- Revolutionizing structural strength: unveiling enhanced reinforced concrete beams infused with cutting-edge Glass Fiber Reinforced Polymer (GFRP) composites

A. Vijayakumara,*, L. Pinky Devib, S. Southamirajanc and T. Pradeepd

aDepartment of Civil Engineering, V.S.B. Engineering College, Karur – 639111, Tamilnadu, India

bDepartment of Civil Engineering, Manipal Institute of Technology Bengaluru, Manipal Education of Higher Education, Manipal- 560064, India

cDepartment of Civil Engineering, Kongunadu College of Engineering and Technology, Tholurpatti, Tamil Nadu 621215, India

dDepartment of Civil Engineering, Kongu Engineering College, Perundurai, Tamil Nadu 638060, IndiaThis article is an open access article distributed under the terms of the Creative Commons Attribution Non-Commercial License (http://creativecommons.org/licenses/by-nc/4.0) which permits unrestricted non-commercial use, distribution, and reproduction in any medium, provided the original work is properly cited.

Fibre-reinforced polymer is a very effective approach to repair and strengthen damaged structures. A less expensive option to conventional repair methods and supplies is offered by FRP repair systems. This study investigates the shear and flexural behaviour of continuous glass fibre reinforced polymer (GFRP) reinforced concrete beams (RC beams). Testing was done on externally reinforced concrete beams using GFRP sheets joined with epoxy. GFRP sheets have been used in varying quantities and configurations to strengthen the beams. The load, deflection, and mode of failure of each beam were examined based on experimental data. The impact of GFRP layer amount and orientation on the ultimate load bearing capacity and beam failure mechanism is being investigated.

Keywords: GFRP, Waste composites, Ductility, Failure modes, Crack pattern.

Numerous RC constructions are regarded as defective structures since they do not adhere to the necessary standards. Increased applied loads, design errors, inadequate detailing, corrosion of reinforcement bars, construction flaws, upgrading of design standards, natural disasters like earthquakes, harsh environmental conditions like deterioration and aging, or inadequate maintenance are some of the possible causes of this [1]. This detailed study probably focuses on innovative research into material properties or engineering techniques, aiming to enhance performance, sustainability, or cost-effectiveness in practical applications. The authors would have set clear research objectives, employed rigorous methodologies, and utilized both experimental and analytical approaches to gather and interpret their data. The results section would present significant findings, potentially showcasing improvements in material strength, durability, or other critical factors. The discussion would interpret these results in the context of existing literature, highlighting the implications for industry practices or future research. Finally, the conclusion would summarize the key outcomes, emphasizing the study’s contribution to the field and suggesting avenues for further investigation or practical implementation [2, 3].

This research likely investigates new developments in construction materials that aim to improve structural performance, sustainability, or cost efficiency. The study would encompass comprehensive experimental methodologies to assess the properties and behavior of these materials under various conditions. Key aspects might include the material’s mechanical strength, durability, and resistance to environmental factors. The results section would provide detailed data and analysis, showing how these new materials compare to traditional ones. The discussion would interpret these findings in the broader context of construction practices, offering insights into potential benefits and applications in real-world scenarios. The conclusion would summarize the main findings, emphasize the contributions to the field of construction materials, and suggest future research directions or practical implementations that could further enhance construction technology and practices [4].

This study likely examines the enhancements in strength, durability, and environmental resistance achieved through the incorporation of innovative materials such as fibers and polymers. The research methodologies may include comprehensive experimental testing and analysis to evaluate these properties, with practical applications highlighted through case studies demonstrating the effective use of these composites in construction projects [5, 6].

This study explores cutting-edge developments in material science and their implications for enhancing structural performance and sustainability [7]. The authors review recent advancements in composite materials, with a focus on their applications in modern engineering. Key topics include the integration of innovative materials into construction practices, their impact on durability and environmental performance, and the potential for improving efficiency in structural design. The paper also discusses the challenges associated with the implementation of these advanced materials, such as cost considerations, material compatibility, and long-term performance under various environmental conditions. Through a comprehensive literature review and analysis of recent research findings, the paper provides valuable insights into how these advancements can be leveraged to meet contemporary engineering demands and contribute to more sustainable construction practices.

Research explores innovative approaches and methodologies within the field. Through rigorous empirical analysis, the authors provide a nuanced understanding of structural concrete, including its performance characteristics and practical applications. Their work contributes significantly to the ongoing dialogue surrounding structural engineering practices, making it a valuable resource for researchers, engineers, and practitioners seeking to stay informed about the latest developments in the field [8].

This research includes experimental analyses of various composite materials, focusing on their mechanical properties, durability, and behavior under different loading conditions. The authors would have detailed the methodologies employed to test these materials, including the specific tests conducted and the parameters measured. The results section would present comprehensive data on the performance of the composite materials, highlighting key findings such as improved strength, flexibility, or resistance to environmental factors compared to conventional materials. The discussion would interpret these results, comparing them to existing literature and discussing the implications for construction practices. Finally, the conclusion would summarize the study's significant contributions, emphasizing the potential benefits of incorporating composite materials into construction projects and suggesting areas for future research to further enhance the understanding and application of these materials in the industry [9].

Focuses on advancements in concrete materials, particularly the development and implementation of new admixtures and reinforcement techniques designed to enhance the performance and durability of concrete structures [10]. The paper examines the impact of various additives on the properties of concrete, such as strength, workability, and resistance to environmental factors like moisture and temperature fluctuations. Also discusses the role of innovative reinforcement strategies, including the use of advanced fibers and composite materials, in improving the structural integrity and lifespan of concrete elements. The review highlights case studies and practical applications where these new technologies have been successfully implemented, offering insights into their benefits and potential limitations. By synthesizing current research and industry practices, provides valuable guidance for engineers and construction professionals seeking to optimize concrete performance and address the evolving challenges in the field of construction. High prestressing forces are produced by post-tensioning utilizing FRP without increasing the strengthened member's self-weight.

Explore the use of composite materials in construction, specifically focusing on the performance and benefits of composite reinforcements in enhancing concrete structures [11-13]. Their study emphasizes the practical applications of composite materials, detailing their impact on structural strength, durability, and overall performance. The research on advanced ceramic processing techniques, investigating how innovative methods can improve the properties of ceramic materials used in construction. The papers highlight recent advancements in processing technologies, which enhance the mechanical properties and functionality of ceramics, contributing to more effective and efficient construction materials. The author examines the structural performance of engineered systems, particularly focusing on the use of modern engineering techniques to assess and optimize structural integrity. It includes detailed analyses of various structural configurations and materials, offering insights into how different factors influence the performance and safety of engineered structures. It contributes to a deeper understanding of composite materials, ceramic processing, and structural engineering advancements, providing practical and theoretical knowledge applicable to current and future engineering challenges.

The paper focus on the use of advanced composite materials, particularly fiber-reinforced polymers (FRPs), in enhancing the structural integrity and durability of engineering systems [14]. The study covers various types of composites, including glass, carbon, and aramid fibers, and evaluates their effectiveness in reinforcing concrete structures and other construction elements. The mechanical properties of these composites, such as their tensile strength, flexibility, and resistance to environmental degradation. Also examines design considerations, including how to integrate composites into existing structures and the impact of composite reinforcement on overall structural performance. Through a review of experimental studies and practical applications, provide valuable insights into the benefits and limitations of using composites in structural engineering. The work highlights the potential for composites to address common challenges in construction, such as corrosion and load-bearing capacity, while also addressing issues related to cost, installation, and long-term durability.

The integration and performance of advanced composite materials in structural applications were investigated, as well as their impact on improving the strength and durability of various structures [15,16]. The study highlights the benefits of using composites in demanding environments, addressing issues such as load-bearing capacity and resistance to environmental degradation. The paper also delves into the methodologies for optimizing composite materials in practical engineering scenarios, offering insights into their effective application in structural reinforcement. The role of composite materials in improving the performance of concrete structures, particularly through innovative reinforcement techniques were discussed. This research provides a detailed analysis of how different composite materials, including fiber-reinforced polymers, contribute to the strength and longevity of concrete elements. The study includes experimental results and case studies that demonstrate the effectiveness of these materials in enhancing structural integrity. Papers offer valuable perspectives on the evolving use of composite materials in construction, emphasizing their potential to address contemporary engineering challenges and improve structural performance.

Brittle failures such as shear failure happen quickly and without warning signs. Certain causes like as design flaws, corrosion in the transverse reinforcement, and an increase in applied stresses might cause RC members to be shear deficient [17, 18]. Contributes significantly to the field’s understanding of innovative materials and construction methodologies. With a focus on advancements in construction technology, delves into the intricacies of material composition, performance characteristics, and structural integrity. Through meticulous analysis and empirical investigation, the author offers valuable insights into the practical applications and implications of their findings.

