- Experimental study on mechanical properties of PVB materials based on laminated glass

Tang Peng*

Nanyang Institute of Technology, Nanyang 473004, Henan, China

This article is an open access article distributed under the terms of the Creative Commons Attribution Non-Commercial License (http://creativecommons.org/licenses/by-nc/4.0) which permits unrestricted non-commercial use, distribution, and reproduction in any medium, provided the original work is properly cited.

PVB laminated glass consists of a single piece of glass and PVB film layers. In order to explore the application of glass plate technology to the mechanical properties of ordinary vehicle road panels, it is particularly important to test the material properties of both for studying the overall mechanical properties of laminated glass. The material properties of glass are relatively clear, and the constitutive parameters are more evidence-based. PVB belongs to polymer materials, and its mechanical properties are influenced by various factors such as temperature, loading rate, strain rate, etc. The determination of elastic modulus values and constitutive relationships under different conditions is relatively complex and usually requires experimental research. By studying the uniaxial tensile properties of PVB interlayer materials at different loading rates, the uniaxial tensile experimental phenomena, uniaxial tensile stress-strain curve, uniaxial tensile constitutive relationship, uniaxial tensile elastic modulus and its rate correlation of PVB materials were analyzed, which is helpful for further research on the mechanical properties of laminated glass under wheel compression load.

Keywords: Loading rate, Mechanical property, PVB material, Uniaxial stretching.

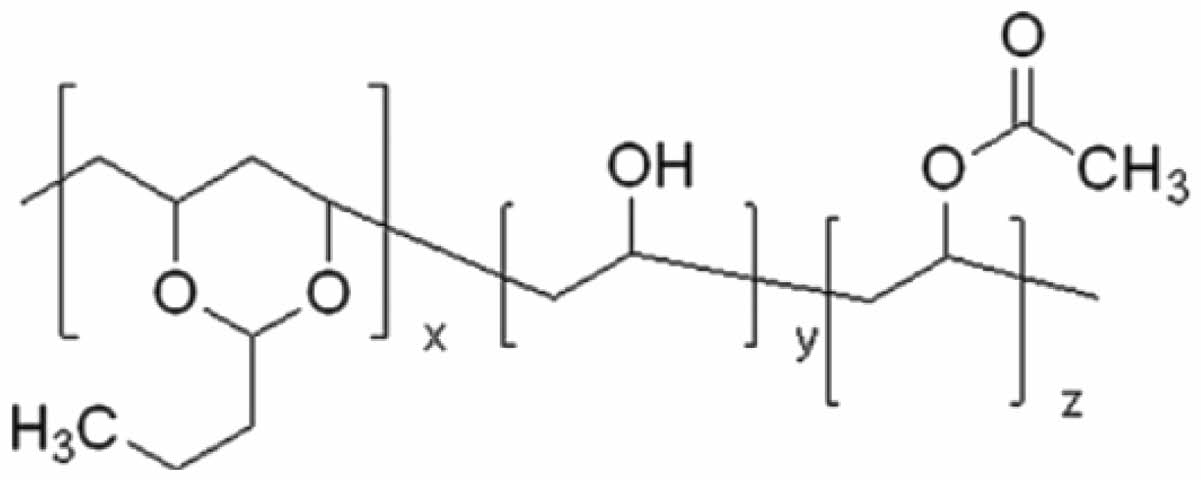

PVB is the first material to be used as the middle layer of laminated glass, and it is also the most widely used intermediate layer material, so it is also the most concerned research object of scholars [1]. PVB is generated by the reaction of polyvinyl alcohol and butanaldehyde, and the chemical structure of the commercial PVB midlayer is shown in Fig. 1 PVB is an amorphous random ternary copolymer composed of three monomers with different properties: vinyl alcohol butyraldehyde (about 76~80%), vinyl alcohol (about 18~22%) and vinyl acetate (about 1~2%). Despite the same chemical structure, the properties of PVB slices vary with the basis of PVB type, manufacturer and PVB slice composition. The PVB chains with higher molecular weight can enhance the toughness of the middle layer, so the plasticizer is often added to prepare PVB. However, the plasticizer can not degrade the bonding performance of PVB and glass, nor can it affect its optical performance [2].

Because stretching is the main stress mode of the middle layer when the laminated glass is stressed, the research on the mechanical properties of PVB materials mainly focuses on the tensile properties. Zhang class [3]The PVB material was tested with low and high speed direct tensile tests at 0.008 s-1~1360 s-1. The stress-strain curve was obtained. It is found that the strength of PVB increases with increasing strain rate, but the ductility of PVB becomes worse. In fact, many investigators’ pilot studies support similar conclusions [3-5], The PVB is usually viewed as an isotropic, incompressible linear elastic material. Linear viscoelastic constitutive relations are suitable to describe the small deformation mechanical behavior of PVB, with its stress as a function of strain and stress increasing in an exponential manner. However, the stress-strain relationship of PVB will change into a bilinear and elastic-plastic viscoelastic stress-strain relationship.

Some scholars have also carried out the compression performance test of PVB. Liu et al. [5]. Both tensile and compression tests demonstrate the rate-related mechanical properties of PVB. PVB is an elastic-plastic material under dynamic tensile load and viscoelastic material under quasi-static tensile load; PVB shows viscoelastic properties under both dynamic and quasi-static load. Moreover, the constitutive model of PVB is defined, which divides the PVB into linear elastic phase, bi-exponential phase and failure stage.In addition to the strain rate, there are significant effects of ambient temperature on the mechanical properties of PVB materials. Tao Zhixiong et al. [6]. It is found that the uniaxial tensile stress-strain relationship of PVB sheet is linear elastic at 20 ℃, but changes to bilinear at 40 ℃, and its initial elastic mode is significantly reduced with temperature increase. However, the shear stress-strain relationship of PVB slices was bilinear at 20 ℃ and 40 ℃, but the initial shear modulus also decreased significantly with increasing temperature [7].

The main purpose of studying the mechanical properties of PVB materials is to more accurately grasp the influence of sandwich materials on the mechanical behavior of laminated glass plates. In 2016, Nawar et al[8]The constitutive relationship of the original PVB and the extracted PVB is investigated, and the mechanical behavior of the laminated glass is studied. It is found that the energy absorption of the original PVB glass sandwich is larger than that of the PVB sandwich after extraction, and the adhesion of the original PVB layer to the glass layer is stronger than that of the PVB layer after extraction to PVB layer.

