- Evaluation of mechanical properties of Nickel-Chromium alloy, Yttrium Stabilized Zirconia Polycrystals, and Zirconium Silicate for dental crown restoration

Jialing Li, Min Huang, Zilu Fan and Jianping Ruan*

Nanchong Central Hospital, the Second Clinical College of North Sichuan Medical College, Nanchong, 637000, Sichuan, China

This article is an open access article distributed under the terms of the Creative Commons Attribution Non-Commercial License (http://creativecommons.org/licenses/by-nc/4.0) which permits unrestricted non-commercial use, distribution, and reproduction in any medium, provided the original work is properly cited.

This study investigates the mechanical properties of Nickel-Chromium (Ni-Cr), Yttrium Stabilized Zirconia Polycrystals (3Y-TZP), and Zirconium Silicate (ZS) for dental crown applications. Characteristic strength, fracture toughness, and crack growth parameters were evaluated to assess the suitability of these materials for clinical use. Nickel-Chromium (Ni-Cr) exhibited moderate strength and toughness, making it a viable option for dental crowns, albeit with slightly lower fracture toughness compared to zirconia-based materials. Yttrium Stabilized Zirconia Polycrystals (3Y-TZP) demonstrated robust mechanical properties with high strength and toughness, particularly suitable for posterior crowns. Conversely, Zirconium Silicate (ZS) showcased exceptional mechanical properties, offering both strength and natural-looking aesthetics, making it an excellent choice for anterior crowns. Clinical observations suggest that material selection should consider mechanical properties alongside patient-specific factors and clinical requirements to achieve optimal treatment outcomes and patient satisfaction in dental restorations. This comparative analysis provides valuable insights for clinicians in selecting appropriate materials for dental crown applications, ultimately enhancing the quality and longevity of dental treatments.

Keywords: 3Y-TZP, Zirconium Silicate, Nickel-Chromium, Dental zirconia all ceramic, Crown and bridge restoration.

Dental zirconia has emerged as a prominent material in modern dentistry due to its excellent mechanical properties, biocompatibility, and aesthetic appeal. Zirconia, a type of ceramic material, has gained popularity as a restorative material for dental crowns, bridges, and implants [1-5]. Understanding its properties, particularly in relation to fracture mechanics, is crucial for its successful clinical application. Traditionally, ceramic materials in dentistry faced limitations due to their brittle nature, which made them susceptible to immediate catastrophic failure under high loads. However, it’s important to note that in clinical settings, instances of extreme loading leading to immediate brittle fracture are rare. More commonly, dental ceramics are subjected to subcritical stresses, which can occur during normal masticatory loading or exposure to the oral environment over time. Subcritical stresses, which are below the threshold for immediate fracture, can still lead to crack initiation and propagation within the material. This phenomenon is of significant clinical concern as it can compromise the longevity and integrity of dental restorations. Understanding the subcritical crack growth behavior of dental ceramics, including zirconia, is essential for predicting their long-term performance.

Fracture mechanics provides a framework for quantitatively assessing the susceptibility of ceramic materials to subcritical crack growth. Studies have utilized fracture mechanics principles to measure parameters such as fracture toughness (KIc) and subcritical crack growth parameters (n and B) for various dental ceramics, including zirconia. Fracture toughness represents the material’s resistance to crack propagation under loading, while parameters like n and B characterize the rate of subcritical crack growth.

Linear elastic fracture mechanics (LEFM) is commonly employed to analyze the behavior of brittle materials like zirconia under stress. LEFM allows for the calculation of a ceramic material’s lifetime under specific loading conditions based on its fracture-mechanical parameters. By understanding these parameters, clinicians and researchers can predict the susceptibility of zirconia restorations to subcritical crack growth and assess their long-term durability. Factors such as the manufacturing process, material composition, and environmental conditions can influence the fracture-mechanical properties of dental zirconia. Therefore, it is essential to consider these factors when selecting zirconia for clinical applications. Additionally, ongoing research aimed at improving our understanding of zirconia’s fracture behavior and optimizing its properties continues to enhance its performance and expand its indications in dentistry [6]. Moreover, the use of osseointegrated dental implants to restore missing teeth is a well-established and scientifically validated treatment modality.

However, the optimal design and materials for implant systems remain a subject of ongoing research. While numerous studies have investigated various features like implant shape, surface characteristics, and connection types, achieving optimal clinical performance for patients remains a significant challenge [7, 8]. Historically, metal-ceramic crowns have been the preferred restoration for dental implants due to their aesthetic appeal and high success rates. However, zirconia, a ceramic material, has emerged as a promising alternative, offering desirable properties like excellent hardness, marginal fit, and bond strength. Despite these advantages, zirconia crowns present unique clinical challenges that can compromise both retention and overall clinical performance.

