- Structural and electrical properties of K(Ta,Nb)O3 thin film prepared by sol-gel method for electrocaloric devices

Min-Su Kwona, Ji-Won Kima, Joo-Seok Parkb and Sung-Gap Leea,*

aDept. of Materials Engineering and Convergence Technology, RIGET, Gyeongsang National University, Jinju 52828, Korea

bBusiness Cooperation Center, Korea Institute of Ceramic Engineering and Technology, Jinju 52851, Korea

This study investigated the

structural and electrical properties of thin K(Ta0.6Nb0.4)O3

films for their applicability to electrocaloric devices. Both of the sol-gel

and spin coating methods were used to fabricate thin films. Those sintered at

650 oC showed a KTN phase with pyrochlore of K2Ta2O6,

but those sintered at 750 oC showed pure polycrystalline phase

without a pyrochlore phase. The lattice constants observed were a= 3.990nm. The

dielectric constant rapidly decreased due to decrease in polarization of space

charge approximately at an applied frequency of 10 kHz. The dielectric constant

and loss at 30 oC of the thin films sintered

at 750 oC were 3,617 and 0.264. The dielectric constant of the

specimen sintered at 750 oC decreased to about -8.27 %/V

according to the applied DC field. The remanent polarization and coercive field

at 36 oC of the specimen sintered at 750 oC were 20.0 μC/cm2 and 122.6 kV/cm. When

the electric field of 247 kV/cm was applied to the specimen sintered at 750 oC, the highest electrocaloric property of 3.02 oC

was obtained.

Keywords: K(Ta,Nb)O3 thin films, Ferroelectric, Electro-caloric effect, Sol-gel method

The K(Ta,Nb)O3 materials with a crystal

structure of ABO3 perovskite is one of the example materials with ferroelectric

properties. These exhibit changes in crystal structure

and various electrical properties according to a

composition ratio of Ta and Nb ions [1, 2]. In general,

the K(Ta,Nb)O3 materials have been studied for their structural

and electrical properties according to fabrication conditions

and composition ratios [3, 4]. By using their excellent crystallographic

and ferroelectric properties, many studies have been conducted on

their applicability to piezoelectric transducers,

capacitors, infrared sensors, and electro-optical devices [5-8].

Recently, the integration and miniaturization of

electronic components has been accelerated by the increasing demand

for more miniaturized multifunctional electronic devices.

Consequently, the heat generated from individual elements or

substrates are recognized as an important issue that needs addressing. Not only

does this heat have an impact on the components, but it also effects the

performance of the electronic devices. Until now, studies on

the heat generation problem in such electronic devices have

mainly focused on the improvement of the heat dissipation characteristics of

the substrates. Still, a small number of studies on the cooling of

devices have been carried out [9-11]. Recently, feasibility of

using the ferroelectric materials of Pb(Zr,Ti)O3 as a cooling device

has been reported [12]. However, the Pb(Zr,Ti)O3-based materials are

limited in practical use due to the environmental problems surrounding the Pb element

and the characteristics of a high phase transition temperature.

This study investigated the applicability of thin

lead-free ferroelectric films of K(Ta0.6Nb0.4)O3

(KTN) as a cooling device. After the films were fabricated by the sol-gel and

screen printing methods, structural and electrical characteristics were

measured by sintering temperature conditions.

In this study, thin ferroelectric films of K(Ta,Nb)O3

were maded by the sol-gel and spin coating methods that are simple to manufacture

without requiring any expensive equipment. A phase transition temperature with

a composition of Ta:Nb = 60:40 near room temperature was selected to investigate

the availability of these films as a cooling device. In an advanced study [13],

potassium ethoxide was used to make the K(Ta0.60Nb0.40)O3

coating solution, but the results were not good. So, in this study, the

experiments were performed using potassium acetate. And, the sol-gel

method used in this study is a simple fabrication process,

and it is easy to control stoichiometric composition. Potassium acetate (Sigma

Aldrich, USA), tantalum ethoxide (Alfa aesar, USA) and niobium ethoxide (Alfa

aesar, USA) were used as starting materials with 2-methoxyethanol (Alfa aesar,

USA) as the solvent. The metal alkoxides used in the

experiment were susceptible to moisture, so the solution was

manufactured in a nitrogen atmosphere. 10mol% potassium was added to compensate

for the volatilization of potassium. Dissolved potassium

acetate in 2-methoxyethanol first, then added tantalum

ethoxide and niobium ethoxide mixed in 2-methoxyethanol in advance according to

the molar ratio 60:40. The three mixed solutions were stirred for 24 h near

100 oC. After 24 h, acetylacetone was added to stabilize the

solution, completing a homogeneous precursor solution. The KTN coating solution

was deposited on Pt/Ti/SiO2/Si substrate, and conducted dried

process at 200 oC for 15 min, pyrolysis process at 400 oC

for 15 min. The previous coating and drying process were repeatd three to six

times and finally sintered at 750 oC for 2 h. The

microstructure of the resultant thin film was observed by the field-emission scanning

electron microscope (FE-SEM, Philips XL30S FEG) and the

crystal structure was determined by X-ray diffraction (XRD)

analysis. The electrical properties of films were measured using

Pt on the KTN films as the top electrode by using dc sputtering method.

Dielectric properties and polarization hysteresis loops were analyzed

using a LCR meter (PM-6036, Fluke) and ferroelectric test system (RT66B, NM,

USA), respectively.