|

Fig. 1 Chemical structure of the PVB. |

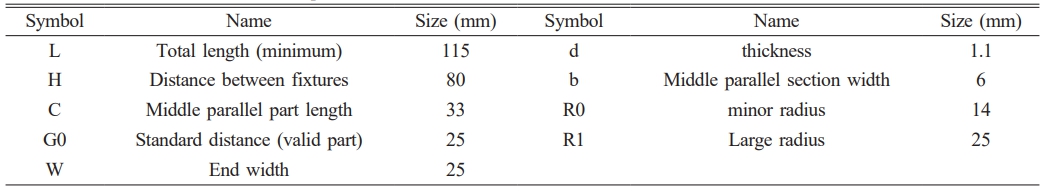

Test Piece Design And Production

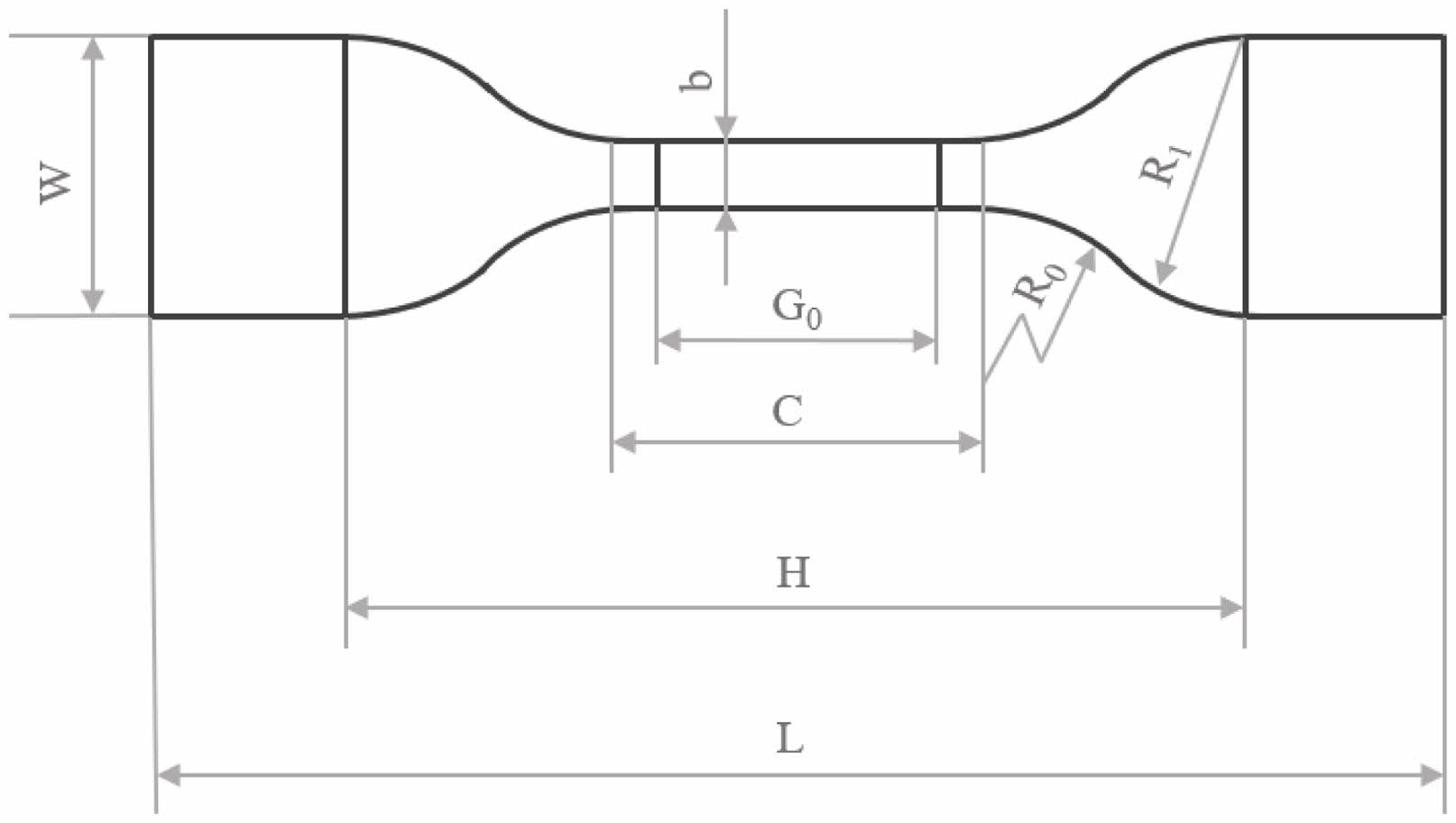

Test piece design refer to GB-T1040-1992 Plastic Tensile Performance Test Method [9], the schematic diagram is shown in Fig. 2, and the specific dimensions are shown in Table 1, the film thickness is 1.1 mm. The specimen is constantly stretched along the longitudinal spindle of the specimen until breaking, testing the load and its elongation during this process. PVB test strips were cropped from the same lot of PVB plates. PVB specimen shape is not distorted, adjacent planes are perpendicular to each other, specimen surface and specimen edge are no scratches, dents, cavity and burr defects. During the test, the dumbbell specimens with shoulder fracture or plastic deformation extending to the whole shoulder width shall be discarded and retested again.

Tensile Test Method

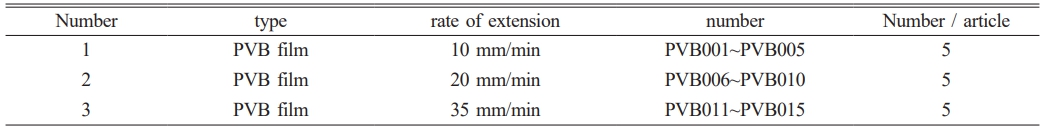

The tensile performance of PVB is greatly affected by the temperature and loading rate, so the pre-experiment was first performed at room temperature to determine the stretching rate. The loading rate of samples given in Article 4.2 of GB-T1040-1992 is 45 mm/min to 220 mm/min, while the tensile rate of Article 5.1 is the lowest speed that can break in 0.5 to 5 min test time. After preliminary experiments at various rates, it was finally determined to perform three sets of tensile tests at 10 mm/min, 20 mm min and 35 mm/min. According to Article 4 of GB-T1040-19924.3.4,5 specimens are set for each group, and all specimens are of the same size and divided into 3 groups with 5 pieces for a total of 15 pieces. The specimen parameters are shown in Table 2.

