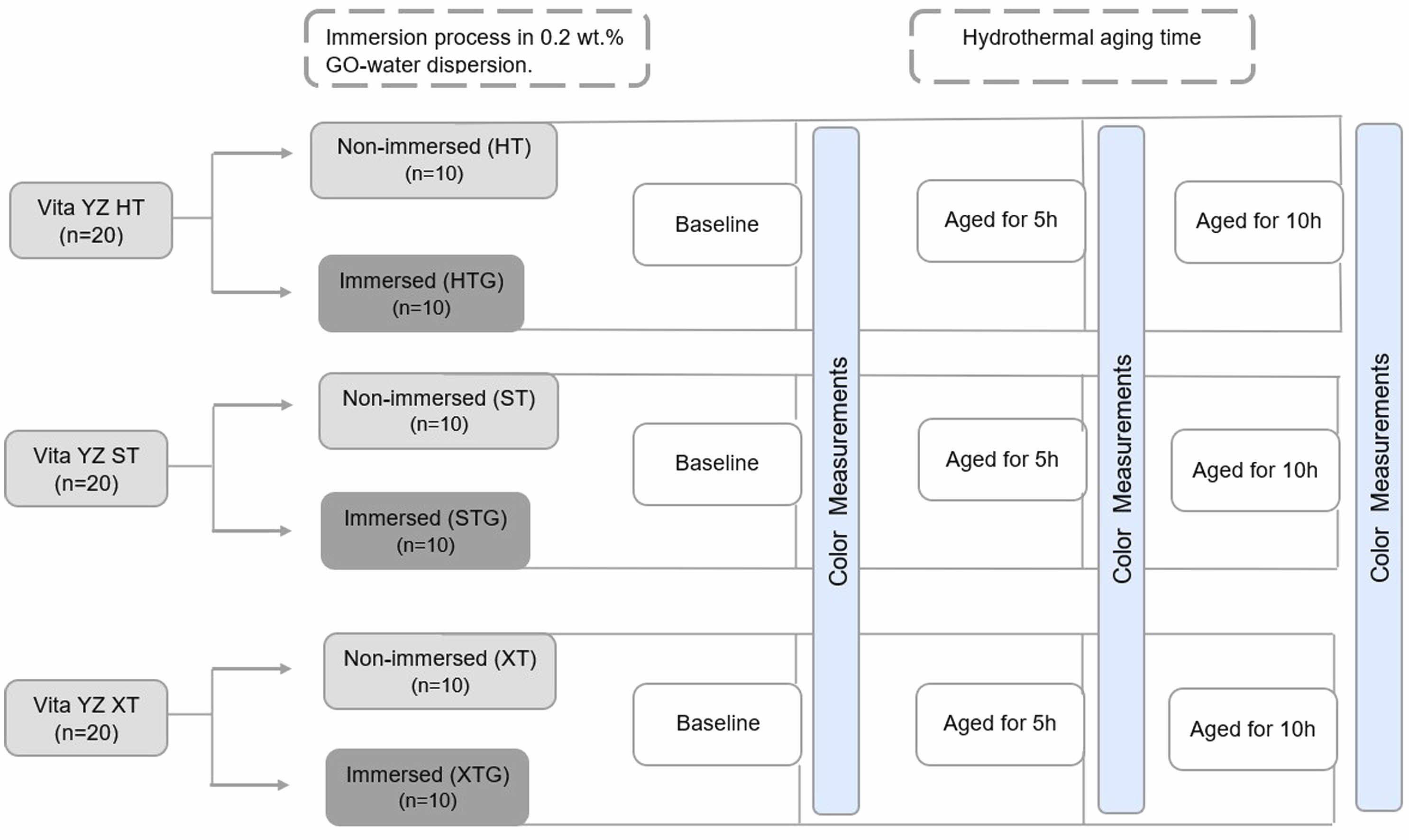

Zirconia blocks characterized by different yttria concentrations [YZ-HT (HT), YZ-ST (ST), and YZ-XT (XT) (Vita Zahnfabrik, Bad Säckingen, Germany)] were used to prepare disc-shaped specimens using CAD-CAM technology (Ceramill Motion 2; Amann Girrbach AG). Table 1 shows the information of materials used in this investigation. A total of 60 white monolithic zirconia discs with a diameter of 15.0 mm and a thickness of 1.0 mm were milled. Half of the specimens (n=30) were immersed in 0.2 wt% GO-water dispersion (Nanografi) for 1-minute and then rinsed with distilled water for 1 to 2 seconds. The discs were then dried under an infrared drying lamp for 20 minutes (Zirkonlamp 250; Zirkonzahn GmbH) (Fig. 1). All the zirconia discs were sintered according to manufacturer’s instructions to reach final dimensions (15.0 mm and 1.0 mm thickness). The final sintering temperature was 1530 °C for the discs of ST and STG; 1450 °C for HT, HTG, XT, and XTG with 2 hours dwell time at the final sintering temperature (VITA Zyrcomat 6000 MS; VITA Zahnfabrik). The heating rate was 8 °C/minute for HT, HTG; 17 °C/minute for ST, STG; and 4 °C/minute for XT, XTG.

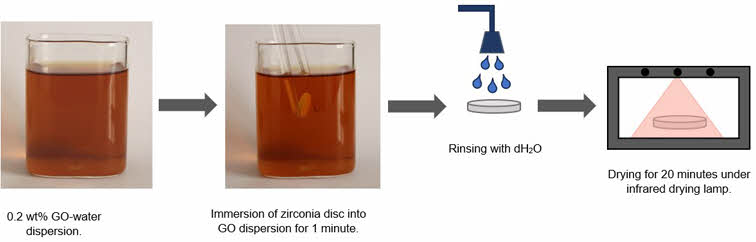

