- Wear behavior of irregular shape Ti6Al4V powder reinforced with carbon nanotubes

Muhammet Ceylana,* and İsmail Topcub

aDepartment of Mechatronics Engineering, Istanbul Commerce University, Istanbul, Turkey

bDepartment of Metallurgy and Materials Engineering, Alanya Alaaddin Keykubat University, Antalya, Turkey

The purpose of this study was

to investigate the sintering behavior, microstructural evolution, and the

effect on wear resistance of carbon nanotubes (CNT) with the addition of a

mechanical alloy (Ti6Al4V) and sintered irregular Ti64 powder. The mechanical

alloy powders utilized in this study were produced through the process of CIP

(Cold Isostatic Press) in order to produce samples by compress on under various

pressures within a 300 MPa floating molded press. The samples were

sintered at a high vacuum (10-5 mbar) for 60 minutes at a temperature of

1275 oC. After sintering, the materials were characterized

using an optic microscope (OM), scanning electron microscopy (SEM) and EDX

(Energy-dispersive X-ray spectroscopy) to determine whether the materials had

wear resistance, density measurement, etc. The Carbon Nanotube wear and

friction behavior were investigated under various conditions using a pin wear

tester on a disc followed by a scanning electron microscopy (SEM) analysis. The

objective of this study was to evaluate the density, metallographic properties

and hardness of Ti64 samples supplemented with different CNT ratios as a

function of sintering temperature. Theoretical density and micro-hardness of

mechanical alloyed and sintered irregular Ti64 powders changed with the

additions to CNT under increased sintering temperatures.

Keywords: Sintering, Ti6Al4V, Carbon Nanotubes, Wear, Ti6Al4V Powder

Titanium alloys can be used in a wide variety of

applications. A few examples include the biomedical, automotive and aerospace

industries. Ti6Al4V alloy with 4% vanadium and 6% aluminum

weight is preferred for use in surgical implants, turbines and

airplanes because of its sufficient mechanical strength, heat

treatment ability, good corrosion resistance, and biocompatibility.

It is a powder metallurgy (PM) technique used in the production of titanium

alloys and their composites [1-4]. As a result of the possibility of

reinforcement in metal matrix composites, the properties of the com- posites can be changed and thus their

applications can be extended. The in situ formation technique

for changing the properties of composites provides the advantage of

greater size and reinforcement control [5, 6].

Since the invention of the aircraft, the need of high

strength and lightweight materials has been recognized and increased. When the

hardness and strength of a material increases, the dimensions and therefore the

mass of the material must also be reduced for a given load bearing application.

This allows many advantages in automobiles and aircraft, such as increased load

and improved fuel efficiency. The increase in fuel efficiency

of engines has become an important issue due to the steady decline in global

oil resources. The reason for the development of metal matrix composites (MMCs)

is the inability of metals and alloys to provide a structure with both strength

and hardness. The strength and ductility in the material are then provided by

the metal matrix produced [7-9]. Titanium carbide (TiC) is used

because of its compatibility and properties favorable in

strengthening titanium alloy matrices [10]. Materials designed

for particulate doped titanium matrix composites, bearings,

abrasion resistant gears, erosion resistant pipes, shafts and

friction resistant motors [11]. Component selection plays a significant role

when it comes to the application of materials exhibiting the properties and

characteristics needed for the production of titanium alloys and composites

[12]. Titanium alloys are well known for their poor tribological properties

[13-18]. In addition, titanium deforms very poorly on the opposite surface and

easily transfers the material in the non-lubricated tribosystems. Furthermore,

due to the great affinity of titanium to oxygen, it is easily transferred to

both metallic and non-metallic surfaces that remain as polymers. This results

in an oxide surface layer which in turn leads to severe adhesive wear. Under

extreme fatigue terms at environmental temperature, force decrease

factors between 2.6 and 3.6 were observed in titanium alloys as a result of the

loss of the respective material [14]. Lastly, titanium alloys have weak wear

resistance; for example, Budinski [16] found that the dry sand rubber wheel for

his wear test utilizing Ti-6Al-4V alloy and pure Ti to wear 15 times higher

than D2 tool steel. This weak tribological conduct is attributed to the low

hardness and absolute values of the tensile-shear strength of titanium and

titanium alloys [17-24].

Carbon nanotubes (CNTs) were first discovered in 1991 by

S. Iijema [25]. From a science and technology perspective, carbon nanotubes

(CNTs) are on their way to becoming one of the fastest growing research areas

in many disciplines including materials and life technologies,

physics and chemistry. Unlike cast graphite and diamond,

carbon nanotubes (CNTs) have unique optical, magnetic, electrical, mechanical,

and thermal properties [26, 27]. Carbon nanotubes (CNTs) have interesting

electrochemical properties as well. In the study by

Hussain et al., it was found that the electroactivity of CNTs was

due to the presence of surface reactive groups [28].

The purpose of this research is to investigate how the

addition of 0.5% - 5% CNT has an effect on the wear properties

of Ti64 P / M alloy. Metallographic techniques

were used to characterize the CNT added as sintered samples. Each sample was

subjected to abrasion tests with a pin on the disc. It was then characterized

by, scanning electron microscopy (SEM), hardness tests, optical microscopy and

X-ray diffraction (XRD). Worn surfaces of the sintered samples were analyzed

under SEM.

Raw

materials and sintering process

In this study the Ti64 and CNT powders were purchased from

industrial suppliers to do the first experiments and tested to determine their

values. The purchase process; Ti64 and composite reinforced with

0.5% - 5% CNT 10-30 nm were used. The materials were fabricated

(Phelly Materials Company) by a PM technique. As raw materials, atomized Ti64

powders having a purity density of 4.43 g / cm3 and a

nominal size of 45-180 99 µm were used. The materials used as matrix

material were CNT and Commercially Ti64 powders. The reinforcement CNT material

utilized in this study were (Chep Tubes Company and Choggo Company China -

density 2.31 g/cm3) particles. The CNT particle has a size of

about 10-30 nm.

Production

of composites

During the production of composites, 0.5% - 5%

Volume CNT was reinforced to Ti64 by means of a tubular milling. Milling was

performed for five hours. The ball / powder weight ratio was 6:1. The grinding

speed was 400 rpm and the alumina ball diameter was 10 mm. Powder

materials were easily pressed at 300 MPa by Cold Isostatic Press (CIP) process.

The reason for its ease is because of the ceramic behavior of the CNT during

the process. The selected sintering atmos-

phere was in high vacuum (1.2 10-5 mbar). Other

sintering atmospheres may cause oxidation of TiO2

material in the working rooms, so that the sintering of the

samples was carried out at two different temperatures (1275 oC).