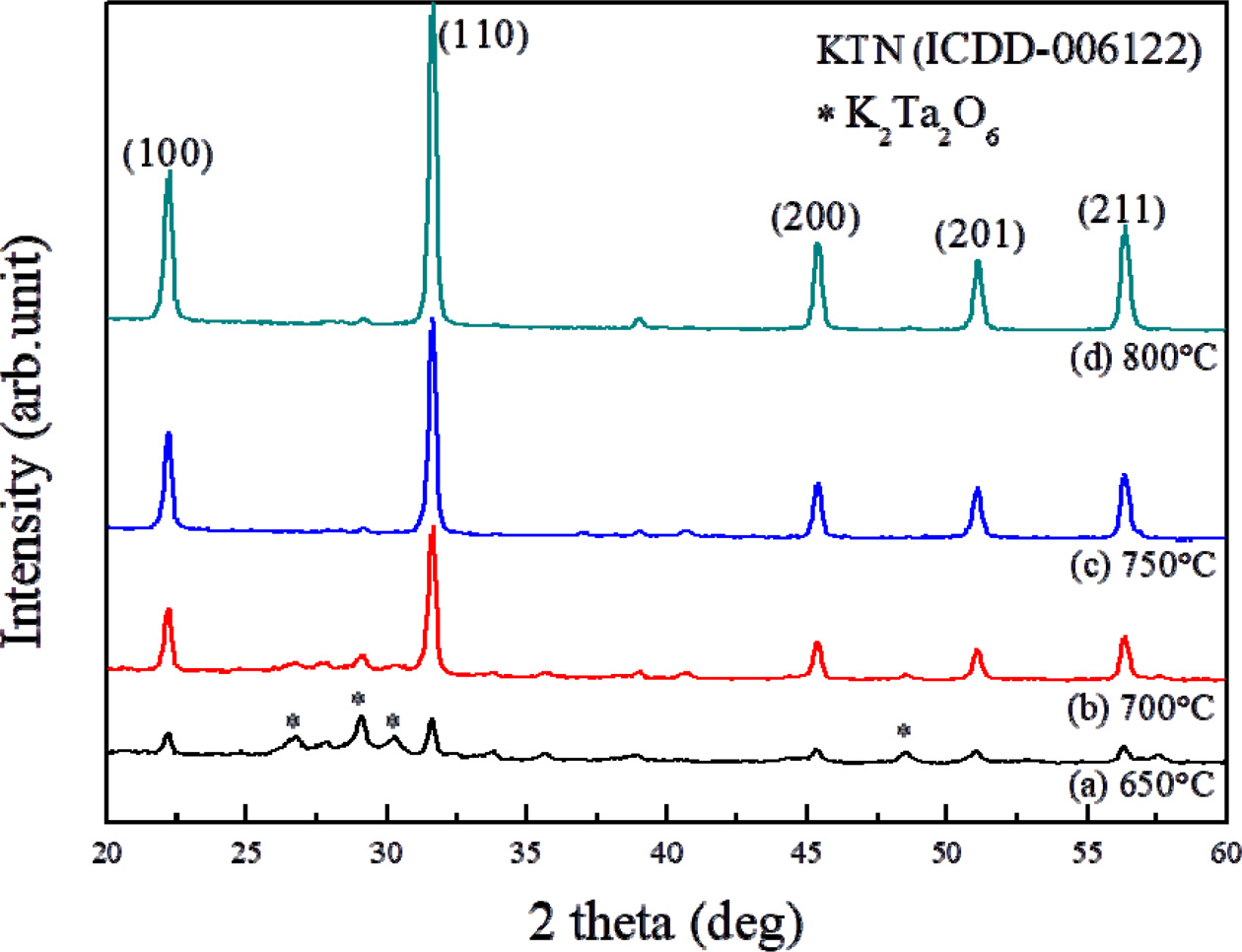

Fig. 1 shows the X-ray diffraction patterns of KTN thin

films according to sintering temperatures. The KTN thin films sintered at 650

degrees exhibited a coexistence of KTN crystal and K2Ta2O6

pyrocholre phases at an initial stage of crystallization. At a sintering

temperature of 700 oC, the peak of pyrochlore phase was greatly

reduced. In the thin films sintered at 750, 800, 850 oC, only

pure KTN phase were observed. The XRD peak’s intensity increased

and FWHM values decreased to 1.369, 0.364, 0.334, and 0.329 when

the sintering temperatures were raised. The thin films sintered at 750 oC

showed a cubic crystal structure with the lattice constants of a = 3.990 nm [14, 15].