Tensile Test Device

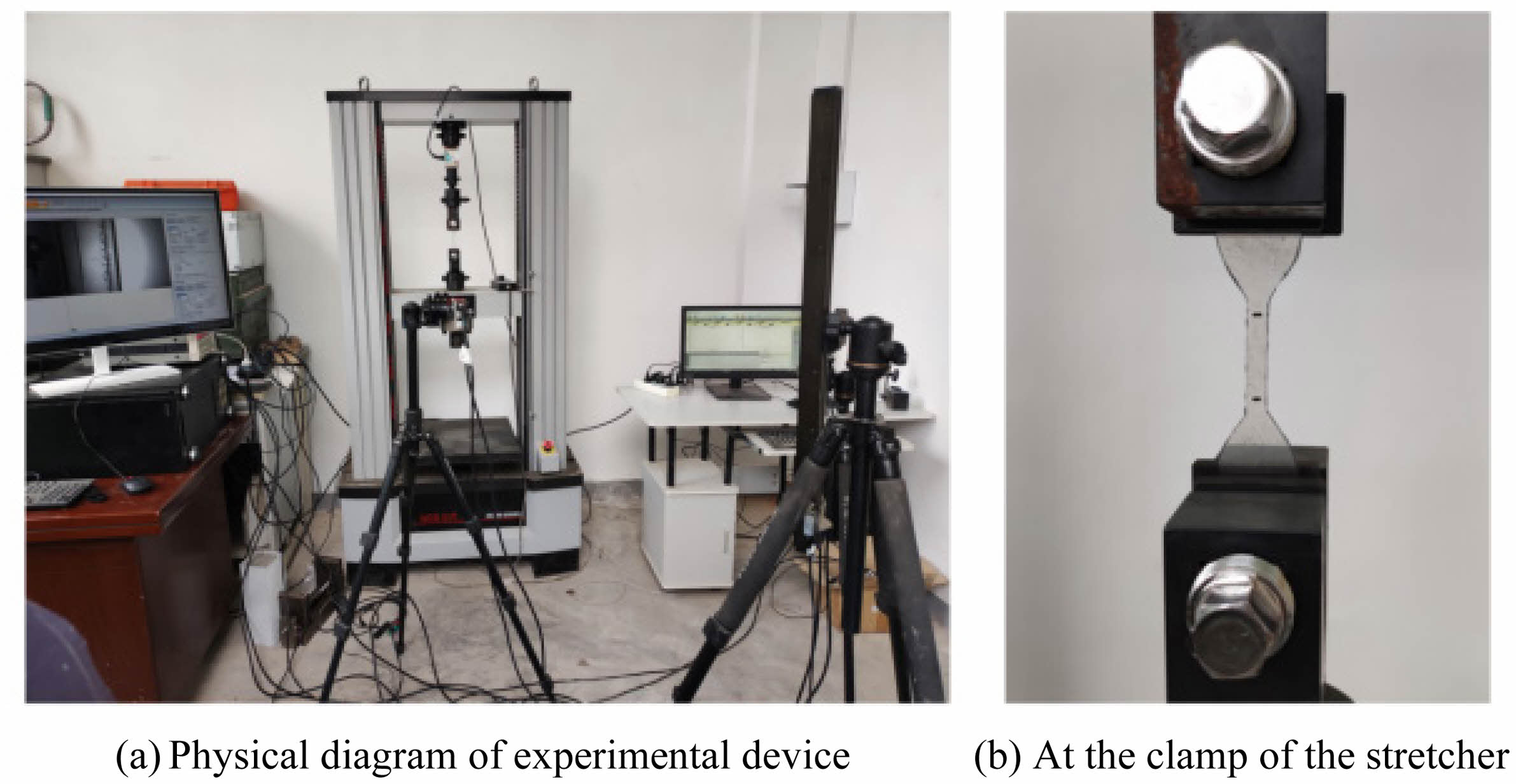

Stretch using Hualong electronic stretching instrument, equipped with load sensor, load value can be displayed in the control end screen in real time. Two synchronous high-speed cameras are set up: one for the stretching process of PVB specimen, the other for the load value of the tension control screen, the automatic photographing interval is set to 1s, the specimen device is shown in Fig. 3.

|

Fig. 2 Schematic diagram of PVB tensile specimen. |

|

Fig. 3 Test device diagram of PVB tension. |

Pvb Uniaxial Tensile Failure Morphology

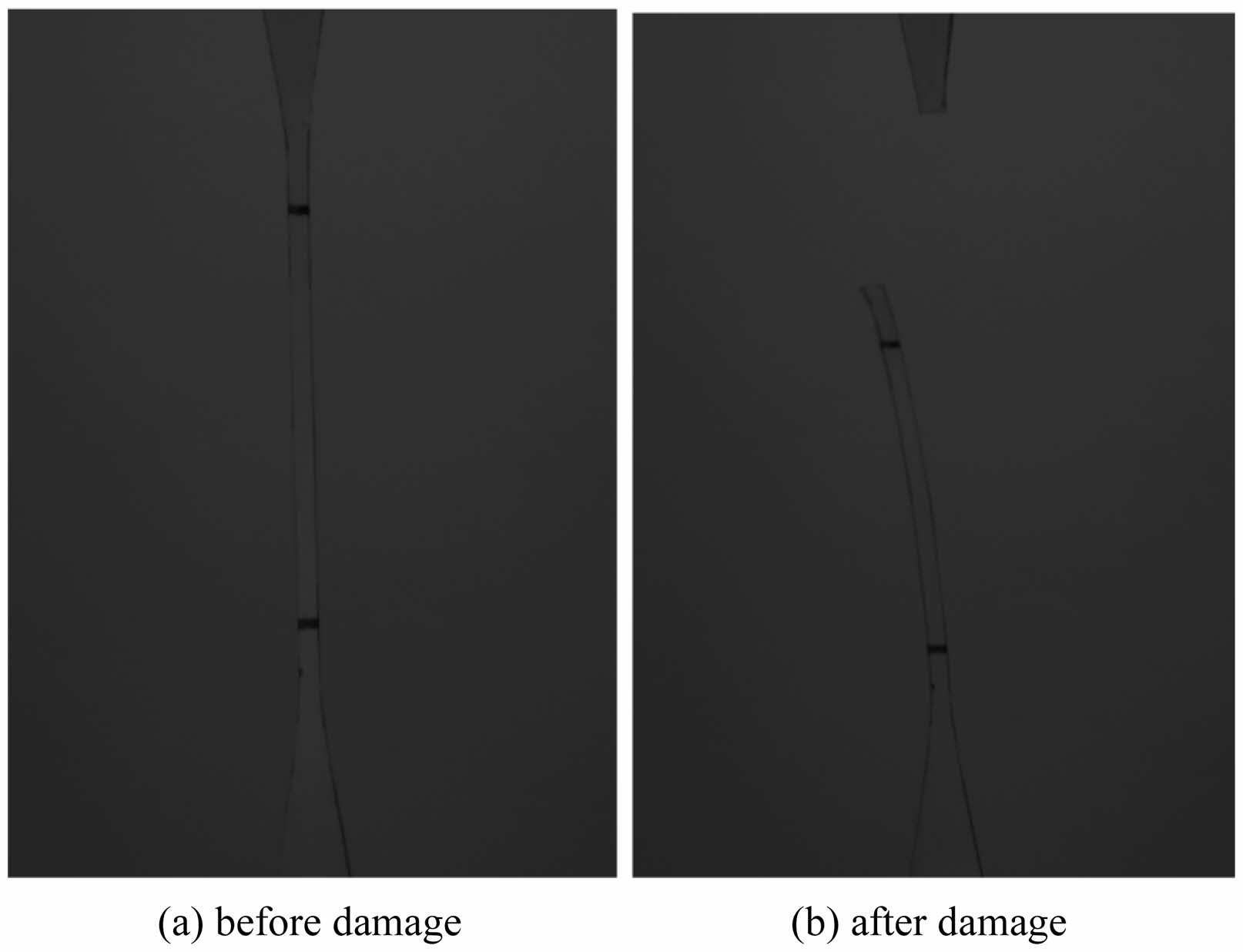

During the stretching process, the length of the specimen gradually increases and the width gradually decreases. The low and dull "bang" sound is broken, and the limit elongation is about 200% (± 10%). The limit failure moment is shown in Fig. 4.

