- Structural investigation and improvement of microwave dielectric properties in Ca1-xBaxTiO3, low loss ceramics

Sarir Uddina,†, Abid Zamanb,†,*, Imtiaz Rasoolc, Sadiq Akbarc, Muhammad Kamranc, Nasir Mehboobb, Asad Alib, Abid Ahmadb, Muhammad Farooq Nasirb and Zafar Iqbalb

aDepartment of Physics, Government College Hayatabad, Peshawar 25000, Pakistan

bDepartment of Physics, Riphah International University, Islamabad 44000, Pakistan

cDepartment of Electronics, University of Peshawar, 25120, Pakistan

The effects of Ba substitution

on the phase analysis, microstructure and microwave dielectric properties of Ca1-xBaxTiO3

ceramics were prepared through conventional solid state reaction route.

The X-ray diffraction analysis of the samples showed that the specimens Ca1-xBaxTiO3

presented single phase compound with orthorhombic structure in the range of

x=0.0 to 0.7 when sintered at 1300oC for 3hrs in air. From the

morphological point of view, it consists of round and rod shaped grains with

porous microstructure. The substitution of Ba2+ ions over Ca2+,

the microwave dielectric constant (εr) diminishes from 145 to 52

whereas the quality factor (Qxf) will increases from 8105 to 24305 GHz and

temperature coefficient of resonant frequency decreases from 705 to 80 ppm/oC

(at 3 GHz).

Keywords: CaTiO3, Solid State Reaction Route, Crystal structure, Microstructure, Dielectric Properties

The last couple of decades, the rapid developments of

microwave communication technology such as several different

wireless communication, rapid production of low-cost, lightweight, television

receiver only (TVRO, 2-5 GHz), direct broadcasting (DBS, 11 GHz to 13 GHz) and

high reliable devices [1, 2]. The necessity for miniature low loss microwave

devices has led to the dielectric material loading of cavity resonator, using

dielectric resonators [3, 4]. These dielectric resonators should

satisfy three foremost criteria; viz a high dielectric constant for

size miniaturization, a low dielectric loss for good selectivity and temperature

coefficient of resonant frequency is close to zero for stable frequency

stability [5].

Calcium titanium oxide CaTiO3 (CT) is an

excellent ceramic for microwave (MW) dielectric since it has a large

permittivity er = 160

and an allowable quality factor, Q = 8,000 at 1.5 GHz. But

unfortunately its feature is a high positive temperature co-efficient of the

resonant frequency tf = +850 ppm K-1 [6, 7]. The dielectric properties of CaTiO3 ceramics will be further improved by

introducing isovalent substitution like Sr+2, Mg+2 or Ba+2

at A-site of ABO3 perovskite-structured CaTiO3 [8].

An alternative MgTiO3 ceramics material has

attracted enormous contemplation because of its

good microwave dielectric properties and far low cost. The

dielectric constant ϵr = 17, quality factor Q × f

= 160,000 GHz and temperature coefficient of resonant frequency tf =

-50ppm/oC are achieve for MgTiO3 ceramics [9]. The doping

A-site, with elements like Ni, Co and Zn led to enrichment within the Q × f

value of MgTiO3(180,000 GHz to 364,000 GHz), ϵr =

17.2 and tf ~ -45

ppm/oC [10, 11].

Another promising example of advanced ceramics (1-x)CaTiO3–xLaAlO3

(0 ≤ x ≤ 1) solid solution. The dielectric

constant “ϵr” decrease from 47.83 to 28.25, Q × f

increase from 30,000 to 42,000GHz and the value of temperature co-efficient of

the resonant frequency “tf”

decreases from 17.77 to -20.42 ppm/oC because the LaAlO3 contented

within the CTLA ceramics increased and the polarizability alteration decreases

from 1.74 to 5.0% by the increase of LaAlO3 [12]. The others

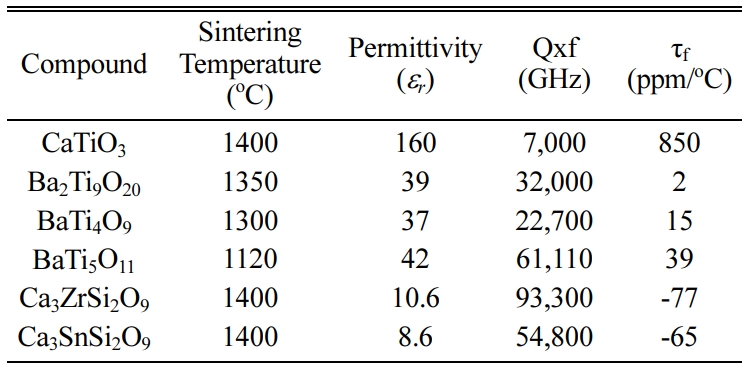

compounds with microwave dielectric properties are shown in Table 1.

A few approaches are received for the synthesis of CaTiO3

either by soft chemistry like Sol-gel or by hydrothermal

or solvothermal methods, co-precipitation, or

organic-inorganic solution [14-17]. High temperature solid state

synthesis of CaTiO3 has been conducted utilizing the mixtures of

calcium carbonate (CaCO3) and titanium dioxide (TiO2)

[18-20].

In the present work, the results on the microstructure improvement

and dielectric properties of CaTiO3 ceramics is

reported. The results prove that the dielectric properties

especially the temperature coefficient of resonant

frequency of the CaTiO3 materials are improved

noticeably.

The samples were arranged through mixed compound

solid state technique as a result it’s the only, the best and

economically route utilized in industries. According to

the formula Ca1-xBaxTiO3 (0 ≤ x ≤ 0.7) with

the highly pure materials of CaCO3 (SIGMA-ALDRICH), BaCO3

(SIGMA-ALDRICH) and TiO2 (SIGMA-ALDRICH) with purity ≥ 99.5%.