Characterization

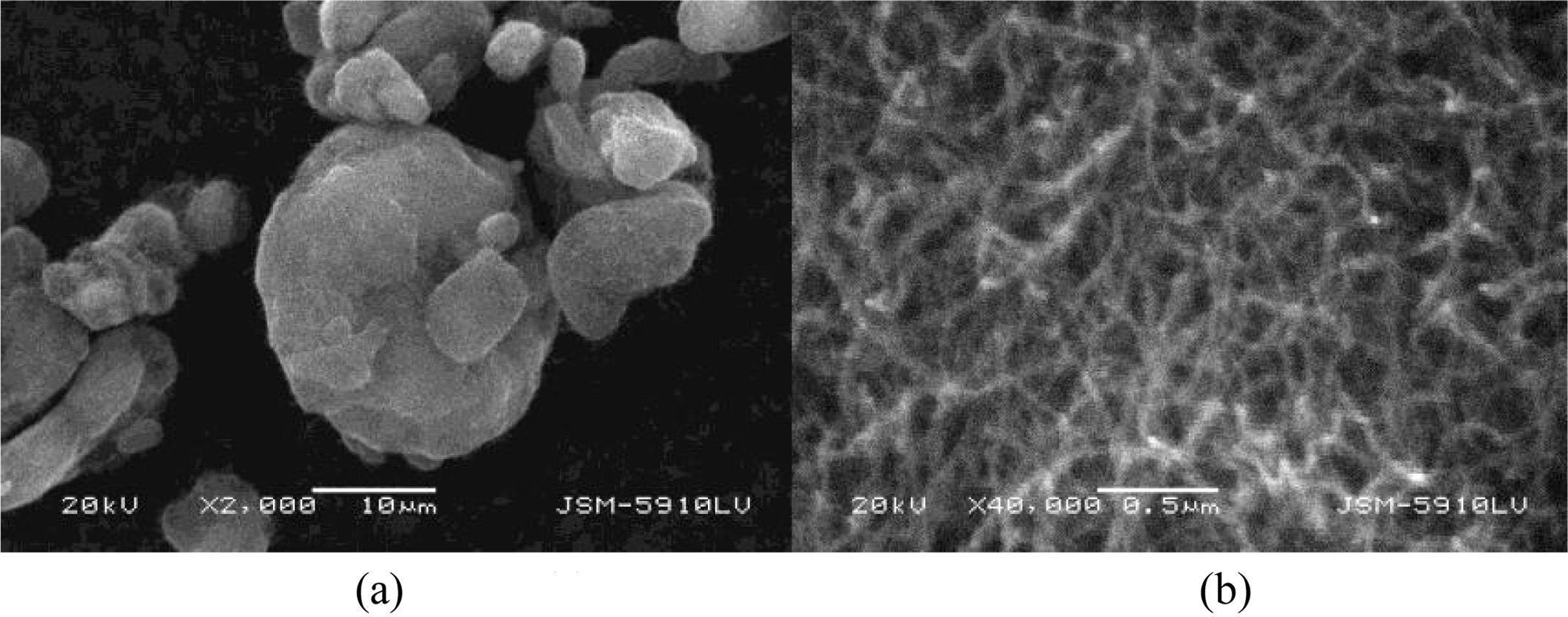

SEM is one of the most versatile tools available in the

field of materials science, used to analyze the microstructural properties of

materials. SEM sends a high energy electron beam to the sample surface and

scans the surface and takes images. The powder morphology

and microstructures of the prepared sintered samples were

examined using a scanning electron microscope (SEM, JEOL Ltd., JSM-5910LV). Fig.

1. shows the morpholFig.ogies of the starting materials.

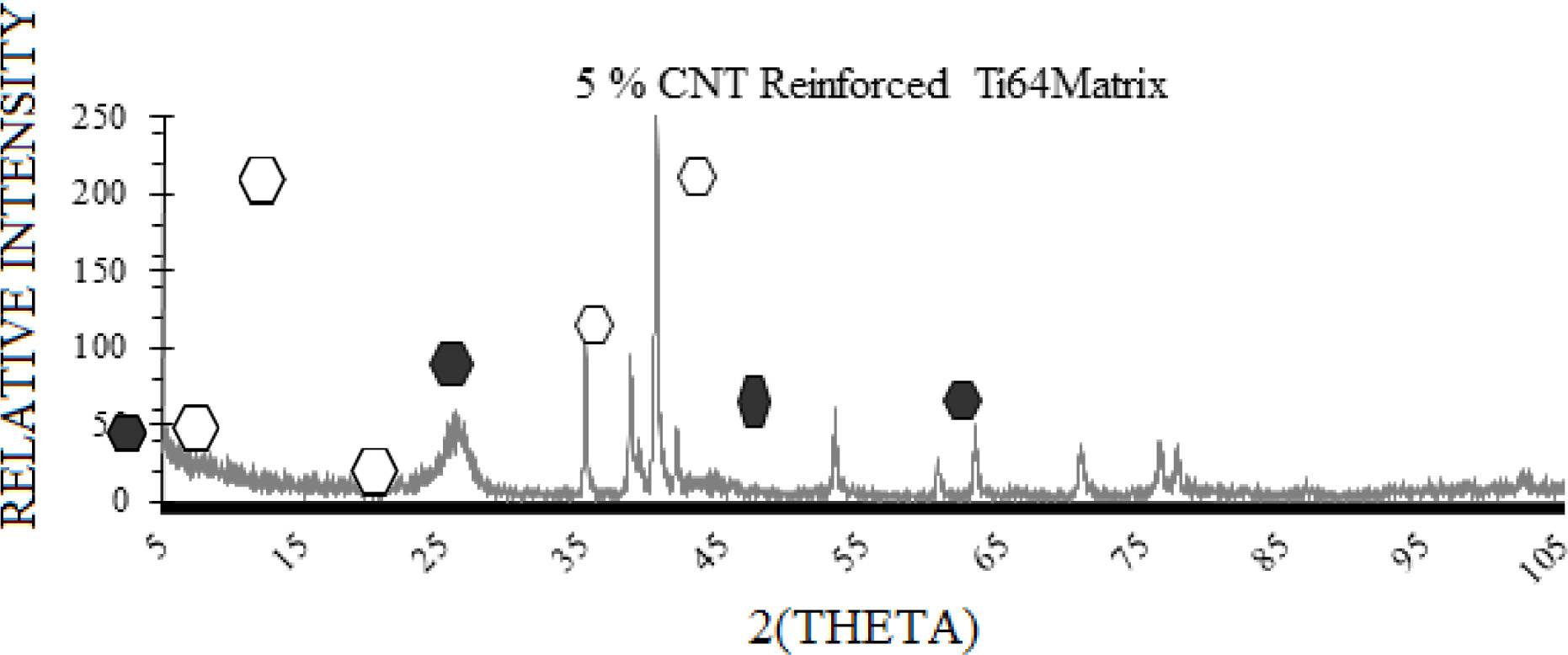

A Rigaku X Ray diffractometer was used to identify the

phases in pure Ti64 powder and CNT powder from different companies as

demonstrated in Fig. 2 with an incident angle of 2 oC / Ka

radiation. The angle of refraction was between 5-120o with a step

increase of 0.02o and a counting time of 1 s. Energy Dispersive

Spectrometer (EDS, OXFORD Industries INCAx-sight 7274, (133-eV

resolution) were used to analyze material

composition.