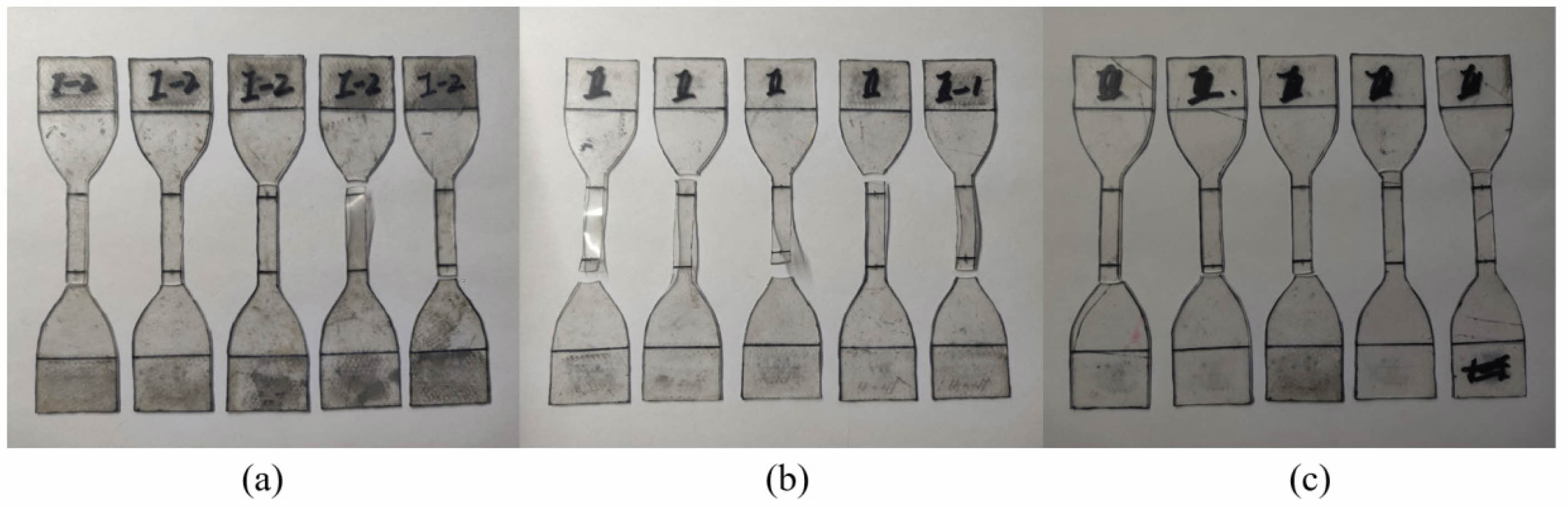

The fracture points of the 15 tensile specimens are all in the landmark section (i.e., where the width is narrowed), as shown in Fig. 5. After fracture, PVB film elongates by more than 90% in one minute, retaining about 10% of the residual deformation. It was measured again after 12 h and two weeks respectively, and a small residual deformation of 0.3 mm (2.5 mm), that is, 12% of the residual deformation was retained. It can be considered that the residual deformation is basically stable in more than one minute after the fracture, and about 10% of the residual deformation is retained.

PVB single-axial tensile stress-strain curve

In tensile experiments, conditional stress is represented by σ, the unit is MPa; conditional strain (engineering strain) is represented by ε. Using the following formula, respectively:

In the formula, F is the load applied to the specimen, in N units; A0 is the cross-sectional area of the specimen before stretching, measured in mm2.

In the formula, L is the length of the specimen after stretching, in millimeters; L0 is the length of the specimen before stretching, in millimeters

