- Investigating the mechanical properties of titanium, steel, and nanostructured NiFe composite for sports equipment

Jingzhuan Wang and Zhen Wang*

Qingdao Agricultural University, Qingdao, Shandong, 266109, China

This article is an open access article distributed under the terms of the Creative Commons Attribution Non-Commercial License (http://creativecommons.org/licenses/by-nc/4.0) which permits unrestricted non-commercial use, distribution, and reproduction in any medium, provided the original work is properly cited.

In recent years, metal baseball bats, particularly those crafted from aluminum, have gained significant traction over traditional wood bats due to their perceived advantages. These metal counterparts offer extended hitting distances and increased durability, appealing traits for players seeking improved performance. However, they also come with their own set of shortcomings. Therefore, this study evaluates the mechanical properties of five distinct materials, including Maraging Steel, Steel PH, Ti 6Al-4V (Grade 5), Ti, SP-500, and nanostructured material NiFe. Following established industry standards, each material underwent rigorous testing procedures to assess key mechanical characteristics such as tensile strength, yield strength, hardness, and ductility. In particular, the focus on the mechanical characteristics of nanostructured material NiFe sheds light on its potential suitability for sports applications, notably in the design and manufacturing of equipment such as baseball bats, softball bats, and golf clubs. NiFe exhibits impressive strength, as indicated by its high yield strength, suggesting its ability to withstand significant mechanical loads without permanent deformation. This attribute is crucial in sports equipment, where durability and resilience are paramount for ensuring performance and safety during use.

Keywords: Surface coating, Wear resistant, Durability.

One of the most notable advancements in the sport has been the transition from traditional wooden baseball bats to metal alternatives, particularly those crafted from aluminum. This shift has sparked considerable debate among players, coaches, and enthusiasts alike, with proponents extolling the virtues of metal bats and traditionalists championing the enduring appeal of wooden counterparts [1-3]. The debate surrounding the superiority of metal versus wood bats hinges on various factors, including hitting distance, durability, tactile feedback, and auditory experience upon impact. Historically, wooden baseball bats have been the staple choice for players at all levels of the game. These bats, typically crafted from ash or maple wood, offer a classic feel and sound that many purists find unmatched by their metal counterparts [4]. However, advancements in materials science and manufacturing techniques have paved the way for the emergence of metal bats, which have gained popularity over the years, particularly in amateur and collegiate baseball leagues. Metal bats, predominantly made from aluminum alloys, boast several advantages over wooden bats, including enhanced hitting distances and increased durability [5-7].

Research into the performance characteristics of metal baseball bats has yielded insightful findings that have influenced their widespread adoption in various levels of competitive play. Studies comparing the performance of metal and wooden bats have consistently demonstrated that metal bats can achieve greater hitting distances, attributed to their superior stiffness and trampoline effect upon contact with the ball. This increased hitting distance has been a significant factor in the preference for metal bats among players seeking to maximize offensive capabilities [8-10]. Moreover, metal bats have shown greater resistance to breakage and deterioration compared to their wooden counterparts, making them a more cost-effective and long-lasting investment for players and teams. This durability advantage has made metal bats particularly appealing in youth leagues and recreational settings, where equipment longevity and affordability are paramount considerations [11]. However, despite their undeniable performance advantages, metal baseball bats are not without their drawbacks. One of the most commonly cited concerns is the transmission of vibrations upon contact with the ball, which can result in discomfort and fatigue for players, particularly during extended gameplay sessions. Unlike wooden bats, which absorb much of the shock upon impact, metal bats tend to amplify and transmit vibrations through the handle, leading to potential discomfort and even injury [12-15]. Additionally, the distinctive sound emitted by metal bats upon contact with the ball has been a subject of scrutiny and contention. While some players appreciate the crisp, high-pitched resonance of metal bats, others find it to be an unwelcome departure from the familiar “crack” associated with wooden bats. This auditory aspect of the game contributes to the overall experience for players and spectators alike, underscoring the importance of addressing any discrepancies between wooden and metal bats in this regard.