The study focuses on the evaluation and application of innovative materials for enhancing the performance and durability of building components [19]. The paper examines various types of construction materials, including those with enhanced mechanical and environmental properties, and their impact on improving structural integrity and longevity. Key topics include the effectiveness of these materials in addressing common issues such as moisture resistance, thermal insulation, and structural reinforcement. Presented experimental data and case studies that illustrate the benefits and limitations of using advanced materials in real-world construction scenarios. The study also discusses design considerations and practical implications for integrating these materials into existing and new construction projects. Through a comprehensive review of current research and industry practices, the paper offers valuable insights into how advanced materials can contribute to more efficient, sustainable, and resilient construction practices.

This research discusses the use of fiber-reinforced polymers (FRPs) to improve the load-bearing capacity and durability of concrete structures, offering experimental data that show the efficacy of these composites in addressing corrosion and fatigue [20, 21]. Their findings offer practical insights into optimizing FRP materials for real-world applications. In contrast, explore the wider integration of advanced composites into both new construction and retrofitting projects, highlighting their role in improving structural strength and stability. This study includes case studies and experimental results that illustrate the benefits of various composite materials and discusses key design considerations for their application. Together, these papers highlight how composites, particularly FRPs, are transforming construction practices by enhancing performance, durability, and addressing practical engineering challenges.

The study examines the effectiveness of various reinforcement materials, including fiber-reinforced polymers (FRPs) and other composites, in improving the structural performance and durability of concrete structures [22]. The authors present experimental data and case studies that highlight the benefits of these materials, such as enhanced load-bearing capacity, resistance to environmental degradation, and improved long-term performance. Additionally, explores practical considerations for integrating these advanced materials into construction practices, including issues related to cost, installation, and compatibility with existing materials. By giving a complete examination of both the theoretical and practical aspects of material performance, researchers can gain significant insights into current improvements in building technology and the optimisation of reinforcement schemes for increased structural integrity.

Provide a comprehensive analysis of various approaches to structural integration, exploring their effectiveness in enhancing the performance and resilience of built environments. Through empirical research and rigorous analysis, the authors elucidate key principles and considerations for implementing structural integration strategies in engineering practice. This paper serves as a valuable resource for researchers, practitioners, and policymakers seeking to deepen their understanding of structural integration and its role in advancing the sustainability and resilience of infrastructure systems [23].

The study focuses on the use of fiber-reinforced polymers (FRPs) in enhancing the performance and durability of concrete structures [24]. Analyse the mechanical properties of various composite materials and their efficiency in reinforcing structural elements under varied loading levels and environmental considerations. The paper includes experimental results and case studies that demonstrate how FRPs can improve load-bearing capacity, reduce susceptibility to corrosion, and extend the service life of reinforced concrete. Additionally, the authors discuss design considerations and practical aspects of implementing composite reinforcement, including factors such as material compatibility, installation techniques, and cost implications.

The mechanical characterization of glass fiber reinforced with aluminum wire mesh under various analyses is the focus of this study [25]. By subjecting the composite material to different analytical methods, researchers aim to understand its mechanical properties and behavior under diverse conditions. This investigation involves assessing parameters such as tensile strength, flexural strength, impact resistance, and fatigue performance. Through comprehensive analysis, the study aims to provide insights into the structural integrity and performance of the composite material, shedding light on its potential applications in engineering and construction industries.

This research aims to investigate the mechanical behavior of the composite material under both tensile and flexural loading conditions [26]. By combining experimental testing with numerical simulations, the authors seek to gain insights into the material’s performance characteristics and structural response. The study’s findings contribute to a better understanding of hybrid composite materials and their potential applications in various engineering fields.

This research delves into the process of optimizing machining parameters to enhance the efficiency and quality of machining operations on GFRP composites. Through the application of Taguchi Grey Relational Analysis, the authors aim to identify the most influential machining parameters and their optimal levels to achieve improved machining performance [27]. The findings of this study contribute to the advancement of machining techniques for GFRP composites, offering insights for practitioners and researchers in the field of composite materials processing.

The use of Fiber Reinforced Polymer (FRP) composites in concrete structures reveals a comprehensive evolution of this technology, highlighting its development, applications, and performance [28]. Initially, FRP composites emerged as innovative materials with high strength-to-weight ratios, providing significant advantages over traditional materials. The literature survey covers various types of FRP composites, including Glass Fiber Reinforced Polymer (GFRP), Carbon Fiber Reinforced Polymer (CFRP), and Aramid Fiber Reinforced Polymer (AFRP), each offering unique properties suited to different applications. Research has extensively documented the mechanisms through which these composites enhance concrete structures, focusing on bonding interactions and load transfer efficiencies. Design guidelines and standards from organizations such as the American Concrete Institute (ACI) provide crucial frameworks for the effective use of FRP composites in structural engineering. Experimental studies and real-world case studies further enrich the survey, offering insights into the practical applications and performance outcomes of FRP composites in various construction scenarios. Despite their benefits, challenges related to durability, environmental impacts, and cost are also addressed, pointing to the need for ongoing research to resolve these issues. The survey concludes by identifying future research directions and emerging trends, emphasizing the potential for further advancements and innovations in the field of FRP composites.

A paper highlighted comprehensive overview of the advancements and applications of Glass Fiber Reinforced Polymer (GFRP) composites in engineering [29, 30]. Both reviews emphasize the superior characteristics of GFRP composites, including their high tensile strength, lightweight nature, and excellent corrosion resistance, which make them particularly advantageous for use in structural and civil engineering. The researchers focus on the fundamental properties of GFRP composites and their application in structural reinforcement, detailing how GFRP is utilized to enhance the performance of concrete structures, such as in bridge and building retrofitting. Also addresses design considerations, including the influence of GFRP's mechanical properties on structural integrity and safety. In contrast, the scope to include recent developments and state-of-the-art applications of GFRP in various civil engineering contexts. It highlights innovative uses of GFRP in new construction, such as in high-rise buildings and infrastructure projects, and discusses the integration of GFRP composites into design codes and standards. Explained about the practical challenges associated with GFRP, including issues related to long-term durability, cost implications, and the need for improved design guidelines. The combined insights from these reviews underscore the transformative potential of GFRP composites in modern engineering practices and outline key areas for future research and development

Provides an in-depth analysis of the long-term performance and durability of Glass Fiber Reinforced Polymer (GFRP)-reinforced concrete structures [31]. The paper systematically examines the longevity and resilience of GFRP composites when used as reinforcement in concrete, addressing key factors that impact their performance over extended periods. The authors explore how GFRP reinforcement performs under various environmental conditions, including exposure to moisture, chemicals, and temperature fluctuations. Also discusses empirical data from long-term studies and field observations, highlighting both the advantages and limitations of GFRP composites in maintaining structural integrity over time. It emphasizes the superior resistance of GFRP to corrosion compared to traditional steel reinforcement, which can significantly extend the service life of concrete structures. However, the paper also identifies potential issues, such as the effects of UV exposure and the long-term stability of the bond between GFRP and concrete. The authors provide a critical assessment of existing performance models and suggest improvements based on recent research findings.

The papers focus specifically on the use of GFRP for strengthening reinforced concrete beams, detailing various methodologies, performance outcomes, and case studies [32, 33]. This paper provides insights into the effectiveness of GFRP in enhancing the load-carrying capacity, ductility, and overall structural performance of concrete beams, emphasizing improvements in design practices and installation techniques. On the other hand, addresses broader advancements in GFRP composites, covering their use in infrastructure applications beyond concrete beams, including bridges, pavements, and other critical structures. Paper highlights recent technological innovations, improvements in material properties, and the integration of GFRP composites into modern infrastructure design. It converges on the significant benefits of GFRP, such as its lightweight nature, high strength, and resistance to environmental degradation, while also discussing challenges like cost, long-term performance, and design standardization.

Provide a multifaceted examination of Glass Fiber Reinforced Polymer (GFRP) composites in modern construction practices [34-36]. Emphasizes the role of GFRP composites in sustainable construction, highlighting their environmental benefits such as reduced material usage, lower life-cycle emissions, and the potential for recycling. They discuss how GFRP contributes to sustainability through its long service life and minimal maintenance requirements, supporting more eco-friendly construction practices. Further focus on the performance of GFRP-reinforced concrete beams, summarizing experimental studies that demonstrate the material’s effectiveness in enhancing structural performance. This includes detailed findings on load-bearing capacity, ductility, and failure modes, offering critical insights into the practical advantages and limitations of using GFRP in beam reinforcement. The paper explores innovative applications of GFRP composites across various construction domains, from traditional structural applications to novel uses in infrastructure and specialized projects. The paper highlights the cutting-edge developments, such as the integration of GFRP in complex architectural designs and advanced engineering solutions, providing a broad view of how GFRP is pushing the boundaries of modern construction.

