- Quadratic magnetoelectric effect of barium titanate-cobalt ferrite (0-3) ceramic composite

Morad Etier* and Hesham Almomani

Industrial Engineering Department, The Hashemite University, Zarqa 13133, Jordan

In this research, the

quadratic magnetoelectric effect for different compositions of barium titanate

cobalt ferrite ceramic composites has been reported. Structural analysis was

firstly demonstrated using different techniques e.g. x-ray diffraction and scanning

electron microscopy, then both the first and the second order magnetoelectric

effects were measured and analyzed. It was shown that the magnetic,

ferroelectric and magnetoelectric properties of the ceramic composites depend

mainly on the weight percentage of the constituents. Sample of 50% weight of

barium titanate gave the highest longitudinal and traverse magnetostriction.

The maximum induced magnetization as a function of electric field was observed

for the sample contains 50% weight of barium titanate with a second order

magnetoelectric coupling coefficient value g333 = 20 × 10-18 s/V.

This value is considered to be the first estimated quadratic magnetoelectric

effect value for a composite material.

Keywords: Mutliferroics, Quadratic magnetoelectric effect, (0-3) Composite

Composites are interesting nowadays due to the new

properties resulting from the combination of two materials, i.e combination of

ferroelectric with ferro- magnetic

material to produce magnetoelectrics (MEs). These materials can be polarized by

magnetic field and magnetized by electric effect which correspond to the direct

and the converse magnetoelectric effect, respectively. Sensors,

MERAMs, transformers, energy harvesters and electric field tunable devices are the

main possible applications for the ME materials [1-5]. In single phase

magnetoelectric materials, the low values of the ME effect restrict their

technological applications. On the other hand, composites that combine

piezomagnetism and piezoelectricity still an adequate option for

optimizing the effect, because of the variety of

synthesizing methods, structures and properties. This may inspire

researchers for finding the optimum conditions in order to gain better results.

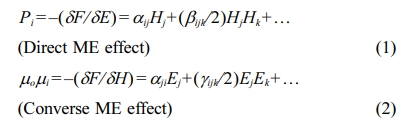

In theory, the direct and the converse magnetoelectric effect are obtained from

the derivative of the free energy (F) of a system with respect to both

electric and magnetic fields as follows [6]:

where P, M are the electric polarization and

the magnetization, respectively. H and E are the magnetic and the

electric fields, respectively, and μo is

the magnetic constant. The first order magnetoelectric effects (αij or αji [unit s/m]) are the

induced magnetization

by electric field M(E), or the induced polarization

by magnetic field P(H), respectively. In case of the second order

magnetoelectric effect (βijk [unit s/A] and γijk [unit s/V]) are the

change of dielectric permittivity with respect to magnetic field e (H) or the variation of

permeability by electric field μ(E)

[7]. Using equations (1) and (2), the second order ME effect γijk is

proportional to the square of the

applied electric field γ = (2μoΔM)/(ΔE)2 while βijk is proportional to

the square of the applied magnetic field β = (Δp)/(ΔH)2 . Utilizing these equations, the first one β is more clear in the converse

ME effect, because it depends on the applied electric field, while the second

one b appears in

the direct ME measurement because it depends on the applied magnetic field.

Both the first and the second order magnetoelectric effect can be detected

experimentally in the same material.

Previously, it was reported that the second order ME effect for single phase

materials was experimentally measured for lithium ferrite (LiFe5O8)

and Yttrium Iron Garnet YIG (Y3Fe5O12) in

the low-temperature interval 4-100K [8-10]. In composites, the magnetoelectric

effect depends on the linear piezoelectric effect of the first constituent

which is usually ferroelectric, and also on the nonlinear magnetostrictive

effect of the second one which is ferromagnetic. For that reason, one should

expect linear and nonlinear magnetoelectric effect obtained from the

combination of ferromagnetic/ferroelectric magnetoelectric

composites. Most of the magnetoelectric studies

for composites with piezomagnetic-piezoelectric phases are

carried out for the linear effect where the ac electric field or voltage is

measured as a function of ac magnetic field. Different connectivies

of magnetoelectrics have been synthesized and analyzed including the

(0-3), (1-3) and (2-2) structures [11-13]. These structures included, sintered

ceramic samples, epitaxial thick and thin films, pillars and others. The

interaction between the piezoelectrics and the piezomagnetics in such structures

is crucial factor to produce the magnetoelectric effect.

Among these structures, the (0-3) connectivity still a good option in order to

give isolated magnetic grains distributed inside a ferroelectric matrix. This

can provide more interaction areas between the phases, excellent poling and

accomplished strain mediated transfer capabilities. However,

different approaches were empolyed to synthesize (0-3)

composites including sol-gel and sintering technique, pulsed laser deposition

and epoxy bonding of layers. In literature, several materials were

selected to synthesize magnetoelectric composites, for

examples, PZT/NFO epitaxial heterostructure [14], CFO/BTO core shell structure

[15], PMN-PT/Terfenol-D plate [16], PZT-NFO-PZT thin films [17] and many

others. Barium titanate (BTO) and cobalt ferrite (CFO) have

excellent piezoelectric and piezomagnetic properties for the

application of electric and magnetic sensors, respectively.

