- Evaluation of the hydration heat and strength progress of cement–fly ash binary composite

Xiao-Yong Wanga,b*

aDepartment of Architectural Engineering, Kangwon National University, Chuncheon 24341, Korea

bDepartment of Integrated Energy and Infra System, Kangwon National University, Chuncheon 24341, Korea

Fly ash is an industry

by-product of thermal power factories that is broadly utilized in the concrete

industry. This research shows a framework for evaluating the hydration heat,

reaction amount, and strength progress of cement–fly ash binary composite.

First, we conducted an experiment to study the isothermal hydration heat of fly

ash composite paste with assorted fly ash contents and temperatures. According

to the experimental outcomes of cumulative hydration heat, the coefficients of

a kinetic reaction model of fly ash were determined. Furthermore, the reaction

amount of fly ash was calculated using a fly ash reaction model. We discovered

that the reaction of fly ash is considerably improved at elevated temperatures.

The reaction amount of fly ash decreases with the growing content of fly ash.

Second, in line with the reaction amount of fly ash and cement, we developed a

straight-line equation for evaluating the strength progress of binary

composite. The strength progress model applies to a number of water-to-binder

ratios and fly ash substitution ratios. Summarily, the suggested

hydration–heat–strength model is helpful for understanding the material style

of fly ash concrete.

Keywords: Fly ash, Hydration heat, Reaction degree, Strength, Model

Fly ash is really a pozzolanic mineral admixture that is

able to interact with calcium hydroxide to create secondary calcium silicate

hydrate. Fly ash concrete shows several benefits, for example, low hydration

heat and low temperature increase of hardening concrete, good workability, high

long-term strength, and high resistance of chloride ingression.

Evaluations of qualities, for example, hydration heat and

strength development, are useful for the rational usage of

fly ash in construction [1, 2].

Many numerical models have been proposed for binary

composite containing fly ash and cement. Lam et al. measured the amount of

reaction of fly ash using the technique of selective dissolution and evaluated

the progress of strength of binary composite using gel–space ratios [3].

Schindler and Folliard predicted the hydration heat of hardening

concrete with supplementary cementing materials, for example,

slag and fly ash. Furthermore, an overall reaction degree of binders was

proposed in Schindler and Folliard’s study [4]. Based on the experimental

results of calcium hydroxide content, Pane and Hansen analyzed the amount of

reaction of mineral admixtures, for example, slag, fly ash, and silica fume

[5]. Based on isothermal hydration heat, Han et al. analyzed the kinetic

hydration process of fly ash composite paste,

and an overall reaction degree was used for binary composite[6]. Baert

et al. proposed a multi-component model for evaluating the release of hydration

heat of blended paste with various fly ash contents [7]. Nath et al. analyzed

the kinetic reaction of fly ash geopolymer using isothermal

hydration heat and the modified Jander equation [8]. Deschner et

al. proposed thermodynamic modeling for fly ash composite concrete, in which

the phase assemblage of binary composite at various curing temperatures is

evaluated [9]. Xu et al. evaluated the hydration heat and amount of reaction of

binary composite using a three-parameter equation [10].

Narmluk and Nawa proposed a theoretical model of hydration and calculated

the reaction amount of cement in composite paste containing fly ash and cement,

and the improvement of the amount of reaction of cement because of the addition

of fly ash addition was clarified [11]. Garcia-Lodeiro et al. proposed a

descriptive model for the reaction of binary composite containing alkalis [12],

and the effects of different types of alkalis on hydration products were

clarified [12].

Although many modeling investigations have been proposed

for fly ash concrete, these investigations show some

weak points. First, most of the studies focus on single

properties of concrete, such as hydration heat [4, 6-8, 10] or strength

development [3]. To rationally use fly ash, an integrated model for both

hydration heat and strength development will be more helpful for engineering

practices. Second, in previous studies [5, 8, 10], the parameters of the models

are dependent on a specific mix of ratios, such as the water-to-binder ratio

and the fly ash substitution ratio. When the mixtures are changed,

it is difficult to use these models [5, 8, 10]. Third, most

hydration models focus on ordinary-strength or high-strength

concrete [4-7, 9-11], which has a water-to-binder ratio higher than

0.3. Studies on the hydration of cement-based materials that have a much lower

water-to-binder ratio are very limited. On the other hand, ultra-high-performance

concrete that has a very low water-to-binder ratio is increasingly being used

in constructions [13, 14]. Thus, it is necessary for us to propose a new

hydration model that is valid for ultra-high-strength,

high-strength, and ordinary-strength concretes.

To overcome the flaws of previous studies, this research

proposes a framework for evaluating the release of hydration heat, reaction

amount, and strength progress of binary composite. According to the

experimental outcomes of isothermal hydration heat with assorted temperatures,

the reaction amount of fly ash is calculated using a kinetic reaction model. Furthermore,

in line with the reaction amount of fly ash and cement, a straight-line

equation is suggested for evaluating the strength progress of binary composite

with assorted water-to-binder ratio and fly ash-to-binder ratio. The suggested hydration–heat–strength

model is helpful for understanding the material style of fly ash

concrete.

The

cement hydration model

Our previous study showed a model for the kinetic

hydration process of Portland cement [13, 15]. This model takes

into account the kinetic phases of hydration, for example,

the phases of initial dormant, boundary reaction, and diffusion. The degree of

hydration of cement a

can be calculated using a method of integration such as a = ![]() , where da/dt

is the rate of hydration of cement. The model of cement hydration considers

the shortage of capillary water and, consequently, the

insufficient hydration of concrete with a low water-to-binder ratio, such as

high-strength and ultra-high-strength concretes. The input

parameters of the hydration model consist of cement

compositions, concrete mix ratios, and curing circumstances. The output result

of the hydration model is the reaction amount of cement.

, where da/dt

is the rate of hydration of cement. The model of cement hydration considers

the shortage of capillary water and, consequently, the

insufficient hydration of concrete with a low water-to-binder ratio, such as

high-strength and ultra-high-strength concretes. The input

parameters of the hydration model consist of cement

compositions, concrete mix ratios, and curing circumstances. The output result

of the hydration model is the reaction amount of cement.

