- Characterization of AA6061-ZrO2-C friction stir welded composite joints

R. Pandiyarajana,* and M. P. Prabakaranb

aAssistant Professor, Dept. of Mechanical, K.L.N College of Engineering -Pottapalayam, Tamil Nadu-63061, India

bAssistant Professor, Department of Mechanical Engineering, Erode Sengunthar Engineering College, Tamilnadu, India

In present work, investigation

of metallurgical and mechanical characterization of Friction Stir Welded MMC

material, the influence of micro structural properties on mechanical properties

using different heat inputs were conducted. These heat input generation depend

on the FSW process parameters such as Tool Rotational Speed, Welding Speed and

Axial Load. The FSW process parameters were set such as the tool rotational

speed in the range of 800 to 1000 rpm, axial load in the range of 4 to 6 kN and

a constant welding speed 50 mm/min to fabricate the FS welded specimen of MMC

materials. These process parameters play a major role in determining grain

growth, phase transformation and change in microstructure of different zones of

weldment like welded nugget zone (WNZ), thermo- mechanically affected zone

(TMAZ), heat affected zone (HAZ) and base metal (BM). Moreover, the effects of

changes in the microstructure help in improvements of mechanical properties

like tensile strength and hardness. The weld joints obtained with medium heat

input produced the fine grains and maximum tensile strength of 198 MPa and

hardness of 56 HRB at the tool rotational speed of 800 rpm, welding speed of 50

mm/min and axial load of 5 kN. The optical microscope (OM) and EDX analysis are

employed to identify the presence of the matrix, reinforcement particulates in

HMMCs and to confirm defect free welds attained at the WZ, TMAZ and HAZ during

the medium heat input condition.

Keywords: MMC, FSW, Metallurgical Characterization, Mechanical Characterization

Advanced lightweight engineering applications like

Aerospace, Automotive, Energy, Military, Electronics and Packaging industries

mostly make use of Friction Stir Welding process (FSW). The FSW is a low heat

input solid-state welding process invented by The Welding

Institute, the UK in 1991 [1]. The FSW process produces

plastic deformation in the material by generating an immense amount of heat.

The welding process of aluminium based MMC is very delicate due to aluminium

being difficult to weld than other metals. However, in the case of aluminium

based MMC, joints made by Fusion Welding processes possess many defects and are

not suitable to serve its purposes. Based on the previous research work carried

out on fusion welding on Aluminium Matrix Composites (AMCs), both

aluminium alloy matrix and hard ceramic reinforcing phase create

some problems during fusion welding like high thermal expansion, high thermal

conductivity, solidification shrinkage, incomplete mixing of parent and filler

materials, coarse grain structure at weld zone due to high heat input, high

solubility of gases in the molten state, presence of oxide inclusions [2-4]. To

this end, several investigations were carried on the FSW of Aluminum Metal

Matrix Composites (AMMCs) and its welding process parameters,

studying their microstructures and mechanical properties of these

joints.

Li et al. [5] investigated the microstructure and

mechanical properties of friction stir welded B4C / Al6061 joints,

and found the uniform distribution of B4C reinforcement in the

excited zone. Compared with base metal (BM) grain size, the weld nugget zone

(WNZ)’s grain size was smaller due to this nature and better mechanical

properties were observed in the WNZ. Shojaei et al. [6] studied the

microstructure and mechanical properties of FSW’ed aluminum based MMC with

bronze material joints, the improvement of mechanical properties from 10 to 15%

in FS welded joints. Also found the WNZ’s microstructure was completely

differed from BM’s microstructure. Guo et al. [7]

investigated the microstructure and mechanical properties

of dissimilar FSW’ed AA1100 / B4C MMC and AA6063 alloy joints, found

better improvements in mechanical properties such as tensile strength and

hardness. The maximum hardness and different grain sizes were observed in the

WNZ, also studied single – sided FSW of thin or dense AMMCs plates. Satish et

al. [8] studied and reported the effects of FSW process parameters of 5083

aluminum alloy joints, also known WNZ had achieved better

mechanical properties with fine grain size. Vijayavel and

Balasubramanian [9] investigated the effects on mechanical properties

for different tool pin profile designs and justified the square pin profile

which produced superior tensile strength compared with other design of profile

pins. Seyed et al. [12] studied the microstructure (OM, SEM and EDS) and

mechanical (microhardness and tensile strength) properties of

friction stir welded Mg-12Li-1Al

Alloy. The simultaneous improvement in grain structures

(19 μm to 73 μm) was to improve the hardness and tensile

strength properties up to 13%.

The survey revealed the most

common types of reinforcement materials such as TiC, Tib2, B4C,

Al2O3, SiC, Si3N4 etc and it also found

that the including usage of ZrO2 based reinforcement materials in

Aluminium MMC were limited. Based on the technical gaps noted from the

literature survey, the objectives have been framed for the present

investigation on enhancement of mechanical and metallurgical characterization of

Friction Stir Welded AA6061- ZrO2-C AMMC. The

present work consists, the investigation of metallurgical and

mechanical characterization of friction

stir welded MMC material, study of the influence of micro structural properties

on mechanical properties in the effect of three different heat inputs

generation such as low, medium and high of FS welded MMC materials. The range

of FSW process parameters were set as the follows: Tool Rotational Speed of 600

rpm, 800 rpm and 1,000 rpm, a constant Welding Travel Speed of 50 mm/min and

Axial Load levels of 4 kN, 5 kN and 6 kN to evaluate the optimum heat input

conditions and to obtain superior mechanical properties (tensile strength and

hardness) to produce a defect free joint. Stir Casting method was used to

fabricate the 92 wt% of AA6061, 6 wt% of ZrO2 and 2 wt% C of MMC

materials.

MMC

Materials preparation

A 92 wt% of AA6061 aluminum alloy was used in this

investigation along with 6 wt% of Zirconium Di-oxide (ZrO2) as the

primary reinforcement particulate and 2 wt% of Graphite (C) as

the secondary reinforcement particulate, the primary

reinforcement particulate of ZrO2 is more sought after in the

multi-industrial and technological applications due to its low co-efficient thermal

expansion, low cost and high thermal conductivity [10], also

it possess hard refractory ceramic quality and better

compatibility with aluminum alloys. For example, ZrO2

has a thermal conductivity of 175 W/mK which is less than the 250 W/mK for SiC.

In this regard, the materialistic stability of ZrO2 is better

because it is more heat resistant than SiC. In addition, ZrO2

possesses hard refractory ceramic compatibility

with Al alloy. The secondary reinforcement particulate,

Graphite (C) has much flexibility (though not elastic), valuable electric as

well as thermal conductivity and high wear resistance. The specification

of reinforcement particulates is of 99.5% purity, 11-39 µm particulate size of

ZrO2 and 98% purity, a 325 mesh size for C to fabricated the MMC

materials.

To fabricate the aluminum metal matrix composite (AMMC)

by stir casting method, AA6061 was chopped into smaller

pieces and placed inside the induction furnace crucible. It was melted at a

furnace temperature of 850 oC. In this molten stage the

primary and secondary reinforcement particulates were

gradually mixed with AA6061 matrix before mixing the particulates it were preheated

to 350 oC for removed moisture contents. The

semi-liquid composition was stirred well for the time duration of 10 minutes at

constant speed of 450 rpm to obtain a homogeneous distribution of particulates

in the mixture [11]. Then the stirred semi-liquid composition

material was poured into a rectangular mold to cast the required number of work

pieces in the size of 100 × 50 × 6 mm.

Friction

stir welding of MMCs

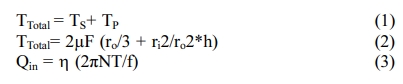

The stir cast MMC plates were successfully welded by

friction stir welding (FSW) process by using square profile tool as shown in

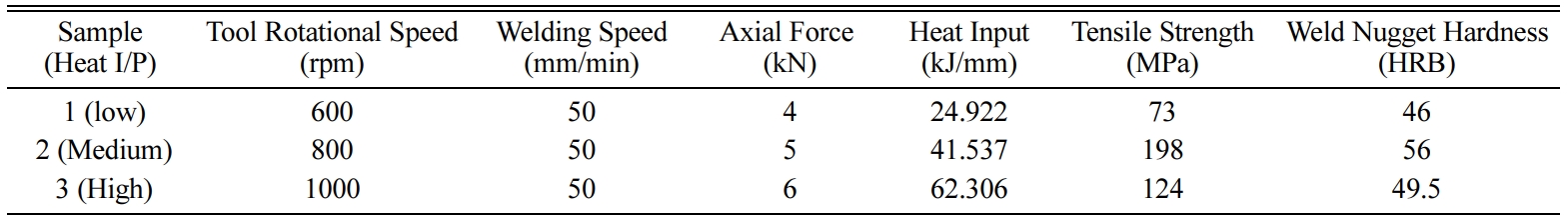

Fig. 1. There are three main process parameters that highly influence the

quality of FS welded joints in MMC such as tool rotational speed,

welding speed and axial load [12-14]. The process parameters and their

respective levels are presented in Table 1.

