- Experimental investigation on mechanical properties of Multi Wall Carbon Nanotubes (MWCNT) reinforced aluminium metal matrix composites

İsmail Topcua, Muhammet Ceylanb,,* and Elif Burcu Yilmazc

aDepartment of Metallurgy and Materials Engineering, Alanya Alaaddin Keykubat University, Antalya, Turkey

bDepartment of Mechatronics Engineering, Istanbul Commerce University, Istanbul, Turkey

cDepartment of Jewellry Engineering, Istanbul Commerce University, Istanbul, Turkey

The aim of this research is to

obtain better micrographs and to perform the mechanical characterization of

Multi Wall Carbon Nanotubes (MWCNT) consolidated aluminum matrix composite

(AMC). This research is focused on the mechanical behavior and microstructure

characteristics in MWCNT consolidated aluminum matrix composites. The

composites of MWCNT/Al were successfully fabricated using powder metallurgy

(PM) mechanical alloying (MA) sintering. X-ray diffraction (XRD) and Scanning

electron microscopy (SEM) micrographs were utilized in order to determine the

porosity, density and hardness characteristics to observe if they are affected

or not concerning the performance of composites in different reinforced % MWCNT

rate conditions. Along with SEM and XRD studies, this study details the

homogeneous distribution of nanotubes which showed no evidence of

decomposition; this was supported by a successive increase in hardness and

abrasion resistance. This increase in abrasion resistance and hardness can be

accredited to the further activation of the slip system due to the presence of

MWCNTs. Based on the conclusions of this study, the authors determined that the

mechanical alloying sintering method provides promising results for the

mechanical alloying fabrication of MWCNT/Al composites, especially due to the

different % rate reinforced up capabilities.

Keywords: Powder metallurgy, Multi Wall Carbon Nanotubes, Mechanical behaviour

Powder Metallurgy (PM) is a significantly important but

also an easy method of fabrication combining shaping of elemental and/or pre

alloyed powders after mixing and pressing, then sintering in an atmosphere

under control, thus rendering metallurgical bonding of compact powders possible

by a cost effective way [1, 2]. Metal Matrix Composites (MMC), which are a

combination of reinforcement material(s) and partly metal(s), present superior

properties compared to that of a single material could offer.

Upgraded mechanical and physical properties such as wear

resistance and thermal expansion coefficients at higher temperatures have

attracted attention for several decades, particularly in case of the

utilization of particles or whiskers that can be produced by

standard metal forming processes [3-7].

Due to their thermal and electrical conductivity, wear resistance

and high impact, elevated melting point, chemical corrosion resistance carbon

nanotubes are used in various applications, such as sensors, nanocomposites,

and transparent electrodes [8-11].

Aluminum MMC, which is part of the new advanced materials,

combines high strength with low density, plus exhibits a low thermal expansion

coefficient and good wear resistance [12]. Despite these improved features,

the application of their use is limited to aerospace and military areas, which

could be attributed to their higher processing cost [13-16].

Powder metallurgy production methods are designed to

produce qualified engineering materials using aluminum material

powder. In this research, CNT and Aluminum materials are chosen as

reinforcement and matrix materials

respectively. This study aimed to examine and improve the mechanical properties

of AMC and identified different

process conditions such as temperature, sintering condition, time and atmosphere, production with Al/CNT type

composite material.

Matrix powder and an additional powder wasmixed by

attrition milling with the help of a mechanical alloying

method. The amount of added powder depended on experimental results and

studies. According to the International American Society of Tests and Materials

(ASTM) standards and MPIF powder mixture shaped by using uniaxial pressing

technique. After the critical temperature determined by

Differential Thermal Analysis (DTA), formed

wet specimens density were measured in different

sintering condition. Then the sintered specimens were

examined in terms of their microstructure, chemical and physical properties,

size change, XRD and SEM analysis, density, hardness and wear

resistance tests one by one.

The pure aluminum and composite made in this research

strengthened the MWCNT particles by 2.5% to 7.5% by weight. The materials were

manufactured by using a PM technique (Alfa Aesar, Johnson Matthey GmbH &

Co. KG). The material used as raw material in this research was atomized

aluminum powders with values of 10 µm (99.99% purity, density 2,699 g /cm3).

The material used as the matrix material was trading naive

aluminum (Al) powder and MWCNT. Alfa Aesar, Johnson

Matthey GmbH & Co. MWCNT reinforcing material purchased by KG (USA) has a

density of 2.31 g/cm3. The mean particle dimension of MWCNTs powders

were about 10-30 nanometers. The variable weights of the MWCNTs were

distributed over the Al matrices using a turbula ball mill (Turbula Ch PM 400

MA, Switzerland). The as-received Al powders and the pre-determined weight

percentage of MWCNTs were charged into glass vials (100 ml capacity and 40 mm

inner diameter) along with stainless steel balls of the same

sizes (diameter (Ø) = 20 mm, combined in a weight

ratio of 2:1). The same size of grinding balls was used to ensure that

sufficient powder energy was provided to the powder particles during the

dispersion process. [17, 18]. All materials used in this research were bought

without being purified and replaced.