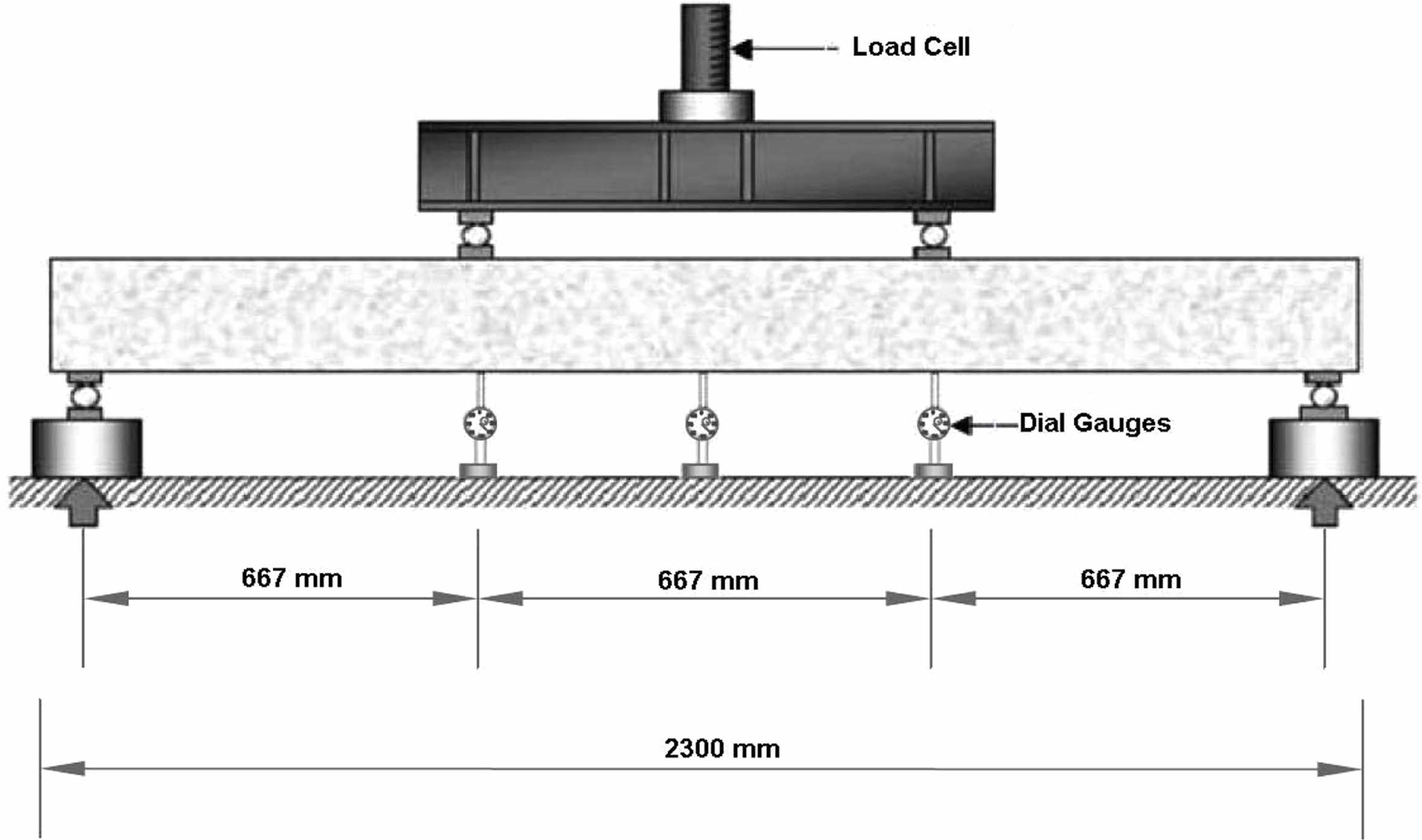

In order to facilitate this experimental test program, two beam sets were cast. Three flexure-weak beams (F1, F2, and F3) in Set I were cast with the identical concrete grade and reinforcing details. Three shear-weak beams (S1, S2, and S3) in SET II were cast with the identical concrete grade and reinforcing details [37]. Every specimen has the same measurements. Both sets of beams have cross-sectional measurements of 275 mm by 250 mm and 2300 mm in span.

Every specimen underwent testing in the laboratory's loading frame. Following the 28-day curing process, the beam was cleaned to ensure that any cracks were easily visible. Two-point loading is the most common load configuration for beam testing [38]. The configuration depicted in Figure 1 can conveniently provide two-point loading. Common testing methods include four-point and three-point bending tests, where loads are applied, and deflections are measured to evaluate the beam's behavior. These tests help in understanding the beam’s performance under different loading conditions.

|

Fig. 1 Experimental setup. |

The governing failure mode determines a section's flexural and shear strength. A section strengthened using fiber-reinforced polymer (FRP) should look at the flexural and shear failure modes listed below: Typical failure modes include rupture of GFRP reinforcement, concrete crushing in the compression zone, and debonding of GFRP from the concrete. Unlike steel, GFRP does not yield before failure, making the failure more brittle. The following scenarios can occur: concrete is crushed under compression before the reinforcing steel yields; the steel yields under tension and the FRP laminate ruptures; the steel yields under tension and the concrete is crushed afterwards; the concrete cover delaminates under shear or tension and the FRP debonds from the concrete substrate [39]. During the investigation concrete is crushing at the top, flexural failure resulting from GFRP rupture, shear failure, and flexural failure. If the concrete's compressive strain reaches its maximum useable strain, it is expected that concrete crushing will occur. Challenges include managing larger deflections due to the lower modulus of elasticity, ensuring adequate bond between GFRP and concrete, and preventing brittle failure through appropriate design and detailing.

Tests on both the control beams and the GFRP reinforced beams were done to find their maximum load bearing capability. The control beams, F1 and S1, were found to have failed in shear and flexure, respectively, suggesting that the beams were deficient in these regions. In set one, beam F2 collapsed as a result of a GFRP sheet breaking into two parts, followed by flexural-shear failure of the beam. Beam F3 collapsed due to GFRP sheet delamination, which in turn caused the beam to fail flexural shear. When strengthening was carried out utilizing both wrapping strategies, GFRP rupture and flexural-shear type of failure were evident in set one beams F2 and F3. The second pair of S2 and S3 beams broke due to flexural failure and the top of the beams being crushed by concrete. Significant flexural fractures developed in the set two beams S2 and S3 at the highest loads. Set two beams S2 and S3 clearly demonstrated the flexural kind of failure when strengthening was carried out utilizing both wrapping procedures.