Heat

input calculation

The square pin profile design tool was used to fabricate

the FS welded MMC material to cause the plastic deformation in the stirred zone

by producing an immense amount of heat during at FSW process. As a result, the

micro structures’ changes were observed in the weldments. Eqs. (1) and (2) were

used to calculate the amount of total torque and heat input values, and Eq. (3)

were employed for finding the average heat input under the tool shoulder pin

[15]. The total frictional torque and heat average input were developed by the

tool rotational speed (rpm) are given by

where, TS = Torque

generated by the tool shoulder (in N-m), TP = Torque generated by

the tool pin (in N-m), µ = Co-efficient of Friction, F = Applied Axial Force

(in N), ri = Radius of the tool shoulder (in m), ro =

Radius of the tool pin (in m), h = height of the tool pin (in m), TTotal=

Total torque (in N-m), h =

Efficiency, N = Tool rotational speed (in rpm), f = welding speed (in mm/min)

and Qin= Average heat input (in kJ/mm). Table 1 presents the amount

of heat generated by the FSW tool for different welding conditions, also each

welding conditions and corresponding amount of heat generations were influenced

in grain growth, phase transformation in the microstructure and hardness of

welded and heat-affected zones. In this study, three levels of

heat inputs were considered to better understand the

effects of heat input in metallurgical characterization. From Table

1, they can be seen as, 24.922 kJ/mm as low, 41.537 kJ/mm as medium and 63.306

kJ/mm as high level of heat inputs generated by FSW tool.

Metallurgical

and mechanical properties

The metallurgical study was carried out along various

zones across the cross sections of FS welded specimens by using of a

metallurgical microscope in different magnification ranges. The chemical

composition of the AMMC’s samples was detected by using of SEM with EDX

spectrum analysis. The FS welded MMC specimen in the size

of 15 mm ´ 15

mm ´ 10 mm

was cut and polished with emery sheets, having the grits in the range

of 220 to 1,200. The specimen surface was further polished

using a diamond polishing disc of 6 µm, 3 µm, and 0.5 µm. Further polishing was

made again by applying the alumina solution to give a glossy finish to the

specimen. Finally, the specimen was etched with the help of Keller’s agent. The

specimen was well prepared to observe the Base Composite (BC), Heat Affected

Zone (HAZ), Thermo Mechanically Affected Zone (TMAZ) and Welded Nugget Zone

(WAZ) under different magnification levels (100X / 100 µm,

100X / 50 µm, 200X / 50 µm) on an optical microscope

and EDX analysis (Zhang et al., 2015; Vijay et al., 2010).

The FSW joints are tested for their mechanical properties

as per ASTM standards E08 M-04 for the tensile test and E10 for the hardness

test. The tensile test characterizes the elastic-plastic behaviour of a

material by applying a uniaxial tensile load. All the tensile tests are

conducted in a displacement control mode at a rate of 0.1 mm/min. The localized

strain variations in the tensile samples were measured using an extensometer,

it is used to measure the change in length of the FS welded MMC. Engineering

stress-strain relation is calculated for each specimen.

The hardness test specimen samples were made in

rectangular shape using the wire-cut EDM process, as per the specification

mentioned earlier (15 mm ´ 15

mm ´ 10 mm).

These samples were placed on the hardness testing machine and subjected to an

axial load of 500 g using a ball indenter for a dwelling period of 10 s. The

spherical indentation induced by the 1/16’ diameter indenter was measured on

various locations in the sample surface. The micro hardness survey is made at

different positions in various zones of welded joints.

|

Fig. 1 Experimental setup of FSW. |

Microstructure

friction stir welded MMCs

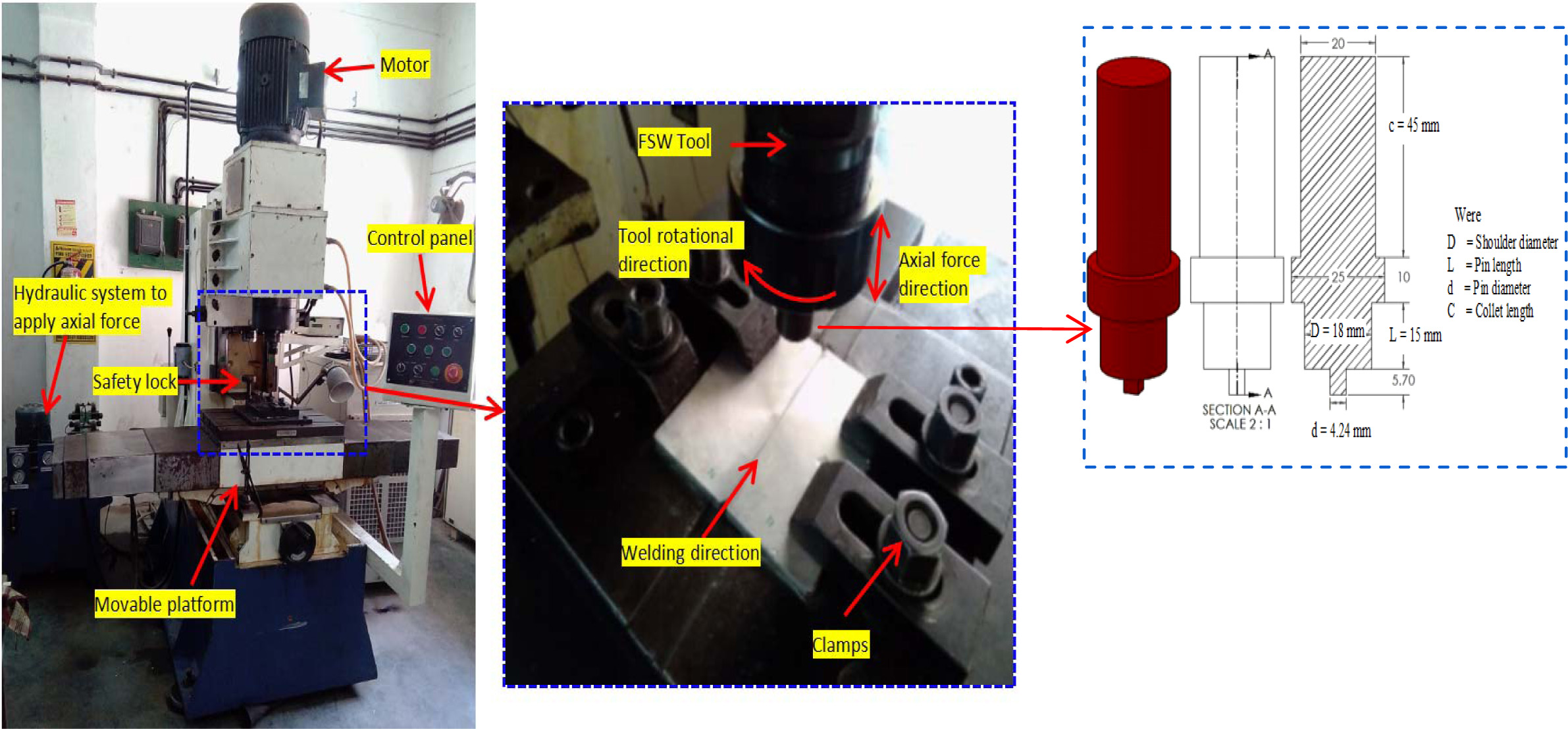

The Scanning Electron Micrograph (SEM) image of 92% Wt% of

AA6061, 6 Wt% of ZrO2 and 2 Wt% of C particulate stir cast aluminum

matrix composite materials is shown in Fig. 2. It clearly shows the

uniform dispersion of reinforcement

particulate in stir cast aluminum AA6061, ZrO2 and C reinforced

composite materials. It is noticed that the particulate

agglomeration was reduced considerably. It makes sure that proper

stirring was employed during fabrication of MMC. The random orientation of

particulates provides uniform strength to cast material in all directions.