In the course of the manufacturing composites, the 2.5% to

7.5% by weight MWCNT was strengthened to aluminum by wear

milling. Milling time was five hours. Ball / powder

weight had a ratio of 2:1. It has a grinding speed of 450

rpm. The ball diameter was 10 mm diameter stainless steel ball. After the

produced material was dried at 60 C, 0.5% (wt.) of

acrowax was appended to the medium as a duration check agent. Powdered

materials were easily pressed with a single axis press at 250 MPa. The selected

sintering atmosphere is a high purity argon. This is due to the fact that other

sintering atmospheres can result in decarbonisation of the material

at operating temperature. Due to the small atomic size of carbon, sintering of

the specimens was performed at 620 oC and 640 oC

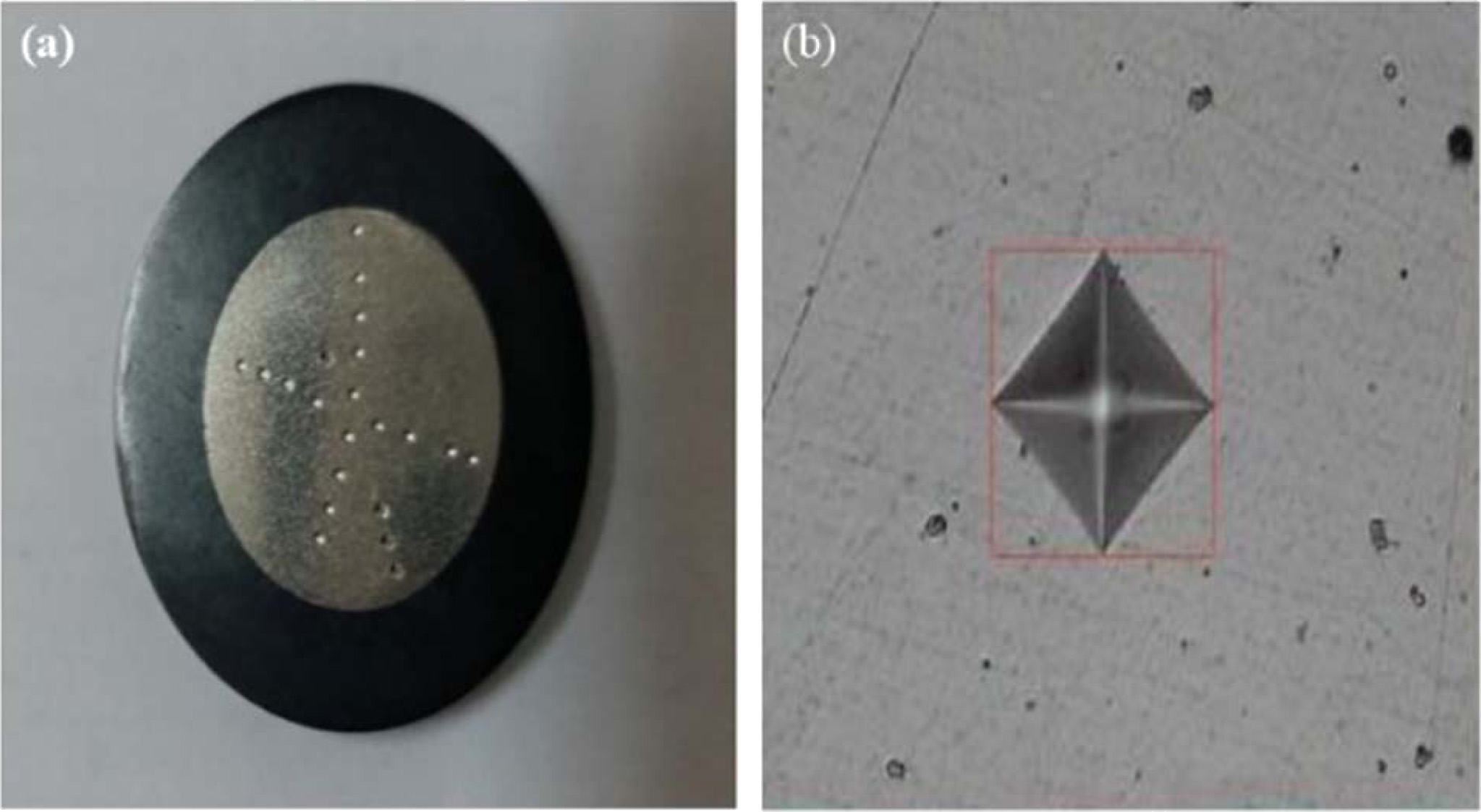

[19]. The horizontal pipe furnace arrangement of the sintering process is as in

Fig. 1.

The longitudinal sections of the specimens were prepared

metallographically. In the next step, the microstructures of the composites

were evaluated with a LEICA optical microscope. The SEM images were obtained by

the specimens surface by scanning it with a high-energy beam of electrons [20,

21]. The powder morphologies and microstructures of sintered

specimens were examined using a SEM (JEOL Ltd.,

JSM-5910LV).

Phase detections of pure Al and MWCNT powders, also

composites of different powder compositions were carried out using a Rigaku X

Ray diffractometer. There is a Cu / Kα radiation with a beam

angle of 2o. The angle of refraction has a value

between 5o-105o. The step increase is

0.02o and the count time is 2 seconds. Energy Dispersive

Spectrometer (EDS, OXFORD Industries INCAx-sight 7274, (133-eV resolution) and Al and

MWCNT powders was analyzed.

