- Enhanced the electrochemical performances of Ni-rich LiNi0.8Co0.1Mn0.1O2 cathode by ZrO2 coating

Sung-Joo Joa,#, Hyun-Soo Kimb,#, Do-Yeong Hwanga, Bong-Soo Jinb, Seong-Ju Simb, Jae-Soo Shina and Seung-Hwan Leea,*

aDepartment of Advanced Materials Engineering, Daejeon University, Daejeon 34520, Republic of Korea

bNext-Generation Battery Research Center, Korea Electrotechnology Research Institute, Changwon, 641-120, South Korea

ZrO2 coated Ni-rich

LiNi0.8Co0.1Mn0.1O2 cathode has

enhanced electrochemical performance and stability compared with the pristine.

The discharge capacity of both samples have no significant difference. However,

the 1.77 wt% ZrO2 coated LiNi0.8Co0.1Mn0.1O2

material delivers enhanced charge-discharge cycling (capacity retention of 97.1

% after 100 cycles at 0.5 C) while the capacity retention of pristine is 94.8 %

under the same condition. Based on these, we can infer that the ZrO2

coated LiNi0.8Co0.1Mn0.1O2 material

shows great cyclability, originated from suppressing undesirable side reaction

and decrease effectively electrolyte decomposition reaction. Therefore, the ZrO2

coated Ni-rich LiNi0.8Co0.1Mn0.1O2

cathode can be considered as an effective strategy for long-life Li-ion

batteries.

Keywords: ZrO2, LiNi0.8Co0.1Mn0.1O2, electrochemical performances

Li-ion batteries (LIBs) have attracted a lot of attention

for electric vehicles (EVs), mobile devices, plug-in hybrid electric vehicles

(PHEVs), hybrid electric vehicles (HEVs) and residential energy storage

applications. This is because LIBs have an advantage of high operating voltage

and energy densities, power performance, low price, long lifetime

and good stability compared to traditional batteries [1]. However,

LIBs suffer from severe potential deposition and capacity fading when

charge-discharge cycling. The energy density, lifetime, material

cost and stability are essential criteria for assessing if they can

be used in practical application in LIBs. Because the energy density of the

LIBs is extremely dependent on the cathode material, thus, significant efforts

have been conducted for high-performance cathode material [2].

In Particular, the layered nickel-rich oxide LiNi1-x-y CoxMnyO2 (x

> 0.8, NCM) cathodes have drawn substantial interest [3]. Among various

cathode materials, Nickel-rich NCM shows good electrochemical performance and it is considered as one

of most effective cathode materials owing to low price and elevated electrochemical

performances [4-5]. The superior energy density,

excellent thermal stability and cyclability of Ni-rich NCM made it an ideal

candidate for next-generation cathode material. However, high Ni content also

results in irreversible capacity and poor cycling performance owing to the

similar ionic radius of Ni2+ and Li+ [6]. Especially, at

higher temperature, the structural instability can lead to rapid performance

fading of Ni-rich NCM [7]. To overcome these problems, various strategies such as TiO2,

SiO2 and carbon coating and/or V, B and Mo doping [8-13] have been

performed.

Among them, in this work, we synthesized well-crystallized

ZrO2 coated LiNi0.8Co0.1Mn0.1O2

(NCM811) in order to stabilize the structure and improve electrochemical performances. Consequently,

the ZrO2 coated NCM811 can be considered for advanced cathode

material.

Co-precipitation method was used to synthesize the Ni-rich

NCM811 powders. the Ni-rich NCM811 powders were

synthesized by using co-precipitation method NiSO4-6H2O,

CoSO4-7H2O and MnSO4-H2O were

prepared to assemble Ni0.8Co0.1Mn0.1(OH)2

precursor. The chelating agent were comprised of NaOH and NH4OH

solution. The as-prepared spherical Ni0.8Co0.1Mn0.1(OH)2

precursor was used to mix with LiOH-H2O at a molar ratio

1.05 : 1. After that, the mixture was fired at 480 oC for 5 h. Then

the mixture was cooled down at 750 oC in air for 15 h. For surface

coating, all samples of ZrO2 coated Ni-rich NCM811 were synthesized

exploiting different ratios of ZrO2: Ni-rich NCM811 and then heated

at 500 oC in air for 5 h.

