- Effect of the conductive materials and press ratio of an anode electrode on the electrical properties in a lithium-ion battery using SiOx

Jong-Kyu Lee and Jung-Rag Yoon*

R&D Center, SAMWHA CAPACITOR, Yongin, South Korea

A Lithium-ion battery was

prepared by controlling the content of conductive materials and the press ratio

of the anode electrode to optimize cell properties. Increasing of the content

of conductive material, increased the capacity, and decreased the DC-ESR. The

discharge capacity retention as a function of current rates increased with an

increasing amount of conductive material. With an increasing press ratio, the

active material was evenly distributed on the Cu collector and a dense anode

was obtained. The capacity and DC-ESR decreased with an increasing press ratio.

The discharge capacity and DC-ESR retention as a function of current rates did

not change remarkably with an increasing press ratio. However, the adhesion

force between the Cu collector and active materials increased with an

increasing press ratio.

Keywords: Li-ion battery, SiOx, Conductive materials, Press ratio

Lithium-ion batteries (LIBs) have been established as one

of the most important energy storage technologies and are widely used in

importable electronics and electric vehicles (EVs) because of their high energy

and power densities as well as long lifespan [1-4]. However, the

increasing energy density and cost demands for general

public acceptance of EVs have begun to exceed the ultimate capability of

current commercial LIB technology [5-8].

Silicon monoxide (SiO) has recently aroused great interest

as one of the most promising alternative anode materials for

next-generation LIBs due to its appropriate working

potential (< 0.5 V vs. Li+/Li), high theoretical specific

capacity (-2,400 mAh g−1), and enhanced cycling

stability compared to Si [9-13]. Silicon monoxides (SiO or SiOx)

have also received some attention as another type of silicon-based anode

because of their based on its ability to offer high energy density while they

suffer from poor electronic conductivity [14].

A conductive additive as a necessary ingredient has been

widely used in the lithium ion battery system to enhance the

conductivity of electrodes [15-18], especially for the

Si-based anode [19, 20]. Conductive additive wrapping around the active

material grains has greatly reduced the contact resistance

between grains, decreased the inner resistance and improved the

rate capability [21]. At present, the commonly used conductive

additives in commercial lithium ion batteries are acetylene black,

Super-P, Ketjen Black, CNTs and vapor-grown carbonfibers (VGCFs).