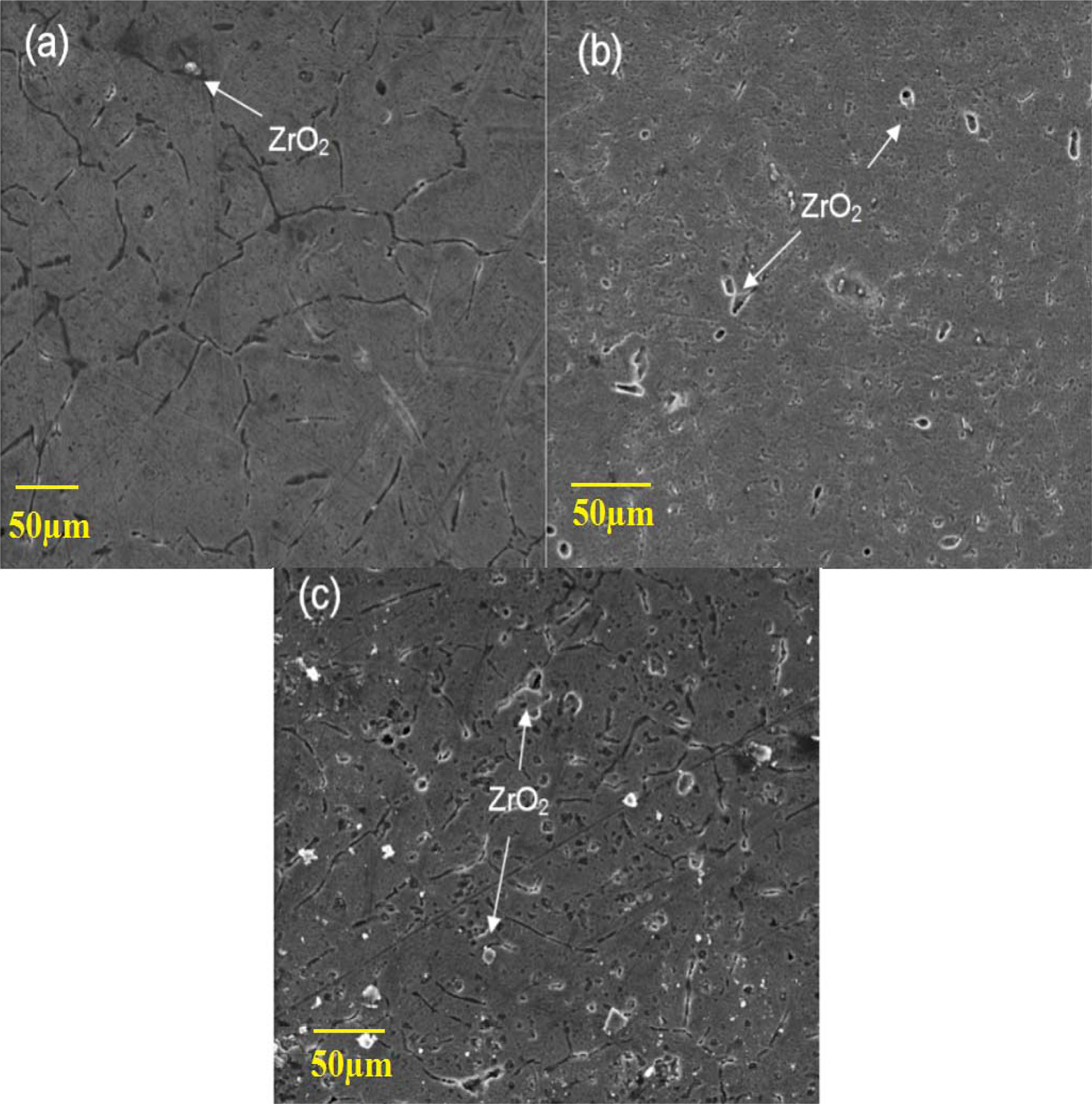

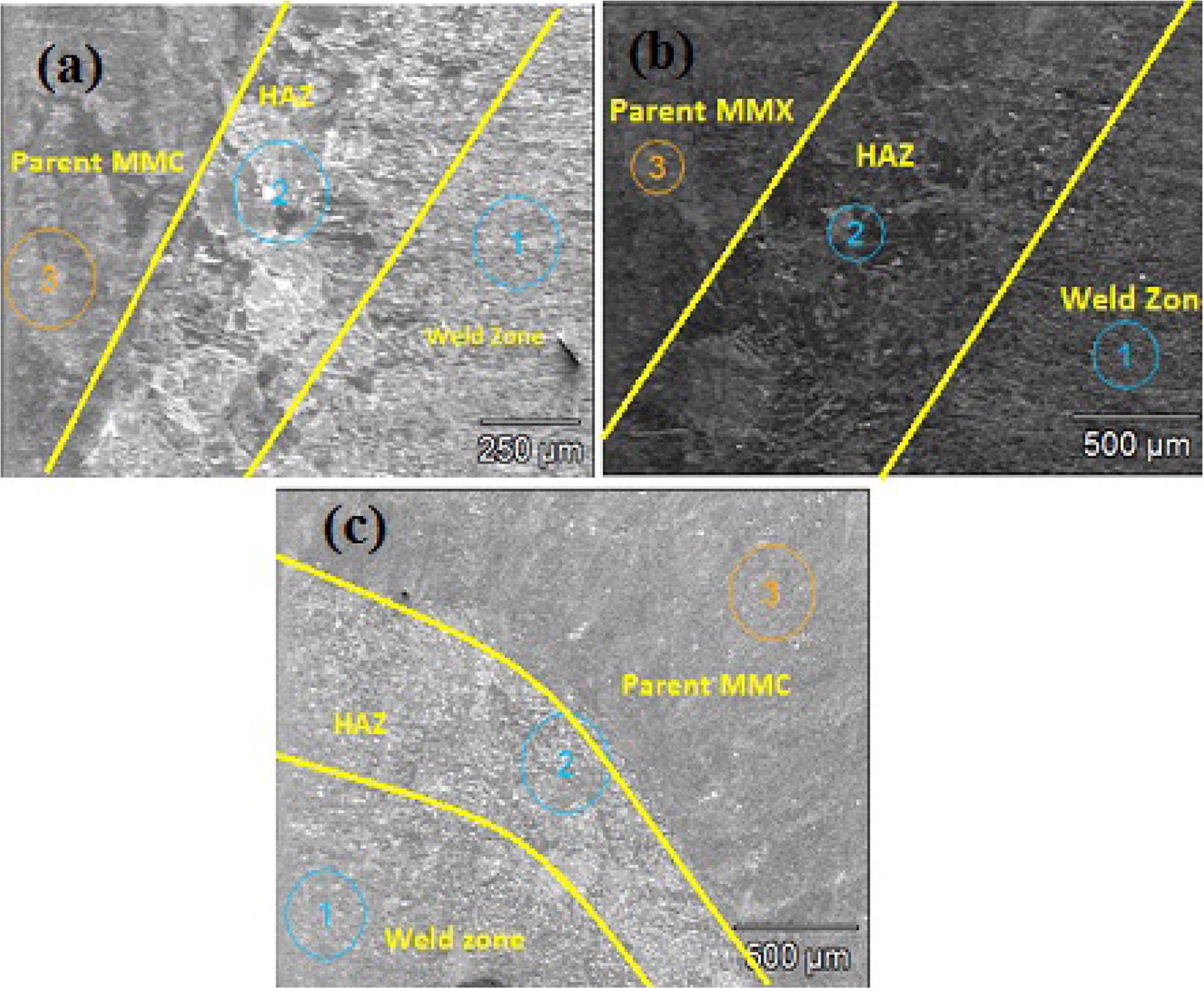

Fig. 3 shows that the optical microscopy images of

friction stir welded joints with different zones like base metal (BM),

thermos-mechanically affected zone (TMAZ), weld nugget zone (WNZ) and heat affected