The hydrothermal aging process was applied in an autoclave (29VS Plus; Melag) at 134 °C under 0.2 MPa steam pressure for 5 and 10 hours, in accordance with the International Organization for Standardization (ISO) 13356:2015 standard for flat samples [21]. One hour at 134 °C was reported to be roughly equivalent to 2-4 years at 37 °C [22]. To evaluate the color differences of the specimens, consecutive spectrophotometric analyses were performed at baseline and after 5 and 10 hours of hydrothermal aging (Fig. 2).

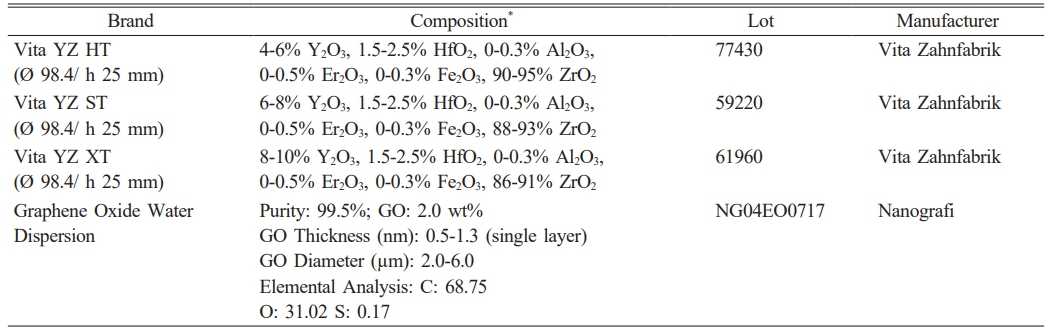

The color differences of the specimens were measured using a reflection spectrophotometer (Color Eye 7000A Xrite; GretagMacbeth) upon a white backing in the wavelength range of 400 to 700 nm at 10-nm data intervals. Calibration of the spectrophotometer was conducted with a standard white (CIE L*=88.83, a*=−4.95, b*=−6.07) backing after each measurement. The CIEL*a*b* coordinates were determined using the standard Commission Internationale de L’éclairage (CIE) illuminant D65 and 2- degree observer function [23, 24]. Color differences were calculated using CIEDE2000 (ΔE00) color difference metric according to following equation [25]:

ΔL', ΔC', and ΔH' correspond to differences in lightness, chroma and hue [25]. RT is the rotation function used for chroma and hue differences in the blue region. KL, KC, and KH are the parametric factors that are set at 1.0 for the present study. Color differences were assessed in accordance with recent data on 50:50% perceptibility (PT: ΔE00=0.81) and 50:50% acceptability (ΔE00=1.77) color thresholds [24, 25].

Data sets were analyzed using a statistical software program (IBM SPSS Statistics, v24; IBM Corp). The normality of data distribution was assessed by Shapiro-Wilk test. Two-way analysis of variance (ANOVA) followed by post hoc comparison tests were applied to analyze color variation data (α=.05).

|

Fig. 1 Schematic illustration of immersion process of zirconia discs in 0.2 wt.% GO-water dispersion. |

|

Fig. 2 Study design. |

|

Table 1 Materials used in the present study. |

*As disclosed by the manufacturers |

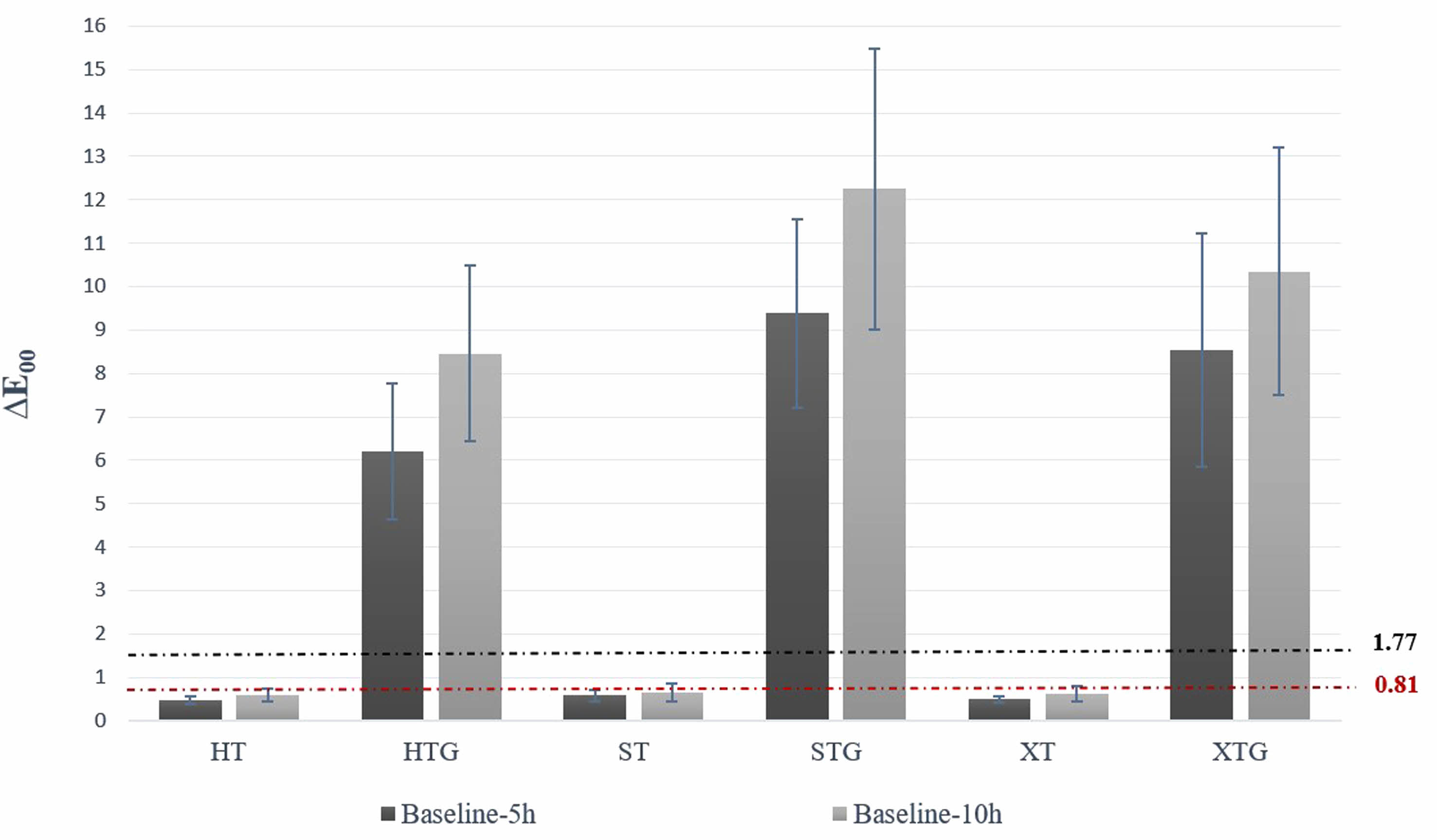

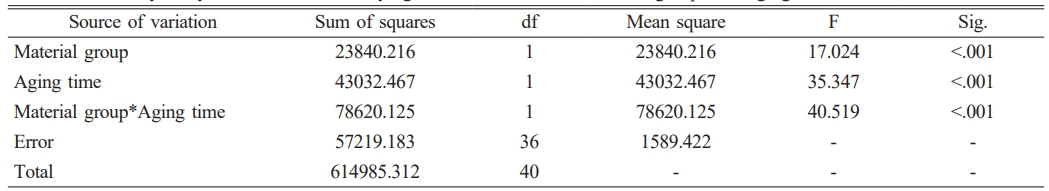

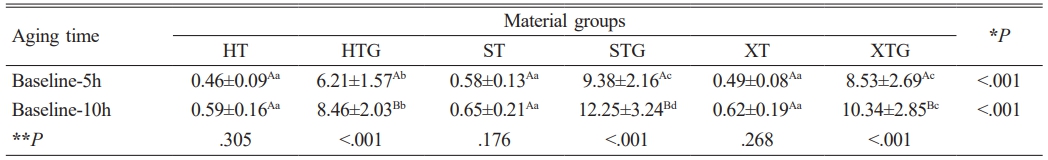