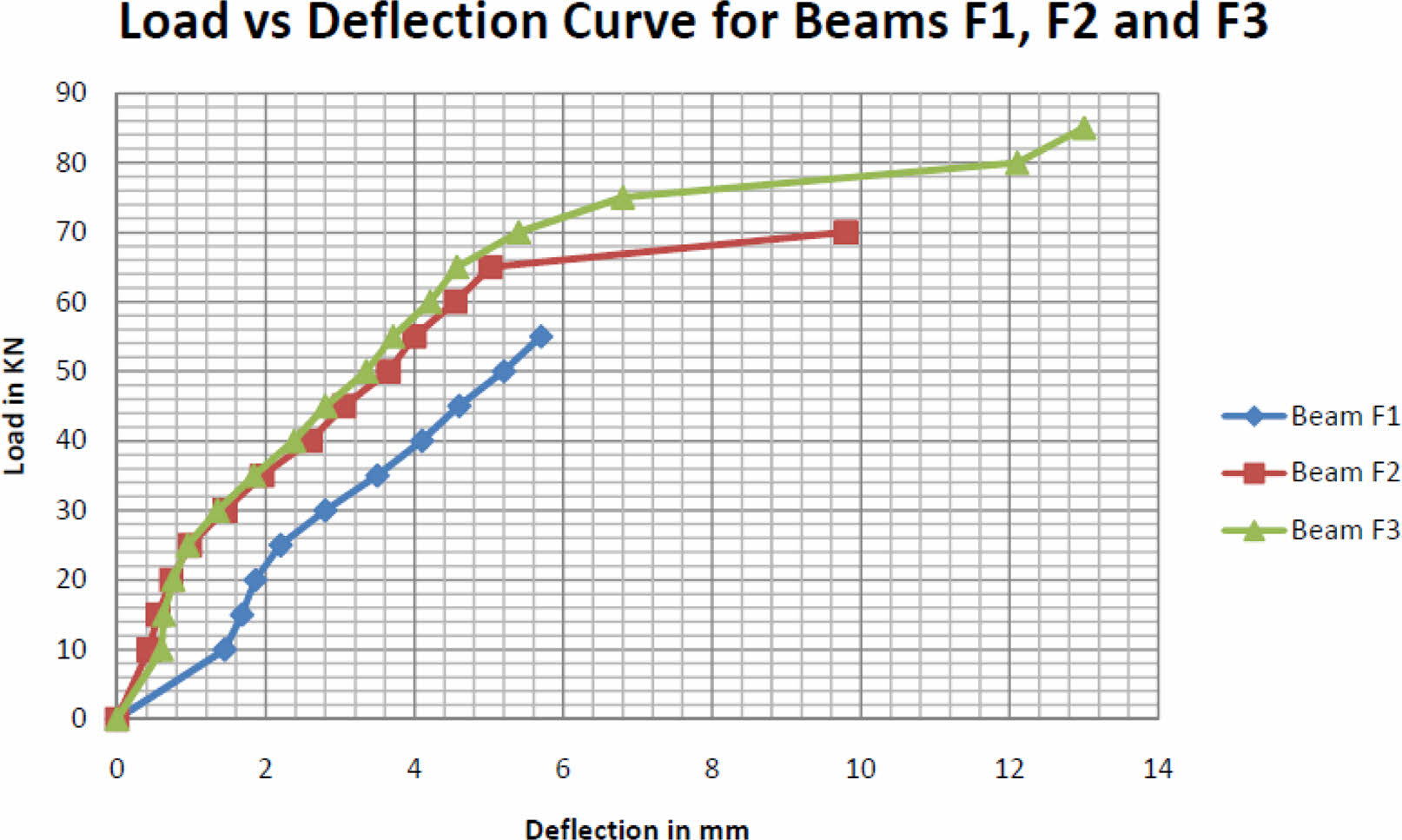

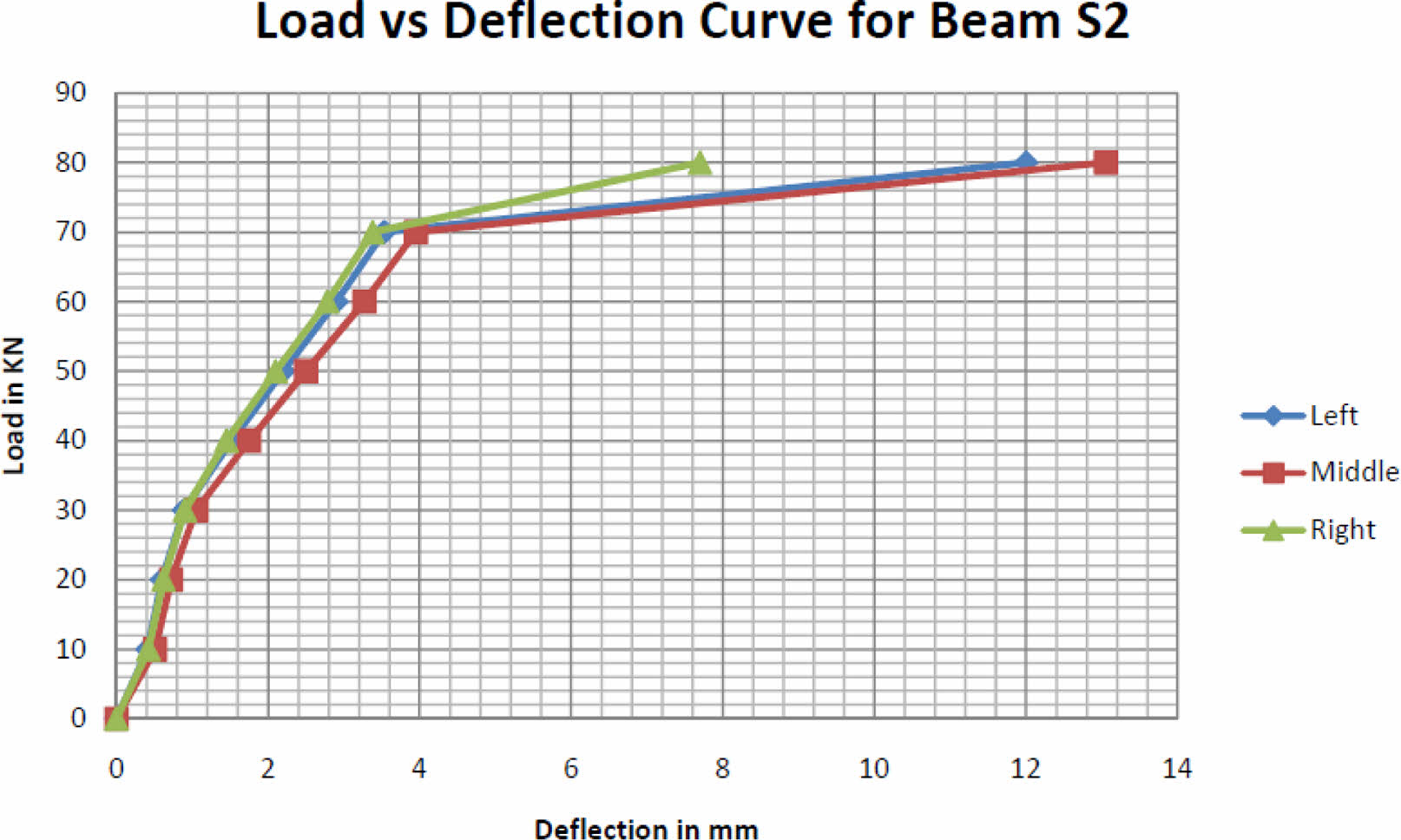

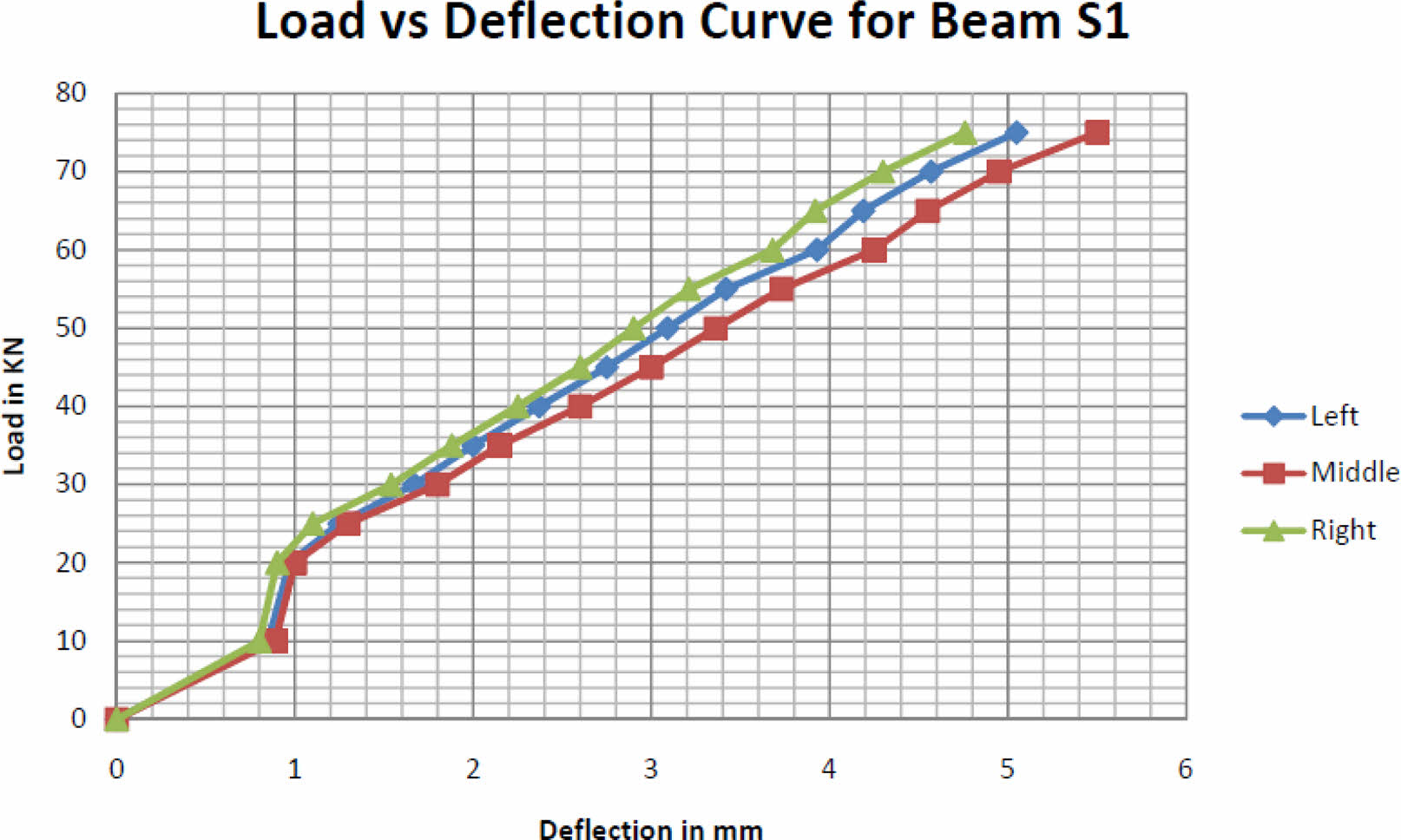

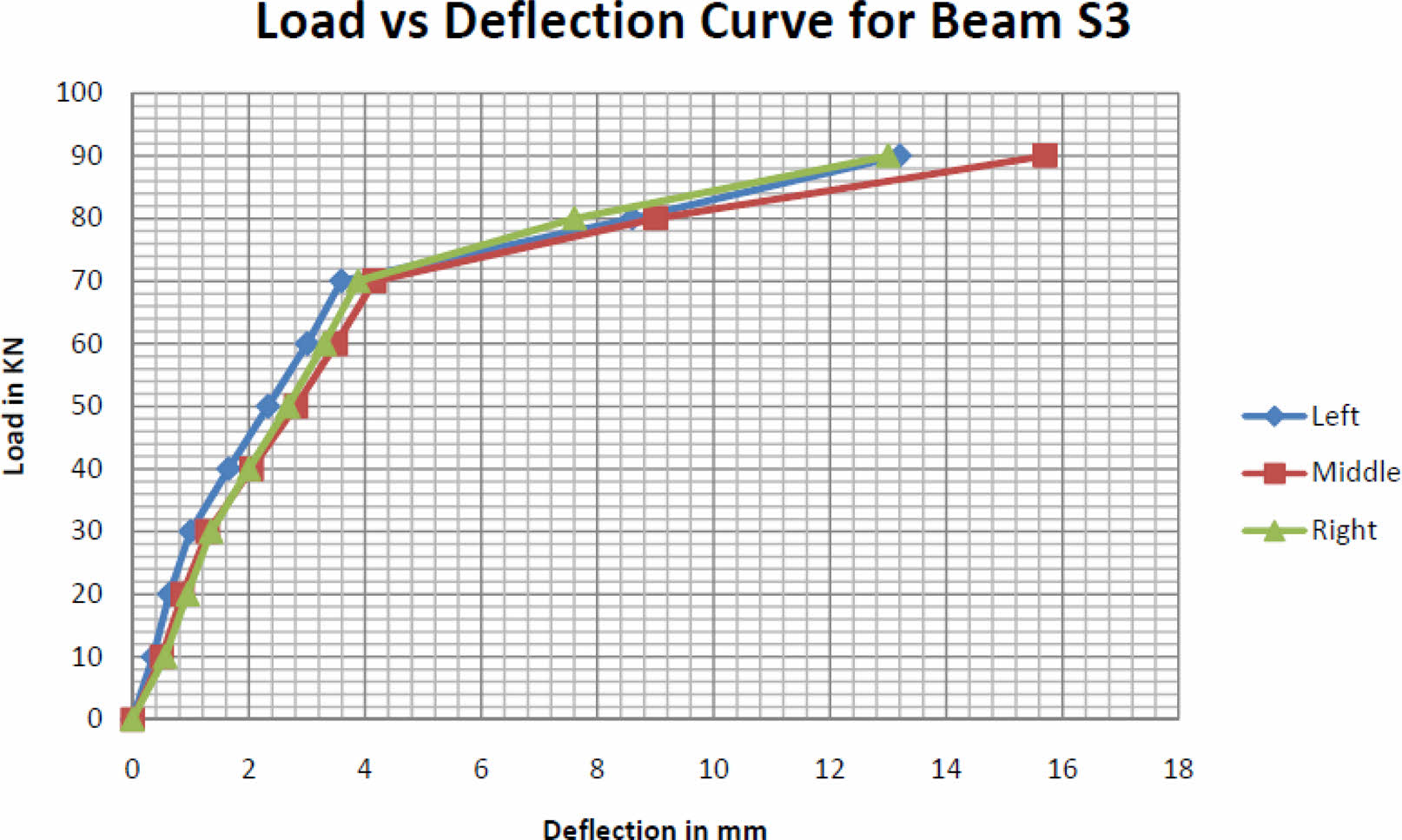

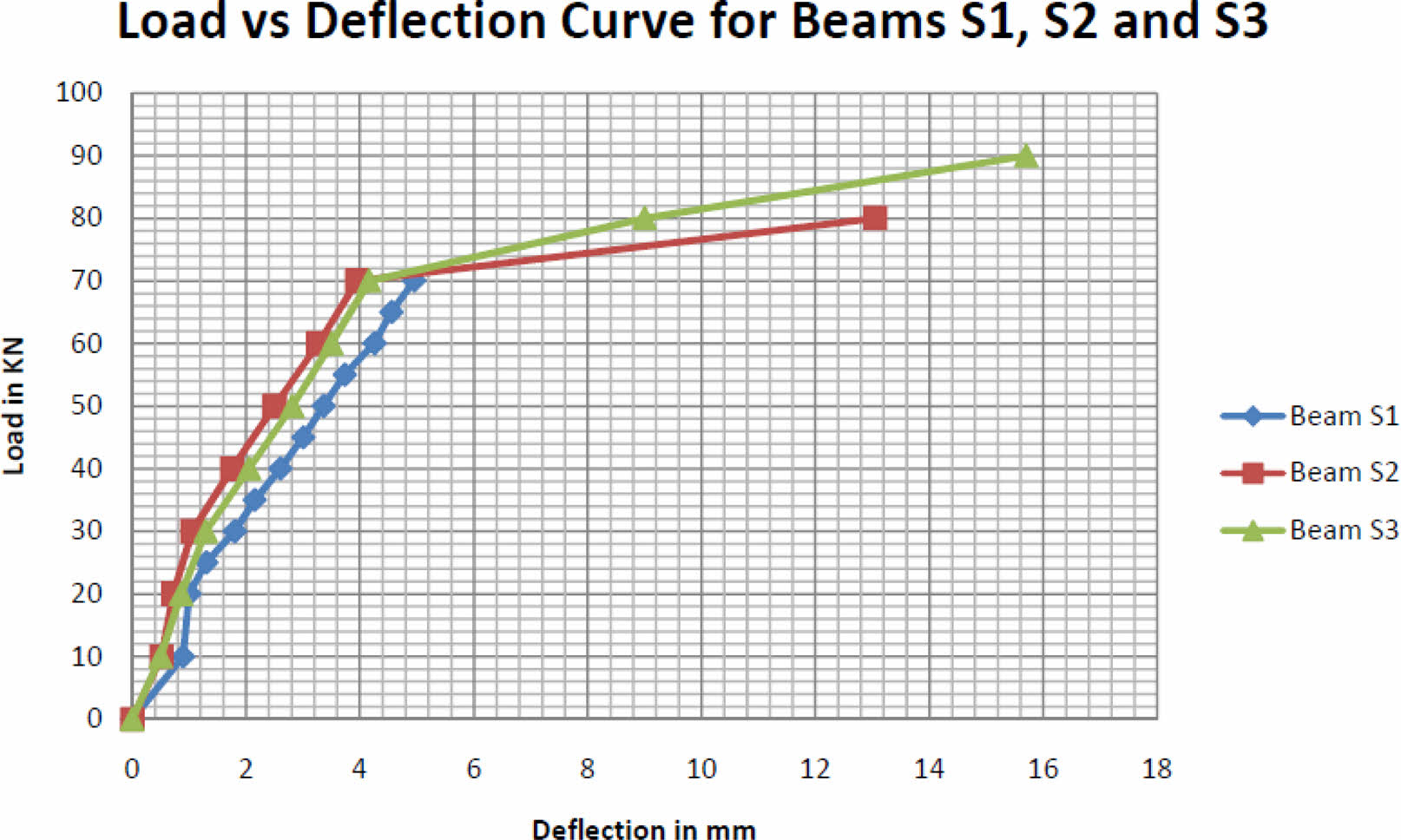

The behavior of flexure and shear deficient beams was found to be improved when bonded with GFRP sheets, compared to the equivalent control beams. When GFRP sheets were bonded externally, the mid-span deflections were significantly reduced. Figures 5 and 9 display the graphs contrasting the equivalent control beams' deflection with those of the flexure and shear defective beams. The initial portion is linear because both concrete and steel are uncracked and behaving elastically, following Hooke's Law, where deflection is directly proportional to the applied load. When both wrapping schemes were taken into account in set one, beam F3, which had GFRP sheeting up to the centre of the beam and the bottom, performed well in terms of load deflection than beam F2, which only had GFRP sheeting at the bottom of the beam. When both wrapping procedures were considered in set two, the beam S3 with U-shaped GFRP sheeting demonstrated superior load deflection behavior than the beam S2 with GFRP sheeting just at the sides of the beam. The modulus of elasticity of GFRP is generally lower than that of steel, resulting in greater deflections under the same load. This characteristic must be considered in the design to ensure serviceability.