zone (HAZ), also represents the size, shape and distribution

of the grain structure of reinforced particulates. Compared

all samples, the sample 1 weld zone had poor penetration and columnar dendrites

along with pores and it causing lower tensile strength. Also it has more

recrystallized structure in the TMAZ surface. Sample 2 & 3 obviously shows

that the cluster and even distribution of C particulates in the FSW’ed WNZ

surface that occurred throughout the matrix, similarly ZrO2

particulates were also evenly distributed. The FSW’ed MMCs of WNZs were

presenting columnar dendrites towards the welding direction, and the TMAZs were

found that the distribution of particles across the matrix was very fine and

uniform. But some amount of coarsening grains was observed in the friction stir

welded TMAZ surfaces of samples 1 & 2. Compared with sample 1, samples 2

& 3 ensuing improved mechanical and metallurgical properties of the welded

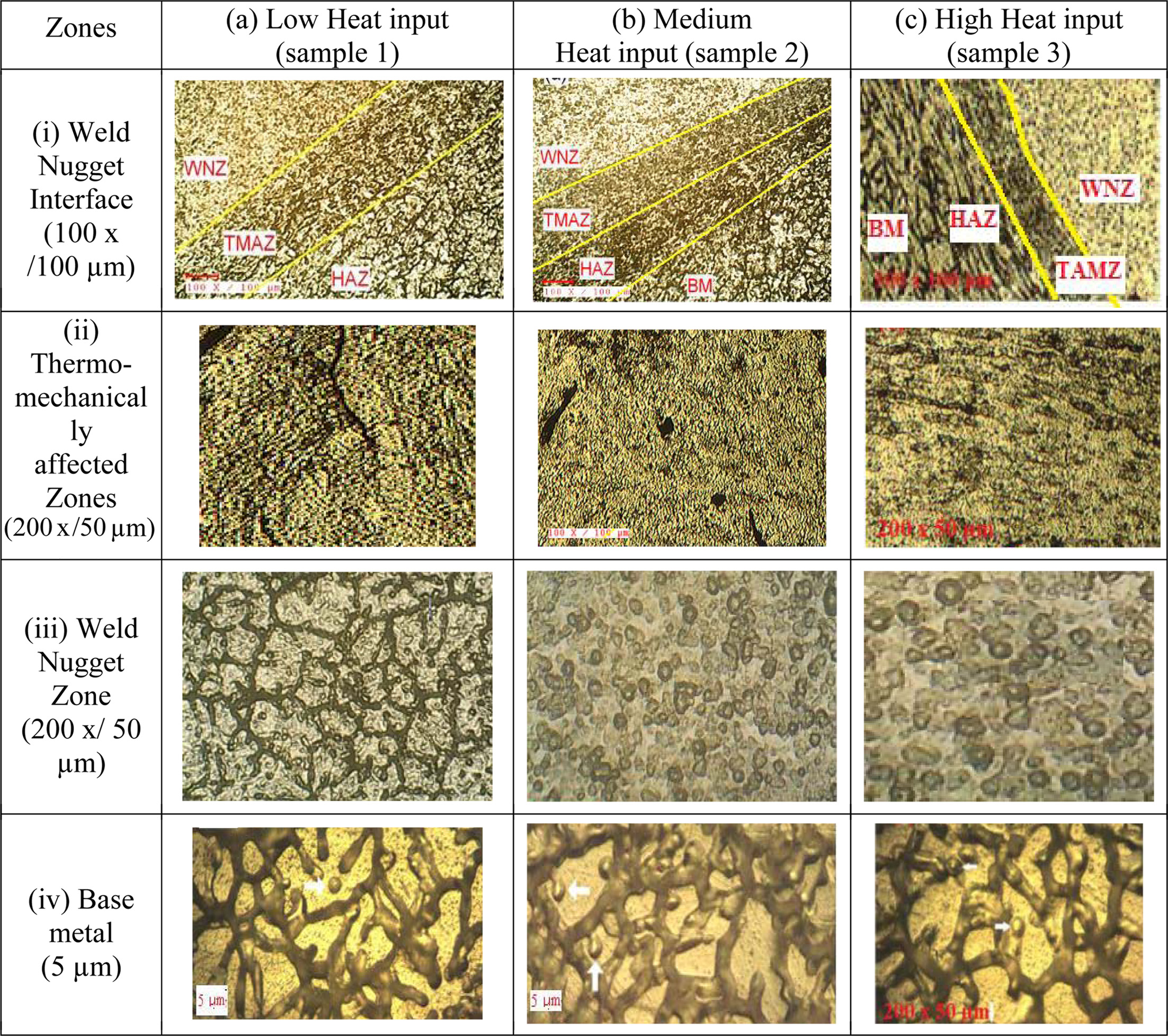

joints. The SEM with EDX spectrum analysis clearly shows the presents of other

elements like Al, Zr, SiC, Mg, C, etc. Fig. 4(a-c) shows the SEM image of the

weld nugget interface zone and also shows the matrix and reinforcement

particulates in friction stir welded MMC and highlights the defect-free joints

of the cross weld. The SEM analysis of FS welded MMC

illustrates the other weld zone like WNZ, TMAZ, HAZ and BM. As observed, in

comparison to BM, the stir zone produces finer grain structure.

The matrix of this zone exhibits a fine grain size and has low segregation.

The grain structure is evenly dispersed in

this case when compared to Low heat input and High heat input conditions.

Furthermore, as observed in section

(ii) of Fig. 3, the thermo mechanically

affected zones of the matrix under Low heat input and High heat input conditions

are very much affected by the process parameters, thereby resulting in uneven

particulate dispersion. The composite matrix under the Medium Heat input

condition has better reinforcement grain

structure dispersion and fewer particulate dislocations. Section (iii) of Fig. 3 compares the Weld nugget

zone of the composite matrix under Low, Medium and High heat inputs. Here the Medium heat input zone is

observed to have better phase

dispersion between the base metal matrix and particulate reinforcements. Section

(iv) compares the base metal under similar conditions as above, therefore there

are no significant differences observed in cases of heat input.