Two-way ANOVA analyses indicated significant interactions between material groups and aging time for ΔE00 values (P<.001) (Table 2). The mean ±SD values of ΔE00 are summarized in Table 3. The lowest ΔE00 was obtained in the material group of HT and followed by the groups of XT and ST aged for 5 hours. Hydrothermal aging significantly increased ΔE00 values in the material groups of HTG, STG, and XTG that presented values above AT (p<.001) (Table 3). Significantly higher mean ΔE00 values were obtained in the groups of HTG, STG and XTG as the aging time increased from 5 hours to 10 hours (p<.001). There were no significant differences in the groups of HT, ST, and XT for different aging conditions (p>.05). Regardless of the aging time applied, ΔE00 values below PT were recorded for the material groups of HT, ST, and XT. The highest ΔE00 value was obtained in the material group of STG aged for 10 hours. Immersion in GO dispersion significantly increased the ΔE00 values of zirconia discs (HTG, STG, and XTG) when compared to zirconia discs without GO immersion (HT, ST, and XT) (p<.05).

The present study investigated the influence of GO and hydrothermal aging on the color stability of monolithic zirconia having different yttria concentrations. The null hypothesis was rejected based on the results revealing significant interactions of GO and hydrothermal aging on the ΔE00 values of zirconia ceramics.

