- Effect of (MgO/CaO) molar ratio on glassy phase viscosity and pyroplastic deformation in floor tiles

Neslihan Tamsu Selli*

Department of Materials Science and Engineering, Gebze Technical University, 41400 Gebze, Kocaeli, Turkey

In this study, effect of MgO/CaO

molar ratio on the floor tiles properties was investigated. The viscosity of

the bodies was successfully calculated by fleximeter analyses data. High

MgO/CaO ratio causes enhancement of the densification temperatures and

dissolution of the crystals in the floor tile body. The results showed a,

during firing, high MgO/CaO ratio up to 6,505 value, formed, low viscosity

liquid phase and allowed low sintering temperature approximately 20 oC

when compared to the standard floor tile body. For YK_3 composition will be

evaluated due to has allowable deformation amount for the production. This

floor tile composition will be successfully produced in production line.

Keywords: Floor tile, Deformation, Viscosity, Sintering

Ceramic floor tiles that are fired at high temperatures

such as 1,150-1,180 oC for 30-45 min and have water

absorption below 3%. Floor tiles can be produced either glazed

or unglazed, or they can be produced as coloured body

by adding color pigments to their initial compositions. Ceramic

floor tiles are partially the vitrified product of mixtures of clay, quartz

sand, and feldspar, after heat treatment at temperatures in range

1,150-1,180 oC. The primary purpose of these three components

may be described as follows [1-3]: Clays provide plasticity to the body and

provide dry strength. They gives the colour depends on their own color and

impurities. After clays, feldspars have also critical role in the ceramic tile

production sector. Feldspars are used as melting agents in the recipes. They

are reduce the sintering temperature by forming liquid phase when the ceramic

body is firing. In addition to the these raw materials which have plastic and

melting properties in ceramic structures, there is a need for a non-plastic

filler which will keep the body integrity in high temperature ranges. Quartz

acts as a skeleton in the body. It is the main filler which is incorporated

into the ceramic body as a real component or as a component from clay and

feldspar. It constitutes the roughest particle size part of the structure. The

large grain size interval provides resistance to cracks during drying and

prevents deformation by forming a skeleton during firing [4, 5]. Maiti et al.

[6], reported that during firing, tile body assists

dissolution of quartz, recrystallization of secondary

mullite and reduction of closed pores in the tile body. It has been also

reported by Bull [7], alkaline earth materials in the tile composition resulted

in the speedy glassy phase formation during fast firing cycle. During fast

firing cycle, for some body compositions, glassy phase viscosity decreases

suddenly and it could create some distortions and deformations on the sample

during firing. Pyroplastic deformation is defined as deformation which occurs

the effect of product weight during high temperatures [8]. By understanding the

compositon effect on melting behaviour of the ceramic body, it can

be understood that pyroplastic deformation, reactions

and mechanical properties during fast firing [5]. Öztürk et al. [9]

investigated the effect of alkaline oxides on porcelain tiles using factorial

design method. MgO, CaO, Na2O and K2O were used in the new compositions. It was

found that the strength increased, and water absorption decreased by means of

alkaline oxide variation in the porcelain tile body. Rastelli et al. [10],

studied effects of spodumene and zirconium based materials on the reology of

the porcelain tile slurry. Nevertheless, in this study effect of these raw

materials on the sintering behaviour body did not mentioned. n

this study, the effect of these compositions on glassy

phase viscosity on wall tile was not investi- gated and only wall tile was taken into

consideration. Elmas et al. [11], studied about the effect of boric acid and

lithium carbonate scombination on sintering and microstructure of single-fired

wall tile bodies. They found that combination of the lithium-carbonate and

boric acid provided low sintering temperature, and high strength values for

single fired wall tiles. Sousa et. al. [12], investigated sintering behavior of

porous wall tile bodies during fast single firing process. In this study, wall

tile composition had red clay, limestone and quartz. Its technical properties

and microstructure was evaluated considering the different

sintering temperatures of the wall tile body.

Many studies about glassy

phase viscosity of ceramic bodies have been reported. Porte et al. [13],

studied about creep viscosity of vitreous china composition containing

different mullite and quartz cystals. They used four point bend rig for creep

measurement. However, they did not report any information about pyroplastic

deformation relation with glassy phase viscosity. Tuna et al. [14], studied influence of

porcelain tile starting composition

containing spodumene on the pyroplastic deformation evolution during firing.

They found that pyroplastic deformation was decreased with increasing Li2O

addition in porcelain stoneware tiles. Tuncel et al. [8], investigated effect

of different Na2O/K2O and SiO2/Al2O3

ratio affects the viscosity of the system as the amount of mullite increases.

Other oxides that affect the vitreous phase viscosity in the ceramic bodies are

magnesium oxide and calcium oxide. These oxides are generally used for allow

the tiles firing at short firing cycle (24-30 min at 1,150-1,180 oC)

and increasing sintering rate in the ceramic bodies. Dondi et al. [15],

reported that magnesium accelerate the sintering

and decrease the ripenning temperature of the body and with this way narrowed

the firing interval of the body. On the

other hand, magnesium containing porcelain stoneware tile compositions shows

lower mechanical strength due to increasing porosity. Mukhopadhyay et al. [16],

investigated the effect of talc component in illitic clay composition on

thermal, mechanical properties and microstructure of the bodies. Talc is shown

as 3MgO.4SiO2. H2O formula and it is magnesium silicate

structure. It was observed that talc/feldspar

composition reduced the vitrification temperature. MgO, which is incorporated

by addition of talc provides more

glassy phase formation with low glassy phase viscosity. Biasini et al. [17],

designed porcelain tile composition containing different talc and chlorite

components. The occurance of

magnesium silicates does not affect the technological properties of

semi-finished product, but it

influences remarkably the firing behaviour. However, in these studies, the effect of glassy phase viscosity on

pyroplastic deformation was not specified for floor tiles. Consequently, the

research objectives of this study were the first to develop and understand

about how viscosity of ceramic floor tile body changes as a function of

alkaline earth oxides molar ratio, (MgO/CaO), the second objective was to

investigate effect of viscosity on

pyroplastic deformation of ceramic floor

tiles an also understanding this compositional change on microstructure of the

tile bodies.

