- A comparative study on tribological characteristics of Ti-6Al-4V and Ti-6Al-4V-ELI alloys using hybrid nanoparticles (Al2O3 /MWCNT) cutting fluid

P. Bagyalakshmia,*, P. Ashoka Varthananb and P. Divyesh Randheerc

aAssistant Professor, Mechanical Department, Nehru Institute of Engineering and Technology, Tamilnadu, India

bProfessor, Sri Krishna College of Engineering and Technology.Tamilnadu, India

cUG Scholar, Production Department, Dr Mahalingam College of Engineering and Technology, Tamilnadu, IndiaThis article is an open access article distributed under the terms of the Creative Commons Attribution Non-Commercial License (http://creativecommons.org/licenses/by-nc/4.0) which permits unrestricted non-commercial use, distribution, and reproduction in any medium, provided the original work is properly cited.

Selection of nanometer sized particles for preparation of hybrid cutting lubrication changes the behavior of the heat transfer area during the turning process. Also, addition of nano-particles to the base cutting lubrication significantly alters the properties in lubrication by reducing the friction during the turning process. These experimental investigations were carried out for four turning process parameters namely speed of cutting, feed of cutting, axial depth of cut and hybrid cutting lubrication (MWCNT and Al2O3). In this investigation, nano cutting lubrication was prepared by adding 1 and 2 % volume concentration of MWCNT and Al2O3 nanosized particles to the industrial cutting fluid. In the turning process, friction between the cutting tool and workpiece (Ti-6Al-4V and Ti-6Al-4V-ELI) is a leading key issue for the outcome of the quality. From the investigation study, it has been observed that selected turning process parameters and cutting lubricants have a direct influence on coefficient of friction and surface roughness. The conclusion of investigation reveals that turning of Ti-6Al-4V and Ti-6Al-4V ELI (Extra Low Interstitials) under nano cutting lubrication improves the quality compared to normal cutting lubrication

Keywords: Ti-6Al-4V, Ti-6Al-4V-ELI, SEM, nanolubricants, friction

In the medical, manufacturing industry produced components for robots, cardiovascular devices, surgical instruments, orthopedics and dental using several pro- cesses such as machining, grinding, polishing, micro-machining, and surface treatment. Titanium alloy is considered as one of the most important materials for the production of these components due to its fracture toughness, rigidity, in the replacement of hard tissues. Among many titanium alloys, the Ti-6Al-4V and Ti-6Al-4V-ELI are widely used in the medical industry [1]. These materials are adopted in the medical industry and implants because of its resistance towards corrosion, higher strength, and biocompatibility [2]. Surface finish of the material is the biggest challenge in producing the orthopedic implants than achieving the accurate dimensional material. So in order to achieve a good surface finish, post-machining hand finishing is required with belt grinding, polishing and buffing. But it is time consuming as it takes nearly 45 minutes for a single part. Several research studies reveal that selection of stable turning process parameters will effectively achieve greater surface finish [3-4]. In the machining process, friction plays a major role for excessive heat generation. The excessive heat generated during machining operation impact deteriorates tool fife and decreases the workpiece dimensional accuracy [5, 6]. Observed that the cutting fluid characteristics could improve with blending of nanoparticles. Also, hybrid nano cutting fluid has significant heat removal capacity and improves tool life. Also, authors found that surface roughness, cutting forces and temperature were drastically reduced at the machining zone. Traditional cutting fluid increases the temperature at the machining zone due to the high amount of heat generation at the cutting tool and workpiece interface due to friction [6]. The machining prepared by conventional cutting fluids showed negative impacts on the environment and severe health hazard on the machining operators which also affected the sustainability of the process. According to [7], speed of cutting, feed of cutting, axial depth of cut and cutting fluid is some of the turning parameters which showed a significant influence on surface roughness. Engineering ceramics particles have an excellent mechanical property such as high strength, hardness and stiffness also it suits for high temperature applications. Aluminum oxide is the most commonly available ceramic particle due to its ease of availability and low cost, also Al2O3 having higher impact energy value of 17 Joules [8, 9]. Al-GnP hybrid nanofluid was developed by hybridizing the graphene nanoplatelets with blended aluminum oxide nanofluid in the ratio of 10:90. [10] conducted an experiment by adopting Response Surface Methodology (RSM) technique to optimize the input machining variable like cutting velocity, rate of feed, axial depth of cut and nanoparticle concentration (Al2O3 and Al-GnP) for the response parameters. The author’s results evidently revealed that the friction reduced on changing the type of nanoparticle and its concentration in base fluid and the MQL flow rate [11]. Perceived that the tangential force and the machining zone temperature can be reduced by the application of nano-fluid. This application also helped in minimizing the grinding force, coefficient of friction. It is also evident from the research that grinding responses can be improved by adding the zinc oxide nano-fluid due to its higher spreadability even at a higher temperature. According to [12], Zinc oxide based nanofluids leads to the sustainable development in grinding of high strength superalloys. [13] investigated with various reinforcements like carbon nanotubes (CNTs), MoS2, SiO2, ZrO2 and Al2O3 were used as lubrication grinding fluids. Among the above reinforcements, investigation results revealed that Al2O3 nanofluid gave lowest sliding friction coefficient and specific sliding energy [14]. Produced hybrid cutting fluids with the ratio of 1:1 (Al2O3 + ZnO), the hybrid nanolubricant resulted in reducing the cutting energy in highest meanwhile the usage of nanolubricant Al2O3 + SiO2 in the ratio of 2:1 Al2O3+ SiO2, 2:1 reduced the spindle power effectively on comparison with other cooling condition. The recent experimental research revealed that, usage of MWCNT/MoS2-reinforced hybrid nanofluid lowered the surface roughness, tool wear and cutting forces when compared to dry conditions [15]. The traditional cutting fluid blended with MWCNT nanoparticles reduces the contact angle up to 33.33% compared to the conventional fluid which improves the wear resistance of cutting tools [16]. Mathematical optimization is the effective method for selection of a best element with respect to some condition. Optimization problem includes of minimizing or maximizing an objective function by analytically choosing process parameter values from within a set of values and figuring the effective optimum values [17]. Desirability function analysis (DFA) is found as a precise method for multi objective optimization as it consumes less time for process and higher accuracy of results in optimization. The DFA method optimizes the multi responses simultaneously without any conflicts and provides the single objective results [18]. The present research work is completely focused to bridge the gap on the benefits of the hybrid nanolubricants cutting fluids on machining process. The investigation is carried out with various turning parameters like speed of cutting, feed of cutting, axial depth of cut and hybrid cutting lubrication (MWCNT and Al2O3). The hybrid cutting lubrication (MWCNT and Al2O3) is prepared by adding 1 and 2% of volume concentration on industrial cutting fluid. The effective turning process parameters and appropriate volume concentration of hybrid cutting lubrication (MWCNT and Al2O3) will be identified to improvise the surface quality.