Several methods including sintering temperature alterations, various additives and yttria concentrations have been studied to improve the mechanical and optical properties of zirconia ceramics [1-3]. Recently, graphene-based nanostructures are considered as suitable alternatives for the reinforcement of ceramic systems [13-19]. The research activity is especially focused on the enhancement of mechanical properties such as fracture toughness and flexural strength by transferring the excellent mechanical properties of graphene to the zirconia ceramics [13-19, 26]. However, graphene can cause difficulties while being mixed with different materials due to its special molecular structure [16, 26]. Different forms of graphene with different production techniques have been studied [13-19, 26]. Among different graphene-based nanostructures, GO has attracted considerable interest due to its hydrophilicity and high solubility in water which helps to prepare compatible ceramic composites [26]. Recent studies on zirconia composites with the addition of GO have shown improvement in mechanical strength [13-19]. However, the influence of GO reinforcement on zirconia ceramics varied among the studies depending on the amount, aspect ratio, thickness, dispersion method and processing route of GO content [16, 26, 27]. Not only the GO content, as it was investigated in the present study, yttria concentration of zirconia ceramic also influenced the resulting color properties [5]. Although there are studies reporting the mechanical, physical, and microstructural features of these composites [13-19, 26, 27], the number of published data is very scarce. To the best of author’s knowledge, no published data is available regarding the color stability of GO reinforced zirconia ceramics.

In this study, color differences were assessed before and after hydrothermal aging to clarify the influence of GO reinforcement on the color stability of zirconia ceramics following different aging conditions. Although aging progresses very slowly in the oral cavity, it has been reported to lead to failures, eventually [9, 11]. Therefore, investigating the influence of artificial aging on the color stability of zirconia ceramics is necessary to predict the long-term clinical success of restorations.

Color and appearance have been considered to be the key factors in determining the success of restorations in esthetic dentistry [1, 3, 5]. Color stability is an important clinical factor for material selection to achieve desired esthetics in long-term [5, 10, 11]. The CIEDE2000 color difference formula was used to calculate the color differences in the present study. Traditionally, CIELab color difference formula is used for the assessment of perceptibility and acceptability of color differences [23-25]. However, CIELab color space is reported to be non-uniform and CIEDE2000 color difference formula is recommended to achieve a better correlation with visual perception [25]. Visual thresholds for color discrimination of dental materials have been used for interpretation of color related findings and as a quality control tool [5, 10, 11, 28]. According to the International Organization for Standardization (ISO 28642:2016), color differences should be assessed based on 50:50% perceptibility (PT) and 50:50% acceptability (AT) color thresholds [24, 29]. The color difference between PT and AT is reported to be an acceptable match while the color difference above AT is considered to be an unacceptable match [29]. The color difference below PT is considered an excellent color match [29]. In the present study, statistically different values of ΔE00 were obtained among different material and aging groups. Color differences below PT were obtained in the material groups of HT, ST, and XT. Hydrothermal aging did not create significant influence on zirconia ceramics with varying yttria concentrations (HT, ST, and XT). The effect of hydrothermal aging on the color coordinates of zirconia ceramics has been investigated in previous studies [5, 9-11, 18, 28]. Contradictory results have been reported regarding the influence of aging on the color differences of zirconia ceramics. In a recent study by Miura et al, the influence of hydrothermal aging on the color coordinates of zirconia ceramics with different yttria concentrations were evaluated.5 The authors concluded that ΔE00values increased significantly after aging for the zirconia ceramics with a higher yttria content [5]. There are also studies that reported no significant influence of hydrothermal aging on the color coordinates of zirconia ceramics [10, 11]. Differing results among the studies could be attributed to different testing conditions, sintering temperatures, aging durations, and zirconia brands used. In the present study, immersion in 0.2 wt% GO-water dispersion significantly increased the ΔE00 values of zirconia ceramics (HTG, STG, and XTG) both in 5h and 10h aging groups. Significantly higher ΔE00 values were obtained in the HTG, STG, and XTG groups after hydrothermal aging. The greatest color difference was obtained in the STG group after 10 hours of ageing. This finding could be attributed to the biggest disadvantage of graphene-based nanomaterials that they are black and produce esthetic drawbacks [12, 26]. Due to the reduction of GO after hydrothermal aging, the ΔE00 values of HTG, STG, and XTG are considered to increase significantly [26, 27]. The differences of ΔE00 values among HTG, STG, and XTG could be explained by referring to differences in microstructure, chemical composition, and sintering temperatures of the materials [1, 3, 8]. Further research using different GO concentrations with different aging conditions including thermomechanical and ultraviolet aging is needed to verify the magnitude and direction of shifts in the color stability of GO reinforced zirconia ceramics. Fig. 3

