- Encapsulation of combined bacterium in clay pellet and silica gel for the autogenous healing of concrete

DhivakarKarthick Mania,*, Gobi Subburaj Rampradheepb, Sampathkumar Velusamyb and Hema Sudhakarc

aDepartment of Civil Engineering, Erode Sengunthar Engineering College, Thudupathi, Erode, Tamil Nadu, India - 638057

bDepartment of Civil Engineering, Kongu Engineering College, Perundurai, Erode, Tamil Nadu, India 638060

cDepartment of Civil Engineering, Sri Ramakrishna Engineering College, Coimbatore, Tamil Nadu, India 641022This article is an open access article distributed under the terms of the Creative Commons Attribution Non-Commercial License (http://creativecommons.org/licenses/by-nc/4.0) which permits unrestricted non-commercial use, distribution, and reproduction in any medium, provided the original work is properly cited.

Autogenous healing material remains a type of exclusive material with the structural capacity to repair mechanical wear and tear over time. Environmentally sustainable autogenous healing materials with lower carbon content are in peak demand across the globe. The investigation was carried out on the immobilization of Bacillus bacteria (megaterium, subtilis) which made a novel bacterium for self-healing concrete. The pH values and temperature are maintained at 4, 7, 10, and 25 °C to 34 °C upon bacterial cultivation, respectively. Clay pellets were used to immobilize the most prominent and positive-sustaining bacteria at 32 °C. The clay pellets are well-shaped and dried to develop efficiency better than wet clay pellets. Those immobilized bacteria in clay pellets are diversified into the concrete and the results are compared to concrete with immobilized bacteria in silica gel. The strength parameters are assessed through compression, tension, and flexure tests as well as water absorption test. Sorptivity analysis ensures the durability of concrete. The crack healing efficiency of potential bacteria is finally found and satisfying. The characterization of clay pellets and bacterial concrete ensures the precipitation produced by the novel bacterium under a favorable methodology. The bacterial concrete integrated with clay pellets with 105 cells/mg-1 produces promising results in all the scales, pre-and post-cracking. Decisively, the catalyst quickly reacted efficiently and prevented the crack from spreading further.

Keywords: Microbial, Bacterial concrete, Bacillus, Clay pellets, Element mapping.

Traditional concrete experiences one disadvantage: it cracks when subjected to tensile pressures. Cracking in concrete structures is caused by a variety of circumstances, including design and detailing errors, changes in temperature and relative humidity, as well as drying shrinkage when the concrete is confined, and stress caused by dynamic loading [1-4]. Concrete cracking remains a significant problem that affects the performance and toughness of a concrete building by admitting water and various types of weathering agents into the concrete. Crack risks severely restrict the efficiency of concrete composites and the operation of concrete buildings [5-7]. The unavoidable presence of fractures may diminish its benefits like the service life of the concrete. The expense of crack identification and repair is exorbitant. Conventional concrete restoration methods, including cement replacement or chemical additives, are limited to accessible cracks and are also tedious and expensive [8-10]. Surface restoration, pressure grout, infill, and cement replacement are currently popular mending procedures in engineering construction. Globally, there is an increasing need for sustainable environmentally friendly building materials that use little energy and emit less carbon [11-16].

The microbial-induced mineralization technique and its use to heal concrete fractures have lately gained much interest due to advancements in concrete and microbiological technology [17-23]. Autogenous healing in concrete has been long recognized, and several studies have been conducted to understand the fracture healing process. Handling several types of bacteria, the self-healing process generates and precipitates calcium carbonate and calcium lactate as bio-depositions are studied [24-29]. There are two forms of self-healing in concrete: autogenous healing and autonomous healing. Although concrete is vulnerable to cracking, it offers the potential to close its fissures on its own to some level owing to autogenous self-healing. In addition to substituting concrete with recycled resources, concrete may benefit from affordable native ingredients to optimize and promote green roofs. Crack healing studies, on the other hand, discovered that the greatest healing occurred in surface fractures with the highest colony count and ca lac concentration. Immobilization represents an excellent way of preserving the high-efficiency mineral-forming potential of implanted bacteria in bacterium-based autogenous healing concrete throughout time [30-34].

The bacteria were discovered by their capacity to thrive in alkaline environs of cement/concrete [57-59]. By experimenting and testing various healing agents like powder and capsule, microbial self-healing concrete in various ratios and techniques [35-40]. In this study, several modified concretes were made by replacing the conventional Portland cement (OPC) with an optimal proportion of effective microorganisms (EM) and fly ash (FA) [41-43]. The advantages discovered as the presence of effective microorganisms aided to minimize the heat of hydration and water loss of the Fly Ash OPC concrete, consequently increasing the premature compressive strength by up to 30%. Among the specimens created using merely OPC and FA as an OPC replacement, the specimens prepared with EM and FA combined possessed the maximum compressive strength [44]. The findings suggested that the bacterial self-healing capacity was not only formed at a recent age but on top grew significantly with time, to the point where the maximum width of fractures could be entirely repaired [45-48].

The purpose of this study is to develop bacteria-based autogenous concrete with encapsulated Bacillus subtilis and Bacillus megaterium for crack self-healing. Encapsulation will protect the bacteria and allow their controlled release when cracks appear, promoting bio-precipitation of minerals to seal the cracks. This research will involve creating a new liquid-tight bacterial strain, comparing its effectiveness with encapsulated forms in concrete against traditional healing materials like silica gel and clay pellets, and finally, evaluating the bacteria’s ability to absorb water (sorption) within the concrete matrix. The following endures the expected consequence of this work:

• To create a new bacterium using Bacillus subtilis and Bacillus megaterium that is liquid-tight for bio-precipitation.

• To compare the competent bacteria encapsulated in self-healing concrete with silica gel and clay pellets.

• To determine the bacterial specimen’s sorptivity and describe the concrete with a prospective crack healing bacterium.

A novel form of the core-shell carrier was designed and prepared to extend the life duration of microorganisms in concrete. Bacillus megaterium and Bacillus subtilis, as well as a mixture of both, are employed in this investigation [1, 7, 29, 30]. Bacterial growth was seen under various circumstances. In the concrete mix water, the bacterial concentration obtains 105 cells.ml-1. Concrete containing microbial self-healing agents of the ureolytic type encapsulated in permeable granules has a higher fracture healing capacity [10, 11, 31, 32]. Using a ureolytic microbial nutrition solution with water-reducing compounds.

The introduction of calcite precipitation bacteria Bacillus subtilis SBI [ICAR] & TNAU, Bacillus Megaterium NBALL [ICAR] & TNAU, and their combination is compared as organic ingredients in concrete, together with calcium lactate pent hydrate and urea [44, 45]. The presence of EM was recognized as a benefit in water loss of the FA-OPC concrete and reducing the heat of hydration. As a result, the early compressive strength is increased [26, 47, 48]. Microbial concrete research has mostly focused on spore-forming microbes, like the Bacillus type, since they may survive in adverse circumstances such as excessive alkalinity and limited water supply by producing spores [4, 7].

The CO2 carbonation process produces calcium carbonate and silica gel by interacting with the aggregate’s existing hydration products [7, 39, 44]. The microcapsule approach employs a healing substance deployed when a fracture occurs and then self-heals with the same [2, 11, 20]. Bacteria that produce urease can improve the strength and durability of concrete [49, 51, 60]. This is because the urease catalyzes a reaction that produces calcium carbonate crystals. These crystals fill in the pores and cracks of the concrete, making it denser and stronger.

Auto clave

An autoclave remains a piece of equipment that utilizes high-pressure vapour to dispose of microorganisms, viruses, and even spores found in the medium inside the container. The autoclave sterilizes goods by thawing them to a particular temperature for a distinct period of time [40, 41, 43].

Laminar air flow cabinet

A laminar airflow chamber is a securely enclosed workstation designed to protect silicon wafers, biological material, and particulate products. The air flows smoothly and is luminary concerning the operator. Due to the general orientation of a flow of air, the specimen is protected from the person, but the viewer is uncovered by the sample. The cabinet is normally made out of stainless steel, with no cracks or cracks where spores might accumulate.

Bacterial cultivation

Agar-agar is added to the distilled water, the above-mentioned components are made by the component of the contained weight (g) of 200 milliliters solution in distilled water and 5.68 gram of agar. The add-on & mixture heated for dissolving, emphasis pH is 7.0-7.2 and 15 pounds of pressure were sterilized 20-30 minute down. This rapidly develop and grow bacterial liquid after autoclave process preparation medium pouring the bacteria on Petri plate. After 1 hour bacteria sprite on petri plate [5, 9, 36, 46]. Predominantly check pH range and temperature.

Selection of clay

Choosing the correct clay remains a critical decision. There are many other varieties of clay, but most potters stick to three primary types, each with its own set of advantages and firing temperatures [24, 29]. Earthenware may represent the ideal alternative for individuals looking for a lump of lower firing clay. These clays are less durable, more porous, and more plastic (easier to mold). Stoneware has a high heat tolerance and may be used in a variety of ways since it is denser and more robust than other clays. Because it is also flexible, this clay represents an excellent choice for novices (easier to mould). Smooth Porcelain has a high heat tolerance, but it is more elastic (does not mould as easily), making it more difficult to work with for novices. The beginnings of river Kaveri, Tamilnadu, India are recognized as the supply of clay.

Wedging of clay

Wedging your clay is a vital process that should be overlooked for various reasons. Most essential, it removes any air bubbles that may be present in the clay. Wedging also enhances workability by providing a homogeneous consistency and moisture level throughout the clay.