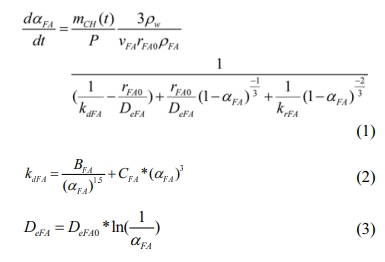

The

fly ash reaction model

Fly ash is a type of pozzolanic material that can react

with calcium hydroxide and can form secondary calcium silicate hydrate [16].

Compared to cement, the reactivity of fly ash is low. The initial dormant

period of the reaction of fly ash is long. In addition, the kinetic reaction process

of binary composite is similar to that of plain cement [17]. At a late age of

hydration, the control stage of pozzolanic reaction is diffusion

[18]. Considering the material characteristics and reaction

kinetics of fly ash, we assume the reaction of fly ash comprises the phases of

initial dormant, boundary reaction, and diffusion. The kinetic reaction

equation process is shown as follows:

where aFA

denotes the reaction amount of fly ash; mCH(t) and P denote the masses of calcium

hydroxide in hydrating binary composite and fly ash in the concrete,

respectively; nFA

denotes the stoichiometric ratio of fly ash to calcium hydroxide (nFA =

0.845 -0.7(P/(C+P)), where C denotes the mass of

cement in concrete [13]); rFA0 denotes the average

radius of the particles of the fly ash; rFA

and rW

denote the density of the fly ash and water, respectively; kdFA

denotes the reaction rate coefficient of the dormant stage (BFA

and CFA are sub-coefficients); DeFA0

denotes the initial diffusion coefficient of the diffusion stage; and krFA

denotes the reaction rate coefficient of the boundary reaction stage.

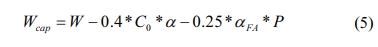

For binary composite, calcium hydroxide content is

dependent on both the hydration of cement and the reaction of fly ash. The mass

of calcium hydroxide can be established as follows:

where RCHCE is the

calcium hydroxide production when the unit mass of cement hydrates; a is the hydration degree of cement;

and RCHCE * C * a

and nFA * aFA * P

denote the calcium hydroxide production from the hydration of cement and from

the reaction of fly ash, respectively.

For binary composite, capillary water is consumed by the

reactions of fly ash and cement. The content of capillary water can be

determined as follows:

where Wcap and W

are the masses of the remaining capillary water and mixed water in concrete

mixtures, respectively; and 0.25 * aFA * P

and 0.4 * C * a refer to the masses of consumed

capillary water from the reaction of fly ash and from the hydration of cement,

respectively.

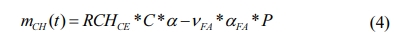

Fly ash reaction is sensitive to temperature. When curing

temperature increases, fly ash reaction accelerates. To

consider the influence of temperature on the reaction of fly ash, we used the

Arrhenius law as follows:

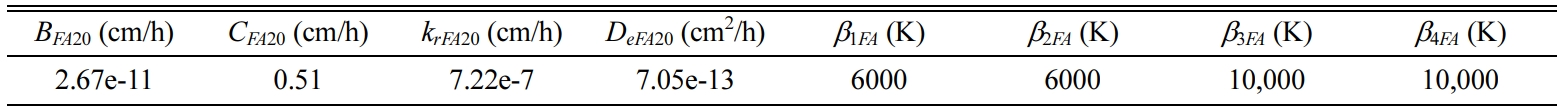

where BFA20,

CFA20, DeFA20, and krFA20

denote the values of coefficients BFA, CFA, DeFA0,

and krFA at 293 K, respectively; and b1FA, b2FA, b3FA,

and b4FA

denote the temperature sensitivity coefficients of BFA, CFA,

krFA0, and DeFA0,

respectively. Based on the reaction quantity of fly ash at various curing

temperatures, the temperature sensitivity coefficients b1FA, b2FA, b3FA,

and b4FA

can be discovered.

For binary composite, fly ash reaction and cement

hydration play a role in the hydration heat. The discharge of hydrate heat is

proportional to the amount of hydration. The entire hydration heat is the sum

of the reaction of fly ash and the hydration of cement. The hydration heat of

binary composite can be established as follows:

where Q is rate of heat

generation; HC and HFA denote of heat generation for cement and fly

ash, respectively, where HC can be determined from cement

compound compositions and HFA is equal to 50 kcal/kg [19]; and P * HFA * aFA

and C * HC * a

denote the release of heat from the reaction of fly ash and from the hydration

of cement, respectively.

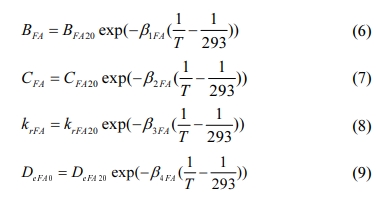

The

strength development model

Compressive strength can be a basic property of

cement-based materials. The construction process and structural design closely

relate to the development of concrete strength. The strength of concrete is

linearly based on the reaction quantity of cement [20]. Con- sidering both the pozzolanic property of

fly ash and the hydration process of cement, the development of the strength of

binary composite can be discovered by:

where fc refers to the concrete strength; A1, A2, and A3 are the coefficients of strength; A*((C*a)/W) considers the influence of cement hydration on

strength; A2*((P*aFA)/W) considers the influence of fly ash hydration on

strength; and A3 considers the concrete strength starts after a threshold time, not after

the mixing time. The coefficients A1, A2, and A3 can be determined according to experimental outcomes of the strength of

concrete. Because the reaction amounts of binders a

and aFA

are dependent on time, the strength of concrete is a function

of time.