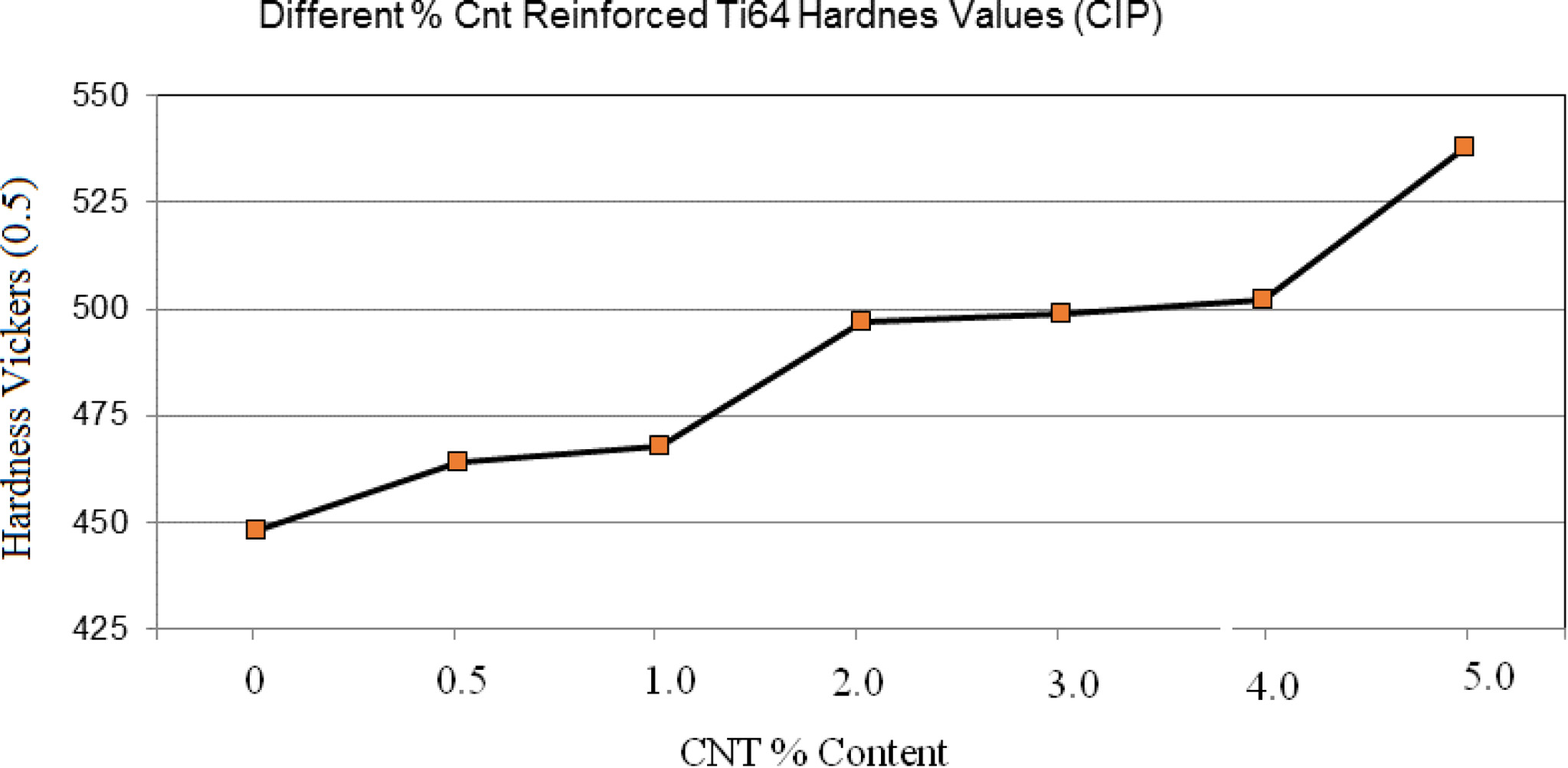

Hardness

and density experiments

The mechanical properties of the produced samples were

determined with the help of hardness measure-

ments. The hardness tests of the samples prepared by metallography were

performed with a Micro-Hardness Tester Machine (FM-700, Future Tech Corp. in

Japan). The Vickers 136o diamond in the metallographic

samples was used to determine the hardness of the cutting

compounds. Test load for each sample was 500 gr. Since the indentation

trace covers both the matrix and the reinforcing material, the stiffness value

shown represents the bulk stiffness of the composite. The results of these

hardness tests were evaluated by taking the average of 10 consecutive test

results. Hardness values with various CNT contents are demonstrated in Fig. 3.

The macro and micro-hardness measurements, which are

referred to as hardness (HRC) (Wolpert Instron Corp. USA) were compared using

the methods described within this section. There is an observed difference in

the macro and micro surface hardness measurements; this significant difference

in material phase change is thought to arise from the matrix material formed by

the CNT material.