Pinch pot

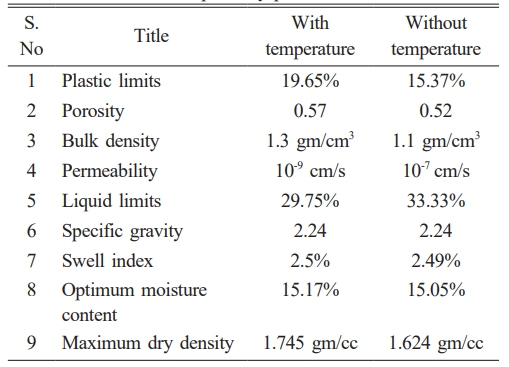

One of the securest methods for producing clay pellets is the pinch pot method. Simply mould a lump of clay into the desired shape. The maximum diameter of clay pellets is bare than 10 mm. After preparing the clay pellets for 28 days of exposure to the sunshine. After 28 days, heat the clay pellets [44] for 1 hour at 30°C to 40°C. Physical properties of clay pellets are shown on Table 1.

Silica gel preparation

Silica gel obtained from SIPCOT Unit, Perundurai is purely a porous, formless mixture of silicon oxide and silicon atoms. When heated over 550 degrees Celsius, all of these translucent beans liberate the trapped chemicals. The silica gel absorbs and releases bacterial compounds under severe circumstances. The constitutional qualities of silica solution include high density (570-700 g/l) and glassy form. The pH of wet extract be 5-6.5% and the rustiness is 99.9% [20, 44].

In this work, self-healing concrete was made operating a microbial carrier and its fracture healing potential was studied. Compressive strength and flexural tests are two of the tests used to evaluate the material [10, 12, 23, 48]. The final concrete mixer’s structural efficiency and microstructure attributes were obtained as a function of the EM and FA replacement for OPC. Furthermore, SEM, EDS, and XRD were used to analyse the microstructure of concrete [13, 17, 28, 32, 36, 37].

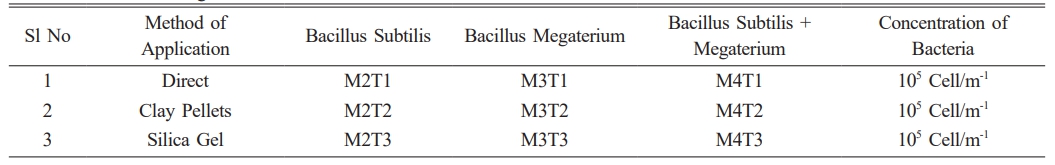

A specific combination of Bacillus subtilis and Bacillus megaterium was used at a constant concentration of 105 cells/ml as shown in Table 2. Clay pellets and silica gel were compared as carrier materials, and concrete specimens were cured under controlled temperature and humidity conditions [50]. The vital goal of this research is to assess the mechanical characteristics of induced fractured concrete specimens by inserting cement capsules with bacteria for crack healing [1, 25, 33].

The concrete specimen is cast and heat hardened evaluated for average compressive strength for a cube, average tensile strength for a cylinder, and average prism flexural strength for an optimal proportion of cultured bacteria with a fixed capsulation of 105 cell/ml based on cement weight. Strength tests are performed on cynical conventional cement concrete and bacterial concrete at 28 and 90 days of age.

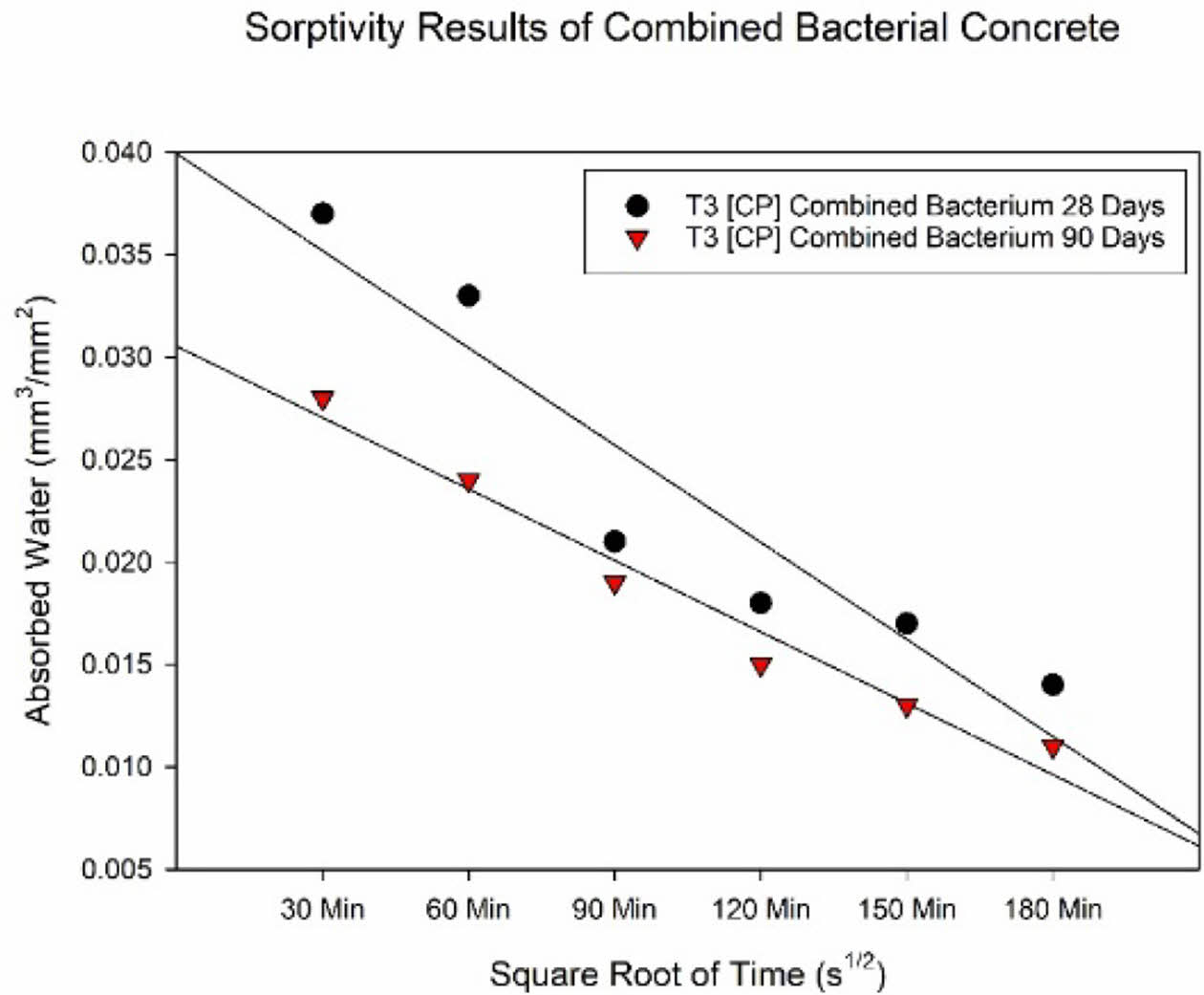

Sorptivity test

Sorptivity represent a measurement of the rate of water transfer on the pores in real time via capillary suction. The specimen utilized is a 50 mm cylinder with a 100 mm quantity of both normal and self-healing tangibles [7, 11, 19, 40]. Individuals are oven dried at 110 oC for 24 hours before being allowed to cool in a dry state for another 24 hours. The test is conducted by exposing one surface of the specimen to mineral water at a depth of 5 mm, as specified in the ASTM C 1585 04e1 matrix of practice. The remarkable section of the beautiful example (other than 5 mm) is coated with highly qualitative normal water proofer (High Attach Polymers) to create a one-way flow pattern through the concrete kind of beauty. Water Sorptivity (thru capillary suction) tests are performed on solid conservative concrete floors and self-healed concrete at the age of 28 days to determine the quantity of water absorption at the given time intervals of 30 min, 75 min, 90 min, 120 min, 150 min, and 180 min.

The following formula is used to calculate the amount of water Sorptivity for the cylinder sample:

Were,

W = Weight of water absorbed in gms

A = Cross sectional area of specimen in cm2

√t = Time in mins.

