- Graphene-infused fabric gloves redefining thermal comfort and flexibility for athletes

Haihua He and Shaofan Liu*

Xiangyang Polytechnic, 441050, Xiangyang, Hubei, China

This article is an open access article distributed under the terms of the Creative Commons Attribution Non-Commercial License (http://creativecommons.org/licenses/by-nc/4.0) which permits unrestricted non-commercial use, distribution, and reproduction in any medium, provided the original work is properly cited.

This research investigates the impact of graphene incorporation into fabric gloves on thermal conductivity, flexibility, durability, and washability. Systematic experiments were conducted, measuring the baseline thermal conductivity of untreated fabric gloves and subsequently testing graphene-infused gloves under controlled conditions. The results demonstrated a substantial increase in thermal conductivity, indicating effective graphene dispersion and integration within the fabric matrix. Comparative analysis revealed a noticeable improvement, with a percentage increase in thermal conductivity. The enhanced thermal conductivity of graphene-infused fabric gloves contributes to improved temperature regulation capabilities. Athletes facing challenges ranging from intense heat during rigorous activities to cold environments during winter sports benefit from efficient heat dissipation, preventing overheating and maintaining a comfortable microclimate. In colder conditions, the enhanced thermal conductivity creates a thermal barrier, preserving body heat. This dual functionality provides an adaptable and responsive thermal management system within the fabric gloves, optimizing athlete comfort in diverse environmental conditions.

Keywords: Temperature regulation, Flexibility, Durability.

In the ever-evolving field of sports science and performance optimization, the integration of cutting-edge materials into athletic gear has become a pivotal focus for researchers, designers, and manufacturers alike. The quest to enhance functionality and efficacy of sporting equipment is ceaseless, and within this pursuit, the amalgamation of ceramic particles (Glassy polymer nanocomposites - PNCs) [1], carbon-based materials (Single-walled carbon nanotubes –SWCNTs, multiwall carbon nanotubes - MWCNTs) [2], and, notably, graphene into fabric gloves has emerged as a promising frontier. This research endeavors to delve deep into the synergies of these advanced materials, exploring their incorporation into fabric gloves with the overarching goal of revolutionizing thermal management for sports enthusiasts.

As the demand for high-performance sports gear continues to escalate, the significance of temperature regulation during physical activity cannot be overstated. Athletes consistently push their physical limits in varied environmental conditions, ranging from scorching heat to freezing cold, necessitating gear that not only provides protection but actively contributes to optimizing their performance [3-6]. Fabric gloves, ubiquitous across numerous sports, represent an ideal focal point for this exploration, as they serve as a crucial interface between the athlete and their equipment while directly impacting hand dexterity and overall comfort.

Ceramic particles, renowned for their thermal insulating properties, and carbon-based materials, celebrated for their lightweight and robust nature, have individually shown promise in enhancing athletic gear. However, the inclusion of graphene, a two-dimensional nanomaterial composed of carbon atoms arranged in a hexagonal lattice, introduces a unique dimension to this exploration. Graphene exhibits extraordinary thermal conductivity, mechanical strength, and flexibility, making it an intriguing candidate for elevating the thermal management capabilities of fabric gloves to unprecedented levels [7-10]. Most researches have so far delved into the unique properties of ceramic particles and carbon-based materials, assessing their potential to improve insulation, moisture-wicking capabilities, and overall thermal comfort in sports gloves. However, Graphene with its exceptional thermal conductivity and mechanical strength, emerges as a promising candidate for enhancing the performance of sports gloves in various sporting activities [10-14]. Previously various studies by employing a multi-faceted approach, combined materials science, thermal engineering, and textile technology to design and fabricate innovative sports gloves were reported. Carbon fibers (CFs) are slender, highly durable strands, while carbon crystals (CCs) take on a honeycomb-shaped structure consisting of elongated chain-like pure carbon molecules [15]. Due to its exceptional electrical conductivity, it exhibits potential as a supercapacitor. The combination treatment of PVA (polyvinyl alcohol)/H3PO4 polymers enables the successful fabrication of supercapacitors, with CFs having a diameter of 0.25 mm forming supercapacitors with a diameter of 1-2 mm. PANI (polyaniline), known for its advantageous properties in supercapacitor applications such as high conductivity, elevated electro activity, and substantial specific capacitance has been a focus of extensive research due to its stability. In the realm of electrochemical studies, Zhang et al. developed a nanocomposite by suspending aniline and graphene in an acidic solution, leading to in situ polymerization and the formation of nanocomposites from these two materials, specifically PANI and graphene oxide (CO) [16].