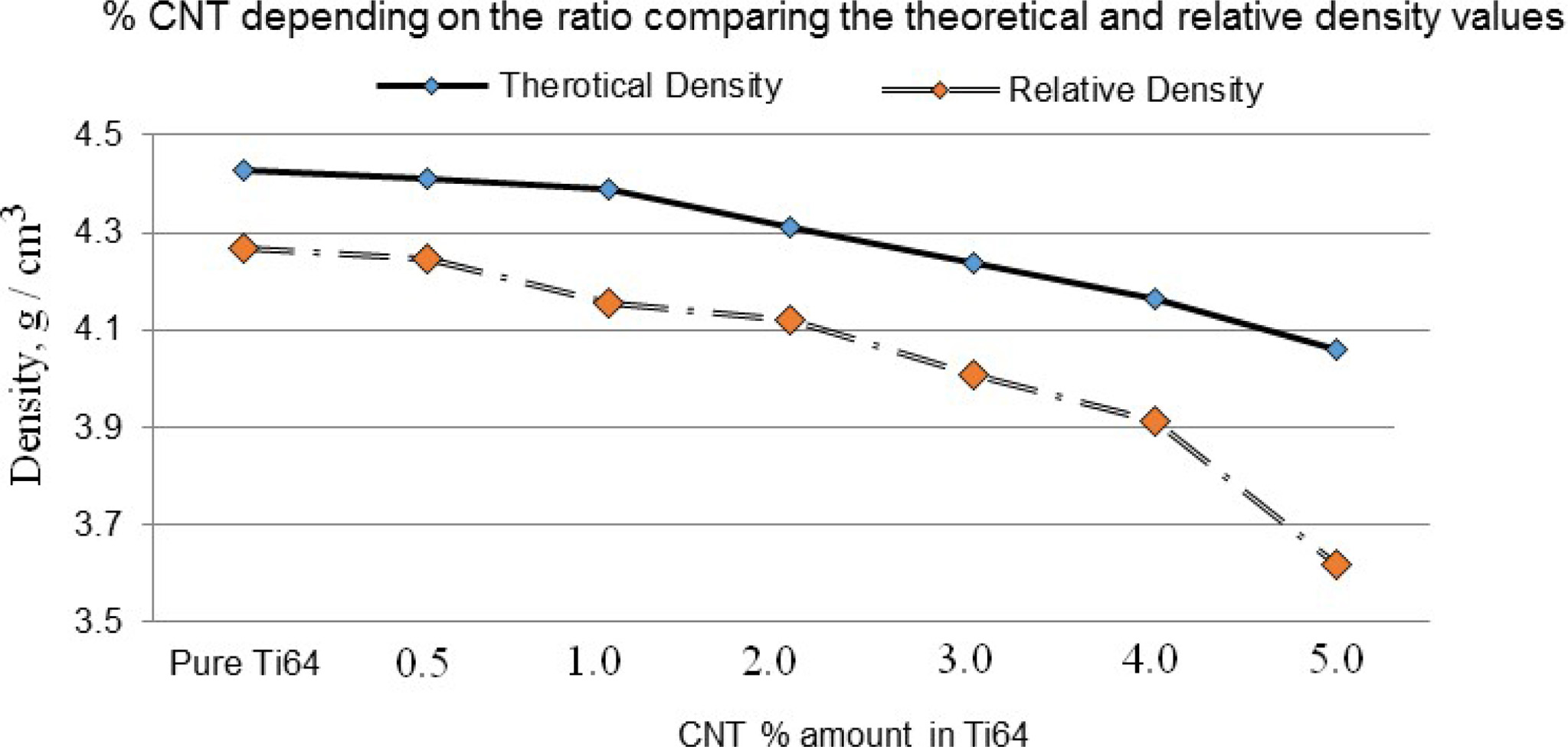

The Archimedes water immersion method was used to

determine the densities of the sintered samples (Precisa XB 320M, Switzerland).

Theoretical density measurements of the composite samples Ti64 /CNT in

different proportions according to the literature ranged from 90 to 99.5%. The

main reason for the variances of density measurements in the range from

literature of these composites is the increased ratio CNT. Density calculations

are presented in Fig. 4. The highest density of CNT, which had the lowest

percentage of low density alloys, was found to have the highest CNT %. Selected

composite samples are CNT-reinforced Ti64 powder produced by powder metallurgy.

Information on the properties of the powders is provided in the previous

section. The average density values of the composites containing different CNTs

are shown in Fig. 4. Here, the densities of the specimens approxi- mate the theoretical density with increasing

sintering temperatures for the CNT contents in all ratios.

Metalographic

examination

For metallographic examination, each sintered test samples

were evaluated for each composite material. A Kroll reagent (3 mL HF,

6 mL HNO3 in 100 mL H2O) was used to etch the

samples for optical metallography. Prepared from longitudinal sections of

composites after examination of metallographic samples. All samples were slowly

ground with 240, 500, 800 and 1000 mesh SiC sand papers, respectively. In the

next step, the samples were slowly polished with Kroll solutions. The

microstructures of the composites were examined using Optimus Optic microscope.