Workpiece, cutting tool and hybrid nanofluids

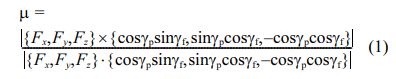

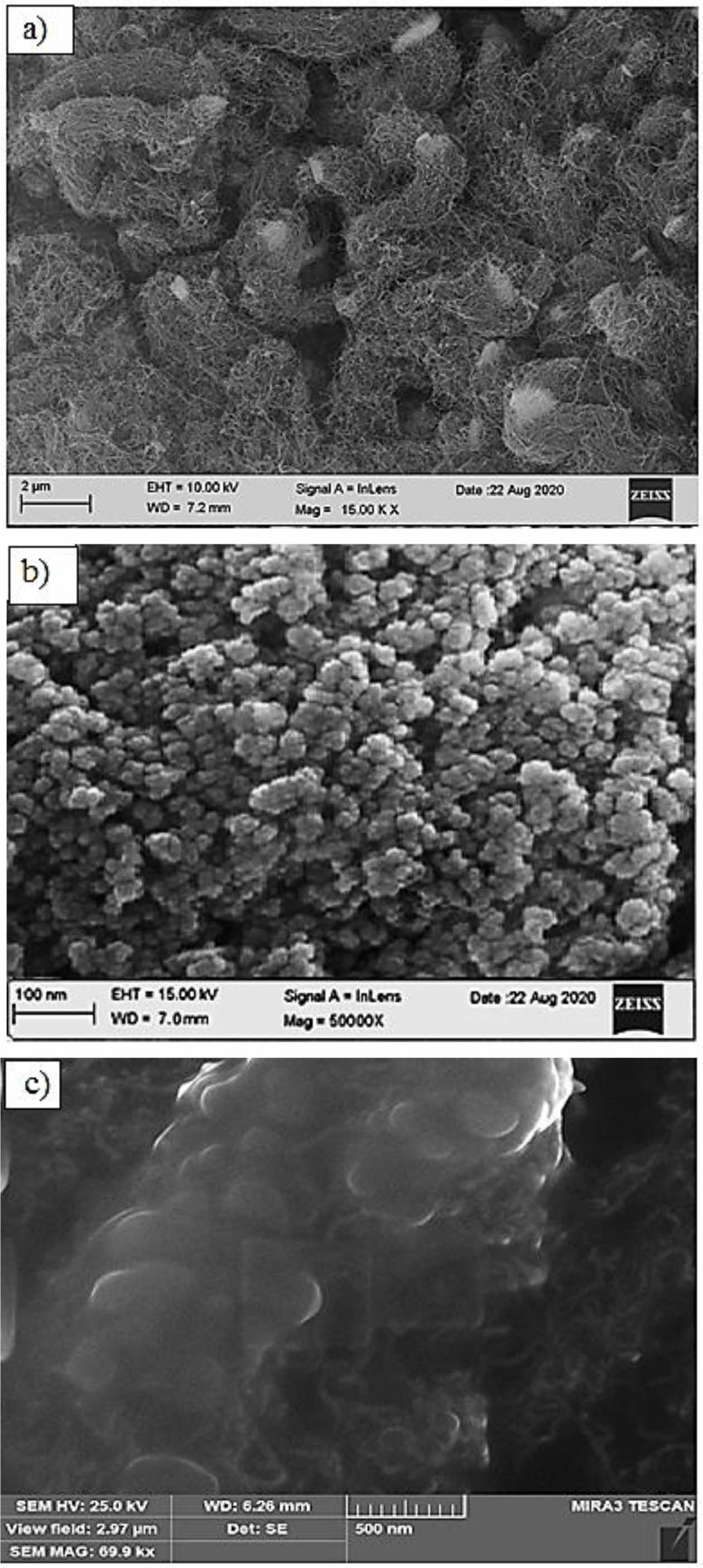

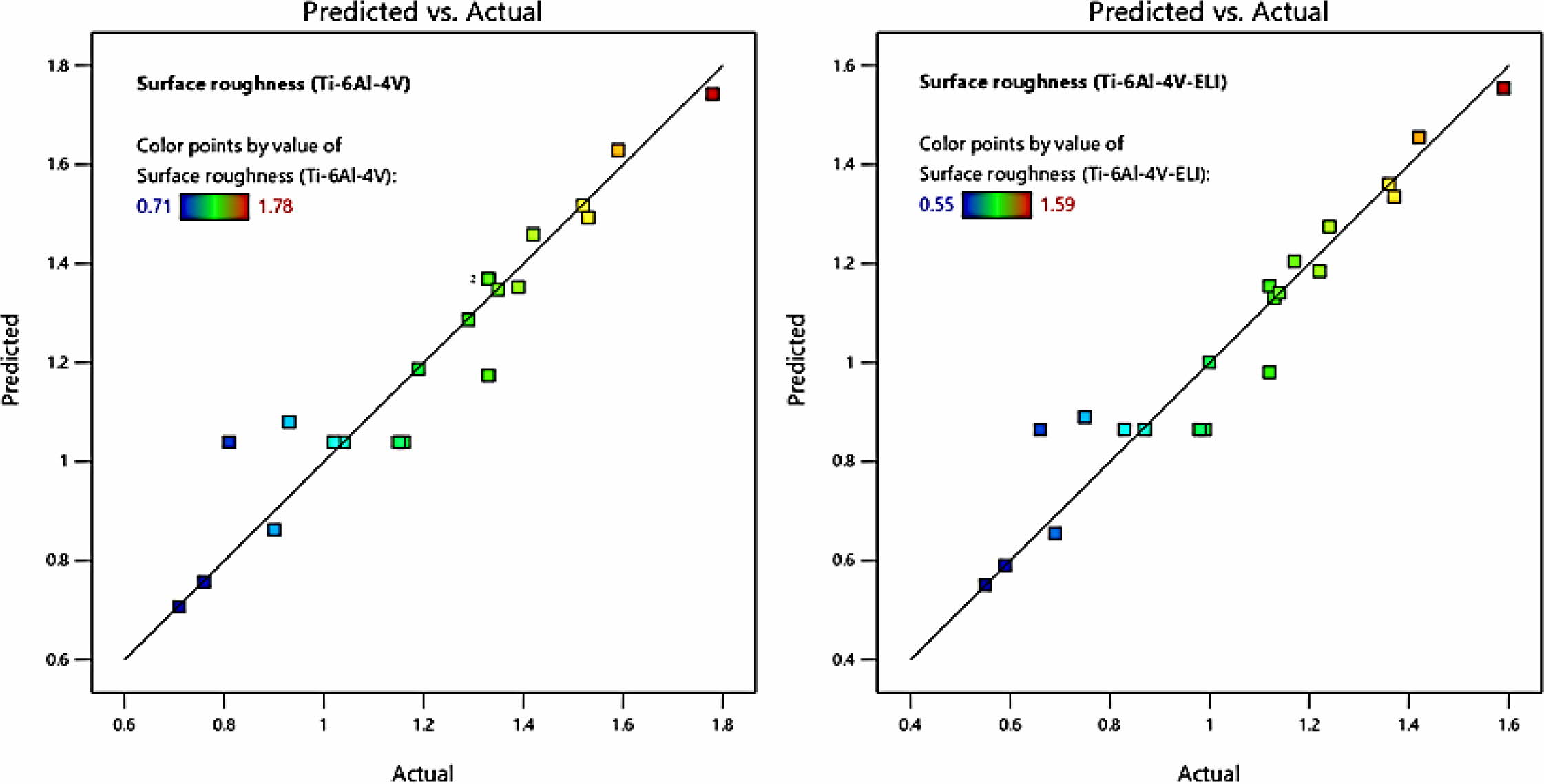

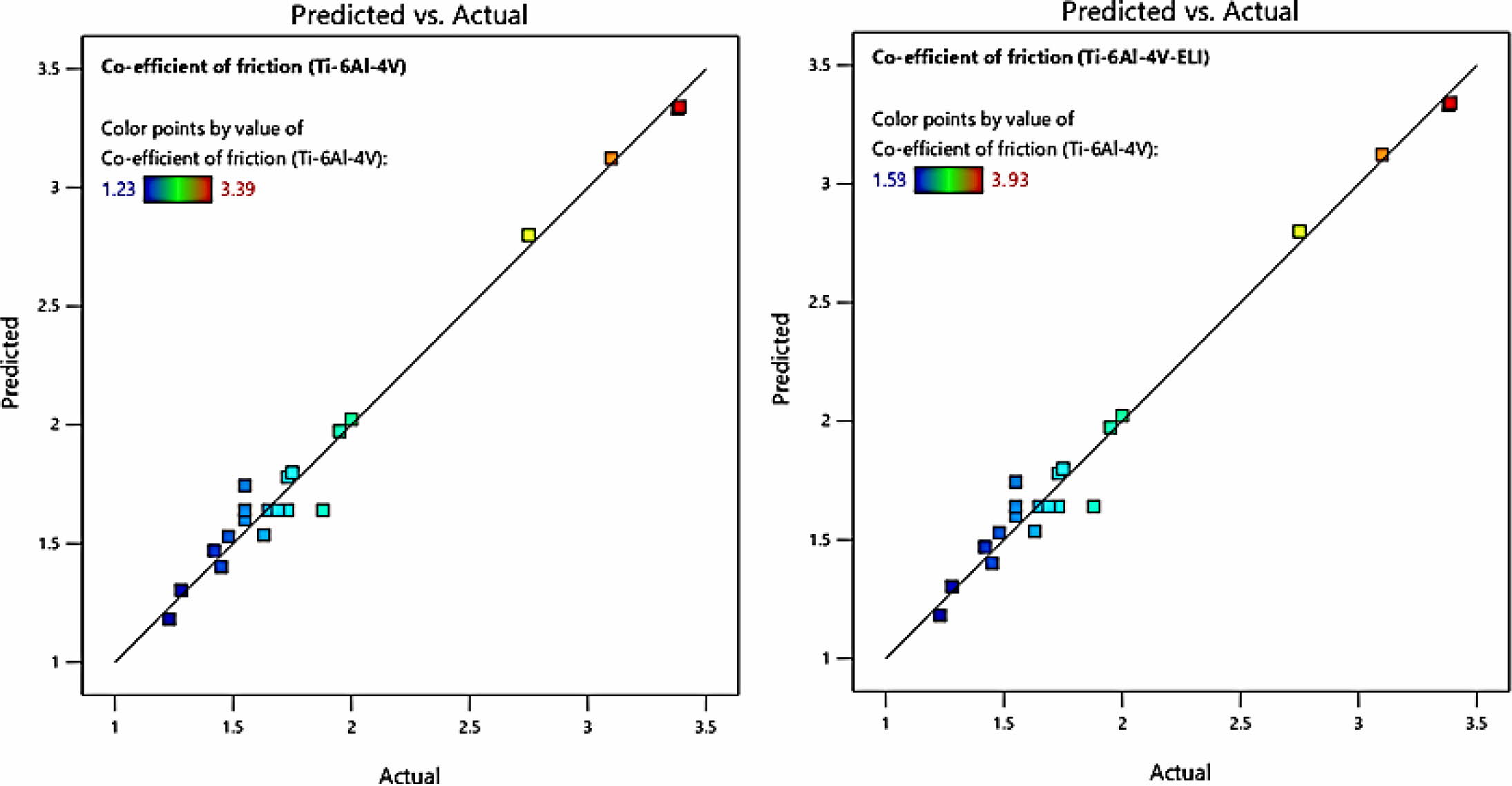

The workpiece selected in this research work for turning experimental investigation is Ti-6Al-4V ELI (Grade 23) and Ti-6Al-4V (Grade 5). The major variance between the Ti-6Al-4V and Ti-6Al-4V ELI is that in ELI. ELI has Extra Low Interstitials, its has maximum oxygen content is reduced to 0.13%. This gives the material improved fracture toughness which is more suitable for orthopedic applications. The Table 1 portrays the mechanical property of Ti-6Al-4V and Ti-6Al-4V-ELI based on Aerospace Specification Metals Inc (ASM). Cubic boron nitride (CBN) insert grade CB7015 used for turning operation for both the alloys Ti-6Al-4V and Ti-6Al-4V-ELI. CBN is the second hardest known material after synthetic diamond. CBN tools are used for machining hardened materials like steels and titanium alloys as they offer a cost-effective and heat resistant. The hybrid cutting lubrication of MWCNT and Al2O3 nano-particles used for dispersion which are cylindrical (MWCNT) and spherical (Al2O3) shapes respectively. To improve the stability of sus- pensions, sodium dodecyl benzene sulfonate (SDBS) used with 1/10 weight of the nano-particle's weight as a surfactant [6]. The hybrid nano lubricant is prepared with appropriate proportion by dispersing the nano-particles in industrial cutting fluid (‘S’ servo cut fluid) and deionized water. The ultrasonic bath sonicator is used for an hour to attain the uniform dispersion. Finally, the prepared hybrid nanolubricant were analyzed and ensured there was no agglomeration found as higher amount agglomeration reduces the quality of hybrid nano lubricant. Table 2 depicts a summarized report of MWCNT and Al2O3 nanofluids on different volume concentrations. Figs. 1(a-c) show the scanning electron microscopy images of preparation of nano cutting lubricants. Figs. 1(a and b) portrays the SEM image of MWCNT and Al2O3 nano-particles at 15 KX and 50 KX magnification respectively. Fig. 1(c) SEM image shows that the MWCNT and Al2O3 nano-particles were uniformly distributed in cutting fluid. Figs. 2(a-b) shows the Energy-dispersive X-ray spectroscopy (EDS) for MWCNT and Al2O3 nano-particles. Highest peak of carbon presence at 20 cps/eV in Fig. 2(a) confirms the MWCNT particles. Fig. 2(b) EDS shows the presence of ‘Al’ and ‘O’ which confirms the Al2O3 particles.

Design of experiments

