- Preparation of nano-TiO2/ purified diatomite coating and its photocatalytic properties of formaldehyde degradation

Lijian Wanga, Junwei Zhaoa, Yujiang Wanga and Shuilin Zhengb,*

aMaterials Science and Engineering School & Henan Key Laboratory of Special Protective Materials, Luoyang Institute of Science and Technology, Luoyang 471023, P. R. China

bSchool of Chemical and Environmental Engineering, China University of Mining and Technology, Beijing 100083, P. R. China

The nano-TiO2 / purified

diatomite composite materials with core-shell structures were prepared by

hydrolysis precipitation using purified diatomite as carrier and titanium

sulfate as precursor. The composite materials were characterized by

transmission electron microscope (TEM), X-ray diffraction (XRD), low

temperature nitrogen adsorption and mercury porosimetry. The photocatalytic

composite coating based on the nano-TiO2 / prified diatomite

composite materials was prepared and its properties of formaldehyde degradation

were investigated. Meanwhile, the degradation mechanism of formaldehyde gas was

discussed. The results showed that the nano-TiO2 / prified diatomite

composite materials were formed core-shell structures, and the TiO2

nanoparticles were anatase with the average size of about 10 nm.The test results show that the

formaldehyde purification performance of the coatings has met the technical

requirements of Class I materials in the Chinese national standard JC/T 1074-2008.

Keywords: Nano-TiO2 / prified diatomite, Photocatalytic coating, Degradation, Formaldehyde gas

With the improvement of people's living standard and

health consciousness, the materials of green environmental protection for interior

decoration become more and more popular. The conventional

decorative materials will gradually release hazardous substances such as

formaldehyde after decoration [1, 2]. Therefore, the indoor gas pollution

has become an urgent problem to be solved. Study on the

environmentally friendly interior decoration materials is significant

in academia as well as application. Formaldehyde, as a common indoor air

pollution chemical, poses a serious threat to people's health [3, 4]. At

present, the methods of removing indoor formaldehyde include physical

adsorption, plant absorption and purification, windowing ventilation, air

purification and catalytic degradation. In recent years, the photocatalytic

degradation method has become available to purify indoor formaldehyde due to

its low energy consumption, simple operation, mild reaction conditions and the

ability to reduce secondary pollution [5, 6]. However, the traditional

methods of adsorption or chemical degradation are not effective in the degradation of

formaldehyde or cause secondary pollution. Therefore,

it is urgent to develop economical and efficient

formaldehyde reduction strategy. Semiconductor

photocatalysis belongs to a new technology for environmental pollution control. The

electronic structures of various semiconductor metal oxides and sulfides as

catalysts make them exhibit excellent photocatalytic activity. Nanoscale

titanium dioxide (Nano-TiO2) is one of the most studied

photocatalytic materials [7-14]. The nano-TiO2 advantages

of photocatalytic degradation of formaldehyde include strong

oxidation ability, complete degradation and no secondary pollution [5].

However, the poor dispersion of nano-TiO2 limits its application in

decorative materials. In order to improve the photocatalytic ability, the

nano-TiO2 coated large porous materials with high specific surface

area have been studied [15]. The obtained composites can not only

prevent the aggregation of fine nano-TiO2 particles,

but also improve the photodecomposition performance [16]. In recent years,

various porous materials have been developed as carriers of

nano-TiO2 [17-20]. Because of the larger specific surface

area, these carriers actually increase the local

concentration of organic compounds and avoid volatilization or dissociation of intermediate

products. Correspondingly, the photocatalyst reaction

rate was accelerated [21, 22].

Diatomite is a kind of siliceous and biogenic siliceous

sedimentary rock, which is mainly composed of the remains of ancient diatoms.

The main chemical composition of diatomite is SiO2. The relative

density of pure and dry diatomite is 0.4-0.9 g/cm3, and the pore

size distribution is 50-800 nm. The multifunctional composites can be

constructed by using the natural pores of diatomite [6, 23-27].