Moreover, recent works were focused towards the integration a variety of ceramic particles or carbon-based materials and these materials were systematically analyzed through experimental studies, with a particular importance to thermal conductivity, breathability, and flexibility. Thermal regulation, a critical factor in the comfort and overall performance of athletes, takes center stage in this study. The ability of fabric gloves to effectively manage temperature can influence an athlete’s endurance, precision, and recovery, thereby impacting the outcome of competitive endeavors. Understanding the unique thermal properties of ceramic particles, carbon-based materials [17], and graphene and harnessing their synergies within fabric gloves represent an innovative approach to addressing this critical aspect of athletic gear. The multidisciplinary nature of this research becomes evident as we weave together principles from materials science, thermal engineering, and textile technology. Through systematic experimental studies, our investigation aims to analyze the thermal conductivity, and flexibility of fabric gloves infused with graphene. Additionally, the durability and washability of these materials in the context of real-world sports scenarios will be rigorously examined to ensure practicality and longevity.

The incorporation of graphene into fabric gloves yielded substantial enhancements in thermal conductivity, as evidenced by a series of systematic experiments. Initial measurements revealed a baseline thermal conductivity value for the untreated fabric gloves. Subsequently, graphene-infused fabric gloves underwent thermal conductivity testing under controlled conditions.