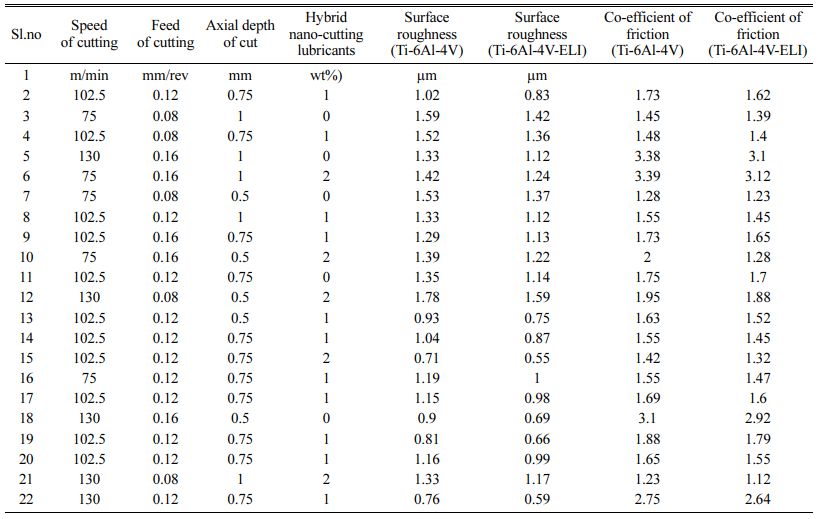

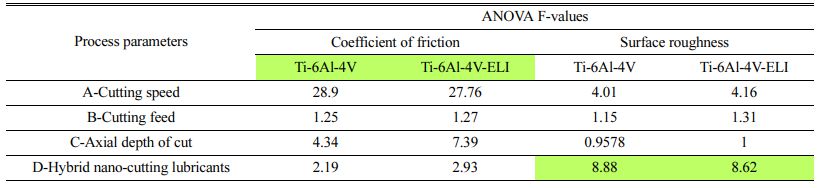

The Response Surface Methodology (RSM) is con- sidered as an important and dynamic tool by various researchers [19].A central composite design is the most commonly used response surface designed experiment. For example, for a three-factor and four response surface experiment, the following second-order model is the standard model for CCD [20]. The central composite design (CCD) experiments developed using Design Expert software Version.11. The turning experiments are carried out based on developed CCD. Speed of cutting, feed of cutting, axial depth of cut and hybrid cutting lubrication (MWCNT and Al2O3) are the major turning process parameters used. For each experiment, the turning process parameters are fed in machining data based on experimental design. After the turning process, each sample is used to measure the responses such as coefficient of friction and surface roughness. After the completion of each experiment, the measured value of normal and tangential components of turning forces is used to calculate coefficient of friction. The Eq. (1) is used to calculate the coefficient of friction [21]. Surf tester is used to measure the surface roughness on turning surface. The responses are measured in order to understand the influence of turning process parameters and hybrid cutting fluids. The central composite design is portrayed in Table 3.

Where, rotating speed of the workpiece (nw) is measured in r/min and the rate of feed (f) is measured in mm/r. The slide rake angle γfis given as 9.05o and the back rack angle γpis given as - 7.31o. As they are the functions of cutting forces (Fx, Fy, and Fz), they are also relatively easy to obtain.

|

Fig. 1 SEM images (a) MWCNT, (b) Al2O3 nano-particles and (c) Hybrid cutting lubrication. |

|

Fig. 2 (a-b) EDS spectroscopy a) Al2O3 b) MWCNT nanoparticles. |

Statistical analysis

Analysis of variance (ANOVA) results for coefficient of friction portrays that speed of cutting has a higher influence compare to the factors such as feed of cutting, axial depth of cut and hybrid cutting lubrication for both the Ti-6Al-4V and Ti-6Al-4V-ELI alloys. The maximum influencing parameters have been identified using F-statistical values. The Table 4 portrays the F-statistical values for coefficient of friction. The maximum coefficient of determination (R2) was obtained for coefficient of friction in between of 98 to 98.5% for both the alloys which shows the higher effectiveness of overall analysis.