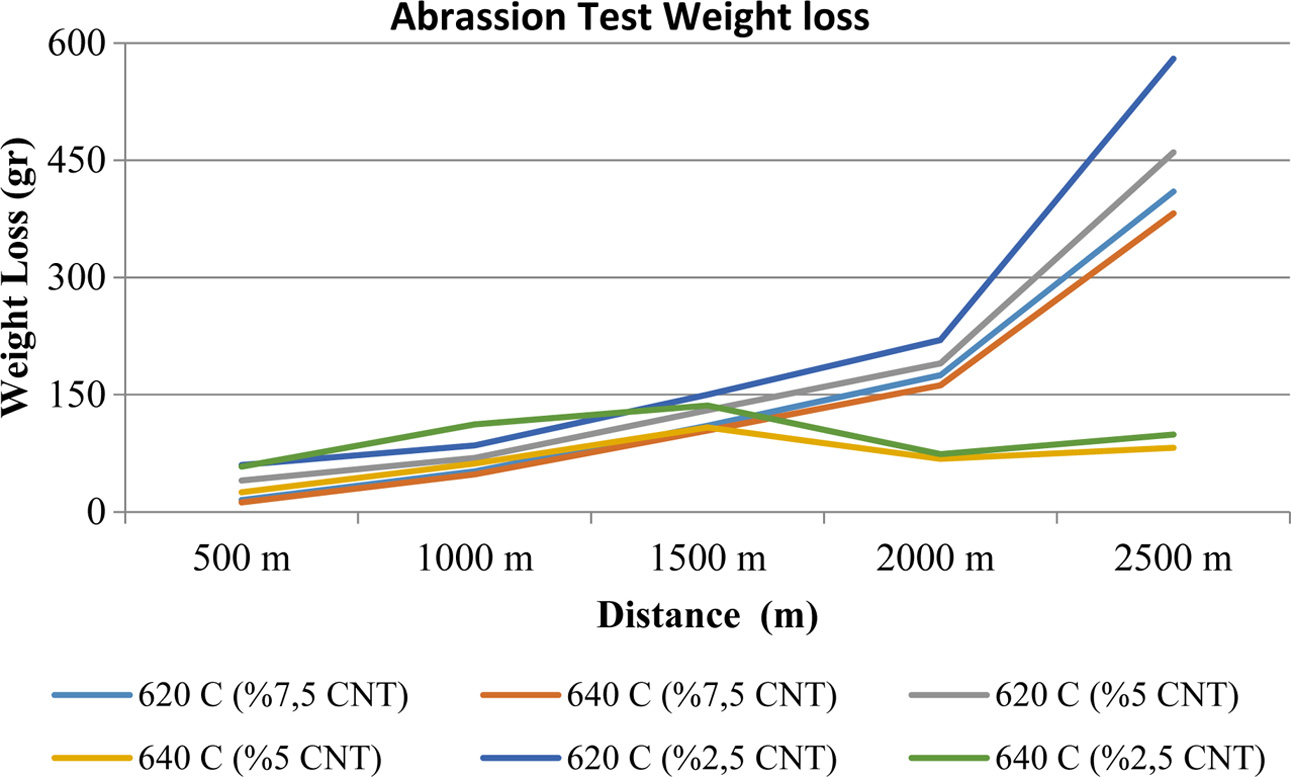

The hardness measurement of specimens is indeed a means of

determination for mechanical properties of the

specimens. In this research, Instron Universal Hardness Tester

Machine, with the help of Vickers 136o diamond indenter, was used.

The testing load used for every specimen was 100 g. The

hardness value of the material refers to the bulk hardness of the composite.

This is because both the matrix and the reinforcing material of the recess

track are coated. The results of the hardness test were

evaluated with approximately 5 consecutive

measurements. Display of the hardness measurement

specimens as shown in Fig. 2. Vickers images produced at

the specimens surface as a result of the measurement made by the

hardness measurement method.

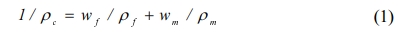

Abrasion testing is used to test the abrasive resistance

of solid materials. The dimensions of the composite specimens were 16 mm in

diameter and 35-45 mm of length. The abrasion testing wheel

has a 60 mm diameter and 550 rev/min. It performed that abrasion

resistance under dynamic load which different distance used as illustrated in

Fig. 3.

|

Fig. 1 Sintering process for horizontal pipe furnace system |

|

Fig. 2 (a) images formed on the specimens surface and (b) magnified view of the specimens surface. |