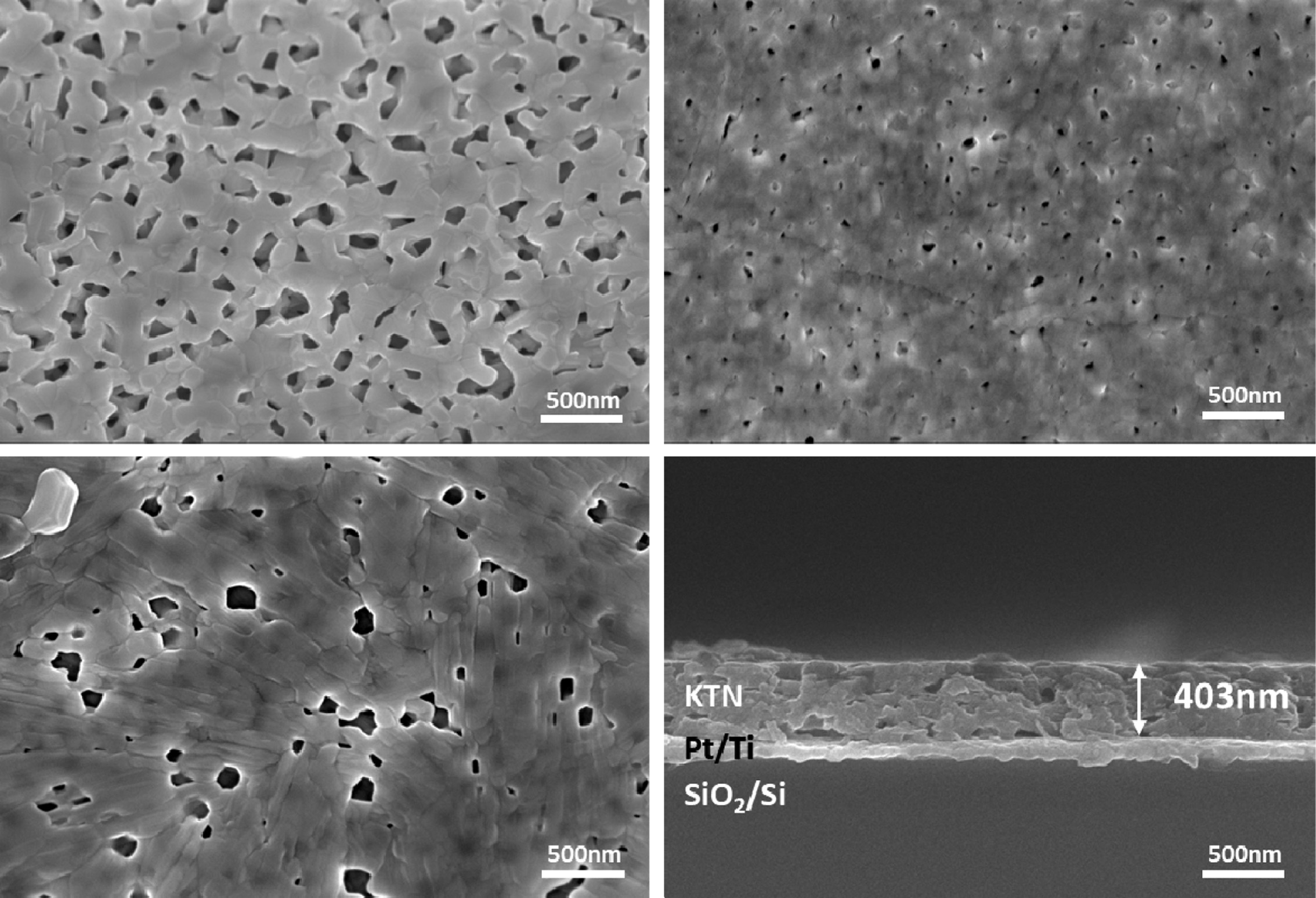

Fig. 2 shows the surface and cross-sectional micro- structures of thin KTN films by

sintered temperature. The thin films sintered at 650 oC showed

many pores and the secondary phase of K2Ta2O6

due to a low sintering temperature. In the specimen sintered at 700 degrees

(Fig. 2(a)), no secondary phase was observed. As the sintering temperature

increased, the pores decreased while the microstructure

was relatively dense. However, pores were distributed in

all thin films. In particular, the specimens sintered at 800 oC

(Fig. 2(c)) exhibited an increase in porosity due to volatilization of K

ion. The thin films sintered at 750 oC showed a dense and

flat cross-sectional microstructure (Fig. 2(d)). The average thickness of thin

KTN films was about 410 nm.

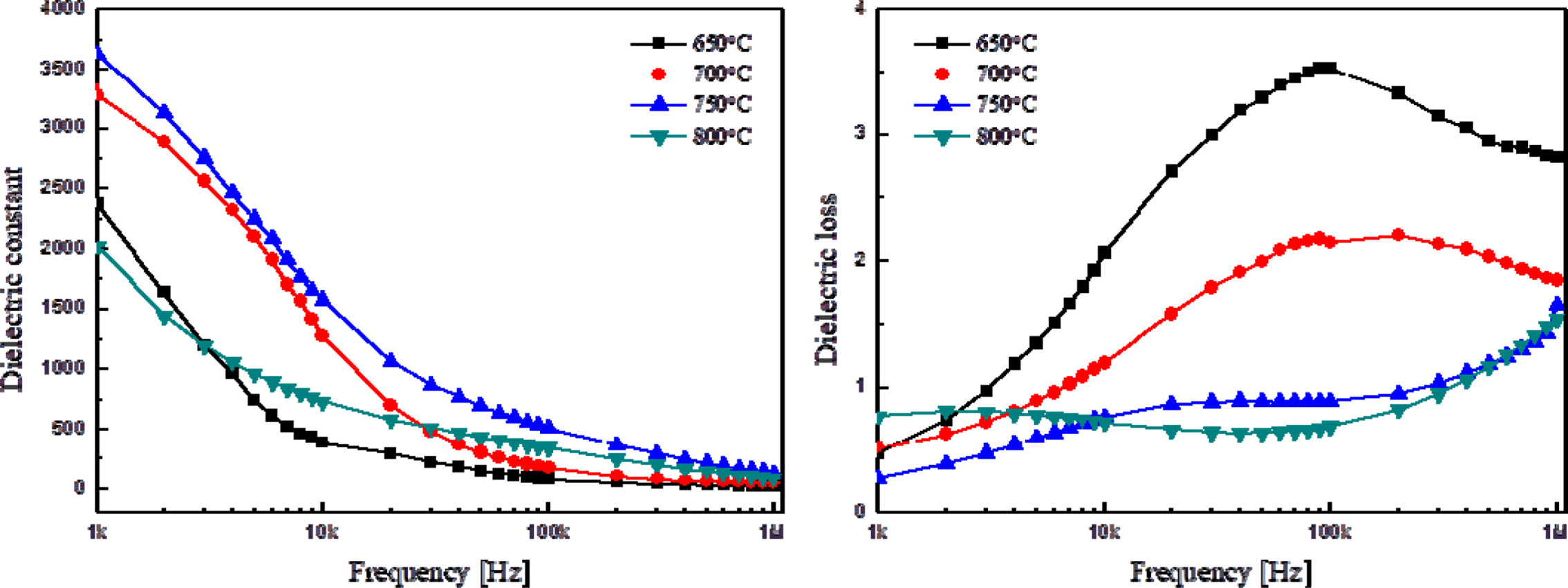

Fig. 3 shows the relative dielectric constant and loss of

thin KTN films by applied frequency. It shows the typical characteristic of

dielectric relaxation [16] in which the dielectric constant decreased when the frequency

was raised. The dielectric constant could have abruptly

decreased at an applied frequency of around 10 kHz due to the reduced

polarization of an internal space charge. The thin films sintered at 750 oC

showed good dielectric constant and loss properties. This is attributed to the

reduction of the pyrochlore phase and pores, as shown in Fig. 2 [17].

