- Parametric optimization in machining of GFRP composite by taguchi grey relational analysis

Sivaperumal Ma, Thirumalai Rb, Kannan Sa and Yarrapragada K S S Raod

aResearch Scholar, Dr.N.G.P Institute of Technology, Coimbatore, Tamilnadu, India

bProfessor, Department of Mechanical Engineering, Dr,N.G.P Institute of Technology, Coimbatore, Tamilnadu, India

cResearch Scholar, Department of Mechanical Engineering, Dr.N.G.P Institute of Technology, Tamilnadu, India.

dProfessor, Department of Mechanical Engineering, Aditya College of Engineering, Surampalem, Andhra Pradesh, IndiaThis article is an open access article distributed under the terms of the Creative Commons Attribution Non-Commercial License (http://creativecommons.org/licenses/by-nc/4.0) which permits unrestricted non-commercial use, distribution, and reproduction in any medium, provided the original work is properly cited.

The glass fibre reinforce polymer composites are fabricated using compression molding technique. The epoxy resin is used as the matrix material and the glass fibres are used as the reinforcing element. The glass fibre with 30 percentage in weight proportion are used as the reinforcing element and the remaining is the epoxy based matrix material. The composite laminates are tested for its machining characteristics in CNC milling machine using solid carbide end mills. The cutting speed, feed rate and depth of cut are used as the milling process parameters and the responses are delamination factor and surface roughness. Optimal machining parameters are determined by the grey relational analysis (GRA) and discussed

Keywords: Glass fibre reinforced composite (GFRP), Grey relational grade (GRG), ANOVA, Delamination factor, Surface roughness

The composites are found applications in several engineering fields due to its excellent properties such as light in weight and high modulus of elasticity. The glass fibre reinforced composite finds applications in space, aerospace, electronic components, energy, marine and defense sectors. The mechanical and the corrosion behavior of the composites are found to be higher because of its combination of properties of both the matrix and the reinforcing element. Initially the mold is prepared and the resin glue is poured into the mold and it is cured. The fabrication techniques used for the preparation of the composite laminate is compression moulding technique. The thickness of the composite laminate is 3mm approximately. The laminates are machined using CNC milling using carbide end mill cutter of diameter of 10mm. A vertical machine centre CNC milling machine is used in this work. The Table size is 800´400 mm with a spindle motor power of 7.5 KW. The spindle speed ranges from 100-7,000 rpm and the machine is capable of moving along X, Y and Z axis. The cutting parameters optimization of metal matrix composites are investigated using ANOVA and GRA [1]. Drilling of GFRP composite using GRA is carried out and optimal machining parameters are obtained using GRG from GRA [2]. Investigation on drilling performance characteristics on hybrid polymer composites using GRA, regression, fuzzy and ANN models are carried out. It is observed that the ANN is the suitable process that determines the optimum machining parameters [3]. The Taguchi method and Pareto analysis is carried out for the investigating the optimum cutting parameters in turning glass fibre reinforce polymer composite. Minimum number of experiments is sufficient to perform machining characterization to achieve best optimal solutions using Taguchi analysis [4].

Filament winding is used to fabricate hollow pipes made of glass fibre reinforce polymer composite. Machining characteristics studies are investigated using multi performance optimization techniques such as GRA and it is reported that the machining performance can be improved effectively using this techniques [5]. The optimal parameters to obtain better responses, the grey relational analysis (GRA) was followed [6]. GRA and Taguchi optimization methods are followed to evaluate the hard turning process [7], multi response characteristics can be solved in GRA as single solution. The degree of higher order of gray relational grade defines the process parameters significance on the responses are noticed [8]. The Taguchi method and GRA to optimize the turning operation to improve hardness and toughness are followed. The multi-objective of the turning process is converted as a single objective function to obtain optimal process parameters [9]. The machinability of the end milling operation through multi-objective function analyzing methodology is studied [10]. The optimization of drilling parameters on natural fibre reinforced composites using central composite design is carried out [11]. The epoxy based composite are tested for the mechanical properties and analysed using ANOVA and Taguchi analysis [12].

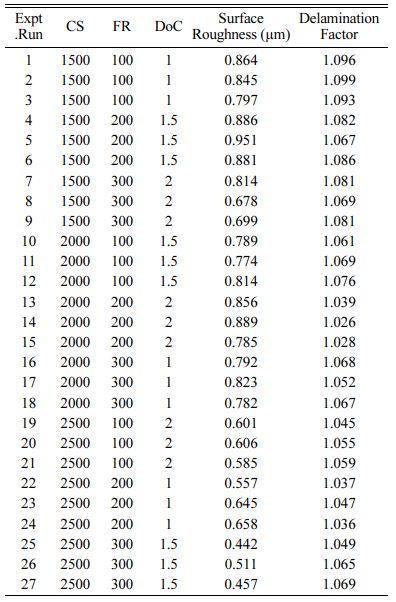

The process parameters selected for this research work are cutting speed, feed rate and depth of cut. The levels of parameters are chosen and experimental design is carried out using design of experiments and L27 orthogonal array is implemented to perform 27 experiments. Delamination factor and surface roughness are investigated as the responses in this work. Delamination is caused by occurrence of cracks and breakages in the layers of the fibre reinforced polymer composite laminate. The delamination will have high influence on the mechanical properties of the composite material. Delamination factor is a dimensionless parameter and defined as ratio of the delaminated diameter and the hole diameter. Delamination is measured with the help of high resolution microscope by moving the cross hair along the direction of the composite laminate and the surface roughness is measured using surface roughness tester. The readings are recorded for every experiment and it is shown in Table 1.

