- Study on electrical conductivity and flow properties of ceramic inks for ceramic surface pattern design

Yijing Li* and Binglu Chen

Wales Institute of Science and Art, University of Wales Trinity Saint David; Swansea, SA1 8PH, United Kingdom

This article is an open access article distributed under the terms of the Creative Commons Attribution Non-Commercial License (http://creativecommons.org/licenses/by-nc/4.0) which permits unrestricted non-commercial use, distribution, and reproduction in any medium, provided the original work is properly cited.

This study focuses on the development and characterization of ceramic inks for inkjet printing with ceramic surface patterns, in particular the examination of their conductivity, surface tension and shear viscosity. Three distinct colored ceramic inks were prepared, each with varying compositions to explore their potential for effective ink-jet printing. The electrical conductivity of the inks was measured to assess their suitability for producing consistent and high-quality prints. Surface tension measurements were conducted to ensure proper ink behavior during the printing process, while shear viscosity was analyzed to determine the flow characteristics essential for avoiding nozzle clogging and ensuring smooth application. Results indicate that the prepared ceramic inks exhibit electrical conductivities within an acceptable range for ink-jet printing, demonstrating their potential for producing electrically conductive ceramic components. Surface tension values were found to be within the optimal range for ink-jet applications, ensuring good droplet formation and deposition. Shear viscosity measurements show that the surface pattern ink has proper flow, and all three colors show a stable viscosity suitable for high-resolution printing.

Keywords: Ceramic surface pattern design, Graphic design.

In recent years, the integration of advanced materials into additive manufacturing processes has significantly expanded the capabilities of ink-jet printing technologies, particularly in the realm of ceramic surface pattern design [1]. A notable area of interest is the development of ceramic inks, which offer the potential to produce high-performance ceramic components with precise control over their properties and intricate graphic designs. This research paper explores the formulation and characterization of ceramic inks specifically designed for ink-jet printing, focusing on their electrical conductivity, surface tension, and shear viscosity [2]. The performance of ceramic inks in ink-jet printing is critically dependent on their physicochemical properties. Electrical conductivity is a crucial factor, influencing the ability of the ink to produce consistent and high-quality prints, especially for applications requiring conductive ceramics [3]. Surface tension plays a significant role in the formation and deposition of ink droplets, affecting print resolution and overall quality. Additionally, shear viscosity determines the ink’s flow characteristics, which is essential for preventing issues such as nozzle clogging and ensuring smooth, reliable application [4].

The field of ink-jet printing has seen significant advancements with the integration of ceramic inks, enabling new possibilities for producing high-quality, intricate ceramic components with detailed graphic designs [5-7]. Traditional approaches to ceramic ink-jet printing often rely on soluble dyes or micronized pigments. While soluble dyes are straightforward to use, they tend to offer limited color saturation and a restricted color palette. On the other hand, micronized pigments can lead to challenges such as nozzle clogging and dispersion instability if not meticulously managed. These limitations highlight the need for more advanced ink formulations.

Recent developments in this area have introduced nano-sized ceramic inks, or nano-inks, which consist of nanometric particles dispersed in a liquid organic vehicle. These nano-inks promise to address the shortcomings of traditional methods by enhancing image quality and ensuring higher reliability in printing systems [8, 9]. The use of nanoscale particles enables better color saturation, finer resolution, and more consistent print results due to their superior dispersion characteristics and smaller particle size, which reduces the likelihood of clogging [10]. The synthesis of nanoscale crystalline materials has been achieved through various chemical methods, with the polyol process emerging as a particularly effective technique. This method allows for the precise control of particle size and distribution, contributing to the enhanced performance of nano-inks in ink-jet printing applications.

This research aims to develop and characterize ceramic inks tailored for inkjet printing applications, specifically focusing on their ability to create intricate surface patterns with desired electrical properties. Three distinct ceramic ink formulations were prepared, each with unique compositional variations, to explore their potential for effective inkjet printing. To assess the suitability of these ceramic inks for inkjet printing, their electrical conductivity, surface tension, and shear viscosity were rigorously evaluated. Electrical conductivity is a critical parameter, ensuring the formation of consistent and conductive ceramic components. Surface tension plays a pivotal role in droplet formation and deposition, while shear viscosity influences the ink's flow properties and prevents nozzle clogging. The results of this study demonstrate the successful development of ceramic inks with electrical conductivity values within the acceptable range for inkjet printing applications. Furthermore, the inks exhibit optimal surface tension and shear viscosity characteristics, making them promising candidates for producing high-resolution ceramic surface patterns. This research contributes to the advancement of inkjet printing technology for the fabrication of functional ceramic components.