|

Fig. 3 Abrasion test results of the specimens in different

temperatures and CNT ratios. |

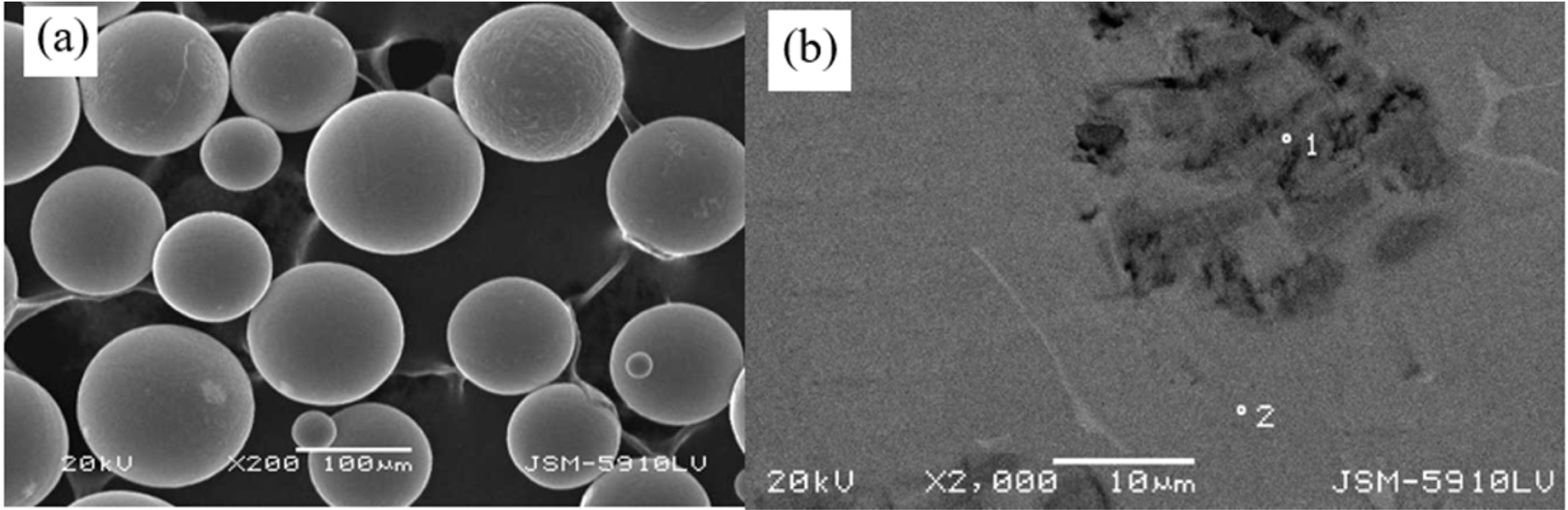

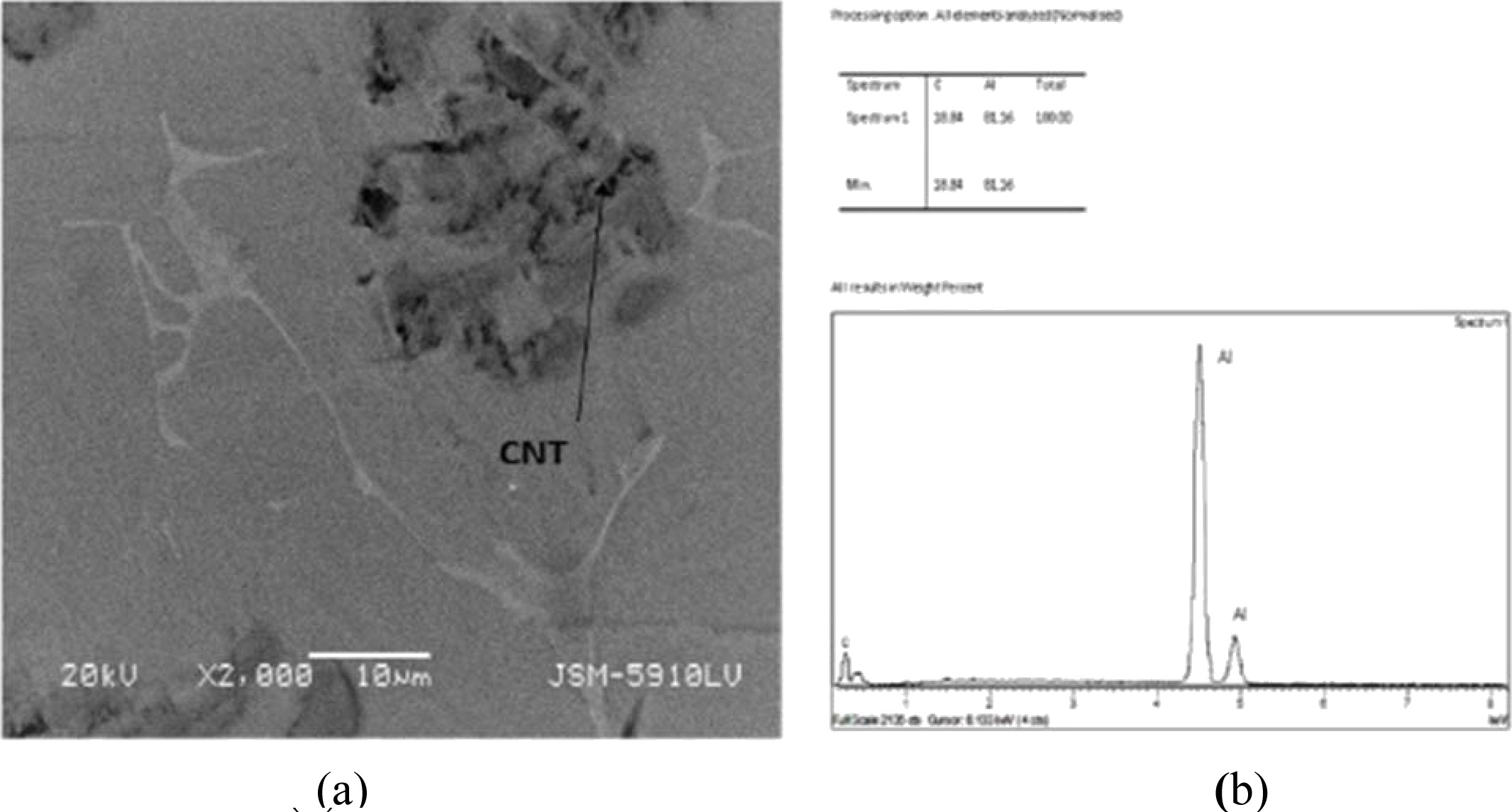

The powder morphologies and microstructures of sintered

specimens were examined using a SEM (JEOL Ltd., JSM-5910LV). The

microstructural analysis of pure aluminum and 7,5% strengthened Al / MWCNT

composite material are shown in Figs. 4(a) and 4(b).