|

Fig. 3 CIEDE2000 (ΔE00) color differences of materials with different aging conditions. Horizontal lines represent visual thresholds for 50:50% perceptibility (∆E00 =0.81) and acceptability (∆E00 =1.77). |

|

Table 2 Two-way analysis of variance identifying interactions between material groups and aging time. |

*R Squared =.570 (Adjusted R Squared =.535) |

|

Table 3 Mean and standard deviation values of ΔE00 considering different aging times and material groups. |

*Different capital letters show statistical differences for mean ΔE00 values between aging time in the same material group (column). |

Based on the findings of this study, the following conclusions were drawn: Color coordinates of zirconia ceramics with different yttria concentrations were not affected by hydrothermal aging.

Immersion in 0.2 wt% GO-water dispersion significantly increased the ΔE00 values of zirconia discs.

The color stability of zirconia discs immersed in 0.2 wt% GO-water dispersion was affected by hydrothermal aging.

The author would like to thank Vita Zahnfabrik for providing zirconia blocks and Nanografi for preparing GO dispersion used in the present study.

- 1. N. Sen and S. Isler, J. Prosthet. Dent 123[5] (2020) 761-768.

-

- 2. B.D. Flinn, A.J. Raigrodski, L.A. Mancl, R. Toivola, and T. Kuykendall, J. Prosthet. Dent 117[2] (2017) 303-309.

-

- 3. N. Sen, I.B. Sermet, and S. Cinar, J. Prosthet. Dent 119[2] (2018) 308.e1-308e7.

-

- 4. S.R. Ha and Y.E. Choi, Ceram. Int. 47[12] (2021) 17057-17068.

-

- 5. S. Miura, A. Shinya, H. Koizumi, P. Vallittu, L. Lassila, and M. Fujisawa, Dent. Mater. J 43[2] (2024) 164-171.

-

- 6. S. Wille, P. Zumstrull, V. Kaidas, L.K. Jessen, and M. Kern, J. Mech. Behav. Biomed. Mater 77 (2018) 171-175.

-

- 7. I.A. Alraheam, T. Donovan, L. Boushell, R. Cook, A.V. Ritter, and T.A. Sulaiman, J. Prosthet. Dent 123[4] (2020) 635-640.

-

- 8. D. Ozturk, N. Sen, and S. Isler, Biomed. Tech. (Berl) 69[3] (2023) 249-255.

-

- 9. N. Lümkemann and B. Stawarczyk, J. Prosthet. Dent 125[3] (2021) 518-526.

-

- 10. A. Theocharidou, E. Kontonasaki, I. Koukousaki, A. Koumpouli, I. Betsani, and P. Koidis, J. Prosthet. Dent 127[3] (2022) 479-488.

-

- 11. H.J. Shin, Y.H. Kwon, and H.J. Seol, J. Prosthet. Dent 130[2] (2023) 254.e1-254.e10.

- 12. A.M. Apostu, I.G. Sufaru, O. Tanculescu, S. Stoleriu, A. Doloca, A.A. Ciocan Pendefunda, and S. Solomon, Biomedicines 11[9] (2023) 2354.

