- Study on the influence mechanism of sintering hydroxyapatite (HA)

Nabilah Afiqah Mohd Radzuan*, Abu Bakar Sulong, Farhana Mohd Foudzi, Mohd Yusuf Zakaria and

Mohd Ikram RamliPrecision Research Group, Department of Mechanical and Manufacturing, Faculty Engineering and Built Environment, Universiti Kebangsaan Malaysia, 43600 Bangi, Selangor, Malaysia

As one of promising

biomaterial, hydroxyapatite (HA) is potentially used as an implant component.

Yet, to date, HA still encounter difficulties to be comerciallise due to the

easily deteriorate and often fluctuate mechanical performance which depends on

the manufacturing process. Thus, this study aims to experiment the influence of

HA composition and sintering parameter on the densification, morphological analysis

and flexural strength in terms of green parts and sintered HA. The HA parts are

fabricated through the powder injection moulding process with the pressure

applied between 10 and 12 bar at 150 oC. The HA compositions

are varied of 54 wt.%, 55 wt.% and 56 wt.% while the sintering parameter are

set at 1,100 oC, 1,200 oC and 1,300 oC.

The 56 wt.% of HA parts recorded the densification of 2.13 g/cm3 and

2.95 g/cm3 for both green parts and sintered parts at 1,300 oC.

However, as the sintering temperature reduced to 1,200 oC, the

densification reached the value of 2.9 g/cm3 with the existence of

porous structure to allow tissue growth. This finding suggested that the HA

parts can be mass produce using powder injection moulding process at

1,200 oC, with a minimum existence of porosity to allow tissue

growth in between the HA structure.

Keywords: powder injection moulding, flexural strength, densification

Hydroxyapatite (HA) shows a similar property as natural

bone based on its chemical compound and structures [1, 2]. Due to this

similarity, HA often used as a bone fillers which enhances growths of natural

tissues as much as potential in connect of bone tissues firmly via the chemical

bonding [3]. Even though, to date, there are extensive research performed

involved the use of HA incorporated either with Titanium alloys or even

Stainless steel (SS316L) materials, yet the optimum that meet the main purpose

of implant materials are yet to come [4]. There are many factors which leaden

the use of HA materials as implant materials including its deficient mechanical

properties that is obvious [5]. Current development reported that coated

implant using HA coated seems promising due to its excellent and progressive

biocompatibility and osteoconductive behavior [6]. However, this technique has

major limitation in terms of latest manufacturing technology that required

depth knowledge and under- standing

of HA materials itself to be mass manufactured and

commercialize. Based on this information, the standard and most common process

are applied in this research involving the powder injection moulding process

[7].

Powder injection moulding (PIM) known as an efficient

process especially when producing a small product components with complex and

acquired high precision of the net shape [8, 9]. Gather potential in

gaining trust among researchers and industrial, PIM process able

to produce a green part as the densification, strength

and defects can be easily determined [10, 11]. Those selected green parts

will later undergo debinding and sintering process to strengthen the structures

[4, 12]. Flexibility offer via this PIM process ensure the parameter

to be adjusted based on needs and sensitivities [12, 13].

Although some investigation has move towards additive

manufacturing (AM) in developing implant materials, yet difficulties often

related with the melting and geometrical precisions [14, 15]. Controlling

its porosity and sintered structured seems much more effective based on current

availability and technology in today’s market [16].

Also, studies reported that the occurrence of porosity

structure within the HA components are crucial as its allowed tissues growth

and filled the porous structure [4]. In fact, studies exhibited that sintering

temperature plays the main domain in the fabrication of implant biomaterials as

its can easily affects the overall thermal stability and mechanical performance

[5]. Therefore, this study aims to investigate the HA materials

fabricate by PIM process using different HA compositions and

sintering parameter in order to identify the influence mechanism of inner HA

structure.

Materials

Raw material of hydroxyapatite (HA) were collected from

Sigma Aldrich Sdn. Bhd., Malaysia with the chemical composition of Ca5(PO4)3OH

in powder form with an average particle sizes of 5.34 µm. The HA was supplied

in spherical shape geometry which suitable for future manufacturing process

using powder injection moulding. Also, low-density

polyethylene (LDPE) used was collected from Cosmothene, The Polyolefin

Company (Singapore) Pte. Ltd. These LDPE used were selected based on its

ability as a binder and a backbone which hold the shapes of the samples before

being debind during the end of the fabrication process. The palm stearin that

supplied by Sime Darby Sdn. Bhd. acted as a lubricant during the powder

injection moulding process.