For composites, the nonlinear magnetoelectic effect was

reported as a voltage coefficient quadratic effect βijk

which appeared in the direct magnetoelectric effect for

different materials [18-20]. To our knowledge the second order ME effect in

composites (γijk) is not reported for such systems nor for other

composites. In this article and for the first time, the values of the second

order of the ME effect γijk

for different composition of xBTO-(1-x)CFO system were measured and reported.

The values of the second order magnetoelectric effect are

detected for such systems based on the converse magnetolectric effect

experiment setup.

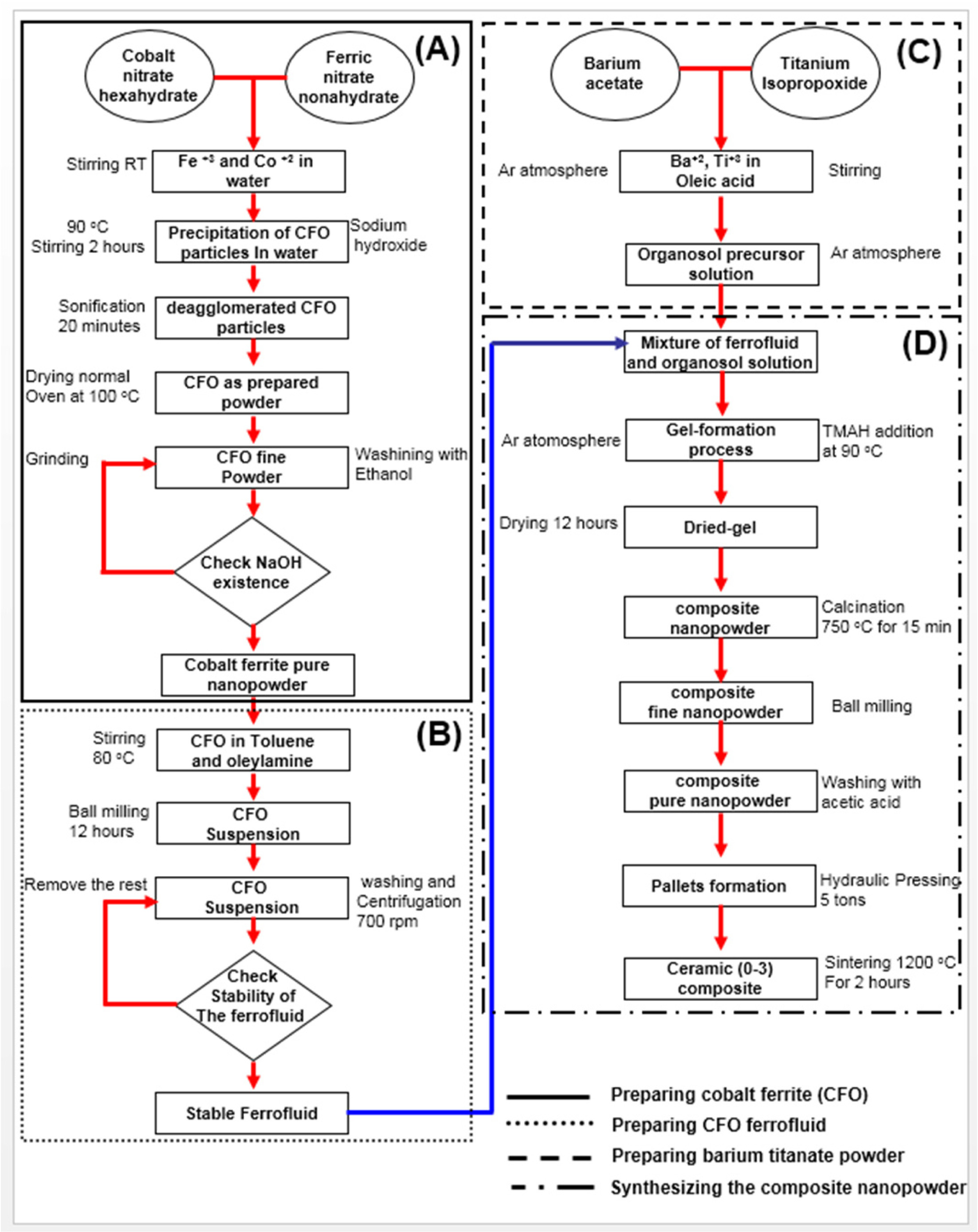

The detailed procedure for synthesizing the composites are

shown in Fig. 1. The co-precipitation method was used to synthesize cobalt iron

oxide nanoparticles using the same molar ratio of Fe(NO3)3·H2O

and Co(NO3)2·6H2O in water.