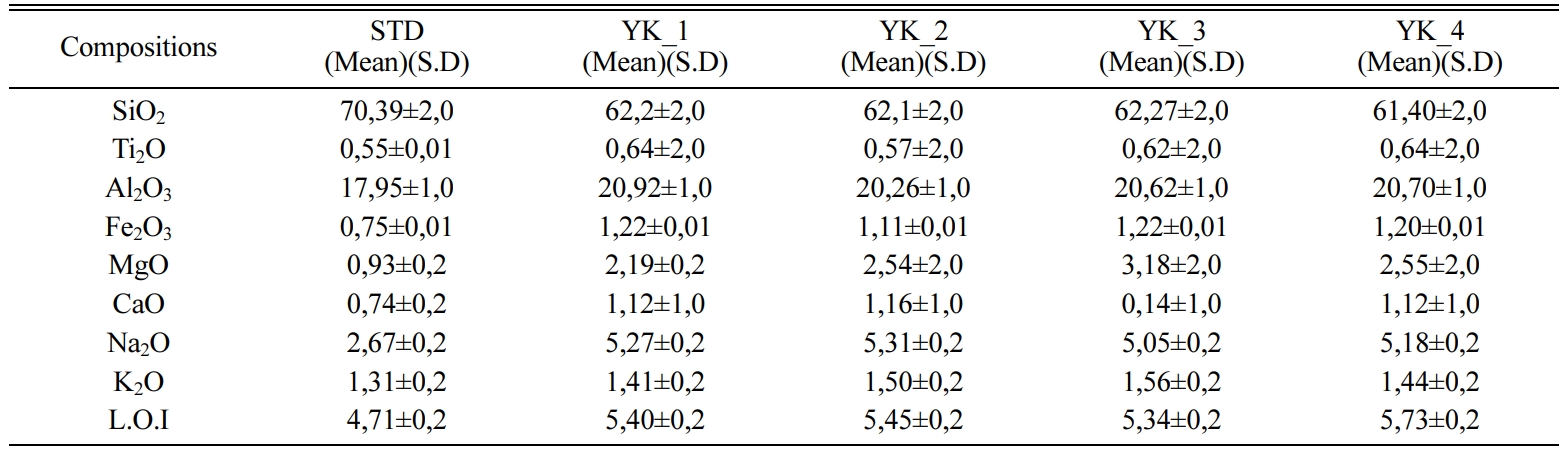

Starting from the standard ceramic floor tile body mix,

different amounts of talc and calcite were added into the system. New

compositions were denoted as YK_1, YK_2, YK_3 and YK_4. Chemical

characterization was carried out by means of wavelength dispersive

X-ray fluorescence spectrometry (XRF), using a Philips model PW 2400 XRF

instrument fitted with an Rh white fluorescent tube. The samples were prepared

as fused beads using a Philips PERL’X3 instrument. Chemical analyses of the

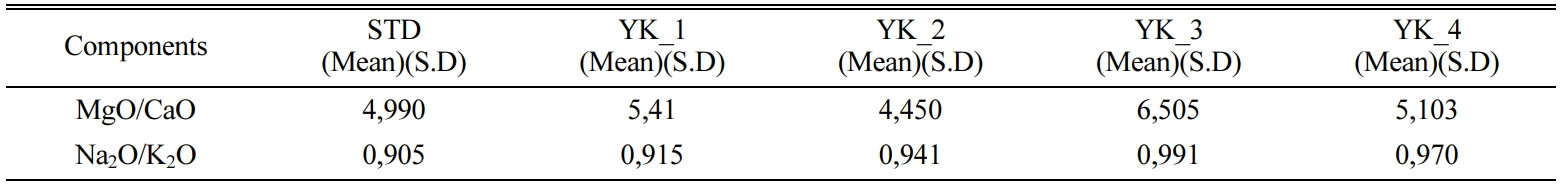

compositions are shown in Table 1. Seger formulation was applied to prepare new

compositions and MgO/CaO molar ratio was chosen as the main

variable parameter to prepare the compositions and amount of

total molar alkaline oxides (Na2O and K2O) was kept approximately constant in

the com- positions. Seger

formulation details of the compositions are given Table 2. New compositions

were wet milled by a laboratory ceramic jar mill containing 70 wt.% solid and

1.0 wt.% deflocculant, for 20 min. Slips were dried at 110 oC.

Samples (50 ´ 50 ´ 6 mm3) and (60 ´ 6 ´ 6 mm3) were hydraulically

compacted using uniaxial pressing at 300-350 kg/cm2.

The shaped samples were dried at 110-120 oC for 24 h till the

moisture content less than 0.5%.

Sintering temperatures of the compositions were determined

by flex point (i.e., temperature at which densification rate is maximum) using

the optical dilatometer (Misura 3.32, ODHT-HSM, Expert System Solutions,

Italy). Samples were heated in an optical dilatometer at a rate of 50 oC/min

up to 1,250 oC without soaking at peak temperature in air

atmosphere condition to determine flex points as stated by Paganelli

[18]. Total heat treatment was approximately 30 min and the peak temperature

was 1,160 oC in roller kiln. The

firing shrinkages were determined by measuring the diameter

of the discs before and after sintering. The water

absorption of the sintered disc was measured by a water

displacement method according to ISO 10545-3.

The colour values of the new compositions and standard

composition were measured by a spectrometer (Minolta CR,

300 Colormeter). The colorimeter operates on the

CIELab method, which is utilized technique in the ceramic production to

determine the whiteness and colour of the tiles by measuring three main

parameters (Hunter parameters) L* (brightness) from absolute white L=100 to

absolute black L=0, an (red–green), bn (yellow–blue) elaborated from the

visible spectra. The bending strength of sintered samples was measured with an

electronic universal tester (Model 5569, Instron Ltd.) by a three-point bending

test with a lower span of 50 mm and crosshead speed of 1 mm/min,

based on ASTM standard C1161-90. The crystalline phases in the fired samples

were determined by XRD analyses. For XRD analyses, sintered samples were

scanned from 2q=5 to 70o,

at a scanning speed of 2o/min, using a Rigaku Rint 2000 Series

diffractometer with Cu Ka

radiation at 40 kV and 30 mA. The crystalline phase composition

was quantatively analysed with the software Material

Analysis Using Diffraction (MAUD) based on the Rietveld method. Microstructural

observations were performed on selected fired samples using a scanning electron

microscope (EVO-50, Carl-Zeiss, Germany). Chemical etching was employed to

reveal the presence of certain crystalline phases by immersing the relevant

samples in 10% hydrofluoric acid (HF) solution at room temperature for 20 s.

Qualitative EDX (Oxford Inst. 5108 Link) analyses were

performed simultaneously with

microstructural observations in order to distinguish the various

phases. To determine the pyroplastic deformation behavior of the compositions,

rod shapes samples having (80 mm ´

7 mm ´ 7 mm)

size were produced and fired using an optical fleximeter (Misura, ODLT Flex

1400-30) with a firing regime of 25 oC/min to 1,160 oC

and waiting 5 min at the peak temperature. After fleximeter analysis, the

pyroplastic index (PI) values of samples calculated according to Eq. (1) [8].

The viscosity of the ceramic floor tile bodies (ɳ) was calculated using the

results of fleximeter analysis according to Eq. (2) [8].