In these studies, the alpha and beta shows the structure

of Al powder which can be seen in Fig. 5(a) and (b). As can be seen by the

black and gray areas of the MWCNT structures. Black and gray

areas increased as the ratio of the MWCNT % increased [22]. EDS

analysis of phases are shown in Fig. 5(a) and Fig. 5(b).

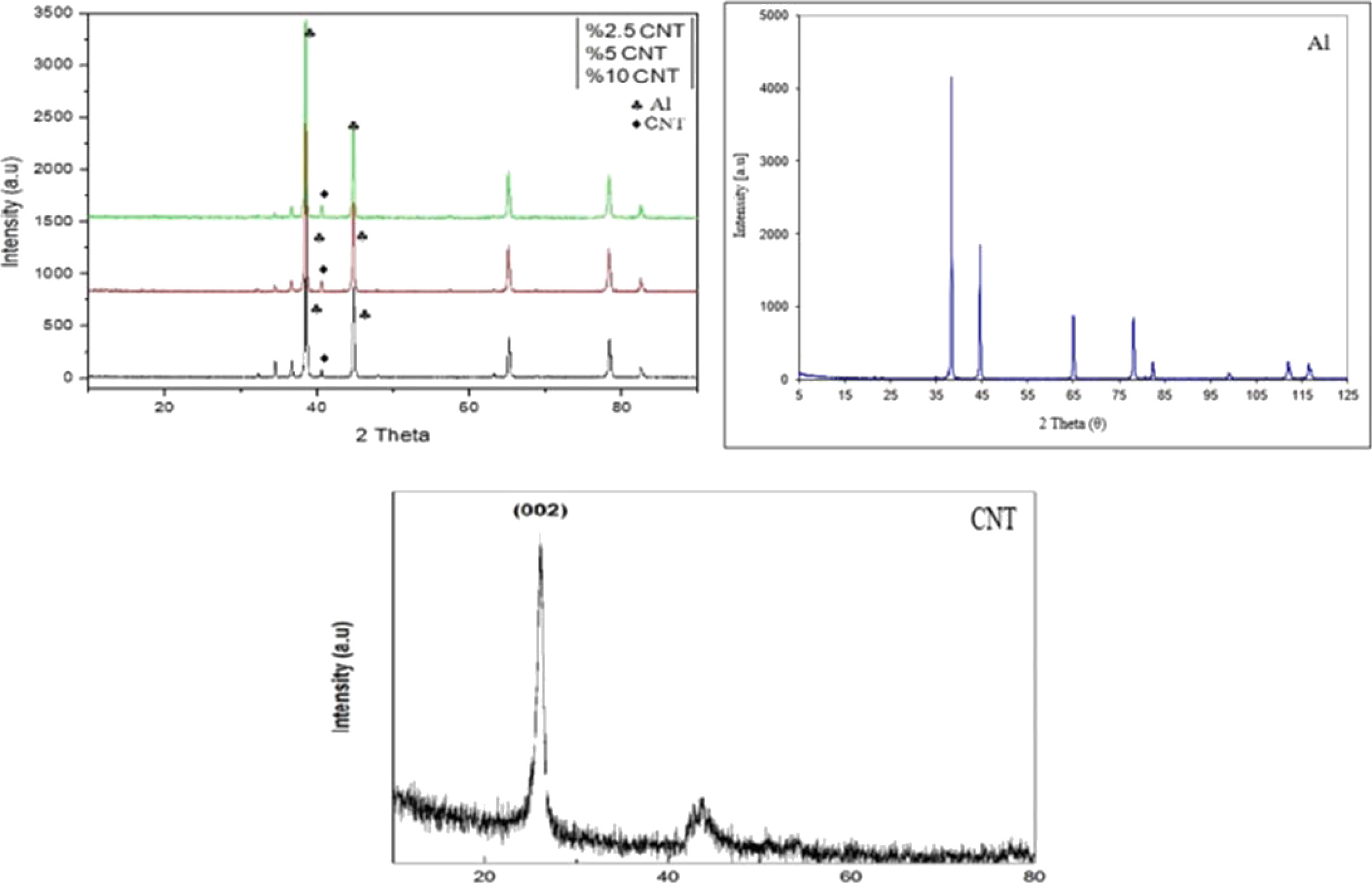

XRD analysis of phases are shown in Fig. 6.

The X-ray diffraction of specimens with several MWCNT

contents, CNT and Al alone is displayed in Fig. 6. Fig. 6 demonstrates the peak

sat 2q of 36,

38.44, 44.7 and 65 belongs to the Al, and, CNT alone peaks are observed at 26.

Moreover, the intensity of the peaks showed an obvious enhancement depending on

the MWCNT ratio. All this suggests that increased MWCNT contents lead to an

increase in the main peaks of the MWCNT. The selected specimens are

MWCNT-reinforced Al powder manufactured by powder metallurgy.