Efforts to mitigate the shortcomings of metal baseball bats have led to the development of innovative designs and materials aimed at enhancing performance while maintaining the integrity of the game. One approach involves the use of multi-layered or multi-walled bat constructions incorporating a combination of metals, polymers, and composites to optimize stiffness, vibration dampening, and sound attenuation. While these advancements have shown promise in improving the overall user experience, challenges remain in achieving a balance between performance, durability, and regulatory compliance within the confines of efficient manufacturing processes [16-19].

In light of these factors, this study seeks to investigate creative techniques for improving the performance and user experience of metal baseball bats. This study intends to add significant insights to the continuing debate over the usage of metal bats in baseball by investigating characteristics such as striking distance, durability, vibration dampening, and sound emission. Furthermore, by optimizing production processes for practical implementation in the sports equipment market, this study aims to answer the changing demands and preferences of players, coaches, and enthusiasts in the ever-changing landscape of baseball equipment.

Mechanical properties of five distinct materials were evaluated following established industry standards. Among these materials, two belong to the steel-based category, including Maraging Steel and Steel PH. Additionally, three materials fall under the titanium-based classification, comprising Ti 6Al-4V (Grade 5), Ti, and SP-500. The fifth material investigated is a nanostructured material known as NiFe. Each material was subjected to rigorous testing procedures to assess its mechanical characteristics, including but not limited to tensile strength, yield strength, hardness, and ductility. These measurements provide valuable insights into the structural integrity and performance potential of each material, aiding in their selection and application across various industries such as aerospace, automotive, and biomedical engineering.