The precipitation of cobalt ferrite particles was started after the addition of

sodium hydroxide at 90 oC. The detailed sequence is shown in flowchart

(A) in Fig. 1. Several times of ethanol washing can remove

the rest of sodium hydroxide which may remain in the solution. The powder was

sonificated for 20 min to reduce the particles' agglomeration then dried

at 100 oC for 2 h. Inside an argon atmosphere, barium

titanate precursor solution was prepared using barium acetate Ba(C2H3O2)2

and titanium isopropoxide TiC12H28O4

in oleic acid (flowchart C in Fig. 1). An organosol precursor

was formed where ions of titanium and barium are dissolved in oleic acid under

magnetic stirring. Flowchart (B) in Fig. 1 shows the procedure for preparing

cobalt ferrite stable ferrofluid, where the cobalt ferrite nanopowder

synthesized in flowchart A was added into a solution of olyamine and toluene at

80 oC under magnetic stirring. Then, the solution was

introduced to the ball milling machine for 12 h in order to deagglomerate the

particles and reduce the particle size. After several times of centrifugation

and washing, well suspended particles of cobalt ferrite particle in liquid were

obtained. After that, adequate amount of this

ferrofluid contains 40 nm of cobalt ferrite nanoparticles

was prepared and added to barium titanate precursor solution obtained in

flowchart C. The amount of cobalt in the ferrofluid was measured in order to

give different weight percentage of the final powder comparing to the barium

titanate amount. The stable ferrofluid and the barium

titanate organ sol precursor were mixed together and an

amount of Tetramethylammoniumhydroxide (TMAH) was added at 90 oC

in order to promote the gelation process. The two phase precursor was well

mixed using ball milling for 12 h and then calcined at 750 oC

for 15 min (flowchart (D) in Fig. 1). To separate the particles and to

prevent agglomeration, the powder was repeatedly milled using different sizes

of ball milling then pressed using hydraulic press (2496 MPa) to form

pallets. The samples were fired in normal oven at temperature 1,200 oC

for 2 h. The pallets ceramic samples (5 mm in diameter and

0.5 mm thickness) were well polished in order to remove any undesirable

layers.

The structural analysis of the ceramic sample were

investigated using x-ray diffraction (Siemens D-5000, BRUKER) with Cu-Kα radiation and λ = 1.54056 Ao.

Then the surface analysis and morphology were analyzed using scanning electron

microscopy (SEM) (Quanta 400 FEG) with EDX capabilities. Magnetostriction of

the samples were measured in both parallel and perpendicular directions using

strain gauges connected onto the sample surfaces. After that two silver

electrodes were painted onto the two faces forming a capacitor for

magnetoelectric measurements. The electrically induced magnetic moments

produced by variable electric field were measured by a modified SQUID

susceptometer [21]. The measurements were carried out where the dc magnetic

field and the ac electric field are perpendicular to the sample surface. The

second order magnetoelectric effect values were extracted for all samples utilizing the quadratic equation fit for the induced magnetization versus ac

electric field relations.

|

Fig. 1 Detailed experimental procedures for producing xBTO-(1-x)CFO composites showing sequence (A) synthesizing method of cobalt

iron oxide nanoparticles by co-precipitation method, sequence (B) preparation of CFO ferrifluid, sequence (C) preparation of barium titanate

nano powder and sequence (D) formation of composite nanopowder and until sintering to reach the (0-3) ceramic. |