Fabrication

process

The critical powder volume percentage (CPVP) of the HA

used were determined at various powder loading including 54 wt.%, 55 wt.% and

56 wt.% based on ASTM D-281-31 [8]. Also, as for the binder, 60 wt.% of palm

stearin and 40 wt.% of LDPE were later added onto the HA powder and mixed using

the Brabender mixer, roller motor types at rotational speed of 30 rpm and

operational temperature of 150 oC. The prepared feedstock was

than undergo the rheological analysis using Shimadzu CFT-500D machine with the die

diameter of 1 mm and 10 mm long based on ASTM D-3835 to

ensure flowability of the feedstock and identify the injection parameter used.

The prepared feedstock then injected using powder injection

moulding, model DSM Xplore with the pressure applied between 10

and 12 bar at 150 oC of operating temperature. The injected

compound is known as green part with the diameter of 5 mm and 20 mm height.

Debinding

and sintering process

The injected green part was debind by chemical debind and

thermal debind in order to remove the LDPE and palm stearin used as a binder in

the HA compound. The chemical debind was performed using heptane

solution prepared in waterbath, model Memmert at 60 oC

for 6 h used to remove the palm stearin. Later, the thermal debind process were

prepared to remove the LDPE by using thermal debind furnace with the operating

temperature of 500 oC for 60 min with the heating rate of

5 oC/min. The temperature of 500 oC remain for

another 60 min before being cooled to room temperature at cooling rate of

5 oC/min. the prepared green part was then sintered using

vacuum furnace, model KOREA VAC-TEC (VTC 500HTSF). Although,

the sintering process acquired several stages, the first stages involved the

heating rate of 5 oC/min till the temperature reach 900 oC

for 1 h. Through the process, only 56 wt.% of powder loading were selected and

studies using different sintering parameter; 1,100 oC,

1,200 oC and 1,300 oC. The heating rate of

3 oC/min was consistent as the temperature reach it maximum and

last for 5 hours before cooled down to room temperature with the cooling rate

of 5 oC/min.

Measurement

and characterization

The densification and porosity of the HA compound was

analysed using Archimedes principal, using Sartorius density

machine, model BSA224S-CW, according to MPIF 42 and ASTM B962 for both green

part and sintered part of the HA compound [4]. Micrographical characteristics

was observed using scanning electron microscope (SEM), model Hitachi TM-1000. The

flexural strength of the HA-compound was

measured using a three-point bending test performed using 1 tonne Universal

Testing Machine, model Instron 5567 with the crosshead speed of 0.1 mm/min [8].

The harden structure of HA compound was measured using Metallic Vickers Tester,

model HVS10 based on ASTM D785 with the maximum load applied is 200g for 15 sec

indentation time.