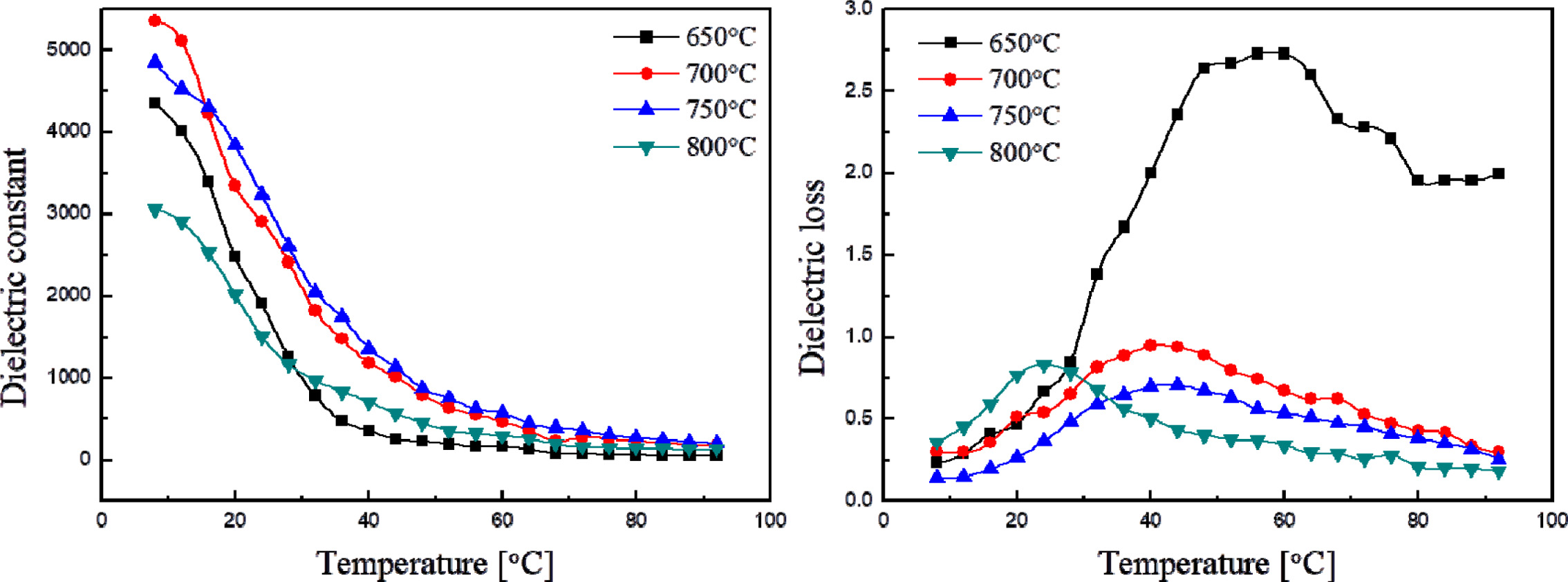

Fig. 4 shows the relative dielectric constant and loss of

KTN films at different temperatures. The relative dielectric constant decreased

when the temperature was raised within the range of 10 oC~90 oC,

while the maximum dielectric loss was around 20~40 oC. From

these properties, the phase transition temperature was considered to be

slightly lower than 10 oC. The phase transition temperature of

thin KTN films slightly increased when compared to that of bulk specimens of

the same composition (Tc=30 oC [18]). This seems to

have been caused by the stress generated at the interface between thin films

and substrates. The thin films sintered at 650 oC showed a high

dielectric loss due to the distribution of secondary phase and pores. The

relative dielectric constant and loss at 30 oC of the specimens

sintered at 750 oC showed excellent properties

of 3617 and 0.264, respectively.