The cathodes were prepared by mixing Ni-rich NCM811

powder, conductive carbon black binder and polyvinylidene fluoride in the

weight ratio of 96 wt%: 2 wt%: 2 wt%. Afterwards, N-Methyl pyrrolidinone (NMP)

solvent was included in the cathodes. The 2032 coin cells were compounded with

Lithium metal disc in argon-gas-filled glove box as an anode. The electrolyte was

consisted of 1 M LiPF6 in ethylene carbonate, dimethyl carbonate,

and ethyl methyl carbonate (EC:DMC:EMC 1:1:1 in volume). The polyethylene (PE,

20 μm) was used as a separator.

The XRD (Philips, X-pert PRO MPD) was used to measure the

crystalline phase of samples. The FE-SEM (Hitachi

S-4800) was prepared to observe the morphology of the

pristine and ZrO2 coated samples. The electron diffraction

spectroscopy (EDS) was used in order to identify the component elements on the

surface of particles. The electrochemical performances were mea- sured with an equipment

(TOSCAT-3100, Toyo system). The Electrochemical Impedance

Spectroscopy (EIS) was measured with frequency range from 1 MHz to 100 mHz and

the amplitude of the AC signal of 10 mV.

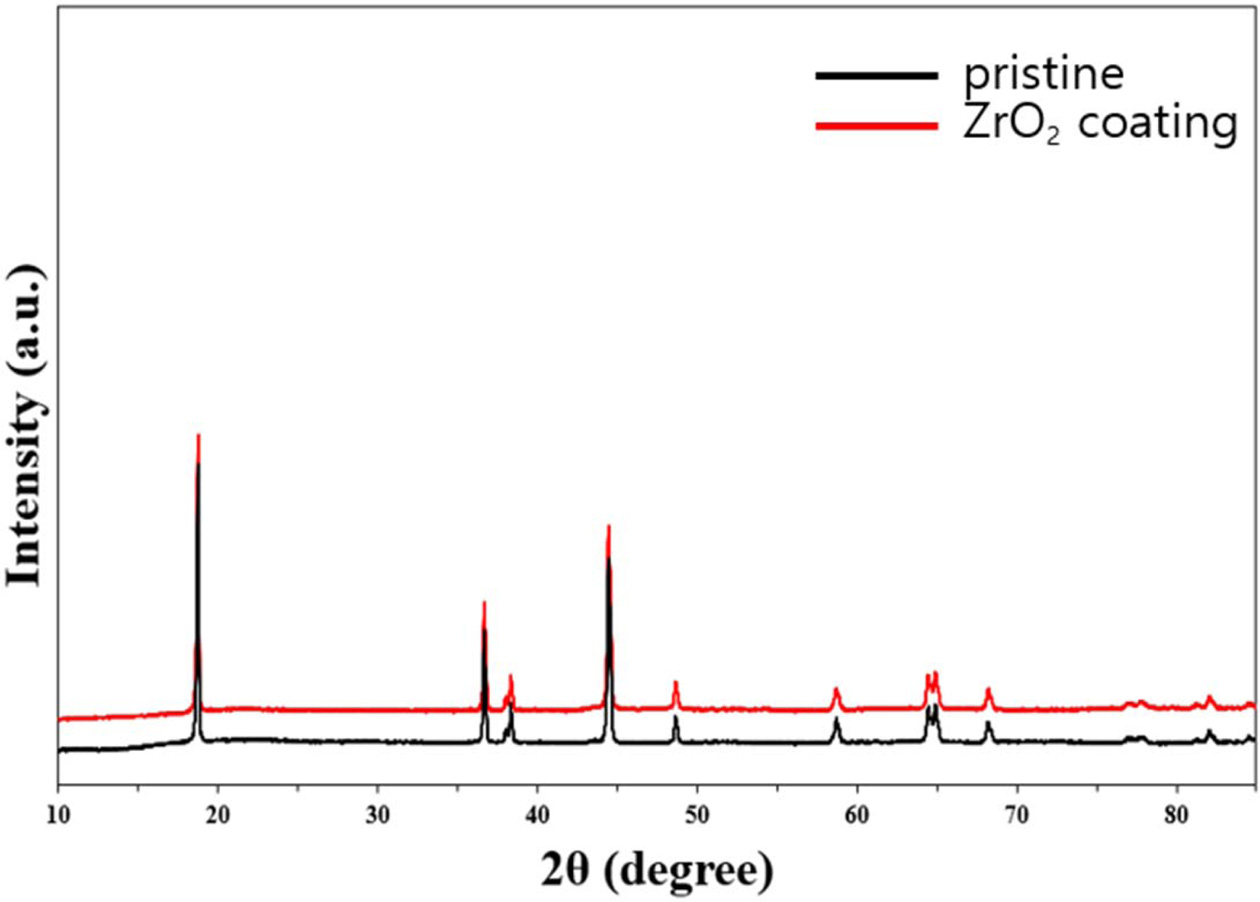

Fig. 1 shows the X-ray diffraction (XRD) spectra of the

pristine and ZrO2 coated NCM811. The shape of all samples is

identical without secondary peaks since ZrO2 coating do not affect

the crystal structure of NCM811 materials. Overall, main diffraction peaks are

indexed as a layered oxide structure in the hexagonal α-NaFeO2

structure with a space group of R-3m [14]. Both obvious splitting of the

(018)/(110) and (006)/(102) peaks suggests well-ordered layered structure.

Also, the ratio of the intensities of (003) and (104) peaks (I(003)/I(104)) are

regarded as index of cation mixing [15]. The cation ordering is resulted from

the similar radius of Ni2+ (0.69 Å) and Li+ (0.76 Å) at

the 3a site [16]. The I(003)/I(104) of all samples are above 1.2, demonstrating

superior cation ordering, which is regarded as an one of the important factor

for good electrochemical performance.