Nickel-Chromium (Ni-Cr) alloys have been a staple in dentistry for many years due to their excellent mechanical properties, biocompatibility, and corrosion resistance. These alloys have been widely used for fabricating dental prostheses, including crowns and bridges, owing to their strength and ability to withstand masticatory forces. However, with the advancement of dental materials, zirconia ceramics have emerged as strong contenders for metal-free restorations due to their superior mechanical properties and aesthetic advantages [9-12]. Comparing the long-term strength of Ni-Cr alloy ceramics with zirconia ceramics provides valuable insights into their performance over extended periods in clinical settings. Long-term strength testing allows researchers to evaluate the material’s resistance to fatigue, wear, and other forms of mechanical degradation, which are crucial factors in determining the longevity and reliability of dental restorations. Zirconia ceramics, known for their high flexural strength, fracture toughness, and biocompatibility, have gained popularity as metal-free alternatives to traditional metal-ceramic restorations [13]. By comparing the long-term strength of Ni-Cr alloy ceramics to various zirconia ceramics, researchers can assess the suitability of these materials for different clinical applications, such as single crowns, multi-unit bridges, and implant-supported prostheses. Moreover, understanding the performance of Ni-Cr alloy ceramics and zirconia ceramics under long-term loading conditions helps clinicians make informed decisions regarding material selection based on factors such as the location of the restoration, occlusal forces, and patient-specific considerations [14-16].

In addition to mechanical properties, other factors such as biocompatibility, esthetics, ease of fabrication, and cost-effectiveness should also be taken into account when evaluating the overall suitability of Ni-Cr alloy ceramics and zirconia ceramics for metal-free crown and bridge frameworks.

The experimental procedure began by utilizing a four-point bending test to assess the fracture strength of bar specimens made from three different materials: Nickel-Chromium (NC), yttrium stabilized zirconia polycrystals (3Y-TZP), and Zirconium Silicate (ZS). Prior to testing, the tensile stress side of each specimen was meticulously smoothed using a 2-step dedicated polishing tool connected to a low-speed handpiece. The cylindrical specimens underwent a gradual polishing process with 200, 800, 1200, and 2000 grit SiC wet abrasive papers, ensuring a surface roughness of Rmax < 2 μm. The resulting polished specimens were 1.5 mm thick, 3.0 mm wide, and 30.0 mm long, consistent across all materials. Subsequently, all specimens were annealed to ensure uniformity, and the fracture strength was determined for each material type using a total of 18 specimens, allowing for comprehensive analysis and comparison of their mechanical properties.