where s is the total

deformation, b is the sample thickness, l is the distance between

supports, ρb is the bulk density of the body, and g is the

gravitational constant

|

Table 1 Chemical composition (wt%) of ceramic floor tiles recipes. |

* L.O.I: Lost of ignition |

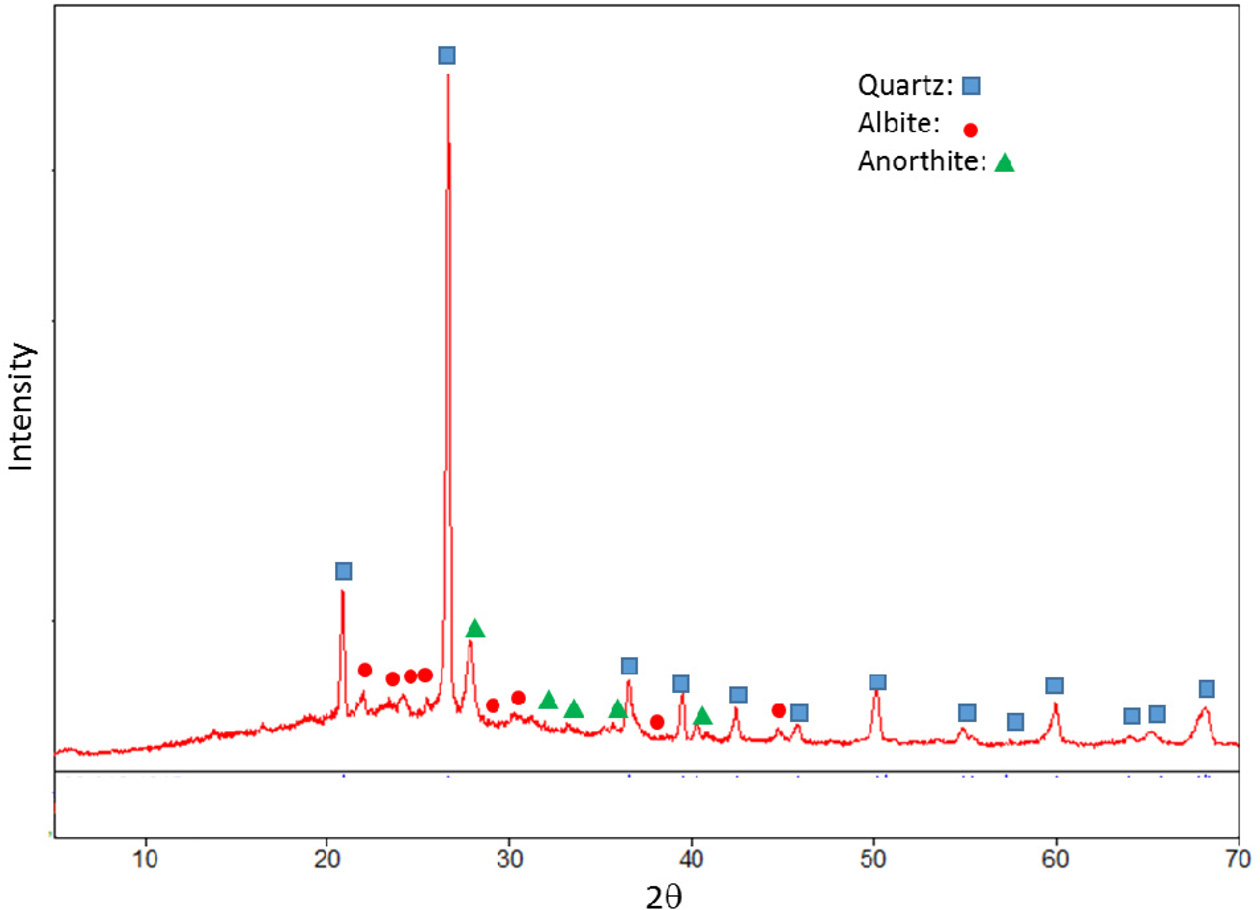

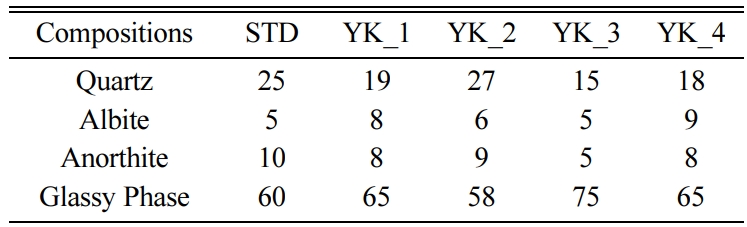

The chemical and mineralogical compositions of the tiles

affect the deformation behaviour of the tiles. For this reason, the crystalline

phase compositions of samples fired at 1,160 oC were

investigated based on XRD patterns. XRD pattern of standard composition is

given in Fig. 1. Quartz, albite and anothite were present in standard floor

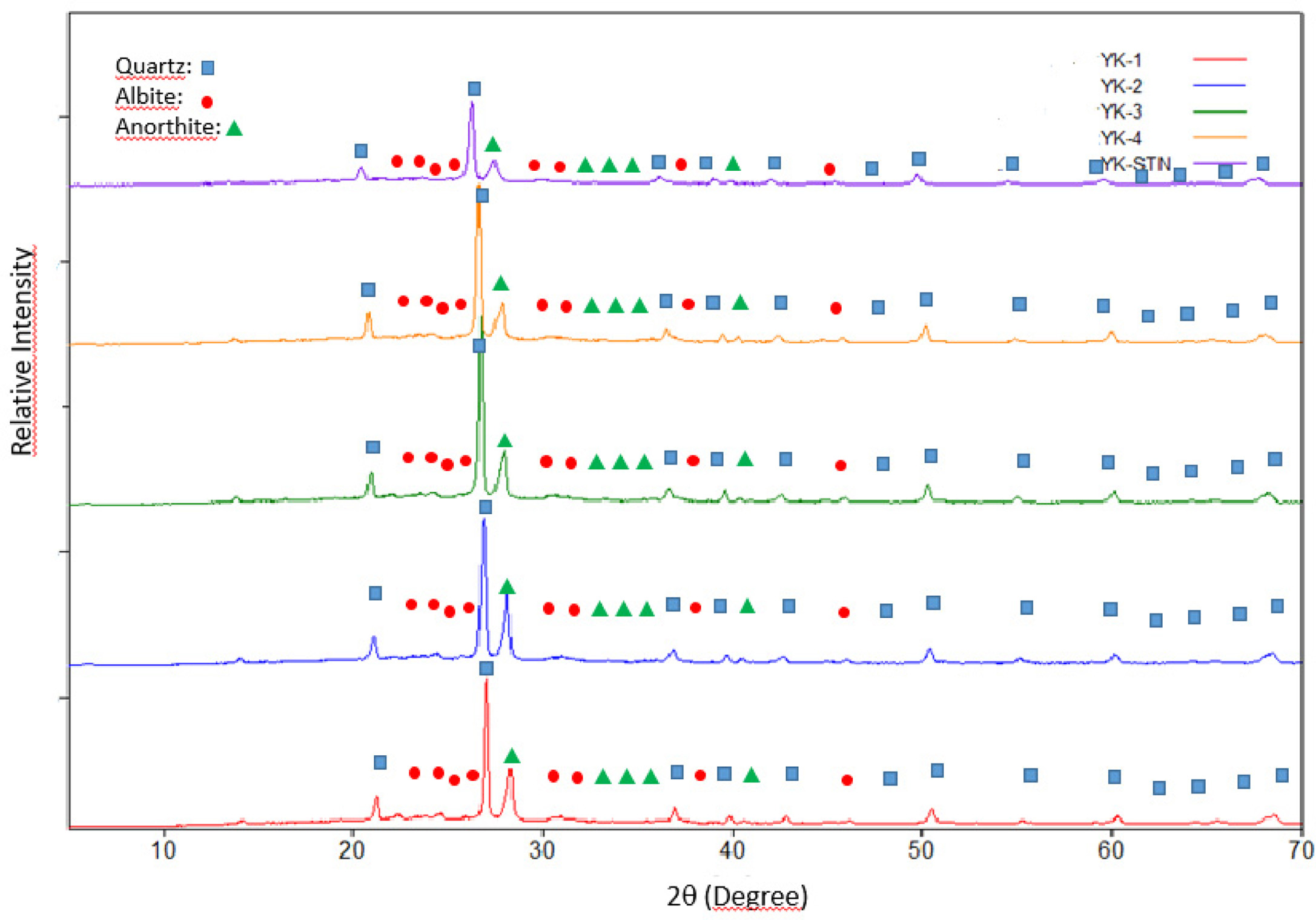

tile. XRD analysis also was performed on the recipes with increasing MgO/CaO

ratio. Com- parison of the XRD

patterns of the recipes was given in Fig. 2. According to the XRD patterns, the

main crystalline phases were quartz, albite and anorthite. In order

to determine the composition effect on the crystalline

phases more clearly, amount of the crystalline phases and

glassy phase were determined. The amounts of crystalline and glassy phases

determined by the MAUD programme for all of the compositions are given in Table

3. Standard floor tile composition has 5 wt% albite, 10 wt% anorthite, 60 wt%

glassy phase. Different MgO and CaO ratio affected the phase content of the

floor tile bodies. When the MgO/CaO molar ratio reached 6,505 in YK-3, the

amount of the quartz decreased compared to the STD, and the amount of albite

