- ZnO nanorods-based piezoelectric nanogenerators on double-sided conducting paper

G M Hasan Ul Bannaa and Il-Kyu Parkb,*

aSchool of Mechanical and Electronic Engineering, East China University of Technology, Nanchang, Jiangxi, People’s Republic of China

bDepartment of Materials Science and Engineering, Seoul National University of Science and Technology, Seoul 01811, South Korea

We report on the voltage

output enhancement from ZnO nanorod (NR)-based bendable piezoelectric

nanogenerators (PENGs) with a conducting paper. Double-sided carbon paper

(DSCP) was used as a conducting substrate. Structural investigations by

scanning electron microscope and X-ray diffraction results showed that ZnO NRs

were successfully grown via a two-step hydrothermal process on both sides of

the CP. Photoluminescence peak intensity ratio of the band-edge to the deep

level emissions from the ZnO NRs on both sides of the CP substrate was similar

values in the range of 1.8 to 2, which indicating a similar crystalline quality

of the ZnO NRs on the front and back sides. The output characteristics from the

two PENG devices on the CP substrate showed identical piezoelectric output. The

output voltage from the DSCP-based PENG was 2.56- and 1.86-fold greater than

that from the single-sided PENG devices on only the front and back of the CP

substrate, respectively. This enhancement was attributed to the synergetic

effect between the PENGs on the front and back of CP and to the modification of

the CP’s electrical properties under an electric field generated by the PENGs

on the opposite side of the CP substrate.

Keywords: ZnO, Nanorods, Nanogenerator, Hydrothermal, Piezoelectricity

The increasing popularity of mobile and portable devices

for internet of things technologies has concen- trated research focus on potential

sustainable powering systems, including electrical energy scavenging from ubiquitous

ambient energy such as nuclear, mechanical, thermal, and electrochemical

energies. Transforming mechanical energy into electrical energy is a promising

avenue anytime and anywhere because of its abundant availability

in the human body and surrounding environ- ments, such as bodily fluid

movement, muscle stretching, mechanical

triggering, and airflow [1-5]. There are three energy conversion techniques

from mechanical sources based on triboelectric, electromagnetic, and piezoelectric

principles [6]. And piezoelectric energy harvesting has attracted strong

attention for energy harvesting ever since the first demonstration

of a one-dimensional nano- structure-based

piezoelectric nanogenerator (PENG) in 2006 and the subsequent improvements in

performance for practical applications [5-14].

Among the piezoelectric materials for self-powering PENG

applications, ZnO has become the most popular due to its adaptability to a wide

variety of substrates, such as silicon, sapphire, metal sheet, and conducting papers

for fabricating nanostructures [10-14]. In addition, it exhibits

superior piezoelectric, semiconducting, non-toxic, and

biodegradability properties due to its asymmetric hexagonal

wurtzite structure and polar crystal structure. The development of self-powering

electronic devices by using piezoelectric materials like ZnO has primarily

focused on enhancing the output power of PENGs by combining

various technologies, including modification of

device structures or hybridization with other harvesting technologies

such as solar or chemical energies [14-18]. However, recent focus has shifted

to the flexibility of PENG devices in order to widen their potential

applications to, for example, in-vitro sensors to monitor health conditions by

a pressure sensor and paper-based diagnosis for fast and reliable detection,

textile, or wearable electronics where flexibility is needed

[15, 19, 20]. Therefore, current investigations

are focusing on various structures and material systems, including sandwich

structures, hybrid composite structures, Schottky-contact

structures, and novel 2D materials [19-21]. In this paper,

we report the growth of ZnO nanorods (NRs) on flexible

and conductive substances. Concerning the flexibility of devices, one of

conducting paper, carbon paper (CP) is a promising substrate for PENGs because

of its porous structure, flexibility, and electrical conductivity [15]. Porous nature of the CP

affords a large surface area for growing higher density ZnO nanorods (NRs),

which resulting in the enhancement of PENG performances. In addition,

conductive CPs offers the possibility of using double-sided surface and the potential

for the PENG to be hybridized with other energy conversion or

storage devices, such as photovoltaics and batteries. To demonstrate these

advantages, we fabricated ZnO NR-based PENGs by using the double sided carbon

paper and investigated the performance of the devices.