The powders were horizontal ball milled in polymer bottle with distilled water

and zirconia balls for 12 h. After the drying method (90 oC for

24 h), the powder were grinded and then calcined at 950 oC

for the composition with x = 0 and 1,000 oC for

the compositions with (0 ≤ x ≤ 0.7) for 3 h at a heating/cooling rate of 5 oC/min.

At that point calcined fine powders (0.5-0.7 g) within the size of 10 mm

diameter and in the thickness 3-4 mm pellets, under the pressure of 100 MPa

with a stainless steel dye during a Carver Manual Uniaxial press. The pellets

were placed on ceramic foil and sintering at 1,300 oC for

3 h at heating/cooling rate of 5 oC/min.

The phase analyses of the samples were carried out via

X-rays diffractometer (XRD) (JDX-3532, JEOL Japan) with

Cu-Kα radiations (λ = 1.540598 Å), operated

at 45 kV and 40 mA was utilize for identification of phases. A step size 0.05º,

a scan rate of 0.5º/min and scan ranges of 10.015-70.015º were embraced. The

microstructures of the sample were analyzed by scanning

electron microscopy (SEM) (JDX-5910, JEOL Japan). For

SEM, samples were polished and thermally etched at temperatures 10% less than

their sintering temperatures for 1 h. The apparent bulk densities of sintered

samples were measured by Archimedes method using

densitometer (MD 300s). The microwave dielectric properties

of the fabricated ceramic pellets were measured by Vector Network Analyzer

(Agilent-R3767CH).