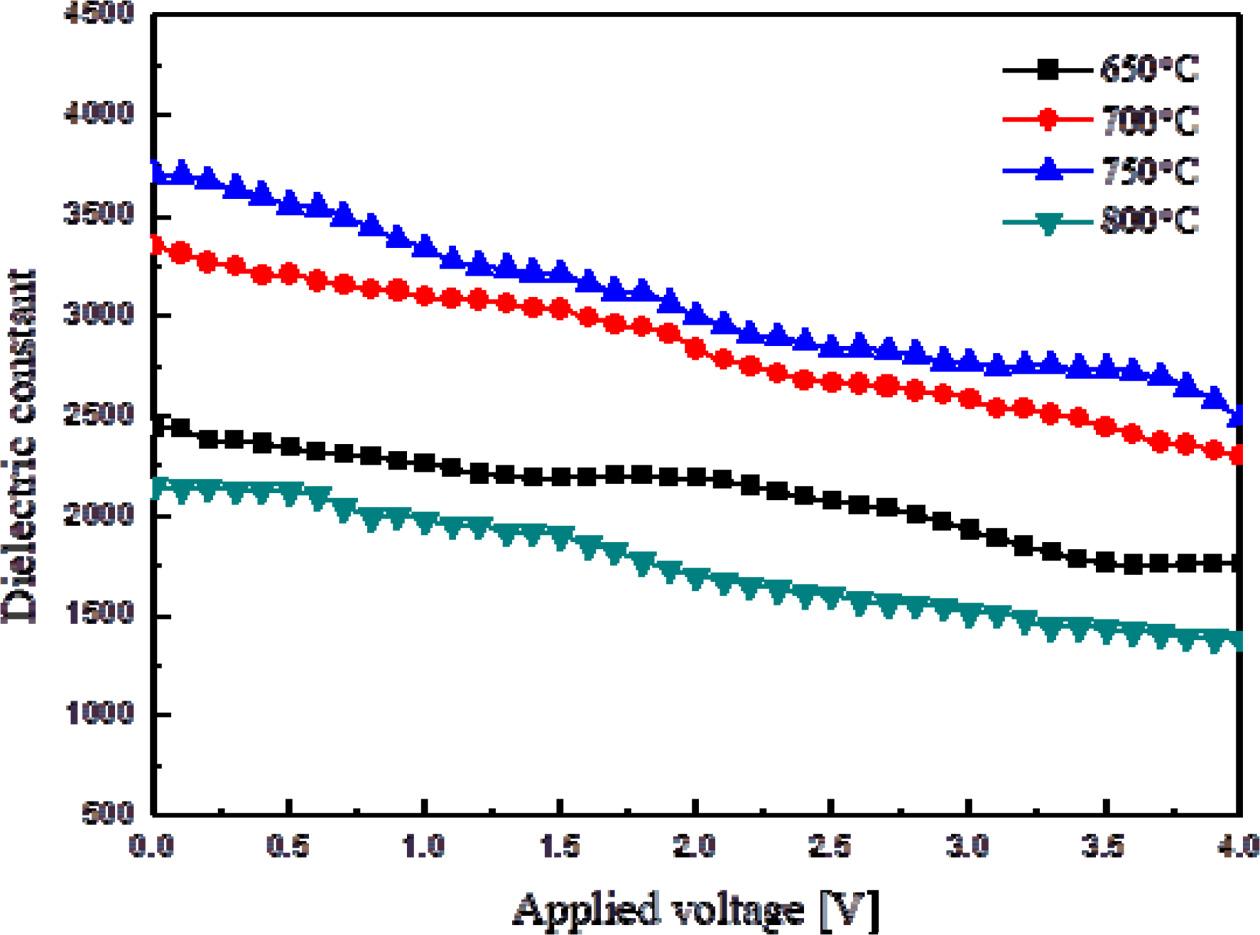

Fig. 5 shows the relative dielectric constant of thin KTN

films by applied DC voltage. The dielectric constant decreased

when the applied DC voltages was raised. This is

because the rotation and displacement of dipoles in the unit

lattice were suppressed by the applied DC voltage. The slope of dielectric

constant according to the DC voltage of the thin films sintered at 750 oC

was about -8.27 %/V.