Chemical

composition

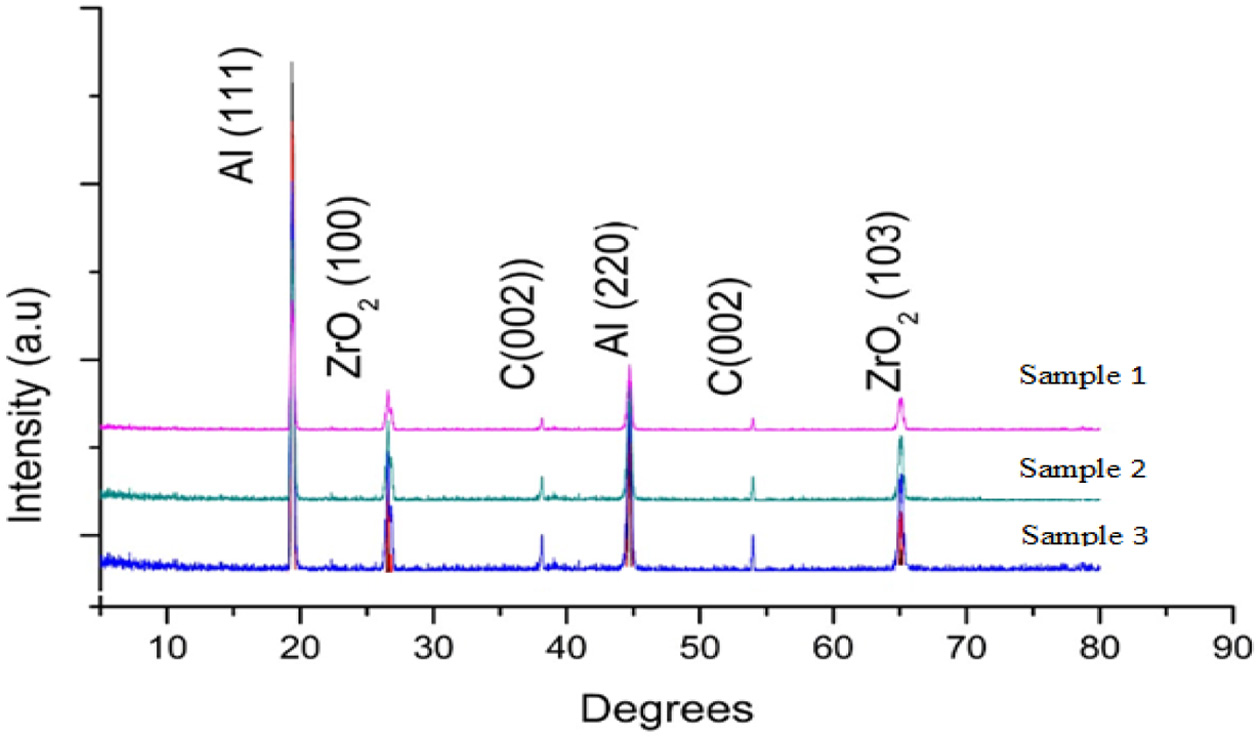

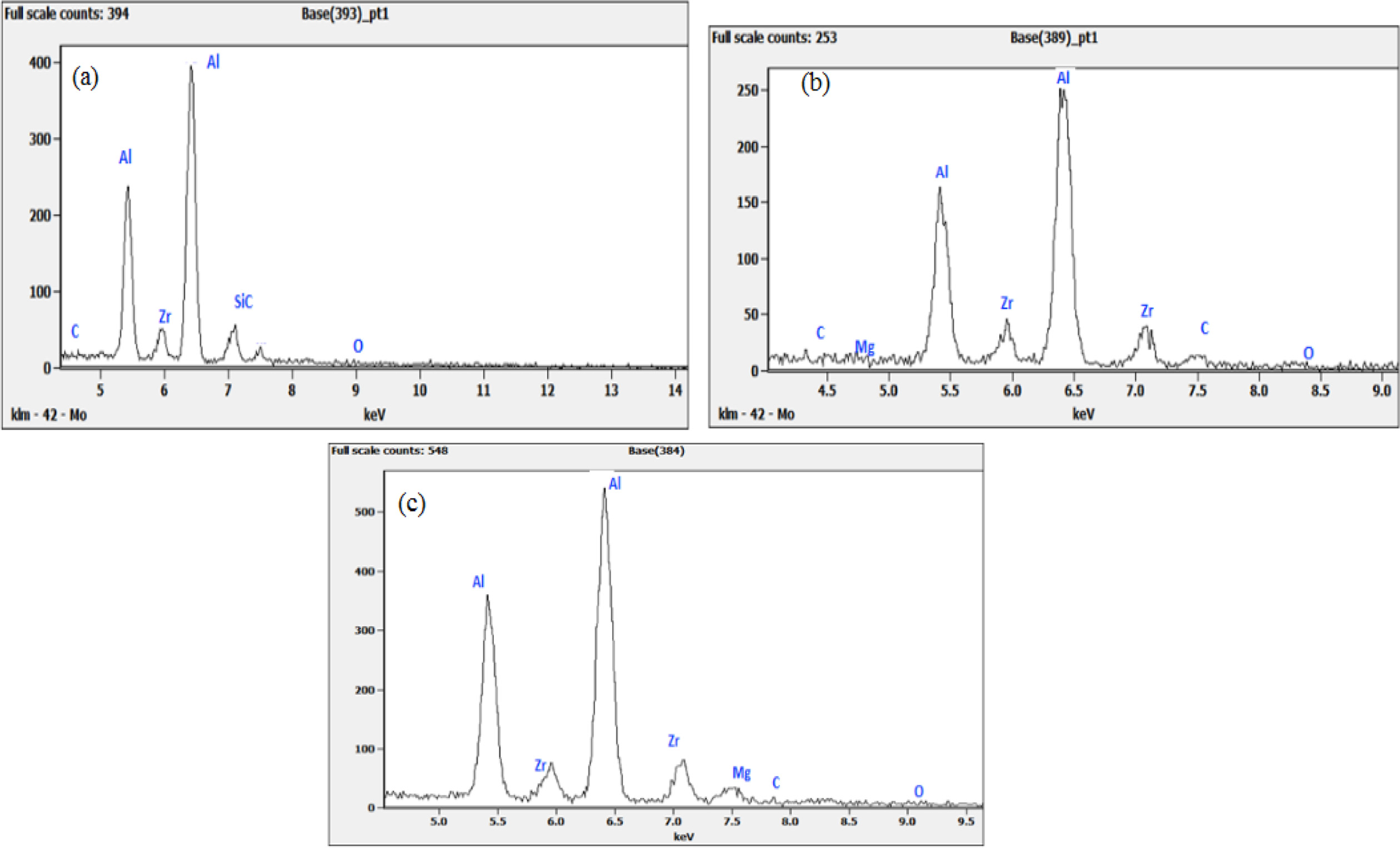

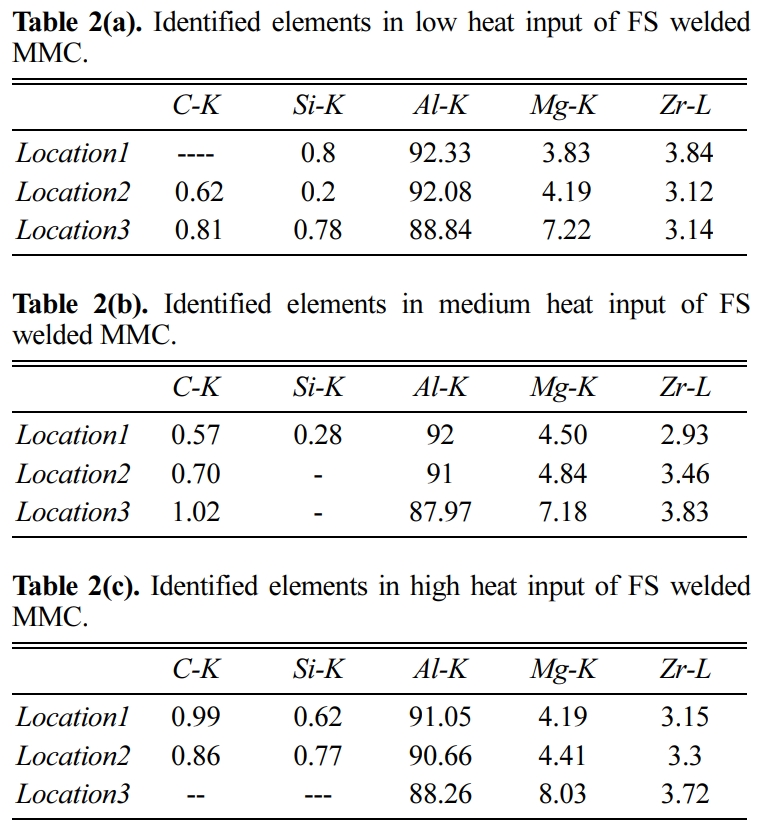

The chemical composition of the FSW’ed MMCs was measured

in the WNZs, and it presented the amount of alloying elements. Fig. 5 shows the

XRD analysis of FS welded AMMC with different heat input conditions like low,

medium and high. It also shows the presence of reinforcement particulates in FS

welded AMMCs materials. Fig. 6(a-c) shows the spectrum analysis of three

samples, and the presence of matrix and oxides can also be noticed. The zones

are marked in SEM image Fig. 6(a-c) at lactation 1, 2 and 3. Table 2(a-c) shows

the presence of elements in FS welded MMC at three different weld zones. The

EDS analysis clearly shows the present alloying elements such as Al, Zr, Si, C,

Mg, etc. in the MMCs welded zones. It has proven the uniform distribution of

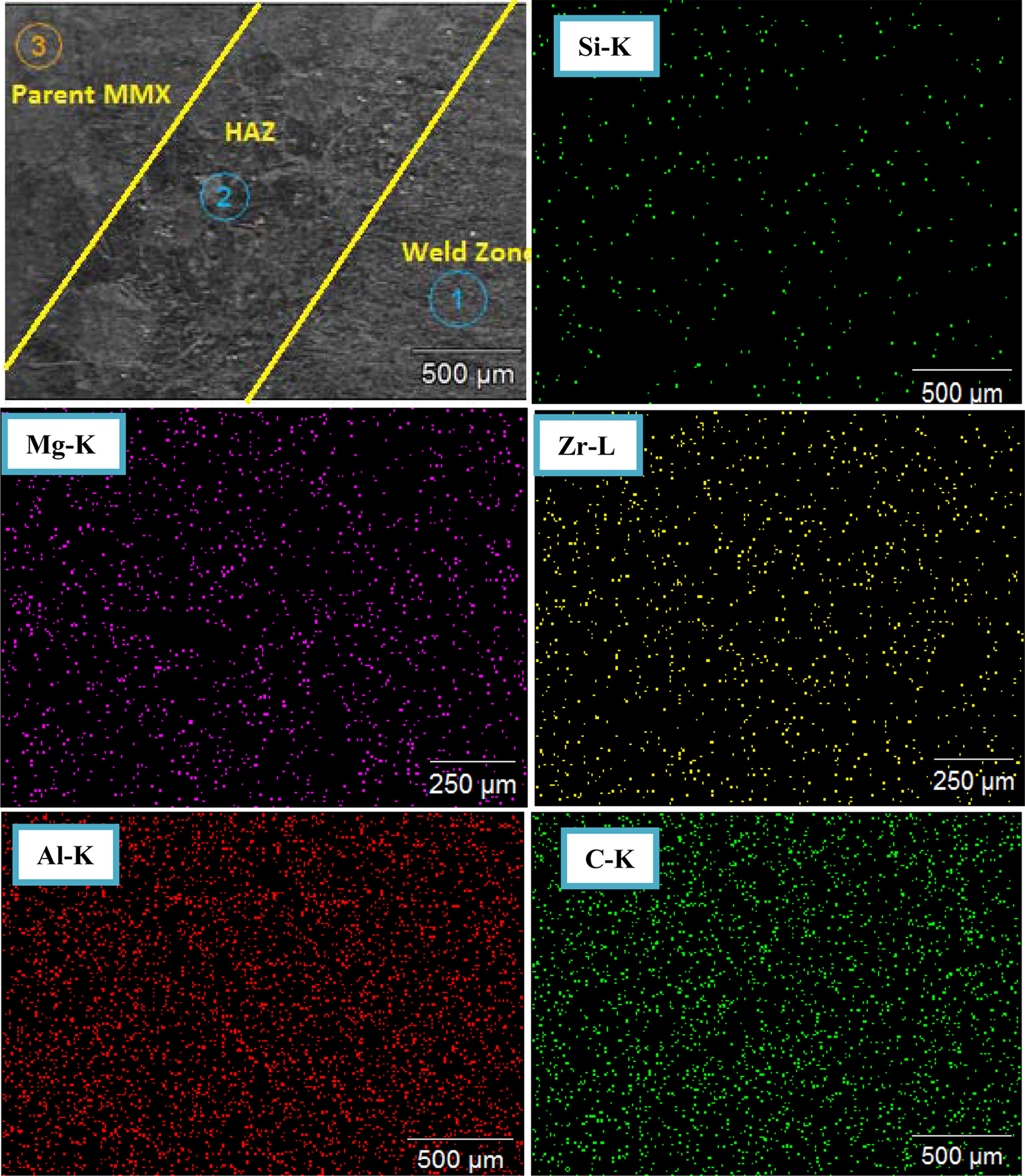

matrix and uniform micro structure of FSW’ed zones. Fig. 7(a) shows that the