Phase

formation analysis

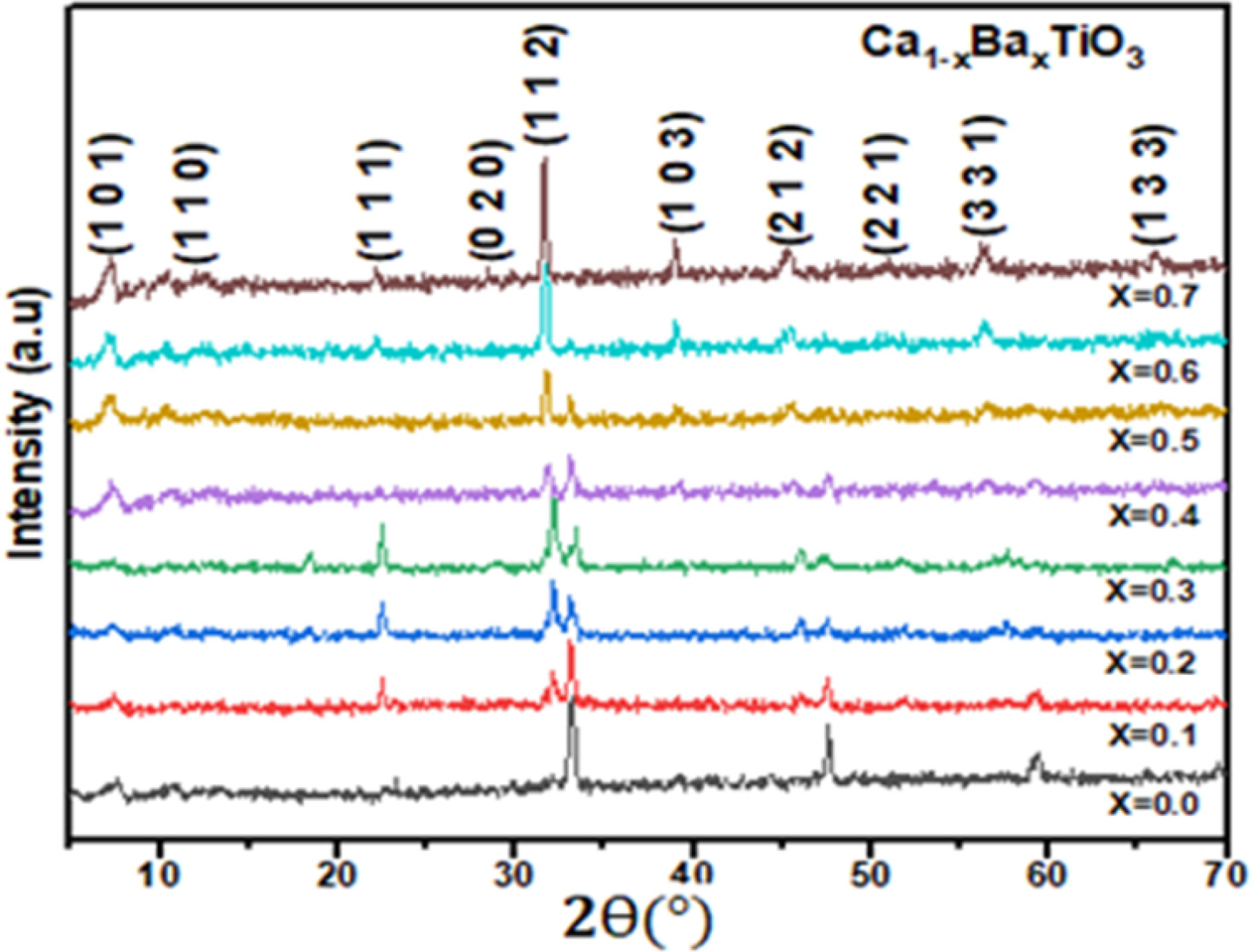

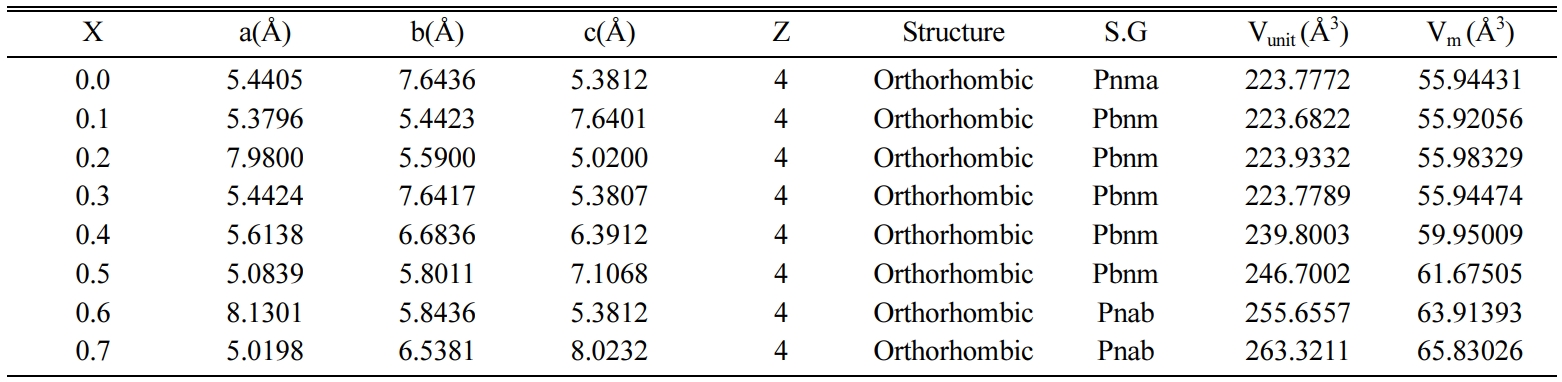

Fig. 1 shows the XRD patterns of Ca1-xBaxTiO3

ceramics sintered at 1,300 oC for 3 h in air where

x = 0.0, 0.1, 0.2, 0.3, 0.4, 0.5, 0.6 and 0.7. At this sintering temperature,

all the samples well developed orthorhombic phase

structures was detected for Ca1-xBaxTiO3 (0 ≤

x ≤ 0.4) but in Ca1-xBaxTiO3 (x ≥ 0.5) the

orthorhombic phase was found. It was observed that the crystal structure of the

synthesized ceramic samples changed from orthorhombic space group

(Pbnm) to orthorhombic space group (Pnab) with the variation

of barium concentration [21,

22]. Besides, with the increasing of “x” the peaks in XRD spectra slowly