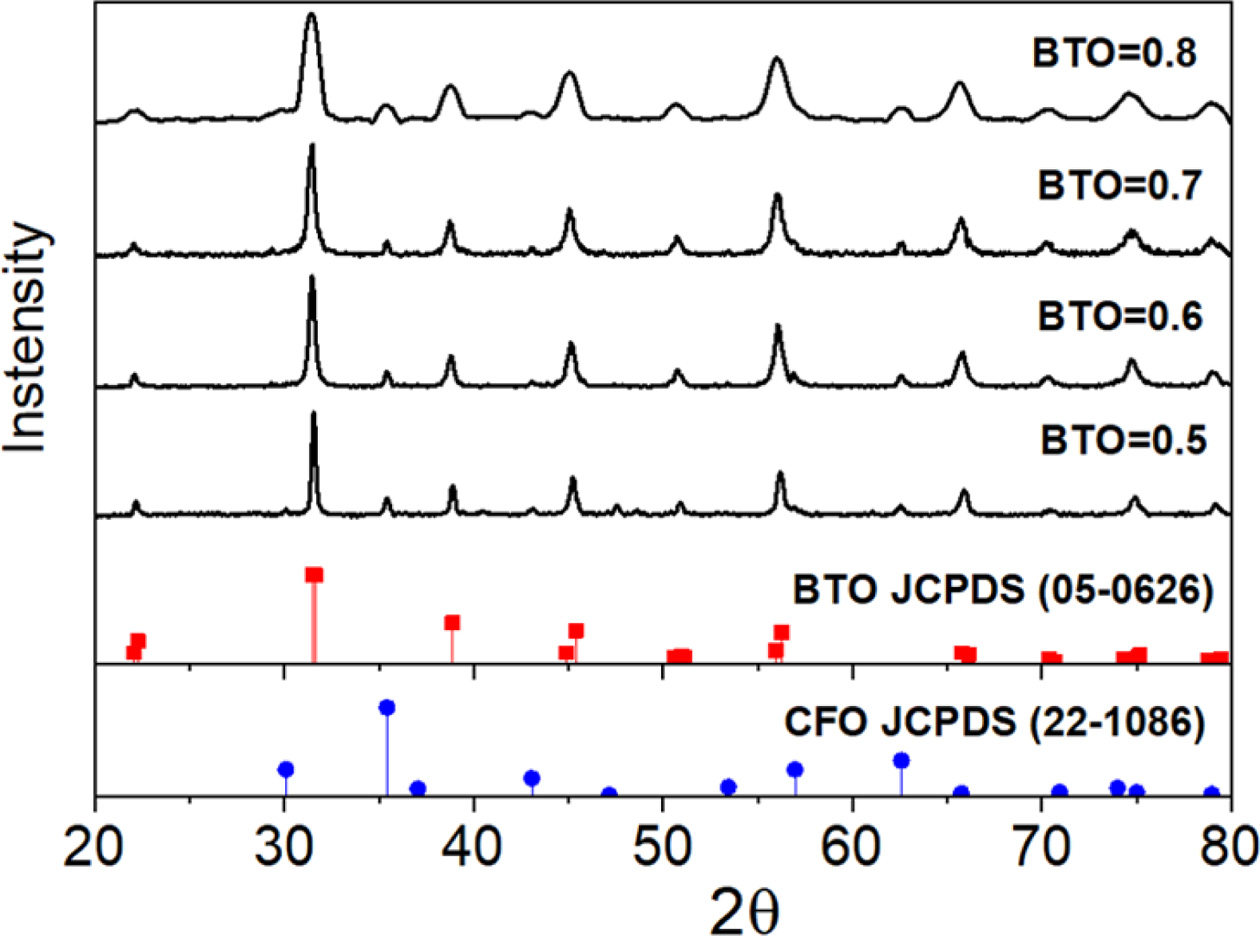

Room temperature x-ray diffraction patterns for different

samples of xBTO-(1-x)CFO (x = 0.5, 0.6, 0.7, 0.8) are shown in Fig.

2. The patterns confirmed the existence of both barium titanate and cobalt

ferrite phases. The peaks of the patterns coincide the peaks of both spinell cubic