In this study, ceramic inks were developed and characterized to evaluate their suitability for ink-jet printing. The experimental methods were designed to assess key properties that impact the performance of the inks, including electrical conductivity, surface tension, and shear viscosity. Additionally, the study involved characterizing the inks’ particle size and flow behavior, as well as investigating the interaction between the inks and ceramic substrates. Three distinct colored ceramic inks (Violet, Green and Blue) were formulated, each with a unique composition to explore their potential in ink-jet printing. The inks were prepared by dispersing ceramic particles in a liquid organic vehicle, with precise control over the particle size and concentration to achieve optimal printing performance. The electrical conductivity of the ceramic inks was measured using a conductivity meter to assess their suitability for producing electrically conductive ceramic components. Surface tension measurements were conducted using a tensiometer to evaluate the behavior of the inks during the printing process. This ensured proper droplet formation and deposition. Shear viscosity was analyzed using a rheometer to determine the flow characteristics of the inks. This measurement is crucial for avoiding nozzle clogging and ensuring smooth application during printing.

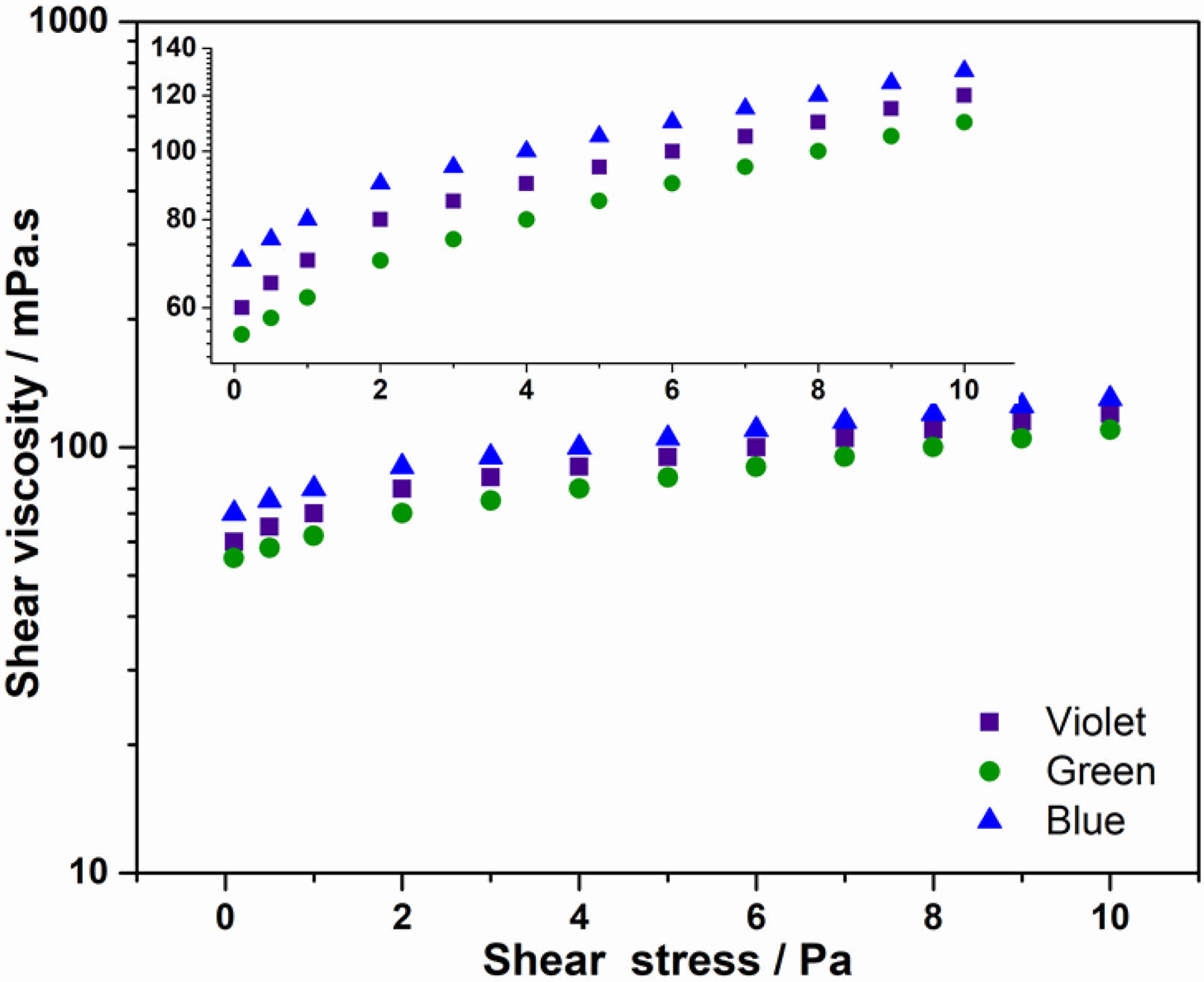

The experimental investigation of the ceramic inks focused on their flow behavior, surface tension, and electrical conductivity, all crucial factors for determining their suitability for inkjet printing. Fig. 1 shows the flow curves for the three different ceramic inks (Violet, Green, and Blue), illustrating the relationship between shear stress and shear viscosity. The flow behavior of ink is a key factor in ensuring successful inkjet printing, as it determines how the ink moves through the nozzle and forms droplets. From the flow curves, it can be observed that the viscosity of each ink decreases with increasing shear stress, indicating shear-thinning behavior. This property is essential for inkjet printing because it enables the ink to flow easily through the small nozzle at high shear rates while maintaining enough viscosity to prevent dripping or leakage when at rest.

Among the three inks, Violet shows a moderate level of shear-thinning behavior, maintaining a stable viscosity across different shear rates. This balance suggests that Violet ink is well-suited for high-resolution printing, as it is less likely to clog the nozzle while still providing controlled deposition during the printing process. The Green ink exhibits slightly higher viscosity than the other inks at low shear rates, indicating a stronger internal structure, possibly due to higher particle loading. However, its shear-thinning behavior ensures that it can still flow smoothly through the nozzle under higher shear stress. This makes it particularly suitable for applications where ink stability is critical, such as printing on textured surfaces. The Blue ink displays the highest initial viscosity at low shear stress, but it also thins rapidly as the shear rate increases. This suggests that Blue ink might be ideal for applications requiring thicker layers or more substantial coverage, as its flow behavior allows for controlled deposition while minimizing the risk of clogging. All three inks exhibit stable viscosity ranges under different shear stresses, with no significant risk of clogging during printing. Their shear-thinning properties enable smooth flow through the nozzle, ensuring that high-quality prints can be achieved.