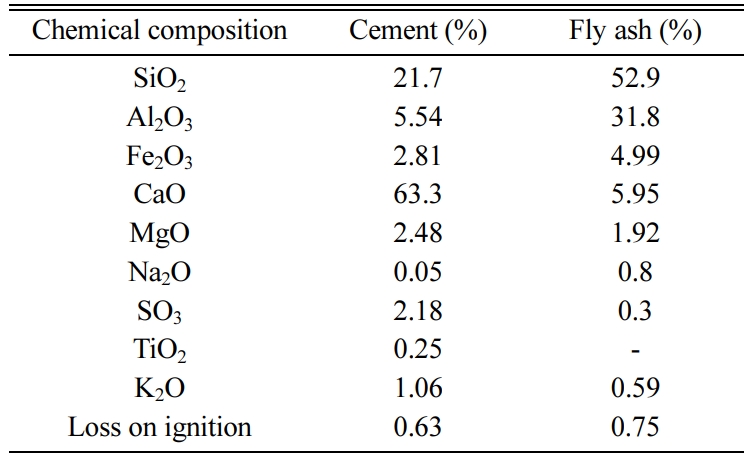

The

hydration heat model

As proven in eq. (10), the discharge of the hydration heat

of binary composite pertains to both cement and fly ash. To look for the

reaction coefficient of fly ash, we conducted experiments on isothermal

hydration heat with elevated temperatures and fly ash contents. The

water-to-binder ratio of the paste specimen was 0.5; the fly ash substitute

ratio was 0%, 20%, or 40%; and the temperatures were set as 20, 35, or 50 oC.

The chemical compositions of fly ash and cement are given in Table 1. The paste

was mixed utilizing a mechanical agitator and 5 g of paste was taken for the

measurement of hydration heat.

The development of hydration heat was measured by using TAM-air, and the

duration of the hydration heat measurement was 72 h [21, 22].

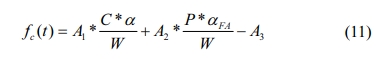

The experimental outcomes of the rate of hydration heat

are shown in Fig. 1. First, Fig. 1(a) shows for plain paste at 20 oC,

the main exothermic peak occurs at about 10 h. This exothermic peak is due to

the hydration of alite. At the deceleration stage, the exothermic peak may be

from the renewed dissolution of C3A [21, 22]. As the temperature

increases from 20 oC to 50 oC (from Fig. 1(a)

to 1(c)), the main exothermic peak occurs much earlier, and the value of the

exothermic peak also increases. Second, for binary composite, with increasing

contents of fly ash, the hydration heat decreases. This is from the dilution effect

of the addition of fly ash. In addition, for specimens with fly

ash, the occurrence time of the exothermic peak slightly retards. This can be

due to the fact that the reactivity of fly ash is gloomier than cement, and the

hydration heat of binary composite is lower than plain cement. Third, Fig. 1(c)

shows at 50 oC, for Portland cement, the exothermic peaks of C3S

reaction and C3A renewed dissolution merge together.

Meanwhile, for binary composite, at the deceleration stage, the

exothermic peak may be from the reaction of fly ash.

The reactivity of fly ash is low at normal temperatures, such as 20 oC,

and also the growing temperature can accelerate the reaction of fly ash and can

increase of heat release of binary composites [21, 22]. However, we ought to

observe that the hydration heat is not the direct measurement of the reaction

amount of fly ash. To calculate the reaction amount of fly ash, the regression

of the reaction coefficients of the blended hydration model is essential.

Within this study, experimental outcomes of cumulative hydration heat can be used for regression

of the coefficients of the blended hydration model.

As proven in eq. (10), hydration heat pertains to fly ash

reaction and cement hydration. The hydration heat of cement can be calculated

using the Portland cement hydration model within our previous

study [15, 21]. Furthermore, the coefficients of fly ash can be established

according to the experimental outcomes of the binary composite. The reaction

coefficients of fly ash are shown in Table 2. When the mixtures of concrete change,

the reaction coefficients do not change.