structure of ferromagnetic cobalt iron oxide with card ID (JCPDS 22-1086), and

the tetragonal peroskite structure of ferroelectric barium titanate with card

ID (JCPDS-0626) without any other interference phases. This is an

indication of two distinct phases with no new other phases

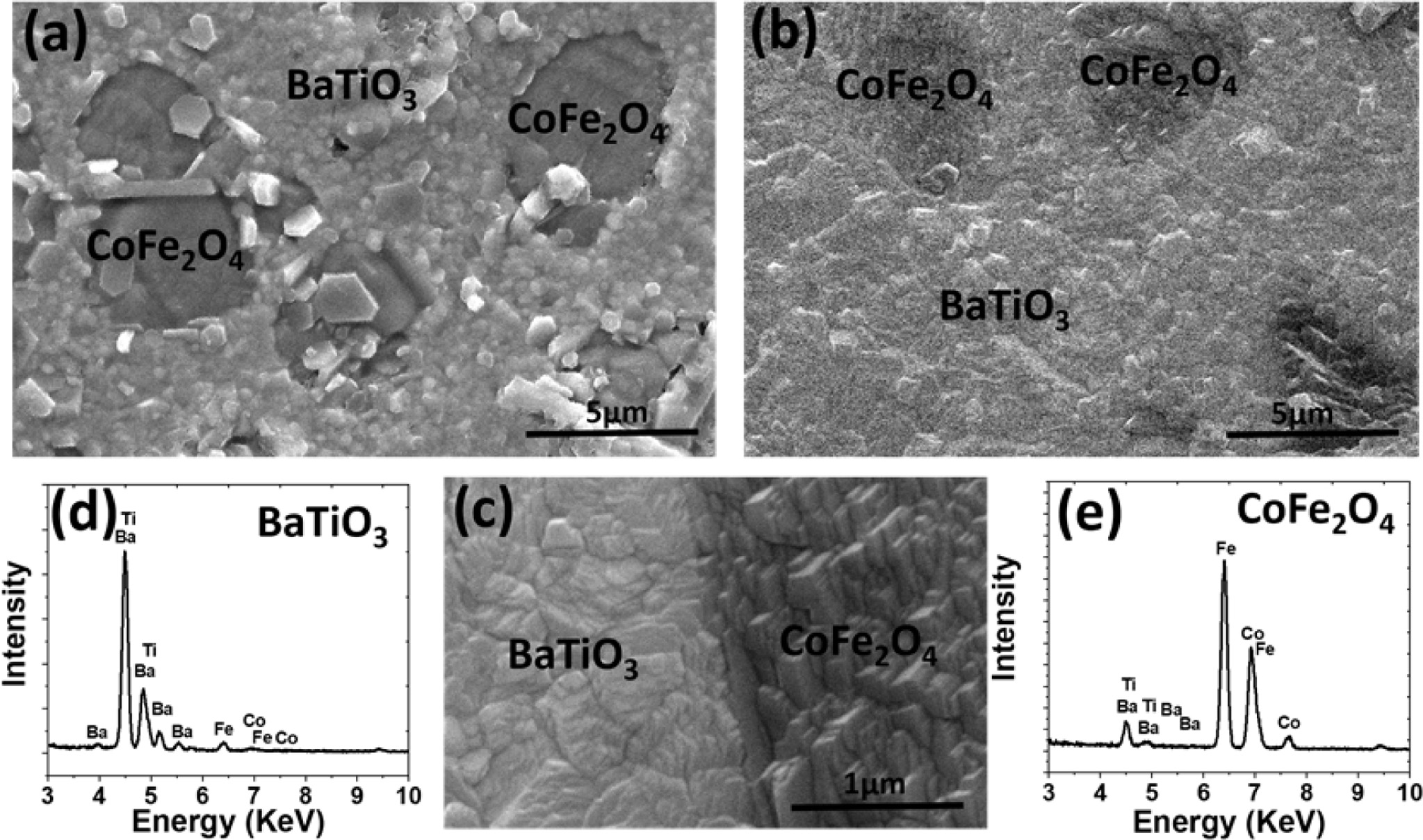

that may generate after high temperature sintering. Fig. 3 shows the surface

morphology for the synthesized samples using the scanning

electron microscopy. The separate distribution of the

magnetic phases of cobalt ferrite (black regions) in barium titantate matrix

(white regions) confirmed the (0-3) connectivity nature of the magnetoelectric

ceramic samples (see Figs. 3(a) and 3(b)). The well-defined and strong

interfaces between the constituents in composite magnetoelectric are prerequisites

in order to enhance the magntoelectric effect [22]. Fig. 3(c) shows a

magnification of the interface region between cobalt ferrite and barium

titante. The two regions are well-connected without any cracks or porous areas.

The elemental composition of the selected area was collected using energy

dispersive spectroscopy. Pure elements of Ba, Ti, Co, Fe are detected in the

regions (see Fig. 3(d) for barium titanate region and Fig. 3(e) for cobalt

ferrite region).

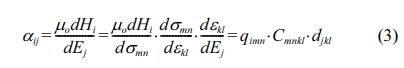

The concept of magnetoelectric effect ![]() is

based on the product properties obtained by a combination of two phases such as

magnetostrictive and piezoelectric phases as shown in the following equation:

is

based on the product properties obtained by a combination of two phases such as

magnetostrictive and piezoelectric phases as shown in the following equation:

where σmn and ![]() are

the stress and the strain tensors, respectively, djkl Cmnk and qim are

the piezoelectric coefficient, stiffness and piezomagnetic coefficient tensors,

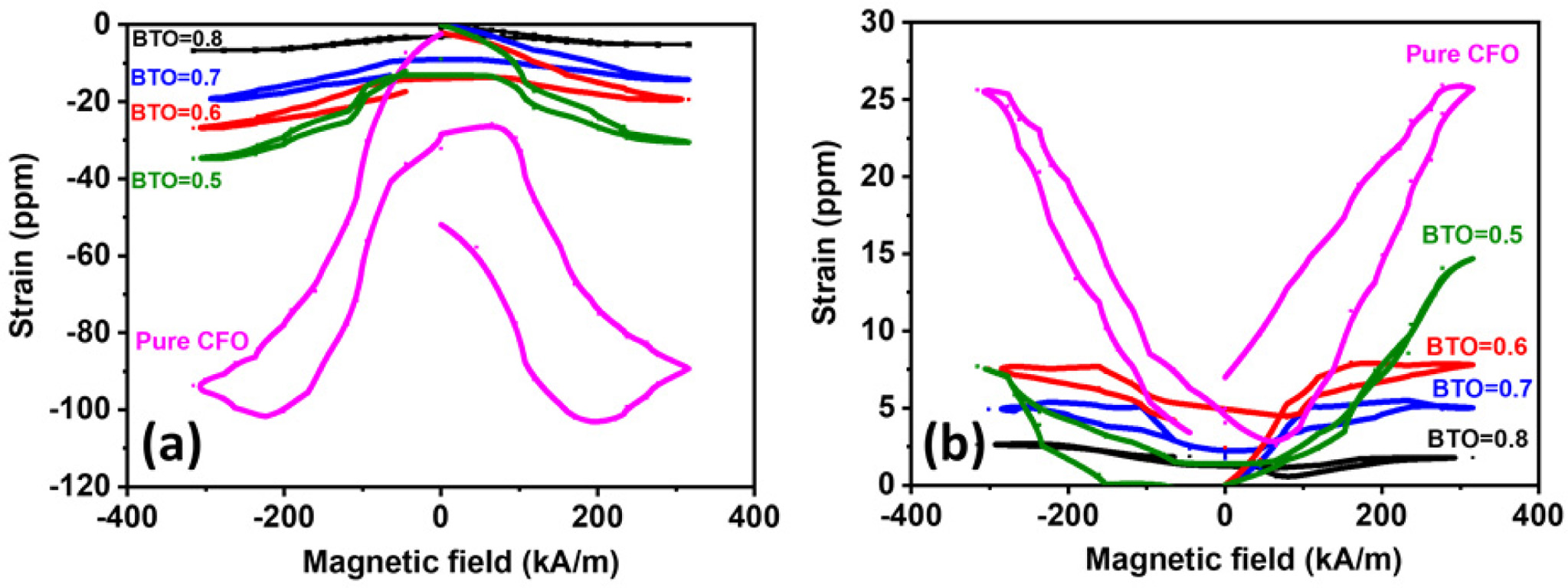

respectively. Fig. 4(a) shows the magnetostriction plots measured parallel to applied external magnetic field. It

is clear that the magnetostriction increased by increasing the content of the

magnetic phase in the samples. Maximum value of strain was recorded for the

sample of pure cobalt ferrite with values about -110 ppm. On

the other hand, the maximum value of magnetostriction of

composites was measured for the sample containing 50 percentage of barium

titatate with value about -40 ppm, these values are comparable with values

reported by Hrib et al. [23]. The low value of magnetostriction of

composite comparing to pure cobalt ferrite may be attributed to the

compression of barium titanate grains on the cobalt ferrite ones which may

reduce the overall magnetostriction.