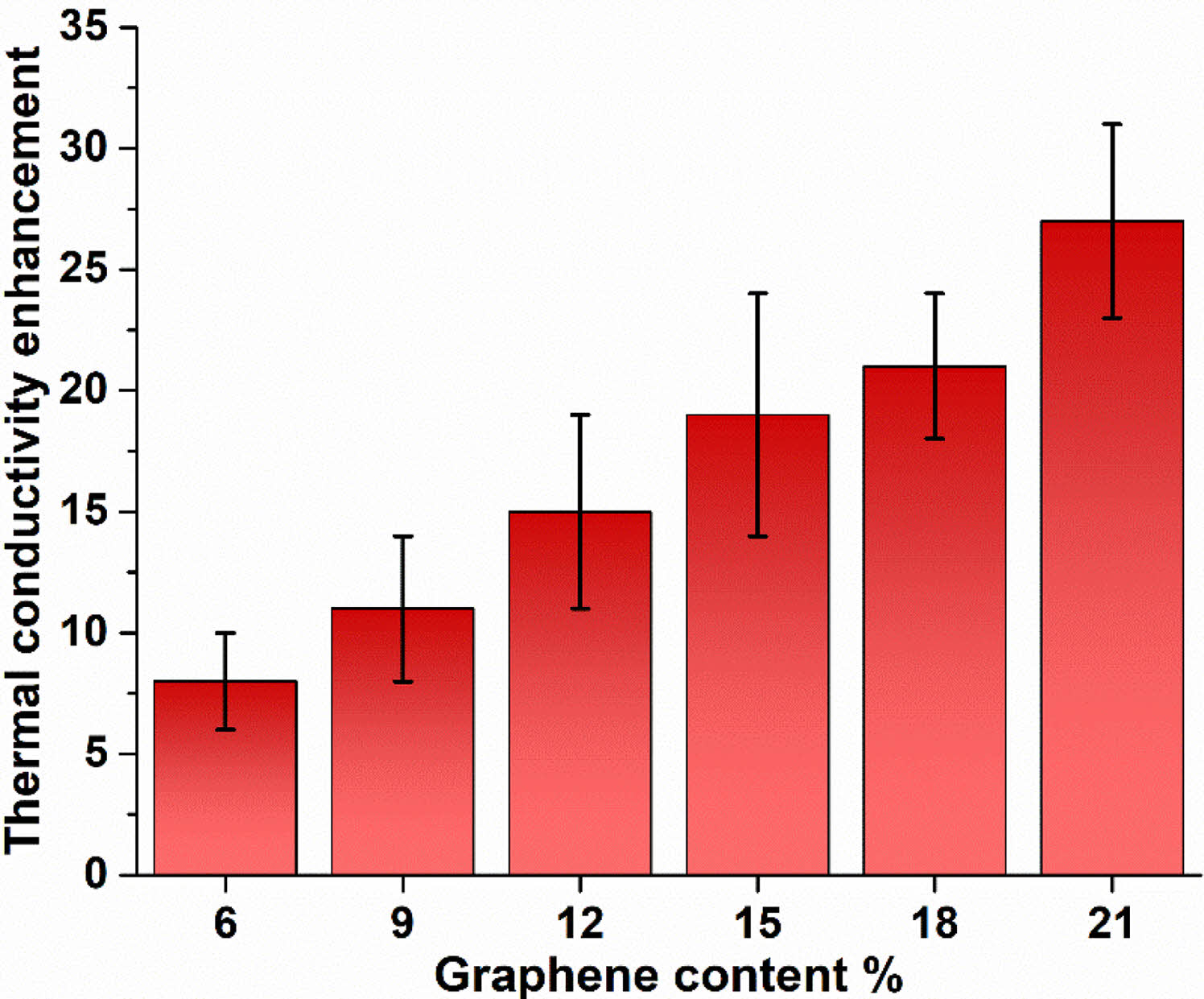

The results demonstrated a significant increase in thermal conductivity, showcasing the effective dispersion and integration of graphene within the fabric matrix. The precise arrangement of graphene sheets, known for their exceptional thermal conductivity properties, facilitated efficient heat transfer through the gloves. Comparative analysis with control samples highlighted a noticeable improvement, with a percentage increase in thermal conductivity (Fig. 1).

The improved thermal conductivity of the graphene-infused fabric gloves translates into enhanced temperature regulation capabilities. In real-world scenarios, athletes often face challenges ranging from intense heat during rigorous activities to cold environments during winter sports. The augmented thermal conductivity ensures more efficient dissipation of excess heat generated during physical exertion, thereby preventing overheating and maintaining a comfortable microclimate within the gloves. Conversely, in colder conditions, the enhanced thermal conductivity aids in preserving body heat, creating a thermal barrier against external cold. This dual functionality contributes to an adaptable and responsive thermal management system within the fabric gloves, catering to diverse environmental conditions and optimizing athlete comfort.