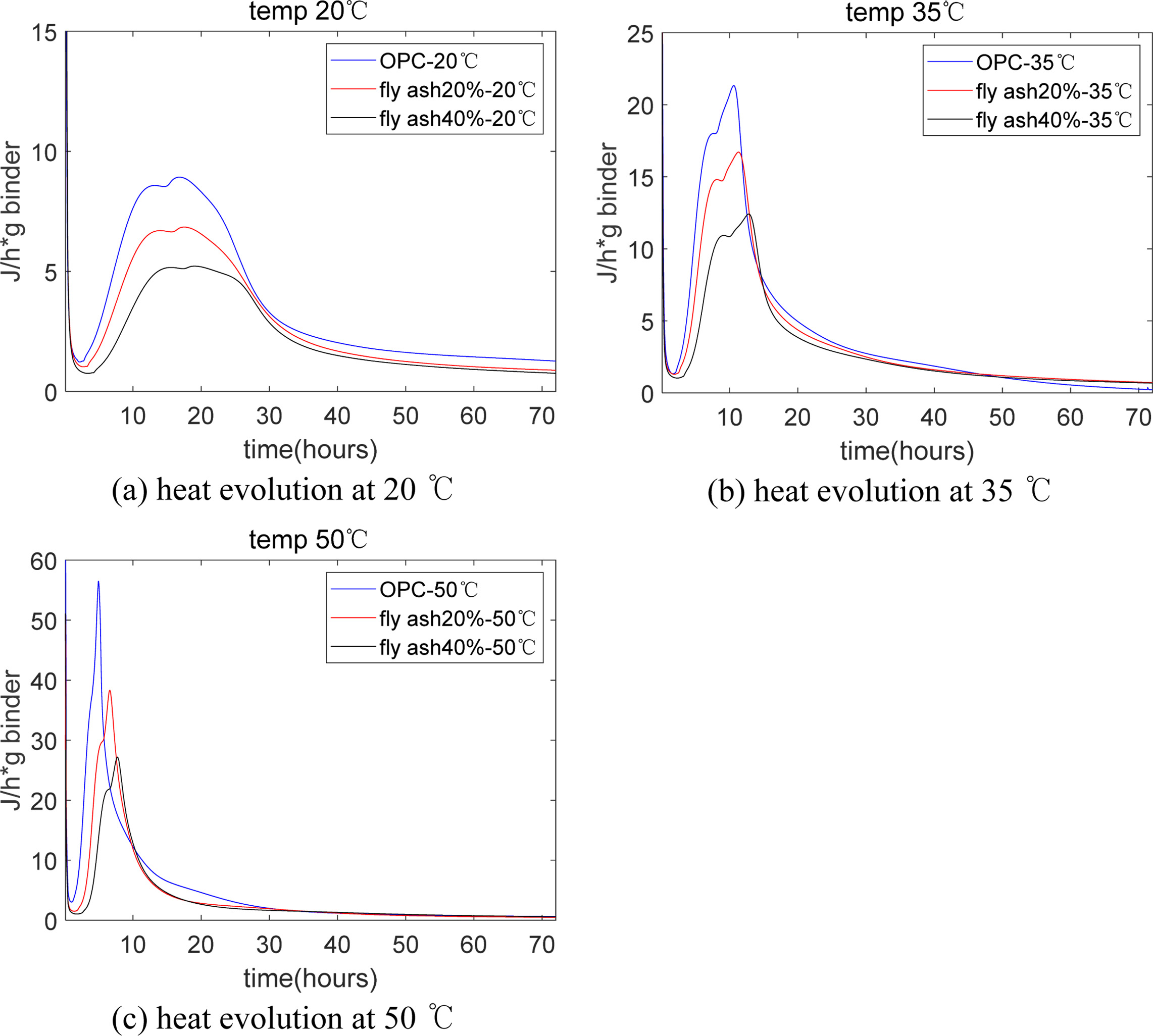

The calculation results of cumulative hydration heat are

shown in Fig. 2. Fig. 2(a) to 2(c) show in the early age, the accumulative

hydration heat rapidly increases, and at late ages, the increase in hydration

heat is not obvious, especially for specimens with a high

temperature of 50 oC. This is

because at the late age, diffusion is the control stage, and the hydration

of the binder is accelerated at elevated temperatures. Generally, the evaluation results show agreement with the experimental outcomes. From Fig. 2(a) to 2(c),

with an increasing fly ash substitution ratio, the cumulative hydration heat

becomes lower. This is because the reaction heat per mass and reactivity of fly

ash are less than that of cement.

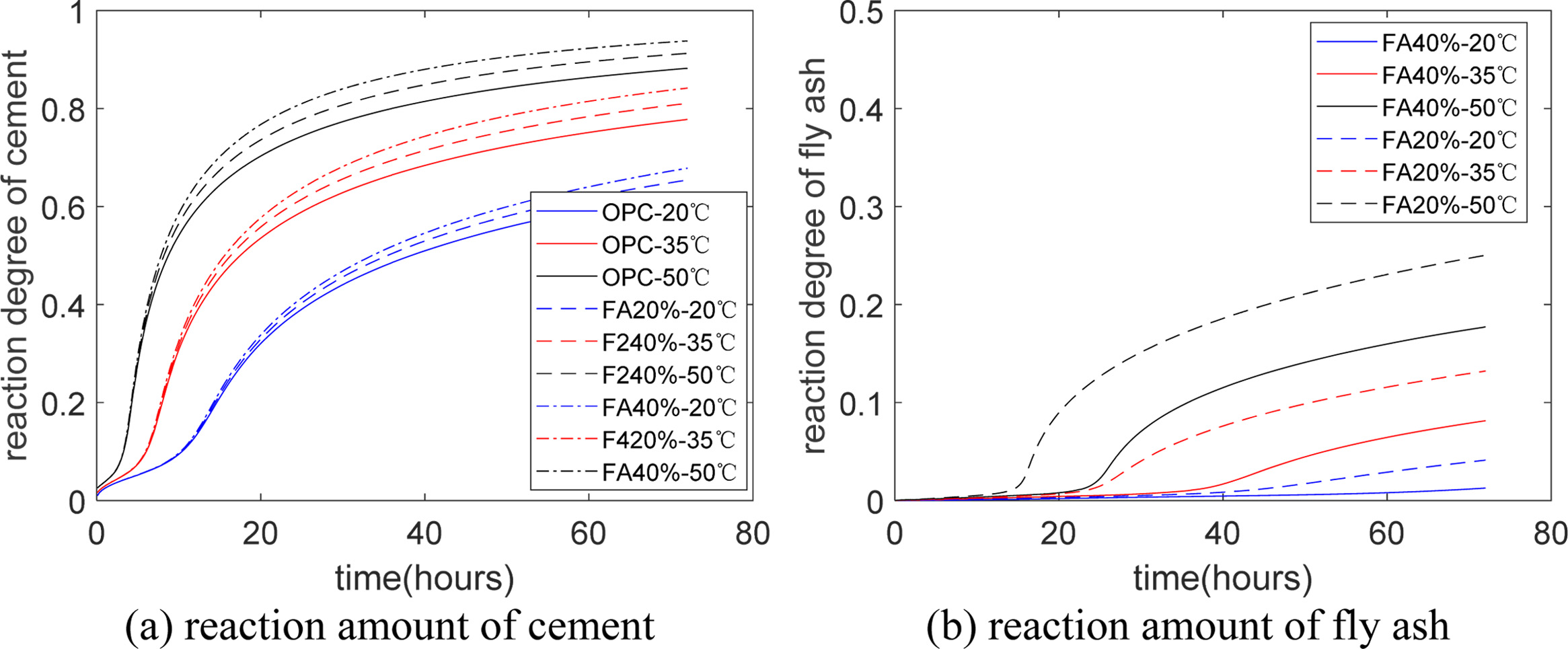

Fig. 3 shows the reaction amount of cement and fly ash.