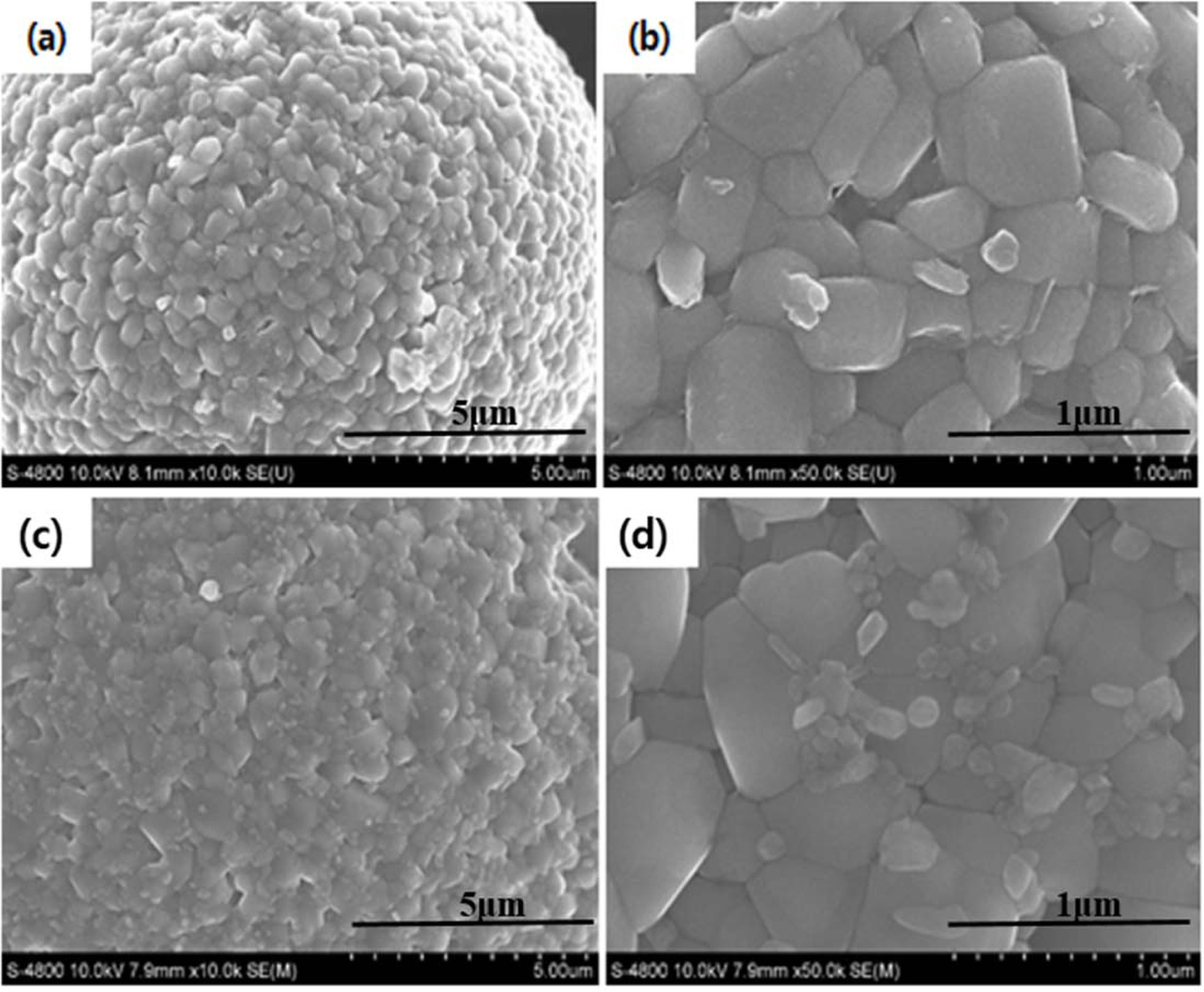

Fig. 2 shows the FESEM images of (a-b) pristine and (c-d)

ZrO2 coated NCM811 cathode materials. The pristine and ZrO2

coated NCM811 sample have similar the morphology (particles size and shape)

[17]. All samples have spherical morphology secondary particles with

the average size of 15 ~ 20 μm, which is composed

of numerous primary particles about 300 ~ 500 nm in diameter. The

benefit of spherical secondary particle can achieve both high tap density and

energy density. The surface of ZrO2 coated NCM811 shows slightly

rough as compared to pristine NCM811.