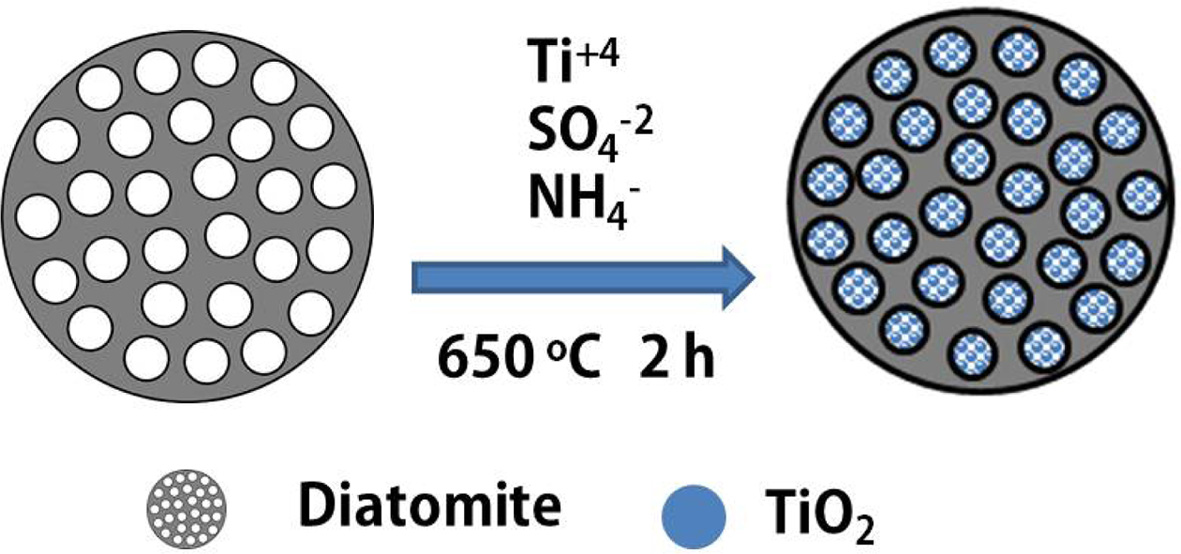

In this study, the nano-TiO2 / purified

diatomite composite materials

were firstly synthesized by typical hydrolytic precipitation method using

titanic sulphate as precursor. And then, the novel photocatalytic coating was

innovatively developed based on the prepared nano-TiO2 / purified

diatomite composite materials, which can effectively degrade

indoor formaldehyde gas. The photocatalytic activity of the

nano-TiO2 / purified diatomite coating

was studied through the photocatalytic degradation of

formaldehyde with a white light source.

Materials

and reagents

Diatomite powder was purchased from Meiston Powder

Material Co., Ltd. (Linjiang City, Jilin Province). Titanic

sulphate (Ti(SO4)2) was purchased from Jingxiang Chemical

Plant (Changping, Beijing). All the chemicals used in the

experiment were analytical pure. The deionized water was prepared in

laboratory, which has a resistivity not less than 18.2 MΩ.

Purification

of diatomite

In order to eliminate the influence of impurities on the

properties of synthetic materials, diatomite was firstly purified. Diatomite

(10.0 g) was calcined at 550 ºC for one hour, and then immersed in 50%

sulphuric acid solution (40.0 g) for 2 h. After centrifuging and washing twice

with water, the purified diatomite was obtained.

Preparation

of nano-TiO2 / purified diatomite composite materials

In an ice water bath, the purified diatomite and deionized

water with a mass ratio of 1:24 were placed in a beaker under vigorous

stirring. And then the diluted sulfuric acid was added to adjust the pH of the

solution to 3. After that, the Ti (SO4)2 solution (3.0 mol/L,

10 mL) was slowly dripped by a constant current pump. Ti (SO4)2

was used as titanium source. Then, the ammonium sulphate solution (1.5 mol/L,

20 mL) was pumped into the beaker. After continuous mixing for half an hour,

the above mixed solution was heated to 40 ºC and remained at this

temperature for half an hour. The pH value of the mixture was adjusted to 5.5

with diluted ammonia solution. After one hour of continuous reaction, the white precipitate

was collected by centrifuging, filtration, washing, drying and calcination at

650 ºC for 2 h. The nano-TiO2 / purified diatomite composite

materials were prepared. The preparation process was shown in Fig. 1.

Preparation

of photocatalytic coating

Deionized water (302.0 g), sodium acrylate salt water

dispersant (5.0 g), defoamer (F111, 2.0 g) and film-forming additives (5.0 g)

were added to a beaker in turn. After being uniform stirred for 5 min, some

nano-TiO2 / purified diatomite composite materials (48.0 g) were

slowly added. At a speed of 2000 r/min, the water-borne

colloid was obtained by stirring and dispersing for half an hour. The pigments

and fillers of calcined kaolin (100.0 g), light calcium carbonate (100.0 g) and

talcum powder (100.0 g) were added into the water-borne colloid by vigorous

stirring for half an hour and then styrene acrylate emulsion (110.0 g) was

added by mild stirring. The pH value of the mixed system was adjusted to 8 with

neutralizer. Finally, thickener (ASE-60, 5.0 g) and levelling agent (RM-2020,

10.0 g) were added with stirring evenly and aging for one hour. The prepared

nano-TiO2/ diatomite photocatalytic coating was obtained.

Characterization

The samples for TEM observation were fabricated by RTO

metal-embedded chip micron-nano characterization method.

First, the powder particles were embedded in copper by ion deposition without

disturbance, and then the samples were thinned to nanometer thickness by

mechanical grinding, polishing and ion shearing. The samples were analyzed by

Hitachi H-800 Microscope for image analysis to observe the profile of nano-TiO2

coated on the surface of diatomite particles. The crystal structure of

nano-TiO2 was analyzed by Brooke X-ray diffractometer (XRD). The

pore size and pore volume were measured by NOVA4000 high-speed automatic

specific surface and porosity meter produced by Conta Company and Autopore IV

9500 mercury intrusion meter produced by Mike Company in the

United States, and the specific surface area of samples was

measured by ST-2000 of Beijing Beibu Instrument Technology Company.