Fig. 4(b) shows the magnetostriction of the samples measured perpendicular to

the external applied magnetic field. Lower values of magnetostriciton were

measured with maxiumum value for pure cobalt ferrite (≈25 ppm).

The lower values of magnetostriction obtained when the

magnetic field perpendicular to the applied magnetic field are attributed to

the magnetocrystalline anisotropy of cobalt ferrite [24].

are

the stress and the strain tensors, respectively, djkl Cmnk and qim are

the piezoelectric coefficient, stiffness and piezomagnetic coefficient tensors,

respectively. Fig. 4(a) shows the magnetostriction plots measured parallel to applied external magnetic field. It

is clear that the magnetostriction increased by increasing the content of the

magnetic phase in the samples. Maximum value of strain was recorded for the

sample of pure cobalt ferrite with values about -110 ppm. On

the other hand, the maximum value of magnetostriction of

composites was measured for the sample containing 50 percentage of barium

titatate with value about -40 ppm, these values are comparable with values

reported by Hrib et al. [23]. The low value of magnetostriction of

composite comparing to pure cobalt ferrite may be attributed to the

compression of barium titanate grains on the cobalt ferrite ones which may

reduce the overall magnetostriction.

Fig. 4(b) shows the magnetostriction of the samples measured perpendicular to

the external applied magnetic field. Lower values of magnetostriciton were

measured with maxiumum value for pure cobalt ferrite (≈25 ppm).

The lower values of magnetostriction obtained when the

magnetic field perpendicular to the applied magnetic field are attributed to

the magnetocrystalline anisotropy of cobalt ferrite [24].

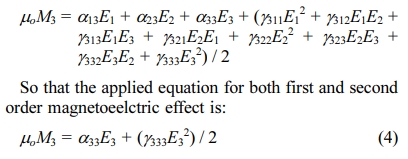

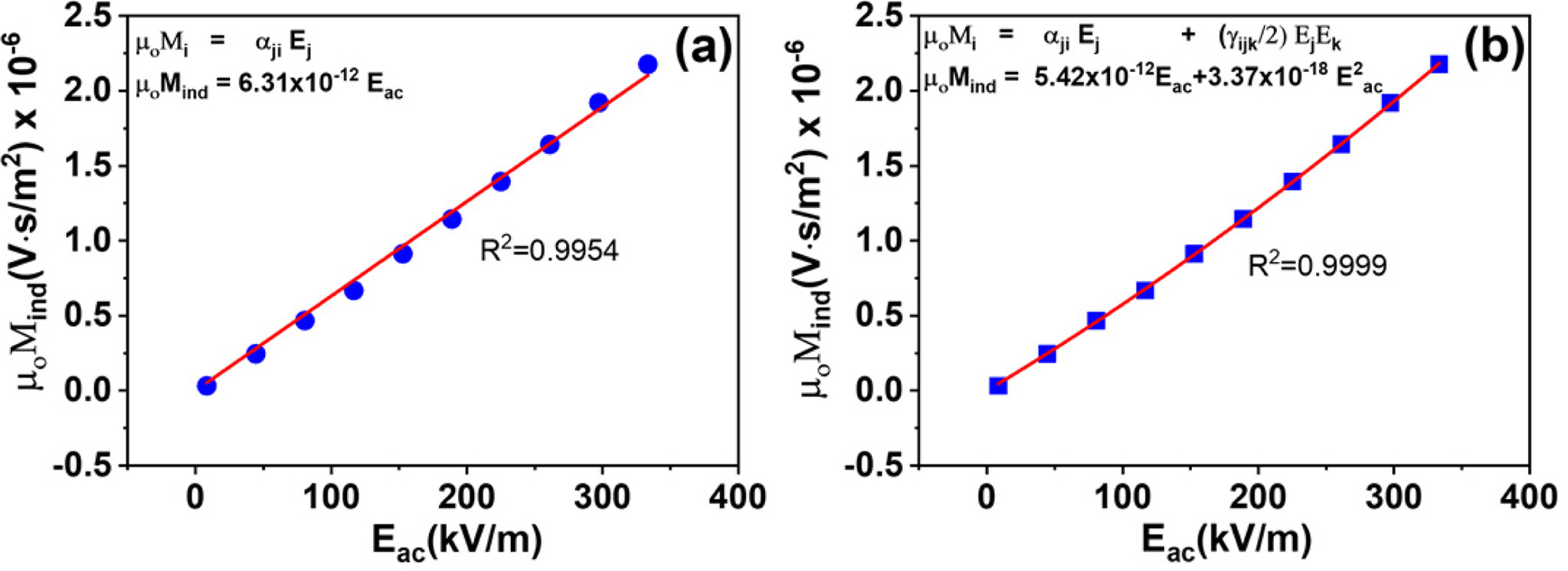

Previously, the converse linear magnetoelctric effect αjji values

for different compositions were measured and reported

[25]. An example of the electrically induced

magnetization of the composite xBTO-(1-x)CFO when x = 0.7 in the

electric field range (0-350 kV/m) is shown in Fig. 5. The relation between

the induced magnetization and the electric field is linear where μoμi =αjiEj. The linearity of the magnetoelectric effect