ANOVA statistical results for surface roughness exposes that hybrid cutting lubrication has a higher influence compared to the factors such as speed of cutting, feed of cutting and axial depth of cut for both the Ti-6Al-4V and Ti-6Al-4V-ELI alloys. Table 4 portrays the F-statistical values for coefficient of friction. The maximum coefficient of determination (R2) was obtained for surface roughness between 92 to 93% for both the alloys which shows the higher effectiveness of overall analysis.

Interaction for coefficient of friction

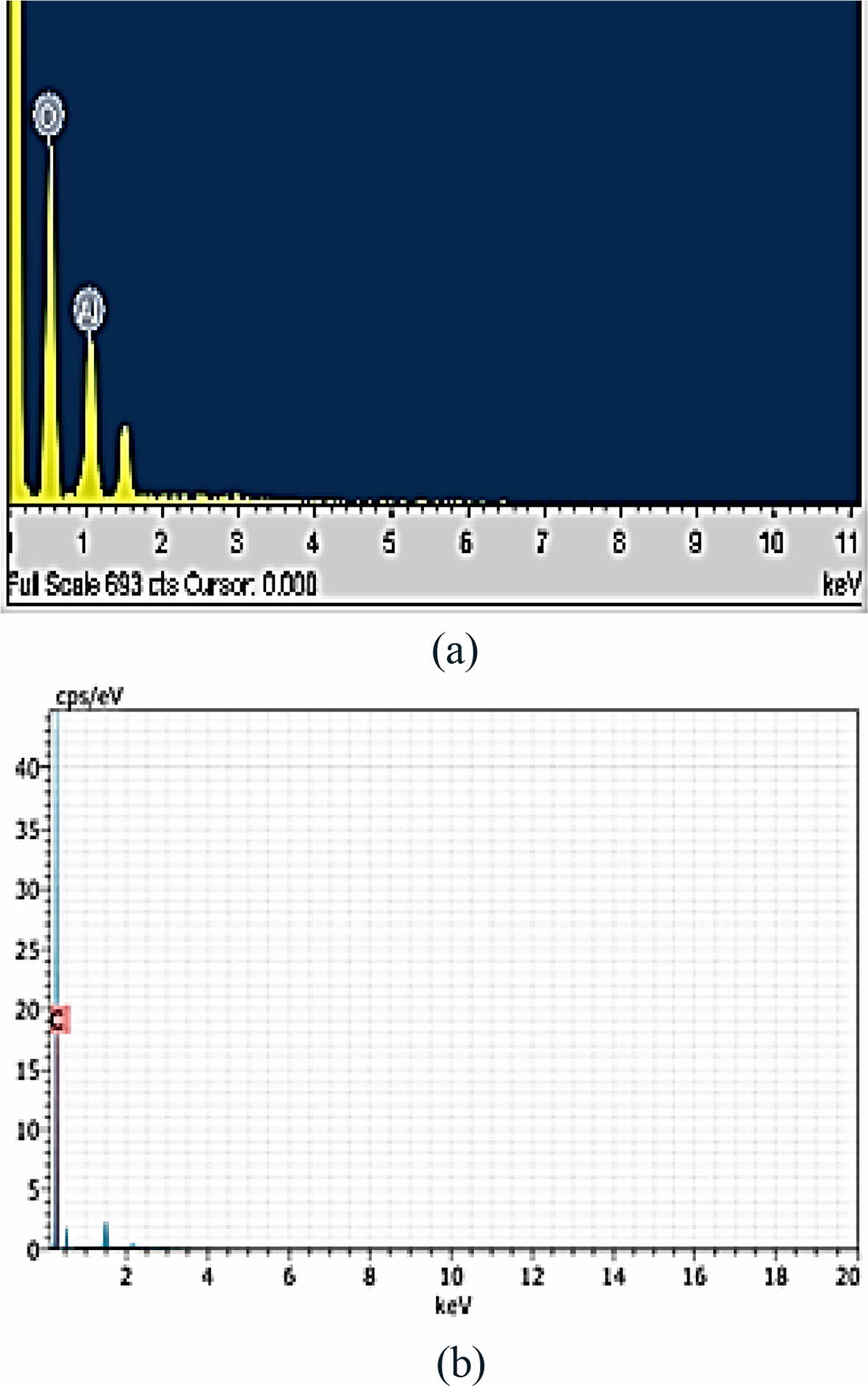

In metal cutting, friction significantly plays an important role during the turning process. Coefficient of friction is responsible for the compression of chip and induces of cutting forces as well as generated heat on the cutting zone which negatively influence the mechanical property and poor surface quality [22]. The impact of the input parameters like speed of cutting, feed of cutting, axial depth of cut and hybrid cutting lubrication (MWCNT and Al2O3) for coefficient of friction on Ti-6Al-4V and Ti-6Al-4V-ELI alloys is depicted in the Figs. 3(a-f). In Fig. 3(a-f), investigations was carried out for Ti-6Al-4V and Ti-6Al-4V- ELI alloys with different process parameters such as speed of cutting, feed of cutting, axial depth of cut and hybrid cutting lubrication (MWCNT and Al2O3) with respect to coefficient of friction. The interaction plot Figs. 3(a) and 3(d), clearly depicts that minimum coefficient of friction could be attained at preference of lower speed of cutting range between 75 to 86 m/min and lower cutting rate of feed ranges between 0.08 to 0.10 mm/rev. In Figs. 3(b) and 3(e), investigation was carried out on coefficient of friction for two turning process parameters such as speed of cutting and axial depth of cut, and the remaining parameters such as cutting rate of feed and hybrid cutting lubrication were kept as constant. From the interaction plot, it has been understood that minimum coefficient of friction could be attained at preference of lower axial depth of cut ranges between 0.5 to 0.60 mm. This is because the higher axial depth of cut increases the chip thickness which causes chip stuck on the tool face turn to increase higher forces, thus coefficient of friction increases. In Figs. 3(c) and 3(f), investigation was carried out on coefficient of friction for two turning process parameters such as speed of cutting and hybrid cutting lubrication, and the remaining parameters such as cutting rate of feed and axial depth of cut were kept as constant. From the interaction plot, it has been understood that minimum coefficient of friction could attain a preference of higher range of hybrid cutting lubrication between 1.8 to 2% for both the alloys Ti-6Al-4V and Ti-6Al-4V-ELI. The research investigation clearly states that the optimal turning process parameters achieves minimum coefficient of friction of 1.23 for Ti-6Al-4V and 1.12 for Ti-6Al-4V-ELI alloys. The optimal turning process parameter comparison for both Ti-6Al-4V and Ti-6Al-4V-ELI alloys with respect to coefficient of friction clearly shows that Ti-6Al-4V-ELI alloy is the good choice of selection for the improvement of surface quality for bio-medical applications. The interaction plot clearly reveals that 2 wt% of hybrid cutting lubrication reduces coefficient of friction significantly compared to the normal base cutting fluid. This is owing to the reason that 2 wt% of hybrid cutting lubrication forming the descent film between the tool and workpiece, also improves the sliding surface and decreases the coefficient of friction. The optimal turning process parameter comparison for both Ti-6Al-4V and Ti-6Al-4V-ELI alloys with respect to surface roughness clearly shows that Ti-6Al-4V-ELI alloy is the respectable choice of selection for the enhancement of mechanical component performance.