matrix elements of sample 1, and few amount of matrix were present in uneven

distribution (uneven mixing) due to insufficient heat input, having poorer

mechanical properties. But sample 2 & 3 shows that the uniform distribution

of matrix (even mixing) because of sufficient heat input, and it has improved

mechanical and metallurgical properties. The identified alloying elements of FS

weld MMCs were recorded in Table 3, Fig. 7(b-f) were showed friction stir

welded MMCs EDAX element mapping.

Mechanical

properties

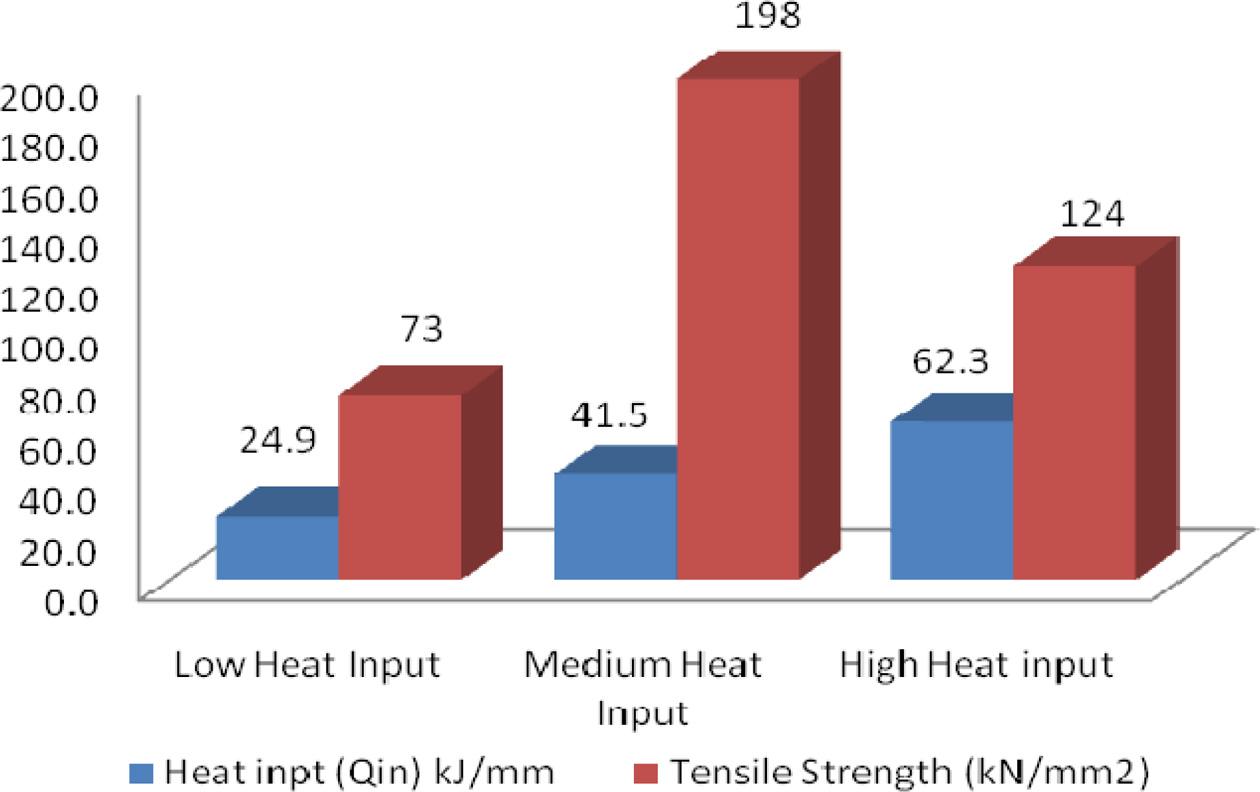

The mechanical properties such as Tensile Strength and

Hardness were measured after FSW’ed MMCs samples. By comparing three samples,

the sample 1 resulting lower tensile strength comparing with other two samples

(sample 2 & 3) due to insufficient heat input and uneven distribution of

matrix. Sample 2 & 3 ensuing higher tensile strength because of fine micro

structure and even distribution of matrix. These are all shown in Fig. 8.