remained constant and there was a decrease in anorthite crystals amount. The

increase in the MgO/CaO ratio in YK-3 composition also affected the glassy

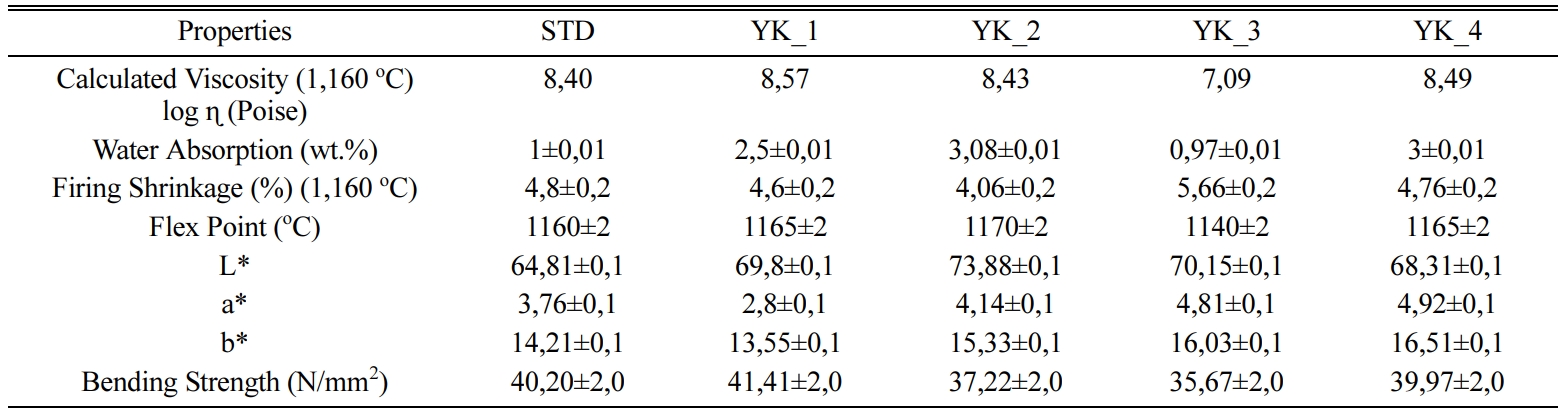

phase viscosity. The amount of deformation during firing was determined and

viscosity values were calculated according

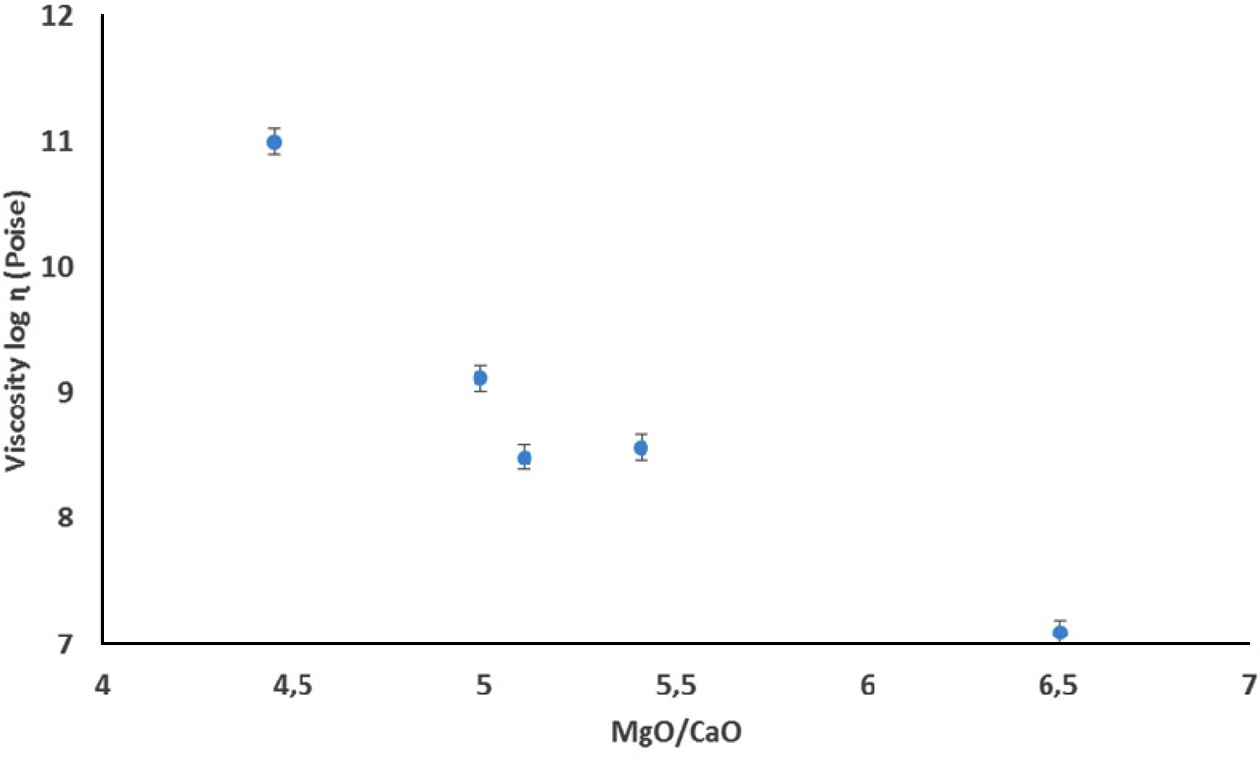

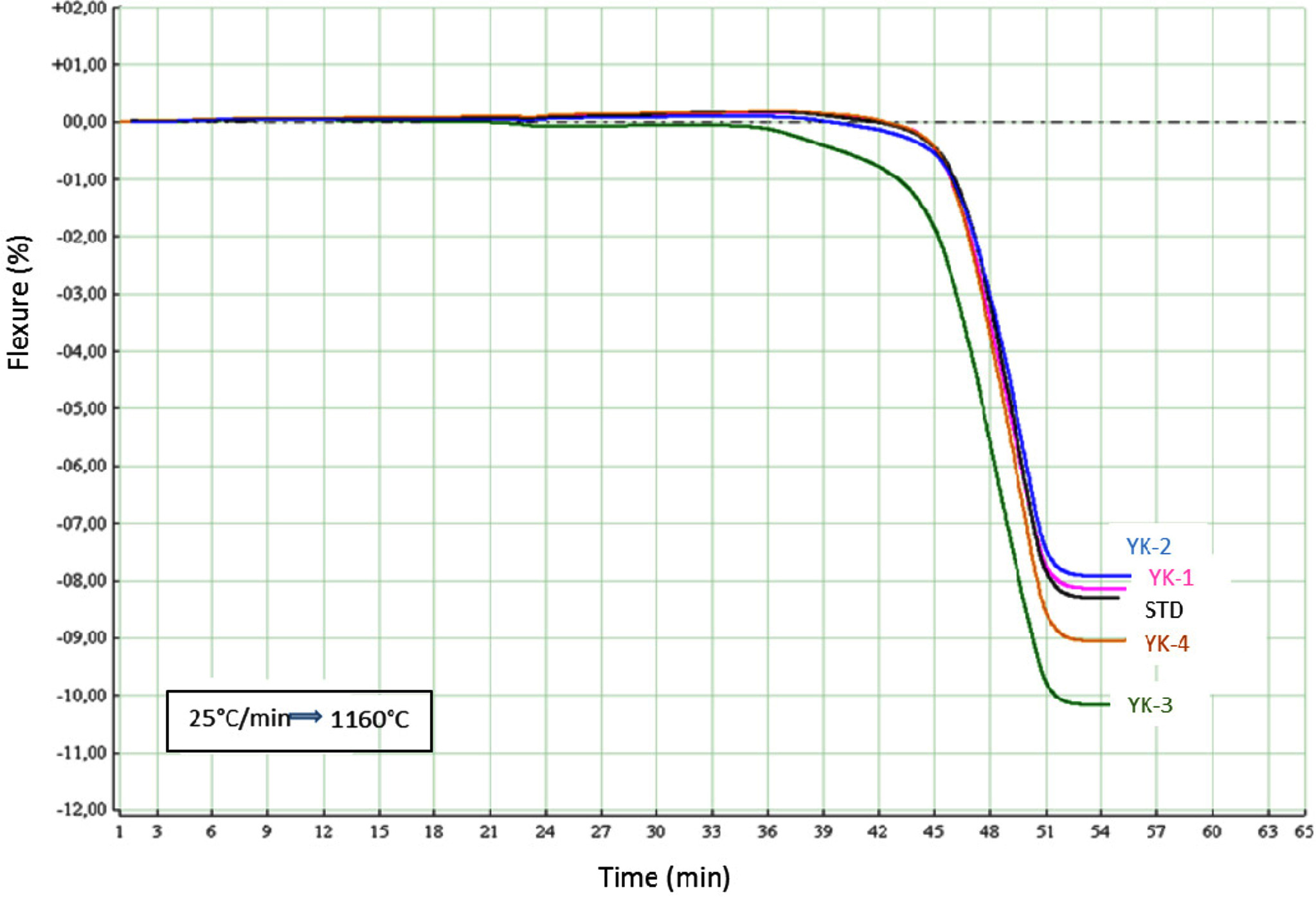

to Eq. (2) by using fleximeter. Fig. 3 shows the deformation behaviour of the

floor tiles according to firing conditions and Table 4 shows the calculated viscosity values depend on the

fleximeter analyses and technological properties of the

compositions. The viscosity value of

the YK_3 composition at 1,160 oC is 107,09 P, while the viscosity

value of the YK_2 composition at 1,160 oC is 108,43 P, it can

be showed that the crystalline phases

are more effectively dissolved. With the increase in MgO/CaO ratio in the

compositions, the increment of glassy

phase fastened dissolution of the crystalline phases when compared the

compositions have low amount of MgO/CaO ratio. When comparing deformation behaviours with fleximeter analysis (Fig. 4), especially for YK_3

composition, the sample started deformation movement after 36 min. During the

sintering period, the deformation movement of the YK_3 composition completed

movement after 51 min and total deformation amount is approximately 10,3%. For

YK_2 composition with the lowest MgO/CaO ratio, deformation movement started

after 45 min and this motion completed

after 54 min. Total deformation is