Interaction for surface roughness

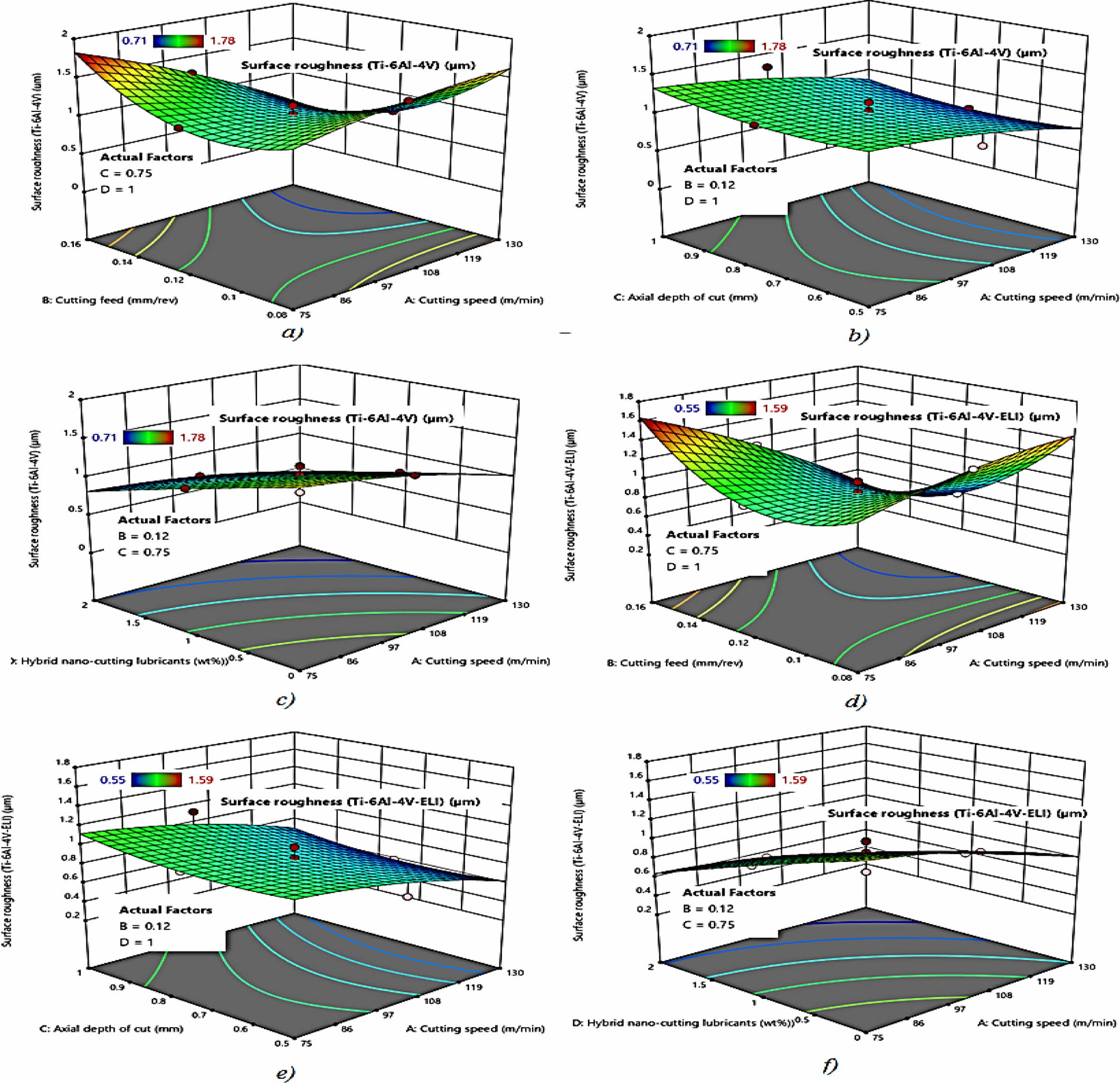

Surface roughness is a surface texture of component which plays an important role in determining how machined components will interact with its environment [20]. The impact of the input parameters like speed of cutting, feed of cutting, axial depth of cut and hybrid cutting lubrication (MWCNT and Al2O3) for surface roughness on Ti-6Al-4V and Ti-6Al-4V-ELI alloys is depicted in the Figs. 4(a-f). In Figs 4(a-f), investigations was carried out for Ti-6Al-4V and Ti-6Al-4V- ELI alloys with different process parameters such as speed of cutting, feed of cutting, axial depth of cut and hybrid cutting lubrication (MWCNT and Al2O3) with respect to surface roughness. The interaction plot Figs. 4(a) and 4(d), clearly depicts that minimum surface roughness could be attained at preference of higher speed of cutting range between 125 to 130 m/min and optimum cutting rate of feed ranges between 0.12 to 0.13 mm/rev. This is because lower speed of cutting and higher cutting rate of feed produces microwelds on machined surfaces which causes increased surface roughness [11]. In Figs. 4(b) and 4(e), investigation was carried out on surface roughness for two turning process parameters –speed of cutting and axial depth of cut, and the remaining parameters such as cutting rate of feed and hybrid cutting lubrication were kept as constant. From the interaction plot, it has been understood that minimum surface roughness could be attained at preference of lower axial depth of cut ranges between 0.5 to 0.60 mm. This is because the higher axial depth of cut increases the chip thickness which causes the chip stuck on the tool face turn to increase higher forces, thus surface roughness increases.

In Figs. 4(c) and 4(f), investigation was carried out on surface roughness for two turning process parameters such as speed of cutting and hybrid cutting lubrication, and the remaining parameters such as cutting rate of feed and axial depth of cut were kept as constant. From the interaction plot, it has been understood that minimum surface roughness could attain a preference of higher range of hybrid cutting lubrication between 1.8 to 2% for both the alloys Ti-6Al-4V and Ti-6Al-4V-ELI. The research investigation clearly states that the optimal turning process parameters achieve minimum coefficient of friction of 1.23 for Ti-6Al-4V and 1.12 for Ti-6Al-4V-ELI alloy. The interaction plot clearly reveals that compared to the normal base cutting fluid. The interaction plot clearly reveals that 2% of hybrid cutting lubrication improves the surface quality compared to normal base cutting fluid. The results analysis clearly reveals that 2% of hybrid cutting lubrication increases the heat transfer rate at the cutting zone and further improves the surface finish.