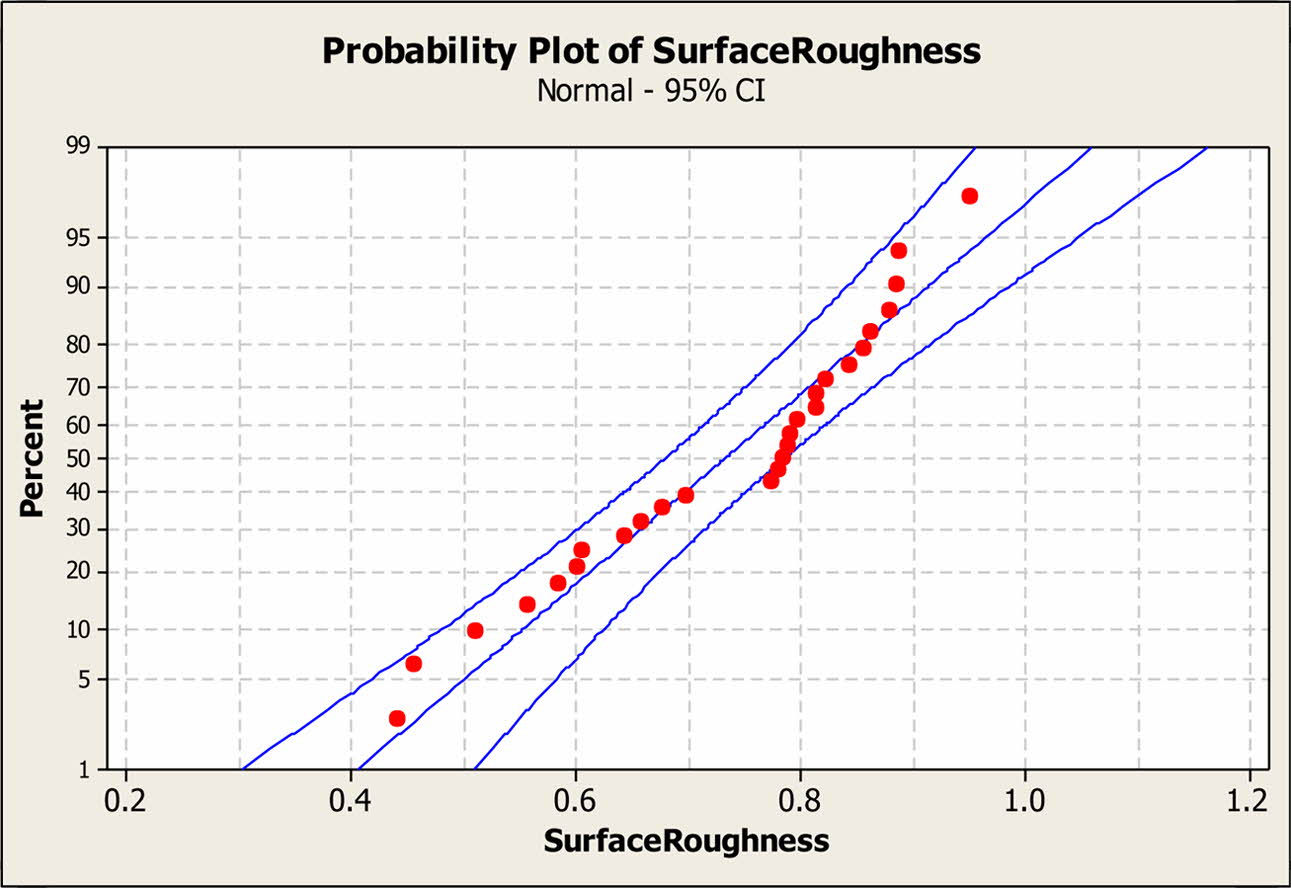

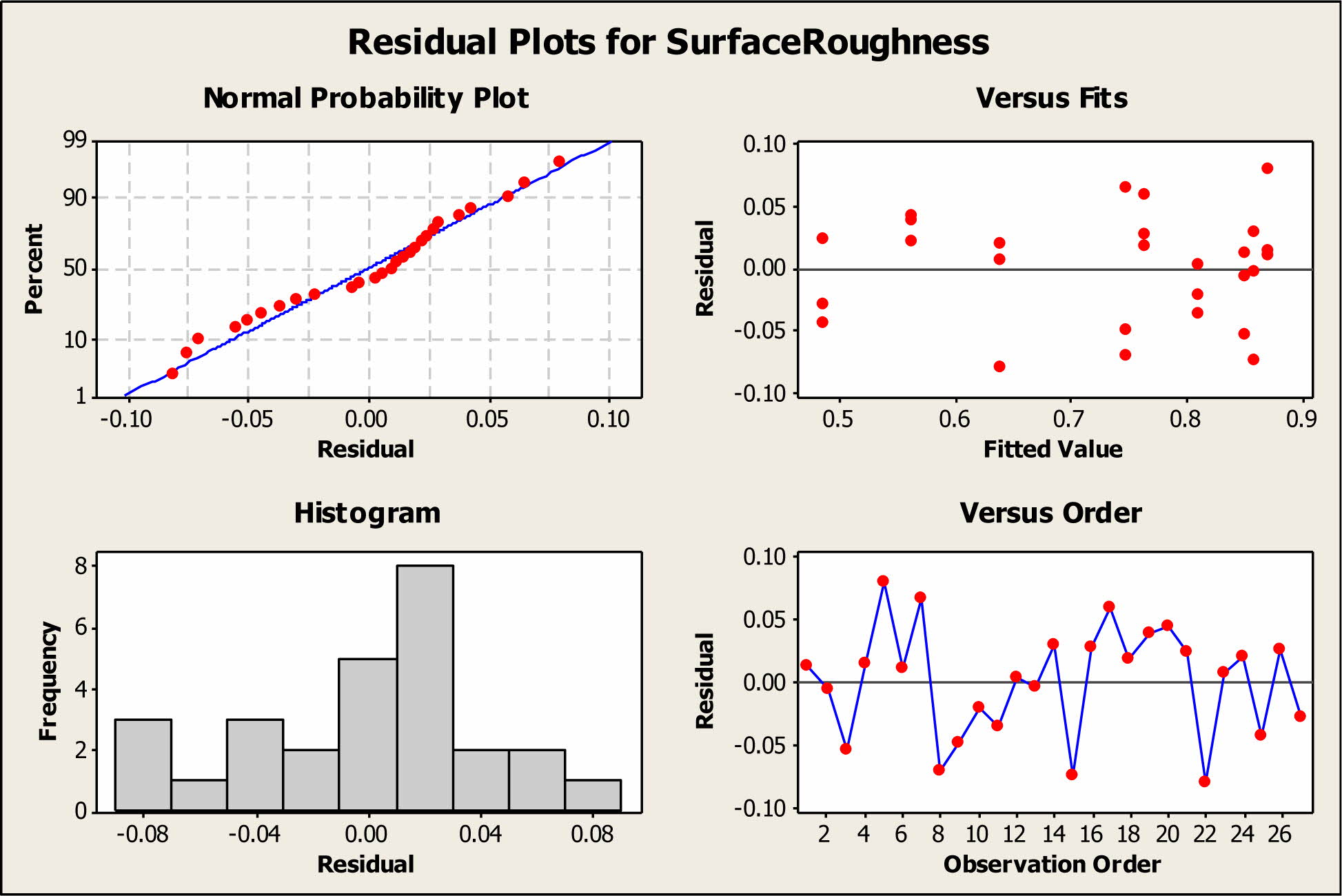

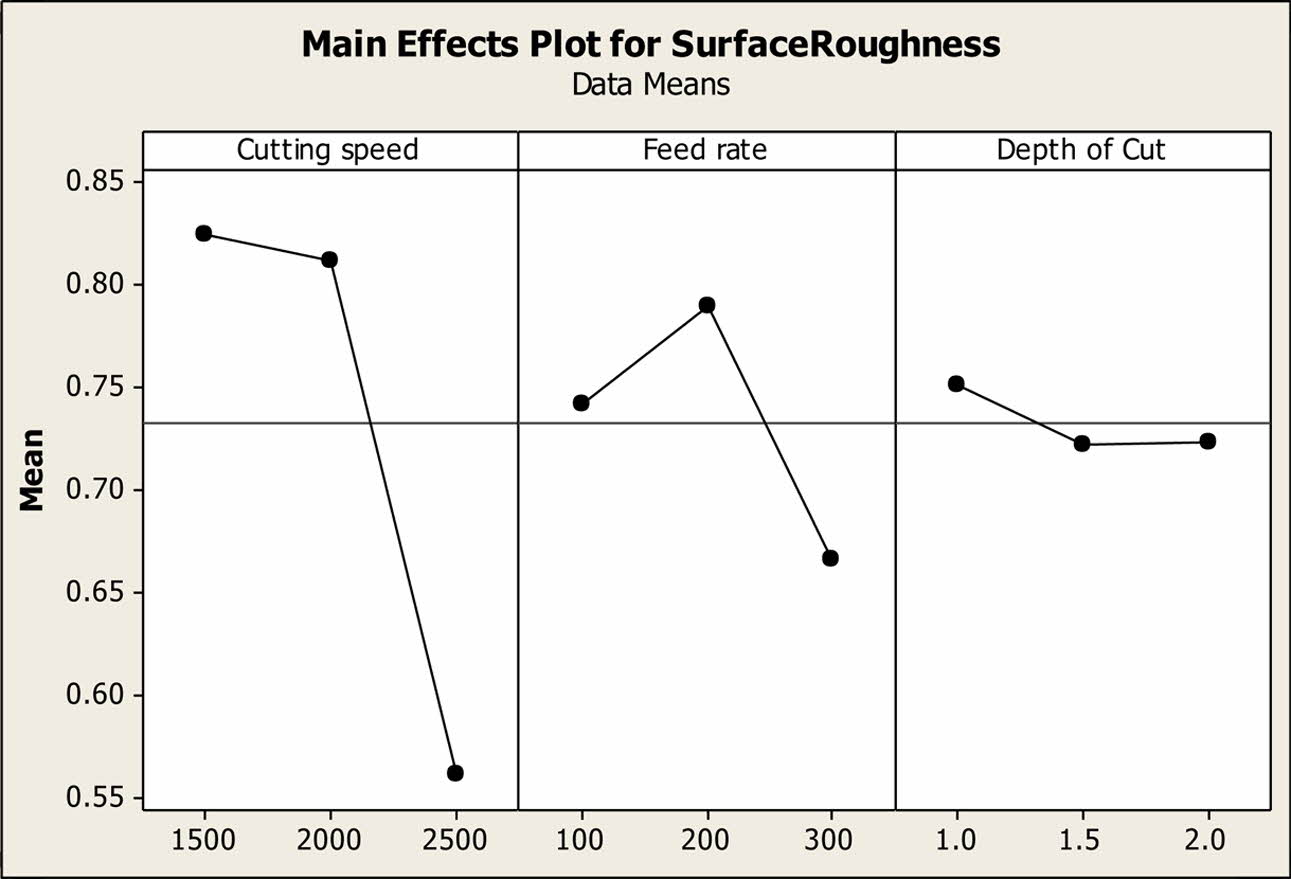

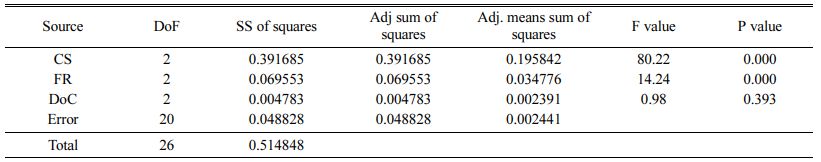

The normal probability plots and the residual plots for the surface roughness are shown in Fig. 1 and Fig. 2 respectively. It is observed that all the values are very close to the central median line and it is highly satisfactory. The ANOVA for surface roughness is analysed and given in Table 2. It is observed that the contribution of cutting speed is higher while the objective function is the minimization of the surface roughness. The R-squared value is found to 90.62% and it is satisfactory. It is observed that the contribution of cutting speed is 38.03%, feed rate is 6.75% and depth of cut is 0.464%. It is concluded that the cutting is the most dominating parameter in the minimization of the surface roughness.