In this paper, Super-P was chosen as a conductive material

for a SiOx/graphite composite anode. We investigated the

effect of the amount of conductive material and the mechanical press ratio of

the anode electrode on the electrical properties for lithium ion batteries

using a SiOx

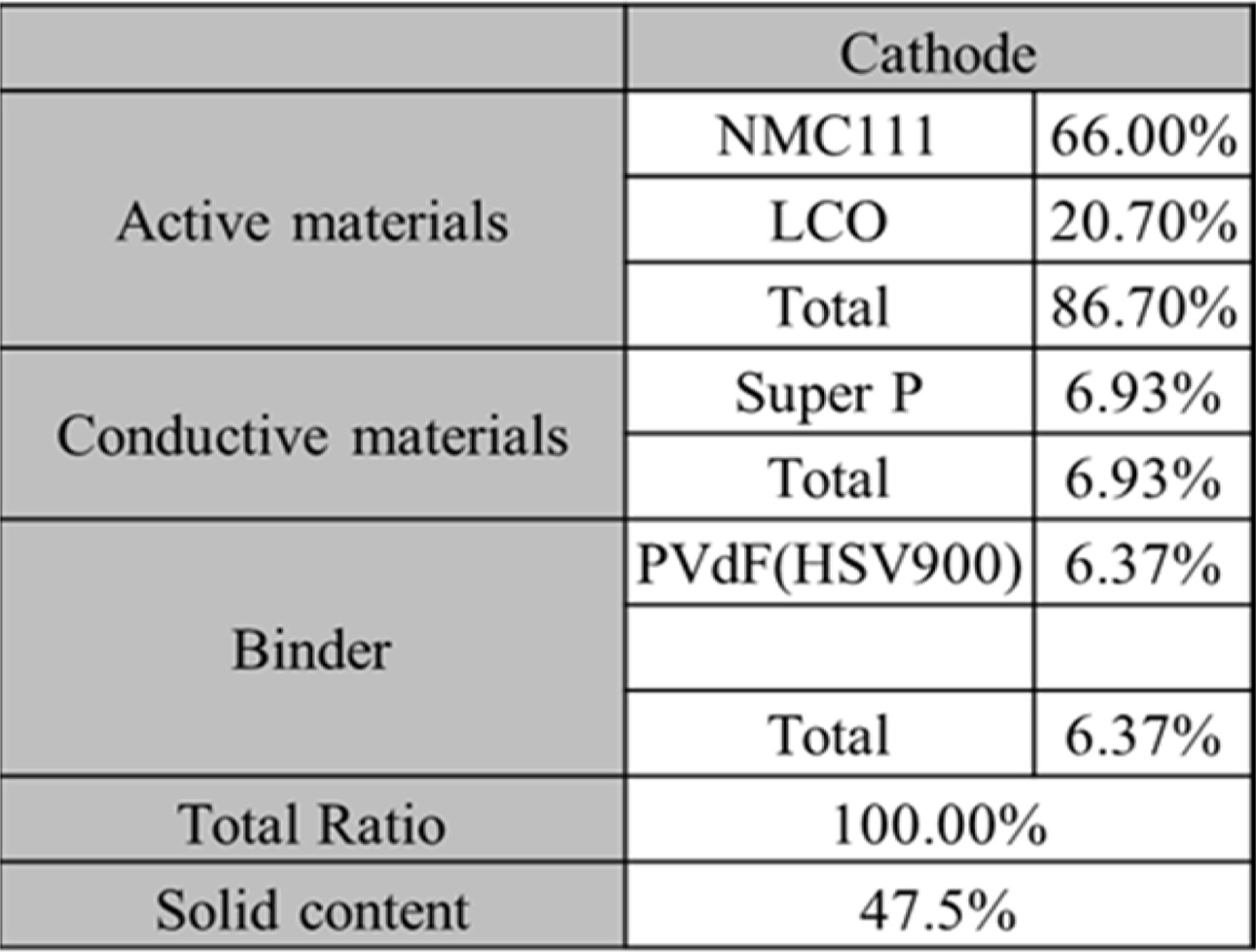

To prepare a cathode electrode, as shown in Table 1(a)

below, NMC111 (LiNiMnCoO2) and LCO (LiCoO2)

as an active material, Super-P (Timcal) as a conductive material,

and PVdF (HSV900) as a binder were slurried at a ratio

of 86.7:6.93:6.37 (vol%) in an NMP (n-methyl-2-pyrrolidone) solvent; the slurry

was coated on an etched Al foil, and then pressed. The thickness of the coated

cathode electrode was adjusted to 130 μm after it was pressed, and the

electrode density was 29 mg/cm2. To prepare an anode electrode, as

shown in Table 1(b), artificial graphite (Sigma Aldrich, 10 μm) and SiOx

were used as anode active materials, Super-P was used as a

conductive material, and a mixed aqueous binder of

CMC (carboxylmethyl cellulose) and PAA (polyacrylic acid) was used as a binder.

Artificial graphite and SiOx (x=1; a product manufactured by

OTC company; average particle diameter: 5 μm) were set at 9:1, and slurries

were prepared in a DI water solvent while the content of the conductive material

super-p was changed to 2%, 6% and 10%, and then it was coated on Cu foils and

pressed, thereby preparing anode electrodes. The thickness of the coated anode

electrode according to the content of the conductive material was set at 100 μm

after pressing, and then the electrode density was adjusted to 9.8 to 11.0

mg/cm2 depending on the press ratio. To fabricate a lithium

secondary battery unit cell, we used the same cathode as described

above, and prepared a jelly-roll by winding using a cellulose-based

separator, and finally we immersed it in a

1.5 M LiPF4/acetonitrile electrolyte for 24 hours, and then sealed

using a curing method in a

cylindrical can with a 2245 size. The fabricated lithium secondary battery unit cell was measured for its

charge/discharge and rate characteristics (C-rate) using an Arbin cycler. To

confirm the crystallinity of powdery SiOx samples, X-ray

diffraction analysis (XRD, D/MAX 2000 by Rigaku Corp.) was performed using Cu Kα1

rays (1.5406 Å). Each sample was measured at 20o to 80o with a scan speed of 5o min-1