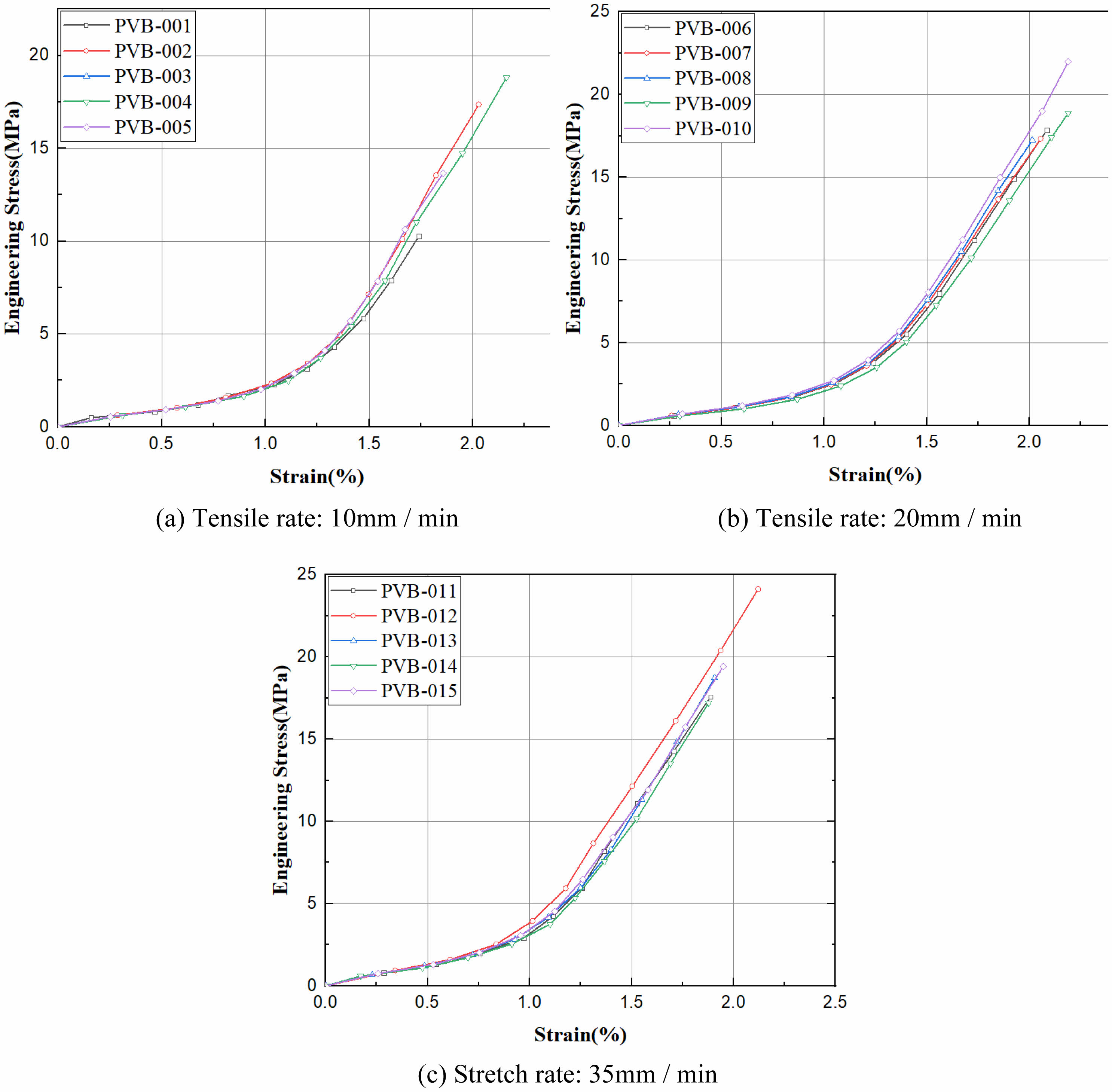

The uniaxial tensile stress-strain curve of PVB is shown in Fig. 6. It can be found that the stress-strain-strain relationship is approximately linear under small deformation; under large deformation, the slope of the curve increases greatly and the elastic modulus increases; under large deformation, the stress-strain relationship begins to show linear characteristics again; regardless of the loading strain rate, the uniaxial tensile stress-strain curve of PVB shows very obvious bilinear characteristics.

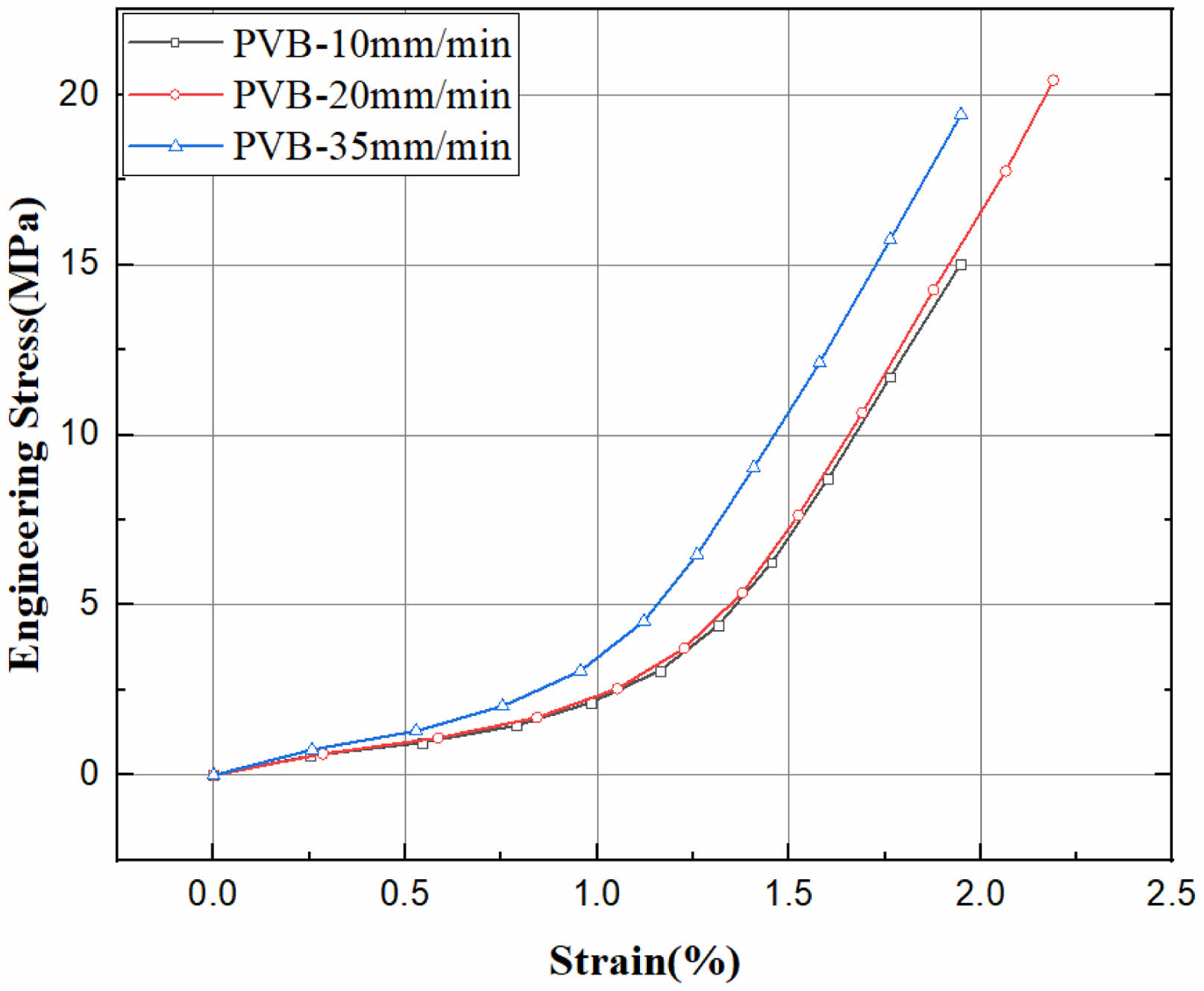

The tests of each group were averaged to obtain stress-strain curves at different loading rates, as shown in Fig. 7. Clearly, the PVB materials exhibit a significant rate correlation. The higher the loading rate, the higher the curve, the lower the tensile deformation, which may be due to the creep performance of the polymer PVB, and the deformation coordination speed at high loading rate lags behind the load change rate. The larger the loading rate, the larger the initial elastic modulus of the PVB. Moreover, the higher the loading rate, the shorter the linear segment of small deformation, and the earlier it begins to exhibit nonlinear characteristics. at the same time, it can be seen that the magnitude of the loading rate corresponds to the shape trend of the stress strain curve.

The Uniaxial Tensile Constitutive Relationship Of Pvb

The shape of the stress-strain curve of PVB uniaxial tension at different rates in this article is basically consistent with the stress-strain curve shape obtained from Iwasaki et al.'s [10] low-speed tensile test (loading rate of 0.0067 s-1~0.2 s-1). The reason is that the loading rate of this article is 10 mm/min~35 mm/min, that is, 0.3.0067 s-1~0.023 s-1, With Iwasaki et al. [11]. The loading rate of the low-speed tensile test is in the same interval. It can be found that the initial inclination of the stress-strain curve is related to the loading rate, which gradually increases with the increasing loading rate.