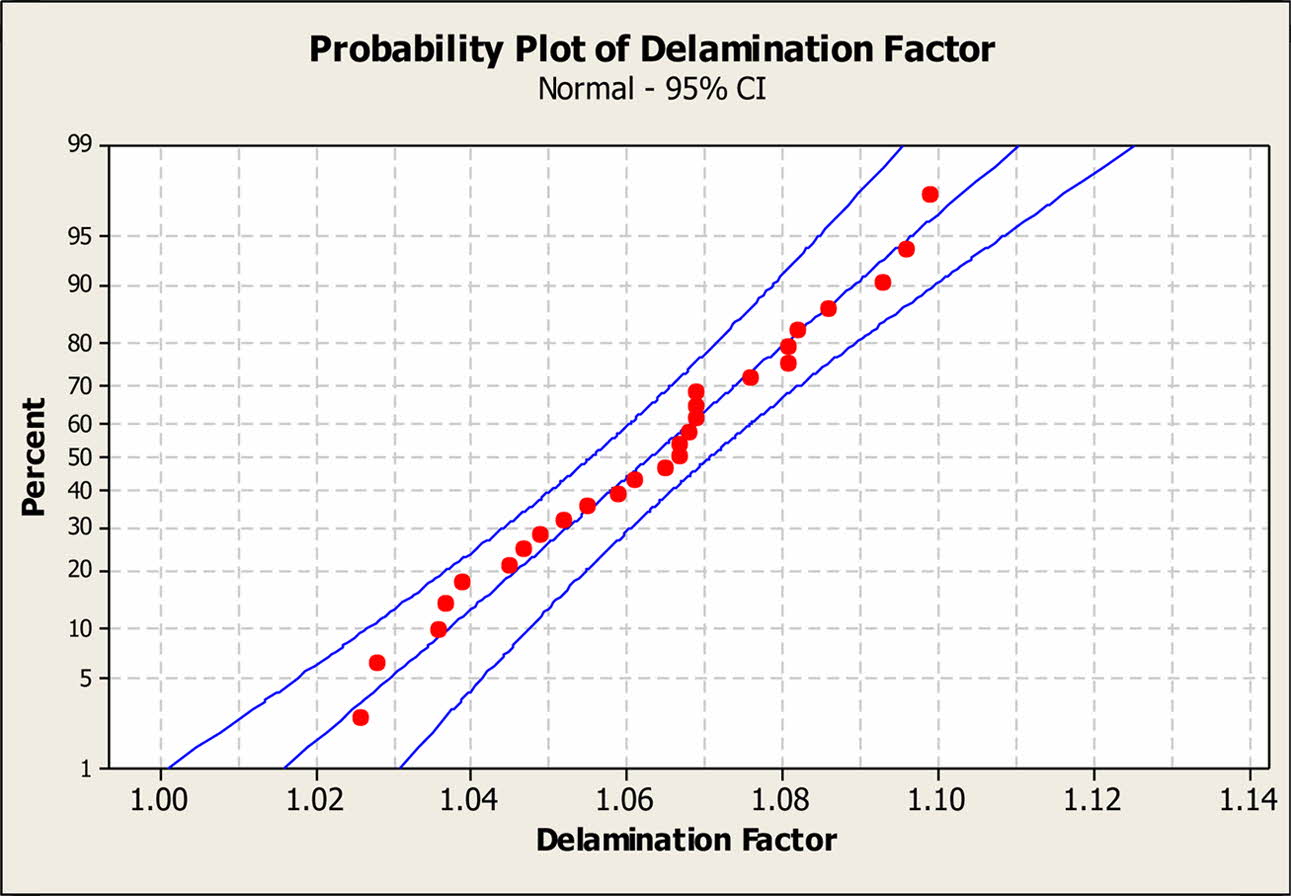

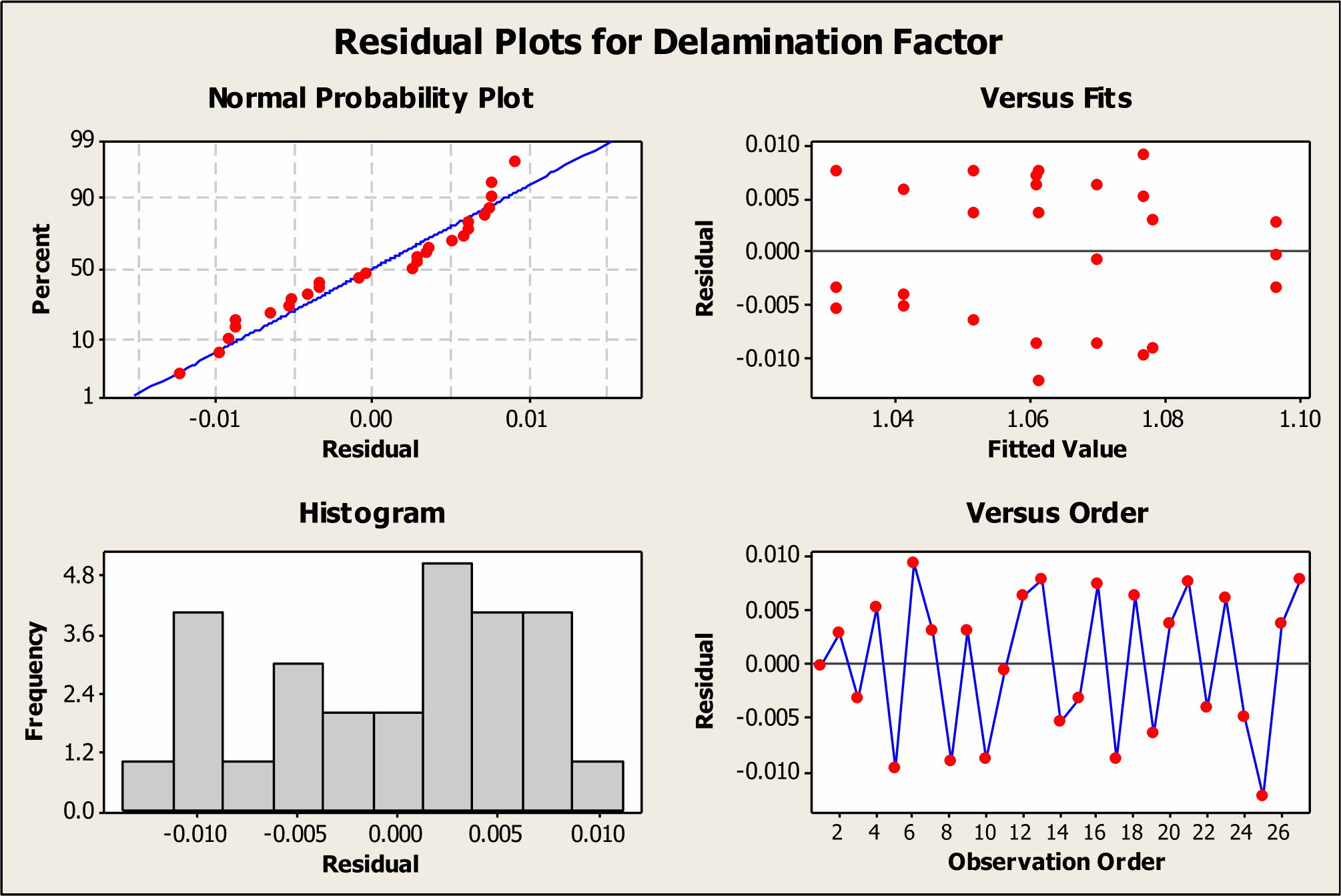

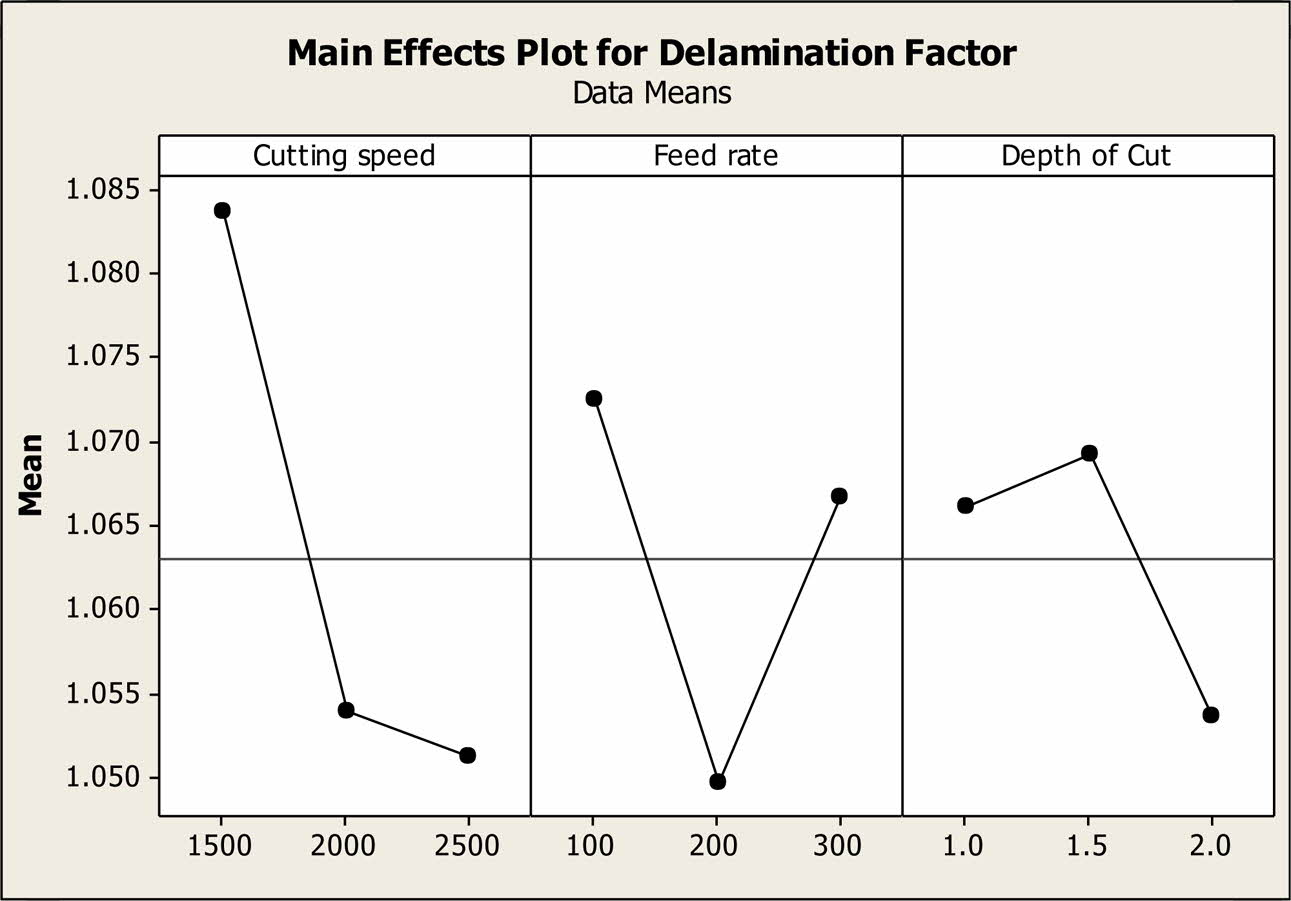

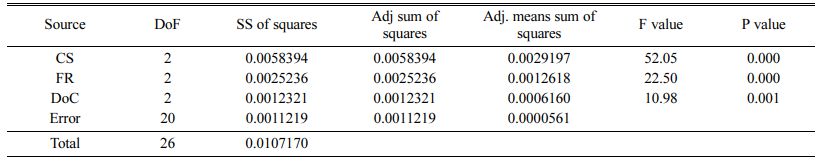

The normal probability plots and the residual plots for the Delamination factor are shown in Fig. 3 and Fig. 4 respectively. It is observed that all the values are very close to the central median line and it is highly satisfactory. The ANOVA for delamination factor is analysed and given in Table 3. It is observed that the contribution of cutting speed is higher while the objective function is the minimization of the Delamination factor. The R-squared value is found to 89.15% and it is satisfactory. It is observed that the contribution of cutting speed is 27.24%, feed rate is 11.7% and depth of cut is 5.74%. It is concluded that the cutting is the most influencing parameter in the minimization for the delamination factor. From the residual plots for the responses, it is noted that all the experimental values are very close to the median line and it represents a good representation of fitting of the model.