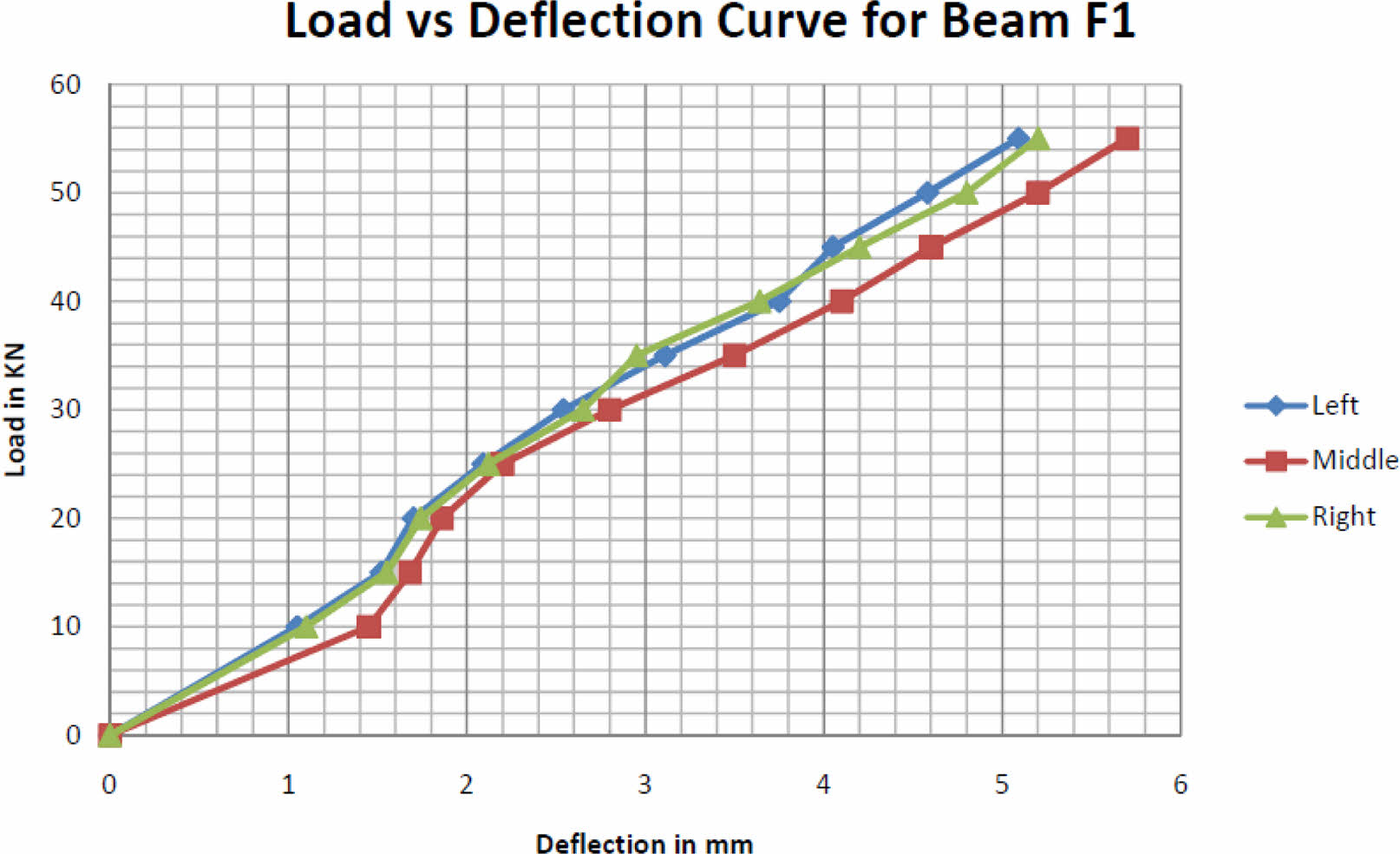

A load vs deflection curve is plotted using the load and deflection data. First cracks appeared on the beams with a weight of 30 KN and maximum load 78 kN respectively. At the ultimate load stage, the beam reaches its maximum load-carrying capacity. Beyond this point, any additional load causes a rapid increase in deflection, leading to failure. The curve typically shows a steep rise. Additionally, when the loading increased, the cracks propagated. In flexure, beam F1 totally failed.

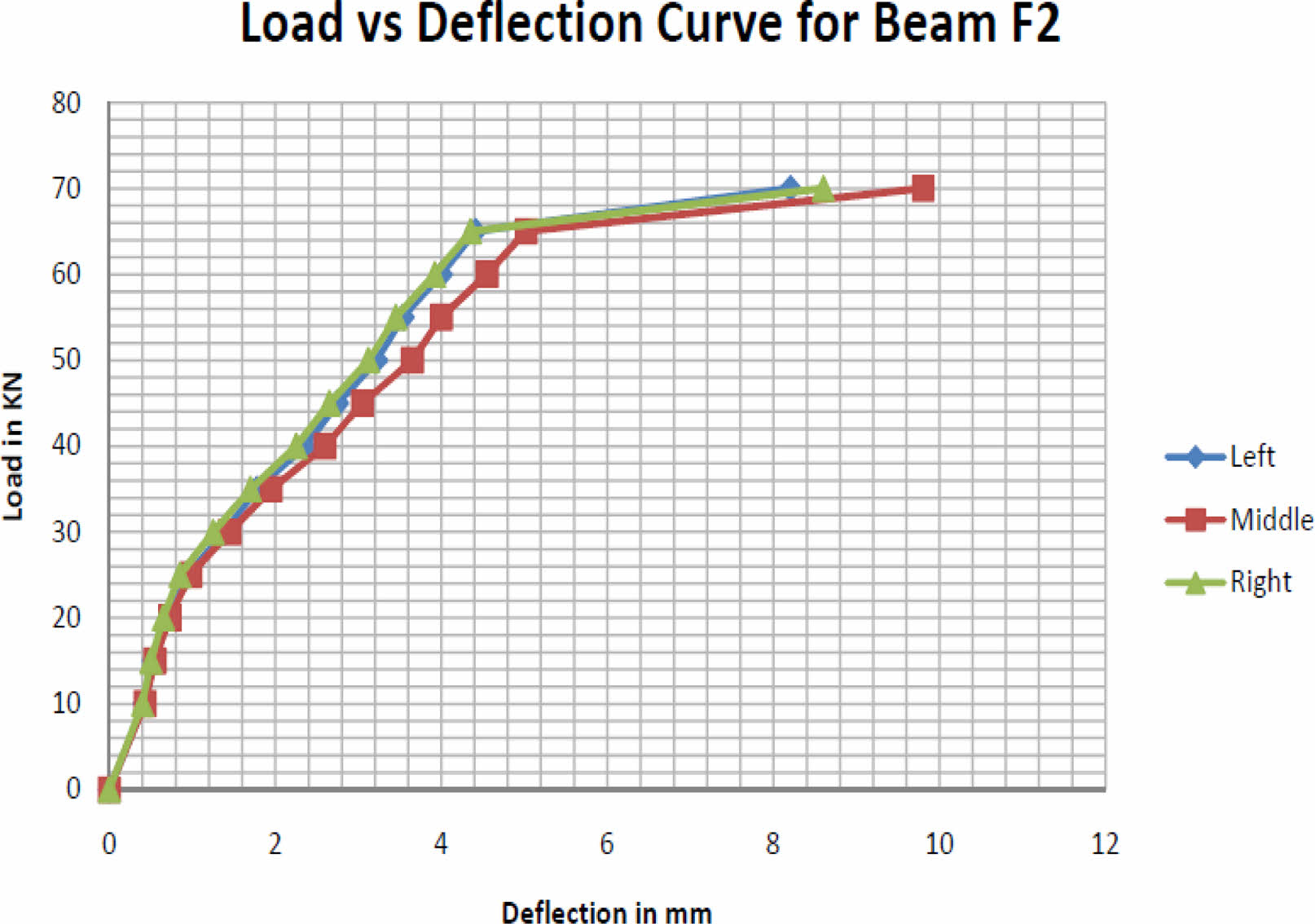

SET's Beam F2 beams with strong shear properties but weak flexure properties. Only the soffit of the beam receives the application of GFRP sheeting for strengthening in beam F2. A load vs deflection curve is plotted using the load and deflection data. First cracks appeared on the beams at a weight of 34 KN maximum load 104 kN respectively. In comparison to beam F1, the initial cracks in beam F2 began at a higher load. Additionally, when the loading increased, the cracks propagated. Flexural shear caused the failure of beam F2. The ultimate load handled by beam F2 was greater than that of beam F1. The bond between GFRP and concrete is crucial for effective load transfer. Poor bonding can lead to premature failure and increased deflections, whereas good bonding ensures composite action and better structural performance.