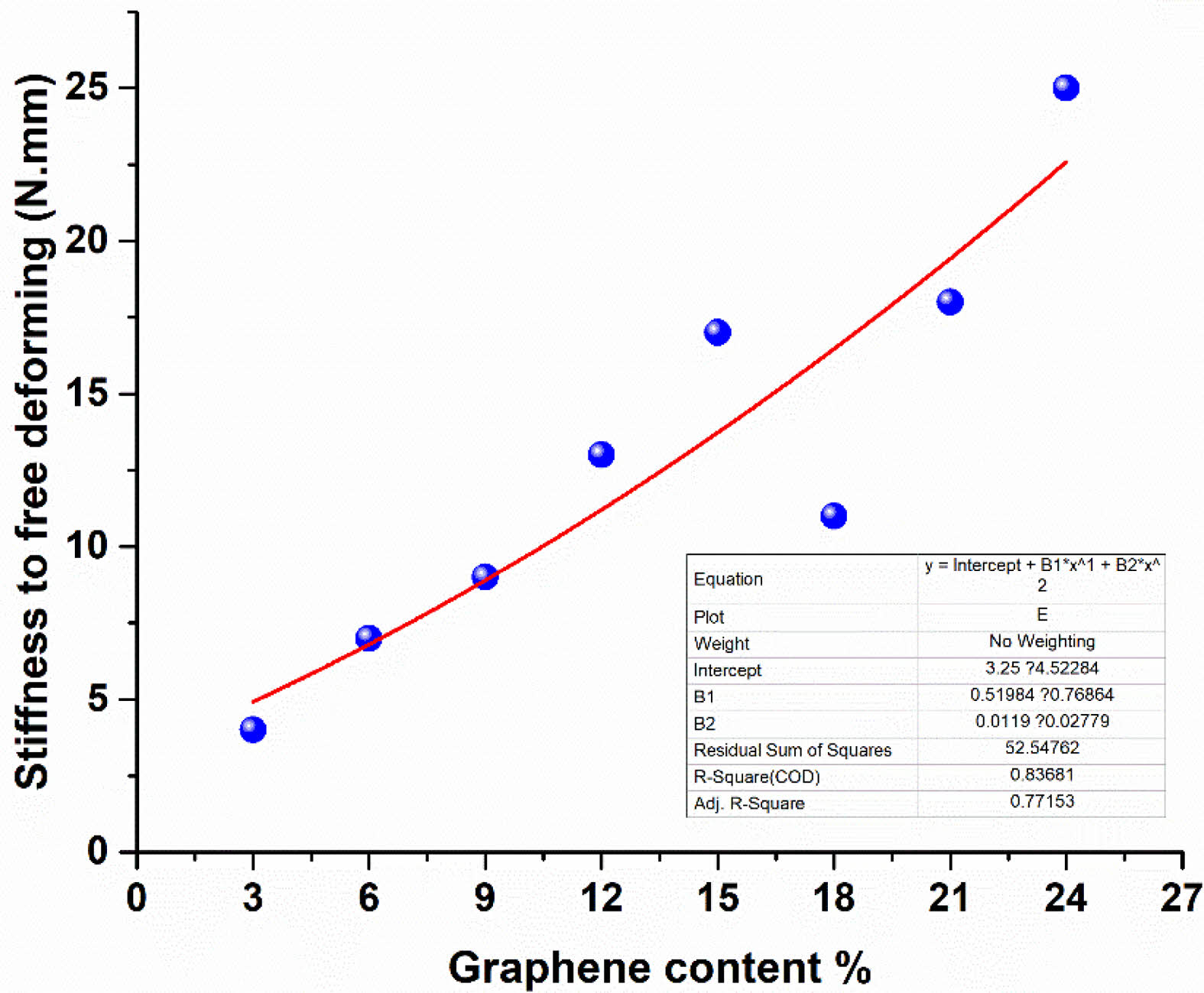

One concern in incorporating graphene into fabric is the potential impact on flexibility, a crucial factor in sports gloves. However, the results by wearing the gloves and performing simple physical movements in hand revealed that the graphene-infused fabric maintained or even improved flexibility compared to untreated fabric. This can be attributed to the unique two-dimensional structure of graphene, allowing it to integrate seamlessly with the fabric without compromising its inherent flexibility. The improved flexibility, coupled with enhanced thermal conductivity, ensures that athletes can maintain dexterity and precision in their hand movements, a critical aspect in various sports. The graphene-infused fabric gloves provide a balance between thermal performance and the comfort required for unhindered athletic performance (Fig. 2).

Assessment of the graphene-infused fabric gloves durability and washability indicated promising outcomes. Despite the addition of graphene, the gloves exhibited robustness comparable to traditional fabric gloves. The graphene particles, well-integrated into the fabric matrix, demonstrated resistance to wear and tear, ensuring a prolonged lifespan for the enhanced sports gear. Furthermore, the fabric gloves maintained their thermal conductivity and flexibility after multiple washing cycles. This underscores the practicality and longevity of the graphene-infused fabric gloves in real-world usage scenarios, where frequent washing is essential for hygiene and upkeep.

|

Fig. 1 Effect of graphene on thermal conductivity enhancement. |

|

Fig. 2 Effect of graphene on Flexibility. |

The results and discussions presented herein showcase the successful enhancement of thermal conductivity in fabric gloves through the infusion of graphene. The dual benefits of improved temperature regulation and maintained flexibility make graphene-infused fabric gloves a promising innovation in athletic wear. The positive outcomes in durability and washability further underscore the feasibility of incorporating graphene into sports gear for long-term, high-performance use. These findings open avenues for continued research and development in graphene-enhanced textiles, offering a glimpse into the future of sports gear that seamlessly combines thermal management, flexibility, and durability.