shifted to lower angle. It’s because of that ionic radii of Ba2+

ions (r = 1.61 Å) are larger than that of Ca2+ ions

(r = 1.34 Å) [23]. The diffraction peaks in the XRD patterns can be

indexed that belonged to the space group (Pnma) and (Pbnm) matching with pdf

card # (22-153) and (78-1013) respectively. With increasing x from 0 to 0.7,

the lattice parameters ‘a’, ‘b’ and ‘c’ changes almost linearly CaTiO3 to

Ca1-xBaxTiO3. The variation in the lattice

parameters ‘a’, ‘b’ and ‘c’ of the Ca1-xBaxTiO3

ceramics with the increase in Ba2+ content is shown in Table 2. The

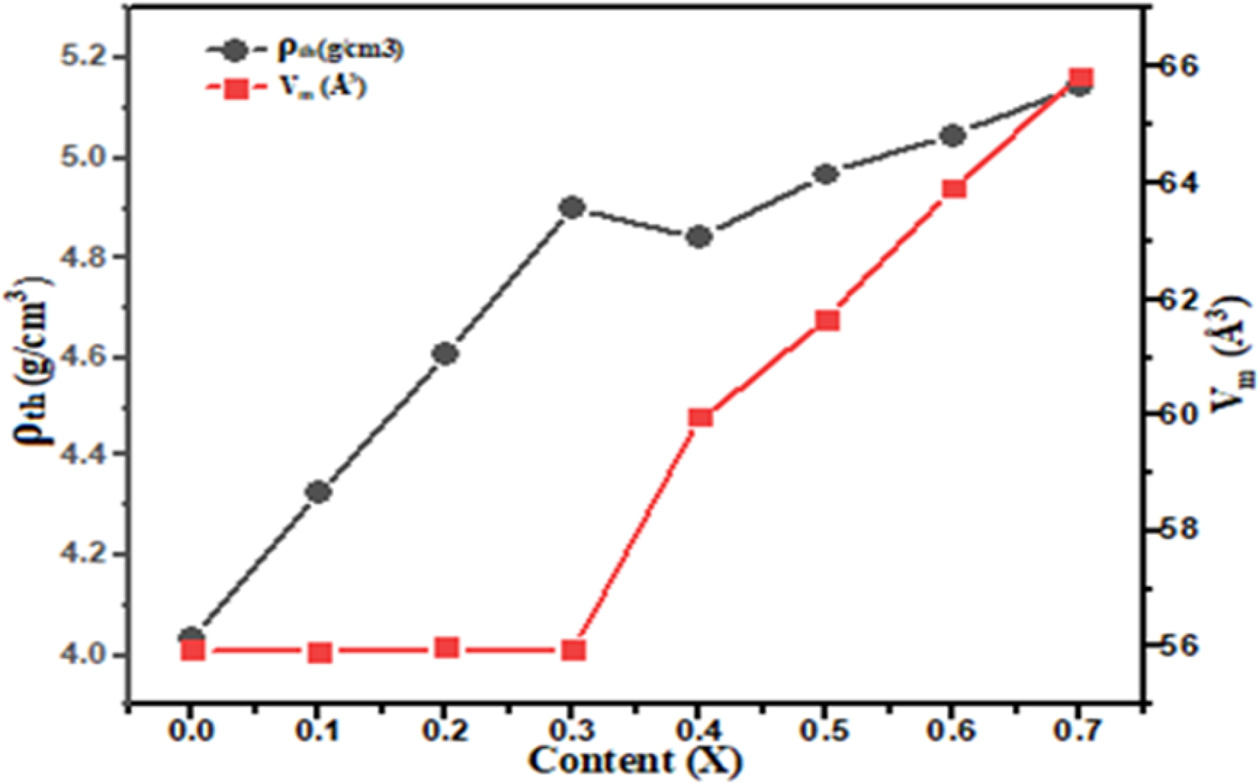

variation of theoretical density (ρth) and molar volume (Vm)