|

Fig. 1 Probability plots for Surface roughness. |

|

Fig. 2 Residual plots for Surface roughness. |

|

Fig. 3 Probability plots for Delamination factor. |

|

Fig. 4 Residual plots for Delamination factor. |

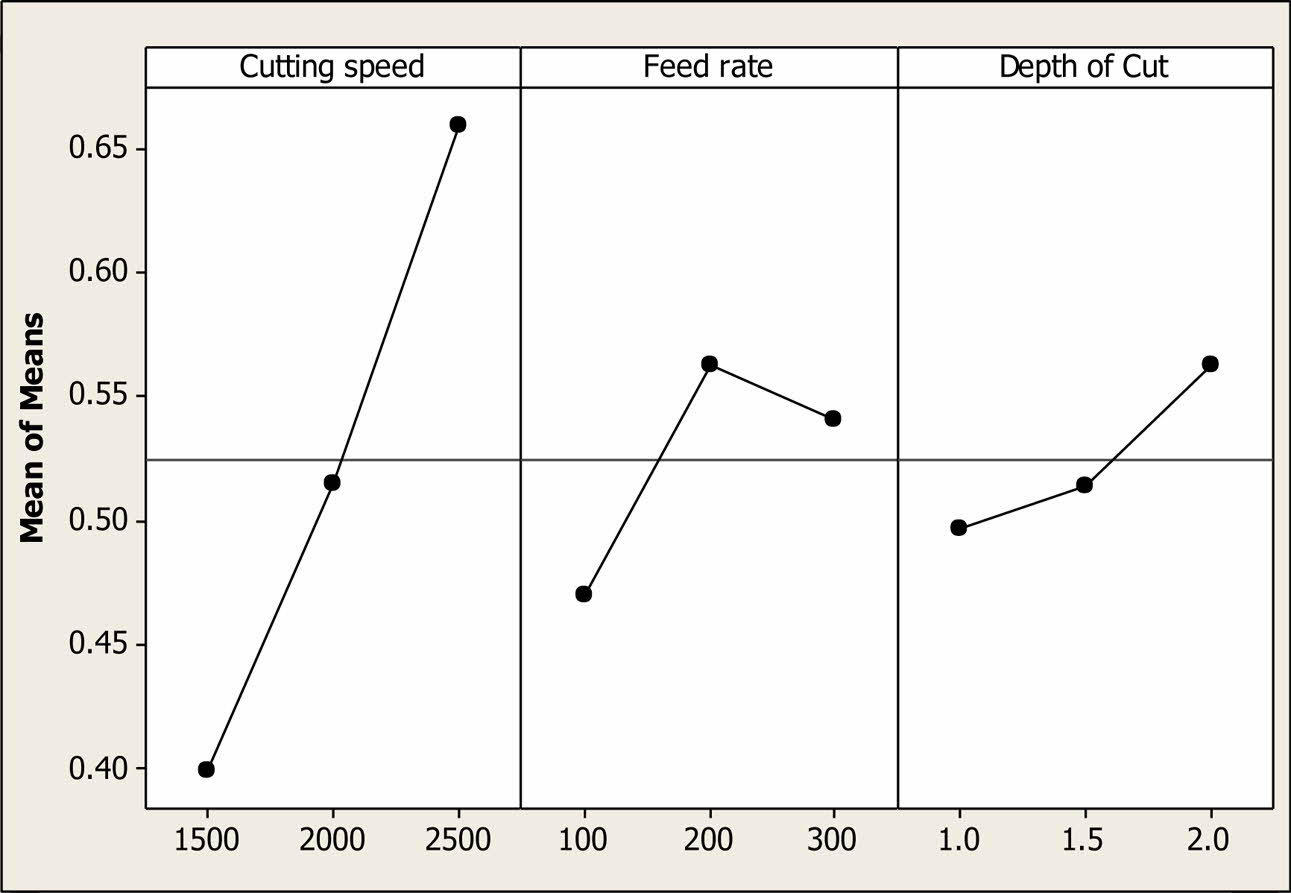

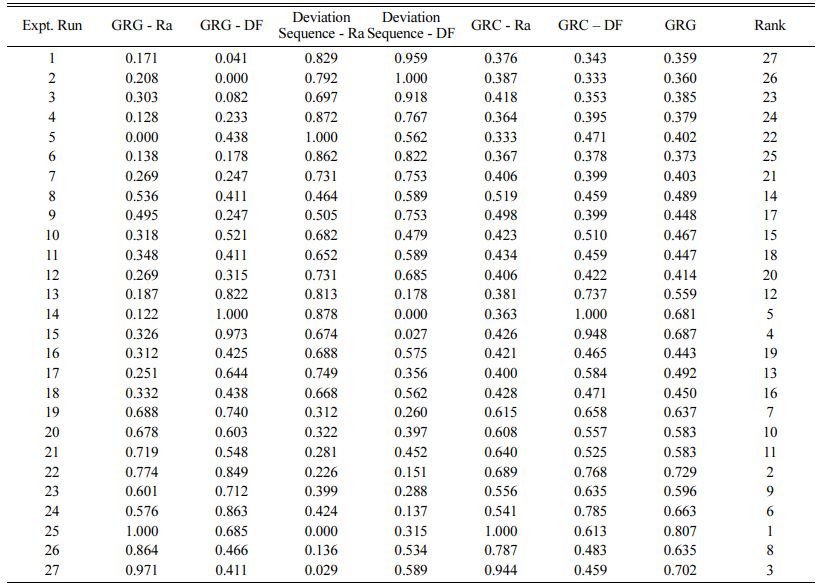

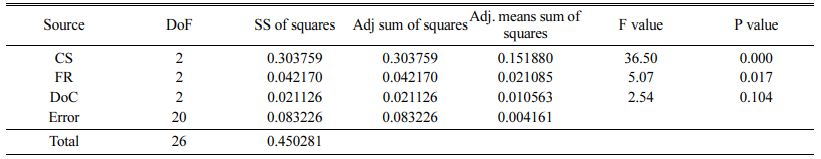

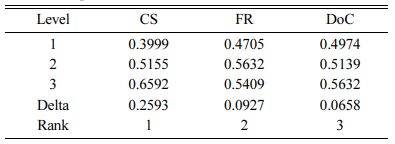

GRA is used to analyse the multi performance charac- teristics and it is implemented in this work to determine multi performance characterization for the optimization of the machining of GFRP composite. Taguchi Grey Relational Analysis (TGRA) is useful in determining the optimum process parameters in obtaining the minimum surface roughness and minimum delamination factor. The grey relational coefficients are calculated for each sequence and grey relational grade are obtained by averaging the grey relational coefficients. The optimum sequence is determined from the higher grey relational grade and the optimum process parameters are determined. The GRG for the surface roughness and delamination factor are obtained. Higher the GRG, it is concluded that the values are closer to ideally normalized value. In this work, experiment run 25 has the optimum multiple performance characterization and has the highest GRG and machining condition at this level are; cutting speed 2,500 m/min, feed rate 300 rpm and depth of cut 1.5 mm. Table 4 represents the grey relational coefficient and GRG for surface roughness and delamination factor. It is observed that the experimental run 25 provides the best optimal results and it is ranked 1. The ANOVA table for the GRG is presented in Table 5 and it is found that the cutting speed is the most influencing parameter in parametric optimization of the machining characteristics of the composite laminate. The response table for means for GRG is also presented in Table 6 and it is noted that the most significant parameter is cutting speed and it is followed by feed rate and depth of cut. The main effect plots for Surface roughness, Delamination factor and GRG are plotted in Fig. 5, 6 and 7 respectively. It is observed that higher cutting speed will provide the minimum surface roughness and delamination factor and it is the most influencing parameter in the determination of the optimum parameter.

|

Fig. 5 Main effect plots for means – Surface roughness. |

|

Fig. 6 Main effect plots for means – Delamination factor. |

|

Fig. 7 Main effect plots for means – GRG. |