K = Sorptivity coefficient

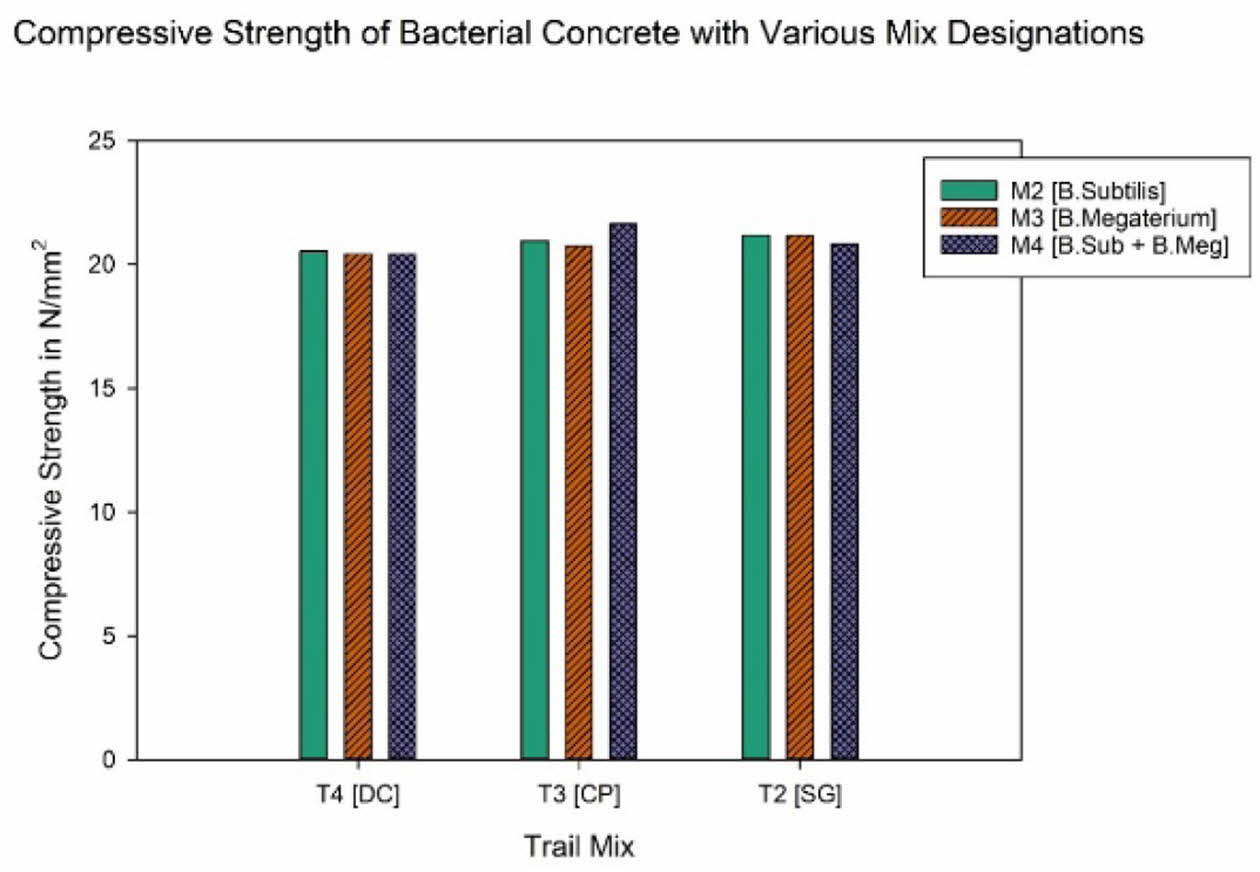

For each type of bacterial culture shown in table 3, three types of trial mixtures are examined for strength behaviour. Figs. 1-4 show that there was a minor variance in the output of each inquiry for all types of combinations, and the average difference under respective condition was used.

Compressive strength

From Fig. 1, For curing age of 28 days the growth of bacterial strains in M4T3 has higher potential than other mix designations. For bacteria bacillus subtilis mix performs better with capsulation rather than direct application of bacterium. The bacterial bacillus megaterium mix with silica gel retain higher strength associated with other method of concrete preparation. And comparing novel bacteria mix with bacillus megaterium mix the combined bacterium mix incorporated with clay pellets has higher potential [12, 28, 43]. But the reduction in strength is obtained mainly due to the cement has lower elasticity modulus than aggregate. The peak strength for the cube compression test is determined to be obtained for the unique bacteria mix, M4T2 greatest of all other specimens. Bacteria in concrete trigger a process that produces calcium carbonate. This calcium carbonate acts as a filler, strengthening the concrete by filling in tiny cracks and pores [52, 57]. This makes the concrete denser and more resistant to compression, which increases its compressive strength. The potential of clay pellets has better efficiency in controlled conditions. In silica gel method both the bacterium possesses more or less similar results due to the metabolic activity of bacteria towards glycolysis [20, 29, 45]. By comparing both the method clay pellets and silica gel we get the greater encapsulation with clay pellets are viable than silica gel.

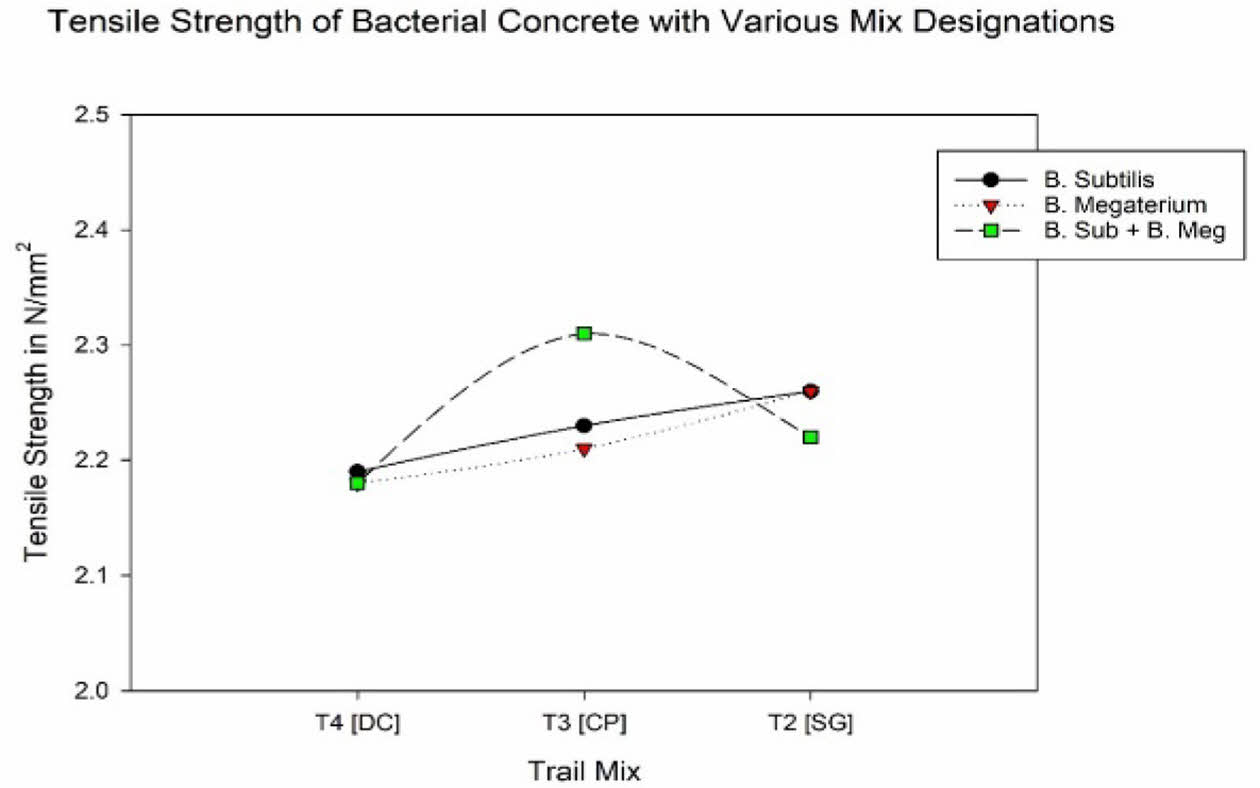

Split tension strength

The conventional cylinder is made and tested for the tensile to find the behaviour for 28 days. From Fig. 2, It has been discovered that M4T2 cells with a mixture of bacteria which is greater tensile strength than other form of specimens. For bacteria bacillus subtilis mix with silicone gel possess promising results due to its bacteriostatic properties [3, 29, 45]. For bacteria megaterium mix has negligible resistance towards tensile strength compared with novel bacterium mix. By comparing novel bacteria mix and bacillus subtilis mix the designated concrete mix with clay pellets has better potential. But comparing novel bacteria mix with bacillus megaterium mix the clay pellets play a controlled strength behaviour due to influence of moisture content. However, the drop in strength relies more on the bond between materials, which may be weakened by the bacteria’s activity and growth [24, 33, 36, 42]. The peak strength for tension test is discovered for unique bacterium mix M4T2 greatest of all other specimens which is also 6.5% higher than conventional mix. Considering methods of application, clay pellets with combined bacterium mix has higher strength than other forms. In silica gel method both the mix possess similar results in terms of combinations and combined matrix. By comparing both the method clay pellets and silica gel we get combined bacterium mix can be utilized.