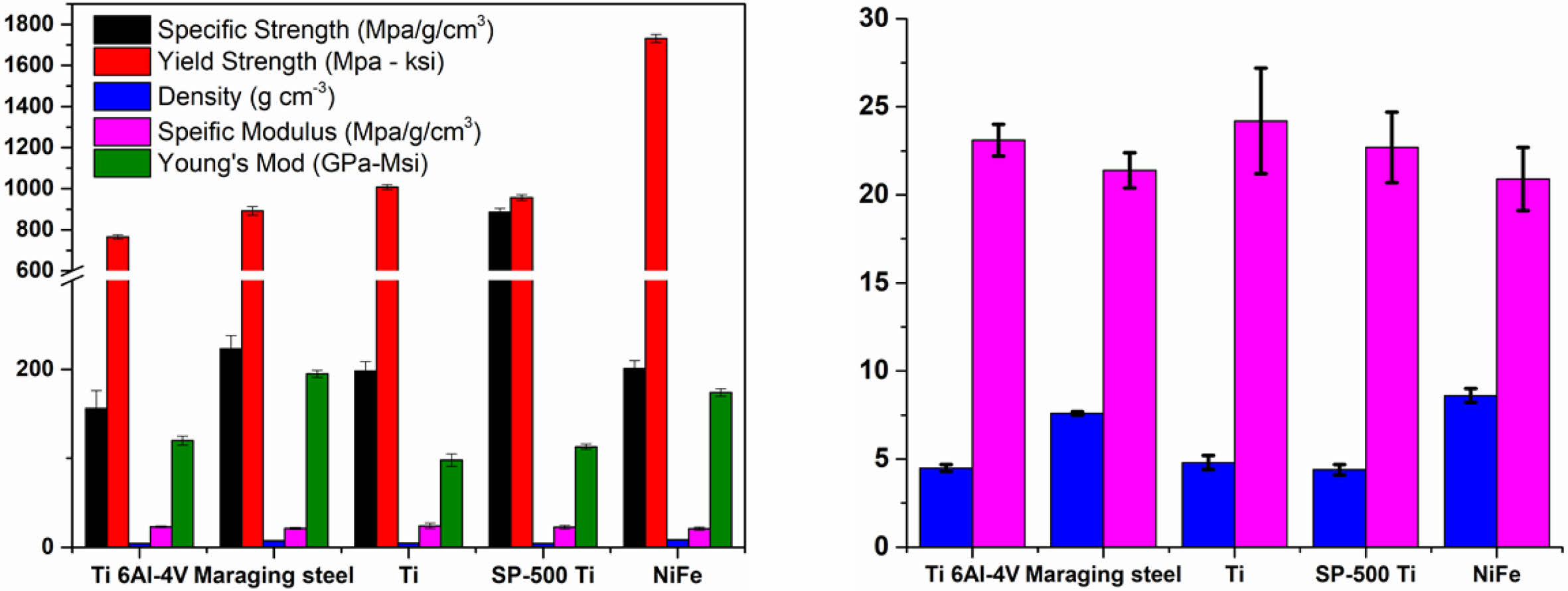

The results of the study, particularly focusing on the mechanical characteristics of NiFe, shed light on its potential suitability for sports applications, particularly in the design and manufacturing of equipment such as baseball bats, softball bats, and golf clubs. The mechanical properties observed in NiFe as illustrated in Fig. 1, present a compelling case for its consideration in the sports equipment industry. First and foremost, the relatively high strength of NiFe, as indicated by its yield strength, underscores its capability to withstand significant mechanical loads without permanent deformation. This attribute is crucial in sports equipment, where durability and resilience are paramount to ensure performance and safety during use. Additionally, the high strength-to-weight ratio of Ni Fe suggests that it can offer exceptional strength while maintaining a lightweight profile, enhancing maneuverability and swing speed in sports such as baseball and golf. Moreover, the discussion surrounding the characteristics and advantages of nanostructured materials, particularly regarding their high density of grain boundaries, provides valuable insights into their unique properties and potential applications. The presence of a significant number of grain boundaries in nanostructured materials, compared to conventional materials, is attributed to their small grain size, which can be ascribed to various fabrication techniques such as mechanical milling, severe plastic deformation, or chemical synthesis methods. This high density of grain boundaries results in a substantial portion of atoms being located near these boundaries, with some instances indicating up to 50 percent or more of the atoms in the material.

One of the key implications of this elevated grain boundary density is its influence on material properties, in accordance with the Hall-Petch Effect. The Hall-Petch Effect describes the phenomenon wherein the mechanical properties of a material, such as strength and hardness, are improved with decreasing grain size. In the case of nanostructured materials, the abundance of grain boundaries promotes several desirable characteristics that are advantageous in various applications. Firstly, the increased density of grain boundaries enhances the material's mechanical properties, including strength and hardness. This is attributed to the barriers presented by grain boundaries to dislocation motion, thereby impeding the propagation of defects and improving mechanical integrity. Additionally, the small grain size facilitates grain boundary strengthening mechanisms, such as grain boundary sliding and grain boundary diffusion, which further contribute to the material's overall strength. Furthermore, the presence of a large number of grain boundaries can also influence other material properties, such as electrical conductivity, thermal conductivity, and corrosion resistance. Grain boundaries serve as pathways for electron transport and phonon scattering, leading to modifications in electrical and thermal transport properties. Moreover, the increased surface area provided by grain boundaries can enhance the material's reactivity, making nanostructured materials attractive for catalytic and sensor applications.

Furthermore, the resilience exhibited by NiFe is particularly noteworthy, surpassing that of steel-based and titanium-based materials tested in the study. Resilience, defined as the ability to absorb energy and recover its original shape after deformation, is critical in sports equipment to maximize the transfer of energy upon impact. In the context of baseball and softball bats, for instance, higher resilience can translate into an enhanced Coefficient of Restitution (COR), leading to increased ball velocity upon contact and improved hitting performance. Moreover, the high elasticity of n-Ni Fe (20), characterized by its elastic limit, indicates its capacity to undergo significant deformation under load while still returning to its original shape once the load is removed. This property is advantageous in sports equipment as it allows for enhanced energy absorption and distribution during dynamic movements, contributing to improved performance and player comfort.

The observed high hardness and wear resistance of n-Ni Fe (20) further reinforce its suitability for sports applications, particularly in contact sports such as baseball and golf. A material with high hardness and wear resistance can withstand repeated impacts and abrasion without experiencing significant deterioration, ensuring longevity and reliability in sporting equipment subjected to rigorous use.

|

Fig. 1 Comparison of Mechanical Properties of Steel, Ti alloy and NiFe composite. |

The comprehensive assessment of mechanical properties presented in the study highlights NiFe as a promising candidate for use in sports equipment manufacturing. Its combination of high strength, resilience, elasticity, hardness, and wear resistance positions it as a viable alternative to traditional materials like steel and titanium. By leveraging the unique mechanical characteristics of NiFe, designers and manufacturers can potentially develop innovative sports equipment that offers enhanced performance, durability, and player experience on the field. However, further research and testing are warranted to fully evaluate its performance under real-world sporting conditions and to optimize its integration into existing equipment designs.