Metallographic images at different magnifications were taken for each sample

after the sample preparation process (X50, X100 and X200), press and sections

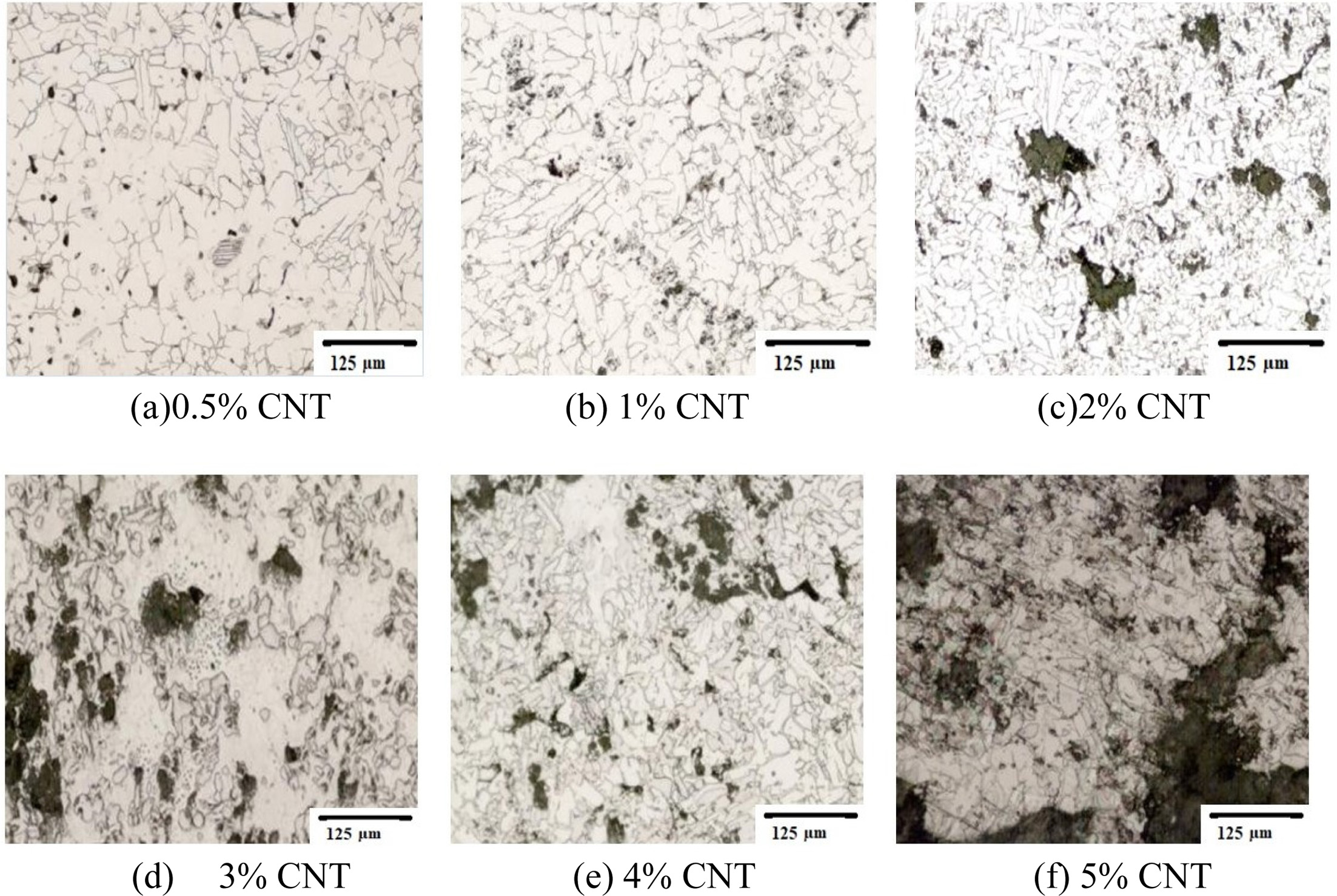

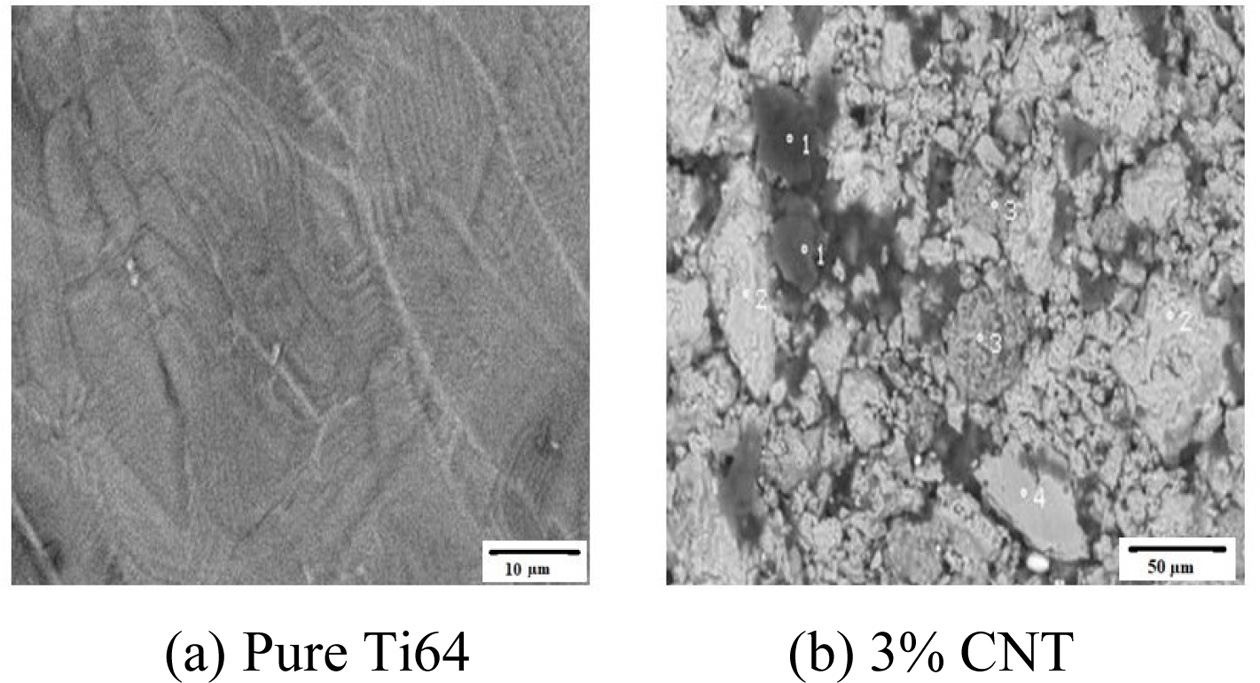

in the direction of the image. Figs. 5 and 6 display these images. In these

studies, the alpha and beta shows the structure of Ti64 powder. As seen in the

figures, the images contain gray areas of TiC structures, the gray area

increased as the ratio of CNT % increased. Porosity can be seen in Fig. 5 and 6

on the other hand, porosity was not calculated in our study.

Wear

tests

Wear tests were performed on a standard disc on a machine

disk with a hardness of 62 HRC, with a continuously rotating D2 set of steel

plates without lubricant at room temperature. The specimen pin for the wear

test is Ø10 × 10 mm and the polished wear surface for Ra

roughness of 0.159 nm. The test was carried out with three trials in order

to ensure its repeatability for each sample. The disk surface was grounded.

Then, 0.830 µm Ra was polished to a roughness 0.830 µm Ra. sliding

speed, sliding distance and load were kept constant at 1.04 m/s,

1,000 m and 10 N respectively for all tests. All the specimens were

carefully cleaned with and dried. The specimens were cleaned with

ethanol before and after test for measuring wear loss

by a balance with an accuracy of ± 0.0001 g.

The wear rate was calculated using the following equation

where Ws is

wear rate, mm3/Nm, Dm the mass loss of test samples during

wear test of N revolutions, g, q the density of test materials, g/cm3. L is

total sliding distance, m and F the normal force on the pin, N. The total

sliding distance was monitored on an auto-recorder. The worn surfaces of all

the samples were examined using SEM.