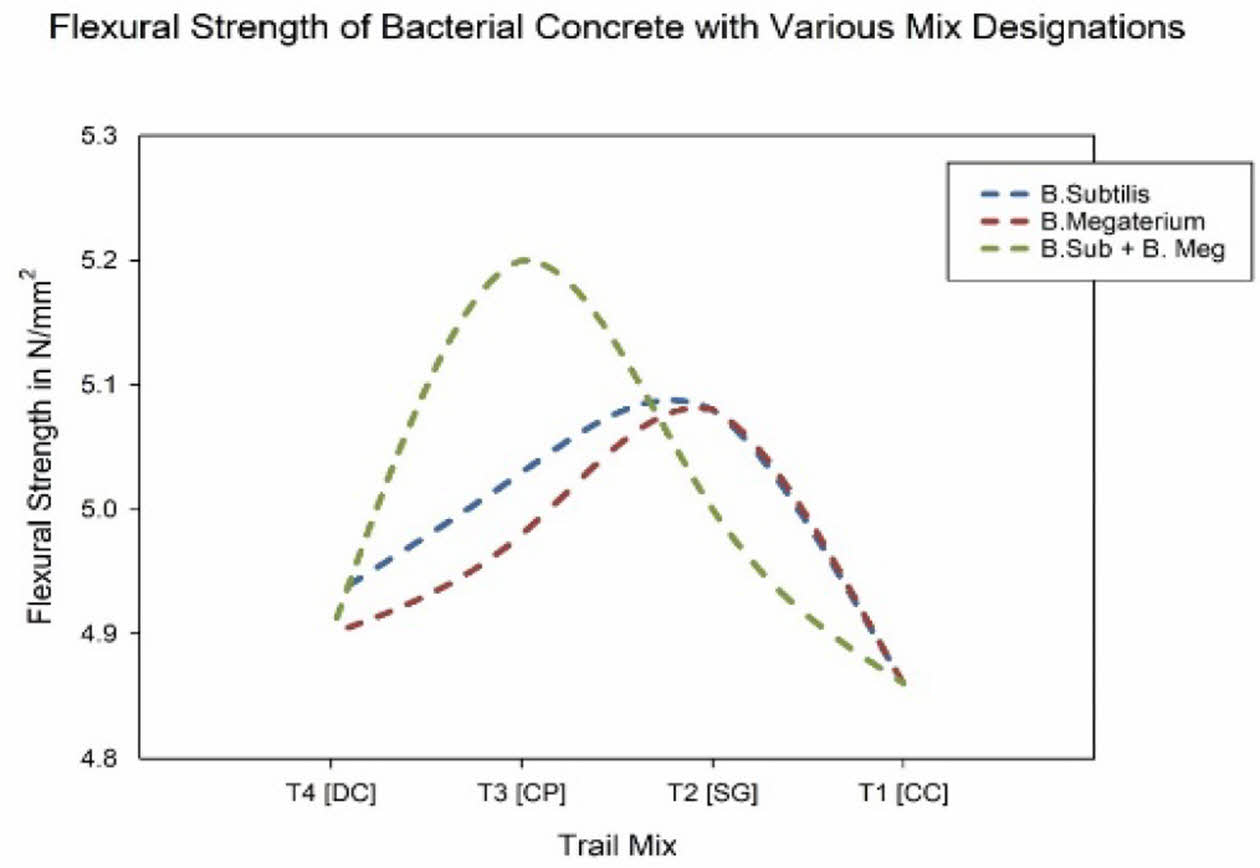

Flexural strength

From Fig. 3, For curing age of 28 days, there is an upturn in strength for the Mix 4 combination of mixed microorganisms with clay pellets which is dominant than other mixed cultures. The mix designated with bacteria bacillus subtilis possess nominal strength values compared with other forms. Similarly, bacterial bacillus megaterium attains the average results convincing the conventional concrete. By comparing novel bacteria mix and bacillus subtilis mix the clay pelletization break the peak result due to its bond. And then comparing novel bacteria mix with bacillus megaterium mix the combined bacterium potential with clay pellets is increased because of its bond strength [5, 27, 41, 45]. The weak bonds stress shows lower modulus in small strains, as the material is more brittle, with low elongation at break. The peak strength flexural test is obtained for the new bacteria combination M4T2 greatest of all other specimens which is also 2 N/mm2 higher than conventional mix. On the other hand, in method clay pellets possess better results compared with other forms of specimens. In silica gel method both bacterium mixes give similar value which is 2 N/mm2 greater than combined matrix with clay pellet. By comparing both the method clay pellets and silica gel we get clay pellets a dominant role flexural behaviour of the concrete.

Sorptivity test

The water absorption and sorptivity values as shown in Fig. 5, indicates that the specimen under any condition irrespective of curing type suffered zero effect, since the capillary voids are filled effectively by the Calcium – Silicate – Hydrate products [5], and too by the reduction in bleed depth of water with respect to age of cement paste.

The reason may be due to presence of hold water by the pores results in effective diffusion of water molecules to the surrounding layer of concrete, thereby helps to enhance secondary hydration mechanism [8, 26, 48]. So, this kind of self-heal concrete with self-heal agent holds good under differential soil-structure interaction to reduce the seepage effect of ground water to the superstructure and thereby protects from bulging effect of base concrete.

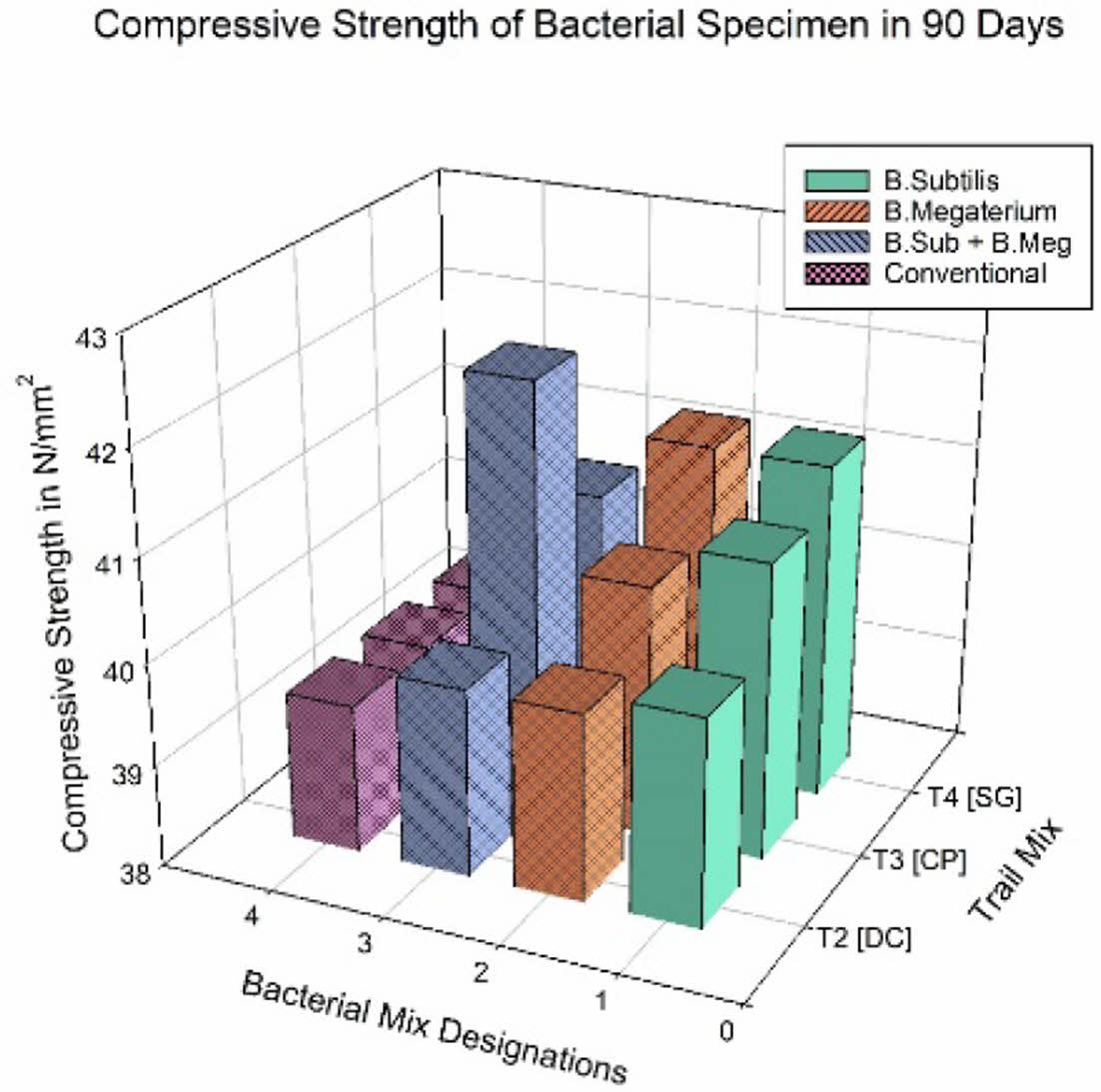

Self-Healed concrete strength

From Fig. 4, there is a rise in strength for the clay pellets concrete mix of mixed bacteria after 90 days of curing which is higher potential than other combined matrix forms. This is due to the bacteria’s predominantly grow in the moisture that clay produces intact. For bacillus megaterium and subtilis mix, the mix designation has minor properties compared to the combined matrix [53, 55]. By comparing novel bacteria mix and bacillus subtilis mix the clay matrix has better results due to its uptake of trace elements from the bacterium [10, 28, 29, 31, 35].