As proven in Fig. 3(a), given a particular temperature, the

hydration amount of cement in binary composite is greater than that in plain

cement. This is because of the dilution aftereffect of fly ash; after the

inclusion of fly ash, the water-to-cement ratio increases, and the rate of

hydration of cement increases correspondingly. As proven in

Fig. 3(b), using the growing fly ash substitute ratio, the

activation aftereffect of calcium hydroxide becomes weaker, and also the

reaction amount of fly ash decreases [23]. The reaction amount of fly ash is a

lot less than cement. Especially at 20 oC, the reaction amount

of fly ash is under 5%. At elevated temperatures, the

reaction amount of fly ash clearly increases [24]. Quite simply, isothermal

calorimetry with high tem peratures may be used for indirectly identifying the reaction amount of

fly ash.

Within this study, the reaction amount of fly ash was

determined using hydration heat. However, there are more experimental means of

measuring the reaction amount of fly ash, for example, the method of selective

dissolution or image analysis. Lam et al. determined the reaction amount of fly

ash using the selective dissolution method [3], in which the water-to-binder

ratio varied from 0.19 to 0.50, the fly ash substitute ratio varied from 0.25

to 0.55, and the testing ages varied from 7 days to 3 months. The

curing temperature of the paste specimen was 27 oC

[3].

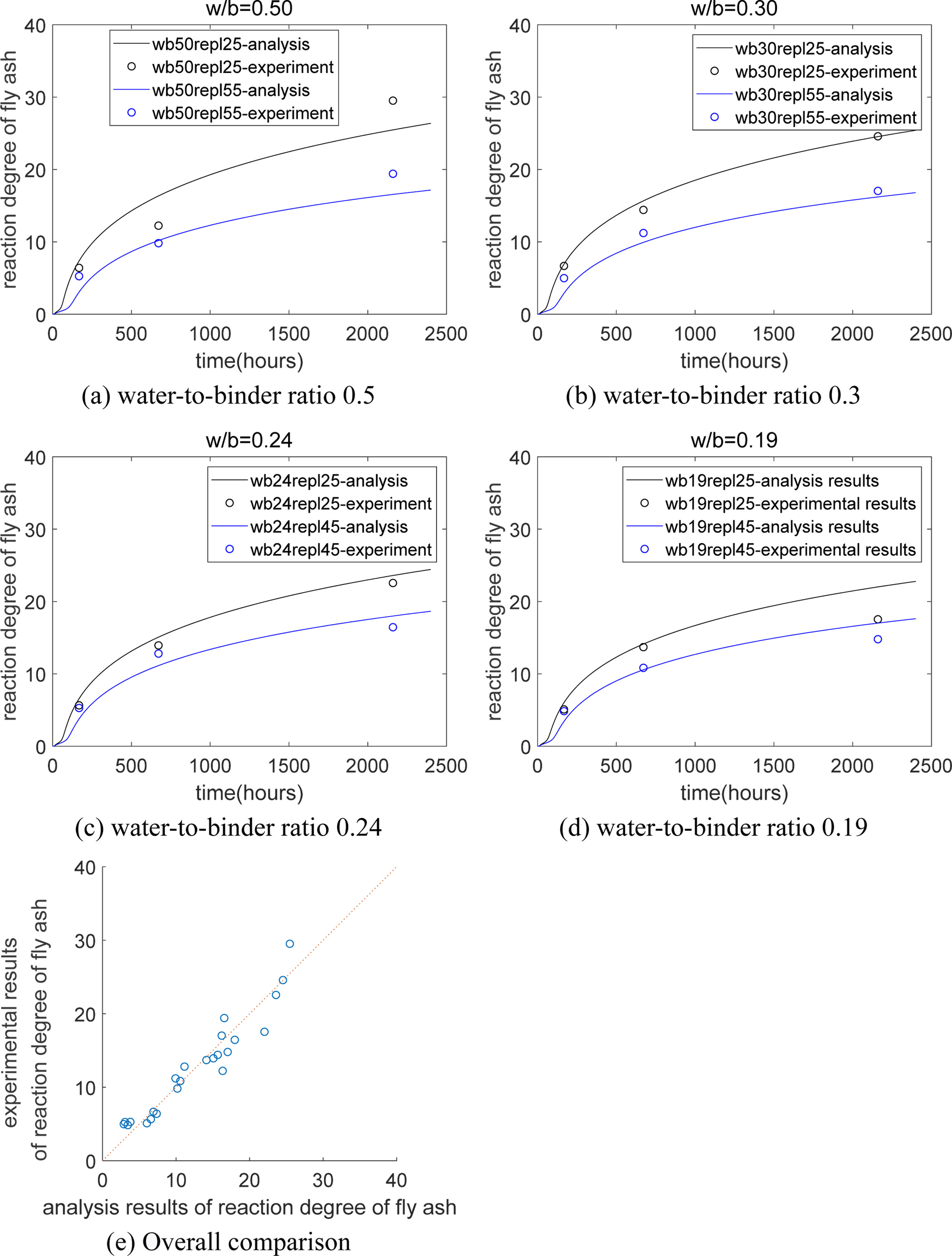

According to the blended hydration model, the reaction

amount of fly ash was calculated. As proven in Fig. 4(a) to

4(d), given a particular water-to-binder ratio, the

reaction amount of fly ash decreases as fly ash-to-binder ratio increases [25].

This trend is comparable with that in Fig. 3(b). Additionally,

given a particular fly ash content, the reaction amount of

fly ash decreases as the water-to-binder ratio decreases. This is because the accessible

deposit space for hydration products becomes inadequate

for concrete that has a low water-to-binder ratio [26].

Fig. 4(e) shows that analysis outcomes generally accept

experimental outcomes. The correlation coefficients between the analysis outcomes and

the experimental answers are

0.97. Summarily, the suggested blended hydration model is applicable for a

number of ages, for example, early-age hydration (isothermal hydration heat)

and lengthy-term hydration (reaction amount at 3 months), and it is valid for

concrete with assorted water-to-binder ratio and fly ash contents. Since the

interactions between the hydration procedure for cement and the reaction

procedure for fly ash are taken into consideration with the items in capillary

water and calcium hydroxide, the coefficients of the binary composite hydration

model do not change for a number of mixtures.