Photocatalytic coating

for degradation of formaldehyde gas

The formaldehyde gas

purification performance of the photocatalytic coatings was tested by

entrusting National Building Material

Industry Technology Monitoring and Research Center of China based on JC/1074-2008

“Cleaning Performance of Indoor Air Purification Functional Coatings”. The

detection process was as follows: First, the indoor environment was simulated

by the environment test chamber under the visible white light source. The

temperature was set at 23 ± 0.5 oC and the humidity was

set at 45 ± 3%. Second, the formaldehyde solution with a

concentration of 37% - 40% at 2.5 μL was dripped onto a petri dish and put into

the environmental test chamber to make it fully volatilized in the

environmental test chamber. Third, the photocatalytic coating was coated on 0.1

m2 glass (250 g/m2, twice), and irradiated by white

fluorescent light source (30 W) to produce photocatalytic effect. The distance

between the light source and the sample was 70 cm. Fourth, acetylacetone

spectrophotometry (GB/T 15516-1995) was used to

detect the concentration of formaldehyde. The gas in the 10 L cabin was

sampled every 6 h to detect the

change of formaldehyde concentration in the environmental test cabin. Fifth, the control group was

conducted in another environmental chamber. According to the above experimental

steps, the glass plate is not coated with photocatalytic coating in step 3.

|

Fig. 1 Preparation schematic diagram of the nano-TiO2/purified

diatomite composite materials. |

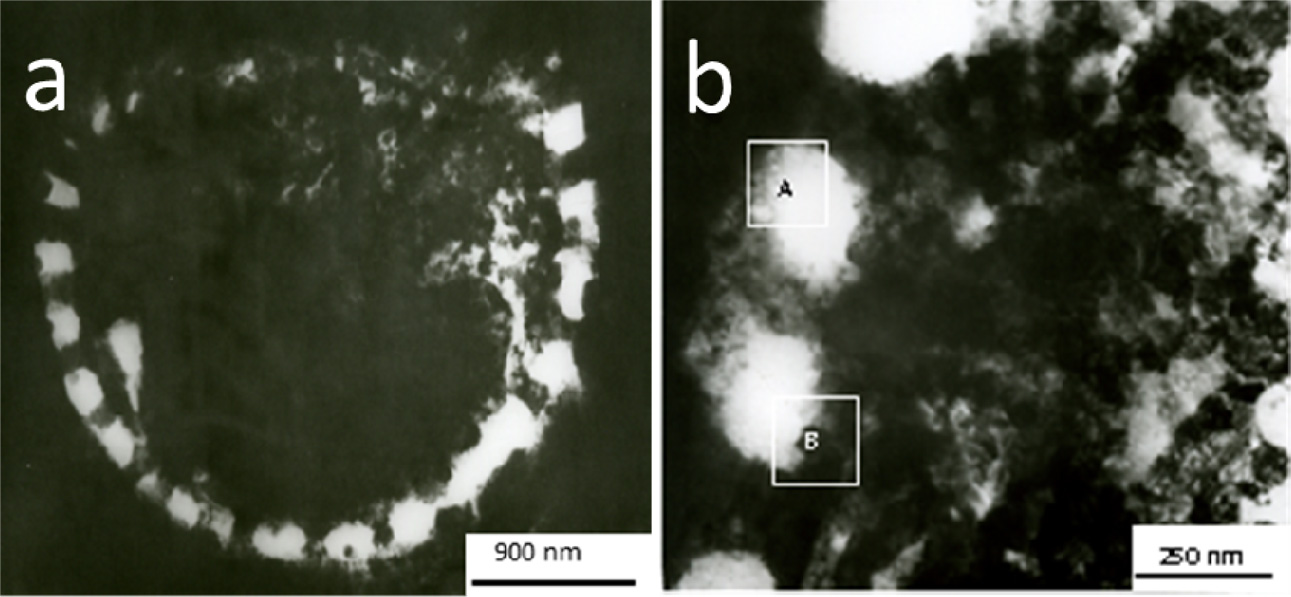

Fig. 2 shows the TEM of cross-section of the nano-TiO2 / purified

diatomite composite materials. Fig. 2(a) is a TEM image of the RTO profile of

nano-TiO2 loaded on the surface of a circular sieve diatomite. Fig.

2(b) is a locally magnified image of the interface between nano-TiO2

and diatomite. It can be seen from Fig. 2(b) that the prepared

nano-TiO2 / purified diatomite composites

show obvious core-shell structure with diatomite as core and nano-TiO2

as shell. The core-shell structure is closely bonded with each other. The thickness

of the coated shell is about 230 nm. The micropores on the surface of diatomite

have been covered by nano-TiO2, and the macropores on the surface

are clearly observed.

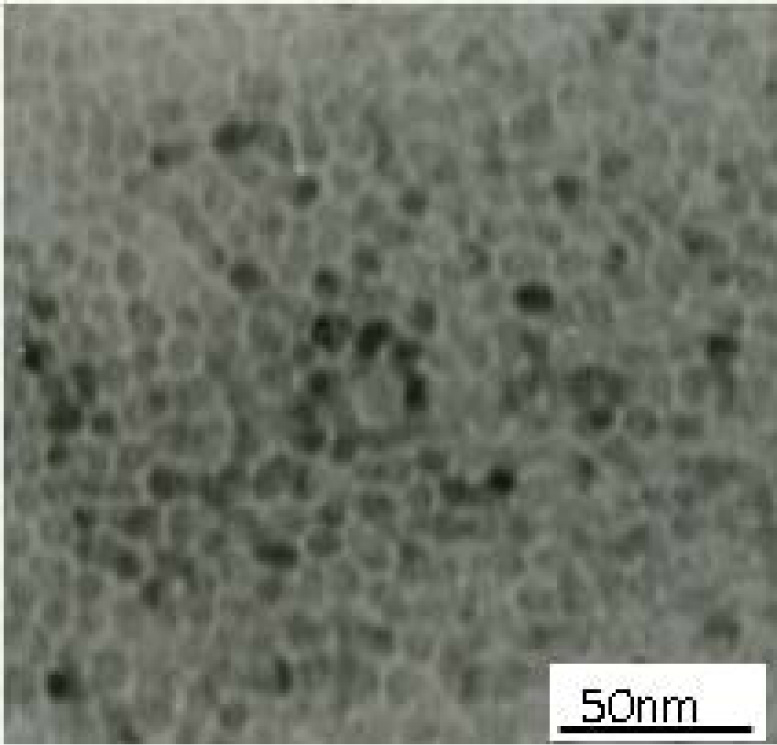

Fig. 3 is a magnified TEM image of point A in Fig. 2(b).