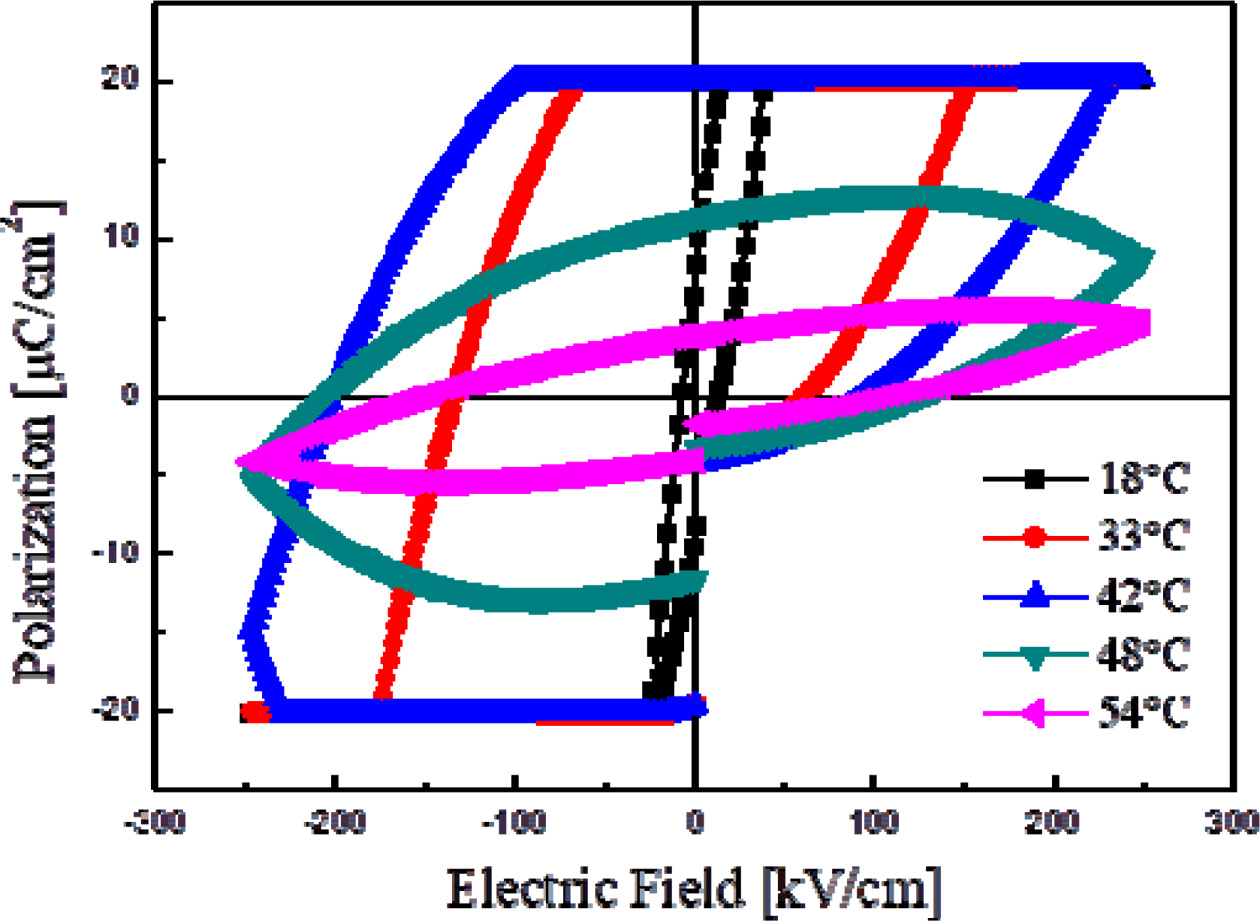

Fig. 6 shows the hysteresis loops of thin KTN films

sintered at 750 oC as a functional temperature. In the thin

films sintered at 650 oC, crystallization was not performed

due to a low sintering temperature, as shown in the XRD

properties of Fig. 1. The thin films sintered at 750 oC showed

the highest remanent polarization as well as coercive field properties of 20.0 μC/cm2,

and 122.6 kV/cm at 36 oC, respectively. When

the measured temperature became higher, the remanent

polarization and coercive fields decreased, while disorder in the dipole

arrangement increased. The ferroelectric properties of thin KTN

films were greatly influenced by pores and crystallinity in the secondary

phase.

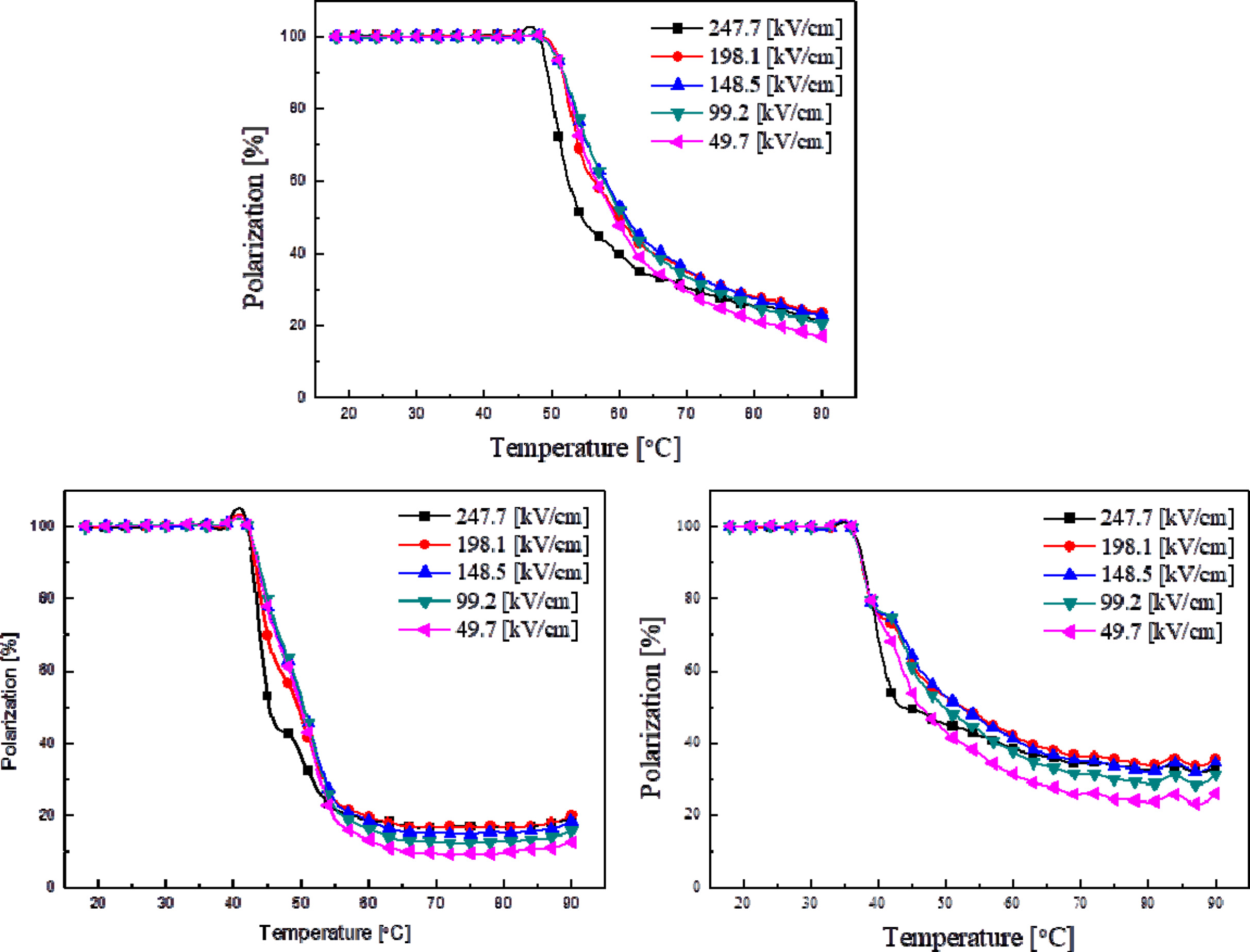

Fig. 7 shows the remanent polarization of thin KTN films

by temperature and applied voltage. While the remanent

polarization at 10 oC were fixed at the maximum value,

this figure shows the relative change in properties at different

temperatures. In the thin films sintered at 750 oC (Fig. 7(b)),

an abrupt decrease in remanent polarization was observed when the temperature

was changed. According to temperatures, materials with higher

crystallinity seem to have more sensitive electrical characteristics.

This could also be observed when single ferroelectric

substances displayed transition characteristics of the first

phase.