as a function of x is shown in Fig. 2. The theoretical density (ρth)

increases due to the replacement of lighter atomic mass Ca+2 ions

unit cell for the higher atomic mass Ba+2 ions.

Microstructural

analysis

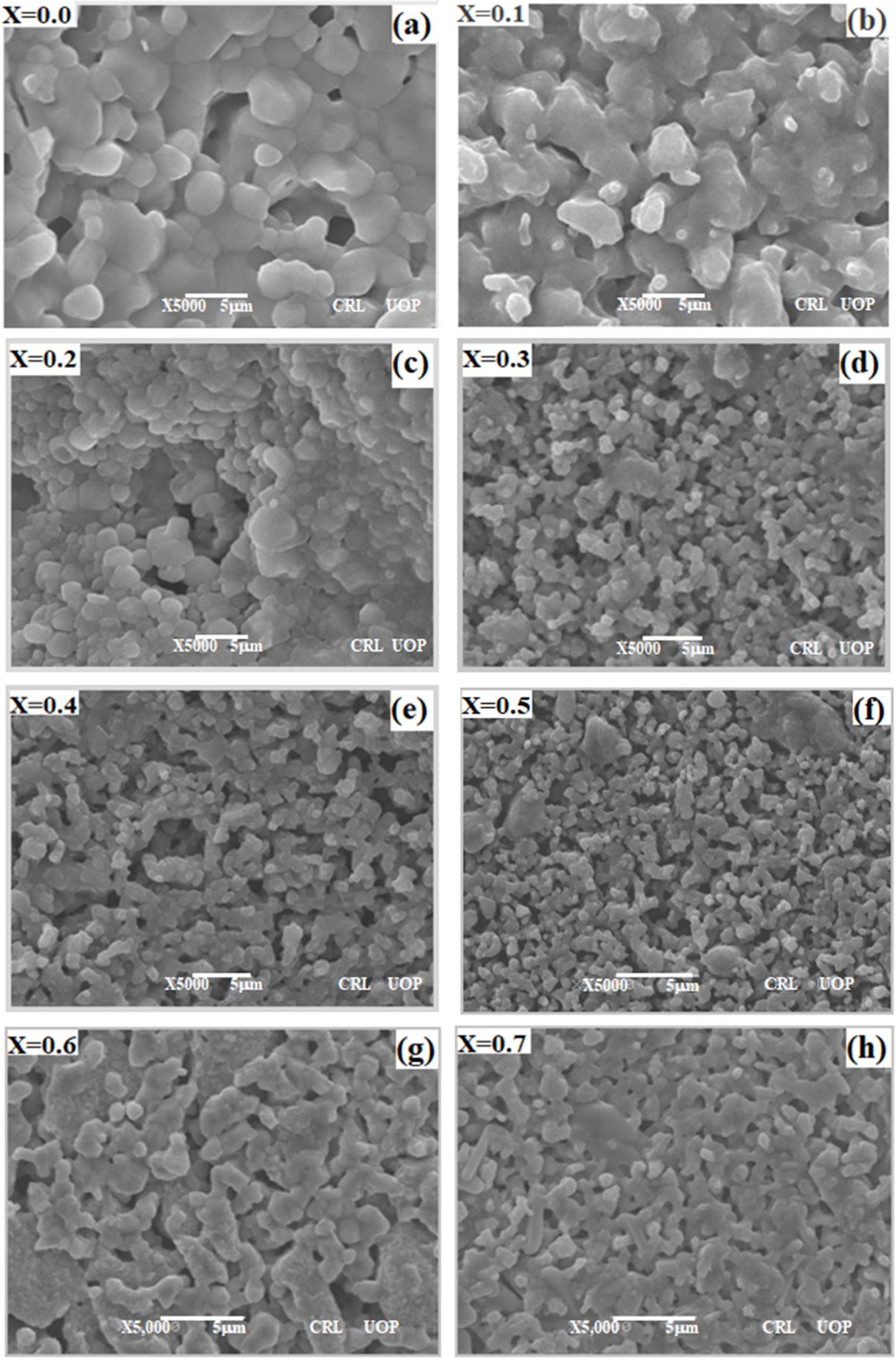

Fig. 3 represents the surface morphology of CBT at

different barium content (x) where (x = 0.0, 0.1, 0.2, 0.3, 0.4, 0.5, 0.6, and

0.7) for the prepared samples by mixed oxide solid state reaction route

sintered at 1,300 oC for 3 h in air. In Fig. 3 the SEM images

have show that microstructure consists of round-like and rod shaped grains with

little pores microstructure in the range of 1 x 1 µm2

to 3 x 3 µm2

sizes. The grains are homogeneous and the surface is smooth in the range x = 0.3

and 0.5 as shown in Fig. 3(d, e, f). The presence of some

bigger grains are often observed within the Fig. 3(a, b, c) sintered at

1,300 oC which may be due to calcium titanate attempting to

diminish the internal energy by reducing the full area of grain boundary,

resulting in the subsequent grain growth [24]. This implies that the

substitution of Ba2+ over Ca2+ in perovskite lattice can

demote the grain growth as shown in Fig. 3(g, h). This type of morphology has

been previously reported for CaTiO3 ceramics [25].