Fabrication

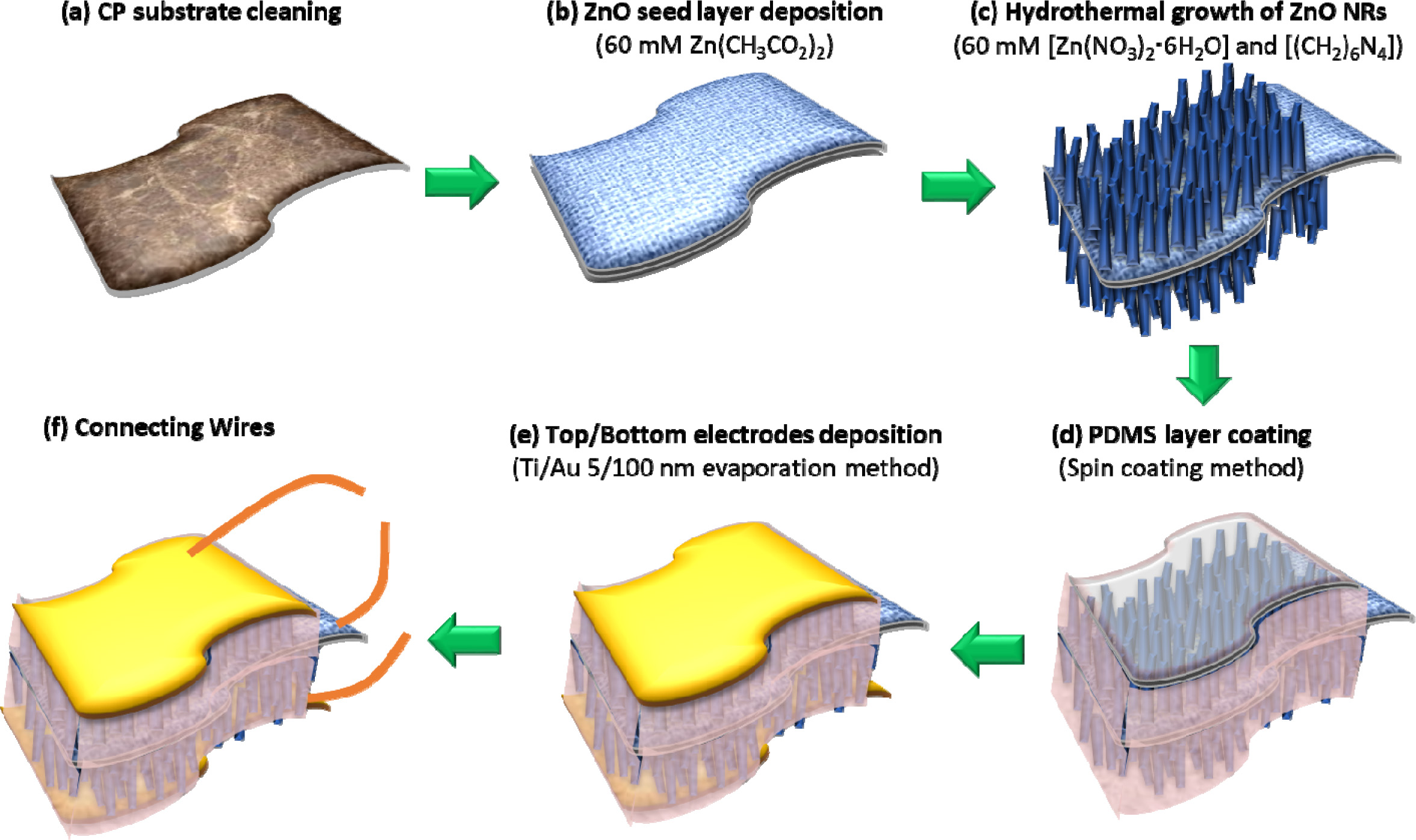

Fig. 1 shows the procedures for fabricating the PENG

devices from the ZnO NRs. The ZnO NRs were grown on both surfaces of the 35 μm-thick

CP substrate with a resistivity of about 10 Ω/cm2. To grow the ZnO

NRs on a single side of the CP substrate, the other side of the substrate was

covered by kapton tape during the growth. For ease of description, one of the

CP surfaces is defined as the front side (FS) and the other as the back side

(BS). To remove all contamination, each CP substrate was cleaned with acetone,

methanol, and deionized (DI) water in an ultrasonic bath for 10 min, and dried

with a mild N2 gas flow. The 0.5 cm2 area of the right

side of CP was then covered with kapton tape to prevent the growth of NRs. The

seed layer of ZnO NRs and the main layer were sequentially coated on the CP

substrate via a two-step hydrothermal process. In the first step, an ethanol

solution with 60 mM of zinc acetate [Zn(CH3CO2)2]

was stirred at 350 rpm and heated to 100 oC and held for 10

min. The process was repeated three times to ensure uniform and complete

coating of the ZnO seed layers on both sides of the porous CP surface.

In the second step, the seed layer-coated CP substrate was

used to grow ZnO NRs by a hydrothermal process using a mixed

solution of 60 mM zinc nitrate hexahydrate [Zn(NO3)2 6H2O]

and 60 mM hexamethylenetetramine [(CH2)6N4] in

DI water with stirring at 2,000 rpm and heating at 90 oC for 2

hr [15]. During the hydrothermal growth, the CP substrates were kept

vertically on a sample holder in the solution, to ensure

the same environment for both sides of the CP substrate. Then the samples were

cleaned in DI water to completely remove free-standing ZnO crystallites from

the samples by using an ultrasonic bath for 5 min. After the growth of the ZnO NRs, a 15-μm-thick

polydimethylsiloxane (PDMS; Sylgard-184, Dow

Corning, Midland, MI) layer was spin-coated on the ZnO NR surfaces. This PDMS

prepolymer was prepared with a weight ratio of 10:1 by mixing a PDMS curing

agent and a PDMS base monomer, which was coated on the ZnO NR surface by using

a spin coating rotation method at 3,000 rpm for 40 sec, followed by curing at

70 oC for 30 min. These processes were repeated for both sides

of the CP substrates. During this step, the possible presence of gas bubbles in

the top layer can hinder the connections between ZnO NRs and PDMS layers.

Therefore, the sample was evacuated in a vacuum chamber to remove the unwanted

gas bubbles from the thick PDMS layers and to strengthen the penetration of the

PDMS layer into both sides of the CP substrate. Ti/Au layers (5/100 nm) were

deposited on both sides of the PDMS-covered ZnO NRs at room temperature (RT) by

using a thermal evaporator. Finally, for observing the electrical output, Cu

wires were connected to the double-sided electrodes, as shown in Fig. 1(f).

Characterization

The surface topography and composition

of the ZnO NRs on

both sides of the CP were observed by using field-emission scanning electron microscopy (FE-SEM) and the structural properties were investigated by X-ray diffraction (XRD). The photoluminescence (PL) spectra of the ZnO NRs on both sides of the CP substrate were measured by using a

continuous wave of He-Cd laser with 24 mW power and 325 nm wavelength at RT.