Surface Morphology

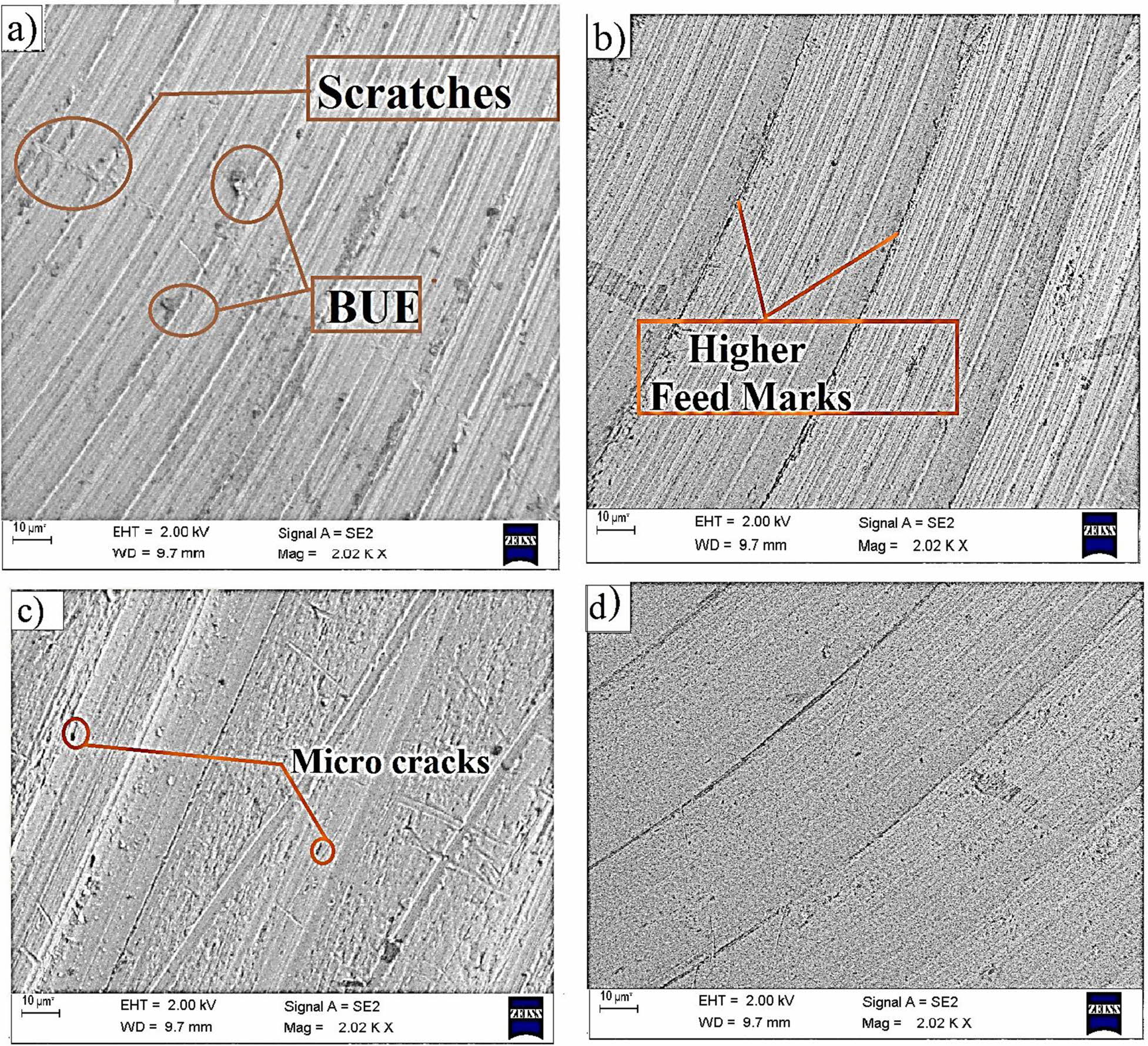

The surface morphology of the machined surface was analyzed using scanning electron microscopy for Ti-6Al-4V and Ti-6Al-4V-ELI. The Figs. 5(a-c) shows a surface morphology of machined surface for normal cutting fluid and 2 wt % of MWCNT and Al2O3 cutting fluid. From Figs. 5(a) and (b), several surface defects were observed such as adhered built-up-edge, higher feed marks, micro cracks and scratches. It was observed from Fig. 5(b), higher feed marks were present due to selection of higher rate of feed values. It was evident from the Fig. 5(a), normal cutting fluids causes formation of built-up-edges over the machined surface. This is because the normal cutting lubrication reduces the heat transfer rate during the turning process which causes higher coefficient of friction and reduces surface finish. Fig. 5(c), it was observed micro-cracks on Ti-6Al-4V alloy compare to Fig. 5(d) Ti-6Al-4V-ELI, this may be owing to the reason ELI (Extra Low Interstitials) material has a good fracture strength and ductility thus prevents from micro cracks.

Multiple responses optimization

Response surface methodology is an advanced technique to determine the mathematical model relationship between the machining process parameters and responses. This technique works with statistical analysis which is used to find the optimal process parameters [23]. For multiple response optimizations, desirability function approach (DFA) is the most widely adopted method. This method is proposed by Derringer and Suich [30]. The present multi objective optimization problem is solved by using the desirability function analysis method. Four turning parameters namely speed of cutting, feed of cutting, axial depth of cut and hybrid cutting lubrication (MWCNT and Al2O3) are considered for multi objective optimization. The aim of adopting the optimization process is to identify the optimal values for turning process parameters, which help in minimizing the values of coefficient of friction and surface roughness. The regression equations developed with the help of design expert software version.11 was adopted to find the multi objective optimization values. The developed quadratic mathematical models were given in eq. (1) to (4).

Regression Equations for surface roughness (Ti-6Al-4V and Ti-6Al-4V-ELI):

Surface roughness (Ti-6Al-4V)

= 1.2525551666052 + 0.053438200768543

*Cutting speed - 25.227725101331

*Cutting feed-2.5266178343948*Axial depth of cut

+ 0.34423639258829*Hybrid nano-cutting lubricants

- 0.35568181818182*Cutting speed

*Cutting feed-0.0020000000000003*Cutting speed

*Axial depth of cut+0.0012272727272728

*Cutting speed*Hybrid nano-cutting lubricants

+ 10.625*Cutting feed * Axial depth of cut-3.53125

*Cutting feed * Hybrid nano-cutting lubricants

- 0.45499999999999*Axial depth of cut

*Hybrid nano-cutting lubricants - 8.9277254303312e-05

*Cutting speed²226.5525477707*Cutting feed2

+ 1.3997452229299*Axial depth of cut2

- 0.012515923566879*Hybrid nano-cutting lubricants2

(2)

Surface roughness (Ti-6Al-4V-ELI)

= 1.3607152445122 + 0.051192082960468

*Cutting speed - 29.933482918355*Cutting feed

- 2.191175448755*Axial depth of cut

+ 0.26618992472494*Hybrid nano-cutting lubricants

- 0.33863636363636*Cutting speed * Cutting feed

- 0.0010909090909094*Cutting speed

* Axial depth of cut + 0.0016363636363637

*Cutting speed * Hybrid nano-cutting lubricants

+ 10.25* Cutting feed * Axial depth of cut-3

* Cutting feed * Hybrid nano-cutting lubricants

- 0.43999999999999*Axial depth of cut

* Hybrid nano-cutting lubricants - 9.1846080960152e-05

*Cutting speed2 + 237.83837579618*Cutting feed2

+ 1.1286624203822*Axial depth of cut2

- 0.019458598726115*Hybrid nano-cutting lubricants2

(3)

Regression Equations for Coefficient of friction (Ti-6Al-4V and Ti-6Al-4V-ELI):

Co-efficient of friction (Ti-6Al-4V)

= + 4.537152892562 - 0.070892561983471

* Cutting speed - 22.204545454545 *Cutting feed

+ 0.70327272727274 * Axial depth of cut

+ 0.85090909090909 * Hybrid nano-cutting lubricants

- 0.077272727272728 * Cutting speed * Cutting feed

- 0.036363636363636 * Cutting speed

* Axial depth of cut - 0.022545454545455

* Cutting speed * Hybrid nano-cutting lubricants

+ 27.75 * Cutting feed * Axial depth of cut + 10.1875

* Cutting feed * Hybrid nano-cutting lubricants + 0.11

* Axial depth of cut * Hybrid nano-cutting lubricants

+ 0.0007404958677686 * Cutting speed2

+ 9.3749999999998 * Cutting feed2

- 4.8672742467467e-16 * Axial depth of cut2

- 0.0050000000000003 * Hybrid nano-cutting lubricants2

(4)

Co-efficient of friction (Ti-6Al-4V-ELI)

= + 3.8883632942044-0.063180133705322

* Cutting speed - 24.922155471917* Cutting feed

+ 2.268818760857 * Axial depth of cut

+ 0.34967429067747 * Hybrid nano-cutting lubricants

- 0.031818181818183 * Cutting speed * Cutting feed

- 0.046909090909091 * Cutting speed

* Axial depth of cut - 0.017272727272727

* Cutting speed * Hybrid nano-cutting lubricants

+ 32.75 * Cutting feed * Axial depth of cut + 8.375

* Cutting feed * Hybrid nano-cutting lubricants + 0.37

* Axial depth of cut * Hybrid nano-cutting lubricants

+ 0.00068646628415013* Cutting speed2

- 6.7874203821658 * Cutting feed2 - 0.81375796178344

* Axial depth of cut2 - 0.025859872611465

* Hybrid nano-cutting lubricants2 (5)