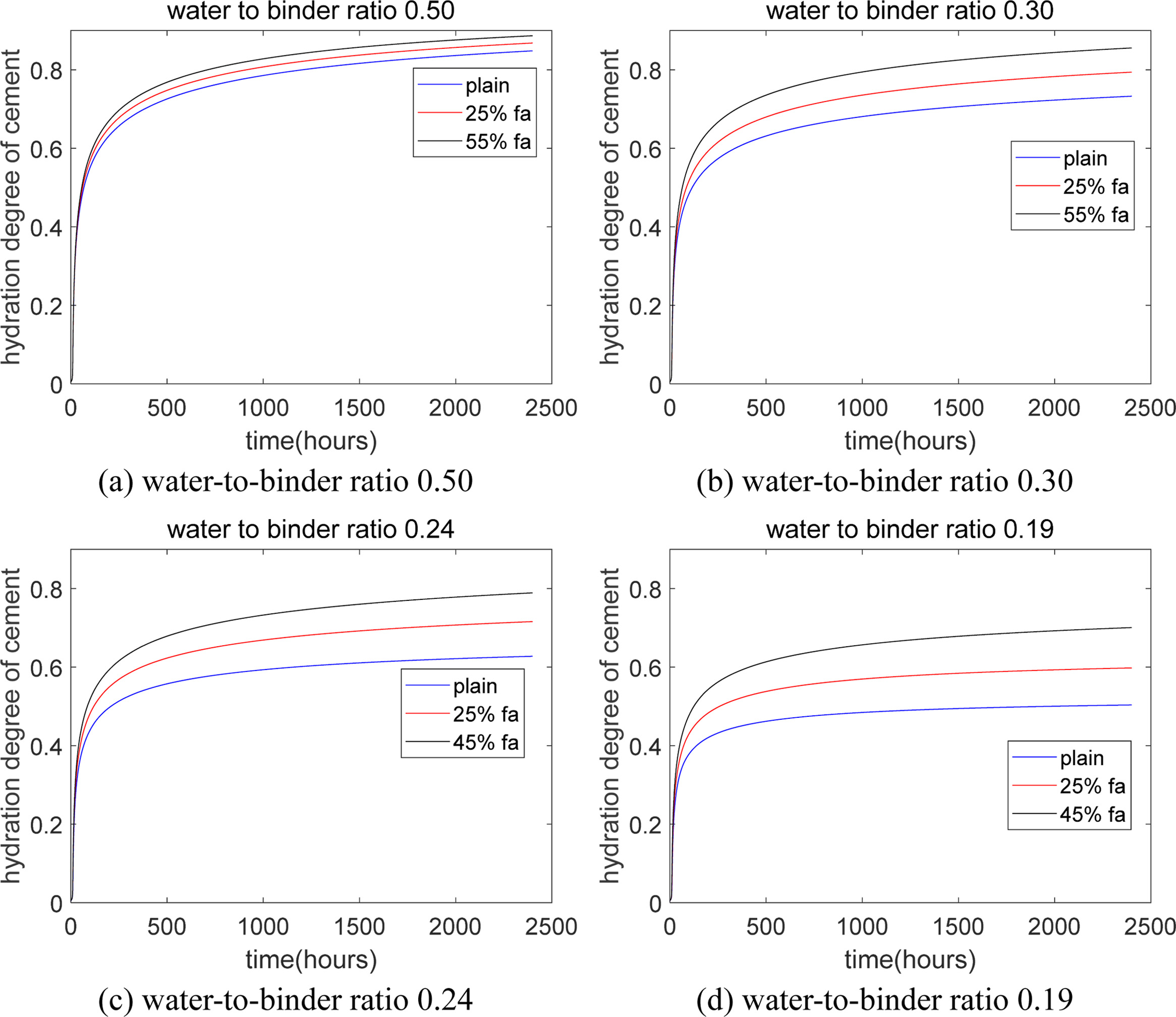

Fig. 5 shows the dilution aftereffect of the addition of

fly ash. Given the same fly ash substitute ratio, for examples with low

water-to-binder ratio, the advance in the water-to-cement ratio is a lot more

significant than that with high water-to-binder ratio. First, Fig. 5(a) shows

for a paste that has a high water-to-binder ratio 0.5, the dilution effect is

not significant; thus, the advance in the hydration amount of cement is not

apparent. In addition, the water-to -binder ratios of Fig. 5(b) and 5c are 0.30

and 0.24, respectively. Compared with Fig. 5(a), the dilution effect shown in

Fig. 5(b) and Fig. 5(c) is more obvious. This is due to the reduction of

water-to-binder ratio from Fig. 5(a) to Fig. 5(b) and Fig. 5(c). Second, Fig.

5(d) shows for a paste that has a much lower water-to-binder ratio 0.19,

because of the dilution aftereffect of the addition of fly ash, the advance in

the hydration amount of cement is more apparent than Fig. 5(a), Fig. 5(b), and

Fig. 5(c).

The

strength progress model

As shown in eq. (11), the reaction amounts of binders can

be used for evaluating the strength progress of concrete. Lam et al. measured

the strength progress of binary composite paste [3]. The

mixture of paste specimens for the strength test was the same as those for the

reaction degree test. According to the experimental

outcomes of strength, the strength coefficients A1, A2, and A3

of eq. (11) were determined as 57.4, 123.1, and -36.2, respectively. The

strength coefficient of fly ash A2 was much higher than coefficient of cement A1.

This is because the SiO2 content of fly ash is a lot greater than

that of cement.