about 7.83%. YK_2 was then followed by YK_1, STD and YK_4 compositions. In

addition to this, the effect of

magnesium oxide and calcium oxide ratio on sintering was investigated by optical dilatometer analyses. In particular,

the results of the analysis of the temperature at which the samples reach their

maximum sintering point (Table 4). As MgO/CaO ratio increases, the flex point of the bodies decreases. YK_2

composition has 4,450 MgO/CaO ratio

and its flex point is approxi- mately 1,170 ± 2 oC,

while YK_3 composition has 6,550 MgO/CaO

ratio and its flex point is approximately 1,140 ± 2 oC.

This decrease in flex point is quite remarkable

in the compositions. It is evident that by increasing the MgO/CaO ratio in the

composition has a sintering accelerating effect. When investigated the

literature, an a study performed Dondi et al., about porcelain tiles, the

effect of magnesium silicates was emphasized

[15]. They stated that magnesium accelerates the sintering of porcelain tile bodies and narrows the firing range of

the body. In a study performed by Mukhopadhyay et al., the role of talc on

porcelain sintering was investigated. They observed that the talc/feldspar composition reduces the vitrification

temperature [16]. It has been

determined that magnesium oxide which is incorporated by the addition of talc,

provides more liquid formation with lower viscosity, decreases the maturation

temperature but narrows the firing range of the body. Therefore, the results of

this study are consistent with in the literature.