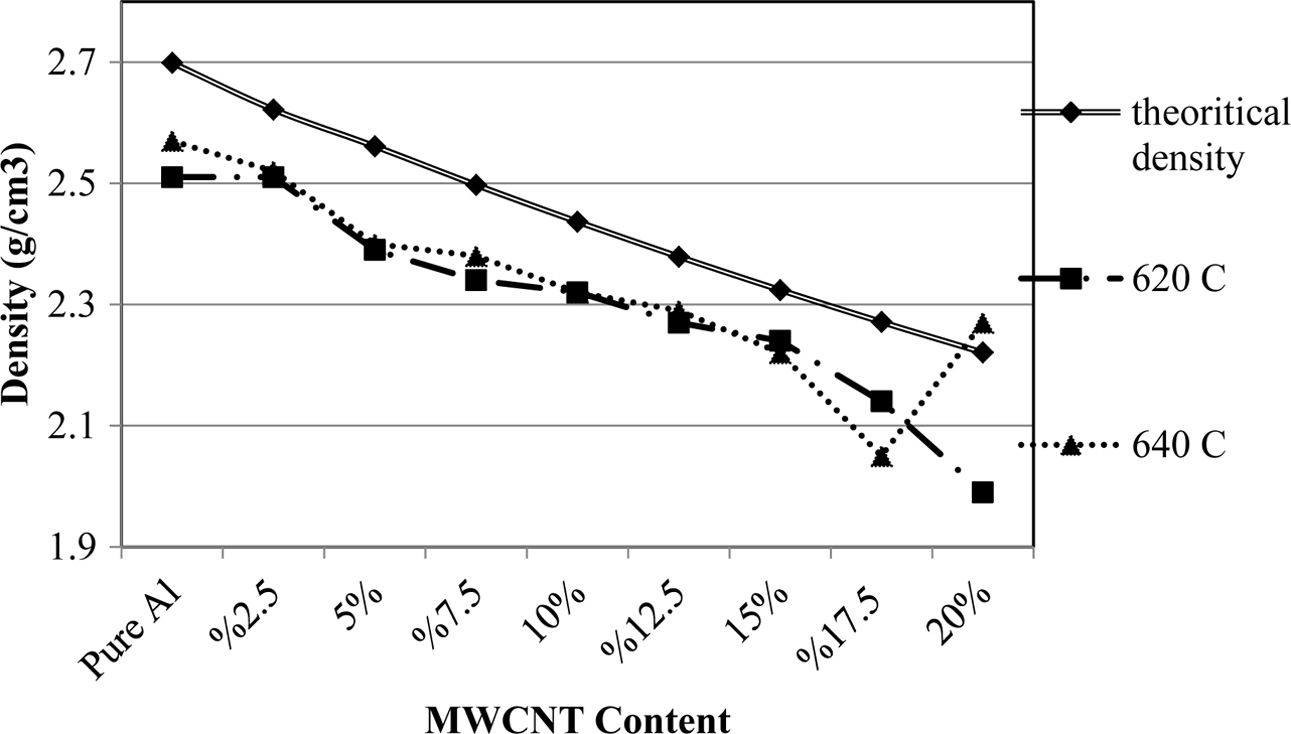

The features and information of these powders are

mentioned in the previous section. In addition, the mean density worth of

composites including dissimilar amounts of MWCNT is given as shown in Fig. 7.

As the temperature of the sintering process increased, the density of the

specimens approached the densities in theory [22].

Theoretic densities of the samples were calculated with

the help of the following equation [23].

Where subscripts c, f, and m,

represent the terms composite, fiber (or in the more general case,

reinforcement), and matrix respectively.

It is the increasing weight percentage of the MWCNT

and the sintering temperature that causes the composite to increase its

hardness. With the addition of MWCNT, the distribution of the rise in stiffness

of the composites can be correlated to the reinforcing effect.