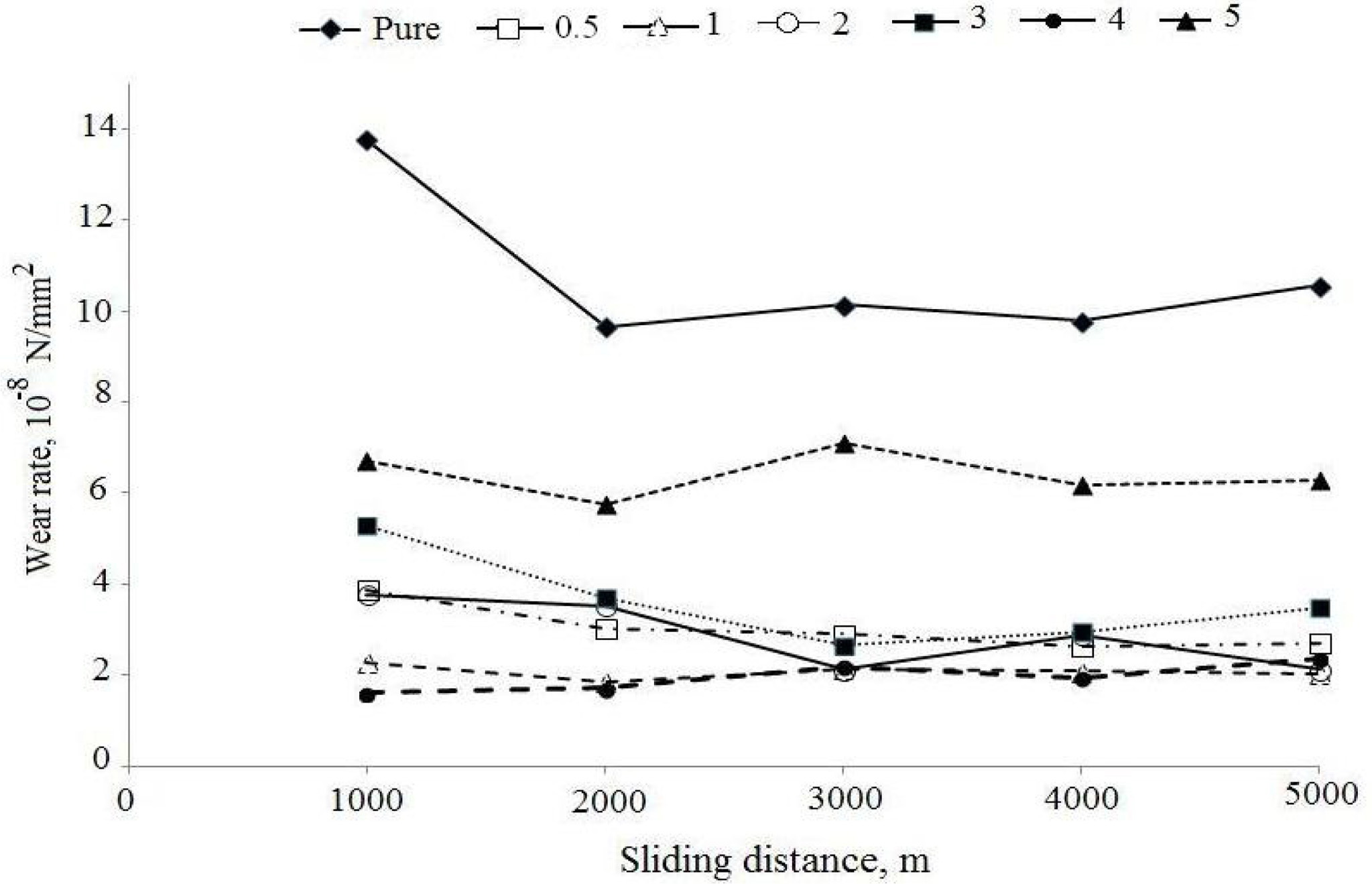

The variation of wear rate with sliding distance for all

samples with and without Ti64 and CNT % are shown in Fig. 7. As seen in Fig. 7,

the wear rate of specimens decreases with increasing CNT % con- centration in the alloy. Wear loss increased

due to increased slip distance and wear rate decreased with increasing slip

distance. In Fig. 7, it can be clearly seen that wear

rate decreased by increased CNT % additions. Generally,

with the increasing hardness dramatically decreased wear rate

until CNT 4% additions. However, the lowest wear rate

obtained 4% CNT addition. The most interesting result of this study was the

fact that the highest wear rate was obtained in materials with the highest

hardness values in the additive materials. As shown in Fig. 7, the CNT additive

was increased to reduce wear loss and wear rate. The hardness observed from

these observations has a significant effect on the wear behavior of the investigated

materials. Wear tests show that CNT addition increases

the wear resistance by 4% on average.

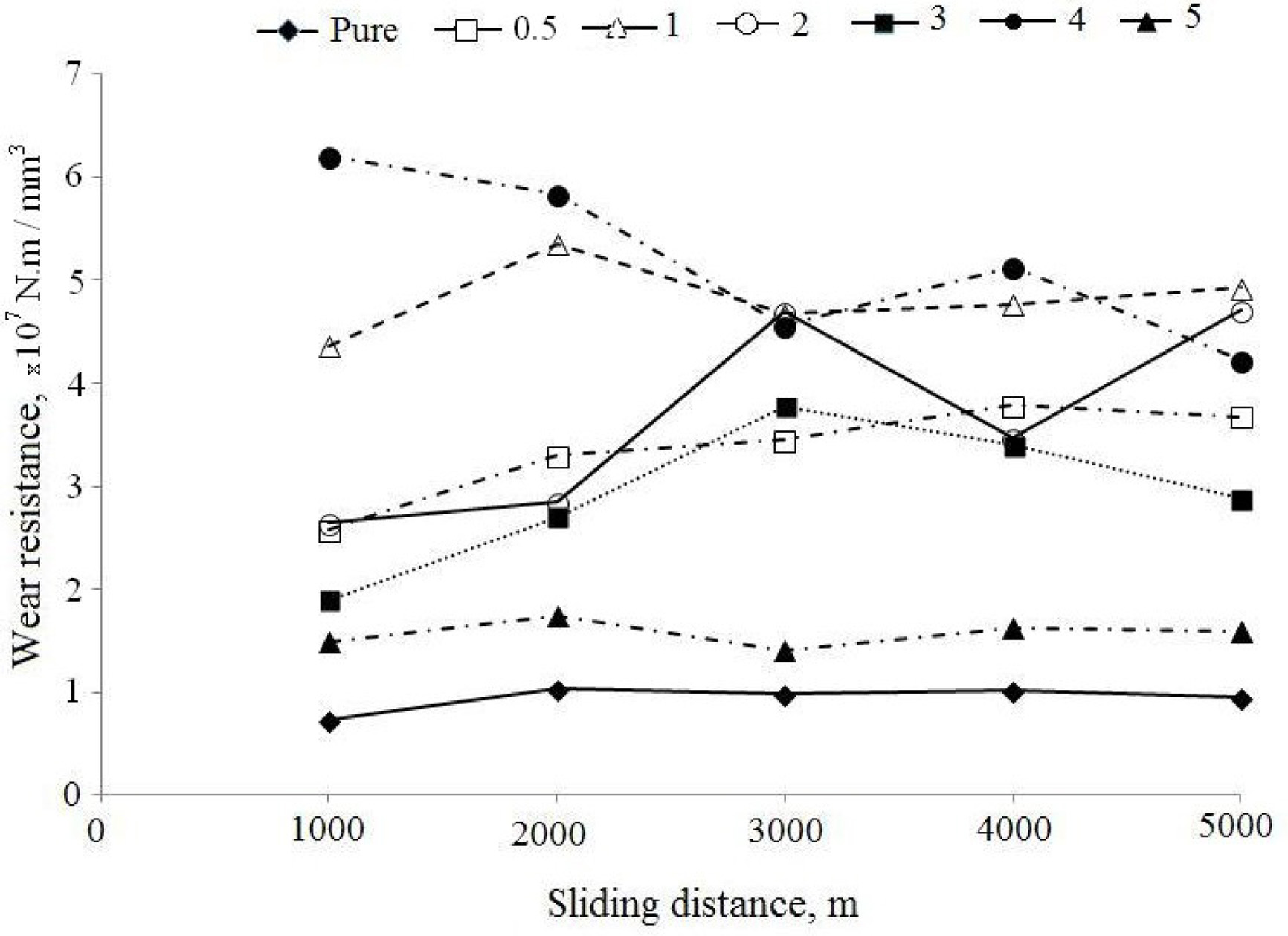

It is clearly displayed in Fig. 8 the effect of CNT additions

on wear resistance. The highest wear resistance and

hardness obtained with 4% CNT addition in Fig. 8 and 3. This observation shows

that hardness has a significant effect on the wear behavior of the inves- tigated CNT materials. The CNT 5% has a

wear rate less than the CNT 4% materials.