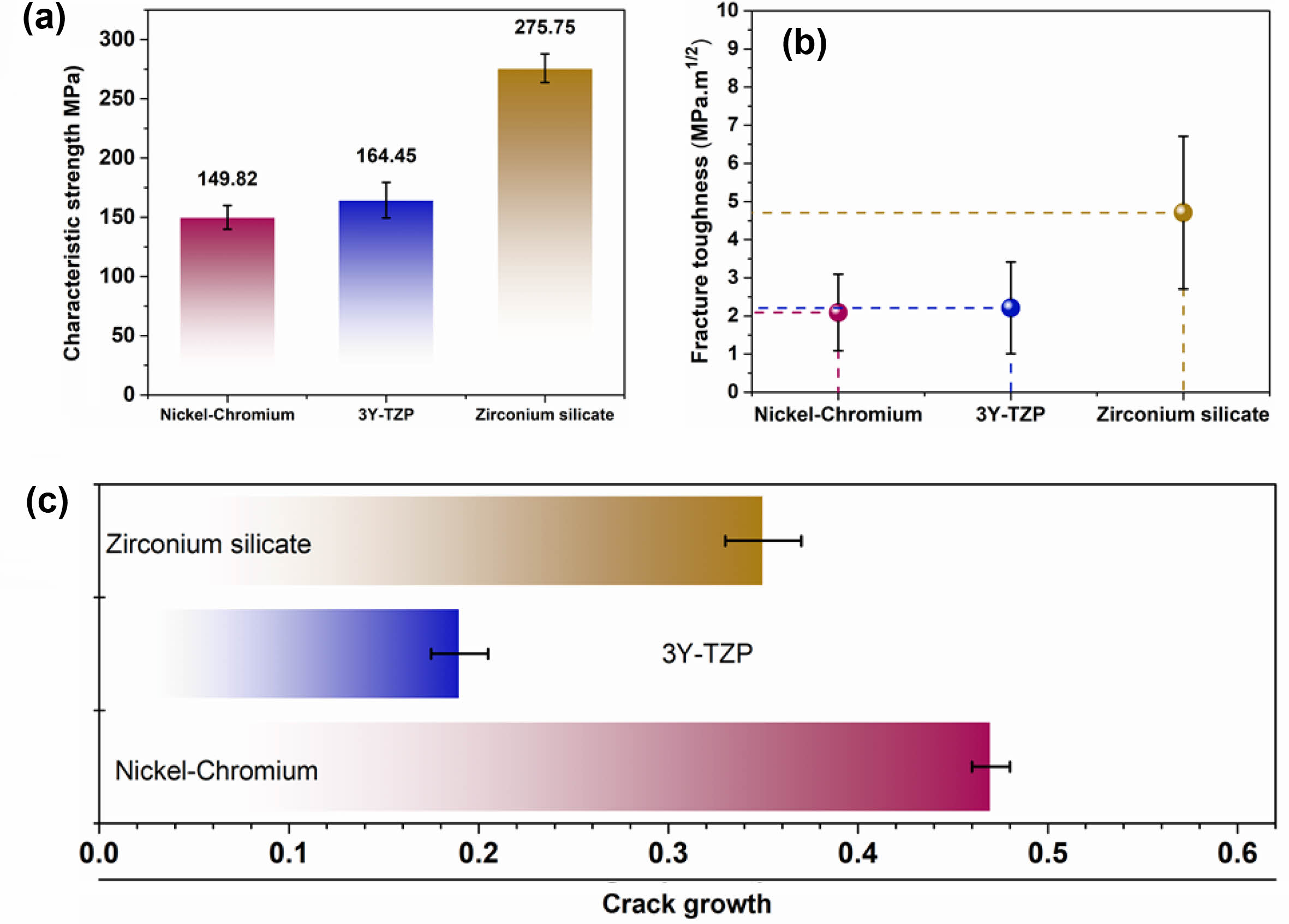

The obtained values for Nickel-Chromium (NC), Yttrium Stabilized Zirconia Polycrystals (3Y-TZP), and Zirconium Silicate (ZS) materials provide valuable insights into their suitability for dental crown applications. The characteristic strength, fracture toughness, and crack growth parameter values of Nickel-Chromium (NC) are essential factors to consider when evaluating its suitability for dental crown applications. With a characteristic strength of 149.82 MPa and a fracture toughness of 2.09 MPa.m1/2, NC demonstrates moderate strength and toughness, rendering it a viable option for dental crowns. These properties indicate that NC can withstand typical occlusal forces encountered during mastication, contributing to its durability in clinical settings [17-19].

However, it’s important to note that NC's fracture toughness is relatively lower compared to zirconia-based materials. Fracture toughness is a critical indicator of a material’s resistance to crack propagation and its ability to withstand sudden or unexpected loading. The lower fracture toughness of NC suggests a slightly higher susceptibility to crack propagation, which could pose challenges in situations where the crown is subjected to excessive force or impact. This may necessitate careful consideration of factors such as the patient’s occlusal habits and the location of the restoration within the oral cavity when determining the suitability of NC for specific cases [20-22].

Moreover, while NC offers moderate strength and toughness, its mechanical properties may not match those of zirconia-based materials, which are known for their superior mechanical strength and fracture toughness. Zirconia-based materials, such as yttrium-stabilized zirconia polycrystals (3Y-TZP), typically exhibit higher fracture toughness values, enhancing their resistance to crack propagation and ensuring long-term stability in dental crown applications. Therefore, clinicians may opt for zirconia-based materials over NC in cases where greater mechanical strength and fracture resistance are desired, particularly for posterior crowns or restorations in patients with heavy occlusal forces.