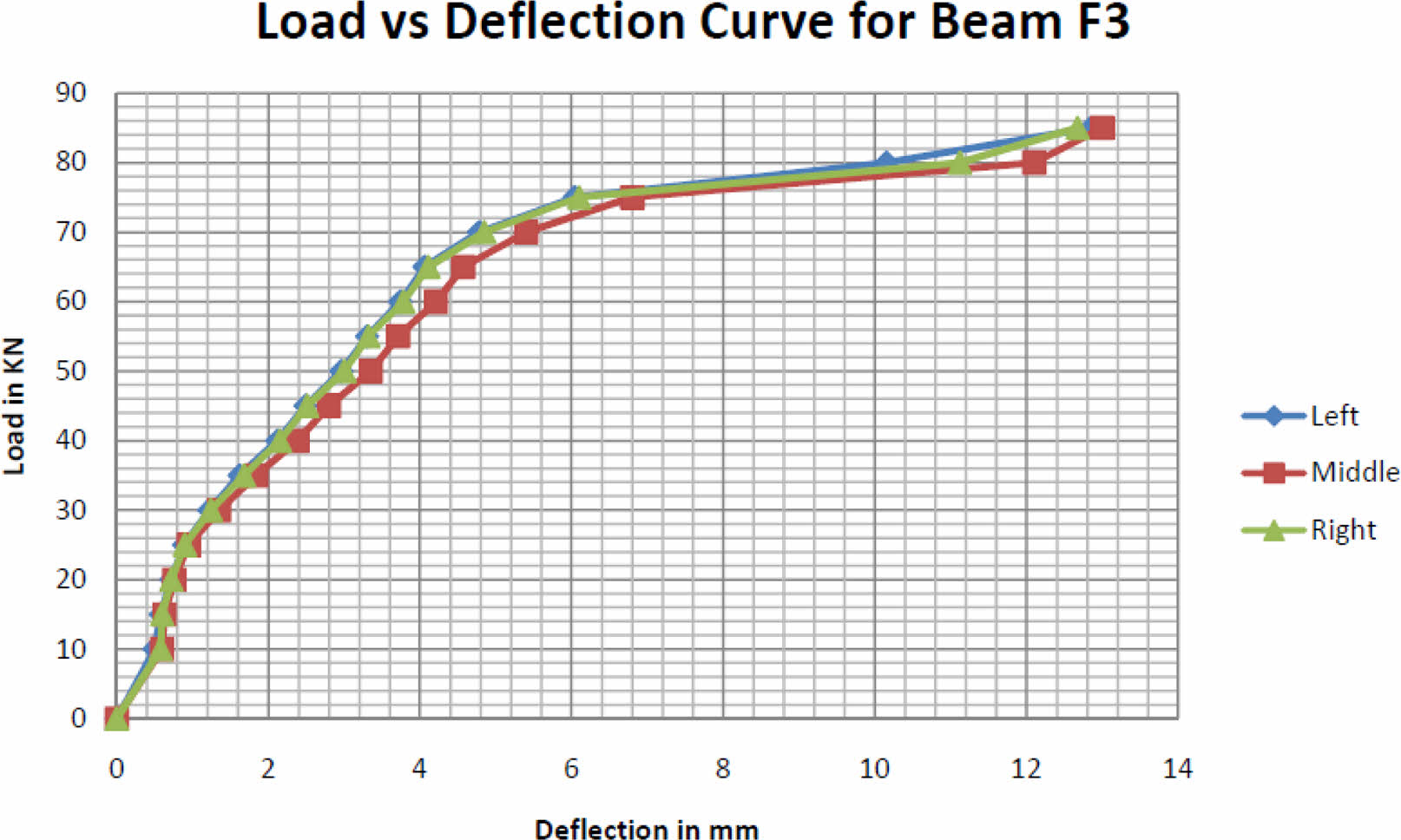

SET's Beam F3 I beams with strong shear properties but weak flexure properties. Beam F3 is strengthened by applying GFRP sheeting up to middle and covering beam's soffit. A load vs deflection curve is plotted using the load and deflection data. The beams do not show signs of initial cracks. Additionally, as the loading increased, the cracks propagated, but because the GFRP sheet was covered, the cracks were difficult to see. Although F3 beam had maximum load than both beams F1 and F2, it failed in flexural shear just like beam F2. In the post-cracking stage, deflection increases more rapidly for a given increase in load. The concrete in the tension zone contributes less to load resistance, and the beam relies more on the GFRP reinforcement.

A deflection curve against load has plotted each of the three set one specimens F1, F2, and F3. According to this load vs. deflection graph, F1 can support less weight in the end than F2 and F3 beams. Like F2 and F3 beams, F1 beam had also seen more deflection at the same tension. Although F2's extreme load carrying capacity was lower than that of F3, it was still higher than that of the controlled F1. F3 had a higher maximum load carrying capacity than F1 and F2. Up to a 65 KN load, F2 and F3 had approximately the same deflection. After a 65 KN load, albeit at a higher load than F2, beam F3 saw the same deflection as beam F2. It is F3 that experiences the largest deflection. F2 has exhibited a larger deflection in comparison to F1.

The control beam for the set of two beams, Beam S1, had a strong flexure but a weak shear strength. Strengthening was not done in beam S1. Initial cracks on the beams appeared at 35 KN of load maximum load 82 kN respectively. The cracks continued to propagate as the loading increased. Beam S1 initially just developed flexural cracks, but eventually beam collapsed in shear.

Beam S2 of the set two beams had a strong flexure but a weak shear strength. Only the two sides of the beam receive the application of GFRP sheeting to reinforce beam S2. A load vs deflection curve is plotted using the load and deflection data. First cracks appeared on the beams at 39 KN of load maximum load 108 kN respectively. In comparison to beam S1, initial cracks in beam S2 began at a higher load. Additionally, when the loading increased, the cracks propagated. Only flexural cracks appeared in beam S2, and eventually the concrete crushed, and the beam failed due to flexural failure. In the end, S2's load was more than beam S1's but less than beam S3's.

Beam S3 of the set two beams has a strong flexure but a weak shear strength. The strengthening of beam S3 is achieved by applying GFRP sheet as a U-wrap to the beam. A load vs deflection curve is plotted using the load and deflection data. First cracks appeared on the beams at 40 KN of load maximum load 122 kN respectively. In comparison to beams S1 and S2, the initial cracks in beam S3 began at a higher load. Additionally, when the loading increased, the cracks propagated. Like beam S2, beam S3 only experienced flexural fractures before failing due to flexural failure and concrete crushing; however, beam S3's ultimate load was greater than that of beam S1 and S2.

According to this load vs. deflection graph, beam S1 can support less weight in the end than beams S2 and S3. For the same load, S1 had likewise experienced greater deflection than S2 and S3. While it was less than that of S3, S2's maximum load carrying capability was higher than that of the controlled beam S1. When comparing S1 and S2, S3's maximum load bearing capacity was higher. The deflection of S2 and S3 was nearly identical up to a load of 71 KN. After a 71 KN load, S3 deflected in the same way as S2, but more so than S2. S3 experiences the greatest deflection. The deflection of S2 is larger than that of S1. Long-term deflections, influenced by factors like creep and shrinkage, are important to consider because GFRP’s lower modulus of elasticity can lead to greater deflections over time, impacting serviceability.

Fig. 2 Fig. 3 Fig. 4 Fig. 6 Fig. 7 Fig. 8

|

Fig. 2 Deflection Curve against Load for Beam F1. |

|

Fig. 3 Deflection Curve against Load for Beam F2. |

|

Fig. 4 Deflection Curve against Load for Beam F3. |

|

Fig. 5 Deflection Curve against Load for Beam F1, F2 and F3. |

|

Fig. 6 Deflection Curve against Load for Beam S1. |

|

Fig. 7 Deflection Curve against Load for Beam S2. |

|

Fig. 8 Deflection Curve against Load for Beam S3. |

|

Fig. 9 Deflection Curve against Load for Beams S1, S2 and S3. |

Both set one and two beams underwent two-point static loading, and crack formation and deflection were noted at each load increment. All the beams’ initial crack loads were noted. In the initial uncracked elastic stage, the RC beam behaves elastically with a linear relationship between load and deflection. Both concrete and steel reinforcement contribute to resisting the load, and no cracks are present. The stress at which the crack in beam F1 starts to form is 30 KN, but in beam F2, the crack starts to form at 34 KN. During the cracking stage, the tensile stress in the concrete exceeds its tensile strength, leading to the formation of cracks in the tension zone. The load-deflection curve starts to deviate from linearity as the steel reinforcement begins to take on more of the tensile load. Beam F3’s crack origin was hidden from view by applying GFRP sheet up to the middle of the beam. Only under a 90 KN load were cracks visible. The crack in S1 begins at a load of 35 KN, which is less than the load in F2, where the crack began at 39 KN, and even less than the load in F3, where the crack began at 40 KN. S2 and S3 did not differ significantly in terms of load for fracture initiation. Reinforcement controls the width and propagation of cracks, ensuring they remain within acceptable limits and do not compromise the structural integrity of the beam.

Stronger beams F2, F3, S2, and S3 were shown to have the extreme load carrying capacity of all the beams, as compared to the controlled beams F1 and S1.The F1, F2, and F3 beams in Set I were subjected to two-point static loading. Cracks started to form as the strain was gradually increased, and eventually the beam gave way. The F1 beam’s ultimate load was 78 KN, which is less than the 104 KN ultimate load carried by the F2 beam and even less than the 104 KN ultimate load carried by the F3 beam.

S1, S2, and S3 beams in SET II were subjected to two-point static loading. Cracks started to form as the strain was gradually increased, and eventually the beam gave way. Compared to S2 and S3 beams, which had ultimate loads of 108 and 122 KN, respectively, and S1’s ultimate load of 82 KN is relatively less. In the post-cracking stage, the deflection increases more rapidly for a given increase in load. The concrete in the tension zone becomes ineffective, and the steel reinforcement carries most of the tensile stresses.

Cracks reduce the stiffness of an RC beam, leading to greater deflections under the same load. This reduction in stiffness is reflected in the nonlinear portion of the load-deflection curve after cracking. The regulated beam F1 in SET I had fewer and more widely distributed cracks than the retrofitted F2 and F3. Additionally, F2 and F3 contain some rather closely spaced cracks. This illustrates the enhanced concrete confinement brought upon by the GFRP strengthening. The failure mechanism for the controlled beam F2 has changed due to this composite action from flexural failure (steel yielding) to peeling of the GFRP sheet for the strengthened beams F2 and F3. The GFRP sheet has debonded and is making cracking noises due to flexural-shear cracks. A fracture often begins vertically and progresses in an inclined direction as the load increases because of the combined effects of flexure and shear. The beam breaks and cracks spread to the top if the load is increased further. We refer to this kind of failure as flexure-shear failure. Environmental exposure, such as UV radiation, moisture, and temperature variations, can affect the properties of GFRP. Proper coating and protective measures are necessary to ensure long-term performance.