The study was supported by the humanities and social science research planed self-financing project in colleges and universities of Shandong province in 2016 (A feasibility study on the implementation of "double referee system" in college football) (Number: J16WI11); The 2023 Ideological and political education project of Qingdao Agricultural University: Research on the application of "three wide education" in college physical education class from the perspective of Olympic Spirit (Number: QNSZ2023058).

- 1. B.F. Li, Appl. Mech. Mater. 340 (2013) 366-369.

-

- 2. Y. Kai, Appl. Mech. Mater. 340 (2013) 348-352.

-

- 3. Q.F. Su, Appl. Mech. Mater. 539 (2014) 925-927.

-

- 4. R. Bagherzadeh, M. Latifi, S.S. Najar, M.A. Tehran, M. Gorji, and L. Kong, Res. J. 82 (2012) 70-76.

-

- 5. Z.G. Gong, Adv. Mater. Res. 662 (2013) 186-189.

-

- 6. J.K. Patra and S. Gouda, J. Eng. Technol. Res. 5 (2013) 104-111.

-

- 7. C. Poon and C. Kan, Carbohydr. Polym. 121 (2015) 457-467.

-

- 8. V. Allahyarzadeh, M. Montazer, N.H. Nejad, and N. Samadi, J. Appl. Polym. Sci. 129 (2013) 892-900.

-

- 9. M. Shahid, R.A. Malik, H. Alrobeib, J. Kimc, M. Latif, A. Hussain, M.U. Iqbal, and A. Hafiz, J. Ceram. Process. Res. 22[2] (2021) 149-157.

-

- 10. M. Ceylan and I. Topcu, J. Ceram. Process. Res. 21[5] (2020) 539-546.

-

- 11. D. Lou, J. Hellman, and D. Luhulima, Mater. Sci. Eng. A 340 (2003) 155-162.

-

- 12. D.A. Stewart, P.H. Shipway, and D.G. McCartney, Acta Mater. 48[7] (2000) 1593-1604.

-

- 13. T. Harifi and M. Montazer, J. Mater. Chem. B 2 (2014) 272-283.

-

- 14. F. Akhavan Sadr and M. Montazer. Ultrason. Sonochem. 21 (2014) 681-691.

-

- 15. H.S. Mohapatra, A. Chatterjee, and S. Maity. Int. J. Rec. Technol. Eng. 2 (2013) 132-138.

- 16. S.A. Kulinich and A.S. Akhtar, Russ. J. Non-Ferr. Metals 53 (2012) 176-203.

-

- 17. M. Alrwashdeh and S.A. Alameri, Energies 15[10] (2022) 3772.

-

- 18. M. Alrwashdeh, S.A. Alameri, and A.K. Alkaabi, Nucl. Sci. Eng. 194[2] (2020) 163-167.

-

- 19. J.K. Pancrecious, S.V. Vineetha, U.S. Bill, E.B. Gowd, and T.P.D. Rajan, Appl. Clay Sci. 211 (2021) 106199.

-

This Article

This Article

-

2024; 25(3): 417-420

Published on Jun 30, 2024

- 10.36410/jcpr.2024.25.3.417

- Received on Mar 22, 2024

- Revised on Apr 2, 2024

- Accepted on Apr 4, 2024

Services

Services

- Abstract

introduction

experiment

results and discussion

conclusion

- Acknowledgements

- References

- Full Text PDF

Shared

Correspondence to

Correspondence to

- Zhen Wang

-

Qingdao Agricultural University, Qingdao, Shandong, 266109, China

Tel : +8613969834231 Fax: +86 0532 58957947 E-mail: wangjz200424@163.com - E-mail: wangjz200424@163.com

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.