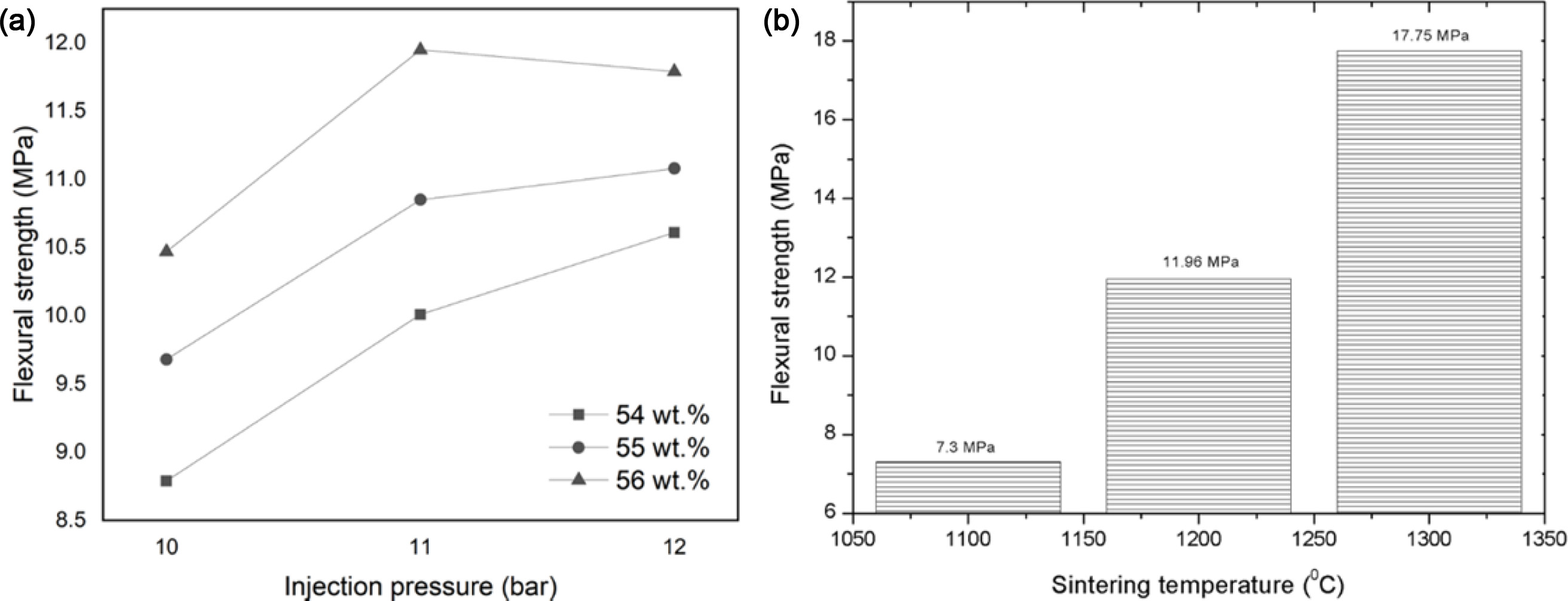

Flexural

strength of green and sintered HA part

HA green part acquired certain level of strength as it may

ease the handling process and able to be produce without any defected in which

studies using HA/Ti6Al4V reported the average flexural strength of 7.6 MPa

which slightly lower compared to these study as shown in Fig. 1(a) [1]. These

demonstrate that there is an improvement in term of green part strength as the

HA compound itself able to reach the minimum of 8.79 MPa for 54 wt.% of powder

loading as seen in Fig. 1a. Although, it is clearly exhibited that the increase

trend of flexural strength reflected the increment of the powder loading which

in consistent with finding using 15 wt.% and 25 wt.% of HA-Al2O3

materials that obtained the maximum strength of 0.25 MPa and 1.01 MPa,

respectively [17]. Also, results indicated that the optimum

injection pressure is 11 bar with the maximum value of

flexural strength of 11.79 MPa at 56 wt.%. Studies reported that suppling less

pressure will result some defects including short sort

occurrence. In contrast, studies reported that by supplying

injection pressure at 13 MPa the maximum strength obtained only at average of

7.6 MPa [1]. These certainly listed in Fig. 1(a) as the pressure increase to 12

MPa, the flexural strength of the HA green part started to deteriorate to 11.78

MPa and remained stagnant. Studies using HA sintered part recorded the

depletion of flexural toughness from 0.65 MPa.m1/2 to 0.4 MPa.m1/2,

as the pressure increase between 7.8 MPa to 62 MPa which explained the phenomenon

occurrence in this study [18]. These supported results indicated in Fig. 1(b)

in which the flexural strength of sintered HA was improved from

7.3 MPa to 17.75 MPa as the sintering temperature increase from

1,100 oC to 1,300 oC, respectively. These are

corresponded to morphological analysis and densification discussed on following subtopics in which the

sintered HA harden and results in excellent flexural strength due to the

occurrence of grain growth and minimum existence of porosity [19].