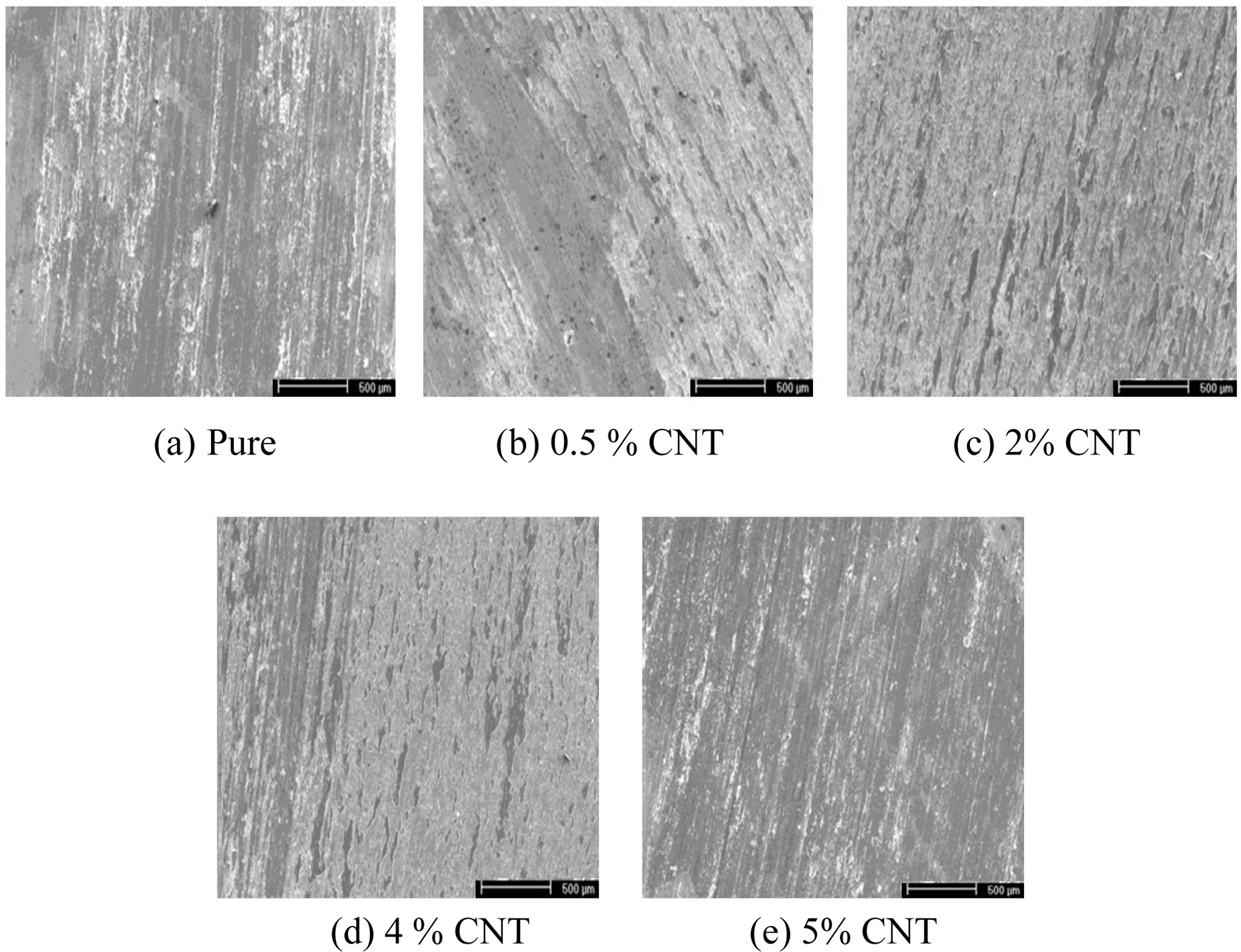

Fig. 9 shows worn surface images of CNT additions affects

s using SEM between several wear mechanisms. On the worn

surface, with the exception of CNT 2% and CNT 4%, many scratches were found

that were eroded by wear and plastic deformation on the surface, as shown in

Figs. 9(c) and (d). In addition, many cracks were observed on the worn surface.

The growth of these cracks leads to an increase in the length of wear residues.

Based on these CNT results, we can state that the amount of wear increased

significantly. Otherwise, as shown in Figs. 9(a), (b) and (e), scratches were

found around the surface caused by abrasive wear. The

results show that the addition in CNT prevents crack propagation to a certain

point as displayed in Fig. 9. This reinforcing microstructure,

effectively prevented the scratching and cracking of the

matrix material during wear and led to the removal of a small amount of debris.

Compared to low content reinforcement (0.5%, 1, 2 CNT), this turned out to be a

very different wear condition. As shown in Figs. 9(a), (b), (e), many particles

were observed on the surface. In fact, it is a transfer layer of hardened

particles caused by adhesion, abrasion, and oxidation. As expected, the

addition of CNT to the reinforcing bars was effective in increasing the wear

resistance and friction properties of titanium. The mechanism of wear has

changed after CNT 4%. The mechanism of wear was obtained pure, 0.5, 1 and 5 CNT

% adhesive wear. Increased reinforcement per-

centages of CNT, lead to the mechanism of wear becoming abrasive wear.

Therefore, the CNT 5% with the highest hardness does not achieve the highest

wear resistance. This shows that the addition of additives should be at a

certain CNT percentage.

|

Fig. 1 SEM images of Ti64 and CNT powders: (a) Ti64 and (b) CNT. |

|

Fig. 2 XRD pattern of 5% content CNT particles in Ti64 Matrix. |

|

Fig. 3 The hardness versus different CNT content (0.5 - 5%). |

|

Fig. 4 CNT % reinforced by the density of different exchange rates. |

|

Fig. 5 Optical microscopy images of Ti64 (a), (b), (c), (d), (e) and (f) different reinforced CNT. |

|

Fig. 6 SEM microscopy images of Ti64 (a) and (b) reinforced

CNT. |

|

Fig. 7 Variation of wear rate with sliding distance for samples. |

|

Fig. 8 Variation of wear rate with sliding distance for samples. |

|

Fig. 9 Worn surfaces of titanium matrix composites. |

The selected examples in this study are CNT-reinforced

Ti64 powder produced by powder metallurgy. The mean density worth of the

composites containing different ratios of CNT are as shown in Fig. 4. As the

sintering temperature decreased, the density of the samples approached the

theoretical density.

The XRD of samples having various CNT contents are

displayed in Fig. 2. Fig. 2 shows the peaks at 2 θ of 36.4 and 40.7 belongs to

the Ti6Al4V, and 25,42, and 53 belongs to the CNT. As can be seen in Fig. 2, an

increase in the intensity and region of the main peak of the CNT with

increasing CNT contents leads to a change.

Vickers hardness tests were performed on six different

compositions and sintering temperatures of 1300 oC. In Fig. 3,

mean hardness values of the samples are given. Increasing the weight percentage

of CNT also increased the stiffness of the composite. The ratio of composite

materials (CNT %), Ti64 / CNT, as increased

demonstrated increased micro-hardness measurements. However, the composite

demonstrated abrasive wear after 4-5% weight of CNT.