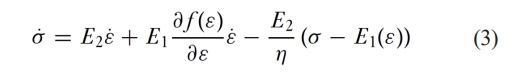

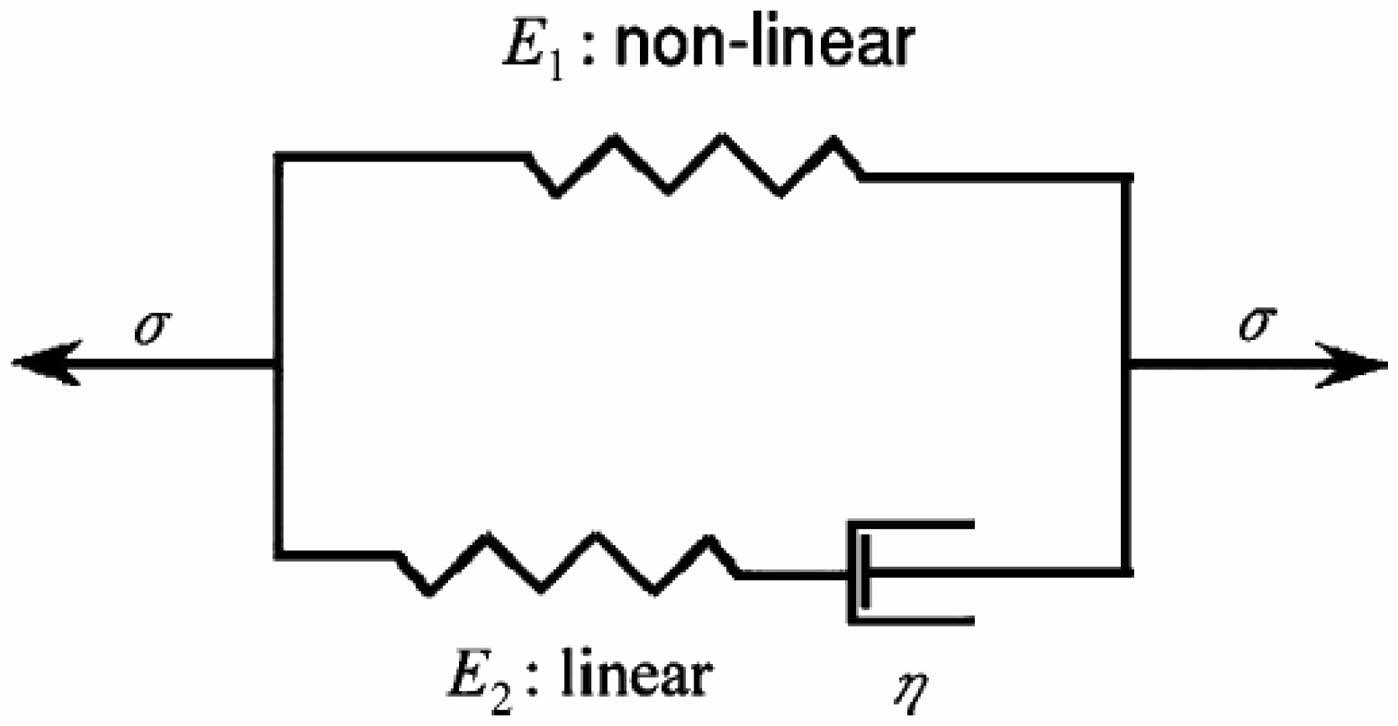

Refer to the reference Iwasaki et al. In this study, PVB is a nonlinear viscoelastic material and introduced a particle-spring model to simply describe its mechanical behavior. As shown in Fig. 8, a nonlinear spring was introduced to correct the particle-spring model to a nonlinear particle-spring model. This nonlinear particle-spring model is shown in Eq. (3).

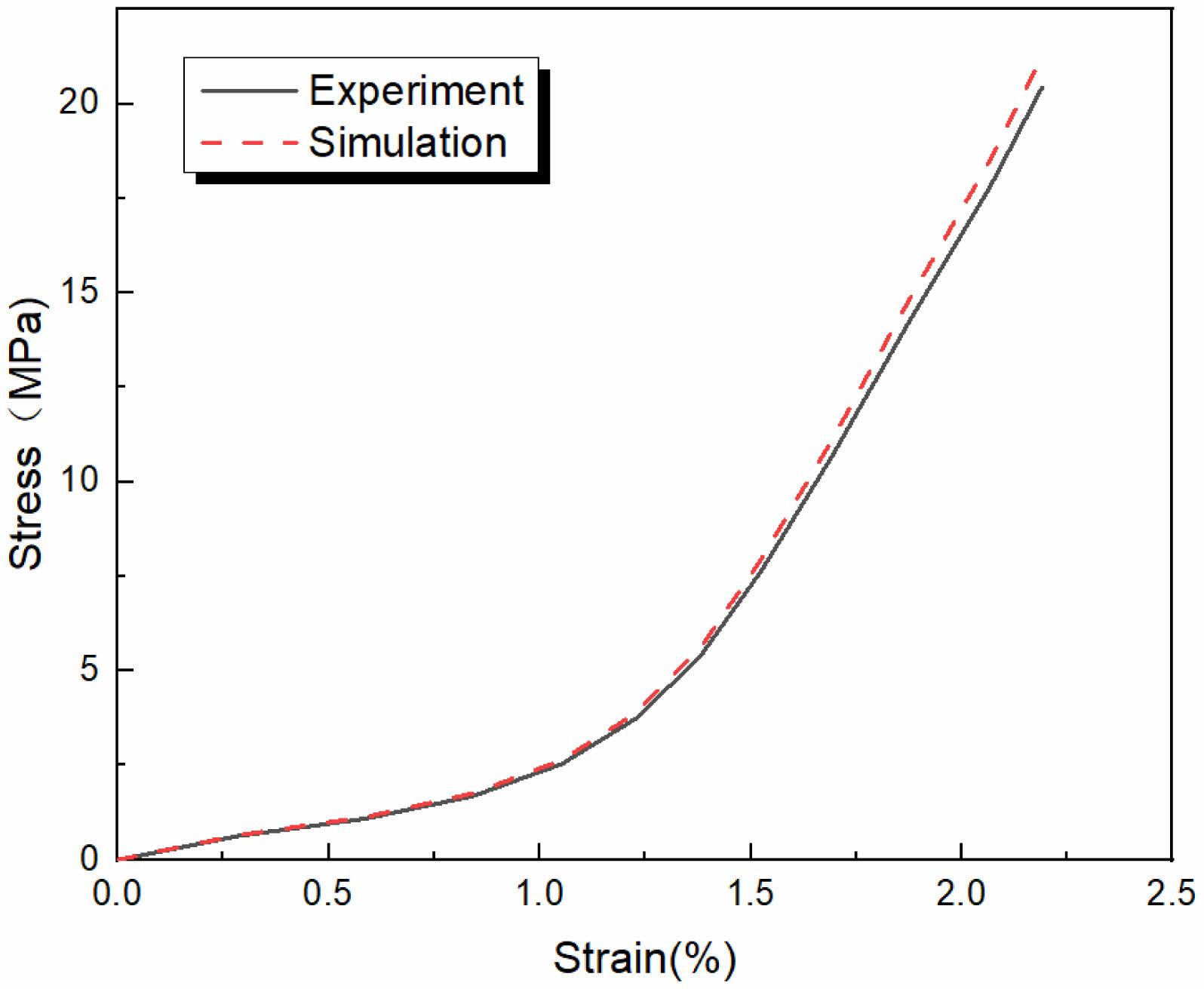

Where f (ε) is a nonlinear function, E1, E2 For the elastic modulus of nonlinear and linear springs, respectively, and η is the damping coefficient of the damper. Taking the experimental results at the loading rate of 20 mm/ min as an example, the analysis results of this function and the experimental results are shown in Fig. 9. In general, within the loading rate range of this paper (10 mm/min~35 mm/min), the stress-strain curve calculation results of the particle spring model are consistent with the experimental results, and the results are similar with good correlation. They can be used to describe the uniaxial tensile stress-strain relationship of PVB materials.