The PENG devices

were subjected to an external mechanical force by a

straining system comprised of a 0.8-cm-diameter cylinder, in which the device

surface was hit repeatedly and

a periodic mechanical compressive stress was applied. In this continuous stress-and-relax process, the output

voltages were measured

simultaneously by using an

oscilloscope (TBS1202B, Tektronix).

|

Fig. 1 Schematic of the processing steps for fabricating ZnO NR-based PENGs on DSCP. |

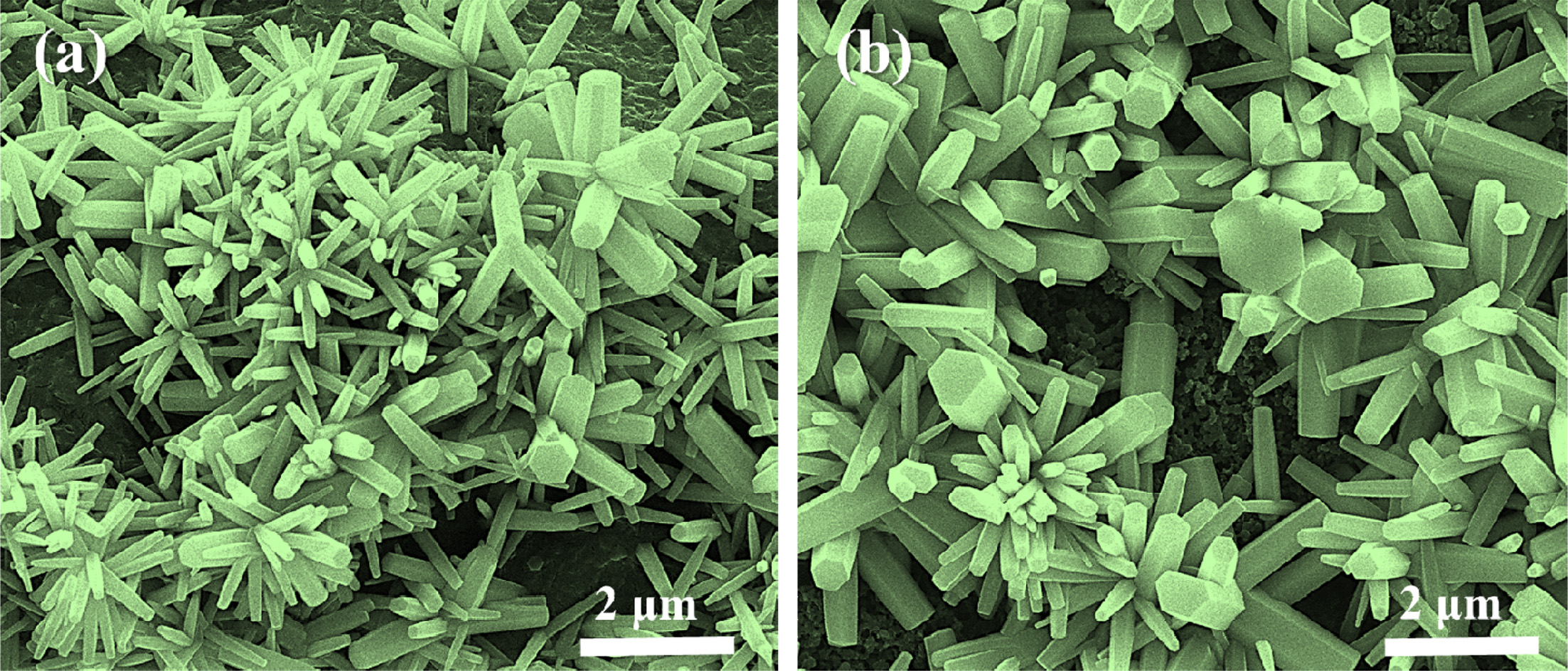

Fig. 2 shows FE-SEM images of the ZnO NRs deposited on the

front and back of CP with a molar concentration of 75 mM. The ZnO NRs on the

porous surface of CP were grown in random directions and showed a similar shape

on both sides. However, the density of the ZnO NRs was slightly higher on the

back of CP compared to that on the front. The surface of the ZnO

NRs showed a hexagonal columnar structure. This

implies that each ZnO NR was a wurtzite-structured single

crystal that was grown along the c-direction.