was approved by different researchers and for different materials [26-28]. In

order to investigate the degree of linearity of the ME effect, the curve was

fitted using linear regression equation as shown in Fig. 5(a) and quadratic

equation (Fig. 5(b)). It was shown that the quadratic equation fitted the curve

perfectly with R-square value 0.9999 which is an indication of the appearance

of the second order ME effect (γijk). For the second order magnetoelectric

effect γijk, it is known that this effect depends mainly

on the square of the electric field as indicated in Eq. (2) (see Fig. 5(b)).

For more explanation, the electric field was applied to

the sample perpendicular to the sample surface so that the converse

magnetoelectric effect - as shown in equation number (2)- can be calculated

considering the applied electric field vector E3=(0,0,E3),

so:

Then, the values of first order ME effect a33 can

be calculated by dividing the induced magnetization on the electric field and

the unit will in s/m, and the value of g333

can be calculated by dividing the induced magnetization by the square of

electric field, so that the unit of the second order magnetoelectric effect g will in s/V. To our knowledge,

this unit of quadratic magne- toelectric

effect has not been measured for any composite magnetoelectric material, while

it has rarely been reported but for single phase materials only. The sample

procedures for fitting curves were followed for the set of different

compositions of xBTO-(1-x)CFO where (x = 0.5, 0.6, 0.7 and 0.8).

Then, the quadratic magnetoelectric effect for different compositions was

extracted and shown in Fig. 6. The same as the first order magnetoelectric

effect, it is clear that the effect depends on the composition between the

ferroelectric and ferromagnetic phases, where the greatest value was recorded

for the composition when x = 0.5. This can be explained by larger

interfaces between the two phases can be obtained when the fifty percent of the

composite are ferromagnetics distributed in ferroelectric matrix, and hence,

more strain generated by electrostriction and transferred to piezomagnetic

phase [29]. The maximum room temperature value of the quadratic magnetoelectric

effect g at

x = 0.5 reached to about 20 × 10-18 s/V whereas

the value of 6.46 ps/MV was measured for Co4Nb2O9

single crystal and at 10K [30]. The quadratic magnetoelectric effect of the

barium titanate cobalt ferrite composite is three times larger than the single

phase values and even at room tem- perature. We believe that having (0-3)

composites, the interface between the two phases with 50% weight percent will

be higher and consequently give higher linear and quadratic ME effect as

indicated in Fig. 6. The results obtained from this paper may be utilized by

other researchers in order to measure linear and quadratic magnetoelectric

effect for other composites with other phase connectivity.

|

Fig. 2 X-ray diffraction patterns for different compositions of

ceramic samples of barium titanate and cobalt ferrite composites. |

|

Fig. 3 Scanning electron micrographs for samples (a) x = 0.5 (b) x = 0.8 and (c) the interface between ferromagnetic and ferroelectric phases

(d) energy dispersive spectroscopy for the barium titanate phase and (e) energy dispersive spectroscopy for cobalt ferrite phase. |

|

Fig. 4 Magnetostriction of barium titanate/cobalt ferrite composites (a) measured along the direction of the external applied magnetic field

(b) measured perpendicular to the external applied magnetic field. |

|

Fig. 5 Room temperature induced magnetic moments as a function of applied electric field, for composition x = 0.7 showing (a) linear

equation fit (b) quadratic equation fit (f = 3 Hz, Hdc = 1500 Oe). |

|

Fig. 6 Room temperature second order (γ) magnetoelectric effect

for different composition of xBTO-(1-x)CFO composites measured

at Hdc = 1500 Oe, f = 3 hz. |

In summary, the quadratic magnetoelectric effect for

different compositions of barium titante and cobalt ferrite

ceramic composites has been successfully extracted by the

employment of fitting quadratic equation of the first order one. The values of

the quadratic magne- toelectric

coupling coefficient (g)

in unit of S/V were reported for the first time for a composite material. The

maximum value of the quadratic magnetoelectric coupling coefficient for such

composite was recorded when the weight percentage of barium titanate is 50% of

the total composite weight with a value of γ333 = 20 × 10-18

s/V. The same as the first order magnetoelectric effect, it was also shown that

the quadratic magnetoelectric effect depends on the constituents amounts of the

ferroelectric/ferrimagnetic phases too. The existence of both the first and the

second order magnetoelectric effect is beneficial for future

applications such as the nonlinear magnetoelectric devices. This

study inspires other researchers to study the relationship

between the first and the second order ME effect in composites rather than

single phases magnetoelectrics.

- 1. Y.K. Fetisov, D.A. Burdin, D.V. Chashin, and N.A. Ekonomov, IEEE Sens. J. 14 (2014) 2252-2256.

-

- 2. M. Bibes and A. Barthelemy, Nat. Mater. 7 (2008) 425-426.

-

- 3. S. Dong, J.F. Li, and D. Viehland. Appl. Phys. Lett. 85 (2004) 3534.