The average size of titanium dioxide at point A is about 10 nm. Fig. 4 is the

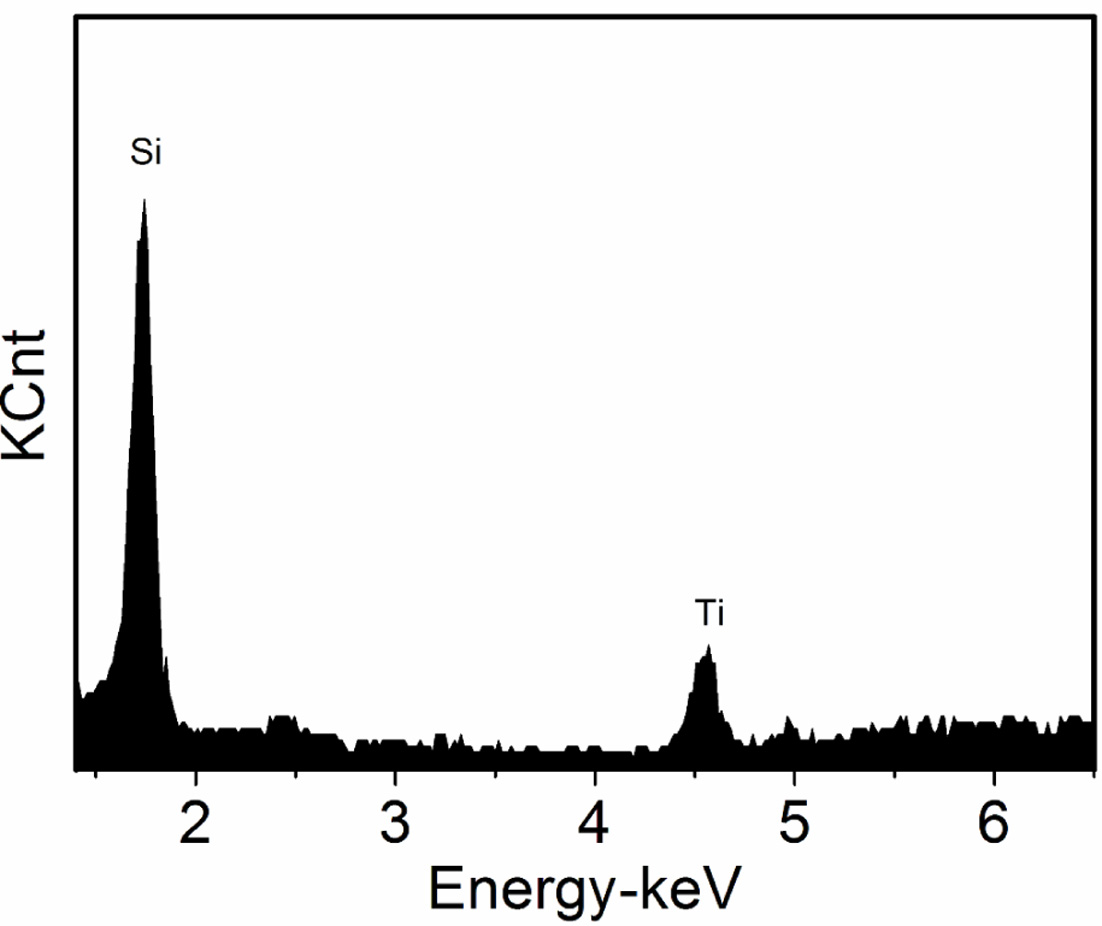

result of energy spectrum analysis at point B in Fig. 1(b), where is the

interface between titanium dioxide and diatomite. The peaks of Si and Ti

elements can be observed in the spectrum. It is further proved that the

nano-TiO2 / purified diatomite composite materials is formed.