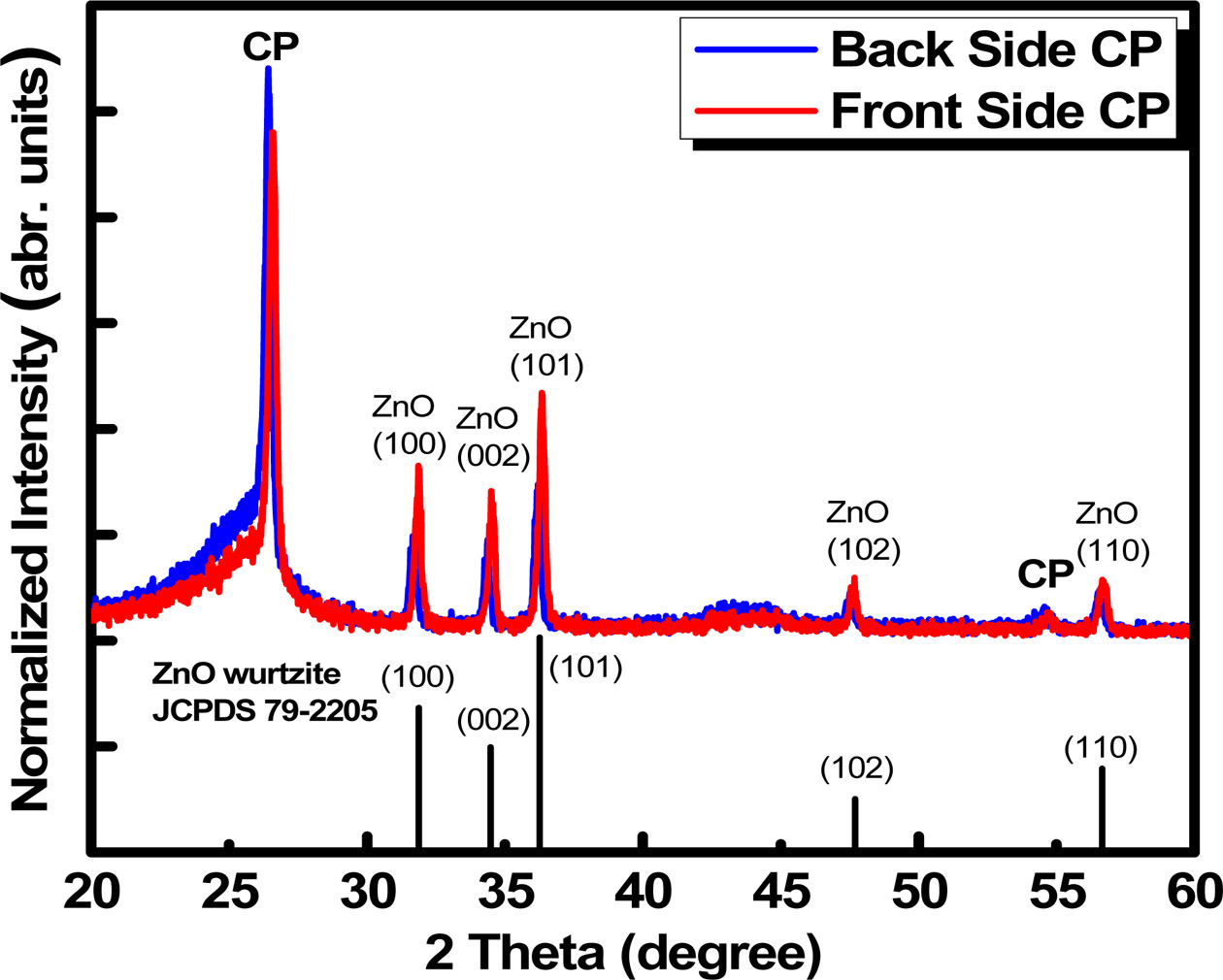

Fig. 3 shows the XRD results that reveal the crystal

structure of the ZnO NRs on both sides of the CP substrate. The broad peak at

around 26.5o is attributed to the short-range order of the amorphous

phase of the CP substrate. The sharp diffraction peaks correspond to the (100), (002),

(101), (102), and (110) planes of hexagonal wurtzite structure of ZnO (space

group: P63mc; a = 0.32501 nm, c = 0.52071 nm). The

diffraction data were in agreement with the JCPDS card for ZnO (JCPDS 79-2205). There were no diffraction peaks except those for the CP substrate and ZnO. This indicates that no secondary

phase or impurity was detected. The

substrate peaks of the ZnO NRs on the FS of the CP have greater intensity than

those of the BS, which confirms the better crystallinity of the NRs in the BS.