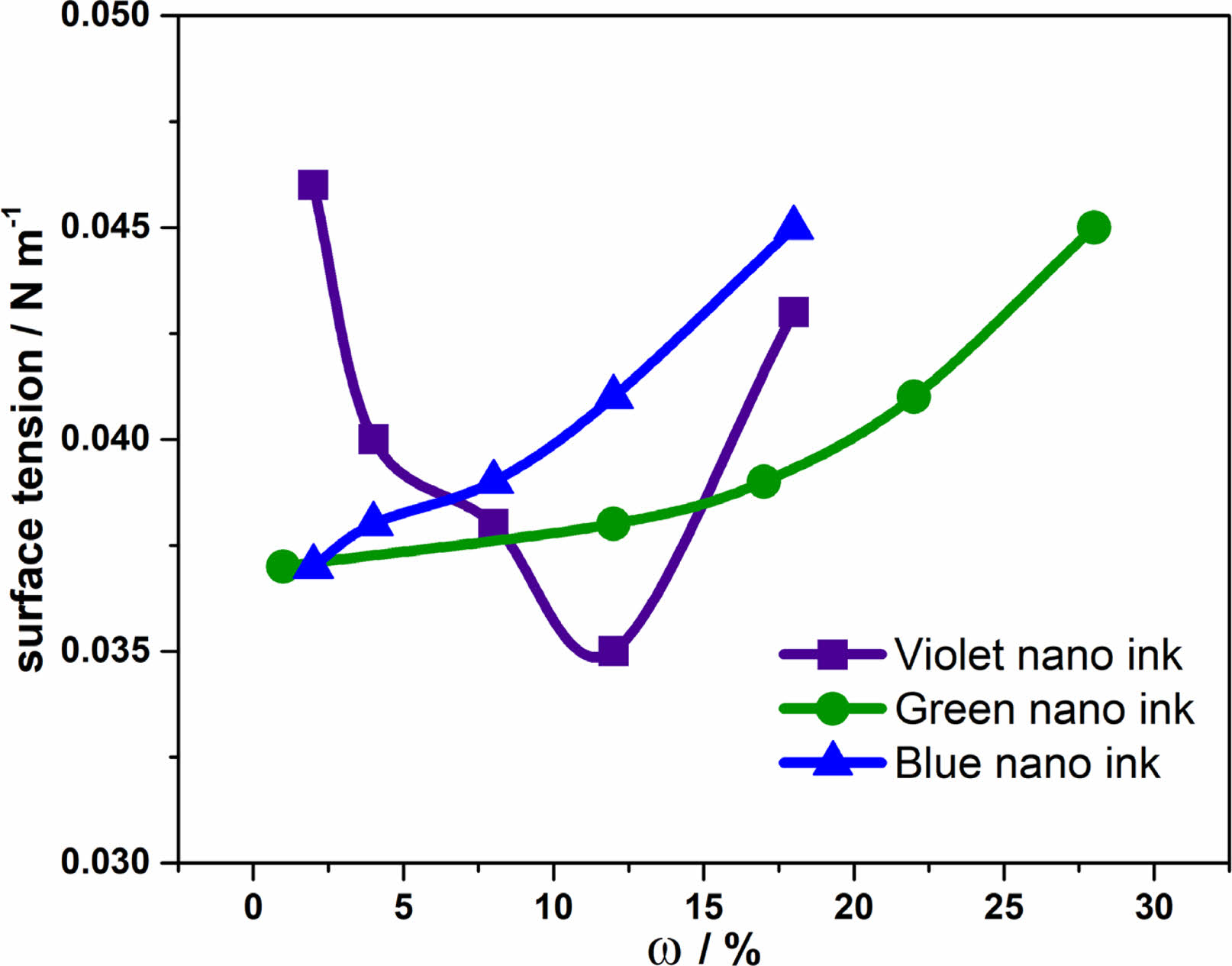

Surface tension plays a vital role in droplet formation, which is critical for the precision and quality of inkjet printing. Fig. 2 provides the surface tension values for the Violet, Green, and Blue ceramic inks. The surface tension values for all three inks were measured immediately after droplet formation to capture the conditions experienced during inkjet printing, as the equilibrium surface tension of colloidal dispersions can vary over time due to factors such as nanoparticle diffusion and environmental contamination. The Violet ink exhibits surface tension values that are within the optimal range for inkjet printing. This ensures that droplets form consistently and are emitted from the nozzle in a controlled manner, preventing unwanted splattering or deviation in the print pattern. Similarly, the Green ink shows favorable surface tension properties, indicating good droplet formation and deposition. The balanced surface tension allows for precise control over droplet placement, which is essential for creating intricate designs or detailed patterns in ceramic printing. The Blue ink demonstrates slightly lower surface tension compared to the other two inks. While still within the acceptable range, this may result in smaller droplets and could be advantageous for fine-line printing or applications requiring high-resolution detail. The ability to control droplet formation through surface tension is essential for the successful application of ceramic inks in inkjet printing. All three inks meet the necessary surface tension requirements, making them suitable for high-resolution, consistent printing processes. The equilibrium surface tension of a colloidal dispersion is not achieved instantly due to the slow diffusion of nanoparticles to the ink-air interface and environmental factors that may cause contamination [11]. Consequently, surface tension values can vary as droplets age. In this