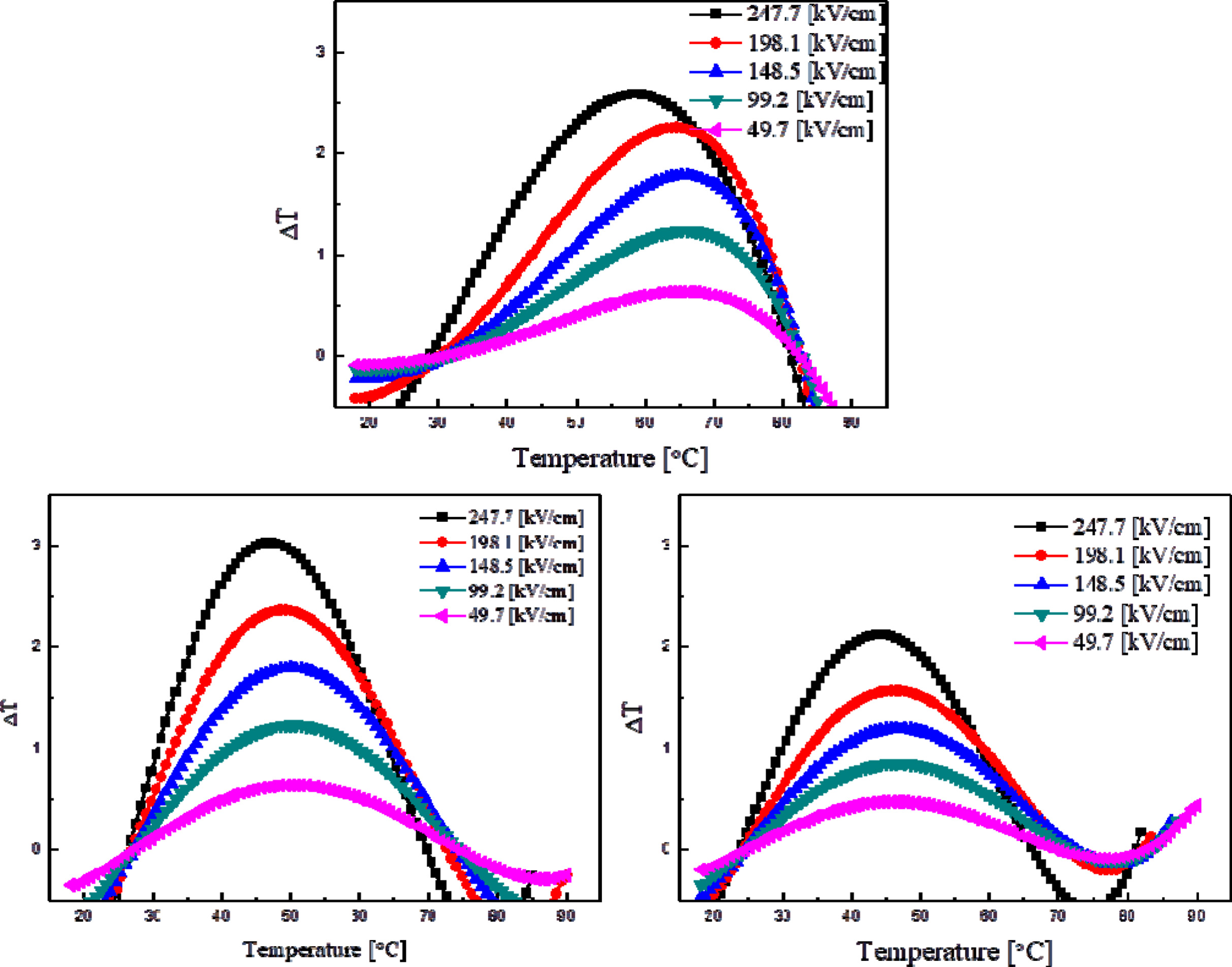

Fig. 8 shows the electrocaloric properties (ΔT) of thin

KTN films at different temperatures. When an electric field of 247 kV/cm was

applied to the specimens sintered at 750 oC, the highest electrocaloric

properties of 3.02 oC

was observed. In all specimens, the maximum

electrocaloric properties were obtained at the phase transition temperature of

around 50 oC,

which is higher than the Curie temperature. This could be attributed to

dipoles’ characteristics of field-induced polarization. This could also be

attributed to the application of an electric field close to the phase

transition temperature at which the ferroelectric and

dielectric phases coexisted [19]. The thin films sintered at 650 oC were not crystallized due to

a low sintering temperature and thus not applicable to a measurement of their

electrocaloric properties. The specimens sintered at 800 oC showed low electrocaloric

properties due to formation of pores caused by excessive sintering.

|

Fig. 1 X-ray diffraction patterns of K(Ta0.6Nb0.4)O3 thin films

according to the sintering temperature. |

|

Fig. 2 Surface and cross-sectional microstructures of K(Ta0.6Nb0.4)O3 thin films with the sintering temperatures; (a) surface, 700 o

C, (b)

surface, 750 o

C, (c) surface, 800 o

C and (d) cross-section, 750 o

C. |

|

Fig. 3 Relative dielectric constant and dielectric loss of K(Ta0.6Nb0.4)O3 thin films with the applied frequency. |

|

Fig. 4 Relative dielectric constant and dielectric loss of K(Ta0.6Nb0.4)O3 thin films. |

|

Fig. 5 Relative dielectric constant of K(Ta0.6Nb0.4)O3 thin films

with DC voltage applied. |

|

Fig. 6 Hysteresis loops of K(Ta0.6Nb0.4)O3 thin films sintered at

750 o

C. |

|

Fig. 7 Polarization of K(Ta0.6Nb0.4)O3 thin film with temperature and voltage application. |

|

Fig. 8 Electrocaloric properties (ΔT) of K(Ta0.6Nb0.4)O3 thin films with temperature changes. |

This study investigated the structural and electrical

properties of thin K(Ta0.6Nb0.4)O3 films for

their applicability to electrocaloric devices. In the specimen sintered at 650 oC, numerous pores and a

pyrochlore phase of K2Ta2O6 were observed.