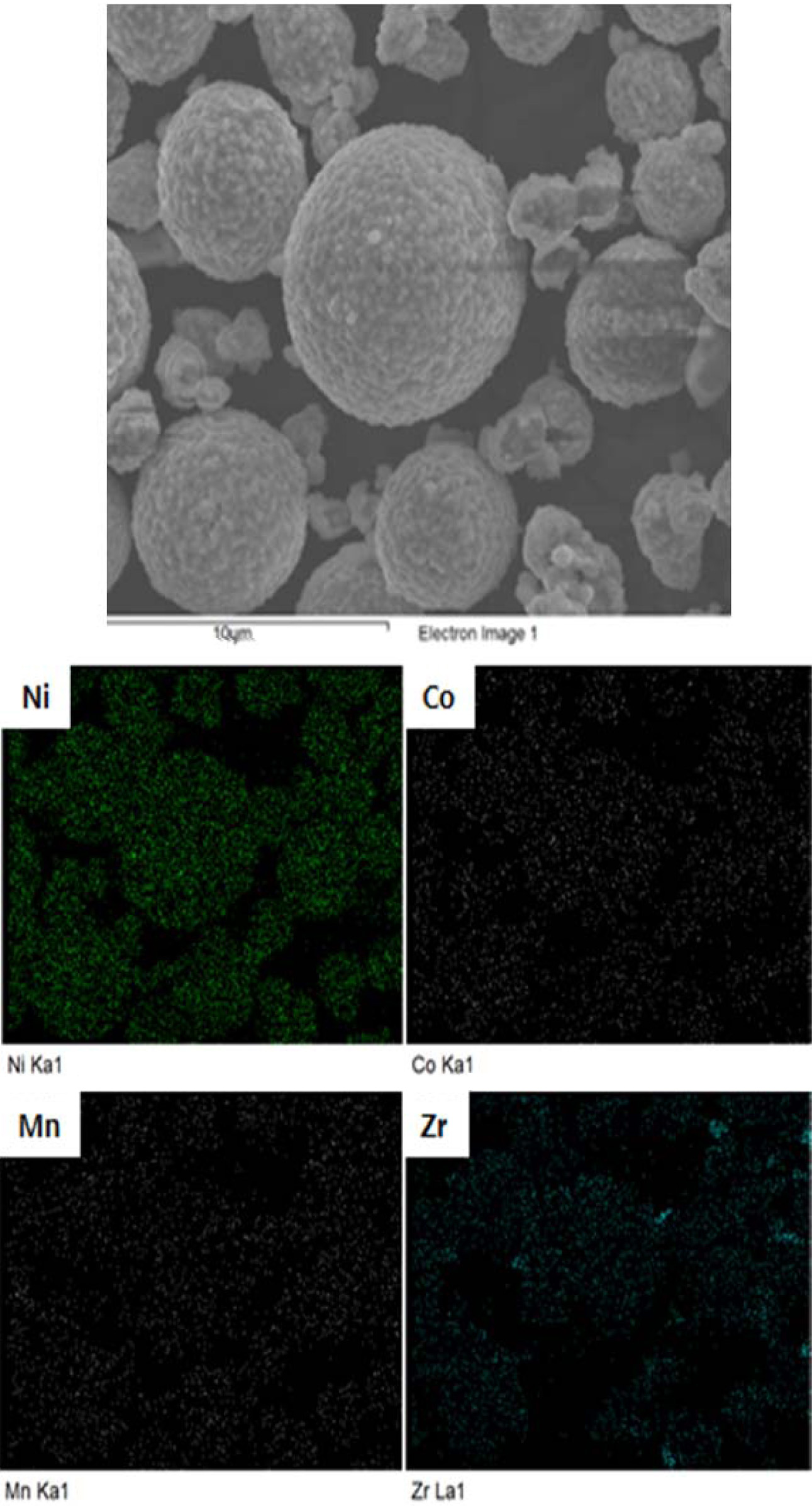

EDS (Energy Dispersive X-ray Spectroscopy) spectrum analysis

of ZrO2 coated NCM811 sample are conducted, as shown in

Fig. 3. It can be confirmed that the Ni, Co, Mn and Zr are equally distributed

and the amount of ZrO2 is 1.77 wt%. The ZrO2 coating can

decrease the contact area between the cathode and the electrolyte, resulting in

suppressing the electrolyte degradation while charge-discharge is cycling [18].