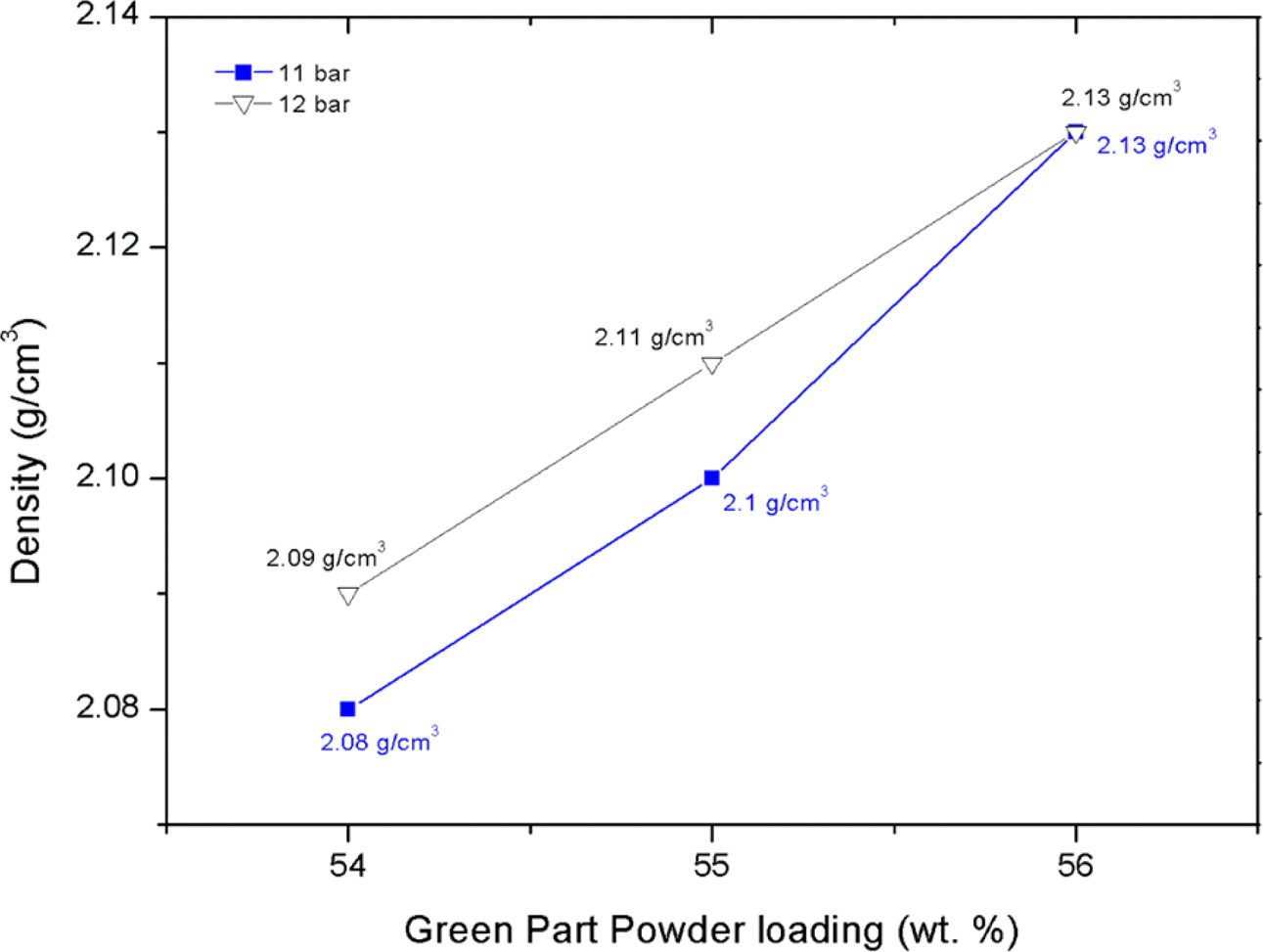

Desitication

of HA compound

Densification of the HA compound were details in Fig. 2 in

which as the temperature maintained 150 oC the prolonged

densification acquired the same value of 2.13 g/cm3 even though the

pressure applied were different. These clearly exhibited that the pressure and

powder loading examine do have a prominent effect, consistent with studies

reported using the HA powders in which the density of the compound are

dramatically increase before shows a plateau sign [20]. Although, the

temperature did not gave any significant different on HA green part, yet, the

powder loading clearly indicated that increase in powder

loading will drastically increase the densification of the HA

compound. As the powder loading increase, theoritically it will cause more

compact structure and allow agglomerations occurancce. Also, the densification

remain constant as the powder loading increase shows that the abilities of

tissues growths to dissolve within these porous HA structures especially after

being sintered.