Microwave

dielectric analysis

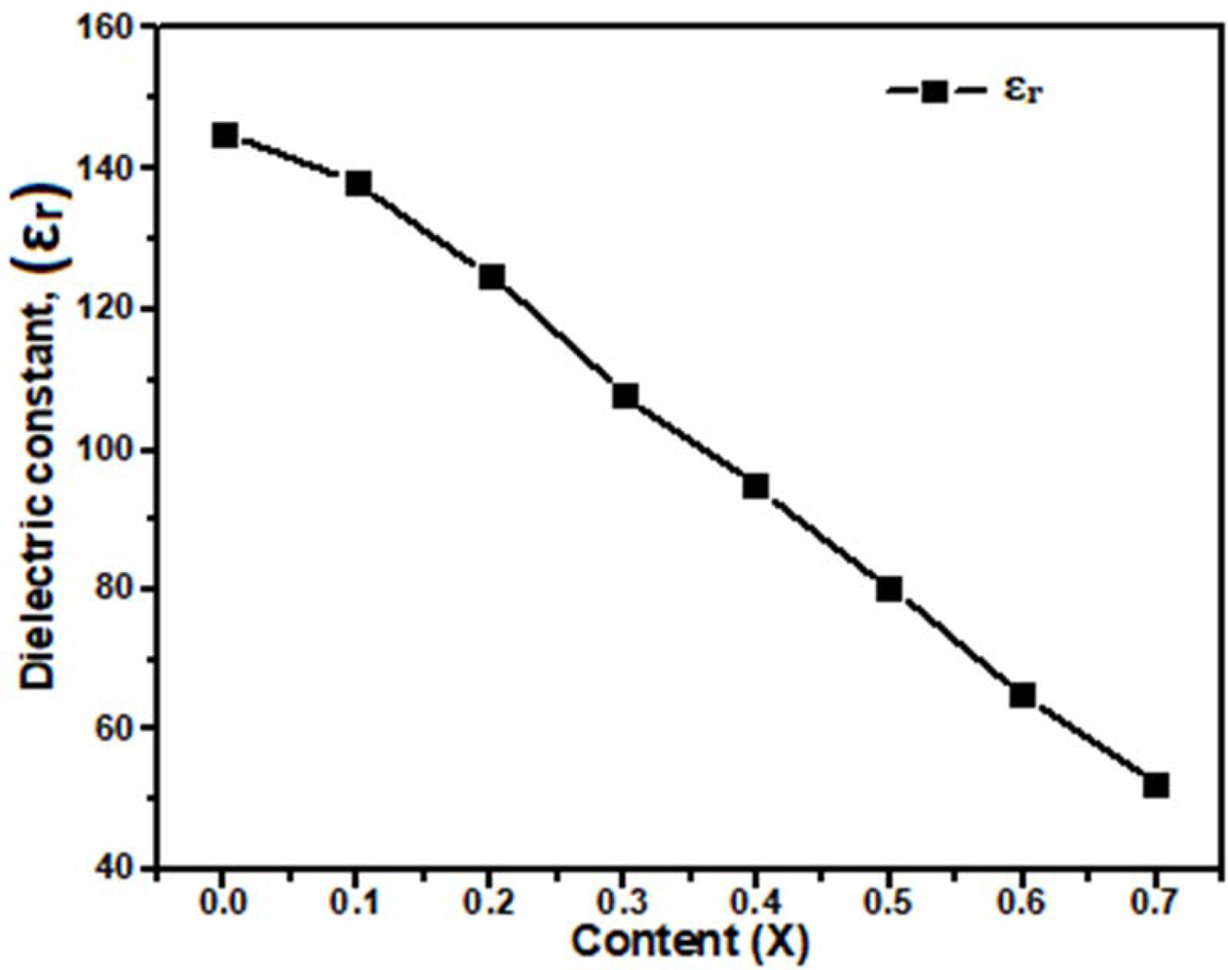

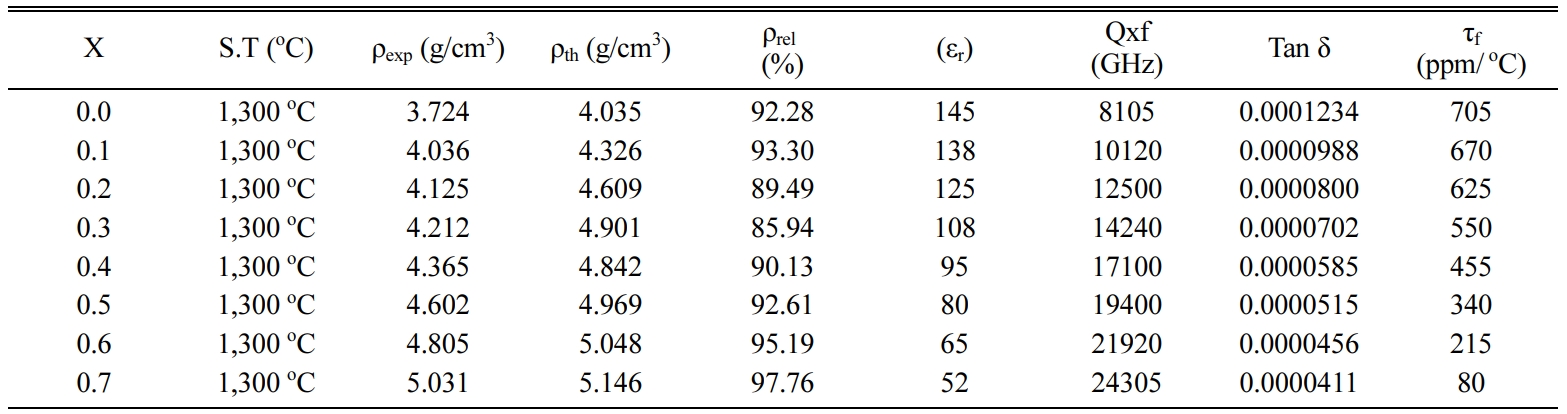

The microwave dielectric properties of Ca1-xBaxTiO3

(0 ≤ x ≤ 0.7) ceramics sintered at 1,300 oC for

3 h was measured with an operating frequency of 3 GHz compared

with Table 3. The obtained dielectric constant (εr) for Ca1-xBaxTiO3

where (x= 0.0, 0.1, 0.2, 0.3, 0.4, 0.5, 0.6, and 0.7) decreases from 145 to 52

at 3 GHz frequency are shown in Fig. 4. This indicated that a small amount of

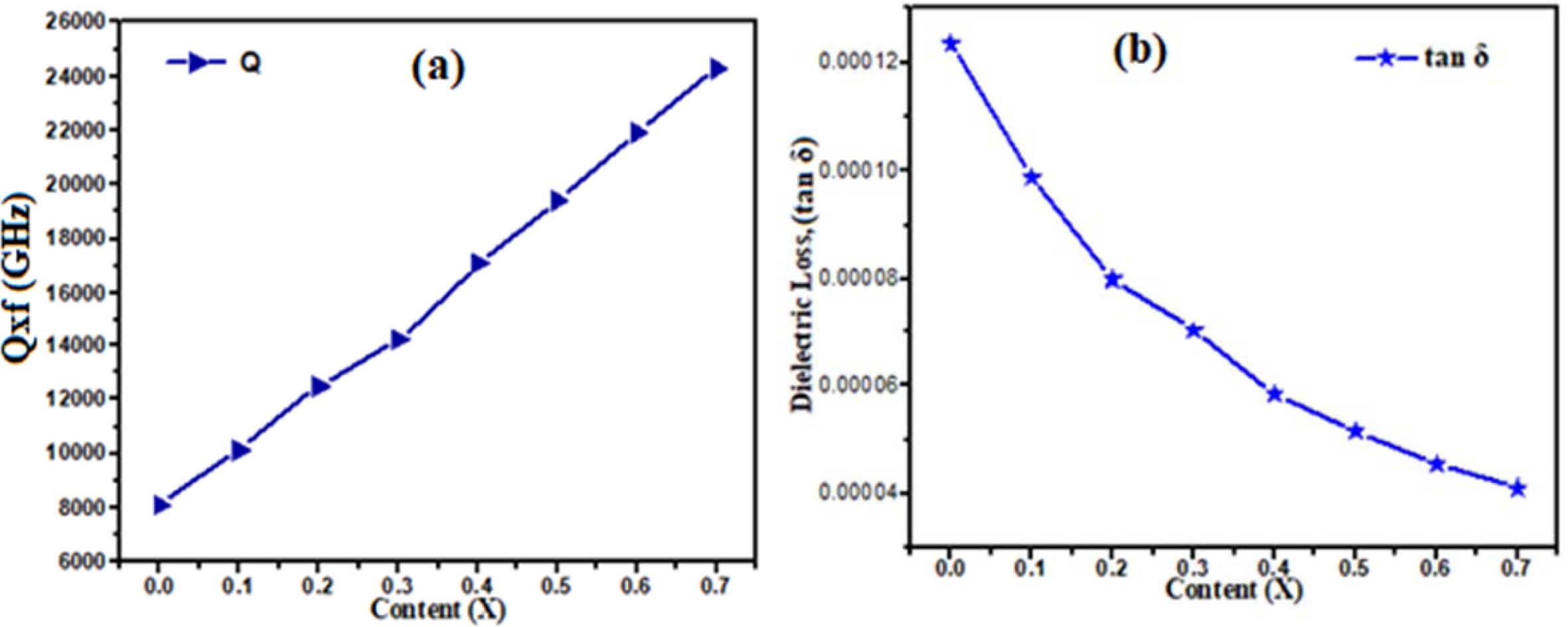

barium doping decreased the dielectric constant value of ceramic. In Fig. 5(a)

shows the quality factor (Q ´ f)