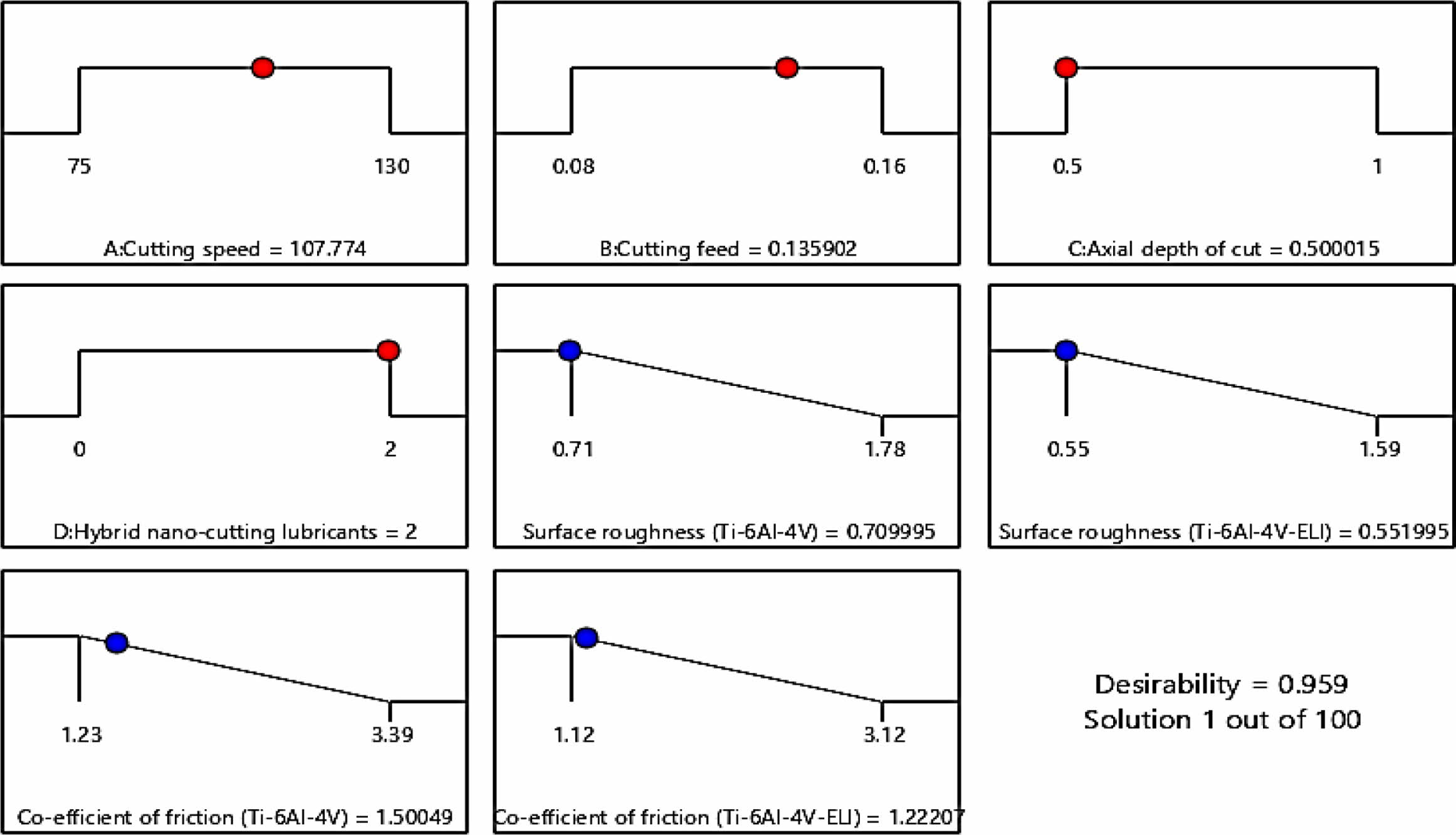

The Fig. 6 depicts the ramp plot which shows the optimal turning process parameters. The red points in Fig. 6 show the optimal values of speed of cutting (107.7 m/min), feed of cutting (0.13 mm/rev), axial depth of cut (0.5 mm) and hybrid cutting lubrication (2 wt%). The blue dot on the curve provides the responses for the optimal turning process conditions for surface roughness (Ti-6Al-4V and Ti-6Al-4V-ELI) were 0.75 µm and 0.55 µm respectively. The blue dot on the curve provides the responses for the optimal turning process conditions for coefficient of friction (Ti-6Al-4V and Ti-6Al-4V-ELI) were 0.5 and 1.22 respectively. The response results achieved for the optimal turning process parameters at desirability of 0.95 shows that Ti-6Al-4V-ELI alloy has good output characteristics.

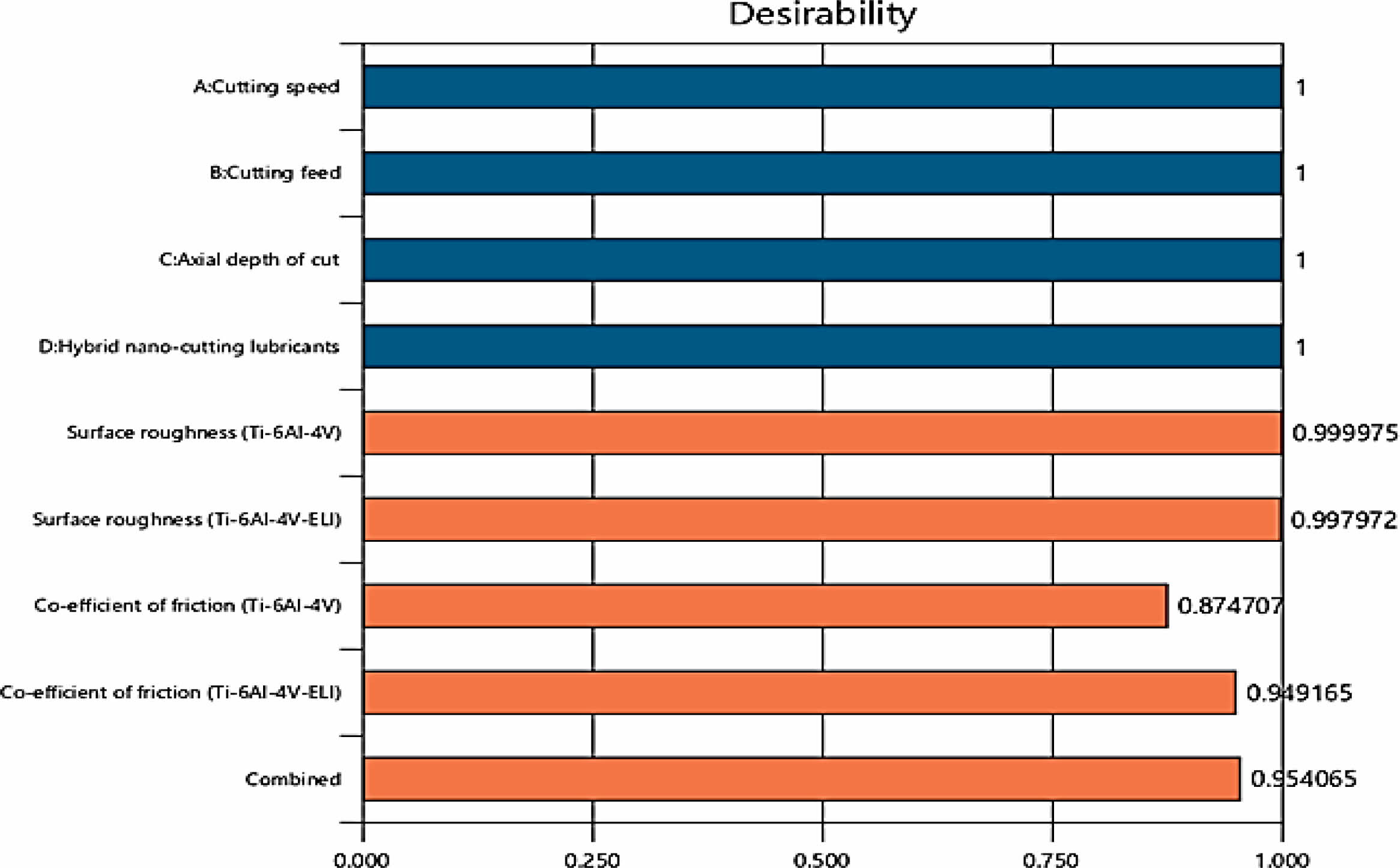

The Fig. 7 shows the bar graph of desirability for each turning process parameters and each response independently. The turning process parameters were set with range to prevent extrapolation. The red histogram bars shows that maximum desirability attained for surface roughness for both the alloys Ti-6Al-4V and Ti-6Al-4V-ELI about 0.99. The combined desirability value about 0.95 shows the good effectiveness of optimal results.