The center of the short shear span is where the shear cracks in set two beam S1 began. The crack began to enlarge and spread in the direction of the loading as the load rose. There were more vertical cracks in strengthened reinforced concrete beams S2 and S3 than in controlled beam S1. Cracks reduce the stiffness of a GFRP RC beam, leading to increased deflections under the same load. This reduction in stiffness is reflected in the non-linear portion of the load-deflection curve post-cracking.

F1, F2 and F3 - Beams

1. By reinforcing the beam at the soffit, first flexural cracks manifest a greater load. The strengthened beam F2 can support 33% more weight in the end than the regulated beam F1.

2. Compared to the controlled F1, the reinforced F3 has a maximum load carrying capacity that is 43% greater and 7% higher than the strengthened F2.

3. A weak beam will fail in flexure; but, if the beam is strengthened in flexure, it will fail in flexure-shear failure, which is more harmful than flexural failure since it gives less notice before failing. It is therefore advised to assess the beam’s shear strength and, if necessary, perform both shear and flexural strengthening.

4. Flexural strengthening up to the beam’s neutral axis raises its maximum load carrying capability, but at higher loads, the cracks that occurred were invisible. Early cracks are undetectable, therefore there is less warning than with beams braced only at the soffit.

S1, S2 and S3 - Beams

1. Because the control beam S1 was purposefully made weak in shear, it failed in shear.

2. In comparison to the weaker beam S1, the strengthened beams S2 and S3 suffer higher stresses at which initial cracks emerge.

3. Following reinforcement of the beam’s shear zone, the first fractures show up at the flexural zone, and as the load increases, the cracks spread and move in the direction of the neutral axis. The final form of failure, flexural failure, demonstrates that the GFRP sheets increase the shear strength of the beam. The strengthened beam S2 can eventually support 31% more weight than the regulated beam S1.

4. When U-wrapping is used to strengthen the beam in the shear zone, the ultimate load carrying capacity rises by 48% compared to the control beam S1 and 13% compared to the beam S2 that was enhanced by glueing the GFRP sheets on the vertical sides alone. GFRP can be used for retrofitting due to its lightweight, high strength, and ease of application. It is often used to strengthen existing beams, columns, and slabs, enhancing their load-carrying capacity and durability.

5. Using GFRP sheet to restore or improve the shear strength of beams can lead to enhanced stiffness and shear strength without the appearance of shear cracks. In seismic zones, the design must ensure adequate ductility and energy dissipation. This can be challenging with GFRP due to its brittle nature, so additional considerations like confinement and hybrid reinforcement may be necessary.

- 1. K.V. Boobala Krishnan, K. Nirmalkumarb, V. Sampathkumar, and P.C. Murugan, J. Ceram. Process. Res. 24[4] (2023) 714-722.

-

- 2. M. Askar, K. Abduka, and L. Askar, J. Duhok Univ. 23[2] (2020) 116-130.

-

- 3. M.K. Askar, M.H. Selman, and S.I. Mohammed, J. Duhok Univ. 23[1] (2020) 149-158.

-

- 4. O. Anil, Constr. Build. Mater. 22[12] (2008) 2355-2368.

-

- 5. S. Dias and J. Barros, Cem. Concr. Compos. 33[2] (2011) 334-345.

-

- 6. L.K. Askar, I.H.M. Albarwary, and M.K. Askar, J. Duhok Univ. 22[1] (2019) 30-38.

-

- 7. G.E. Arunkumar, K. Nirmalkumar, P. Loganathan, and V. Sampathkumar, Glob. Nest J. 25[5] (2023) 126-135.

-

- 8. K. Zdanowicz, R. Kotynia, and S. Marx, Struct. Concr. 20[3] (2019) 872-885.

-

- 9. R. Wight, M. Green, and M. Erki, J. Compos. Constr. 5[4] (2001) 214-220.

-

- 10. C.W. Dolan, Concr. Inst. J. 46[2] (2001) 76-87.

- 11. O. Chaallal, M.J. Nollet, and D. Perraton, J. Compos. Constr. 2[2] (1998) 111-113.

-

- 12. M. Varuthaiya, C. Palanisamy, V. Sivakumar, and G. Pushpanathan, J. Ceram. Process. Res. 23[6] (2022) 912-919.

-

- 13. S. Lee and C. Lee, Eng. Struct. 61 (2014) 99-112.

-

- 14. A.S. Mosallam and S. Banerjee, Compos. Part B: Eng. 38[5-6] (2007) 781-793.

-

- 15. A. Godat, F. Hammad, and O. Chaallal, Compos. Struct. 254 (2020).

-

- 16. A. Belarbi, S.W. Bae, and A. Brancaccio, Constr. Build. Mater. 32 (2012) 27-40.

-

- 17. G.M. Chen, Li S.W.D. Fernando, P.C. Liu, J.F. Chen, Int. J. Solids Struct. 125 (2017) 1-21.

-

- 18. G. Chen, J. Teng, and J. Chen, Int. J. Solids Struct. 49[10] (2012) 1266-1282.

-

- 19. El. Ghandour, Constr. Build. Mater. 25[3] (2011) 1419-1429.

-

- 20. D. Baggio, K. Soudki, and M. Noel, Constr. Build. Mater. 66 (2014) 634-644.

-

- 21. A. Godat, Z. Qu, X.Z. Lu, P. Labossière L.P. Ye, and K.W. Neale, J. Compos. Constr. 14[3] (2010) 260-271.

-

- 22. G. Kim, J. Sim, and H. Oh, Constr. Build. Mater. 22[6] (2008) 1261-1270.

-

- 23. H.H. Mhanna, R.A. Hawileh, and J.A. Abdalla, Procedia Struct. Integr. 17 (2019) 214-22.

-

- 24. S.J. Dias and J.A. Barros, Compos. Struct. 99 (2013) 477-490.

-

- 25. A. Manikandan and G.B. Bhaskar, J. Ceram. Process. Res. 25[2] (2024) 159-167.

-

- 26. Kalyani Gurram and N. Pannirselvam, J. Ceram. Process. Res. 24[3] (2023) 560-568.

-

- 27. M. Sivaperumal, R. Thirumalai, S. Kannan, and Yarrapragada K S S Rao, J. Ceram. Process. Res. 23[3] (2022) 404-408.

-

- 28. X. Yu, H. Fan, and Y. Tang, Constr. Build. Mater. 184[6] (2018) 586-602.

- 29. J. Bai, C.O. Anya, and A.J. Majewski, J. Compos. Mater. 53[13] (2019) 1793-1812.

- 30. L.C. Bank and P.S. Mosallam, Compos. Part B: Eng. 136[2] (2017) 94-107.

- 31. M. Masmoudi and M. Tighiouart, J. Compos. Constr. 24[3] (2020) 220-234.

- 32. F. Ceroni, A. Cosenza, and E. Gaetano, J. Struct. Eng. 141[3] (2015) 102-115.

-

- 33. S.A. Miller and R.M. Haj-Ali, J. Adv. Mater. 48[40] (2016) 301-318.

- 34. M.F. Ashby and K.W.J. Yeung, Sustain. Struct. Mater. 7[2] (2021) 67-83.

- 35. N.M. Karim, A.F. Ahmad, and M.W. Hussin, Mater. Struct. 51[10] (2018) 243-258.

- 36. E.R. Morgado and P.A. Selvaganapathy, J. Ceram. Process. Res. 20[8] (2019) 489-504.

- 37. G.E. Arunkumar, K. Nirmalkumar, P. Loganathan, and V. Sampathkumar, Glob. Nest J. 25[5] (2023)126-135.

-

- 38. A.S. Kumaraswamy, K. Nirmalkumar, V. Sampathkumar, and S. Karthikeyan, J. Environ. Prot. 23[2] (2022) 616-623.

- 39. S. Velusamy, A. Subbaiyyan, K. Ramasamy, M. Shanmugamoorthi, V. Vellingiri, Y. Chandrasekaran and V. Murugesan, Mater. Today: Proc. 65 (2022) 549-553.

-

This Article

This Article

-

2024; 25(4): 589-598

Published on Aug 31, 2024

- 10.36410/jcpr.2024.25.4.589

- Received on Mar 11, 2024

- Revised on Jun 13, 2024

- Accepted on Jul 16, 2024

Services

Services

- Abstract

introduction

casting of beams

experimental setup

failure modes

history of load deflection

load at initial crack

ultimate load carrying capacity

crack pattern

conclusions

- References

- Full Text PDF

Shared

Correspondence to

Correspondence to

- A. Vijayakumar

-

Department of Civil Engineering, V.S.B. Engineering College, Karur – 639111, Tamilnadu, India

Tel : +91 9994426298 - E-mail: vijayakumarkct@gmail.com

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.