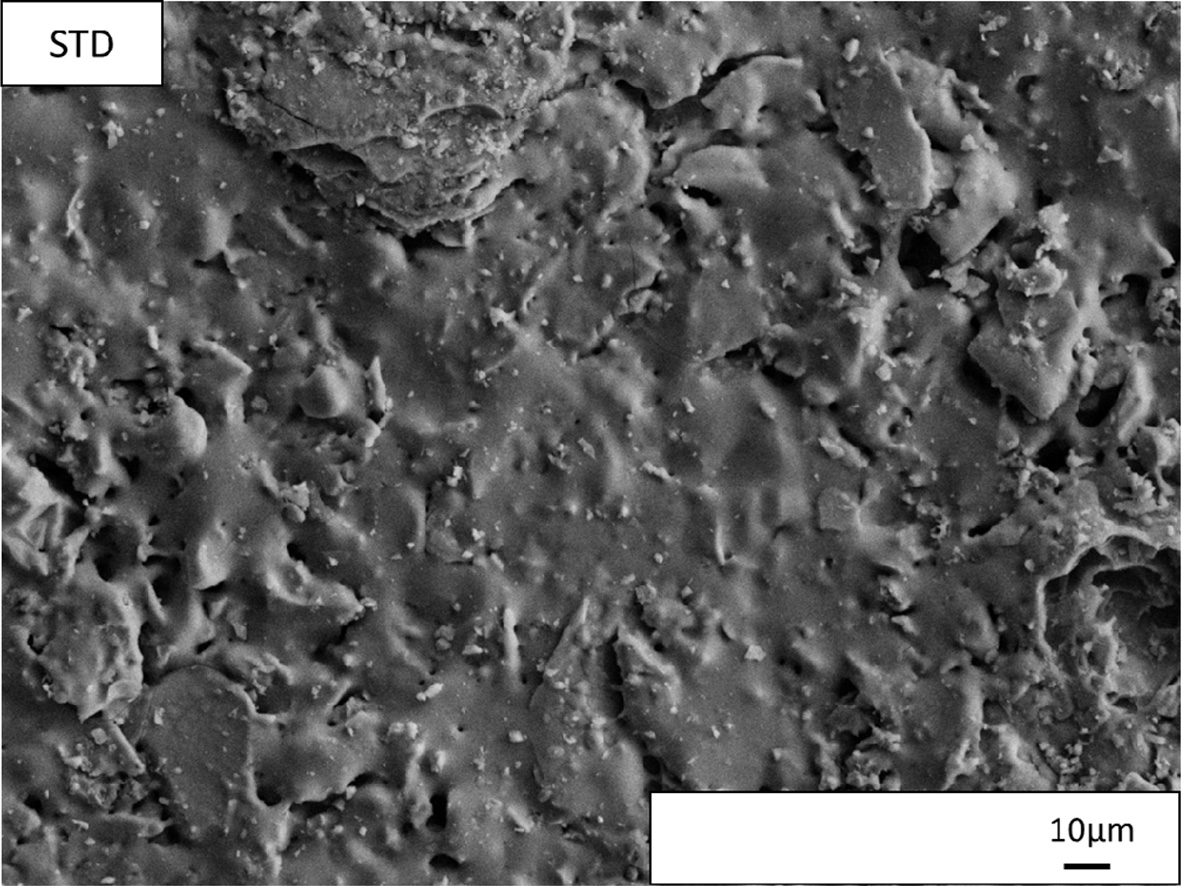

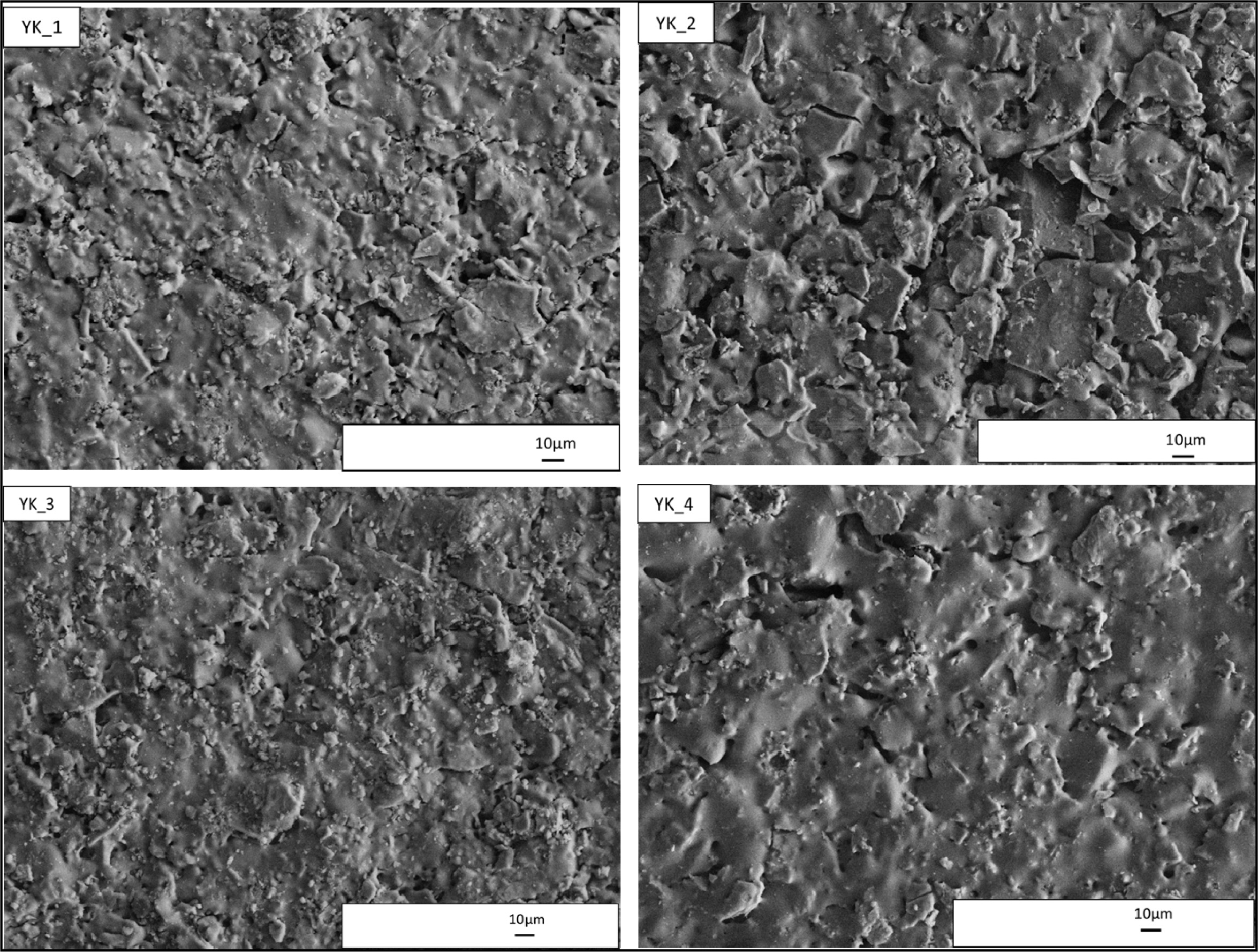

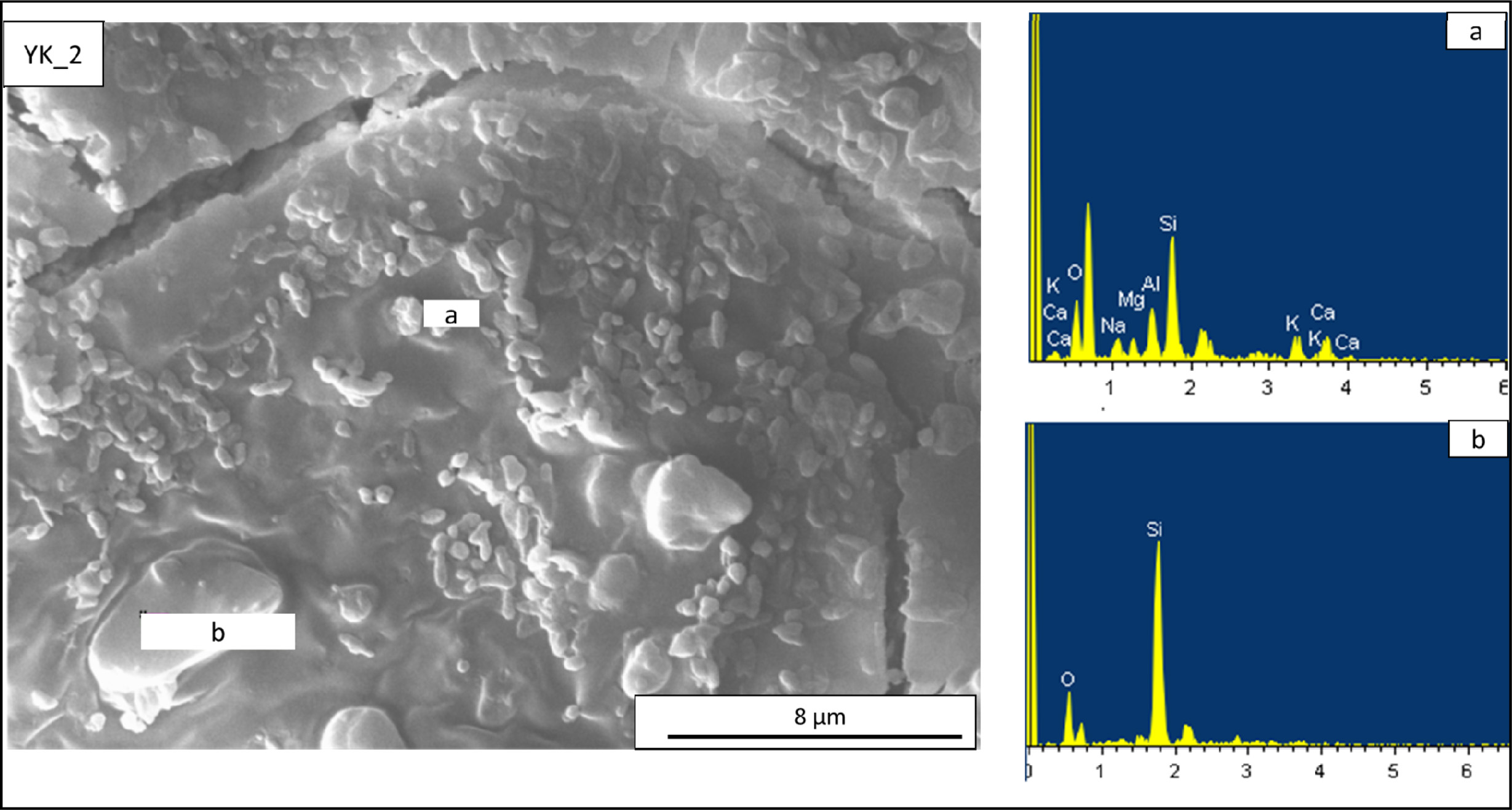

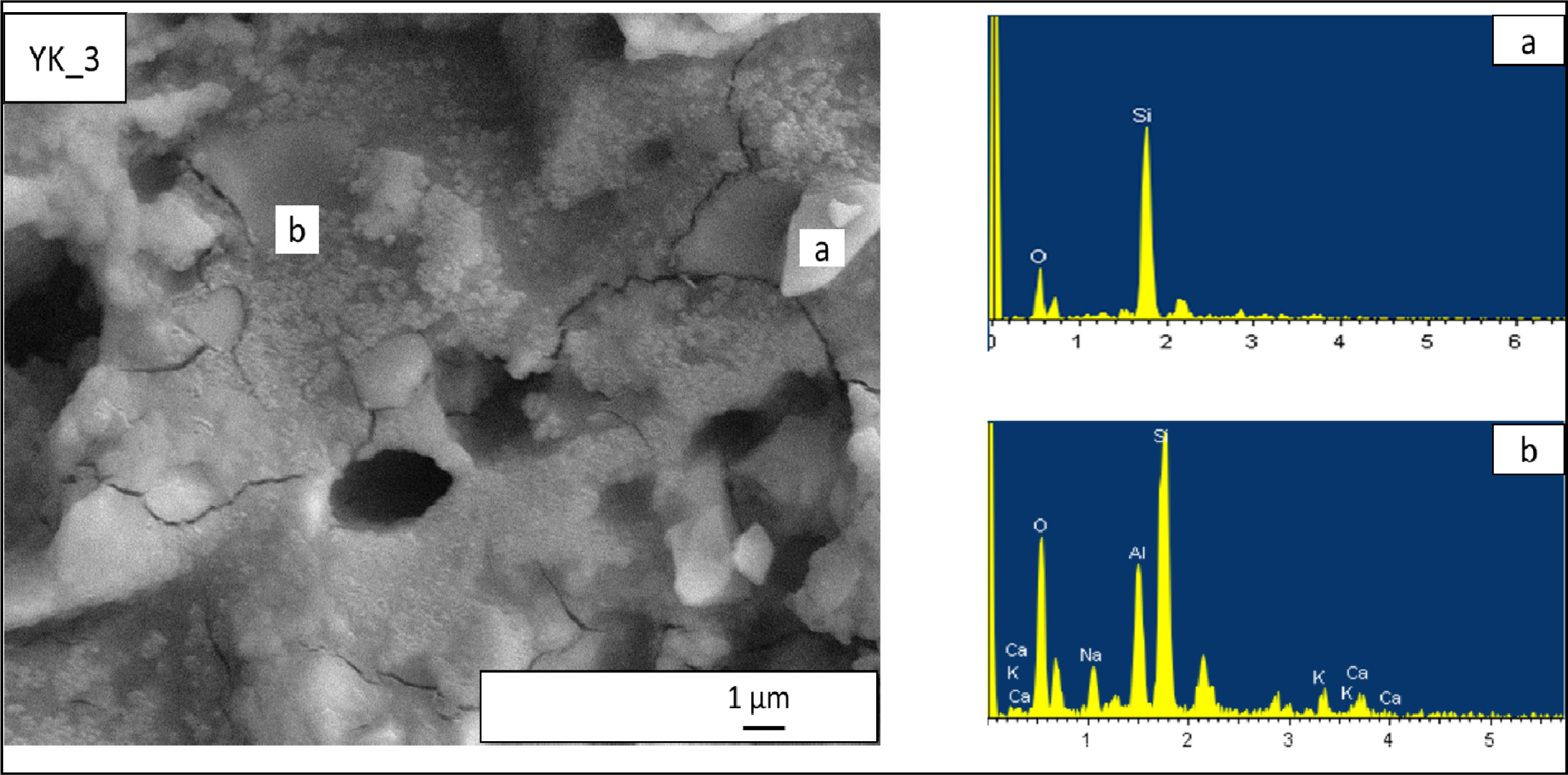

SEM images taken from the polished surfaces of the

industrially fired standard and new floor tile bodies are represented Fig. 5

and Fig. 6. When the surface micro-

structures were investigated, generally similar structures

could be seen Fig. 6. Therefore, EDX analyses of the samples were carried out

in order to see types and distributions of the crystalline

phases, pores, etc. depend on the compositions.