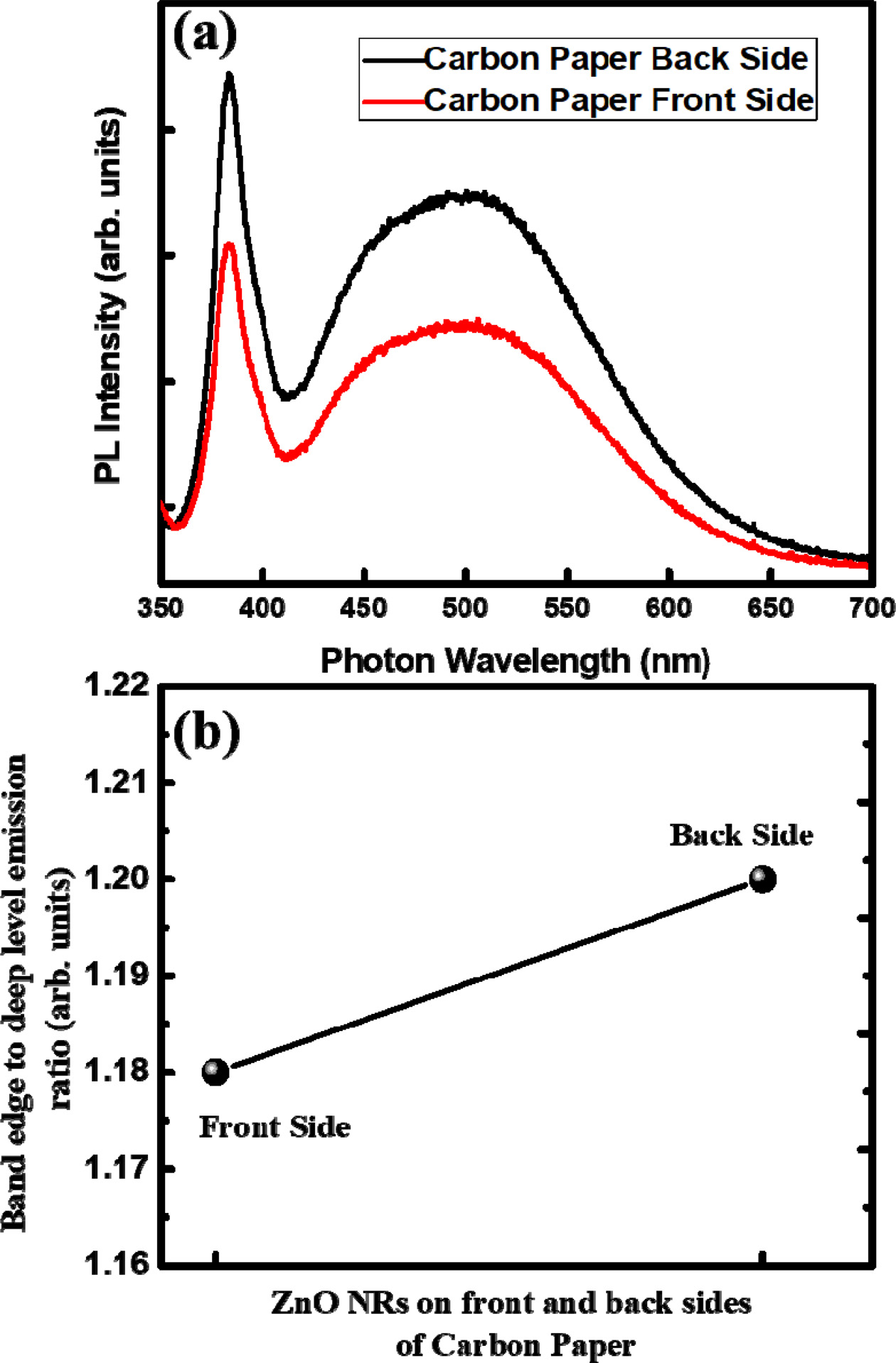

Fig. 4(a) shows the PL spectra of the ZnO NRs grown on

both sides of the porous CP substrate at RT. A sharp peak at 380 nm and a

relatively weak peak at 520 nm were observed in both FS and BS spectra. The

sharp peak in the ultraviolet range corresponds to the band-edge emission of

ZnO NRs. The broad emission band in the visible spectral range is due to the

deep level emissions from the ZnO NRs, which originate from various impurities

in the ZnO crystal, such as oxygen deficiency due to electron recombination,

zinc interstitials, and their complexes [22, 23]. These point defects usually

act as a donor to generate free charge carriers. The generated free charge

carriers in the ZnO NRs are detrimentally affected by screening the

generated piezoelectric potential on the output

voltage performance of the designed PENG devices [7, 24, 25].

Therefore, the crystalline quality of the ZnO NRs on each side of the CP

substrate was investigated by comparing the intensity of the deep level

emission. Fig. 4(b) shows the PL peak intensity ratio of the band-edge to the

deep level emissions from the ZnO NRs on both sides of the CP substrate. The

intensity ratios of 1.18 and 1.20 on the FS and BS, respectively, imply that

the ZnO NRs’ crystalline quality was slightly better on the BS than on the

FS. This result agrees with the morphological results that show

the vividly uniform and denser growth of ZnO NRs on the back as shown in Fig.

2(b). This is attributed to the inevitable difference in the amounts of Zn and

O supplied to both sides of the substrate during the hydrothermal growth.