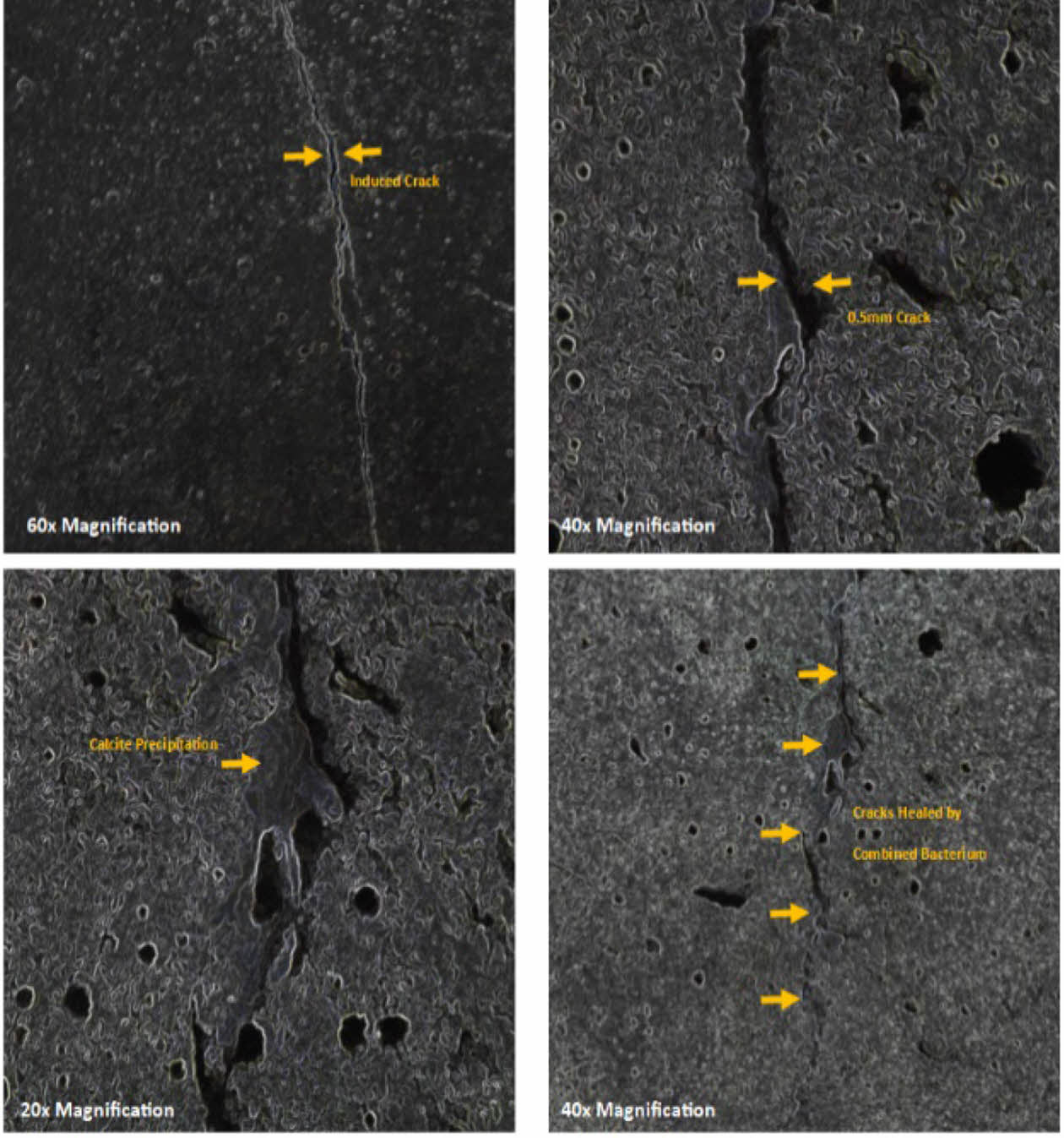

And then comparing novel bacteria mix with bacillus megaterium mix the clay pelletization makes the dominant role in providing healing capacity to the concrete. However, the decline in strength is mostly owing to organic bacteria’s moisture holding inability in relation to the total presence of other elements. The peak strength for the cube compression test is determined to be obtained for the unique bacteria mix M4T2 greatest of all other specimens which is also higher than conventional mix. The clay pellets matrix M4T2 predominant in strength values because of its transformation towards concrete. In silica gel method, the enzymatic activity provokes the problem of long-term viability of organic cells to its mark. By comparing both the method clay pellets and silica gel we get the most effective desiccant for its technical performance and characteristics and ability to absorb moisture is leading in clay pellet immobilization [29, 36, 44]. The potential of crack healed in concrete were found satisfying. The X-Ray CT image (Fig. 6) shows that the M2T3 has the highest potential of healing the cracks up to 0.5 mm, further supporting the idea that smaller cracks are effectively healed by the bacterial concrete. Future research will investigate the kinetics of crack healing in more detail, including quantifying the timeframes for various crack sizes and examining the influence of factors like crack width and environmental conditions on healing efficiency.

|

Fig. 1 Compressive strength examination of bacterium after 28 days curing reveals the specimen strength neck and neck with varied mix proportions and bacterial - additions. A potential increase in strength has been detected in M4T3 specimens. |

|

Fig. 2 Split tensile strength of Bacillus Subtilis after 28 days curing reveals that specimen strength level M2T3 with 15% flyash combined with cement wrapped 105 Bacillus subtilis in silica gel displays superior tensile strength. |

|

Fig. 3 Flexural strength of Bacillus Subtilis after 28 days of curing demonstrates that concrete with additives has much less strength than concrete with varying amounts. |

|

Fig. 4 Compressive strength examination of bacteria after 90 days curing indicates the specimen strength neck and neck with varied mix proportions. |

|

Fig. 5 Specimen sorptivity data reveal the potential of Mix T3, mixed bacteria after 28 and 90 days of curing. |

|

Fig. 6 X Ray CT Image shows the potential of crack healed by the Combined bacterium upto 0.5 mm. |

Cement concrete

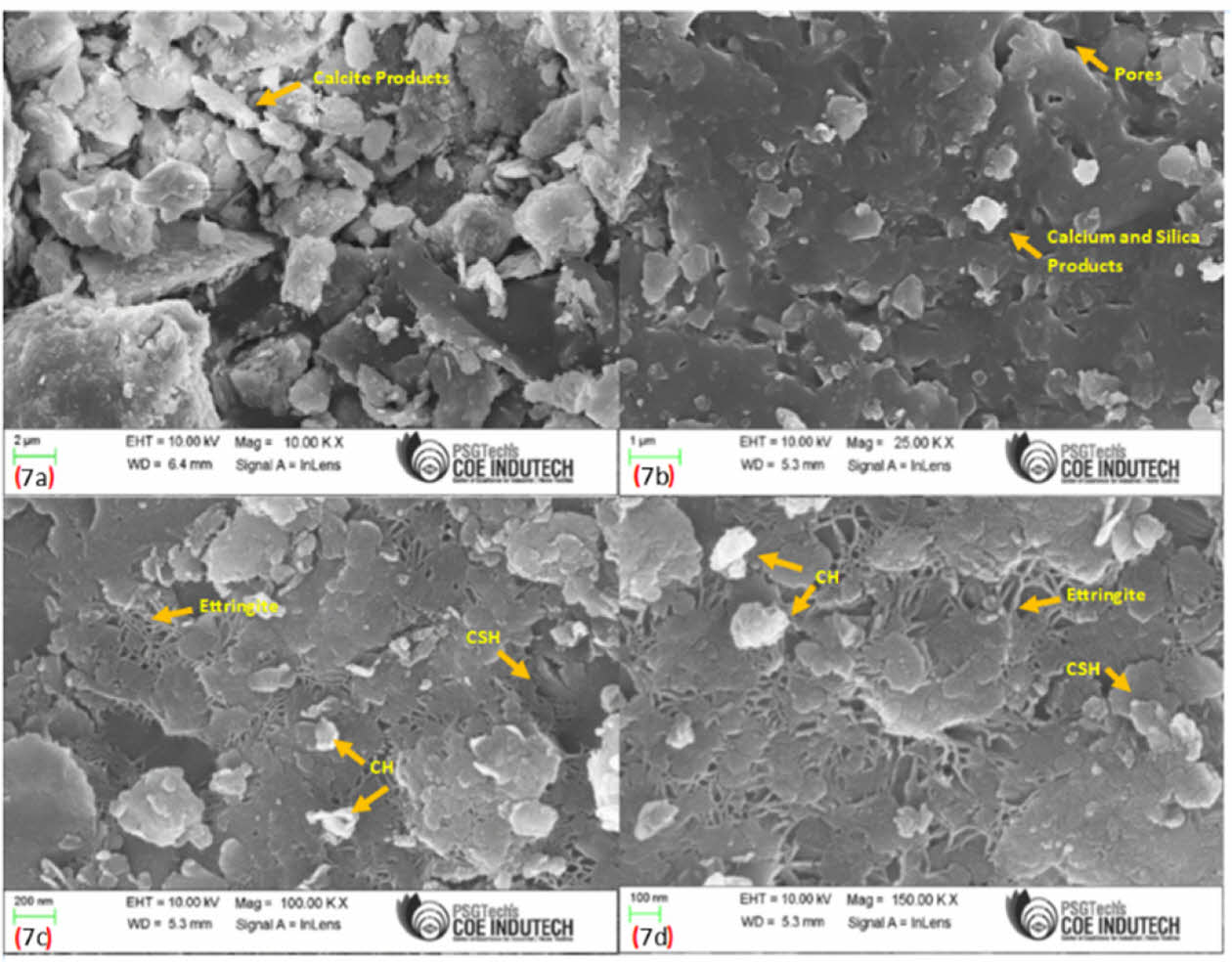

SEM analysis revealed a correlation between calcite formation density and moisture/nutrient availability. Denser calcite formations were observed in regions with higher moisture and nutrient content, supporting the hypothesis that these factors promote bacterial activity and subsequent biomineralization [54, 56]. The particular shattered specimens are devoured in an air and water proof guard to ensure that the intrusion of external moisture is not welcomed. The particular small amount of the particular broken sample through Mix – I with 5-millimeter CP is used and golden covering is given on the surface of smaller sized grain.

It will be allowed free for half 60 minutes to increase full bonding with the grain and obtain flawless out group during the test. Then, it will be carefully put within the small box in the electron microscope. The away box of the particular machine is shut and the inside nature of the particular sample is after that examined through program attached interface.

Fig. 7a denotes the whole concrete mixture including less than 0.5 percent clay pellet (CP) The picture shows the existence of efficient calcite products, which effects in an operative surface region with no holes. The image provides proof of final satisfaction of durable features. From Fig. 7a, it is observed that the presence of crystal shaped structures provides uniform stability for the mix. The presence of minute pores as found from the image does not affect sustainability as the ratio is very low in comparable with the volume of the Fig. 7b clearly displayed the calcium and silica products of the reaction with hydrogen molecules. Non-clearance of hydration has been found in some of the faces, resulting in a decreased part of pores. However, additional hydration through the utilization of hold water by the concrete might successfully fill those voids [7, 15]. Fig. 7b shows the reaction products from hydration due to the use of 0.5% of CP in concrete mix. The output delivers the perfect surface area of the grain as it results in negligible absorption nature of the sample. It is appeared mainly due to the water holding capacity of the Combined bacterium. From the image, it could be the perfect justification for the durability characteristics.