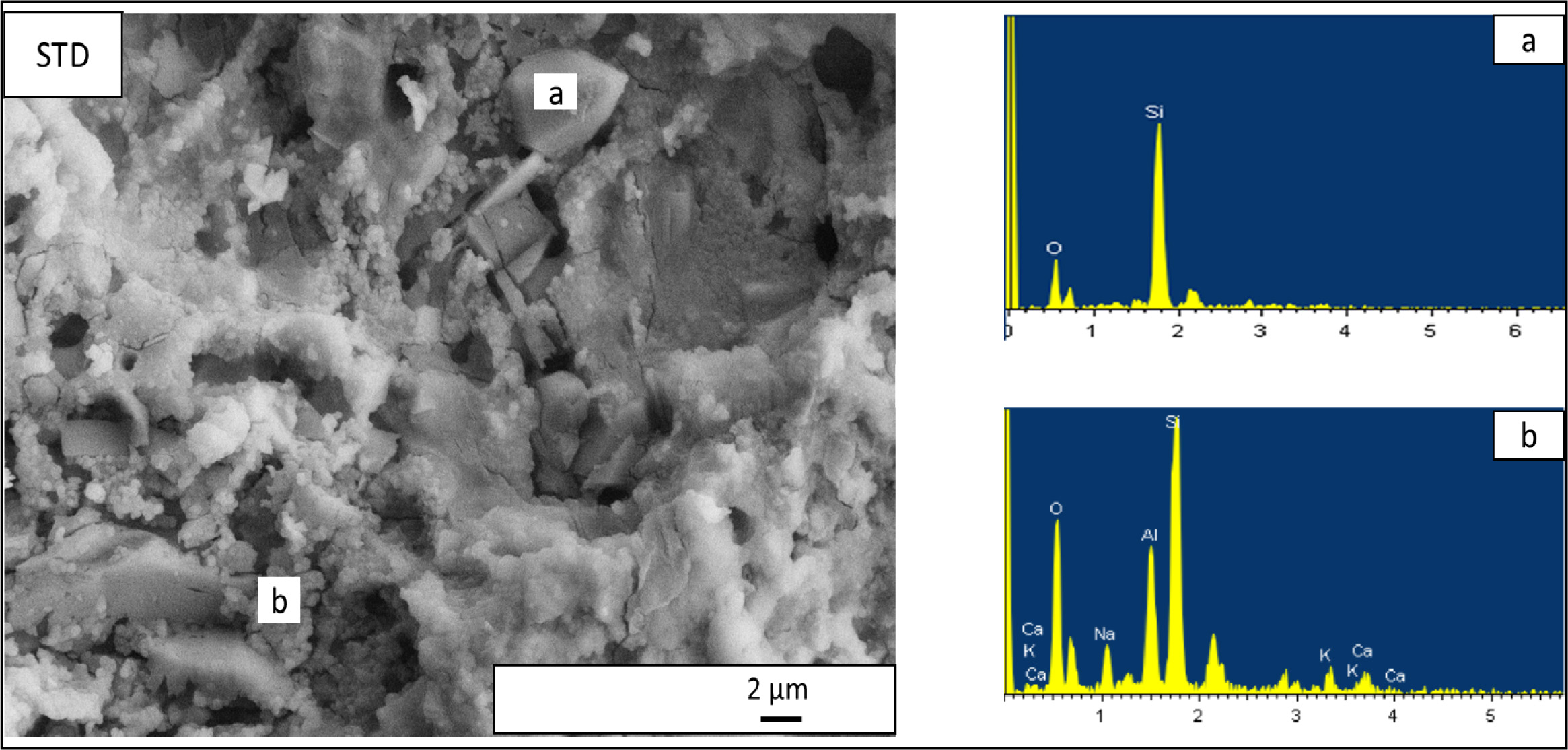

In addition, a typical SE (secondary electrons) image taken on the

fractured surface etched with 10%HF solution for 20 s to selectively remove the

glassy matrix shows some of the constituent crystalline phases. For standard

floor tile body composition (Fig. 7), irregular shaped particles contain mainly

silicon and oxygen so being quartz crystals (Fig. 7 (a)), presence of small

spheroidal crystals forming clusters that contain mainly

calcium, sodium, aluminium, silicon and oxygen so being

attributable to anorthite and albite crystals (Fig. 7(b)). Selected

microstructures of the YK_2 and YK_3 compositions are shown in Fig. 8 and Fig.

9. The microstructure of the YK_2 composition is shown in Fig. 8. In this

composition, according to the results of (a) EDX analysis of round crystalline

clusters, it is seen that there is a region of albite and anorthite crystals

and the grain sizes are around 1-2 microns. Irregular and

large grains are also present (b), according to the EDX

analysis taken from these regions, it is seen that these grains are quartz

crystals. Microstructure of YK_3 composition is given in Fig. 9. This

composition also contains quartz crystals (Fig. 9(a)), albite,

anorthite (Fig. 9(b)) and but the crystalline dimensions are quite

small (400-500 nm). Less viscous liquid phase and its able to eliminate larger

pores and increase crystals dissolutions.

|

Fig. 1 XRD pattern of the standard (STD) composition. |

|

Fig. 2 Comparison of the XRD patterns of the floor tile compositions with standard floor tile body. |

|

Fig. 3 Effect of MgO/CaO molar ratio on the viscosity of the floor

tile bodies at 1,160 oC. |

|

Fig. 4 Deformation behaviour of STD and new compositions. |

|

Fig. 5 SEM micrograph of the standard floor tile (STD). |

|

Fig. 6 SEM micrographs of the floor tile compositions. |

|

Fig. 7 EDX patterns taken from the standard floor tile (STD) compositon. (a) EDX analyses of irregular shaped crystal in STD composition,

(b) EDX analyses of a cluster of spheroidal crystals in STD composition. |

|

Fig. 8 EDX patterns taken from the newly developed porcelain stoneware tile (YK_2) composition. (a) EDX analyses of rounded shaped

crystal in (YK_2) composition, (b) EDX analyses of a irregular shaped crystals in (YK_2) composition. |

|

Fig. 9 EDX patterns taken from the newly developed porcelain stoneware tile (YK_3) composition. (a) EDX analyses of rounded shaped

crystal in (YK_3) composition, (b) EDX analyses of a irregular shaped crystals in (YK_3) composition. |

|

Table 3 Quantative mineralogical analyses of the floor tile

bodies by MAUD method after firing at 1,160 oC (in wt %). |

|

Table 4 Calculated viscosity values & Technological properties of the floor tiles |

In this study, floor tile compositions which contain

different MgO/CaO ratio, has been studied. It has been founded that MgO/CaO

ratio affects the viscosity of the floor tiles and as the ratio increases the

viscosity decreases. This viscosity decrease plays an important role for

pyroplastic behaviour of the tiles. This means that when effect of

compositional changes (in particular if there is any change in amount of liquid

phase formers) on sintering of the tiles are investigated, the viscosity should

be monitored and used as a key parameter during sintering of the tiles. For

YK_3 composition will be evaluated due to has allowable deformation amount for

the production. This floor tile composition will be successfully produce in

production line.

- 1. W.M. Carty and U. Serapati, J. Am. Ceram. Soc. 81[1] (1998) 3-20.

-

- 2. F.H. Norton, in “Fine ceramics: Technology and applica- tions” (McGraw Hill, 1970) p.70-75.

- 3. A. Dinsdale, in “Pottery science: Materials, Processes and Products” (Ellis Horwood Limited, 1986) p.40-52.

- 4. W.E. Warrol, in “Ceramic raw materials” (Pergamon, 1982) p.70-100.

-

- 5. A. Vari, in “Raw material preparation and forming of ceramic tiles” (S.A.L.A, 2000) p.45-60.

- 6. K.N. Maiti, C.S. Prasad, K.C. Singh, and A.K. Gupta, Trans. Ind. Ceram. Soc. 60[2] (2000) 77-81.

- 7. A.C. Bull, Trans. Brit. Ceram. Soc. 81[3] (1982) 69-74.

- 8. D.Y. Tuncel and E. Ozel, Ceram. Int. 38[2] (2012) 1399-1407.

-

- 9. Z.B. Ozturk and N. Ay, J. Ceram. Process. Res. 13[5] (2012) 635-640.

- 10. E. Rastelli, A. Tucci, L. Esposito, and L. Malmusi, Key Eng. Mater. 264-268 (2004) 1531-1534.

-

- 11. S. Elmas and İ. Tarhan, J. Sci. Perspect. 3[2] (2019) 85-98.

-

- 12. S.J.G. Sousa and J.N.F. Hollanda, Mater. Res. 8[2] (2005) 197-200.

-

- 13. E. Porte, R. Brydson, R. Rand, and R. Riley, J. Am. Ceram. Soc. 87[5] (2004) 923-928.

-

- 14. T. Aydın and A. Kara, J. Ceram. Process. Res. 15[6] (2014) 486-491.

- 15. M. Dondi, V. Biasini, G. Guarini, M. Raimondo, A. Argnani, and S. Primio, Key Eng. Mater. 206-213 (2002) 1795-1798.

-

- 16. T.K. Mukhopadghyay, M. Das, S. Glosh, S. Chacrabarti, and S. Ghatak, Ceram. Int. 29[5] (2003) 587-597.

-

- 17. V. Biasini, M. Dondi, G. Guarini, M. Raimondo, A. Argnani, and S.D. Primio, Silicates Industries 68[5-6] (2003) 67-73.

- 18. M. Paganelli, Am. Cer. Soc. Bull. 81[11] (2002) 25-30.

This Article

This Article

-

2020; 21(6): 632-639

Published on Dec 31, 2020

- 10.36410/jcpr.2020.21.6.632

- Received on Mar 24, 2020

- Revised on Jun 9, 2020

- Accepted on Jun 10, 2020

Services

Services

Shared

Correspondence to

Correspondence to

- Neslihan Tamsu Selli

-

Department of Materials Science and Engineering, Gebze Technical University, 41400 Gebze, Kocaeli, Turkey

Tel : +902626052661 - E-mail: ntamsu@gtu.edu.tr

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.