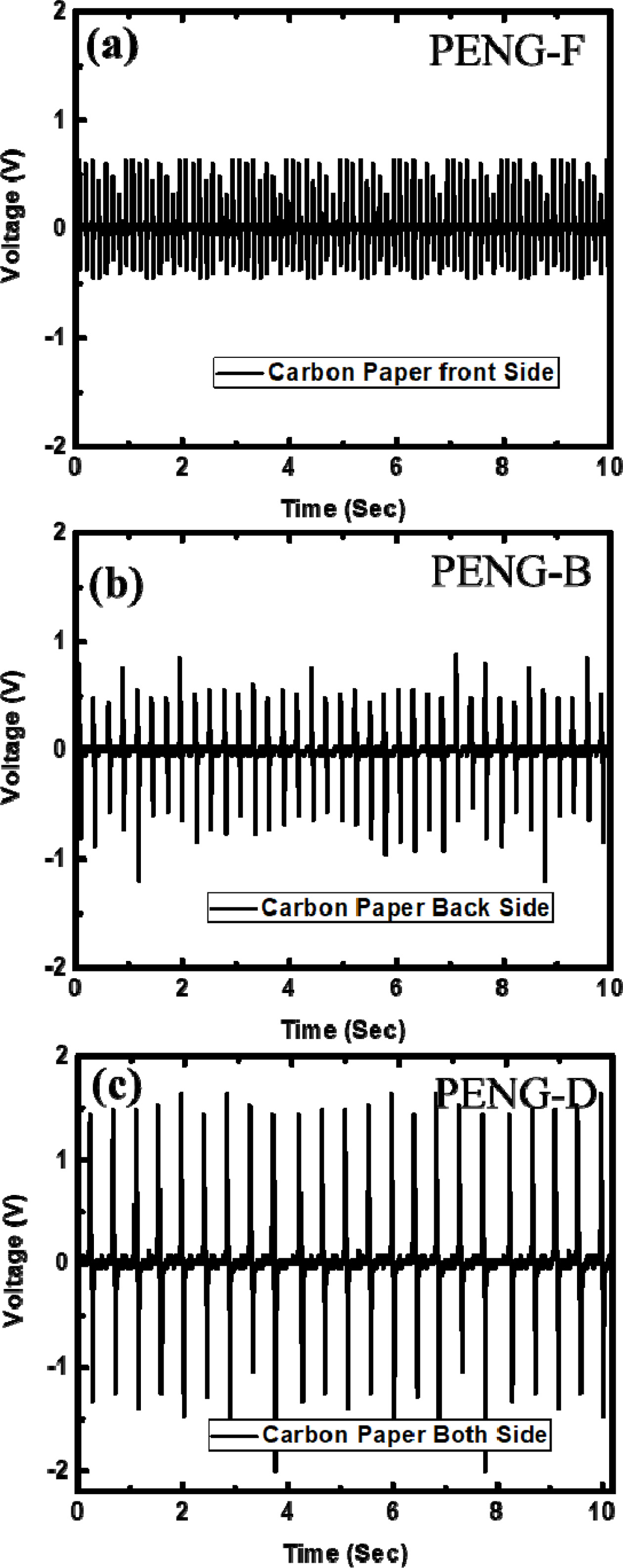

Fig. 5 shows the voltage outputs of the PENG devices

fabricated on the DSCP substrate with the same strain frequency at

2.2 Hz. For simplicity, we denoted PENGs on the front

only, back only, and double sided as PENG-F, PENG-B, and PENG-D, respectively.

When stress is applied to and released from the PENGs, despite the variation in

output voltage on each side, all three PENGs showed positive and negative peaks

due to the charging and discharging, respectively. This is attributed

to the alternating current (AC) signals produced by the

stress along the perpendicular direction to the vertically aligned ZnO NRs in

the PENG device. The figure shows that the output voltage remains an AC signal while the ZnO NRs

are grown in random direction, which is

attributed to the elastomeric property

of the PDMS polymer layer which helps the transfer of the applied strain to

both the whole PENG device and the individual ZnO NRs. The Young’s modulus of

the PDMS polymer ranges between 0.57 and 3.7 MPa [26], while that of the ZnO

NRs is about 29 GPa [27]. Therefore, the Young’s modulus is about four orders

of magnitude larger for the ZnO NRs than that for the PDMS layer. As a result,

when the stress is applied to the PENG device, the PDMS layer is deformed first

and the stress is distributed to the individual ZnO NRs equally [28]. Therefore, the PDMS layer plays a

critical role in transferring the

applied stress in this PENG device in the isotropic directions to the ZnO NRs.

PENG-B generated a larger output voltage (0.88V) than

PENG-F (0.64 V) due to the denser ZnO NRs, as shown in Fig. 2, and exhibited

better crystallinity, as shown in Fig. 3. The free charge carriers that were

generated by impurities in the ZnO NRs detrimentally affected the PENG

performance by screening the generated piezoelectric potential [8, 29]. The

voltage output of PENG-D (1.64 V) was enhanced about 2.56 and 1.86-fold

compared to that of PENG-F and PENG-B, respectively. The enhanced voltage

output would attributed to the electric field-induced synergetic effect between

the front and back of the CP substrate and the modification of the CP substrate

resistance under the electric field generated by the PENGs. And this enhancement mechanism can be explained as follows.