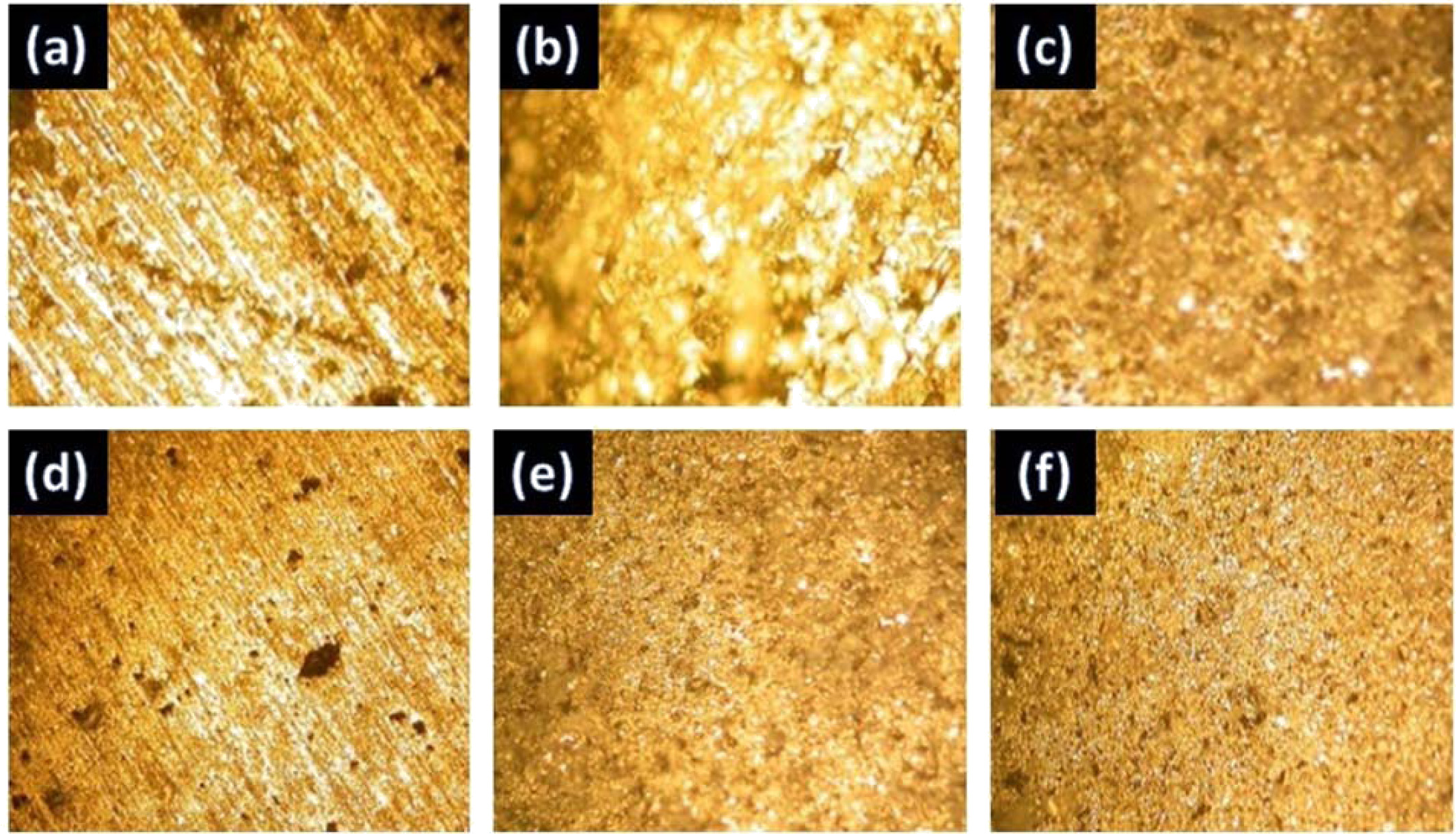

The results of the abrasion test are as shown in Fig. 3.

It is localized as a function of MWCNT, meaning about changing sintering temperatures.

Even though the rise in MWCNT meaning and sintering temperature in the matrix

causes an increase in wear resistance, there is little difference between the

2.5% and 5% reinforced MWCNT at 640 C. Fig. 3 shows the weight loss for all

specimens as calculated using Eq. (2) and abrasion resistance for all specimens

calculated with Eq. (3) [24].

Wa: Percantage of Abrassion, ΔG:

Weight Loss, M: Force, S: Distance, d: Density

Aluminum density, wear properties and hardness of the

aluminum reinforced MWCNT specimens were examined by a mission of temperature

and time.

The results of this research are; the density of the

specimens approaches the theoretic density with the rise in

sintering temperatures for all dissimilar MWCNT means.

Microscopic images displayed that the MWCNT particles

were particularly homogeneously dispersed in the matrix, the MWCNT did not

dissociate. However, the asset of porosity at the ends of

the MWCNT particles is present. Microscopic pictures of the experiments

in which MWCNT reinforced aluminum particles are present

showed that MWCNT particles is not distributed

homogenously. Carbon may have a negative effect with aluminum matrix [25].

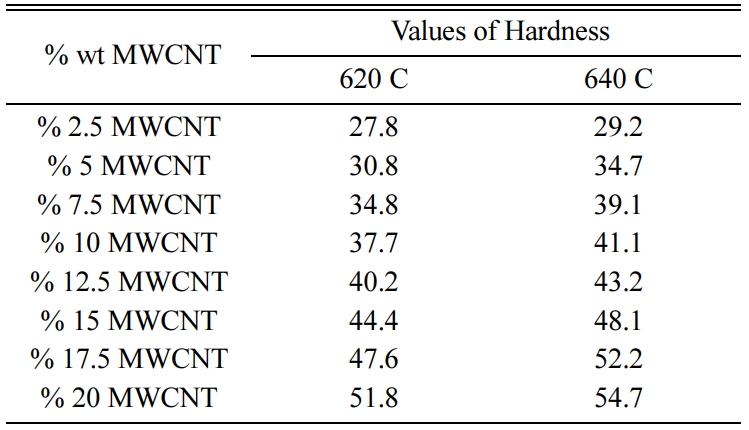

Increasing the weight percentage of the MWCNT and the

sintering temperature leads to an increase in the hardness of the composite

demonstrated in Fig. 8. Increasing the hardness with extra MWCNT may be

connected to the distribution reinforcement effect. The increase in the weight

percentage of MWCNT and the sintering temperature resulted in an increase in

the wear resistance of the composites. Content of composite

has much more effective than the sintering temperature. However, some

differences were observed between specimens, 2.5% and 5% MWCNT content which

had a 640 oC sintering temperature. The 7.5% MWCNT content

specimens have lower abrasion resistance than the others. 2.5% and 5% MWCNT

content may be more homogeneously distributed compared to 7.5% MWCNT content.

All values are shown in Table 1.

|

Fig. 4 The MWCNTs reinforced matrix Al SEM images of the composite material. (a): Spherical Al particulate, (b): 1. Al/MWCNT phase

and 2. Al composite materials. |

|

Fig. 5 The composite material's (7.5 % content Al/MWCNT) of (a) SEM image, (b) EDS analysis. |

|

Fig. 6 XRD pattern of 2.5-7.5 % content MWCNTs particles in Al matrix, Aluminum and CNT. |

|

Fig. 7 Density at different % MWCNT content sintering

temperatures. |

|

Fig. 8 Wear-tested MWCNT reinforced Al/MWCNT composites. (a) 620 C % 2,5 MWCNT, (b) 620 C % 5 MWCNT, (c) 620 C % 7,5

MWCNT, (d) 640 C % 2,5 MWCNT, (e) 640 C % 5 MWCNT, (f) 640 C % 7,5 MWCNT. |

In this study, density, hardness and abrassion properties

of aluminum specimens reinforced with different MWCNT ratios were

investigated as a function of temperature and time.The results

of this research may be expressed as follows; The composites of MWCNT/Al were successfully

fabricated using a PM sintering process. Approaches the theoretical density

with the effect of increasing specimens density and increased sintering

temperature with all different MWCNT contents. Microstructural analysis showed

the homogeneous distribution of MWCNT

particles in the matrix.