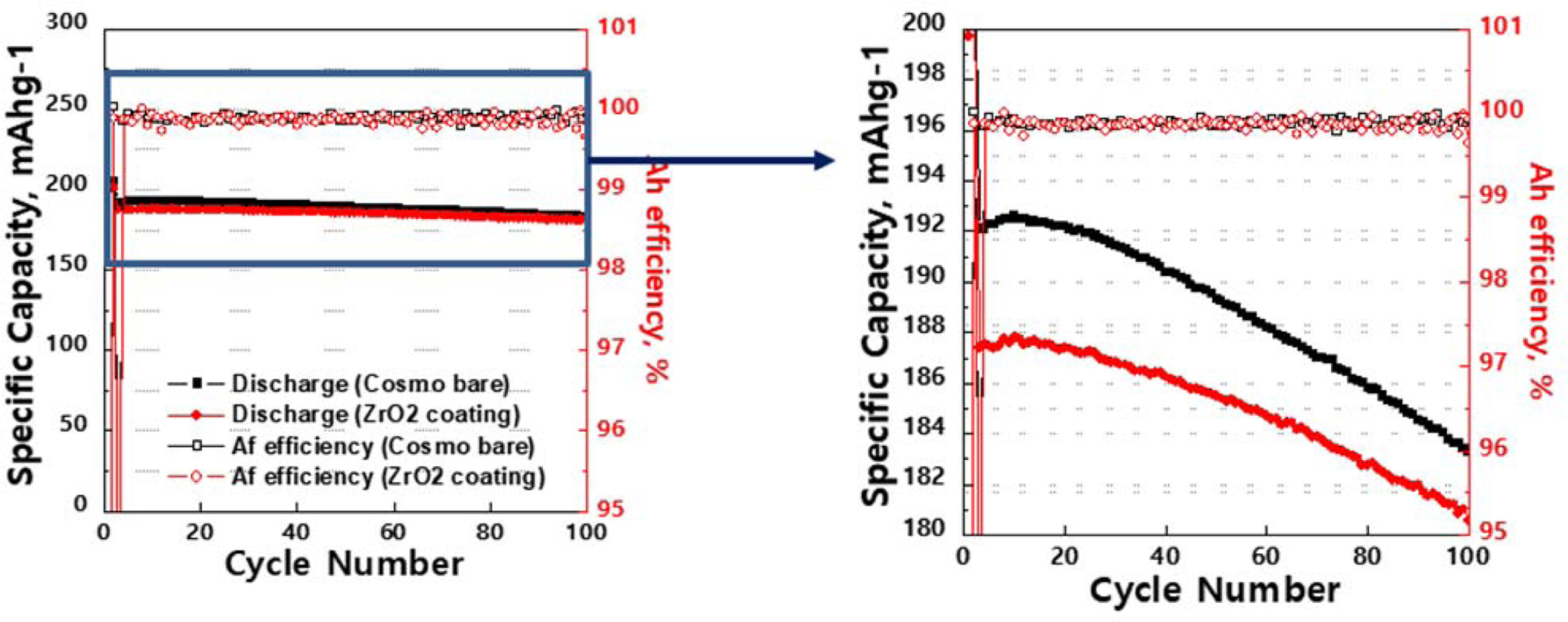

In order to investigate the long-term performance, Fig. 4

presents the cycle performance of the pristine and ZrO2 coated

NCM811 with vinylene carbonate (VC) and propane sultone (PS) additives. The

cycle performances are measured at 0.5 C in the voltage between

3.0 and 4.3 V. It has been proved that additives can increase

the cyclability for both samples since additive is designed to form the

passivating layer on the surface, which can deactivate the active “catalytic”

centers [19]. The ZrO2 coated sample exhibits lower capacity fading

than pristine sample after 100 charge-discharge cycles. This is because ZrO2

coating could stabilize the interface between NCM811 and

electrolyte. The ZrO2 coated and pristine NCM811 have

capacity retentions of 97.1% and 94.8%, respectively, after 100 cycles.

We can confirm that the ZrO2 coating effectively delay

the capacity fading. In other words, it is demonstrated that the ZrO2

coating on the Ni-rich NCM811 leads to superior cycle performance. This is

because the bond dissociation energies of Zr-O, Ni-O, Co-O and Mn-O have 760,

391.6, 368 and 402 kJ·mol-1

at 25 oC. The excellent cyclability of ZrO2 coated

Ni-rich NCM811 is closely related to the stable crystal structure, resulting

from stronger iono-covalent of Zr-O [20].