Fig. 7c depicts the hydrated products of the reaction with 0.5 percent SG and basic components. This may contribute to the arrest of pores and hence act as a barrier against eventual degradation. Fig. 7c clearly states the due to a lack of free water, unhydrated products shown. It causes the construction of a fault plane and the deboning effect, as well as the subsequent growth of hair fractures in the Interfacial Transition Zone [34]. Over-evaporation of the mixed water, accompanied by dryness of the core structure within the concrete, creates a pathway for external agents to penetrate.

The common energy dispersive X-Ray microanalysis was performed by atomic spectrometer. Here the EDX image and its individual mapping component were represented for the sample high strength and low strength concrete. Figs. 7d and 7a shows the EDX characteristics for high strength concrete followed by its spectrum map and, Figs. 7b and 7c shows the EDX characteristics for Low strength concrete with its spectrum map [42]. The output from the image directs the efficient nature of concrete based on the basic materials. In Fig. 7a the presence of calcium and silica content was high and the condition is reverse for the Fig. 7b. It is proved that the efficiency of hydration products with respect to hydroxyl ions as mainly relates to calcium and silica to block the mouth opening of pores.

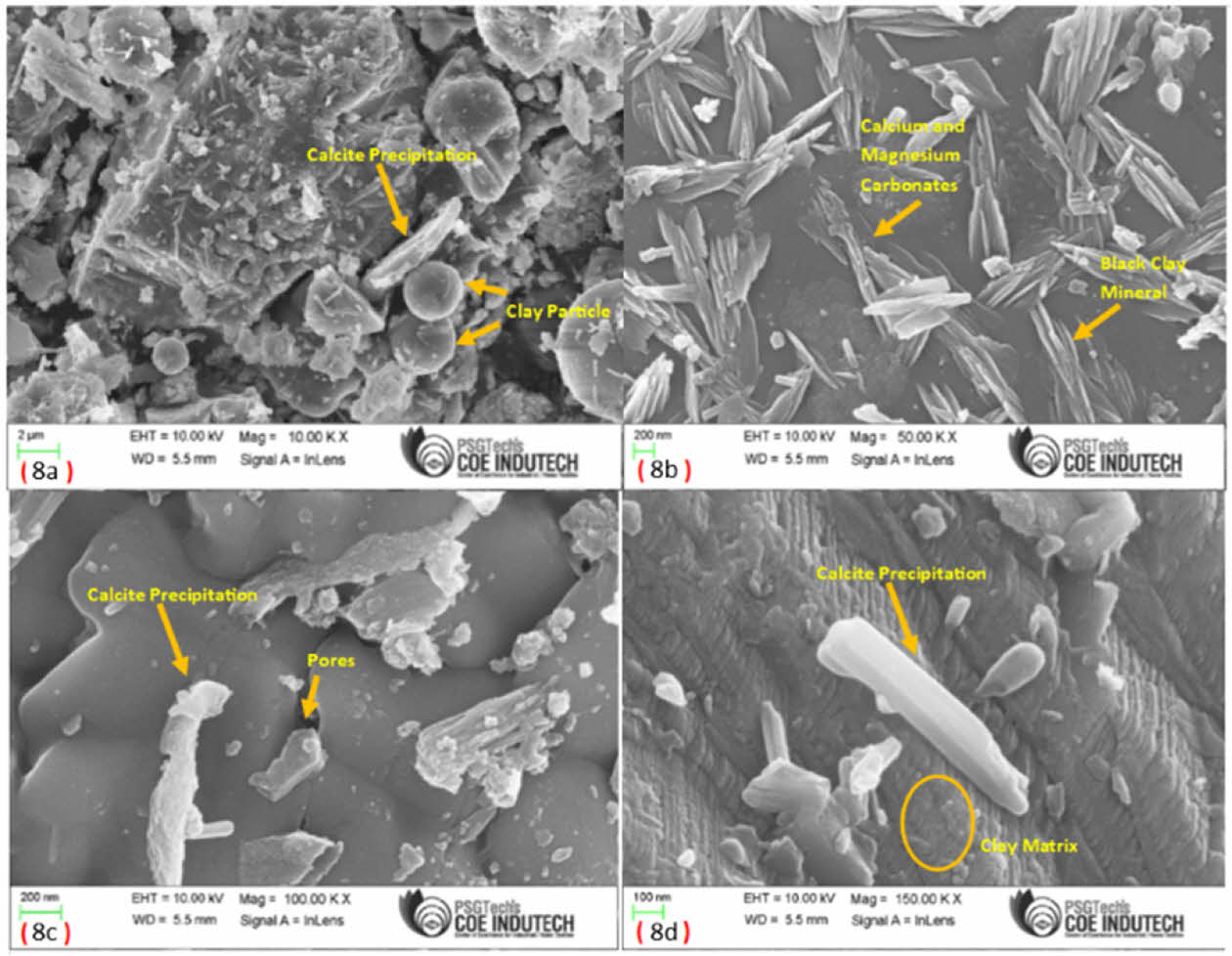

Clay pellet

The internal pore structure of concrete with clay pellets were examined using scanning electron microscope and the test images are shown in Fig. 8a to Fig. 8d. From the 8a, it is examined that the bacteria usage represents dense microstructure which increases the strength of concrete. The sample of clay used is spherical in shape which shows the samples contain coarse particles. The cement paste containing flyash exhibit a lower pore size than the portland cement paste.

Specimen prepared with bacteria appear to be less porous, more adhesive which shows that the microstructure of the clay pellet is dense and more homogeneous than of the conventional concrete due to secondary hydration of Ca (OH)2, and formation of tightly packed calcium magnesium carbonates which fill the pores system as in Fig. 8b.

The mechanical test revealed that, In the short time, the strengths of cement-stabilized soil increased but the hydraulic conductivity coefficient decreased. SEM is used to assess calcite precipitation and pore formation on clay textiles (Fig. 8c). Reduced pore spaces resulted in harder soil structures, higher strength, and a lower hydraulic conductivity coefficient. The impact of magnification on SEM pictures of expanding soils to determine size proportion values, researchers magnified and enlarged frame sizes. Inside the matrix, values were combined with fractal analysis to relate magnifying scale to plane permeability and geometric dimensions of soils. As a consequence, it is discovered significant spread in assessed absorbencies throughout an extended soil.

Fig. 8d depicts the SEM scans after 28 days. Images depict the addition of lime to fly ash and overburden particles. Furthermore, pictures revealed that the pozzolanic process caused calcium precipitation and the formation of a clay mineral matrix around surface and overburden particles. As a result, the SEM pictures demonstrate the link between bearing ratio development and microstructural development.

The effect of aggregate size on variations in the mineralogy and morphology of lime-treated granular soil. After curing, crystallized calcium silicate hydrate (C-S-H) was discovered in lime-treated soil produced with big aggregates (Fig. 8d). The formation of C-S-H caused an increase in Nano holes fewer than 0.1 m in calcite. When limestone was applied in a thin coating across the whole surface of treated soil consisting of small particles, the C-S-H phases formed [5].

|

Fig. 7 SEM Image indicates the bacterial concrete with different magnification and presence of calcite compounds under different mix designations. |

|

Fig. 8 SEM Image indicates the clay pellets with different magnification and presence of calcite compounds induced in concrete. |