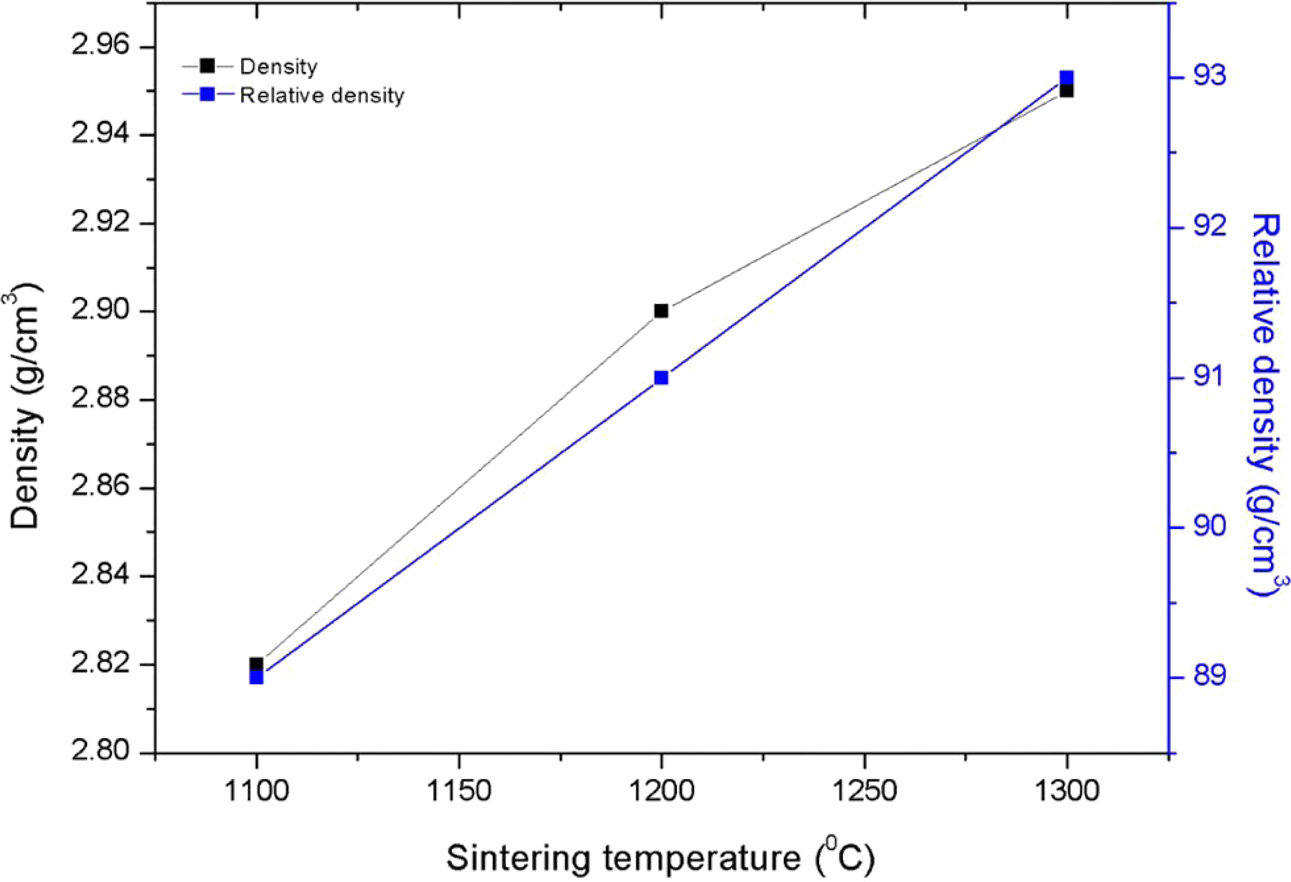

The HA green parts were then sintered and analysed as

shown in Fig. 3 which the density of sintered parts increase as

the sintering temperature increase. Although, the

densification of the overall sintered part increase at the minimum amount of

2.82 g/cm3, its clearly demonstrate that the HA parts are now

solidified hence, results in strengthen its overall structure. Also, as the

sintering temperature rise to 1,300 oC, the maximum

densification recorded at 2.95 g/cm3. Studies using ceramic

materials reported that the sintering temperature of

1,300 oC, seems an acceptable temperature which reveals

a pure material [21]. These phenomena indicated that any

higher temperature will only worsen its properties. Moreover, the study also

posted that as the sintering temperature increase to 1,300 oC,

the structure of materials tends to encounter a grain growth which reflected

its densification. However, the results obtained in this

study slightly contrast with other study using HA-sodium alginate materials in

which the sintering temperature between 1,000 oC and

1,100 oC The study reported that the acquired densification

values remain in average of 1.82 g/cm3. These are due to the fact

that as the sintering temperature increase, the sodium alginate started to

dwindle hence the densification of produce HA-sodium alginate is unstable

[17, 22]. Meanwhile, studies using SS316L-HA composites reported that insufficient sintering temperature and sintering time will lead to excessive porosity

occurrence which lower the

end-produced materials [8]. Noted that the type of solvent used during the

densification measurement has insignificant effects toward the relative

density, Fig. 3 lists the maximum density of 2.95 g/cm3 at sintering

temperature of 1,300 oC. Fig. 3 recorded that the relative

density stabilized at approximate 99% during the sintering temperature of

1,100 oC and 1,300 oC. Yet, at sintering

temperature of 1,200 oC the relative density seems slighly

lower at 96% which clearly suggestsed

the existance of excessive porosity

or agglomeration which invisible to physical view as reported by others

research [8, 20].