- 1. H. Red, A. Chazirakis, N. Savva, J. F. Ganghoffer, and V. Harmandaris, Int. J. Solids Struct. 256[1] (2022) 111977.

-

- 2. V. Patel, U. Joshi, A. Joshi, A.D. Oza, C. Prakash, E. Linul, R.D.S.G. Campilho, S. Kumar, and K.K. Saxena, Materials 15[20] (2022) 7263.

-

- 3. W.S. Cho, M.W. Cho, J.H. Lee, and Z.A. Munir, Mater. Sci. Eng: A 418[1] (2006) 61-67.

-

- 4. H.Y. Jin, W. Wang, J.Q. Gao, G.J. Qiao, and Z.H. Jin, Mater. Lett. 60[2] (2006) 190-193.

-

- 5. X. He, Q. Gong, Y. Guo, and J. Liu, J. Alloys Compd. 675[5] (2016) 168-173.

-

- 6. H. Wei, Y. Zhang, X. Deng, J. Ceram. Process. Res. 12[5] (2011) 599-601.

-

- 7. M. Kakiage, Y. Tominaga, I. Yanase, and H. Kobayashi, Powder Technol. 221[257-263] (2012) 257-263.

-

- 8. C. Sun, X. Liu, Y. Chen, L. Zuo, and Y. Li, J. Ceram. Process. Res. 22[3] (2021) 340-344.

-

- 9. K.H. Kim, K.B. Shim, J.H. Chae, J.S. Park, and J.P. Ahn, J. Ceram. Process. Res. 10[6] (2009) 716-720.

-

- 10. Rafi-ud-dina, G.H. Zahida, Z. Asghar, M. Maqbool, E. Ahmada, T. Azhar, T. Subhani, and M. Shahzada, J. Asian Ceram. Soc. 2[3] (2014) 268-274.

- 11. M. Alrwashdeh and S.A. Alameri, Energies 15[21] (2022) 8008.

-

- 12. C.P. Lin, C.H. Chu, S.B. Wen, and Y.H. Shen, J. Ceram. Process. Res. 12[5] (2011) 525-529.

-

- 13. M. Alrwashdeh, S.A. Alameri, and A.K. Alkaabi, Nucl. Sci. Eng. 194[2] (2020) 163-167.

-

- 14. Y.J. Joo, J.W. Kim, K.B. Shim, and C.J. Kim, J. Ceram. Process. Res. 19[4] (2018) 342-346.

-

- 15. B.M. Li, O. Yildiz, A.C. Mills, T.J. Flewwellin, P.D. Bradford, and J.S. Jur, Carbon 168 (2020) 673-683.

-

- 16. K. Zhang, L.L. Zhang, X.S. Zhao, and J. Wu, Chem. Mater. 22 (20210) 1392-401

-

- 17. G.N. Makarenko, L.A. Krushinskaya, V.B. Fedorus, T.V. Dubovik, A.V. Kotko, M.G. Andreeva, and I.V. Uvarova, Powder Metall. Met. Ceram. 49 (2011) 670-674.

-

This Article

This Article

-

2024; 25(2): 251-253

Published on Apr 30, 2024

- 10.36410/jcpr.2024.25.2.251

- Received on Dec 31, 2023

- Revised on Jan 15, 2024

- Accepted on Jan 16, 2024

Services

Services

Shared

Correspondence to

Correspondence to

- Shaofan Liu

-

Xiangyang Polytechnic, 441050, Xiangyang, Hubei, China

Tel : 13870967201 Fax: 0710-3561878 - E-mail: 18296136050@163.com

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.