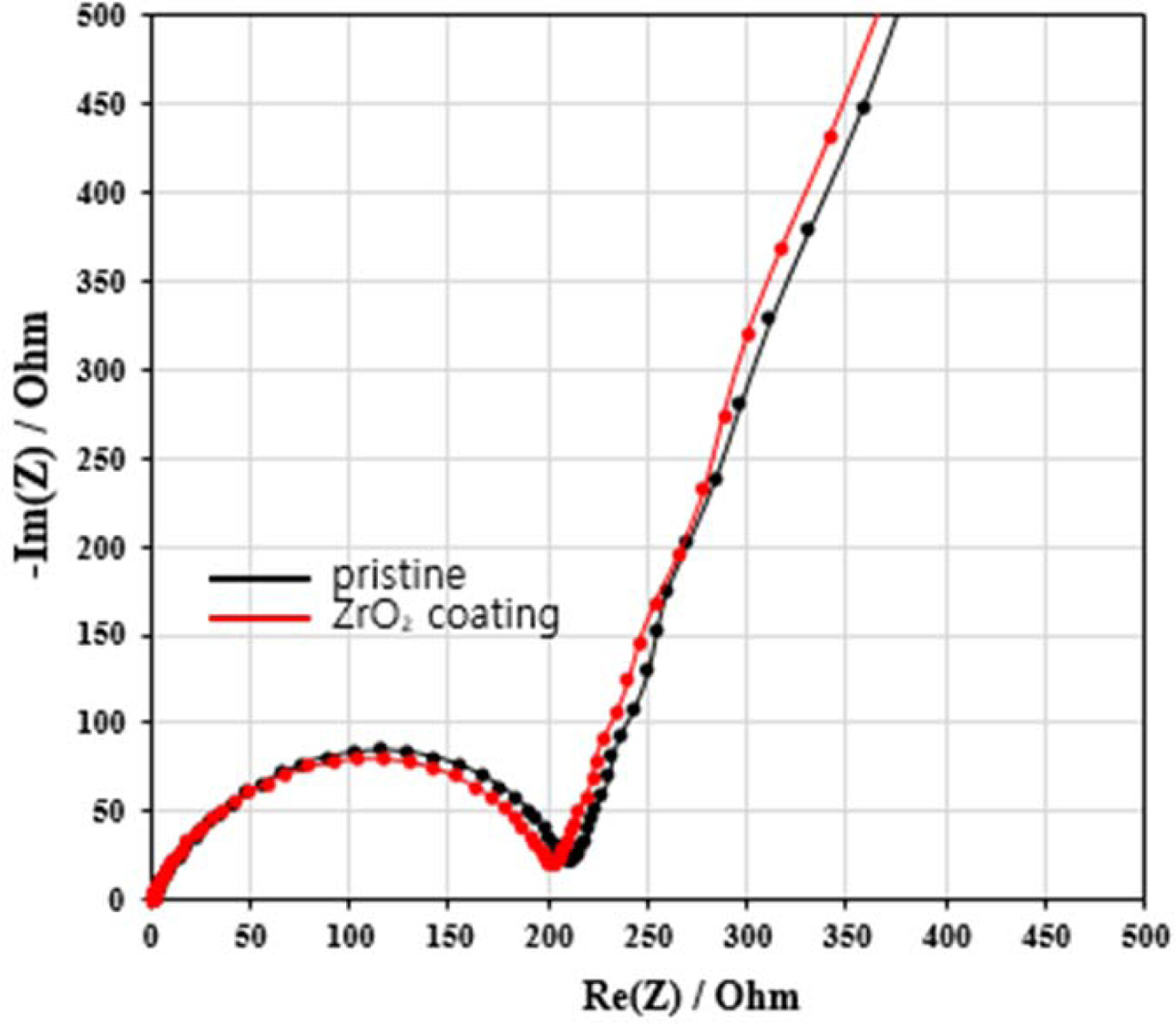

Electrochemical Impedance Spectroscopy (EIS) measurements are used in order to

investigate the charge-transfer kinetics of the electrodes. Nyquist plots of

the pristine and the ZrO2 coated NCM811 are measured after

first cycle in the voltage range 3.0 – 4.3 V. Usually,

Nyquist plot is composed of semicircle and one slope. Fig. 5 shows the EIS

curves of the pristine and ZrO2 coated NCM811. All samples have same

electrolyte resistance (Re) in the high-frequency because we used

same electrolyte. The medium-frequency semicircle is contributed to the

resistance of Rct at the interface between the surface of the

particles and the electrolyte [21]. The straight line of low frequency region

is the Warburg impedance (W). There is a gap between pristine and ZrO2

coated Ni-rich NCM811 for Rct. The Rct of ZrO2

coated NCM811 is lower than the Rct of pristine. After first cycle,

the Rct of pristine is 211.5 Ω, while the Rct of ZrO2

coated NCM811 is 203.7 Ω. This is because the ZrO2 coating layer

suppresses the formation of SEI due to accelerating the Li+ movement

at the surface of cathode [21]. Based on this, we can infer that ZrO2