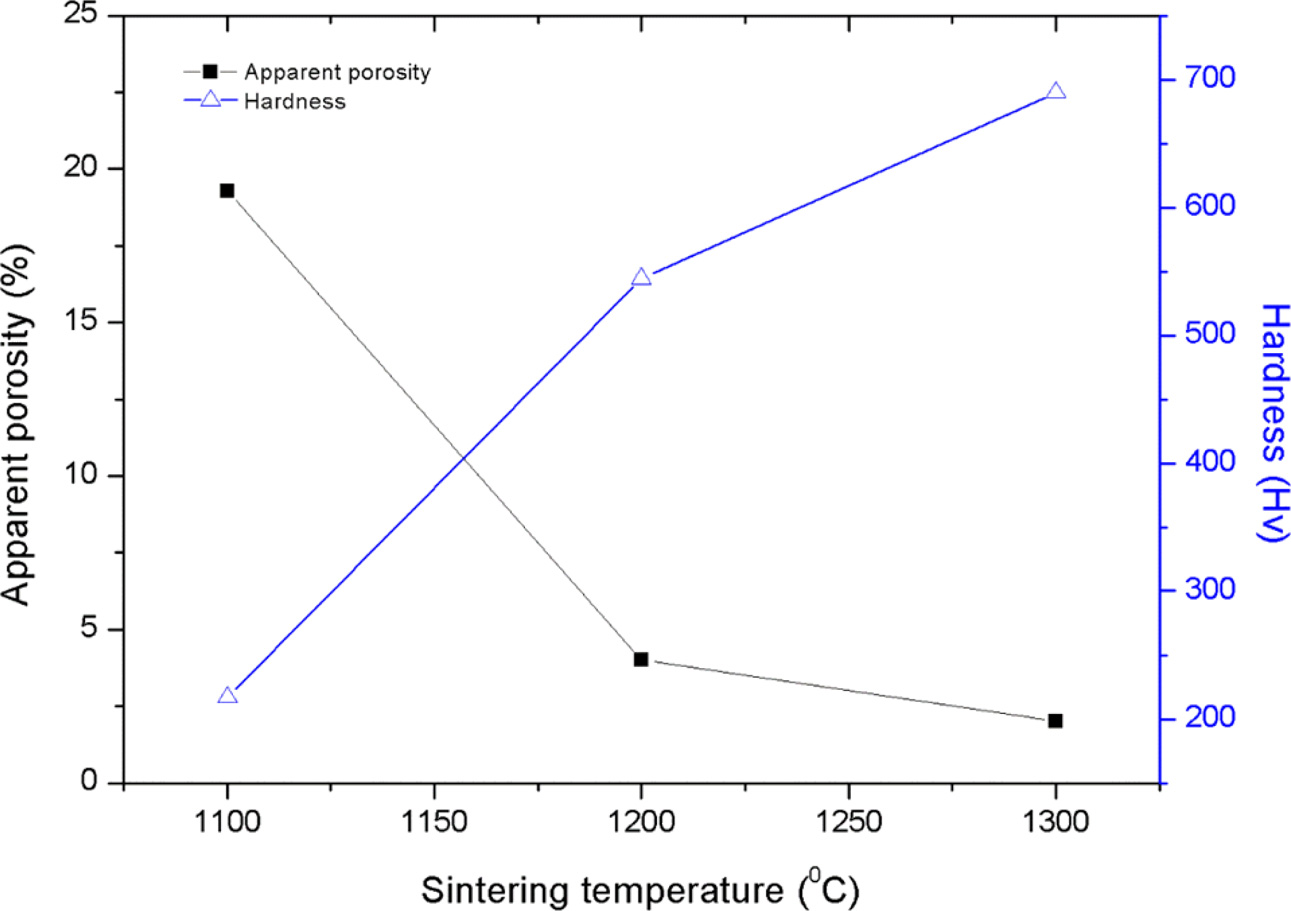

Hardness,

porosity and morphological evolution of sintered part

Fig. 4 clearly indicated that the hardness of sintered HA

parts is increase as the sintering temperature increase which in accordance

with studies using HA-sodium alginate [22]. Studies suggested that the HA

particles are closely packed hence, form a dense structure at higher sintering

temperature [23]. For instance, undoped HA usually reported with an average of

3 GPa (~305 Hv), while doped HA materials usually will further harden and able

to reach ~4 GPa [23, 24]. Yet, this study as shown in Fig. 4, able to attain

700 Hv (~7 GPa) for pure sintered HA parts due to the fact that the occurrence

of packed and grain arrangement onto the HA microstructure. Also, as seen in

Fig. 4, the increment in HA hardness are contradict with the porosity eventuate

in the HA structures. This result is constants with others findings that

reported the porosity reduction as the sintering temperature increase hence

harden the structural materials [25]. It can be noted that the maximum porosity

of 20% value recorded at 1,100 oC meanwhile, the porosity value

decreases till 2.5% as the temperature increase to 1,300 oC.