- 4. T. Onuta, Y. Wang, C.J. Long, and I. Takeuchi, Appl. Phys. Lett. 99 (2011) 203506.

-

- 5. C. Pettiford, S. Dasgupta, J. Lou, S.D. Yoon, and N.X. Sun, IEEE T. Magn. 43 (2007) 3343-3345.

-

- 6. M. Fiebig, J. Phys. D: Appl. Phys. 38 (2005) R123.

-

- 7. L. Mitoseriu, J. Span. Cer. Glas. Soc. 44 (2005) 177-184.

-

- 8. M. Mercier, G. Velleaud, and J. Puvinel, Physica B+C. 86-88 (1977) 1089-1090.

-

- 9. J. Cardwell, Phys. Status Solidi B. 45 (1971) 597.

- 10. S. Takano, E. Kita, K. Siratori, K. Kohn, S. Kimura, and A. Tasaki, J. Phys. Soc. Jpn. 60 (1991) 288-293.

-

- 11. F.L. Zabotto, F.P. Milton, A.J. Gualdi, A.J.A. de Oliveira, J.A. Eiras, and D. Garcia, J. Alloy Compd. 829 (2020) 154517.

-

- 12. G. Jian, H. Shao, C. Yan, N. Zhao, B. Song, and C.P. Wong, J. Magn. Magn. Mater. 449 (2018) 263-270.

-

- 13. H. Song, M. Peddigari, A. Kumar, S. Lee, D. Kim, N. Park, J. Li, D. R. Patil, and J. Ryu, J. Alloy Compd. 834 (2020) 155124.

-

- 14. Z. Zheng, P. Zhou, Y. Liu, K. Liang, R.G. Tanguturi, H. Chen, G. Srinivasan, Y. Qi, and T. Zhang, J. Alloy Compd. 818 (2020) 152871.

-

- 15. P. Kaviraj, R. Pramanik, and A. Arockiarajan, J. Ceram. Int. 45 (2019) 12344-12352.

-

- 16. K.Y. Fang, L.H. Gong, W.Q. Jing, and F. Fang, Mater. Today Commun. 21 (2019) 100650.

-

- 17. L. Jian, A.S. Kumar, C.S. Chitra Lekha, S. Vivek, I. Salvado, A. L. Kholkin, and S.S. Nair, Nano Structures and Nano. Objects. 18 (2019) 100272.

-

- 18. D.A. Burdin, D.V. Chashin, N.A. Ekonomov, L.Y. Fetisov, Y.K. Fetisov, G. Sreenivasulu, and G. Srinivasan, J. Magn. and Magn. Mat. 358-359 (2014) 98-104.

-

- 19. J. Ma, Z. Li, Y. Lin, and C.W. Nan, Magn and Magn. Mater. 323 (2011) 101-103.

-

- 20. Y. Wang, Y. Shen, J. Gao, M. Li, J. Li, and D. Viehland, Appl. Phys. Lett. 102 (2013) 102905.

-

- 21. P. Borisov, A. Hochstrat, V.V. Shvartsman, and W. Kleeman, J. Rev. Sci. Instr. 78 (2007) 106105.

-

- 22. C.-W. Nan, M.I. Bichurin, S. Dong, D. Viehland, and G. Srinivasan, J. of appl. phys. 103 (2008) 031101.

-

- 23. L.M. Hrib and O.F. Caltun, J. Alloy. Compd. 509 (2011) 6644-6648.

-

- 24. R.M. Bozorth and J.G. Walker, Phys. Rev. 88 (1952) 1209.

-

- 25. M. Etier, V.V. Shvartsman, S. Salamon, Y. Gao, H. Wende, and D.C. Lupascu, J. Amer. Cer. Soc. 99 (2016) 1-9.

-

- 26. P. Yanda, N.V. Ter-Organessian, and A. Sundaresan, J. Phys. Rev. B. 100 (2019) 104417.

-

- 27. X. Shen, L. Zhou, Y. Chai, Y. Wu, Z. Liu, Y. Yin, H. Cao, C. Cruz, Y. Sun, C. Jin, A. Munoz, J. Alonso, and Y. Long, J. NPG Asia Mat. 11 (2019) 50.

-

- 28. D. Viehland, M. Wuttig, J. McCord, and E. Quandt, MRS Bull. 43 (2018) 834-840.

-

- 29. Y. Wang, J. Hu, Y. Lin, and C.-W. Nan, NPG Asia Mat. 2(2010) 61-68.

-

- 30. Y. Cao, G. Deng, P. Beran, V Feng, B. Kang, J. Zhang, N. Guiblin, B. Dkhil, W. Ren, and S. Cao, Sci. Rep. 7 (2017) 14079.

-

This Article

This Article

-

2020; 21(5): 565-570

Published on Oct 31, 2020

- 10.36410/jcpr.2020.21.5.565

- Received on Apr 22, 2020

- Revised on Jun 5, 2020

- Accepted on Jun 10, 2020

Services

Services

Shared

Correspondence to

Correspondence to

- Morad Etier

-

Industrial Engineering Department, The Hashemite University, Zarqa 13133, Jordan

Tel : +962 (5) 3903333-5013

Fax: +962 (5) 3826613 - E-mail: morad.etier@hu.edu.jo

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.