coating can reduce side reaction, cell impedance increases and Rct.

Therefore, the better cycle performance of ZrO2 coating can be

explained by lower Rct.

|

Fig. 1 |

|

Fig. 2 |

|

Fig. 3 |

|

Fig. 4 |

|

Fig. 5 |

In this work, we prepare the ZrO2 coating on

the surface of Ni-rich NCM811 cathode in order to enhance the electrochemical

performance. The ZrO2 coating has no effect on the crystal structure,

particle size and shape. It is proved that ZrO2 can not only

stabilize the NCM811 structure but also improve the electrochemical

performances due to the deceasing side reaction and the increasing

electrochemical reaction kinetics of lithium ion. These factors can enable good

cycling performance. Therefore, the ZrO2 coating lead to being

considered as an efficient way for Ni-rich NCM811 cathode.

This research was supported by the Daejeon University fund (2020)

- 1. W.S. Cho, S.M. Kim, K.W. Lee, J.H. Song, Y.N. Jo, T.E. Yim, H.T. Kim, J.S. Kim, and Y.J. Kim, Electrochim. Acta. 198 (2016) 77-83.

-

- 2. Q. Hou, G. Cao, P. Wang, D. Zhao, X. Cui, S. Li, and C. Li, J. Alloy. Comp. 747 (2018) 796-802.

-

- 3. J.Z. Kong, Y. Chen, Y.Q. Cao, Q.Z. Wang, A.D. Li, H. Li, and F. Zhou, J. Alloy. Comp. 799 (2019) 89-98.