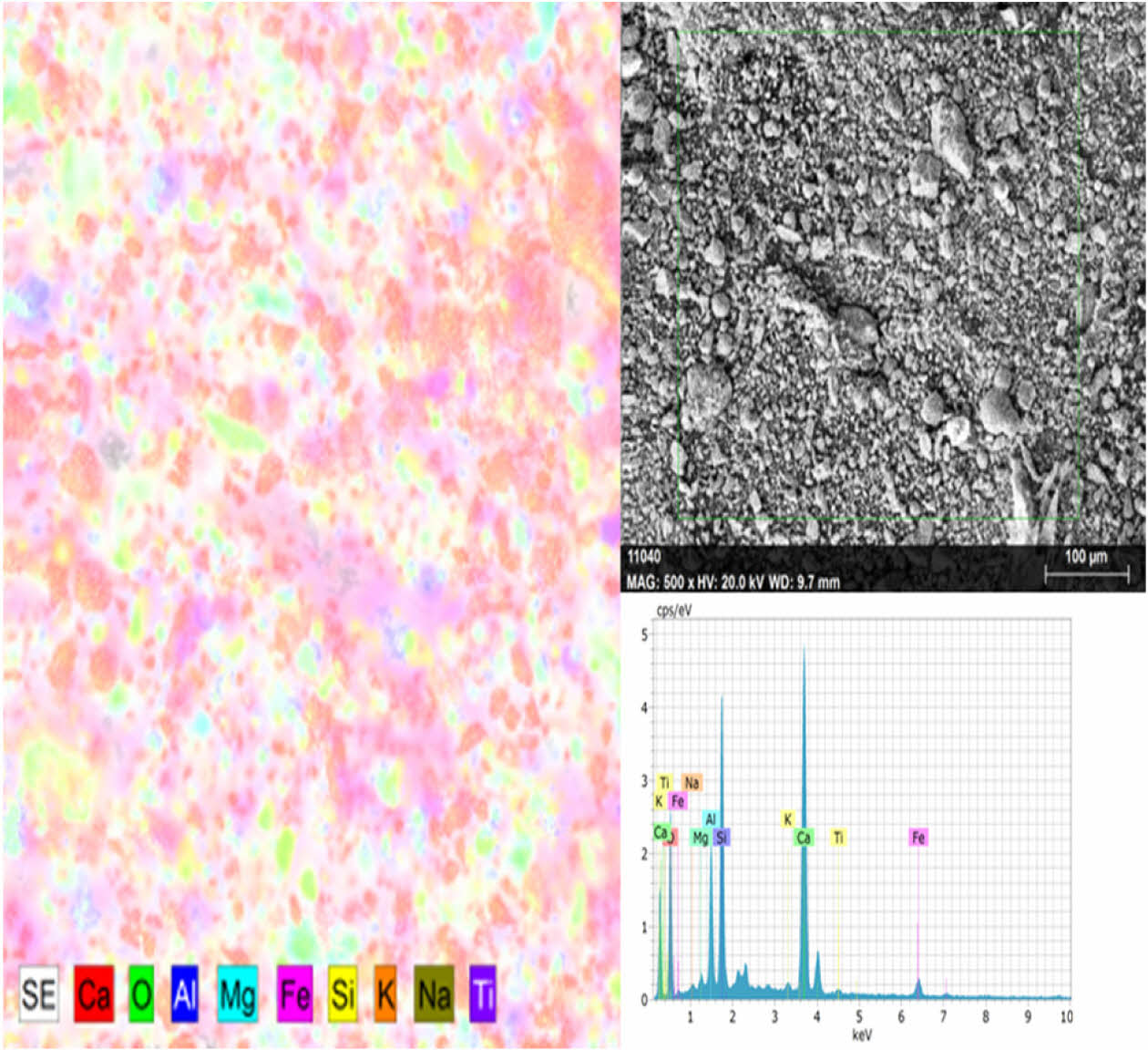

Cement concrete

Fig. 9(b) depicts a spectrum map containing the chemical components selenium (Se), iron (Fe), magnesium (Mg), oxygen (O), silicon (Si), aluminium (Al), potassium (K), calcium (C), sodium (Na), and titanium (Ti). Fig. 9 shows a significant concentration of calcium and silica. It has been demonstrated that the effectiveness of hydration products in blocking the mouth opening of pores in relation to hydroxyl ions is mostly related to calcium and silica. Fig. 9 depicts the EDX properties of low-strength concrete together with its spectrum map [3]. When compared to Fig. 10, the output from the image shows the efficient nature of concrete based on the fundamental elements, and the presence of calcium and silica content was noticed as high.

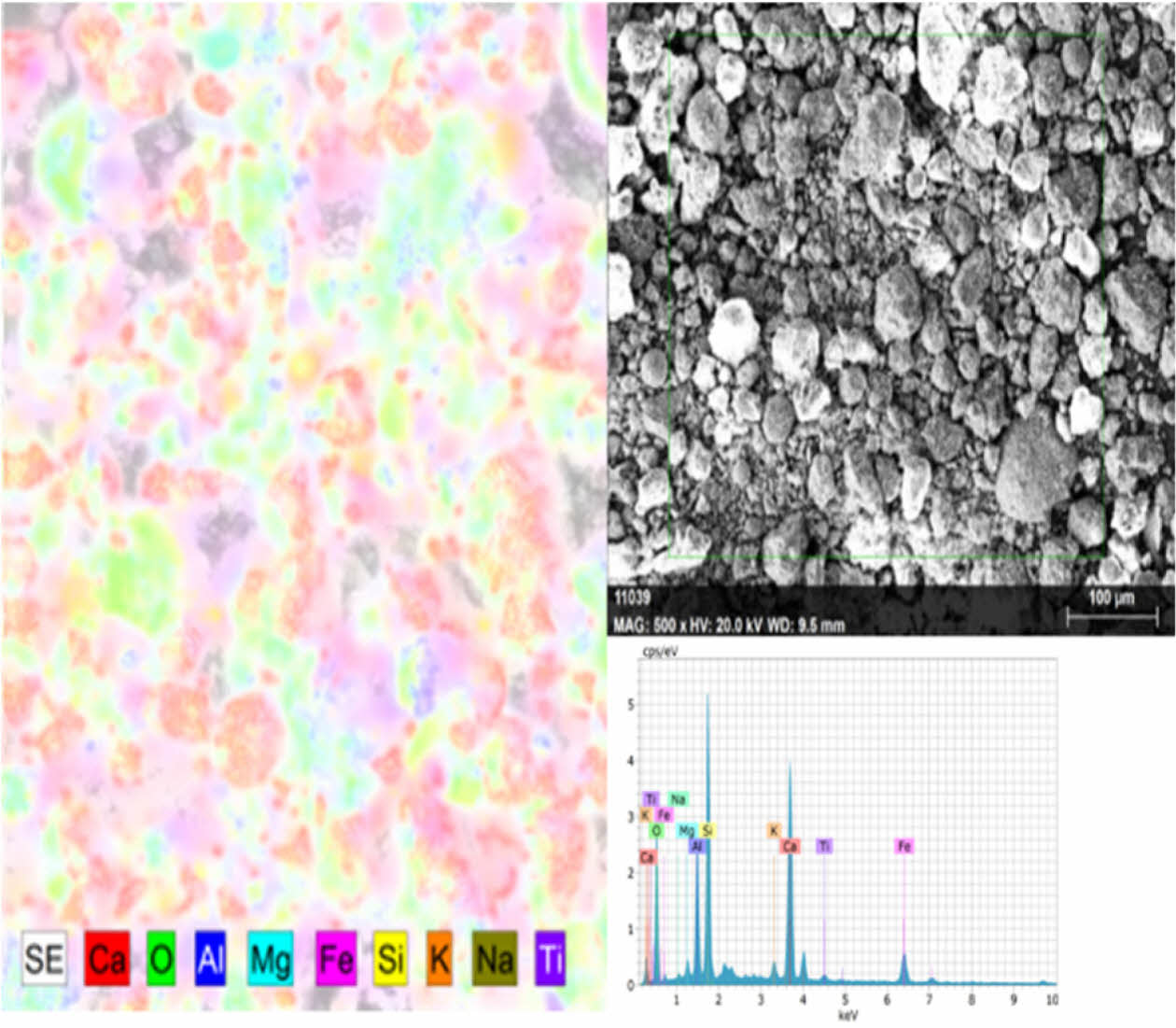

Clay pellet

The auto-scaled strength maps show the three-dimensional dissemination of the following elements: oxygen (O), calcium (C), magnesium (Mg), aluminium (Al), silicon (Si), iron (Fe), potassium (K), selenium (Se), sodium (Na), and titanium (Ti). As a result, their superposition displays the three-dimensional scattering of possible phases of different stoichiometry inside the scrutinized ROI.

Among these are Al-bearing segments such as enduring ferrite (C4AF) and its hydration products, as well as aluminate hydration products, and the C-S-H controlled matrix. The aluminates and their hydration products are distinguished by the deceptive progression of the detailed aluminium strength, i.e. regions of high aluminium concentration appear to be connected with enduring ferrite, whereas regions of lower concentration and more drawn-out signal appear to designate aluminate hydration products. This discovery is corroborated further by the observed regional distribution of iron and sulphur, which are also superimposed in the composite map.

Scalability is a key factor in the feasibility of incorporating microbial agents into large-scale concrete production. However, the long-term viability of the bacteria and potential environmental impacts need further investigation before widespread use.

|

Fig. 9 Elemental Mapping indicates the presence of organic compounds responsible for precipitation of calcite in concrete specimens. |

|

Fig. 10 Elemental Mapping indicates the confirms the presence of organic compounds responsible for precipitation of calcite from clay pellets. |

The results showed that the integration of the EM and FA as alternates for the OPC greatly enhanced the technical characteristics of the proposed concrete mixes. Indeed, specimens with microencapsulated bacterial spores had larger ultimate burdens than equivalent control specimens.

• The results reveal that the inclusion of the bio-agent has no effect on the concrete tensile strength of Subtilis or Megaterium. However, when the bio-agent is combined, it improves its compressive strength by 5%.

• Introducing Immobilized denitrification bacteria into fresh concrete while mixing can increase the concrete’s compressive strength.

• The findings of the experiments reveal that microbial calcite precipitations increased the compressive and tensile strength and water absorption of all specimens at all ages.

• The SEM photographs of the specimens demonstrate that the bacterial-treated specimen with clay pellets had more calcite crystals than the untreated specimen.

• It was also discovered that a novel bacterium [B. Subtilis and B. Megaterium] precipitated more calcium carbonate as a healing product, resulting in homogeneous healing over the full length of concrete fractures.

• Initially, there was no visible indication of crack sealing; the crack sealing begins at the fracture tip and progresses to the crack mouth.

• Elemental analysis also confirmed that the mineral precipitation on cracked surface is calcite crystals. The chemical composition of EDX analysis resembles the amount of silica and calcium content is also high.

• The findings of the Sorptivity test revealed that by adding bacteria and nutrients to the concrete water mixture, the chloride penetration into specimens was reduced by roughly 28 percent owing to CaCO3 precipitations, which plugs pores and improves concrete performance.

• The water permeability studies confirmed this finding. After 90 days, the greatest compressive strength was detailed for a combination of self-healed cement concrete and clay pellets with bacterial concentrations of 105 cells/ml-1.

• The capacity of subsequent cracks to self-repair was substantially increased, and there was no noticeable detrimental influence on the basic performance of concrete.

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

- 1. C. Gaylarde, M. Ribas Silva, and T. Warscheid, Mater. Struct. 36 (2003) 342-352.

-

- 2. Bertron, Mater. Struct. 47[11] (2014) 1787-1806.

-

- 3. M. Sarkar, T. Chowdhury, B. Chattopadhyay, R. Gachhui, and S. Mandal, J. Mater. Sci. 49[13] (2014) 4461-4468.

-

- 4. M. Luo, C. Qian, R. Li, and H. Rong, J. Wuhan Univ. Technol.-Mater. Sci. Ed. 30[6] (2015) 1255-1259.