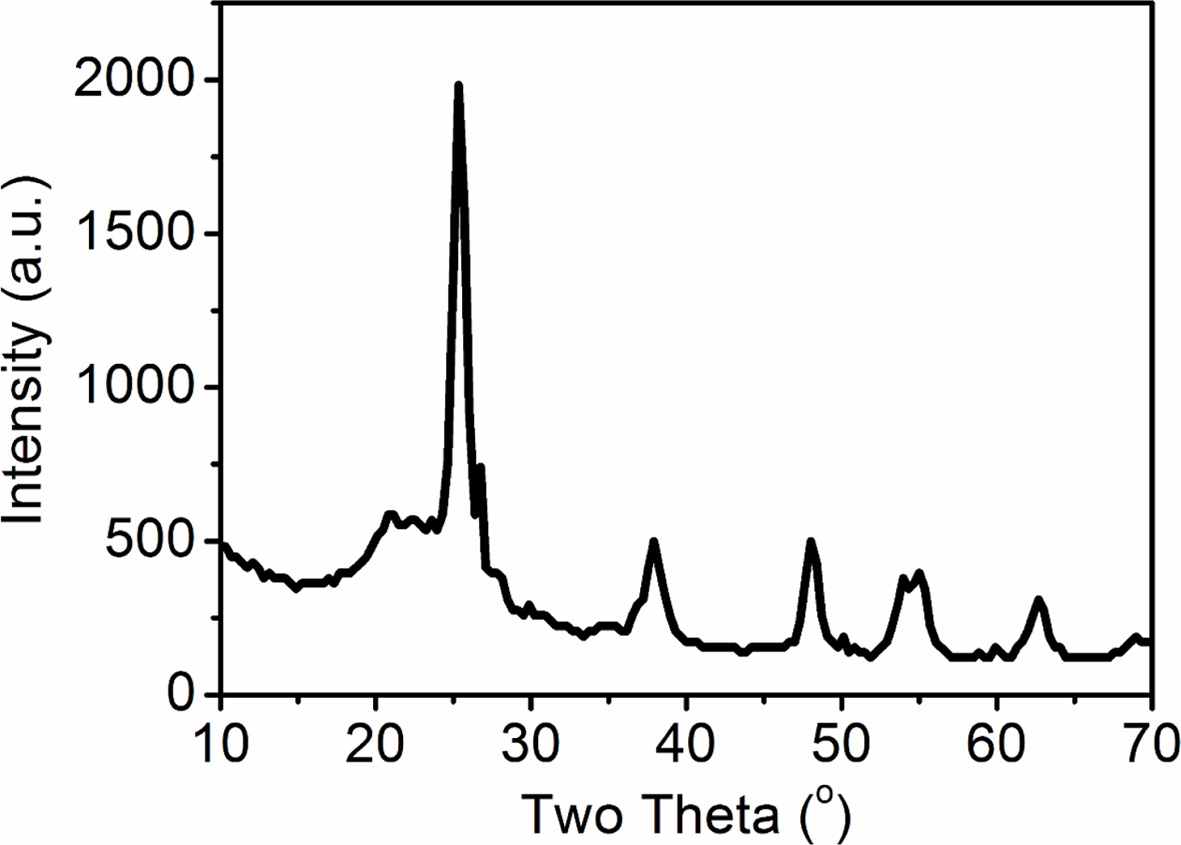

The synthesized nano-TiO2 / purified diatomite

composite materials were analyzed by XRD. In

the previous work, the temperature of crystalline phase

transformation of TiO2 in the composite powder is about 800 oC

[25]. Therefore, in this work, the synthesized nano-TiO2 / purified

diatomite composite materials were calcined at 650 oC for 2 h.

The results are shown in Fig. 5. The diffraction peaks of the prepared samples

are 25.2, 37.7 and 48.0 degrees, which are matched well with the standard

spectra of anatase-type titanium dioxide (JCPDS71-167). This indicates that the

crystal structure of titanium dioxide loaded on the surface of diatomite is

anatase. The average single crystal size of the sample can be calculated by

Scherrer formula: D = Kλ/Bcosθ, where K is Scherrer constant,

K = 0.89, λ = 0.15406 nm and B is the half-width of the

crystal plane with the strongest diffraction peak (101). The average size of

the loaded titanium dioxide is about 11 nm, which is consistent with that

observed by TEM.

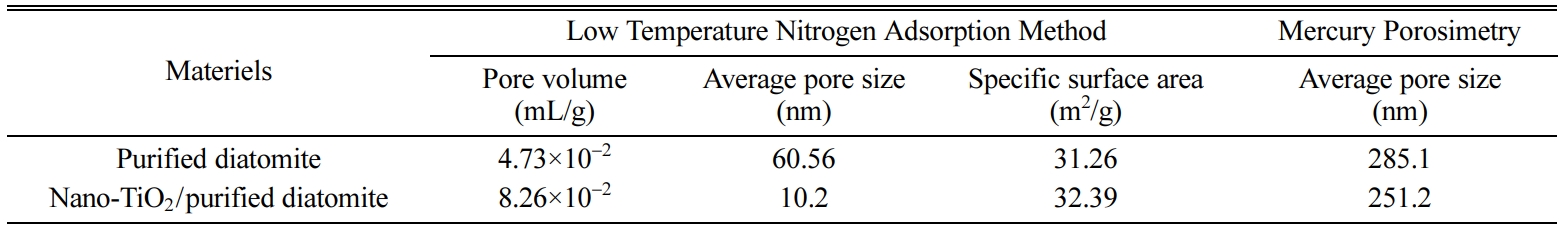

The pore size and specific surface area of the purified diatomite

and the nano-TiO2 / purified diatomite composite

materials were determined by low temperature nitrogen adsorption and mercury

porosimetry, respectively, which are

summarized in Table 1. The results of nitrogen adsorption at low temperature

show that the mesoporous volume and

specific surface area of the nano-TiO2 / purified diatomite

composite materials are significantly higher than that of the purified

diatomite, while the average pore size is significantly lower than that of the

purified diatomite. These results indicate that the nano-TiO2 / purified

diatomite composite materials own mesoporous structure. The results of mercury

intrusion test show that the average pore size of the nano-TiO2 / purified

diatomite composite materials become lower, which further indicate that the

inner surface of the larger pore of purified diatomite was loaded with nano-

TiO2.