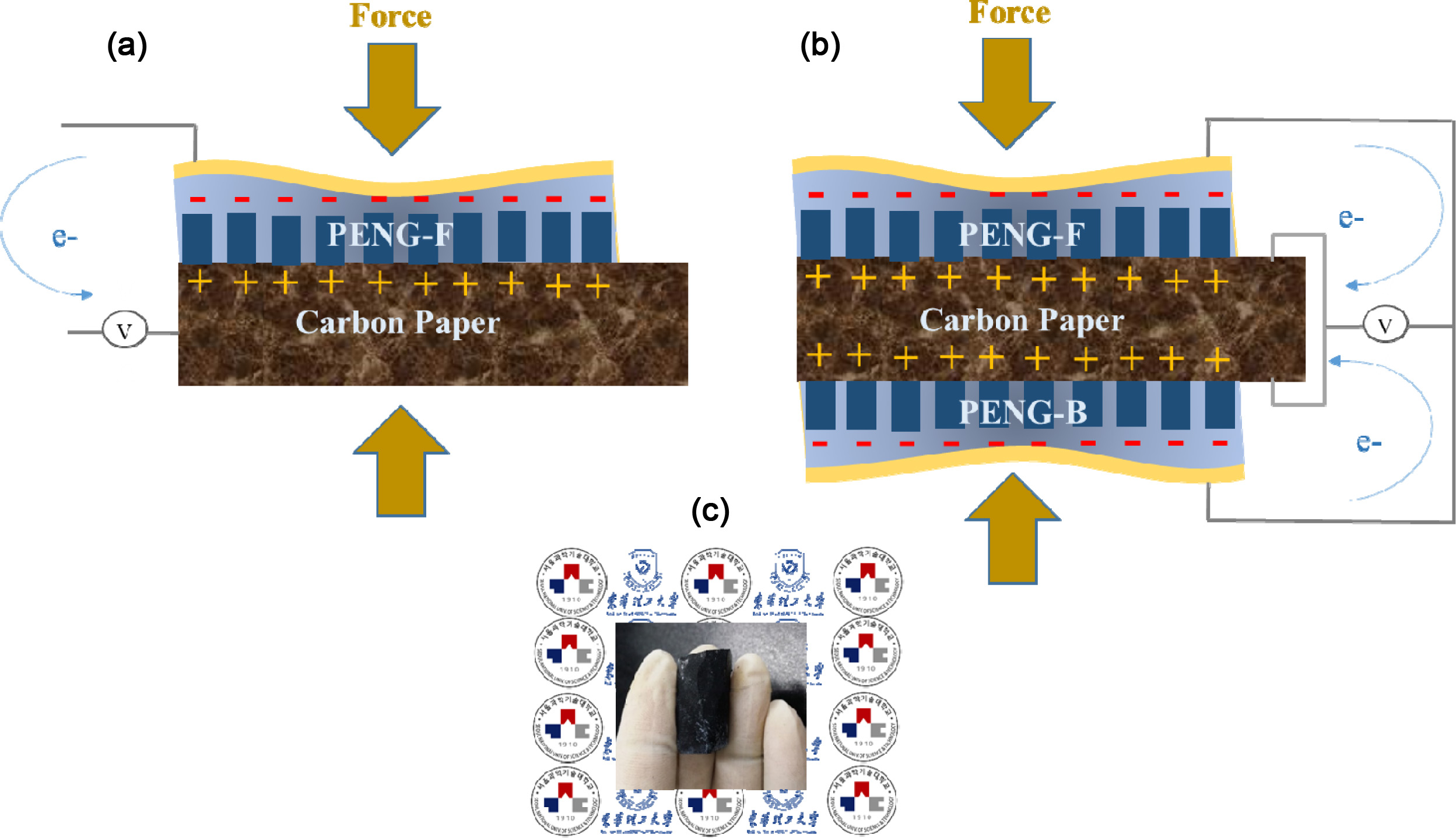

Fig. 6 shows the operating principle and enhancement mechanism of the PENG

device on the CP substrates. A negative potential is initially created at the

top of the ZnO NRs when stress is applied to only one side of the PENG device,

and is then delivered to the electrodes through the PDMS layers, thus

generating a negative pulse. As the stress is subsequently removed, the

piezoelectric potential suddenly vanishes, which allows the stored charge in

the electrode to return through the external circuit and generate a positive

pulse, as occurs in other ZnO NR-based PENG devices. The operation principle of

PENG-D can be regarded as a combination of two devices. The piezoelectric potential generated as the ZnO NR experiences an external tensile or com- pression

stress on the surface causes relative displacement of Zn2+ cations with respect to O2-

anions. The amount of maximum piezoelectric potential generated from a single ZnO NR under external mechanical stress for

vertical (FV) and lateral (FL)

directions can be expressed as Vmax = |FV|gV(L/pR2)

and Vmax = |FL|gL(1/pR),

respectively [7,10,28], where gV

and γL denote the piezoelectric voltage parameters in

vertical and lateral directions of ZnO NRs, respectively, and R and L

denote the radius and length of each ZnO NR, respectively. These equations

imply that if the NR’s radius and length are unchanged then the piezoelectric

output from each ZnO NR is always constant and is directly proportional to the

maximum deflection of the individual NR. Therefore, as the number of ZnO NRs in

the PENG devices increases, greater piezoelectric potential is generated

because each ZnO NR can act as an individual voltage source. This is consistent

with the results that the output voltages from PENG-D are enhanced by 2.56 and

1.86-fold compared to that of PENG-F and PENG-B, respectively. In PENG-D, the

electrons of both sides sequentially enforce and then reinforce the flow from

the PENG device where the electric field is generated. This enables more

electrons to flow through the external circuit and accumulate together

and finally be measured by using the connected measurement

systems. An electric field-induced synergetic effect

between PENG-F and PENG-B enhanced the PENG-D output, which was 1.08-fold

greater than the sum of the individual voltage outputs of PENG-F and PENG-B.

This explains the enhanced output voltage performance from PENG-D compared to

that of the two single-sided PENG devices. This enhancement is further

attributed to the modification of the electrical properties under a generated

electric field. Due to the electron scattering mechanism, the resistance of the

substrate can be modified under an electric field [30]. Therefore, PENG-D can

enhance the output voltage. In addition, the flexibility of the fabricated

device, as shown in Fig. 6(c), will allow its use in bendable applications such

as for in-vitro medical sensors and textile devices.

|

Fig. 2 FE-SEM images of the ZnO NRs on DSCP: (a) FS and (b) BS. |

|

Fig. 3 XRD patterns of ZnO NRs on DSCP. |

|

Fig. 4 (a) Comparison of PL spectra for the front and back of

carbon paper measured at RT for ZnO NRs on DSCP. (b) The

band-edge emission to deep level emission ratio for the ZnO NRs

grown on the front and back of DSCP. |

|

Fig. 5 Output voltage from ZnO NRs-based PENGs on carbon

paper: (a) PENG-F, (b) PENG-B, and (c) PENG-D under a strain

frequency of 2.2 Hz. |

|

Fig. 6 Schematic of PENG device structure on (a) single side (either front or back) and (b) DSCP substrates operating under compressive

stress. (c) Bendability of the PENG device on DSCP. |

In summary, we have fabricated ZnO NR-based PENGs

exhibiting enhanced output voltage by using a DSCP substrate. Morphological

investigation showed that the ZnO NRs were grown in the similar shape and

length on both sides of the CP surface, but with a slightly larger density on

the back. The XRD and PL results confirmed that the crystal quality of the ZnO

NRs on both sides of the substrate exhibited similar degree. The voltage output

from PENG-D was 2.56- and 1.86-fold greater than those from PENG-F and PENG-B,

respectively. The enhanced voltage output is attributed to the electric

field-induced synergetic effect between the front and back of the CP substrate

and the modified electrical resistance of the CP substrate under the electric

field generated by the operating PENGs. These results demonstrate the

capability of the ZnO NR-based PENG on the DSCP to enhance their output voltage

as well as the possible application to bendable self-powering devices.

This study was supported by the Research program funded by

the Seoultech (Seoul National University of Science & Technology)

- 1. Z.L. Wang and J. Song, Science 312 (2006) 242-246.

-

- 2. Z.L. Wang, Sci. Am. 298 (2008) 82-87.

-

- 3. Y. Hu, Y. Zhang, C. Xu, L. Lin, R.L. Snyder, and Z.L. Wang, Nano Lett. 11 (2011) 2572-2577.