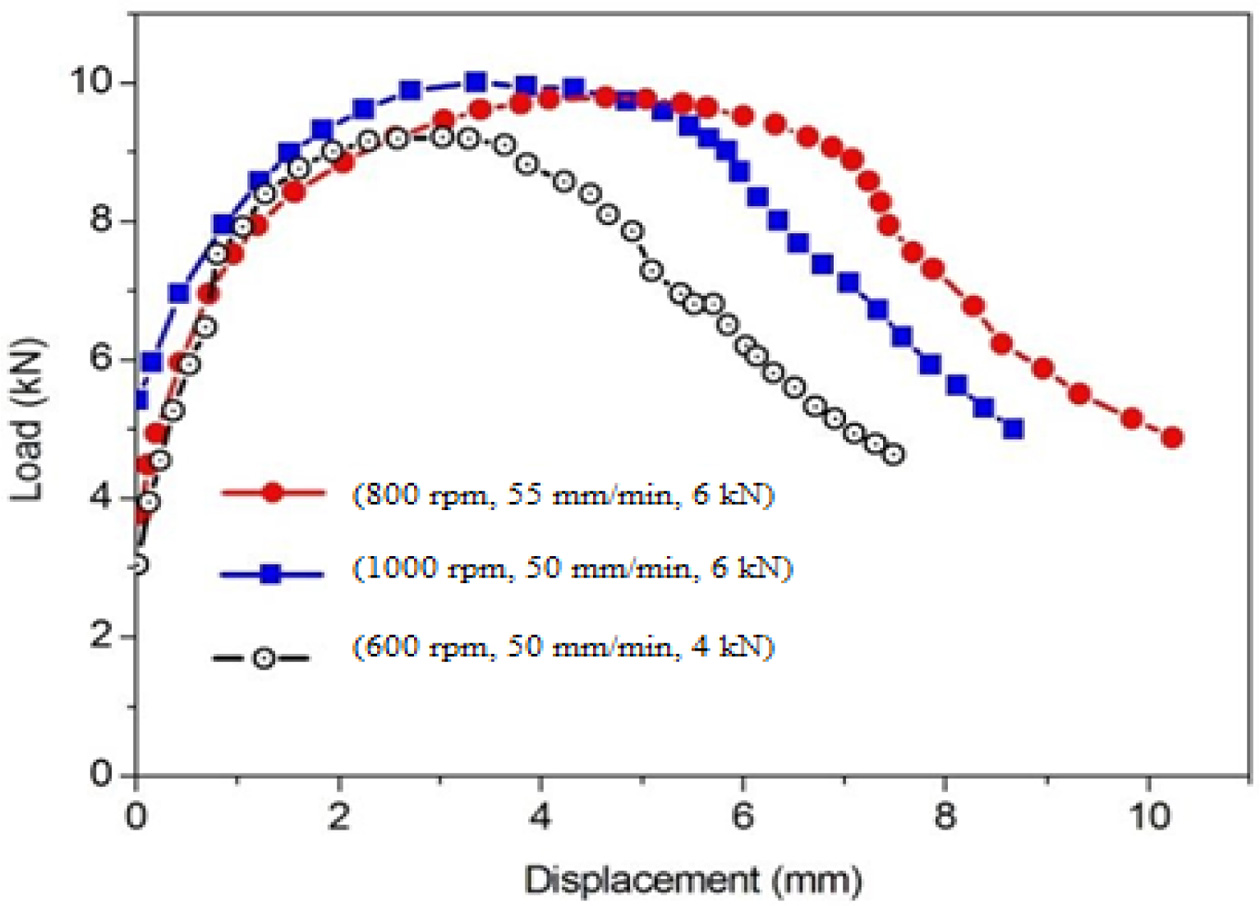

The significant contribution of reinforcement in the MMC

can be analyzed from Fig. 9. It is noticed that the variation in load-bearing

capacity of FS welded MMC is decreased by increasing the

heat input generation during FSW process. The maximum

breaking load of FS welded MMC is improved by lowering of heat generation to

the intermediate (Medium) conditions. Similarly the maximum displacement and

displacement at the breaking load of FS welded MMC is reduced by

increasing of heat generation and dispersion of reinforcement

due to stirring action of the FSW process. Due to

ceramic particulate reinforcement, it loses its strength rapidly during plastic

deformation.

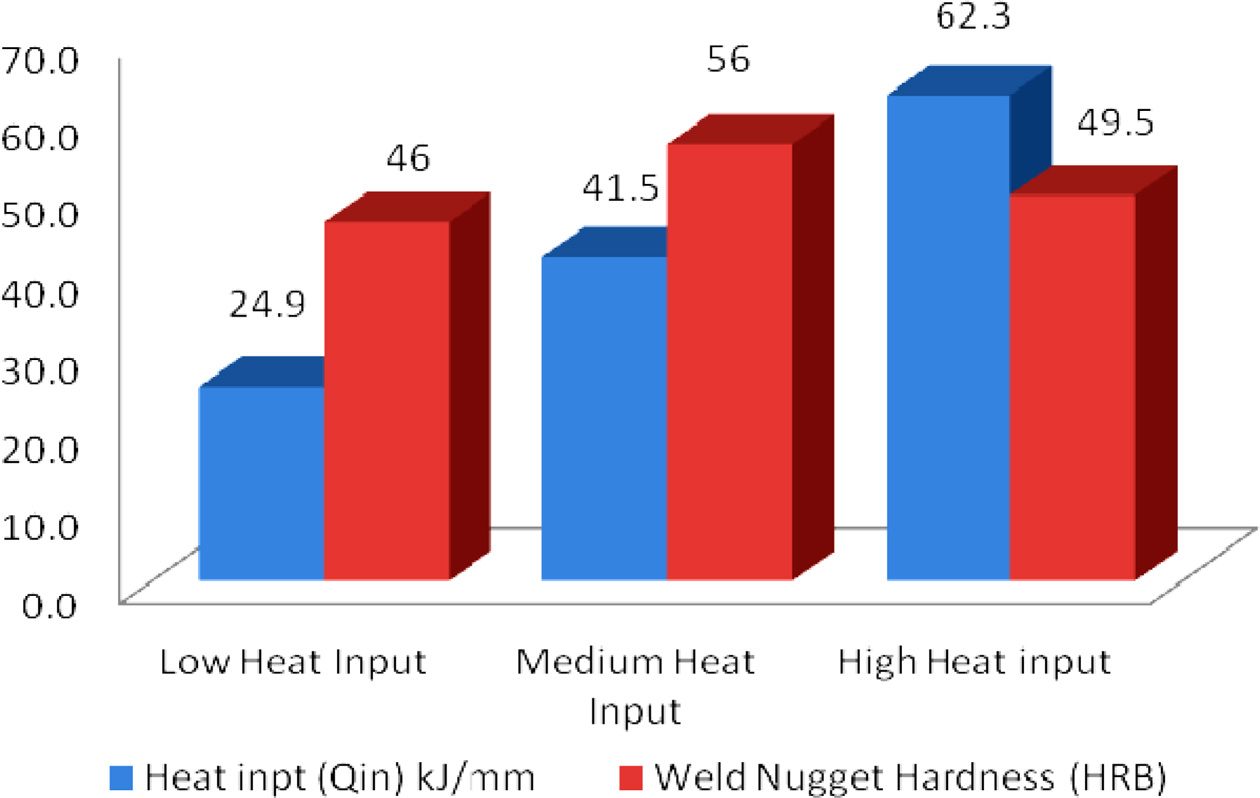

The hardness levels of the FSW’ed MMCs joints are shown in

Fig. 10. The higher hardness values were observed in

the sample 2 & 3 due to columnar dendrites with fine

and uniform mixing of matrix. Sample 1 has the resulting lower hardness value

compared to other samples because of its uneven mixing of matrix due to the

insufficient heat input.

The process parameters for these conditions were as

follow: For Low Heat Input condition, the parameters were: Tool Rotational

Speed -600 rpm, Welding Travel Speed- 50 mm/min, Axial Force- 4 kN

and the obtained Tensile strength and Hardness values were 73 kN/mm2

and 56 HRB respectively. Correspondingly, the process parameters for the Medium

Heat Input condition were: Tool Rotational Speed - 800 rpm, Welding Travel Speed-

50 mm/min, Axial Force- 5 kN, observed Tensile strength

-198 kN/mm2 and Hardness of 46 HRB. In the case of High Heat Input condition,

the parameters were, Tool Rotational Speed -1000 rpm, Welding Travel Speed- 50

mm/min, Axial Force- 6 kN which resulted in the observed Tensile strength of

124 kN/mm2 and Hardness of 49.5 HRB.