study, to ensure accurate surface tension measurements for ink-jet printing, where droplet formation and emission from the print-head occur rapidly values are recorded immediately after droplet formation. All tested inks meet the necessary surface tension requirements for effective ink-jet printing.

However, notable variations in surface tension are observed with changes in particle concentration. For Violet, Green, and Blue inks, surface tension decreases with increasing particle loading up to a certain concentration, after which it rises sharply [12-14]. This trend is due to nanoparticles migrating to the ink-air interface, which initially reduces the cohesion among the liquid molecules and thus lowers surface tension. At higher particle concentrations, the capillary forces between nanoparticles at the interface become predominant, causing an increase in surface tension [15]. The specific particle concentration at which surface tension begins to rise differs among the inks. In addition to viscosity and surface tension, electrical conductivity is a critical parameter for ceramic inks, especially for applications involving functional ceramic components such as sensors or electronic devices. The electrical conductivity of the three inks was found to be within the acceptable range for inkjet printing, ensuring that they can produce consistent and high-quality prints. The combination of proper electrical conductivity, controlled flow behavior, and favorable surface tension makes these ceramic inks highly suitable for inkjet printing applications. Specifically, the prepared inks are ideal for creating both aesthetic surface patterns and functional ceramic components, such as electrically conductive layers or sensors.

|

Fig. 1 Flow curves for Violet, Green, and Blue ceramic inks, showing shear stress (Pa) versus shear viscosity (mPa.s). |

|

Fig. 2 Surface tension values for the ceramic inks in Violet, Green, and Blue colors. |