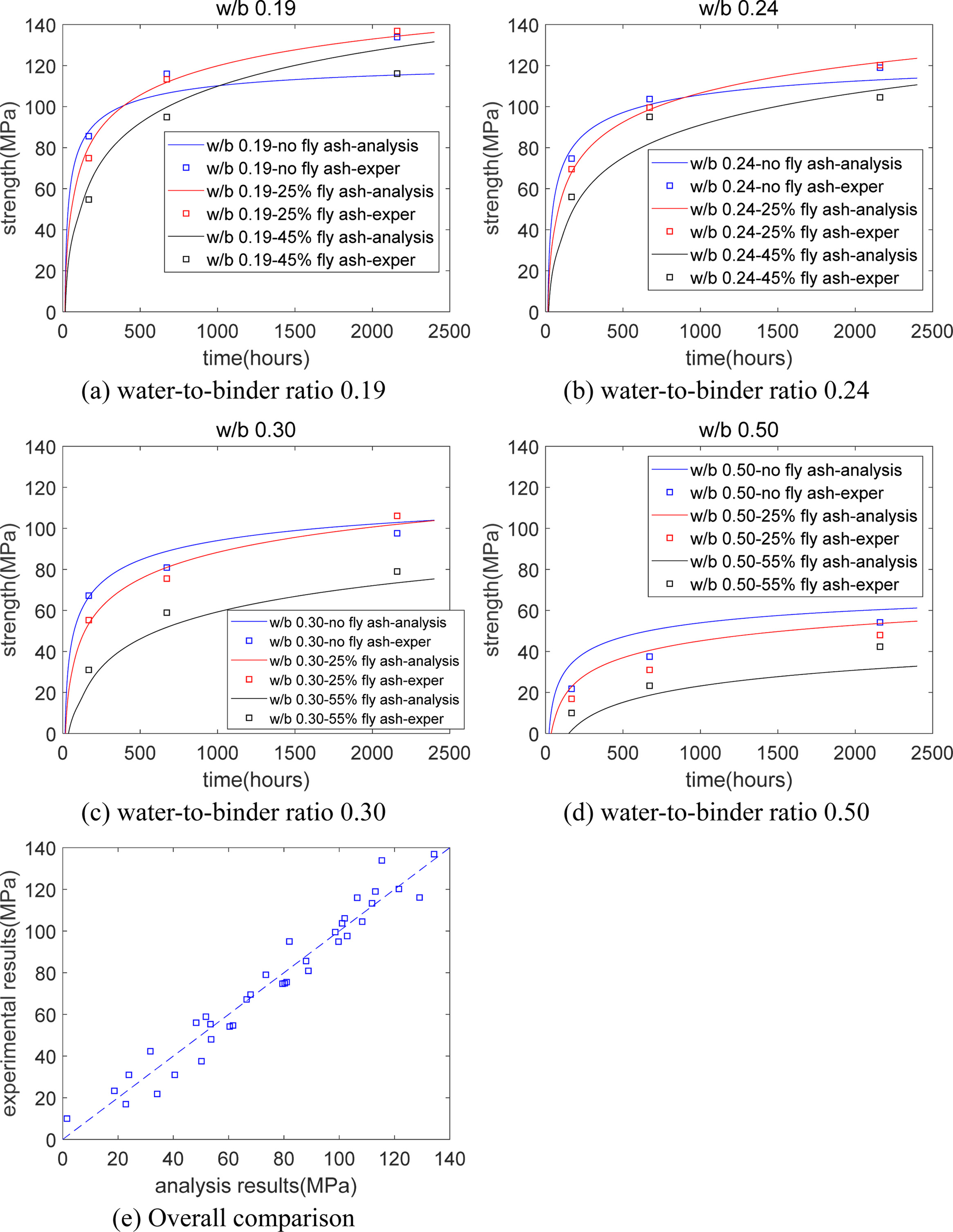

Fig. 6 shows the strength development. First, Fig. 6(a)

shows for paste that has a low water-to-binder ratio 0.19, in the early age,

the strength of the binary composite paste is gloomier than that of plain

paste. Meanwhile, at a late age, because of the evolution of pozzolanic

reaction, the strength of the blended paste can exceed

the plain paste [27]. As the fly ash-to-binder ratio increases, the time akin

to strength crossover retards [1]. This is because the reaction

amount of fly ash decreases as the fly ash-to-binder ratio increases (shown in

Fig. 4). Second, from Fig. 6(a-d), as the water-to-binder ratio increases, the

time akin to strength crossover retards. This is because the dilution effect is

a lot more apparent for concrete that has a low water-to-binder ratio [28].

Third, as the fly ash-to-binder ratio and water-to-binder ratio increase, the

intercept of the strength curve on the x axis increases. This trend of

intercepts is comparable to the trends of the final setting of concrete, which

increase when water-to-binder ratio or fly ash-to-binder ratio increases [29,

30]. Fourth, Fig. 6(e) shows that analysis outcomes generally

accept experimental outcomes. The correlation coefficients

between the analysis results and the experimental answers are 0.95. Summarily, the

suggested strength development model is applicable for ordinary-strength

(water-to-binder ratio 0.5), high-strength (water-to-binder ratio 0.3), and

ultra-high-strength (water-to-binder ratio 0.24 and 0.19) concrete that

contains various fly ash contents (0%–55%).

|

Fig. 1 Experimental results of the rate of heat evolution. |

|

Fig. 2 Evaluation results of cumulative heat. |

|

Fig. 3 The reaction amount of binders. |

|

Fig. 4 Verifications of the reaction amount of fly ash. |

|

Fig. 5 Dilution effect of fly ash addition. |

|

Fig. 6 The strength progress of binary composite paste |

This research presented a framework for evaluating the

hydration heat, reaction amount, and strength progress of cement–fly ash binary

composite.

First, isothermal calorimetry testing with high tem- peratures was used to indirectly

identify the reaction amount of fly ash. According to the experimental outcomes

of cumulative hydration heat at various temperatures, by using the hydration

heat model considering the contribution of fly ash and cement, the reaction

coefficients of a kinetic reaction model of fly ash were determined.

Second, the reaction amount of binders was calculated

using the composite reaction model. We discovered that the hydration amount of

cement in composite binder is greater than that in plain cement, the reaction

amount of fly ash is significantly improved at elevated temperatures, and also

the reaction amount of fly ash decreases as the contents of fly ash increase.