In addition, the presence of porosity is present at the

ends of the MWCNT particles. The studies carried out in SEM and

XRD detailed the homogeneous distribution of

nanotubes. As a result of this research, no evidence of

decomposition was found. This was further supported by a

simultaneous increase in forces, stiffness and ductility. The results showed

increased wear resistance in all composites having high nanotube concentration

of 5% by weight due to the homogeneous MWCNT distribution

in the matrix phases [26]. The simultaneous increase in

hardness and wear resistance can be attributed to the activation of more slip

systems due to the presence of CINs. Due to the effects on the mechanical

features of carbides and composites formed on the surface of MWCNTs, MWCNTs

should be evaluated further as they can improve load transfer ability and

strength.

- 1. R.M. German, in Powder Metallurgy and Particulate Materials Processing (Metal Powder Industry, 2005) p.331-333.

-

- 2. I. Topcu, H.. Gulsoy, N. Kadıoglu, and A.N. Gulluoglu, J. Alloys Compd. 482[1-2] (2009) 516-521.

-

- 3. M.D. Huda and M.S. Hashmi. Key Eng. Mater. 104-107 (1995) 37-64.

-

- 4. I. Topcu, Tehnicki glasnik 14[1] (2020) 7-14.

-

- 5. G.M. Dieter, in Mechanical Metallurgy, Second Edition (McGraw-Hill Education, 1988) p.139-362.

- 6. T.-W. Chou, in Microstructural Design of Fiber Composites (Cambridge University Press, 1992) p. 589-592.

-

- 7. S. Iijima, Nature 354 (1991) 56-58.

-

- 8. H.W. Kroto, J.R. Heath, S.C. O'Brien, R.F. Curl, and R.E. Smalley, Nature 318 (1985) 162-163.

-

- 9. M.M. Schwartz, in Composites Materials Handbook (Mc Graw-Hill Book Company, 1984) p. 651.

- 10. J.M. Berthelot and J.M. Cole, in Composite Materials, Mechanical Behavior and Structural Analysis (Springer, 1999) p.620.

- 11. S. Park, S.W. Choi, C. Jin. J. Ceram. Process. Res. 20[5] (2019) 464-496.

-

- 12. F.F Komarov, A.M. Mironov, Phys. Chem. Solid. State. 5[3] (2004) 411-429.

- 13. Y. Feng, Hai Long Yuan, Min Zhang, Mater. Charact. 55[3] (2005) 211-218.

-

- 14. H. Kwon, M. Estili, K. Takagi, T. Miyazaki, A. Kawasaki, Carbon 47[3] (2009) 570-577.

-

- 15. R. George, K.T. Kashyap, R. Rahul, S. Yamdagni, Scripta. Mater. 53[10] (2005) 1159-1163.

-

- 16. S. Jain, in Nano -Scale Events with Macroscopic Effects in Polypropylene / Silica (University of Twente, 2005) p.2-4.

-

- 17. D. Gavrilov, O. Vinogradov, and W. Shaw, in Tenth International Conference on Composite Materials. III. Processing and Manufacturing (Woodhead Publishing, 1995) p.11-17.

- 18. X. Feng, J. Sui, W. Cai, and A. Liu, Scr. Mater. 64[9] (2011) 824-827.

-

- 19. İ. Topcu, A.N. Güllüoğlu, M.K. Bilici, H.Ö. Gülsoy, J. Fac. Eng. Arch. Gazi Univ. 34[3] (2019) 1441-1449.

-

- 20. S. Panigrahi, S. Praharaj, S.Basu, S.K. Ghosh, S. Jaha, S. Pande, T. Vo-Dinh, H. Jiang, and T. Pal, J. Phys. Chem. B 110[27] (2006) 13436-13444.

-

- 21. G.. Gül and F. Kurtulmuş, Mater. Sci (Mezıagotyra) 24[1] (2018) 104-111.

-

- 22. K. Dvorak, D. Dolak, D. Paşousek, L. Čelko, and D. Jech. Mater. Sci (Mezıagotyra) 24[1] (2018) 29-34.

-

- 23. F. Huang and L. Shangguan, Mater. Sci (Mezıagotyra). 23[2] (2017) 129-132.

-

- 24. I. Topcu, B.. Nilgün, A.N. Güllüoglu, and H. Gülsoy, J. Chem. Soc. Pakistan 42[1] (2020) 70-80.

- 25. R. Wu, Q. Li, L. Guo, and Y.M. Taiyuan, Mater. Sci (Mezıagotyra) 23[4] (2017) 317-321.

-

- 26. M.K. Esawi Amal and A. El Borady Mostafa, Compos. Sci. Technol. 68 (2008) 486-492.

-

This Article

This Article

-

2020; 21(5): 596-601

Published on Oct 31, 2020

- 10.36410/jcpr.2020.21.5.596

- Received on May 26, 2020

- Revised on Jul 25, 2020

- Accepted on Aug 14, 2020

Services

Services

Shared

Correspondence to

Correspondence to

- Muhammet Ceylan

-

Department of Mechatronics Engineering, Istanbul Commerce University, Istanbul, Turkey

Tel : +90 4440413-3311

Fax: +90 (216) 489 02 69 - E-mail: mceylan@ticaret.edu.tr

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.