The characteristic strength, fracture toughness, and crack growth parameter values of Yttrium Stabilized Zirconia Polycrystals (3Y-TZP) underscore its suitability and reliability for dental crown applications, particularly in scenarios involving posterior crowns where higher occlusal forces are expected. With a characteristic strength of 164.45 MPa and a fracture toughness of 2.21 MPa.m1/2, 3Y-TZP exhibits robust mechanical properties, signifying its ability to withstand substantial occlusal loads encountered in posterior regions of the mouth. These values suggest that 3Y-TZP can provide adequate strength and toughness to withstand the stresses associated with masticatory forces, ensuring the long-term stability and functionality of dental restorations. Furthermore, the low crack growth parameter of 0.19 indicates enhanced resistance to crack propagation within 3Y-TZP. This attribute is particularly advantageous for dental crowns as it contributes to the material’s long-term durability and reliability. By minimizing the susceptibility to crack propagation, 3Y-TZP restorations are less prone to failure or fracture over time, thereby ensuring their longevity and effectiveness in clinical use. Zirconium Silicate (ZS) showcases a characteristic strength of 275.75 MPa, a fracture toughness of 4.71 MPa.m1/2, and a crack growth parameter of 0.35. These results portray ZS as a material with exceptional mechanical properties, offering high strength and toughness. ZS is an excellent choice for anterior crowns where esthetics are paramount, as it can provide both strength and natural-looking aesthetics.

The characteristic strength, fracture toughness, and crack growth parameter values of Zirconium Silicate (ZS) highlight its exceptional mechanical properties, positioning it as an excellent choice for anterior crowns where esthetics play a crucial role. With a characteristic strength of 275.75 MPa and a fracture toughness of 4.71 MPa.m1/2, ZS exhibits impressive mechanical strength and toughness. These values indicate that ZS can withstand significant occlusal forces while maintaining structural integrity, making it highly suitable for dental restorations requiring durability and resilience. Moreover, the combination of high strength and toughness in ZS makes it an ideal option for anterior crowns where esthetics are paramount. In addition to providing excellent mechanical properties, ZS offers natural-looking aesthetics, blending seamlessly with the surrounding dentition to create aesthetically pleasing smiles. Its ability to mimic the translucency and color of natural teeth enhances patient satisfaction and ensures optimal esthetic outcomes in anterior restorations. Furthermore, the relatively low crack growth parameter of 0.35 indicates enhanced resistance to crack propagation within ZS, further bolstering its long-term durability and reliability in clinical use. By minimizing the risk of crack initiation and propagation, ZS crowns are less susceptible to failure or fracture, ensuring their longevity and effectiveness in dental treatments.

Based on the results of the study, the clinical observations suggest that while Nickel-Chromium (Ni-Cr) demonstrates moderate strength and toughness, its slightly lower fracture toughness compared to zirconia-based materials may warrant careful consideration in cases where higher resistance to crack propagation is crucial, such as in restorations subjected to heavy occlusal forces. In contrast, Yttrium Stabilized Zirconia Polycrystals (3Y-TZP) exhibit robust mechanical properties with high strength and toughness, making them particularly suitable for posterior crowns where higher occlusal forces are anticipated. The low crack growth parameter of 3Y-TZP further enhances its resistance to crack propagation, contributing to the long-term durability of restorations. Meanwhile, the exceptional mechanical properties of Zirconium Silicate (ZS), including high characteristic strength and fracture toughness, make it an excellent choice for anterior crowns where esthetics are paramount. ZS offers both strength and natural-looking aesthetics, ensuring successful clinical outcomes in aesthetic dentistry. Clinicians should carefully consider the mechanical properties and clinical implications of each material when selecting the most appropriate option for dental crown applications. Factors such as the location of the restoration, occlusal forces, and esthetic requirements should be taken into account to achieve optimal treatment outcomes and patient satisfaction. Fig. 1

|

Fig. 1 Characteristic strength, fracture toughness, and crack growth parameter of the samples tested. |

The evaluation of characteristic strength, fracture toughness, and crack growth parameters provides valuable insights into the suitability of Nickel-Chromium (Ni-Cr), Yttrium Stabilized Zirconia Polycrystals (3Y-TZP), and Zirconium Silicate (ZS) for dental crown applications. Nickel-Chromium (Ni-Cr) demonstrates moderate strength and toughness, making it a viable option for dental crowns, although its fracture toughness is relatively lower compared to zirconia-based materials, indicating a slightly higher susceptibility to crack propagation. On the other hand, 3Y-TZP exhibits robust mechanical properties with high strength and toughness, making it particularly suitable for posterior crowns where higher occlusal forces are anticipated. Additionally, its low crack growth parameter indicates enhanced resistance to crack propagation, contributing to the long-term durability of restorations. Meanwhile, Zirconium Silicate (ZS) showcases exceptional mechanical properties with high characteristic strength and fracture toughness. ZS is an excellent choice for anterior crowns where esthetics are paramount, as it offers both strength and natural-looking aesthetics.