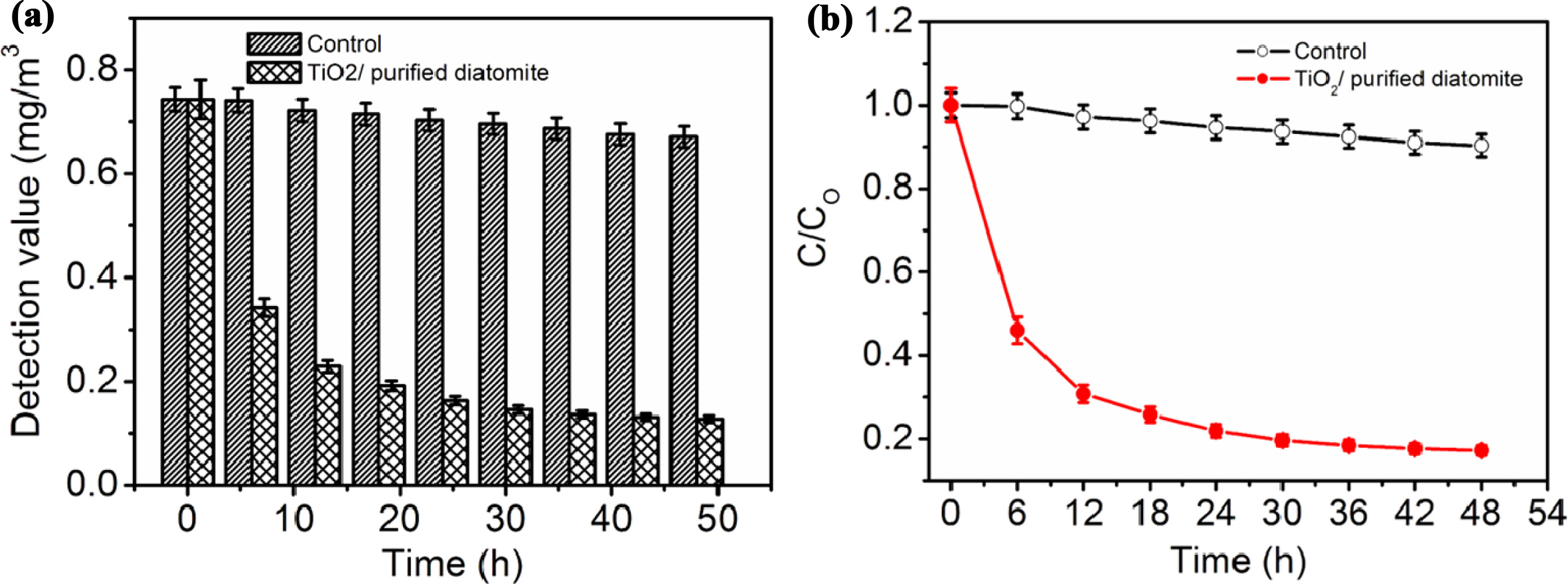

The formaldehyde gas purification performance of the

photocatalytic coating was tested by entrusting National Building Material

Industry Technology Monitoring and Research Center of China. The test results of

formaldehyde gas degradation

are shown in Fig. 6. As shown in Fig. 6, the degradation rate of the

photocatalytic coating increases gradually with the prolongation of irradiation

time. After 48 h of illumination, the degradation rate of the photocatalytic

coating reached 82.8%, which meets the technical requirements of Class I

materials in the standard JC/T 1074-2008 of China. Correspondingly, the control

group without the photocatalytic

coating had lower photocatalytic degradation rate.

It is well known that the degradation rate of substrates in photocatalytic reactions was

achieved by adsorbing on the surface of catalysts or reaching the surface of

catalysts of free molecules [28]. In our case, the main mechanism of formaldehyde

gas degradation in photocatalytic coating is that the molecules of formaldehyde

gas were adsorbed on the surface of the coatings firstly, and then were

oxidized and degraded by the catalyst in the coating under irradiation of

fluorescent light source. The prepared photocatalytic coating consists of the

nano-TiO2 / purified diatomite composite materials, which increase

the adsorption of the coating. The adsorption effect enriches

formaldehyde and other pollutants in the air onto the surface of

the photocatalytic coating, thus accelerating the degradation

of pollutants by accepting electrons and holes directly on the surface of the

nano-TiO2 / purified diatomite.