Optical microscopy and SEM test were taken from the

samples. In Fig. 5 and 6 displays increasing the percentage of CNT, lead to

increase porosity.

The wear rate of the samples decreased rapidly due to the

increase in theoretical density. However, in this case the hardness increased

in the opposite direction. From 0.5 and 4 wt% CNT addition decreased

sintered density, but increased hardness. Therefore, the highest wear

resistance is obtained with 4 wt% CNT addition. The result of the wear

test, despite being with the hardest 4 wt% CNT, wear resistance is not the

highest. After 4% CNT additional, the wear mechanism has changed

as displayed in Fig. 9(d) and (e). Therefore, the wear

resistance is lower and identifies 4% wt CNT as the critical value. Due to

5 wt% CNT additive material having almost as much wear rate as pure

material in Fig. 7. High wear resistance has been obtained in the case of

adhesive wear in Fig. 7. Many scratches were found on the worn surface, except

for those containing 1%, 2% and 4% CNT. In the case of CNT, the surface is worn

with wear and plastic deformation, as shown in Figs. 9(c) and (d). Also, many

cracks were observed on the worn surface, especially 5 wt% CNT. The spread

of these cracks increases the size of the wear residues. On the other hand, as

shown in Figs. 9(a), (b) and (e), we have found scratches around the worn

surface caused by abrasive wear. Supplementing in CNTs have been proposed to

prevent spreading of abrasive wear at certain rates.

The aim of this study was to investigate the density, metallographic

properties and hardness of Ti64 samples supplemented

with different CNT ratios as a function of sintering temperature. The densities

of the samples obtained from the results of this study approach the theoretical

density with increasing sintering temperatures applicable

to all different ratios of CNT contents. Besides, low CNT content resulted in a

closer result density. The images obtained from the SEM analysis show that the

CNT particles are homogeneously dispersed in the matrix and there is no

disintegration in a particular region. However, the presence of porosity at the

ends of the CNT particles is present. XRD indicates that the increased CNT

content causes an increase in density or area of the main peak. By increasing

the weight percentage and the sintering temperature of the CNT, the hardness of

the composite also increased. The effect of the sintering temperature above

1,300 oC is lost after 4-5 wt% of CNT. The dispersion

strengthening effect can be attributed to increased hardness by addition of

CNT. The addition of CNT to the base alloys leads to a reduction in weight loss

and wear rate during sliding wear tests. In addition, the 4 wt% Carbon

Nanotube content was found to be the best way to improve friction properties.

Looking at the result of the abrasion test, the wear loss is clearly reduced as

the Carbon Nanotube content increases. The highest wear

resistance has been obtained in the case of adhesive wear at

Carbon Nanotube 4 wt % content. It is clearly demonstrated that with the

increased addition of carbon nanotubes, the wear mechanisms

change. The results showed that the addition of carbon

nanotube up to 4 wt% lowered wear loss and increased wear resistance.

- 1. A.G. Jackson, J. Moteff, and F.H. Froes, J. Met. 31 (1979) 145.

- 2. L. Bolzoni, E.M. Ruiz-Navas, and E. Gordo, Mater. Sci. Forum 765 (2013) 383-387.

-

- 3. Z.Y. Ma, R.S. Mishra, and S.C. Tjong, Acta Mater. 50 (2002) 4293-4302.

-

- 4. M. Hagiwara, Y. Kaieda, Y. Kawabe, and S. Miura, ISIJ Inter 31 (1991) 922-930.

-

- 5. L. Wang, Z.B. Lang, and H.P. Shi, T. Nonferr. Metal Soc. 17 (2007) 639-643.

- 6. J.Q. Jiang, T.S. Lim, Y.J. Kim, and B.K. Kim, Mater. Sci. Techno. 12 (1996) 362-365.

-

- 7. A. Kelly, J. Mater. Sci. 41 (2006) 905-917.

-

- 8. S. Rawal, JOM, 53 (2001) 14-24.

-

- 9. J.S. Shelly, R. LeClaire, and J. Nichols, JOM 53[4] (2001) 18-21.

-

- 10. P. Rohatgi, JOM, 43 (1991) 10-15.

-

- 11. S. Ranganath, J. Mater. Sci., 32 (1997) 1-16.

- 12. M. Yamada, Mater. Sci. Eng. A. 213 (1996) 8-15.

-

- 13. S.L. Rice, S.F. Wayne, and H. Nowotny, Wear 65 (1980) 215-226.

-

- 14. S.R. Nutt and A.W. Ruff, Wear of Mater. (1983) 426-433.

- 15. R.B. Waterhouse and A. Iwabuchi, Wear 106 (1985) 303-313.

-

- 16. K.G. Budinski, Wear of Mater. (1991) 289-299.

- 17. F.M. Kutas and M.S. Misra, ASM Handbook, 18 (1992) 778-784.

- 18. A.P. Mercer and I.M. Hutchings, Wear, 124 (1988) 165-176.

-

- 19. I. Topcu, H.Ö. Gülsoy, N. Kadıoğlu, and A.N. Güllüoğlu, J Alloy Compd. 482 (2009) 516-521.

-

- 20. D.E. Alman and J.A. Hawk, Wear (1999) 629-639.

-

- 21. I. Topcu, B.N. Çetiner, A.N. Güllüoğlu, and H.Ö. Gülsoy, J. Chem. Soc. Pak. 42 (2020) 70-80.

- 22. I. Topcu, A.N. Güllüoğlu, M.K. Bilici, and H.Ö. Gülsoy, J Fac Eng Arch. Gazi Univ. 34 (2019) 141-149.

- 23. I. Topcu, H.Ö. Gülsoy, and A.N. Güllüoğlu, Gazi Univ. J. Sci. 32 (2019) 286-298.

- 24. I. Topcu, J Teh. Glas. 14 (2020) 7-14.

-

- 25. K. Saeed and N. Khan, J. Chem. Soc. Pak 37 (2015) 284-289.

- 26. K. Saeed, J. Chem. Soc. Pak. 32 (2010) 559-564.

- 27. D.H. Lee, B. Jang, C. Kim, and K.S. Lee, J. Ceram. Process. Res. 20 (2019) 499-504.

-

- 28. S.T. Hussaın, S.M. Abbas, M.A. K. Bangash, M.U. Rehman, and N. Ahmad, J. Chem. Soc. Pak. 35 (2013) 604-610.

This Article

This Article

-

2020; 21(5): 539-546

Published on Oct 31, 2020

- 10.36410/jcpr.2020.21.5.539

- Received on Mar 6, 2020

- Revised on Apr 5, 2020

- Accepted on Apr 7, 2020

Services

Services

Shared

Correspondence to

Correspondence to

- Muhammet Ceylan

-

Department of Mechatronics Engineering, Istanbul Commerce University, Istanbul, Turkey

Tel : +90 444 0 413-331

Fax: +90 (216) 489 02 69 - E-mail: mceylan@ticaret.edu.tr

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.