This work investigates the machining performance characteristics of glass fibre reinforce polymer composites. L27 orthogonal array is implemented to carry out 27 experiments. The responses considered in the work are delamination factor and surface roughness. The grey relation grades for the surface roughness and delamination factor are obtained. Higher the GRG, it is concluded that the values are closer to ideally normalized value. The ANOVA tables for surface roughness, delamination factor and GRG are analysed and main effects plots are also plotted. The 25th run is observed to be ranked 1 among the 27 experiments and the corresponding parameters are cutting speed – 2500 rpm; Feed rate – 300 rpm and depth of cut – 1.5 mm. The validation test is conducted at the optimum parameters and the surface roughness is measured to be 0.461µm and delamination factor is found to be 1.053 and the results are validated.

- 1. Ramanujam, Radhakrishnan, N. Muthukrishnan, and R. Raju, INT J PR ENG MAN. 12[4] (2014) 651-656.

-

- 2. K. Palanikumar, B. Latha, V. S. Senthilkumar, and J. Paulo Davim. Mater. Manuf. Process, 27[3] (2012) 297-305.

-

- 3. G. Anand, G, N. Alagumurthi, R. Elansezhian, K. Palanikumar, and N. Venkateshwaran. J Braz Soc Mech Sci. 40[4] (2018) 1-20.

-

- 4. K. Palanikumar. J. Reinf. Plast. Compos. 25[16] (2006) 1739-1751.

-

- 5. K. Palanikumar, L. Karunamoorthy, and R. Karthikeyan. Mater. Manuf. Process. 21[8] (2006) 846-852.

-

- 6. C.J. Rao, D. Nageswarara, P. Sriharic, Procedia Eng. 64 (2013) 1405-1415.

-

- 7. D.K. Das, A.K. Sahoo, R. Dash, and B.C. Routara, Procedia Materials Science 6 (2014) 1351-1358.

-

- 8. C.-J. Tzeng, Y.-H. Lin, Y.-K. Yang, and M.-C. Jeng, J. Mater. Process. Technol. 209 (2009) 2753-2759.

-

- 9. S.K. Madhavi, D. Sreeramulu, and M. Venkatesh. Int. J. Eng. Sci. Technol. 7 (2016) 1-8.

-

- 10. B. Rajeswari and K.S. Amirthagadeswaran, Measurement. 105 (2017) 78-86.

-

- 11. R. Vinayagamoorthy, I.V. Manoj, G. Narendra Kumar, I. Sai Chand, GV Sai Charan Kumar, and K. Suneel Kumar, J. Mech. Sci. Technol. 32[5] (2018) 2011-2020.

-

- 12. KM. Senthilkumar, R. Thirumalai, M. Seenivasan, and T. Venugopal, J. Ceram. Process. Res. 22[6] (2021) 731-738.

-

This Article

This Article

-

2022; 23(3): 404-408

Published on Jun 30, 2022

- 10.36410/jcpr.2022.23.3.404

- Received on Feb 19, 2022

- Revised on Mar 6, 2022

- Accepted on Mar 10, 2022

Services

Services

- Abstract

introduction

experimental methodology

results and discussions

grey relational analysis

conclusions

- References

- Full Text PDF

Shared

Correspondence to

Correspondence to

- Shivaperumal M

-

Research Scholar, Dr.N.G.P Institute of Technology, Coimbatore, Tamilnadu, India

Tel : +91 9442224322 - E-mail: shivaperumalvasu@gmail.com

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.