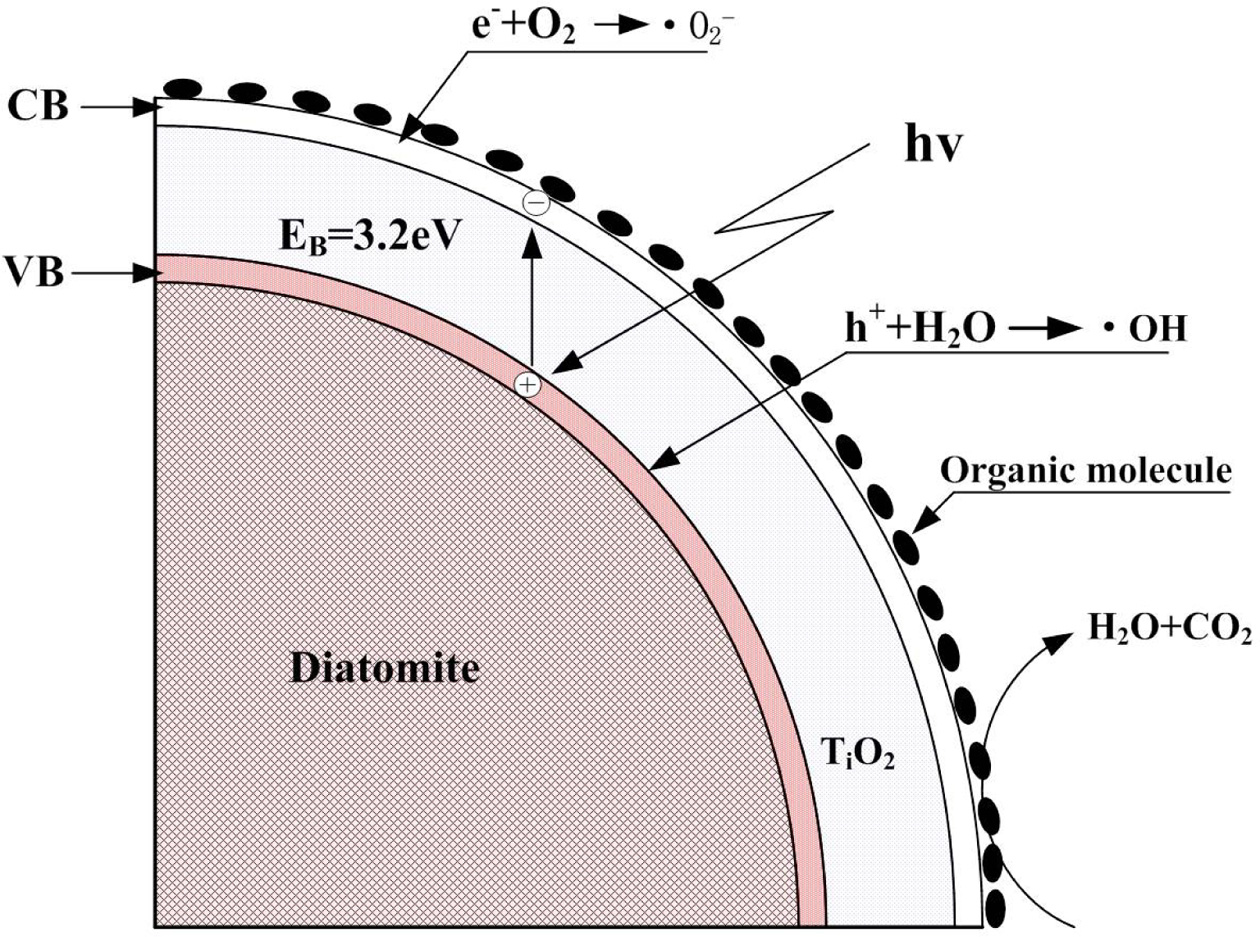

Fig. 7 is a schematic diagram of the photocatalytic

degradation mechanism of formaldehyde by the nano-TiO2 / purified

diatomite composites with core-shell structures. In Fig. 7, the photon energy

which is greater than the band gap of titanium dioxide (3.2 eV) directly excite

electrons transition from the top of valence band to the bottom of conduction

band, resulting in the formation of electron and hole pairs of nano-TiO2 in

photocatalytic coating:

Photogenerated holes can react directly with pollutants

already adsorbed on the surface of coating and oxidize them, or react with

hydroxyl groups and water to produce hydroxyl radicals ·OH.

Photogenerated electrons react with oxygen molecules

adsorbed on the coating surface to produce superoxide radicals. Molecular

oxygen not only participates in the reduction reaction, but also is another

source of hydroxyl radicals on the surface. The specific reaction formulas are

as follows:

In the above reaction, hydroxyl radicals (·OH) and

superoxide radicals (·O2-) have been produced. They are

very active free radicals with strong oxidation ability, which can directly

oxidize various organic substances to small inorganic molecules such as CO2

and H2O. Moreover, the oxidation reaction generally does not stop in

the intermediate step and does not produce intermediate products because of

their strong oxidation ability. The above analysis shows that the degradation

of formaldehyde gas is determined by the adsorption and photocatalytic

degradation properties of the nano-TiO2 / purified diatomite

coating, and the degradation effect is the result of the synergistic effect of

the two.

|

Fig. 2 TEM of cross-section of the nano-TiO2/purified diatomite

composite materials. |

|

Fig. 3 The magnified TEM of point A in Fig. 2(b). |

|

Fig. 4 EDS spectrum of the nano-TiO2/purified diatomite

composites. |

|

Fig. 5 XRD patterns of the nano-TiO2/purified diatomite

composite materials. |

|

Fig. 6 The test results of formaldehyde gas degradation with and without the photocatalytic coating, respectively. |

|

Fig. 7 Schematic diagram about the photocatalytic degradation

mechanism of the nano-TiO2/purified diatomite coating. |

|

Table 1 The pore size and specific surface area of the purified diatomite and the nano-TiO2/purified diatomite composite materials |

The nano-TiO2 / purified diatomite composites

were prepared by hydrolytic precipitation method using purified diatomite as

carrier and titanium sulfate as precursor. The nano-TiO2 / purified

diatomite composite particles show obvious core-shell structure with

diatomite as core and nano-TiO2 as shell. The nano-TiO2 / purified

diatomite photocatalytic coating was prepared by using the prepared nano-TiO2 / purified

diatomite composite as filler. The test results of the formaldehyde

degradation performance of the coating show that the formaldehyde

degradation performance of the coating has met the technical

requirements of Class I materials in the national

standard JC/T 1074-2008 of China. The degrading effect of photocatalytic

coating on formaldehyde gas is the result of the synergistic effect of

adsorption and photocatalytic degradation.