Also, a peak of pure KTN crystalline was observed in the sintering at 750 oC. The porosity of specimens

sintered at 800 oC

increased due to the volatilization of K ion caused by an excessive

sintering temperature. The optimum sintering temperature of the

specimens was 750 oC. A rapid reduction of the dielectric constant at an

applied frequency of around 10 kHz could

have been caused by the decrease in polarization of space charge. According to

the temperatures, the higher crystallinity seems correlated to higher

ferroelectric properties. In all specimens,

the maximum electric energy was obtained at a temperature slightly higher than

the phase transition temperature.

This could be attributed to the dipoles characteristics of field-induced

polarization. This could also be attributed to the application of an electric

field close to the phase transition temperature at which the ferroelectric and

dielectric phases coexisted. Also, when an electric field of 247 kV/cm was

applied to the specimens sintered at 750 oC,

the highest electrocaloric properties of 3.02 oC

was observed.

This research was supported by Basic Science Research

Program through the National Research Foundation of Korea (NRF) funded by the

Ministry of Education (No. 2017R1D1A3 B03032164) and by Korea Institute of

Planning and Evaluation for Technology in Food, Agriculture, Forestry and

Fisheries (IPET) through Agriculture, Food and Rural Affairs Research Center

Support Program, funded by Ministry of Agriculture, Food and Rural Affairs

(MAFRA) (717001-7).

- 1. E. Jabry, G. Boissier, A. Rousset, R. Carnet, and A. Lagrange, J. Phys. Colloque. 47[Suppl.2] (1986) C1-843.

-

- 2. S. Guillemet-Fritsch, J.L. Baudour, C. Chanel, F. Bouree, and A. Rousset, Solid State Ionics 132 (2000) 63-69.

-

- 3. F.C.M. Driessens and G.D. Rieck, J. Inorg. Nucl. Chem. 28 (1966) 1593-1600.

-

- 4. J. Jung, J. Torfer, J. Murbe, and A. Feltz, J. Eur. Ceram. Soc. 6 (1990) 351-359.

-

- 5. H.J. Van Daal and A.J. Bosman, Phys. Rev. 158 (1967) 736-747.

-

- 6. S. Guillemet-Fritsch, C. Chanel, J. Sarrias, S. Bayonne, A. Rousset, X. Alcobe, and M.L. Martinez Sarrion, Solid State Ionics 128 (2000) 233-242.

-

- 7. J. Yang and X. Hao, J. Am. Ceram. Soc. 102[11] 6817-6826.

-

- 8. B. Liu, H. Zhang, Y. Zhang, X. Lv, Y. Yang, L. Wei, X. Wang, H. Yu, C. Zhang, and J. Li, Acta. Phys. Pol. A. 135 (2019) 396-400.

-

- 9. D. Fang, Z. Wang, P. Yang, W. Liu, and C. Chen, J. Am. Ceram. Soc. 89 (2006) 230-235.

-

- 10. J.L. Martin De Vidales, P. Garcia-Chain, R.M. Rojas, E. Vila, and O. Garcia-Martinez, J. Mater. Sci. 33 (1998) 1491-1496.

-

- 11. S.E. Shirsath, C. Cazorla, T. Lu, L. Zhang, Y.Y. Tay, X. Lou, Y. Liu, S. Li, and D. Wang, Nano. Lett. 20 (2019) 1262-1271.

-

- 12. M.N. Muralidharan, P.R. Rohini, E.K. Sunny, K.R. Dayas, and A. Seema, Ceramics International, 38 (2012) 6481-6486.

-

- 13. K.M. Kim, S.G. Lee, and M.S. Kwon, Journal of Ceramic Processing Research, 19 (2018) 302-305.

- 14. S. Hirano, T. Yogo, K. Kikuta, T. Morishita, and Y. Ito, J. Am. Ceram. Soc. 75[6] (1992) 1701-1704.

-

- 15. A.X. Kuang, C.J. Lu, G.Y. Huang, and S.M. Wang, J. Cryst. Growth. 149[1-2] (1995) 80-86.

-

- 16. E.L. Dereniak and D.G. Crowe, “Optical radiation detectors”, John Wiley & Sons (1984).

- 17. F.M. Pontes, E.R. Leite, E. Longo, J.A. Varela, E.B. Araujo, and J.A. Eiras, Appl. Phys. Lett. 76[17] (2000) 2433-2435.

-

- 18. V.M. Joseph, L.M. Adolph, W.S. Norman, B.C. Antonio, Y.L. Chen, A.W. Richard, and A.W. Curtis, J. Appl. Phys. 72[2] (1992) 615-619.

-

- 19. D. Hennings, A. Schnell, and G. Simon, J. Am. Ceram. Soc. 65[11] (1982) 539-544.

-

This Article

This Article

-

2020; 21(6): 725-730

Published on Dec 31, 2020

- 10.36410/jcpr.2020.21.6.725

- Received on Jun 12, 2020

- Revised on Sep 3, 2020

- Accepted on Oct 6, 2020

Services

Services

- Abstract

introduction

experimental

results and discussion

conclusions

- Acknowledgements

- References

- Full Text PDF

Shared

Correspondence to

Correspondence to

- Sung-Gap Lee

-

Dept. of Materials Engineering and Convergence Technology, RIGET, Gyeongsang National University, Jinju 52828, Korea

Tel : +82-55-772-1687 Fax: +82-55-772-1689 - E-mail: lsgap@gnu.ac.kr

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.