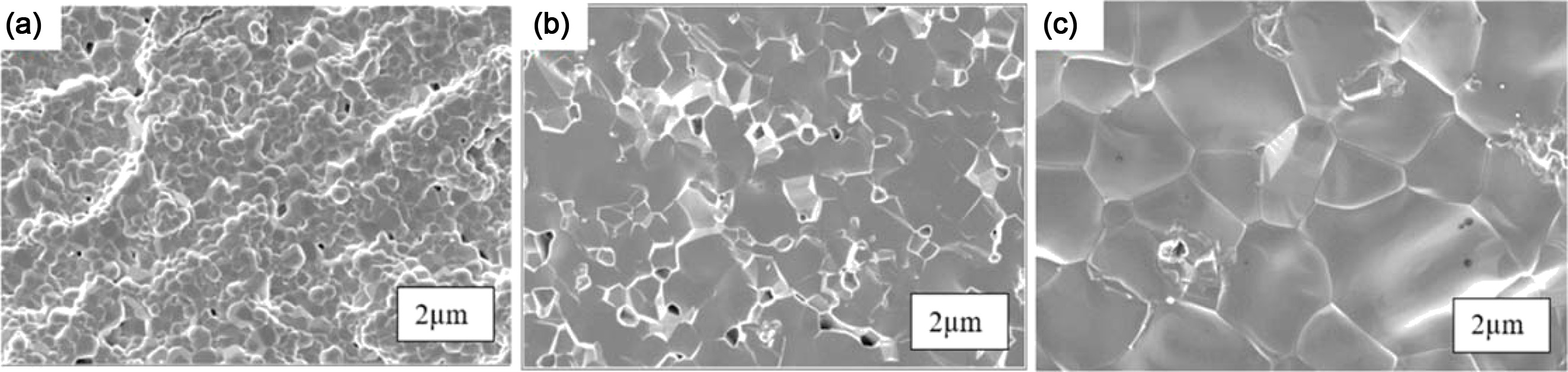

These evidences clearly indicated by Fig. 5 in which the porosity occurrence

decreased as the sintering temperature increase from

1,100 oC to 1,300 oC. Fig. 5(a) demonstrate

that the existence of porosity is obvious with no sign of grain growth.

Meanwhile, as the temperature increase to 1,200 oC, it seems

that a slight porosity emerges within the sintered HA materials as indicated in

Fig. 5(b). Also, Fig. 5(c) provided clear evidence that the

grain growth appears to minimize the porosity occurrence hence

result in very little porosity. These morphological images

correlated well with the measured density which showed

almost full of densification at temperature of

1,300 oC. Although the fully dense HA parts are not attained in

this present work, yet, the obtained data has a great potential for clinical

implant application as supported by others finding [11]. Also, studies of

ceramic materials, silicon carbides (SiC) porosity reported that the reduction

of porosity percentage as the temperature increase was subjected to the necking

behavior [26].

|

Fig. 1 Flexural strength of (a) HA green part at different injection pressure and powder loading of 54 wt.%, 55 wt.% and 56 wt.% and (b)

sintered HA part at 1,100 ºC, 1,200 ºC and 1,300 ºC. |

|

Fig. 2 Densification of HA green parts at different powder

loading. |

|

Fig. 3 Densification of HA green parts at different sintering

temperature. |

|

Fig. 4 Hardness and porosity at different sintering temperature. |

|

Fig. 5 Morphological images of the sintered HA part at sintering temperature of (a) 1,100 oC, (b) 1,200 oC, (c) 1,300 oC. |

Sintered parts of HA potential in behaviour as implants

materials as the flexural strength can reached up till 17.75 MPa meanwhile the

hardness recorded at 700 Hv that prove as the HA parts being sintered the

mechanical performance improved and strengthen due to minimum occurrence of

porosity. Also, the critical powder loading of 56 wt.% able to obtain the dense

with minimum porous structure compared to 54 wt.% and 55 wt.%. This research

also clearly highlights that as the sintered HA parts able to possess a smooth

and compact structure at 1,300 oC compared to 1,100 oC

and 1,200 oC of sintering temperature. These findings allow a benchmarks

of HA compound acquired in order to form a proper strength and

micrograph structure of implant materials. In order to allow enough

tissues growth the optimum 56 wt.% and sintering temperature of 1,200 oC

seems the appropriate parameter to be consider of.

The authors wish to gratefully thank and acknowledge the

Center for Research and Instrumentation Management (CRIM),

Universiti Kebangsaan Malaysia for their financial support to complete this

study under grant number DCP-2017-001/2.

No potential conflict of

interest was reported by the authors

- 1. A. Arifin, A.B. Sulong, and N. Muhamad, J. Syarif, and M.I. Ramli, Mater. Des. 65 (2015) 1028-1034.

-

- 2. M.R. Nikpour, S.M. Rabiee, and M. Jahanshahi, Compos. Part B. 43[4] (2012) 1881-1886.

-

- 3. Q. Peng, X. Bin, H. Xuxing, Y. Wang, Z. Peng, and Z. Tang, J. Alloys Compd. 825 (2020) 153102.

-

- 4. M.I. Ramli, A.B. Sulong, N. Muhamad, A. Muchtar, A. Arifin, and S.J. Park, J. Phys. Conf. Ser. 1198[4] (2019) 042017.

-

- 5. A. Arifin, A. Bakar, N. Muhamad, J. Syarif, and M. Ikram, J. Mater. 55 (2014) 165-175.

-

- 6. D. Arcos and M. Vallet-Regí, J. Mater. Chem. B. 8[9] (2020) 1781-1800.

-

- 7. S.B. Hein and A. Otte, Bernhard Heiden Winter. 1 (2020) 1-7.