A comprehensive analysis of ceramic inks developed for ink-jet printing, focusing on their electrical conductivity, surface tension, and shear viscosity was studied. The results demonstrate that the formulated inks (Violet, Green, and Blue) exhibit distinct rheological and physical properties that are crucial for effective ink-jet printing applications. The electrical conductivity measurements indicate that the inks are suitable for producing electrically conductive ceramic components, with values aligning well within acceptable ranges for high-quality printing. Surface tension analysis shows that all tested inks meet the required standards for ink-jet printing, with variations in particle concentration leading to predictable changes in surface tension. Specifically, an initial decrease in surface tension with increasing particle loading is observed, followed by a rise at higher concentrations due to increased capillary forces between nanoparticles. Shear viscosity results reveal that the inks exhibit appropriate flow characteristics, essential for smooth application and prevention of nozzle clogging. Each ink color demonstrated stable viscosity profiles, suitable for high-resolution printing, although some variations in viscosity were noted depending on the particle concentration. These findings contribute to advancing ceramic ink formulations and enhancing the versatility and efficiency of ink-jet printing technologies in various industrial applications. Future work may focus on refining these formulations further and exploring their performance in more diverse printing scenarios.

- 1. J.H. Park, J.H. Lee, D.J. Kim, K.T. Hwang, J.H. Kim, and K.S. Han, J. Korean Ceram. Soc. 56[5] (2019) 461-467.

-

- 2. P. Gingter, A.M. Watjen, M. Kramer, and R. Telle, J. Ceram. Sci. Technol. 6[2] (2015) 119-124.

-

- 3. D. Herzog, V. Seyda, E. Wycisk, and C. Emmelmann, “Additive Manufacturing of Metals,” Acta Mater, 117 (2016) 371-392.

-

- 4. D. Herzog, V. Seyda, E. Wycisk, and C. Emmelmann, Acta Mater. 117 (2016) 371-392.

-

- 5. G. Rivers, J.S. Austin, Y. He, A. Thompson, N. Gilani, N. Roberts, P. Zhao, C.J. Tuck, R.J.M. Hague, R.D. Wildman, and L. Turyanska., Addit. Manuf. 66 (2023) 103452.

-

- 6. N.T. Brannelly and A.J. Killard, Electroanalysis 29[1] (2017) 162-171.

-

- 7. E. Bihar, D. Corzo, T.C. Hidalgo, D. Rosas-Villalva, K. N. Salama, S. Inal, and D. Baran, Adv. Mater. Technol. 5 (2020) 2000226.

-

- 8. G.F. Trindade, F. Wang, J. Im, Y. He, A. Balogh, D. Scurr, I. Gilmore, M. Tiddia, E. Saleh, D. Pervan, L. Turyanska, C.J. Tuck, R. Wildman, R. Hague, and C.J. Roberts, Commun. Mater. 2[1] (2021) 47.

-

- 9. C.A. Lamont, T.M. Eggenhuisen, M.J.J. Coenen, T.W.L. Slaats, R. Andriessen, and P. Groen, Org. Electron. 17 (2015) 107-114.

-

- 10. Y. Galagan, I.G. de Vries, A.P. Langen, R. Andriessen, W.J.H. Verhees, S.C. Veenstra, and J.M. Kroon, Chem. Eng. Process. Process Intensif. 50 (2011) 454.

-

- 11. F. Wu, S. Hsu, H. Cheng, W. Chou, and F. Tang, J. Phys. Chem. C 117 (2013) 8691.

-

- 12. M.A. Green, K. Emery, Y. Hishikawa, W. Warta, and E.D. Dunlop, Prog. Photovoltaics 22 (2014) 701.

-

- 13. W.J.E. Beek, M.M. Wienk, M. Kemerink, X. Yang, and R.A.J. Janssen, J. Phys. Chem. B 109 (2005) 9505.

-

- 14. S.D. Hoath, I.M. Hutchings, and O.G. Harlen, J. Rheol. 56 (2012) 1109.

-

- 15. Y. Galagan, I.G. de Vries, A.P. Langen, R. Andriessen, W.J.H. Verhees, S.C. Veenstra, and J.M. Kroon, Chem. Eng. Process. Process Intensif. 50 (2011) 454.

-

This Article

This Article

-

2024; 25(5): 922-925

Published on Oct 31, 2024

- 10.36410/jcpr.2024.25.5.922

- Received on Aug 28, 2024

- Revised on Oct 10, 2024

- Accepted on Oct 10, 2024

Services

Services

Shared

Correspondence to

Correspondence to

- Yijing Li

-

Wales Institute of Science and Art, University of Wales Trinity Saint David; Swansea, SA1 8PH, United Kingdom

Tel : +86-15836582726 Fax: +86-029-88749084 - E-mail: Liyijing1027@163.com, 15136253340@163.com

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.