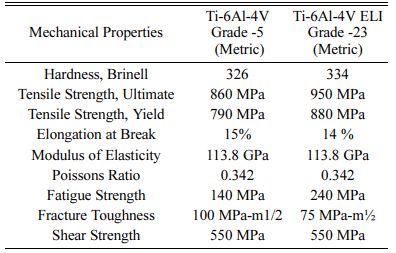

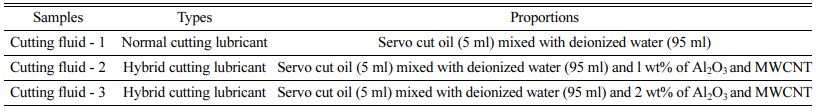

Predicted versus Actual results

The residuals of the experimental data could be analyzed with the help of validation work. The precision of the predicted results can be confirmed by comparing the actual and predicted graphs portrayed in Fig. 8 and 9. Fig. 8 and 9 show the deviation points of actual versus predicted values were very close for both the alloys Ti-6Al-4V and Ti-6Al-4V-ELI. Also the maximum data points lie closer with the linear line. Thus, it can be assumed that the error percentage of actual versus predicted would be at the rate of minimum.

|

Fig. 3 (a-f) Interaction for co-efficient of friction. |

|

Fig. 4 (a-f) Interaction for surface roughness. |

|

Fig. 5 (a-d) – Surface Morphology of machined surface, (a) normal cutting fluid, (b) 2 wt % of MWCNT and Al2O3 cutting fluid on Ti-6Al4V, and (c-d) 2 wt % of MWCNT and Al2O3 cutting fluid on Ti-6Al-4V and Ti-6Al-4V-ELI. |

|

Fig. 6 Optimal turning process parameters |

|

Fig. 7 Desirability bar graph. |

|

Fig. 8 Actual vs. Predicted for surface roughness (Ti-6Al-4V and Ti-6Al-4V-ELI). |

|

Fig. 9 Actual vs. Predicted for Coefficient of friction (Ti-6Al-4V and Ti-6Al-4V-ELI). |

The following conclusions were drawn for Ti-6Al-4V and Ti-6Al-4V- ELI alloys with different turning process parameters such as speed of cutting, feed of cutting, axial depth of cut and hybrid cutting lubrication (MWCNT and Al2O3) with respect to coefficient of friction and surface roughness:

The interaction plots of turning process parameters clearly reveals that 2 wt.% of hybrid cutting lubrication reduces the coefficient of friction and surface roughness significantly for both the alloys Ti-6Al-4V and Ti-6Al-4V-ELI compared to the normal base cutting fluid.

The maximum coefficients of determination (R2) were obtained for coefficient of friction and surface roughness in between of 98 to 98.5 % and 92 to 93 % respectively for both the alloys which shows the higher effectiveness of overall analysis.

SEM analysis shows that hybrid cutting fluid reduces the built-up-edges over the workpiece surface and enhances the quality of surface finish on both the alloys Ti-6Al-4V and Ti-6Al-4V-ELI.

Desirability function analysis – ramp result clearly portrays that selection of optimal turning process conditions such as speed of cutting (107.7 m/min), feed of cutting (0.13 mm/rev), axial depth of cut (0.5 mm) and hybrid cutting lubrication (2 wt%) reduces the coefficient of friction and surface roughness effectively.

The optimal turning process parameters comparison for both Ti-6Al-4V and Ti-6Al-4V-ELI alloys with respect to coefficient of friction and surface roughness clearly shows that Ti-6Al-4V-ELI alloy is the respectable choice of selection for the enhancement of surface quality.

- 1. C. Manivel and L.Savadamuthu, Dg. J. Nanomater. Biostructures 15[3] (2020) 787-798.

- 2. M. Ceylan and I. Topcu, J. Ceram. Process. Res. 21[5] (2020) 539-546.

-

- 3. M. Mia, M.K. Gupta, J.A. Lozano, D. Carou, D.Y. Pimenov, G. Krolczyk, A.M. Khan, and N.R. Dhar, J Cleaner Prod. 210 (2019) 121-133.

-

- 4. S. Pradhan, S. Singh, C. Prakash, G. Królczyk, A. Pramanik, and C.I. Pruncu, J. Mater. Res. Technol. 8[5] (2019) 4849-4862.

-

- 5. M.A. Sofuoglu, Sadhana J. 46[2] (2021) 1-9.

-

- 6. V. Singh, A.K. Sharma, R.K. Sahu, and J.K. Katiyar, J. Manuf. Process. 62(2021) 378-387.

-

- 7. A. Thakur, A. Manna, and S. Samir, Silicon 12[1] (2020) 71-85.

-

- 8. M. Shahid, R.A. Malik, H. Alrobeib, J. Kimc, M. Latif, A. Hussain, M.U. Iqbal, and A. Hafiz, J. Ceram. Process. Res. 22[2] (2021) 149-157.

-

- 9. T. Nithyanandhan, and R. Ramamoor, J. Ceram. Process. Res. 22[4] (2021) 369-376.

-

- 10. R.K. Singh, A.K. Sharma, A.R. Dixit, A.K. Tiwari, A. Pramanik, and A.Mandal, J. Clean. Prod. 162 (2017) 830-845.

-

- 11. D. Setti, M.K. Sinha, S. Ghosh, and P.V. Rao, Int. J. Machine Tools and Manuf. 88 (2015) 237-248.

-

- 12. M.K. Sinha, R. Madarkar, S. Ghosh, and P.V Rao, J. Clean. Prod. 141 (2017) 1359-1375.

-

- 13. B. Li, C. Li, Y. Zhang, Y. Wang, D. Jia, M. Yang, N. Zhang, Q. Wu, Z. Han, and K. Sun, J. Clean. Prod. 154 (2017) 1-11.

-

- 14. M.A.H.M. Shariff, Y.A. Rahim, A.N.M. Khalil, A.M. Ali, A.I. Azmi, and H.M. Salleh, In Intelligent Manufacturing and Mechatronics 18 (2021) 365-372.

-

- 15. Y. Touggui, A. Uysal, U. Emiroglu, S. Belhadi, and M. Temmar, Int. J. Adv. Manuf. Technol. 115 (2021) 3983-3997.

-

- 16. R. Anand, A. Raina, M. Irfan Ul Haq, M.J. Mir, O. Gulzar, and M.F Wani, Tribology Transactions 64[2] (2021) 350-366.

-

- 17. D.R. Joshua and A. Jegan, J. Ceram. Process. Res. 23[1] (2022) 69-78.

-

- 18. C. Chanakyan and S. Sivasankar, J. Ceram. Process. Res. 21[6] (2020) 647-655.

-

- 19. N. Zeelanbasha, V. Senthil, and G. Mahesh, Int. J. Operat. Res. 38[2] (2020) 221-254.

-

- 20. Z. Zeelanbasha, V. Senthil, and B.R. Senthil Kumar, Transactions of FAMENA 42[3] (2018) 115-128.

-

- 21. N. Li, Y.J. Chen, and D.D. Kong, Adv. Manuf. 7[2] (2019) 142-154.

-

- 22. M. Linus, N. Schaal, and K.Wegener, Procedia Cirp 58 (2017) 163-168.

-

- 23. K.M. Senthilkumar, A. Sivakumar, R.M. Shivaji, S.K. Tamang, and M. Giriraj Journal of Ceramic Processing Research 23[2] (2022) 233-236.

-

This Article

This Article

-

2022; 23(3): 356-366

Published on Jun 30, 2022

- 10.36410/jcpr.2022.23.3.356

- Received on Jan 18, 2022

- Revised on Mar 7, 2022

- Accepted on Mar 8, 2022

Services

Services

Shared

Correspondence to

Correspondence to

- P. Bagyalakshmi

-

Assistant Professor, Mechanical Department, Nehru Institute of Engineering and Technology, Tamilnadu, India

Tel : +91 7867034545 - E-mail: sowmiya2110research@gmail.com

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.