- 8. M.I. Ramli, A.B. Sulong, N. Muhamad, A. Muchtar, A. Arifin, F.M. Foudzi, and M.S. Hammadi Al-Furjan, PLoS One. 13[10] (2018) e0206247.

-

- 9. F.M. Salleh, A.B. Sulong, N. Muhamad, I.F. Mohamed, and N.N. Mas’ood, and B.E. Ukwueze, Procedia Eng. 184 (2017) 334-343.

-

- 10. M.H.I. Ibrahim, N. Muhamad, A.B. Sulong, K.R. Jamaludin, S. Ahmada, and N.H.M. Norb, Int. J. Mech. Mater. Eng. 5 (2010) 282-289.

- 11. S. Ramesh, C.Y. Tan, S.B. Bhaduri, W.D. Teng, and I. Sopyan, J. Mater. Process. Technol. 206[1-3] (2008) 221-230.

-

- 12. E. Aygul, S. Yalcinkaya, and Y. Sahin, Mater. Res. Express. 7[3] (2020) 035402.

-

- 13. N. Verma, S. Zafar, and M. Talha, Manuf. Lett. 23 (2020) 9-13.

-

- 14. A. Tufail, F. Schmidt, and M. Maqbool, "Handbook of Ionic Substituted Hydroxyapatites" (Elsevier Ltd, 2020) p.355-381.

-

- 15. J.D. Avila, Z. Alrawahi, S. Bose, and A. Bandyopadhyay, Addit. Manuf. 34 (2020) 101241.

-

- 16. D. Yan, B. Zeng, Y. Han, H. Dai, J. Liu, Y. Sun, and F. Li, Addit. Manuf. 34 (2020) 101305.

-

- 17. G. Gunawan, A. Arifin, I. Yani, and M. Indrajaya, IOP Conf. Ser. Mater. Sci. Eng. 620 (2019) 012107.

-

- 18. S. Kobayashi, W. Kawai, and S. Wakayama, J. Mater. Sci. Mater. Med. 17[11] (2006) 1089-1093.

-

- 19. B. Cui, R. Zhang, F. Sun, Q. Ding, Y. Lin, L. Zhang, and C. Nan, J. Adv. Ceram. 9[1] (2020) 123-128.

-

- 20. H.Z. Shen, N. Guo, L. Zhao, and P. Shen, Scr. Mater. 177 (2020) 141-145.

-

- 21. N.A. Baharuddin, A. Muchtar, and M.R. Somalu, Mater. Lett. 194 (2017) 197-201.

-

- 22. N. Kanasan, S. Adzila, N.A. Mustaffa, S.M. Sidi, M.N.A. Rahman, N.F. Nasir, and P. Gurubaran, MATEC Web Conf. 135 (2017) 00063.

-

- 23. T.Y. Ching, R. Singh, T.C. Yong, and Y.B. Kar, in Procee- dings of 2016 Int. Conf. Appl. Syst. Innov. IEEE ICASI, June 2016 (2016) p.3-6.

-

- 24. L.A. Pires, L.J. de Azevedo Silva, B.M. Ferrairo, R. Erbereli, J.F.P. Lovo, O. Ponce Gomes, J.H. Rubo, P.N. Lisboa-Filho, J.A. Griggs, C.A. Fortulan, and A.F.S. Borges, Dent. Mater. 36[2] (2020) e38-e46.

-

- 25. T.G.M. Bonadio, E.R. Fiorentin, A.G. Candido, R.Y. Miyahara, V.F. Freitas, H.J. Kiyochi, L. Hernandes, J.M. Rosso, J.A. Burato, I.A. Santos, M.L. Baesso, and W.R. Weinand, Ceram. Int. 46[8] (2020) 12837-12845.

-

- 26. J.F. Zhang, X.N. Zhou, Q. Zhi, S. Zhao, X. Huang, N.L. Zhang, B. Wang, J.F. Yang, and K. Ishizaki, J. Asian Ceram. Soc. 8[2] (2020) 255-264.

-

This Article

This Article

-

2020; 21(6): 662-666

Published on Dec 31, 2020

- 10.36410/jcpr.2020.21.6.662

- Received on Jul 3, 2020

- Revised on Jul 22, 2020

- Accepted on Aug 14, 2020

Services

Services

- Abstract

introduction

experimental

results and discussion

conclusion

- Acknowledgements

- Conflict of Interest

- References

- Full Text PDF

Shared

Correspondence to

Correspondence to

- Nabilah Afiqah Mohd Radzuan

-

Precision Research Group, Department of Mechanical and Manufacturing, Faculty Engineering and Built Environment, Universiti Kebangsaan Malaysia, 43600 Bangi, Selangor, Malaysia

Tel : +603-89217190 Fax: +60389218000 - E-mail: afiqah@ukm.edu.my

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.