of Ca1-xBaxTiO3 ceramics with different

content x. The quality factor (Qxf) increases from 8105 to 24305 GHz with

increase in barium concentration. The maximum value of Qxf as 24,305 GHz was

obtained for the Ca0.3Ba0.7TiO3 ceramics

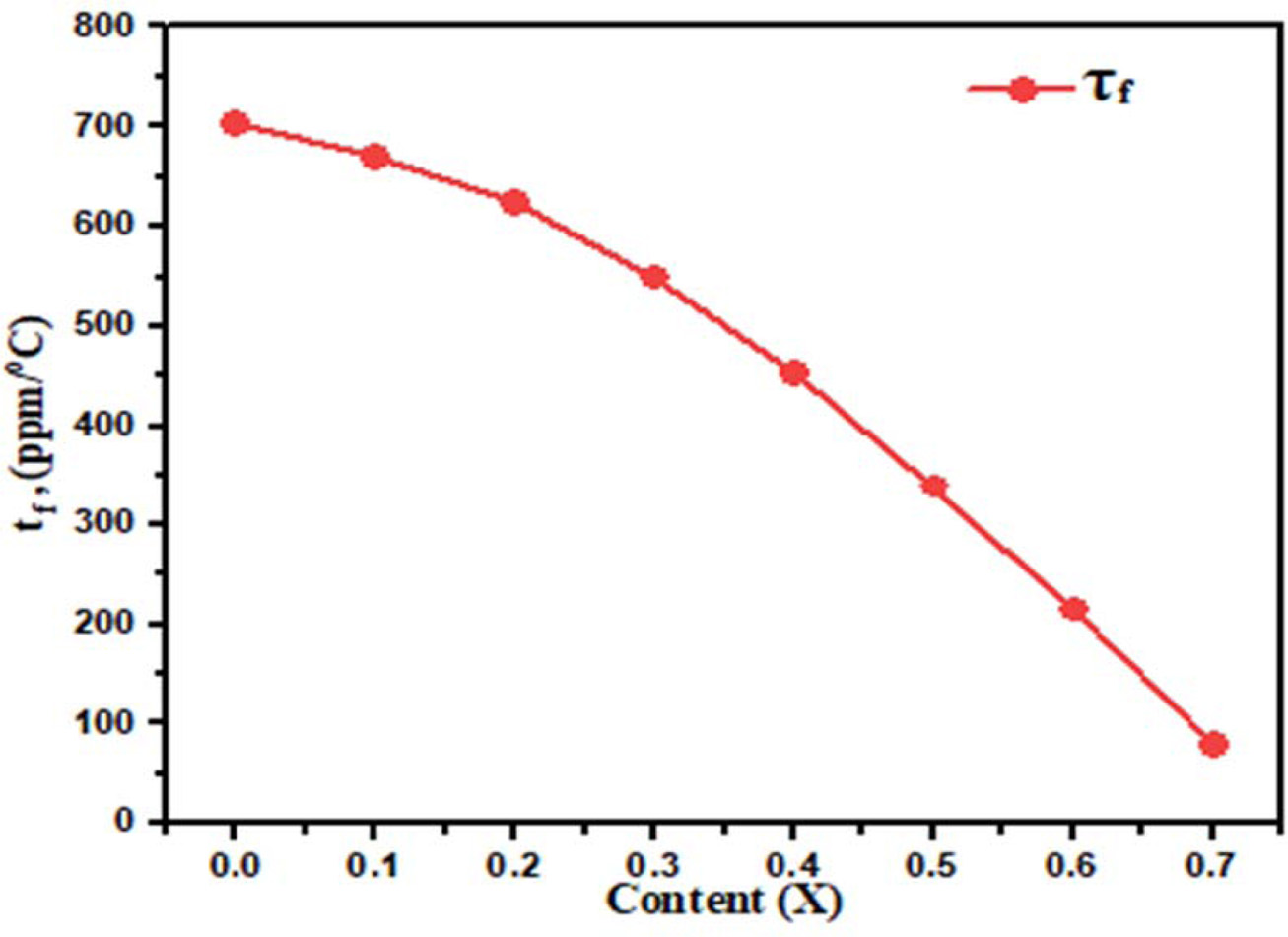

sintered at 1,300 oC for 3hrs. In Fig. 5(b) shown the

temperature coefficient of resonant frequency (τf) decrease from 705

to 80 ppm/ oC, with increase in Ba2+ concentration,

assume that due to the lower ionic polarizability of Ca+2 (3.16 Å3)

compared with Ba+2 (6.40 Å3) [26]. In Fig. 4 the

dielectric constant was observed to follow the relative density and (εr)

~ 52 was obtained for the ~ 97.76%

dense ceramics with x = 0.7. In general, Q x f increases when smaller cations are

replaced by larger cations because larger cations cause a rise

within the movement of A-site cations resulting to an increase in

dielectric losses and therefore a decrease in Qxf [27]. Fig. 6

|

Fig. 1 XRD patterns of the Ca1-xBaxTiO3 (0 ≤ x ≤ 0.7) ceramics

sintered at 1,300 o

C in air. |

|

Fig. 2 Plot of theoretical density (ρth) and Molar volume (Vm) with

different concentration Ba2+ content “x”. |

|

Fig. 3 SEM micrograph of the Ca1-xBaxTiO3 0 ≤ x ≤ 0.7) ceramics sintered at 1300 °C for 3hrs in air; (a) x = 0.0, (b) x = 0.1, (c) x = 0.2,

(d) x = 0.3, (e) x = 0.4, (f) x=0.5, (g) x=0.6, (h) x=0.7; indicating a slight change in grain sizes with increase in x. |

|

Fig. 4 Plot of dielectric constant (εr) versus Ba2+ content (x) for

Ca1-xBaxTiO3 (0 ≤ x ≤ 0.7). |

|

Fig. 5 Comparison of (a) Quality factor and (b) Dielectric loss with different concentration Ba2+ Content (x) |

|

Fig. 6 Plot of Temperature coefficient of resonant frequency with

different concentration Ba2+ content (x). |

|

Table 2 Structural Data of Ca1-xBaxTiO3

ceramics from XRD Analysis sintered at 1,300 oC. |

X = Ba2+ content, Z

= No. of atom per unit cell, S.G = Space group, Vunit = Volume of

unit cell, Vm = Molar volume, a, b & c = Lattice Parameters |

|

Table 3 MW dielectric properties of

the fabricated Ca1-xBaxTiO3 samples sintered

at 1,300 oC. |

X = Ba2+ content,

S.T = Sintering Temperature, ρexp = Experimental density, ρth =

Theoretically density, ρrel = Relative density |

Ca1-xBaxTiO3 (0 ≤ x ≤ 0.7)

was successfully synthesized by

mixed oxide solid state method. Microstructure and

microwave dielectric properties of Ca1-xBaxTiO3

system have been studied for the composition variation (0 ≤ x ≤ 0.7).