-

- 13. V. Morales-Flórez and A. Domínguez-Rodríguez, Prog. Mater. Sci. 128 (2022) 100966.

-

- 14. G. Meng, Y. Sui, S. Liu, Q. Tian, X. Cui, and Y. Wu, J. Ceram. Process. Res. 23[6] (2022) 831-838.

-

- 15. I.J. Shon, Ceram. Process. Res 17[11] (2016) 1171-1174.

-

- 16. R. Moriche, E. Guisado-Arenas, C. Munoz-Ferreiro, C. Lopez-Pernía, A. Morales-Rodríguez, E. Jimenez-Pique, A. Gallardo-Lopez, and R. Poyato, Ceram. Int. 50[11] (2024) 1917-1927.

-

- 17. A. Morales-Rodríguez, C. Gonzalez-Orellana, A.A. Pérez-García, C. Lopez-Pernía, C. Munoz-Ferreiro, R. Poyato, and A. Gallardo-Lopez, J. Eur. Ceram. Soc 42[4] (2022) 1784-1795.

-

- 18. T.V. Khai, P.T. Trang, L.N. Long, L.V. Thang, T.D. Chau, V.V. Dat, and M.T. Phong, J. Ceram. Process. Res 22[4] (2021) 425-435.

-

- 19. Z. Xiulinga, C. Yuhonga, L. Limenga, Q. Wubina, H. Wanxiua, X. Mina, and H. Tianxianga, J. Ceram. Process. Res 25[4] (2024) 483-489.

-

- 20. H.K. Kim and S.H. Kim, J. Prosthet. Dent 121[4] (2019) 676-682.

-

- 21. International Organization for Standardization, ISO 13356:2015 Implants for Surgery - Ceramic Materials Based on Yttria-Stabilized Tetragonal Zirconia (YTZP), International Organization for Standardization, Geneva, Switzerland, 2015.

- 22. J. Chevalier, B. Cales, and J.M. Drouin, J. Am. Ceram. Soc 82[8] (1999) 2150-2154.

-

- 23. Commission Internationale de lEclairage, CIE Pub No. 15.3 CIE technical report: colorimetry. Vienna: CIE Central Bureau; 2004.

- 24. International Organization for Standardization. ISO/TR 28642: Dentistry-Guidance on Color Measurement. Geneva: International Organization for Standardization; 2016.

- 25. G. Sharma, W. Wu, and E.N. Dalal, Color. Res. Appl 30[1] (2005) 21-30.

-

- 26. X. Li, X. Liang, Y. Wang, D. Wang, M. Teng, H. Xu, B. Zhao, and L. Han, Front. Bioeng. Biotechnol 10 (2022) 804201.

-

- 27. Z. Zeng, Y. Liu, W. Chen, X. Li, Q Zheng, K. Li, and R. Guo, J. Am. Ceram. Soc 101[8] (2018) 3498-3507.

-

- 28. M. Kurt and B. Turhan Bal, J. Prosthet. Dent 121[4] (2019) 712.e1-712.e8.

-

- 29. M. Perez Mdel, R. Ghinea, L.J. Herrera, A.M. Ionescu, H. Pomares, R. Pulgar, R.D. Paravina, J. Dent 39[3] (2011) e37-e44.

-

This Article

This Article

-

2024; 25(6): 1007-1012

Published on Dec 31, 2024

- 10.36410/jcpr.2024.25.6.1007

- Received on Aug 16, 2024

- Revised on Sep 24, 2024

- Accepted on Nov 5, 2024

Services

Services

- Abstract

introduction

experimental

results and discussion

conclusions

- Acknowledgements

- References

- Full Text PDF

Shared

Correspondence to

Correspondence to

- Nazmiye Şen

-

Associate Professor, Department of Prosthodontics, Faculty of Dentistry, University of Istanbul, Istanbul, Turkey

- E-mail: nazmiye.sonmez@istanbul.edu.tr

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.