-

- 4. A.Y. Kim, F. Strauss, T. Bartscch, J.H. Teo, T. Hatsukade, A. Mazilkin, J. Janek, P. Hartmann, and T. Brezesinski, Chem. Mater. 31 (2019) 9664-9672.

-

- 5. C.S. Yoon, H.H. Ryu, G.T. Park, J.H. Kim, K.H. Kim, and Y.K. Sun, J. Mater. Chem. A. 6 (2018) 4126.

-

- 6. S.J. Sim, S.H. Lee, B.S. Jin, and H.S. Kim, Sci. Rep. 9 (2019) 8952.

-

- 7. X. Li, K. Zhang, M. S. Wang, Y. Liu, M. Z. Qu, W. Zhao, and J. Zheng, Sustain. Energy Fuels. 2 (2018) 413-421.

-

- 8. Y.H. Cho, Y.S. Lee, S.A. Park, Y.I. Lee, and J.P. Cho, Electrochim. Acta 56.1 (2010) 333-339.

-

- 9. S.H. Lee, G.J. Park, S.J. Sim, B.S. Jin, and H.S. Kim, J. Alloy. Comp. 791 (2019) 193-199.

-

- 10. Q. Hou, G. Cao, P. Wang, D. Zhao, X. Cui, S. Li, and C. Li, J. Alloy. Comp. 747 (2018) 796-802.

-

- 11. S.J. Sim, S.H. Lee, B.S. Jin, and H.S. Kim, Sci. Rep. 9 (2019) 8952.

-

- 12. L. Pan, Y. Xia, B. Qiu, H. Zhao, H. Guo, K. Jia, Q. Gu, and Z. Liu, J. Power Sources. 327 (2016) 273-280.

-

- 13. Y. Li, Q. Su, Q. Han, P. Li, L. Li, C. Xu, X. Cao, and G. Cao, Ceram. Int. 43 (2017) 3483-3488.

-

- 14. G. Shang, Y. Tang, Y. Lai, J. Wu, X. Yang, H. Li, C. Peng, J. Zheng, and Z. Zhang, 423 (2019) 246-254.

-

- 15. J. Yang and Y. Xia, J. Electrochem. Soc. 163 (2016) 2665-2672.

-

- 16. J.Z. Kong, Y. Chen, Y.Q. Cao, Q.Z. Wang, A.D. Li, H. Li, and F. Zhou, J. Alloy. Comp. 799 (2019) 89-98.

-

- 17. F. Schipper, H. Bouzaglo, M. Dixit, E. M. Erickson, T. Weigle, M. Talianker, J. Grinblat, L. Burstein, M. Schmidt, J. Lampert, C. Erk, B. Markovsky, D.T. Major, and D. Aurbach, Adv. Energy Mater. 8.4 (2018) 1701682.

-

- 18. Z. Wang, E. Liu, L. Guo, C. Shi, C. He, J. Li, and N. Zhao, Surf. Coat. Technol. 235 (2013) 570-576.

-

- 19. Z.D. Li, Y.C. Zhang, H.F. Xiang, X.H. Ma, Q.F. Yuan, Q.S. Wang, and C.H. Chen, J. Power Sources. 240 (2013) 471-475.

-

- 20. S. Chang, Y. Chen, Y. Li, J. Guo, Q. Su, J. Zhu, G. Cao, and W. Li, J. Alloy. Comp. 781 (2019) 496-503.

-

- 21. J.W. Seok, J. Lee, T. Rodgers, D.H. Ko, D.H. Ko, and J.H. Shim, Trans. Electr. Electron. Mater. 20 (2019) 548-553.

-

This Article

This Article

-

2020; 21(6): 731-735

Published on Dec 31, 2020

- 10.36410/jcpr.2020.21.6.731

- Received on Jul 30, 2020

- Revised on Sep 2, 2020

- Accepted on Oct 2, 2020

Services

Services

- Abstract

introduction

experimental

results and discussion

conclusions

- Acknowledgements

- References

- Full Text PDF

Shared

Correspondence to

Correspondence to

- Seung-Hwan Lee

-

Department of Advanced Materials Engineering, Daejeon University, Daejeon 34520, Republic of Korea

Tel : +82-42-280-2414 - E-mail: shlee@dju.kr

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.