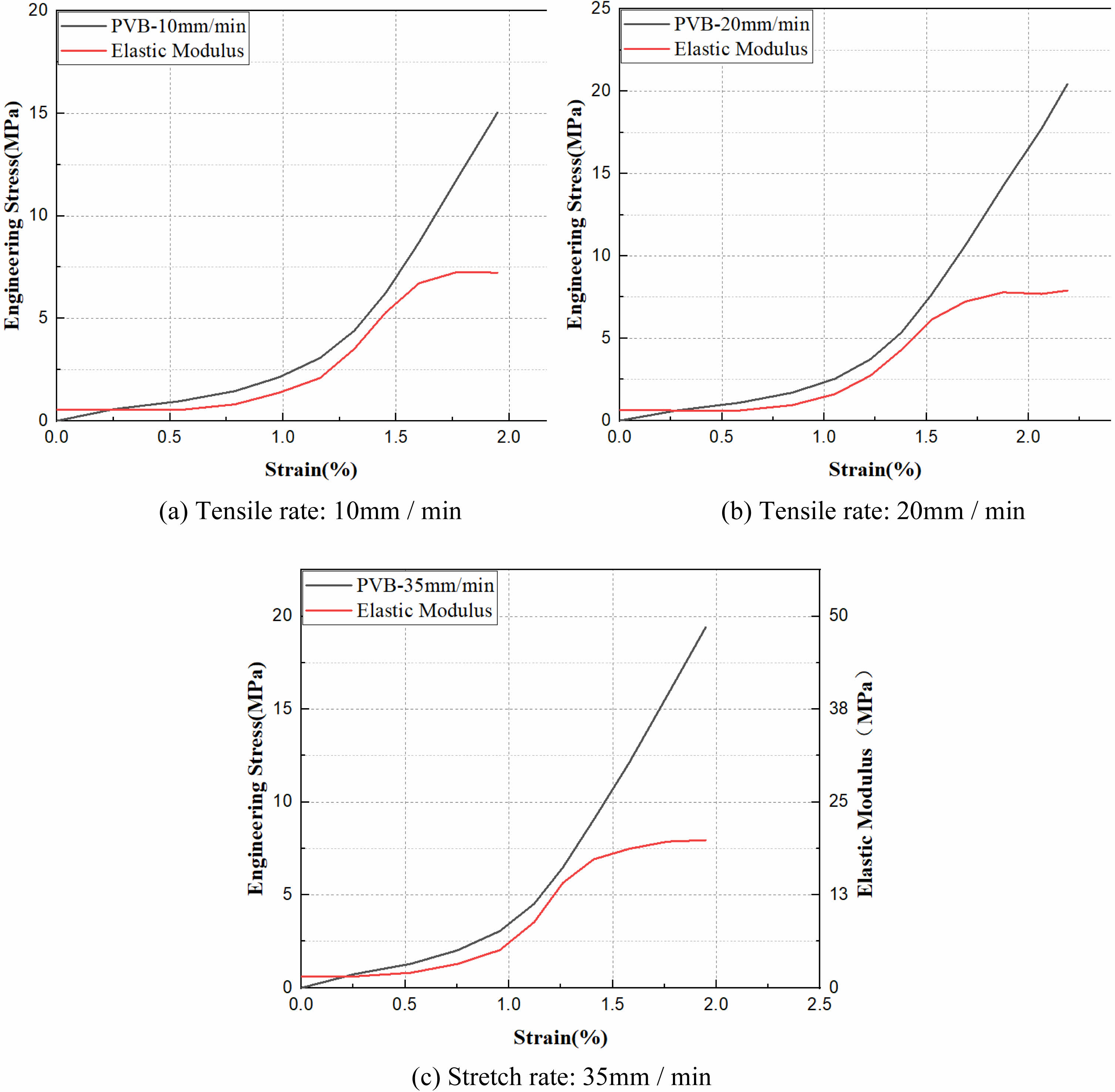

Pvb Uniaxial Tensile Elastic Modulus

The constitutive curve shows bilinear characteristics in small deformation and large deformation. We calculate each set of elastic mode step by step, and obtain the stress and strain curve and elastic modulus diagram as shown in Fig. 10 respectively. The origin underwent three Lagrange interpolations due to the accidental error.

When the strain rate is lower than 60%, the constitutive curve can be regarded as linear. The initial elastic modulus E of PVB materials at 10 mm/min, 20 mm/min and 35 mm/min is 1.34 MPa, 1.543 MPa, 2.084 MPa, and the elastic mode of small deformation is relatively stable. With the increase of strain rate, the elastic mode increases, and the deceleration increases and finally flatten. The elastic modulus curve is composed of trilinear segment. The elastic modulus E finally stabilized at 17.75 MPa, 18.780 MPa, 19.992 MPa at three loading rates of 10 mm/min, 20 mm/min and 35 mm/min, respectively. Obviously, the larger the loading rate, the larger the elastic modulus.

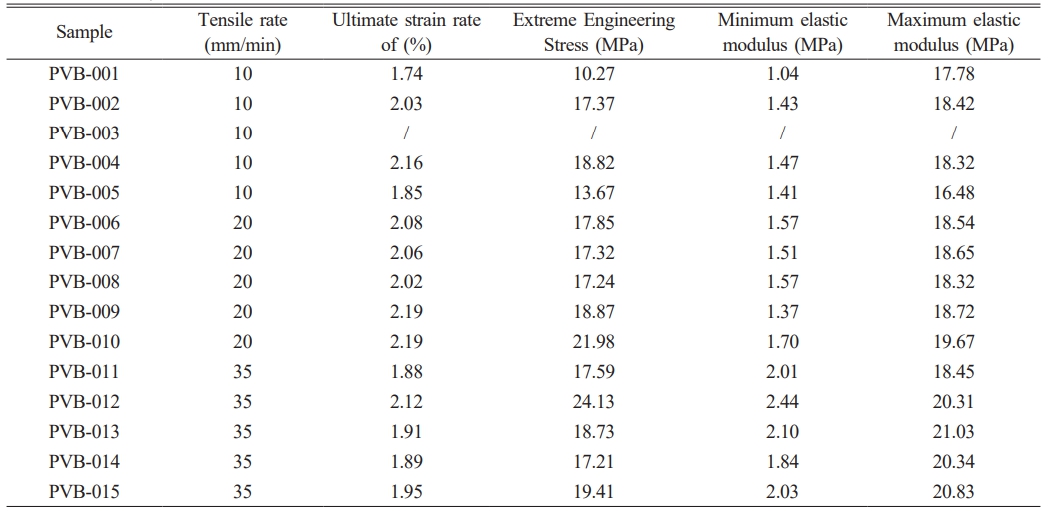

Correlation Analysis Of Pvb

The uniaxial tensile performance test results for all specimens are shown in Table 3. Compared with the initial mode at 10 mm/min loading rate, the initial mode at 20 mm/min and 35 mm/min increased by 15.15% and 55.52%, respectively. Compared with the maximum mode at 10 mm/min loading rate, the maximum mode at 20 mm/min and 35 mm/min increased by 5.80% and 12.63%, respectively. Obviously, the rate correlation of the initial mode is much higher than that of the maximum mode.