A single phase was obtained of Ca1-xBaxTiO3

(0 ≤ x ≤ 0.7) ceramic sintering at 1,300 oC

for 3 h in air. The SEM morphology it

consists of round and rod shaped grains with porous

microstructure. The ceramics samples

sintered at 1,300 oC

for 3 h exhibited a maximum density of 5.146 g/cm3.

The dielectric constant (εr) decreases

from 145 for x = 0.0 to 52 for x = 0.7. The near

zero (tf)

value decreases from 705 to 80 ppm/oC (at 3 GHz) with an increase in

Ba2+ concentration from 0.0 to 0.7.

The authors gratefully acknowledged to the staff of

Materials research laboratory (MRL) and Centralized resource laboratory (CRL),

Department of Physics, University of Peshawar for the

technical support provided.

- 1. R.C Kell, A.C Greenham, and G.C.E Olds, Chem. Inform. 4[38] (1973) 352-354

-

- 2. D. Suvorov, M. Valant, B. Jancar, and S.D. Skapin. Acta Chimica Slovenica 48[1] (2001) 87-99.

- 3. T. Ishizaki, M. Fujita, H. Kagata, T. Uwano and H. Miyake, Microwave theory Tech. 42[11] (1994) 2017-2022.

-

- 4. I.M. Reaney and D. Iddles, J. Am. Ceram. Soc. 89[7] (2006) 2063-2072.

-

- 5. C.L. Huang, C.F. Tseng, W.R. Yang, and T.J. Yang, J. Am. Ceram. Soc. 91[7] (2008) 2201-2204.

-

- 6. C.L Huang, C.L Pan, and S.J Shium, Mater. Chem. Phys. 78[1] (2003) 111-115.

-

- 7. R.D. Shennon, Acta crystallographica A. 32[5] (1976) 751-767.

-

- 8. A. Zaman, S., Uddin, and N. Mehboob, Iranian J. of Sci. and Tech. Tranc. A: Science (2020) 1-5.

-

- 9. K. Wakino, Ferroelectrics 91[1] (1989) 69-86.

-

- 10. E.S. Kim and C.J. Jeon. J. of the Eup. Cerm. Soci. 30[2] (2010) 341-346.

-

- 11. C.L. Huang and S.S. Liu. Jap. J. of app. Phy. 46[1] (2007) 283-285.

-

- 12. Z. Dou, G. Wang, J. Jiang, F. Zhang, and T. Zhang J. of Adv. Cerm. 6[1] (2017) 20-26.

-

- 13. J. Kumar and N. Gupta. Wireless Personal Communi-Cations 75[2] (2014) 1029-1049.

-

- 14. P. K. Mallik, G. Biswal, S.C. Patnaik, and S. K. Senapati, IOP Conference Series Materials Science and Engineering 75 (2015) 012005.

-

- 15. S. Holliday and A. Stanishevsky, Surf. Coat. Technol. 188-189 (2004) 741-744.

-

- 16. D. Wang, Z. Guo, Y. Chen, J. Hao, and W. Liu, Inorganic Chem. 46[19] (2007) 7707-7709.

-

- 17. W. Dong, G. Zhao, Q. Bao, and X. Gu, Materials Sci. 21[4] (2015) 583-585.

-

- 18. G. Gralik, C. Zanelli, F. Raupp-Pereira, M. Dondi, and D. Hotza, in proceeding of 21 Congresso Brasileiro de Engenharia Materiais, October 2014, p.504-510.

- 19. M. Sh. Khali and F.F. Hammad, Egypt. J. Solid. 25[2] (2002) 175-183.

- 20. G. Gralik, A. Thomson, C. Moreas, F. Raupp-Pereira, and D. Hotza, Proc. Appl. Ceram. 8[2] (2014) 53-57.

-

- 21. J. Guevarra, A. Schonleber, S.V Smaalen, and F. Lichtenberg, Acta Cryst. B. 63[2] (2007) 183-189.

-

- 22. A.R. Drews, W. Wong-Ng, R.S. Roth, and T.A. Vanderah, Mater. Res. Bull. 31[2] (1996) 153-162.

-

- 23. P.L. Wise, I.M. Reaney, W.E. Lee, T.J. Price, D.M. Iddles, and D.S. Cannell, Euro. J. Ceram. Soc. 21[10-11] (2001) 1723-1726.

-

- 24. J. Varghese, T. Joseph, K. P. Surendran, T. P. D. Rajan, and M. T. Sebastian, D. Trans, Royal Society of Chem. 44[11] (2015) 5146-5152.

-

- 25. R.D. Shannon, J. Appl. Phys. 73[1] (1993) 348-366.

-

- 26. J. Mitroy, M.S. Safronova, and C. W. Clark, J. of Phys. B Atomic Molecular and Optical Phys. 43[20] (2010) 202001.

-

- 27. Y. Tohdo, K. Kakimoto, H. Ohsato, H. Yamada, and T. Okawa, J. Eur. Cerm. Soc. 26[10-11] (2006) 2039-2043.

-

This Article

This Article

-

2020; 21(6): 745-750

Published on Dec 31, 2020

- 10.36410/jcpr.2020.21.6.745

- Received on Sep 11, 2020

- Revised on Oct 30, 2020

- Accepted on Nov 11, 2020

Services

Services

- Abstract

introduction

experimental procedure

results and discussion

conclusions

- Acknowledgements

- References

- Full Text PDF

Shared

Correspondence to

Correspondence to

- Abid Zaman

-

Department of Physics, Riphah International University, Islamabad 44000, Pakistan

Tel : + 00923348257783 - E-mail: zaman.abid87@gmail.com

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.