Each material presents distinct advantages and considerations for dental crown applications, and the selection should be based on a thorough evaluation of the patient's clinical needs, esthetic requirements, and occlusal forces. Continued research and clinical evaluation are essential to further optimize the performance and longevity of these materials in dental restorations, ensuring successful treatment outcomes and patient satisfaction in aesthetic and functional dentistry.

- 1. M. Guazzato, M. Albakry, S.P. Ringer, and M.V. Swain, Dent. Mater. 20[5] (2004) 449-456.

-

- 2. P. Gehrke, G. Dhom, J. Brunner, D. Wolf, M. Degidi, and A. Piattelli, Quintessence Int. 37[1] (2006) 19-26.

- 3. R.J. Kohal, G. Klaus, and J.R. Strub, Clin. Oral Implants Res. 17[5] (2006) 565-571.

-

- 4. N.R. Silva, P.G. Coelho, C.A. Fernandes, J.M. Navarro, R.A. Dias, and V.P. Thompson, J. Biomed. Mater. Res. B Appl. Biomater. 88[2] (2009) 419-426.

-

- 5. O.D. Moraguez, H.A. Wiskott, and S.S. Scherrer, Clin. Oral Investig. 19[9] (2015) 2295-2307.

-

- 6. M.H. Nabbouh, R. Naghizadeh, F.G. Fard, and H. Rezaie J. Ceram. Process. Res. 18[9] (2017) 621-627.

-

- 7. T. Derand, M. Molin, E. Kleven, P. Haag, and S. Karlsson, Eur. J. Prosthodont. Restor. 16[1] (2008) 35-38.

- 8. M. Okutan, G. Heydecke, F. Butz, and J. Strub, J. Oral Rehabil. 33[11] (2006) 827-832.

-

- 9. I. Kucuk and T. Boyraz, J. Ceram. Process. Res. 20[1] (2019) 73-79.

-

- 10. R.E. Jung, B.E. Pjetursson, R. Glauser, A. Zembic, M. Zwahlen, and N.P. Lang, Clin. Oral Implants Res. 19[2] (2008) 119-130.

-

- 11. J. Sun, X. Chen, J. Wade-Zhu, J. Binner, and J. Bai, J. Addit. Manuf. 43 (2021) 101994.

-

- 12. X. Li, H. Zhong, J. Zhang, Y. Duan, J. Li, and D. Jiang, Int. J. Appl. Ceram. Technol. 17 (2020) 844-853.

-

- 13. C. Marsico, M. Øilo, J. Kutsch, M. Kauf, and D. Arola, Addit. Manuf. 36 (2020) 101450.

-

- 14. H.C. Alexander Chee, R.S.K. Singh, and K.Y. Sara Lee, J. Ceram. Process. Res. 21[4] (2020) 495-500.

-

- 15. M. Alrwashdeh and S.A. Alameri, Energies 15[21] (2022) 8008.

-

- 16. A. Alraisi, Y. Yi, S. Lee, S.A. Alameri, M. Qasem, C.Y. Paik, and C. Jang, Ann. Nucl. Energy 165 (2022) 108784.

-

- 17. L. Sadighpour, F. Geramipanah, A. Fazel, M. Allahdadi, and M.J. Kharazifard, J. Dent. (Tehran) 15[2] (2018) 97-105.

- 18. F. Beuer, J. Schweiger, M. Eichberger, H.F. Kappert, W. Gernet, and D. Edelhoff, Dent. Mater. 25[1] (2009) 121-128.

-

- 19. M. Alrwashdeh and S.A. Alameri, Energies 15[10] (2022) 3772.

-

- 20. M. Alrwashdeh, S.A. Alameri, and A.K. Alkaabi, Nucl. Sci. Eng. 194[2] (2020) 163-167.

-

- 21. I. Dimitrova, J. Ceram. Process. Res. 25[1] (2024) 16-21.

-

- 22. S. Mohandoss, S. Sureshkumar, V. Balasubramani, B. Venkatachalapathy, and T.M. Sridhar 18[4] (2017) 313-319.

-

This Article

This Article

-

2024; 25(3): 413-416

Published on Jun 30, 2024

- 10.36410/jcpr.2024.25.3.413

- Received on Mar 20, 2024

- Revised on Mar 26, 2024

- Accepted on Mar 27, 2024

Services

Services

Shared

Correspondence to

Correspondence to

- Jianping Ruan

-

Nanchong Central Hospital, the Second Clinical College of North Sichuan Medical College, Nanchong, 637000, Sichuan, China

Tel : +86 15228282299 Fax: +86 0817 3373887 E-mail: ruanjianping6688@163.com - E-mail: ruanjianping6688@163.com

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.