-

- 5. R.S. Kunal, A. Rajor, and M. Singh, J. Mater. Civ. Eng. 28[10] (2016).

-

- 6. K.-C. Lee, Y.S. Yoon, F.-Z. Li, and J.-B. Eun, Appl. Biol. Chem. 60[1] (2017) 33-40.

-

- 7. M. Seifan, A.K. Samani, and A. Berenjian, Appl. Microbiol. Biotechnol. 100[6] (2016) 2591-2602.

-

- 8. E.-J. Lee, G.-R. Kim, K. Ameer, H.-K. Kyung, and J.-H. Kwon, Appl. Biol. Chem. 61[1] (2018) 79-89.

-

- 9. E.-S. Lim, Appl. Biol. Chem. 61[1] (2017) 25-37.

-

- 10. M.V.S. Rao, V.S. Reddy, and C. Sasikala, J. Inst. Eng. (India): Ser. A 98[4] (2017) 501-510.

-

- 11. M.J.C. Alonso, C.E.L. Ortiz, S.O.G. Perez, R. Narayanasamy, G.D.J. Fajardo San Miguel, H.H. Hernandez, and N. Balagurusamy, Environ. Sci. Pollut. Res. Int. 25[22] (2018) 21451-21458.

-

- 12. K. Ganesh Babu, H. Sudarsana Rao, and Y. Amarnath, Lect. Notes Civ. Eng. 61 (2018) 393.

- 13. K. Ganesh Babu, H. Sudarsana Rao, and Y. Amarnath, Emerging Trends in Civil Engineering (Springer, India, 2018).

-

- 14. Q. Mao, X. Feng, P. Liang, R. Wang, Z. Wang, S. Cui, and M. Lan, J. Wuhan Univ. Technol.-Mater. Sci. Ed. 33[5] (2018) 1108-1112.

-

- 15. M. Seifan and A. Berenjian, World J. Microbiol. Biotechnol. 34[11] (2018).

-

- 16. K. Vijay and M. Murmu, Front. Struct. Civ. Eng. 13[3] (2018) 515-525.

-

- 17. C. Ganesh, M. Muthukannan, R. Malathy, and C. Ramesh Babu, KSCE J. Civ. Eng. 23[10] (2019) 4368-4377.

-

- 18. S. Han, E.K. Choi, W. Park, C. Yi, and N. Chung, Appl. Biol. Chem. 62[1] (2019).

-

- 19. S. Morsali, G.Y. Isildar, Z.H. Zargari, and A. Tahni, J. Build. Pathol. Rehabil. 4[1] (2019).

-

- 20. R. Shirdam, M. Amini, and N. Bakhshi, Int. J. Environ. Res. 13[6] (2019) 909-924.

-

- 21. Tayebani and D. Mostofinejad, J. Mater. Civ. Eng. 31[3] (2019).

-

- 22. K. Vijay and M. Murmu, SN Appl. Sci. 1[11] (2019).

-

- 23. Z. Zhang, Y. Weng, Y. Ding, and S. Qian, Materials (Basel) 12[23] (2019).

-

- 24. A. Fernandez, M. Correa, M.-T. Nguyen, K.A. Rod, G.L. Dai, L. Cosimbescu, R. Rousseau, and V.-A. Glezakou, J. Mater. Sci. 56[1] (2020) 201-230.

-

- 25. M. Hayek, M. Salgues, F. Habouzit, S. Bayle, J.-C. Souche, K. De Weerdt, and S. Pioch, Cem. Concr. Compos. 113 (2020).

-

- 26. M.S. Jafarnia, M.K. Saryazdi, and S.M. Moshtaghioun, Constr. Build. Mater. 242 (2020).

-

- 27. M.K. Reddy, B. Ramesh, D. Macrin, and Kanth Reddy, Mater. Today: Proc. 33 (2020) 4206-4211.

-

- 28. S. Jena, B. Basa, and K.C. Panda, A Review on the Bacterial Concrete Properties, in IPO Conf. Ser. (IPO Publishing, 2020).

-

- 29. H. Thiyagarajan, S. Maheswaran, M. Mapa, S. Krishnamoorthy, B. Balasubramanian, A.R. Murthy, and N.R. Iyer, J. Adv. Concr. Technol. 14[4] (2016) 125-133.

-

- 30. S. Jena, B. Basa, and K.C. Panda, IOP Conf. Ser.: Mater. Sci. Eng. 970 (2020).

-

- 31. H. Singh and R. Gupta, Case Stud. Constr. Mater. 12 (2020).

-

- 32. R. Vashisht and A. Shukla, J. Build. Pathol. Rehabil. 5[1] (2020).

-

- 33. M. Wu, X. Hu, Q. Zhang, W. Cheng, D. Xue, and Y. Zhao, Cem. Concr. Compos. 113 (2020).

-

- 34. B. Balzano, J. Sweeney, G. Thompson, C.-L. Tuinea-Bobe, and A. Jefferson, Eng. Struct. 226 (2021).

-

- 35. F.H. Ghasan, Z.H. Joudah, N.H.A. Khalid, A.R.M. Sam, M.M. Tahir, N.H.A.S. Lim, R. Alyousef, and J. Mirza, Constr. Build. Mater. 267 (2021).

-

- 36. R. Jakubovskis, A. Jankute, S. Guobuzaite, R. Boris, and J. Urbonavicius, Materials (Basel) 14[11] (2021).

-

- 37. G. Mokhtar, A.A.-E.-A. Ahmed, and A.M. Reyad, Beni-Suef Univ. J. Basic Appl. Sci. 10[1] (2021).

-

- 38. D. Mori and K.V. Uday, Environ. Earth Sci. 80[8] (2021).

-

- 39. C. Qian, T. Zheng, X. Zhang, and Y. Su, Constr. Build. Mater. 290 (2021).

-

- 40. S. Shi and A.N. Netravali, J. Mater. Sci. 56[20] (2021) 12030-12047.

-

- 41. L. Skevi, B.J. Reeksting, T.D. Hoffmann, S. Gebhard, and K. Paine, Cem. Concr. Compos. 120 (2021).

-

- 42. Y. Su, T. Zheng, and C. Qian, Constr. Build. Mater. 273 (2021).

-

- 43. J.M. van der Bergh, B. Miljević, S. Vučetić, O. Šovljanski, S. Markov, M. Riley, J. Ranogajec, and A. Bras, Sustainability 13[8] (2021).

-

- 44. M.D. Karthick, G.S. Rampradheep, and S. Shankar, Environ. Sci. Pollut. Res. Int. 29[15] (2022) 21670-21681.

-

- 45. N. Sidhu, S. Goyal, and M.S. Reddy, AMB Express 12[1] (2022) 59.

-

- 46. H. Tanyildizi, M. Ziada, M. Uysal, N.D. Güngör, and A. Coşkun, Case Stud. Constr. Mater. 16 (2022).

-

- 47. R. Zaerkabeh, A.M. Sadeghi, H. Afshin, and R. Majdani, Periodica Polytech. Civ. Eng. (2022).

-

- 48. Z. Zhang, D. Liu, Y. Ding, and S. Wang, J. Infrastruct. Preserv. Resil. 3[1] (2022).

-

- 49. L.F. Rodríguez-Alfaro, L.M. Torres-Martínez, M.Z. Treviño-Garza, et al., Ceram. Int. 49[13] (2023) 21370-21383.

-

- 50. H. He, G. Li, J. Zhang, et al., J. Ceram. Process. Res. 20[5] (2019) 470-478.

-

- 51. M.G. Sierra Beltran and H.M. Jonkers, J. Ceram. Process. Res. 16 (2015) s33-s39.

-

- 52. M. Safaei, S. Moloudi, R. Souri, et al., J. Ceram. Process. Res. 25[4] (2024) 563-571.

-

- 53. K.K. Gaayathri, K. Suguna, and N.R. Pulipaka, J. Ceram. Process. Res. 24[4] (2023) 595-602.

-

- 54. R. Cardoso, I. Borges, J. Vieira, et al., Appl. Clay Sci. 240 (2023) 106972.

-

- 55. C. Fu, Q. Zhan, X. Zhang, et al., Constr. Build. Mater. 400 (2023) 132686.

-

- 56. V. Uz, H. Ozdag, S. Ilhan, et al., J. Ceram. Process. Res. 11[5] (2010) 606-611.

-

- 57. A. Hidalgo López, J.L. García Calvo, J. García Olmo, et al., J. Am. Ceram. Soc. 91[4] (2008) 1258-1265.

-

- 58. J. Xiang, Z. Li, J. Qiu, et al., Ceram. Int. 49[9] (2023) 13490-13500.

-

- 59. W. Dong, W. Li, K. Wang, et al., Ceram. Int. 48[14] (2022) 19851-19863.

-

- 60. G. Zhou, Q. Gu, H. Sun, et al., J. Eur. Ceram. Soc. 44[4] (2024) 1959-1971.

-

This Article

This Article

-

2024; 25(6): 997-1006

Published on Dec 31, 2024

- 10.36410/jcpr.2024.25.6.997

- Received on Aug 8, 2024

- Revised on Oct 10, 2024

- Accepted on Nov 27, 2024

Services

Services

- Abstract

introduction

materials and methods

bacterial immobilization research

experimental investigation

results and discussion

sem analysis

elemental mapping

conclusions

- Acknowledgements

- References

- Full Text PDF

Shared

Correspondence to

Correspondence to

- DhivakarKarthick Mani

-

Department of Civil Engineering, Erode Sengunthar Engineering College, Thudupathi, Erode, Tamil Nadu, India - 638057

Tel : +91 9566846331 - E-mail: divakarthick@gmail.com

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.