The suggested blended hydration model is applicable for various mixtures at

both early and late ages.

Third, in line with the reaction amount of fly ash and

cement, we proposed a straight-line equation for evaluating the strength

progress of binary composite. The results of the analysis can reflect the

crossover of the strength progress of fly ash composite concrete. As the

content of fly ash and the water-to-binder ratio increase, the threshold time

of strength development increases, and the time akin to strength crossover

retards. The dilution effect is apparent for concrete that has a low water to

binder ratio.

Fourth, the suggested model is applicable for ordinary-strength,

high-strength, and ultra-high-strength concrete with assorted fly

ash contents and water-to-binder ratios. The coefficients of hydration model,

heat model and strength model are constants for a number of mixtures. The

suggested hydration heat-strength progress model is helpful for material style

of concrete that contains fly ash.

This research was supported by the Basic Science Research

Program through the National Research Foundation of Korea (NRF), funded by the

Ministry of Science, ICT & Future Planning (No.

2015R1A5A1037 548), and an NRF grant

(NRF-2020R1A2C4002093).

- 1. C.S. Poon, L. Lam, and Y.L. Wong, Cement. Concrete Res. 30 (2000) 447-455.

-

- 2. W. Wongkeo, P. Thongsanitgarn, A. Ngamjarurojana, and A. Chaipanich, Mater. Design. 64 (2014) 261-269.

-

- 3. L. Lam, Y.L. Wong, and C.S. Poon, Cement. Concrete Res. 30 (2000) 747-756.

-

- 4. A.K. Schindler and K.J. Folliard, Aci. Mater. J. 102 (2005) 24-35.

- 5. I. Pane and W. Hansen, Cement. Concrete Res. 35 (2005) 1155-1164.

-

- 6. F. Han, Z. Zhang, J. Liu, and P. Yan, J. Therm. Anal. Calorim. 124 (2016) 1691-1703.

-

- 7. G. Baert, N.D. Belie, and G.D. Schutter, J. Mater. Civil. Eng. 23 (2011) 761-766.

-

- 8. S.K. Nath, S. Mukherjee, S. Maitra, and S. Kumar, J. Therm. Anal. Calorim. 127 (2017) 1953-1961.

-

- 9. F. Deschner, B. Lothenbach, F. Winnefeld, and J. Neubauer, Cement. Concrete Res. 52 (2013) 169-181.

-

- 10. Q. Xu, J. Hu, J.M. Ruiz, K. Wang, and Z. Ge, Thermochim. Acta 499 (2010) 91-99.

-

- 11. M. Narmluk and T. Nawa, Cement. Concrete Res. 41 (2011) 579-589.

-

- 12. I. Garcia-Lodeiro, S. Donatello, A. Fernández-Jiménez, and Á. Palomo, Materials 9 (2016) 604-620.

-

- 13. X.-Y. Wang, Constr. Build. Mater. 64 (2014) 1-10.

-

- 14. W. Huang, H. Kazemi-Kamy, W. Sun, and K. Scrivener, Cement. Concrete Comp. 77 (2017) 86-101.

-

- 15. X.-Y. Wang and K.-B. Park, Cement. Concrete Res. 102 (2017) 1-15.

-

- 16. V.G. Papadakis, Cement. Concrete Res. 30 (2000) 291-299.

-

- 17. T. Hemalatha and A. Ramaswamy, J. Clean. Prod. 147 (2017) 546-559.

-

- 18. F. Moghaddam, V. Sirivivatnanon, and K. Vessalas, Case Studies in Construction Materials 10 (2019) e00218.

-

- 19. K. Maekawa, T. Ishida, and T. Kishi, in “Multi-Scale Modeling of Structural Concrete” (Taylor & Francis, 2009) p.72-74.

-

- 20. V.G. Papadakis, Adv. Concr. Constr. 1 (2013) 201-213.

-

- 21. X.-Y. Wang, Materials 10[2] (2017) 115-130.

-

- 22. R.-S. Lin, X.-Y. Wang, H.-S. Lee, and H.-K. Cho, Materials 12 (2019) 458-478.

-

- 23. Q. Zeng, K. Li, T. Fen-chong, and P. Dangla, Constr. Build. Mater. 27 (2012) 560-569.

-

- 24. X. Gao, Q.L.Yu, and H.J.H.Brouwers, Constr. Build. Mater. 80 (2015) 105-115.

-

- 25. A. Wang, C. Zhang, and W. Sun, Cement. Concrete Res. 34 (2004) 2057-2060.

-

- 26. H. Ma, B. Xu, and Z. Li, Cement. Concrete Res. 65 (2014) 96-104.

-

- 27. G. Hannesson, K. Kuder, R. Shogren, and D. Lehman, Constr. Build. Mater. 30 (2012) 161-168.

-

- 28. Y. Luan, T. Ishida, T. Nawa, and T. Sagawa, J. Adv. Concr. Technol. 10 (2012) 1-13.

-

- 29. J. Hu, Z. Ge and K. Wang, Constr. Build. Mater.50 (2014) 657-663.

-

- 30. D.P. Bentz and C.F.Ferrari, Cem. Concr. Compos. 32 (2010) 265-270.

-

This Article

This Article

-

2020; 21(6): 622-631

Published on Dec 31, 2020

- 10.36410/jcpr.2020.21.6.622

- Received on Mar 24, 2020

- Revised on Jun 15, 2020

- Accepted on Jul 16, 2020

Services

Services

- Abstract

introduction

the hydration and strength development models

verifications of the hydration heat and strength progress model

conclusions

- Acknowledgements

- References

- Full Text PDF

Shared

Correspondence to

Correspondence to

- Xiao-Yong Wang

-

aDepartment of Architectural Engineering, Kangwon National University, Chuncheon 24341, Korea

bDepartment of Integrated Energy and Infra System, Kangwon National University, Chuncheon 24341, Korea

Tel : +82332506229 Fax: +82332595542 - E-mail: wxbrave@kangwon.ac.kr

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.