-

- 4. Z.L. Wang and W. Wu, Angew. Chem. Int. Ed. 51 (2012) 11700-11721.

-

- 5. K.K. Kim and I.K. Park, J. Ceram. Process. Res. 18 (2017) 435-439.

- 6. S. Beeby, M. Tudor, and N. White, Meas. Sci. Technol. (2006) R175.

-

- 7. J. Sohn, S. Cha, B. Song, S. Lee, S. Kim, J. Ku, H. Kim, Y. Park, B. Choi, Z L. Wang, J.M. Kim, and K. Kim, Energy Environ. Sci. (2013) 97-104.

-

- 8. M.Y. Choi, D. Choi, M.J. Jin, I. Kim, S.H. Kim, J.Y. Choi, S.Y. Lee, J.M. Kim, and S.W. Kim, Adv. Mater. 21 (2009) 2185-2189.

-

- 9. H.K. Park, K.Y. Lee, J.S. Seo, J.A. Jeong, H.K. Kim, D. Choi, and S.W. Kim, Adv. Funct. Mater. 21 (2011) 1187-1193.

-

- 10. Y. Gao and Z.L. Wang, Nano Lett. 7 (2007) 2499-2505.

-

- 11. D.Y. Lee, H. Kim, H.M. Li, A.R. Jang, Y.D. Lim, S.N. Cha, Y.J. Park, D.J. Kang, and W.J. Yoo, Nanotechnology 24 (2013).

-

- 12. D.Y. Jung, S.H. Baek, M.R. Hasan, and I.K. Park, J. Alloy Compd. 641 (2015) 163-169.

-

- 13. G.H. Nam, S.H. Baek, C.H. Cho, and I.K. Park, Nanoscale 6 (2014) 11653-11658.

-

- 14. M.R. Hasan, S.H. Baek, K.S. Seong, J.H. Kim, and I.K. Park, ACS Appl. Mater. Inter. 7 (2015) 5768-5774.

-

- 15. G.M.H.U. Banna and I.K. Park, Nanotechnology 28 (2017) 445402.

-

- 16. S.H. Baek, M.R. Hasan, and I.K. Park, Nanotechnology 27 (2016) 065401.

-

- 17. C. Xu and Z.L. Wang, Adv. Mater. 23 (2011) 873-877.

-

- 18. C. Liu, A. Yu, M. Peng, M. Song, W. Liu, Y. Zhang, and J. Zhai, J. Phys. Chem. C 120 (2016) 6971-6977.

-

- 19. K. Y. Lee, J. Chun, J.H. Lee, K.N. Kim, N.R. Kang, J.Y. Kim, M.H. Kim, K.S. Shin, M.K. Gupta, J.M. Baik, and S.W. Kim, Adv. Mater. 26 (2014) 5037-5042.

-

- 20. K.I. Park, C.K. Jeong, J. Ryu, G.T. Hwang, and K.J. Lee, Adv. Energy Mater. 3 (2013) 1539-1544.

-

- 21. G. Zhu, R. Yang, S. Wang, and Z.L. Wang, Nano Lett. 10 (2010) 3151-3155.

-

- 22. L.E. Greene, M. Law, J. Goldberger, F. Kim, J.C. Johnson, Y. Zhang, R.J. Saykally, and P. Yang, Angew. Chem. Int. Ed. 42 (2003) 3031-3034.

-

- 23. A.C. Arsenault, T.J. Clark, G. Von Freymann, L. Cademartiri, R. Sapienza, J. Bertolotti, E. Vekris, S. Wong, V. Kitaev, I. Manners, R. Z. Wang, S. John, D. Wiersma, and G.A. Ozin, Nat. Mater. 5 (2006) 179-184.

-

- 24. D. Li, Y.H. Leung, A.B. Djurišić, Z.T. Liu, M.H. Xie, S.L. Shi, S.J. Xu, and W.K. Chan, Appl. Phys. Lett. 85 (2004) 1601-1603.

-

- 25. R. Yang, Y. Qin, L. Dai, and Z.L. Wang, Nat. Nanotech. 4 (2009) 34-39.

-

- 26. J. Song, X. Wang, E. Riedo, and Z.L. Wang, Nano Lett. 5 (2005) 1954-1958.

-

- 27. X. Li, Y. Chen, A. Kumar, A. Mahmoud, J.A. Nychka, and H.J. Chung, ACS Appl. Mater. Inter. 7 (2015) 20753-20760.

-

- 28. G. Romano, G. Mantini, A. Di Carlo, A. D’Amico, C. Falconi, and Z.L. Wang, Nanotechnology 22 (2011) 465401.

-

- 29. D. Kim, K.Y. Lee, M.K. Gupta, S. Majumder, and S.W. Kim, Adv. Funct. Mater. 24 (2014) 6949-6955.

-

- 30. E. Ahilea and A.A. Hirsch, J. Appl. Phys. 42 (1971) 5601-5608.

-

This Article

This Article

-

2020; 21(6): 656-661

Published on Dec 31, 2020

- 10.36410/jcpr.2020.21.6.656

- Received on May 20, 2020

- Revised on Jul 2, 2020

- Accepted on Jul 16, 2020

Services

Services

- Abstract

introduction

experimental procedure

results and discussion

conclusions

- Acknowledgements

- References

- Full Text PDF

Shared

Correspondence to

Correspondence to

- Il-Kyu Park

-

Department of Materials Science and Engineering, Seoul National University of Science and Technology, Seoul 01811, South Korea

Tel : +82-2-970-6349 Fax: +82-2-973-6657 - E-mail: pik@seoultech.ac.kr

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.