This work was supported by 135 National Key R&D

Program Projects of the Ministry of Science and Technology

(2016YFC0700901) and the Opening Foun- dation

of Henan Key Laboratory of Special Protective Materials (Grant No.

SZKFJJ201903).

The authors declare no competing financial interests.

- 1. K.-S. Liu, F.-Y. Huang, S.B. Hayward, J. Wesolowski, and K. Sexton, Environ. Health Perspect. 94 (1991) 91-94.

-

- 2. C.H. Ao, S.C. Lee, J.Z. Yu, and J.H. Xu, Appl. Catal., B 54 (2004) 41-50.

-

- 3. O. Merk and G. Speit, Environ. Mol. Mutagen. 32[3] (1998) 260-268.

-

- 4. C.W. Kim, J.S. Song, Y.S. Ahn, S.H. Park, J.W. Park, J.H. Noh, and C.S. Hong, Yonsei Med. J. 42 (2001) 440-445.

-

- 5. A. Fujishima, T.N. Rao, and D.A. Tryk, J. Photochem. Photobiol., C 1 (2000) 1-21.

-

- 6. Q. Sun, H. Li, S. Zheng, and Z. Sun, Appl. Surf. Sci. 311 (2014) 369-376.

-

- 7. N. Uekawa, M. Suzuki, T. Ohmiya, F. Mori, Y.J. Wu, and K. Kakegawa, Int. J. Mater. Res. 18[4] (2003) 797-803.

-

- 8. H. Choi, E. Stathatos, and D.D. Dionysiou, Thin Solid Films 510 (2006) 107-114.

-

- 9. A. López, D. Acosta, A. I. Martínez, and J. Santiago, Powder Technol. 202 (2010) 111-117.

-

- 10. X.Z. Li, H. Liu, L.F. Cheng, and H. J. Tong, Environ. Sci. Technol. 37[17] (2003) 3989-399

-

- 11. S. Narakaew, J. Ceram. Process. Res. 18[1] (2017) 36-40.

- 12. A. Maddu, I. Deni, and I. Sofiana, J. Ceram. Process. Res. 19[1] (2018) 25-31.

- 13. Y.-S. Song, M.-H. Lee, B.-Y. Kim, and D.Y. Lee, J. Ceram. Process. Res. 20[2] (2019) 182-186.

-

- 14. Y.-S. Song, S. Son, D.Y. Lee, M.-H. Lee, and B.-Y. Kim, J. Ceram. Process. Res. 17[11] (2016) 1197-1201.

- 15. R.-q. Gao, Q. Sun, Z. Fang, G.-t. Li, M.-z. Jia, and X.-m. Hou, Int. J. Miner. Metall. Mater. 25[1] (2018) 73-79.

-

- 16. R.-q. Gao and X.-m. Hou, Int. J. Miner. Metall. Mater. 20[6] (2013) 593-597.

-

- 17. S. Qiu, S. Xu, F. Ma, and J. Yang, Powder Technol. 210 (2011) 83-86.

-

- 18. J. Wang, B. He, and X.Z. Kong, Appl. Surf. Sci. 327 (2015) 406-412.

-

- 19. T. Georgakopoulos, N. Todorova, K. Pomoni, and C. Trapalis, J. Non-Cryst. Solids 410 (2015) 135-141.

-

- 20. E.P. Reddy, L. Davydov, and P. Smirniotis, Appl. Catal., B 42 (2003) 1-11.

-

- 21. S.-y. Lu, Q.-l. Wang, A.G. Buekens, J.-h. Yan, X.-d. Li, and K.-f. Cen, Chem. Eng. J. 195-196 (2012) 233-240.

-

- 22. B. Wang, G. Zhang, X. Leng, Z. Sun, and S. Zheng, J. Hazard. Mater. 285 (2015) 212-220.

-

- 23. Y. Chen and K. Liu, J. Hazard. Mater. 324 (2017) 139-150.

-

- 24. K.-J. Hsien, W.-T. Tsai, and T.-Y. Su, J. Sol-Gel Sci. Technol. 51 (2009) 63-69.

-

- 25. Z. Sun, Z. Hu, Y. Yan, and S. Zheng, Appl. Surf. Sci. 314 (2014) 251-259.

-

- 26. Y. Xia, F. Li, Y. Jiang, M. Xia, B. Xue, and Y. Li, Appl. Surf. Sci. 303 (2014) 290-296.

-

- 27. G. Zhang, Z. Sun, Y. Duan, R. Ma, and S. Zheng, Appl. Surf. Sci. 412 (2017) 105-112.

-

- 28. C.S. Turchi and D.F. Ollis, J. Catal. 122 (1990) 178-192.

-

This Article

This Article

-

2020; 21(6): 751-756

Published on Dec 31, 2020

- 10.36410/jcpr.2020.21.6.751

- Received on Nov 25, 2019

- Revised on Mar 13, 2020

- Accepted on Mar 16, 2020

Services

Services

- Abstract

introduction

material and methods

results and discussion

conclusion

- Acknowledgements

- Conflict of Interest

- References

- Full Text PDF

Shared

Correspondence to

Correspondence to

- Shuilin Zheng

-

School of Chemical and Environmental Engineering, China University of Mining and Technology, Beijing 100083, P. R. China

Tel : +8637965928196 Fax: +8637965928196 - E-mail: shuilinzheng8@gmail.com

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.