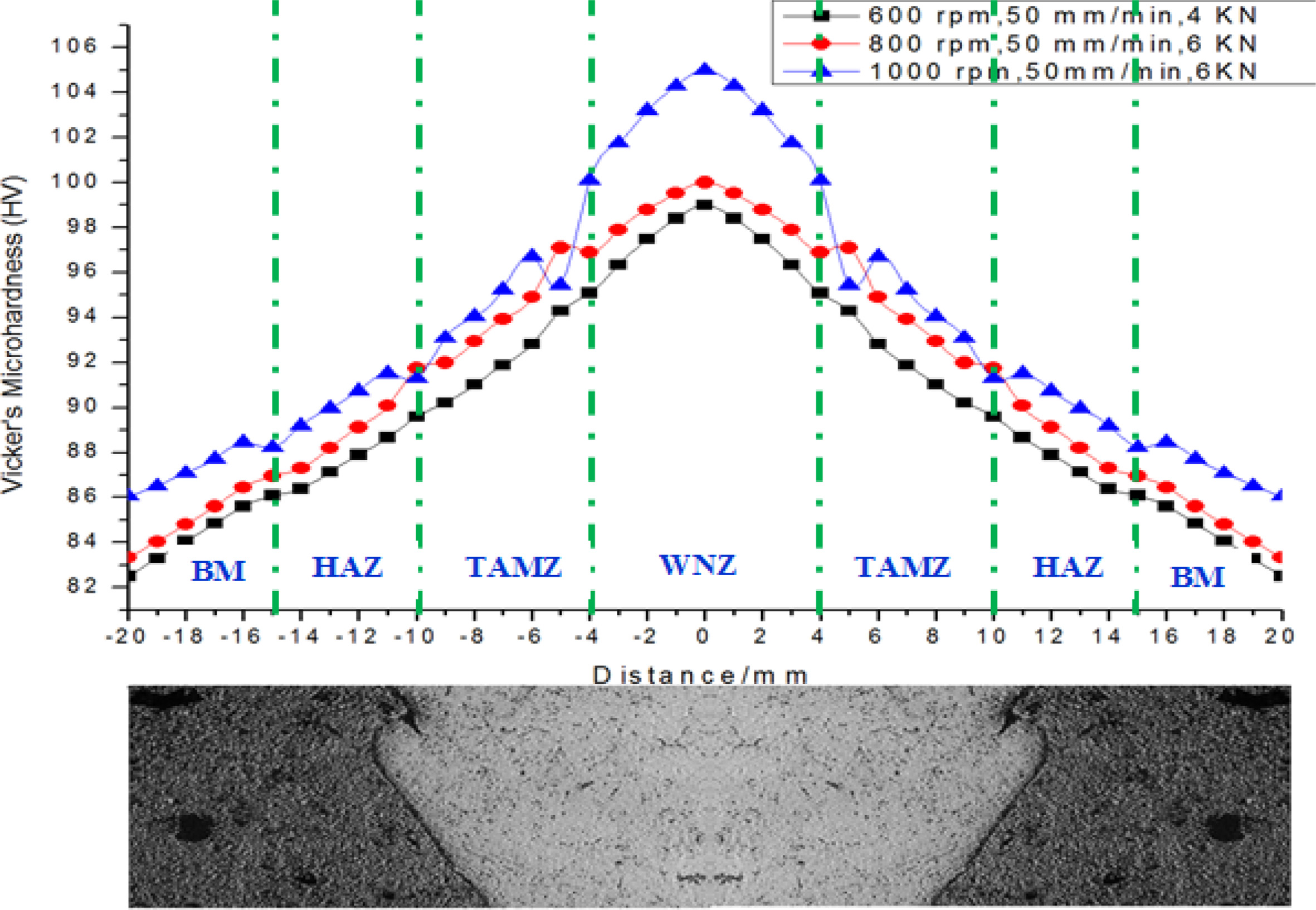

While Fig. 11 shows that the micro-hardness survey of

friction stir welded MMCs, it also proves the uniform mixing of

matrix and uniform heat inputs during entire friction stir welding process. In

micro-hardness survey analysis, the whole surface of FSW’ed joints was measured

against the affected zones. The result of the survey

provides accurate and detailed information about the surface

features of FSW’ed AMMCs that have fine microstructure

and multi-phases of homogeneous matrix. The weld nugget zone (WNZ)

was considered as the centre-line for the hardness measurement of test sample’s

surface, based on the centre-line the hardness values that were measured on

both sides (negative and positive) of the surface against the zones. From the

survey result, found the WNZs had highest hardness value compared with other

zones, also found the hardness values gradually reduced from centre-line to

tail ends on both sides and zones had approximately equal value range on both

sides. Based on the hardness values, the hardness range of the zones are in the

manner of

BM < HAZ < TMAZ < WNZ > TMAZ >

HAZ > BM. Furthermore, it was

found that Sample 2 & 3 ensuring higher hardness value at all zones in

comparison with sample 1 because of the uniform mixing of matrix due to the

sufficient heat inputs. The hardness is measured in Vickers Hardness scale

(HV).

|

Fig. 2 SEM micrograph of stir cast MMC material (a) sample 1, (b) sample 2, (c) sample 3. |

|

Fig. 3 Micro structural analysis FS welded MMC (a) sample 1, (b) sample 2, (c) sample 3. |

|

Fig. 4 SEM micrographs of FSW’ed MMCs of (a) Sample 1, (b) Sample 2, (c) Sample 3. |

|

Fig. 5 XRD analysis of FSW’ed MMCs of (a) sample 1, (b)

sample 2, (c) sample 3. |

|

Fig. 6 Spectrum analysis of FSW’ed MMCs of (a) sample 1, (b) sample 2, (c) sample 3. |

|

Fig. 7 (a) SEM images of FS welded MMC, (b)–(f) EDAX results from designated area for element mapping. |

|

Fig. 8 Tensile strength Analysis of FS welded MMC. |

|

Fig. 9 Load-displacement curve of FS welded joint in MMC. |

|

Fig. 10 Hardness analysis. |

|

Fig. 11 Micro-hardness survey Analysis of FS welded MMC. |

This

investigation has dealt with the metallurgical characterization of Friction

Stir Welded MMC and has observed that, the homogeneously distributed reinforcements and recrystallized grain structures

were the predominant characters of the weld zone. In the FSW’ed joints, the

weld nugget zones resulted in columnar dendrites along with even mixing of

matrix and fine microstructure, also observed the grains coarsening in the TMAZ

of the FSW’ed joints of AMMCs. During the FSW process, an optimum (Intermediate)

heat input resulted in even mixing of matrix, obtained higher mechanical and

metallurgical properties of the joints whereas, insufficient heat input lead to

uneven mixing of matrix, obtained lower mechanical and metallurgical properties

of the joint.

Metallurgical characterizations of the welded MMC were

done by SEM, EDX and EDX analyses. Microstructure comparison was done between

the WNZ, TMAZ, HAZ and BM under three heat input levels: Low heat input, Medium

heat input, and High heat input conditions. The Tensile strength and Hardness

are higher in the case of the Medium Heat Input condition when compared to low

and high heat input conditions. The process parameters for the Medium Heat

Input condition were: Tool Rotational Speed - 800 rpm, Welding Travel Speed- 50

mm/min, Axial Force- 5 kN, observed propertied were: Tensile Strength -198

kN/mm2 and Hardness of 46 HRB. The weld nugget hardness was found on

the WNZ, TMAZ, HAZ, and BM. The maximum micro hardness of 62.3HRB was observed

under 800 rpm Tool Rotational Speed, 4 mm/min Welding Travel Speed, 6 kN of

Axial Force.

- 1. W.M. Thomas, E.D. Nicholas, J.C. Needham, M.G. Murch, P. Temple-Smith, and C.J. Dawes, GB Patent No. 9125978.8 (1991).

-

- 2. A. Urena, M.D. Escalera, and L. Gil, Comp. Sci. Tech. 60[4] (2000) 613-622.

-

- 3. D. Storjohann, O.M. Barabash, S.S. Babu, S.A. David, P.S. Sklad, and E.E. Bloom, Mett. Mat. Trans. A. 36A (2005) 3238-3247.

-

- 4. F.F. Wang, W.Y. Li, J. Shen, S.Y. Hu, J.F. dos Santos, Mat. Des. 86 (2015) 933-940.

-

- 5. Y.Z. Li, Q.Z. Wang, BL. Xiao and Z.Y. Ma, J. Mat. Process. Tech. 251 (2018). 305-316.

-

- 6. A. S. Zoeram, S.H.M. Anijdan, H.R. Jafarian, and T. Bhattacharjee, Mat. Sci. Engg. 687 (2017) 288-297.

-

- 7. J. Guo, P. Gougeon, F. Nadeau, and X.G. Chen, Can. Metall. 51[3] (2012) 277-283.

-

- 8. P. S. Kumar, S.R. Shastry, and A. Devaraju, Mat. Tod. Proc. 4[2] (2017) 330-335.

-

- 9. P. Vijayavel and V. Balasubramanian, J. All. Comp. 729 (2017) 828-842.

-

- 10. R. Pandiyarajan, P. Maran, S. Marimuthu, and K.C. Ganesh, J. Mech. Sci. Tech. 31 (2017) 4711-4717.

-

- 11. X.J. Wang, N.Z. Wang, L.Y. Wang, X.S. Hu, K. Wu, Y.Q. Wang, and Y.D. Huang, Mat. Des.57 (2014) 638-645.

-

- 12. A.A. Seyed, P. Hassan, and M. Mahdi, J. All. Comp. 724 (2017) 859-868.

-

- 13. R. Ashok Kumar, M.R. Thansekhar, Metallofiz. Noveishie Tekhnol. 41[2] (2014) 203-211.

-

- 14. R. Pandiyarajan, P. Maran, N. Murugan, S. Marimuthu, and T. Sornakumar, Mat. Res. Exp. 6[6] (2019) 066553.

-

- 15. H. Lombard, D. G. Hattingh, A. Steuwe, and M .N. James, Engg Fracture Mech. 75[3-4] (2008) 341-354.

-

This Article

This Article

-

2020; 21(6): 690-698

Published on Dec 31, 2020

- 10.36410/jcpr.2020.21.6.690

- Received on Jul 21, 2020

- Revised on Oct 7, 2020

- Accepted on Oct 23, 2020

Services

Services

Shared

Correspondence to

Correspondence to

- R. Pandiyarajan

-

Assistant Professor, Dept. of Mechanical, K.L.N College of Engineering -Pottapalayam, Tamil Nadu-63061, India

Tel : +91 9940833549 - E-mail: pandiyan.rajan8@gmail.com

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.