Compared with the limiting engineering stress at the 10 mm/min loading rate, the limiting engineering stress at the 20 mm/min and 35 mm/min loading rates increased by 24.08% and 29.15%, respectively. It can be seen that the rate correlation of the limit engineering stress is higher than that of the maximum elastic mode. Compared with the limiting strain rate at 10 mm/min loading rate, the limiting strain rate at 20 mm/min and 35 mm/min increased by 6.64% and-1.35% per load rate, respectively. It can be seen that the rate correlation of the limit strain rate is generally the least and is lower than the elastic modulus and the limit engineering stress [12].

In general, the mechanical parameters have obvious differences in the degree of the loading rate. The ultimate strain rate is the least affected by the loading rate, followed by the maximum elastic mode, and the ultimate engineering stress, the nominal strength, is the most affected by the loading rate, which is basically consistent with the findings in the literature.

|

Fig. 4 PVB tensile failure morphology. |

|

Fig. 5 The PVB sample finally recovers its shape after destruction. |

|

Fig. 6 Stress-strain curve of PVB sample under 10 mm/min, 20 mm/min, 35 mm/min. |

|

Fig. 7 Comparison of stress-strain curves of PVB samples under different loading rates. |

|

Fig. 8 Mass-spring model. |

|

Fig. 9 Representative simulated stress-strain curve of PVB compared to an experimental result (20 mm/min). |

|

Fig. 10 Stress-straain and elastic modulus curves of PVB specimen at 10 mm/min, 20 mm/min, 35 mm/min. |

This chapter mainly studies the uniaxial tensile properties of PVB intermediate layer materials at different loading rates, and analyzes the uniaxial tensile experiment phenomenon of PVB materials, uniaxial tensile stress-strain curve, uniaxial tensile constitutive relationship, uniaxial tensile elastic modulus and its rate correlation.The primary conclusions are drawn as follows.

(1) The residual deformation of the PVB intermediate layer material is basically stable for more than one minute after the uniaxial tensile fracture, and about 10% of the residual deformation is retained.

(2) Regardless of the size of the loading strain rate, the uniaxial tensile strain-strain curve of PVB shows very obvious bilinear characteristics. The PVB material showed a significant rate correlation. The larger the loading rate, the higher the curve, the slower the loading, the greater the tensile deformation and the lower the strength. The larger the loading rate, the larger the initial elastic modulus of the PVB. The larger the loading rate, the shorter the linear segment of the small deformation, and the earlier the onset reflects the nonlinear characteristics.

(3) PVB is regarded as a nonlinear viscoelastic material, and the particle-spring model is introduced to simply describe its uniaxial tensile mechanical behavior. For the experimental results under the loading rate, the analysis results of this function are close to the experimental results, and the correlation is good.

(4) In the uniaxial stretching of PVB, the elastic mode of the linear section of small deformation is relatively stable. With the increase of strain rate, the elastic mode acceleration increases, and then the deceleration increases and eventually tends to flatten out. The elastic modulus curve is roughly composed of trilinear segment. With the loading rate, the elastic modulus gradually increases. In the uniaxial stretching of PVB, the mechanical parameters are significantly affected by the loading rate, the ultimate strain rate is the least affected by the loading rate, and the maximum elastic mode is the second, and the ultimate engineering stress is the most affected by the loading rate.

(5) Changes in environmental temperature, freeze-thaw cycles, and other factors may cause changes in the mechanical properties of PVB materials. Therefore, it is necessary to further study the durability requirements of laminated glass panels under long-term effects.

This study is funded by the Doctoral Research Start-up Fund Project of Nanyang Institute of Technology (NGBJ-2024-17), Henan Province Science and Technology Research Project (242102240035), which are gratefully acknowledged.

- 1. X. Centelles, J.R. Castro, and L.F. Cabeza, Eng. Struct. 180 (2019) 192-204.

-

- 2. H.D. Hidallana-Gamage, D.P. Thambiratnam, and N.J. Perera, Constr. Build. Mater. 98 (2015) 502-518.

-

- 3. X.H. Zhang, H. Hao, Y.C. Shi, and J. Cui, Constr. Build. Mater. 93 (2015) 404-415.

-

- 4. X.Q. Xu, Tsinghua University (2017).

- 5. B. Liu, Y. Sun, Y. Li, Y. Wang, D. Ge, and J. Xu, Polym. Eng. Sci. 52[5] (2012) 1137-1147.

-

- 6. Z.X. Tao, Q.L. Zhang, and J. Chen, J. Build. Struct. 31[10] (2010) 114-119.

- 7. Y.J. Shi, Y. Ma, and Y.Q. Wang, J. Comput. Mech. 5 (2007) 664-668.

- 8. M. Nawar, H. Salim, M. Lafta, and A. Elshihy, J. Mater. Civ. Eng. 28[1] (2016) 4015084.1-4015084.10.

-

- 9. National Standards of the People's Republic of China Test method for tensile properties of plastics (GB-T1040-1992), Beijing, (1992).

- 10. H.G. Feng, Plast. Ind. (China). 7 (2005) 29-31.

- 11. R. Iwasaki, C. Sato, J.L. Lataillade, and P. Viot, Int. J. Crashworthines. 12[3] (2007) 293-298.

-

- 12. N. Balasubramaniam and I. Padmanaban, J. Ceram. Process. Res. 23[6] (2022) 806-816.

-

This Article

This Article

-

2024; 25(5): 798-804

Published on Oct 31, 2024

- 10.36410/jcpr.2024.25.5.798

- Received on Jun 21, 2024

- Revised on Aug 1, 2024

- Accepted on Aug 13, 2024

Services

Services

- Abstract

introduction

test method

results and discussion

conclusion

- Acknowledgements

- References

- Full Text PDF

Shared

Correspondence to

Correspondence to

- Tang Peng

-

Nanyang Institute of Technology, Nanyang 473004, Henan, China

Tel : 18338332666 - E-mail: tangpeng0830@nyist.edu.cn;tangpeng0830@126.com

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.