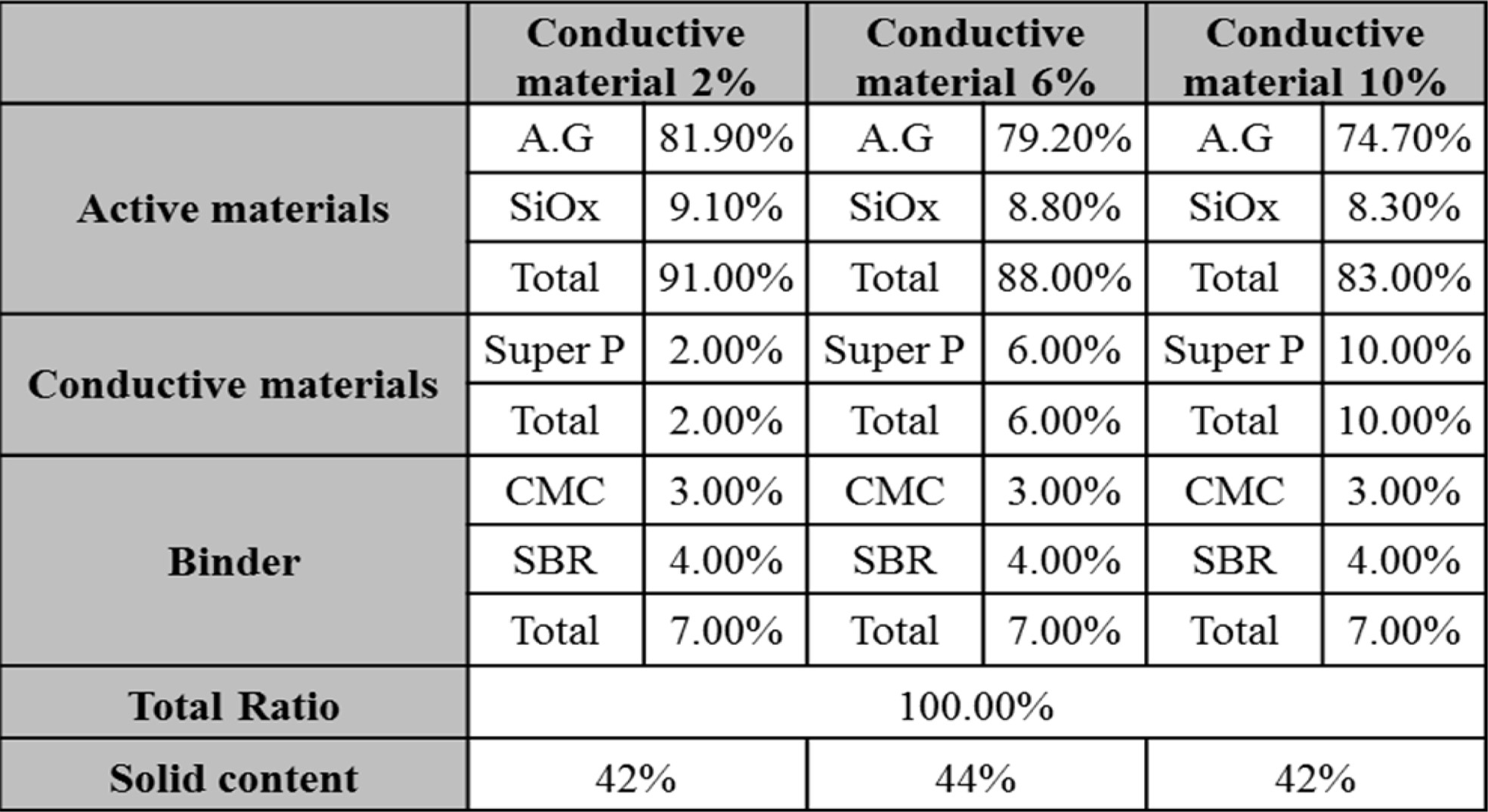

(40 kV, 100 mA). Table 2

|

Table 2 Composition of the anode as a function of the amount of conductive material. |

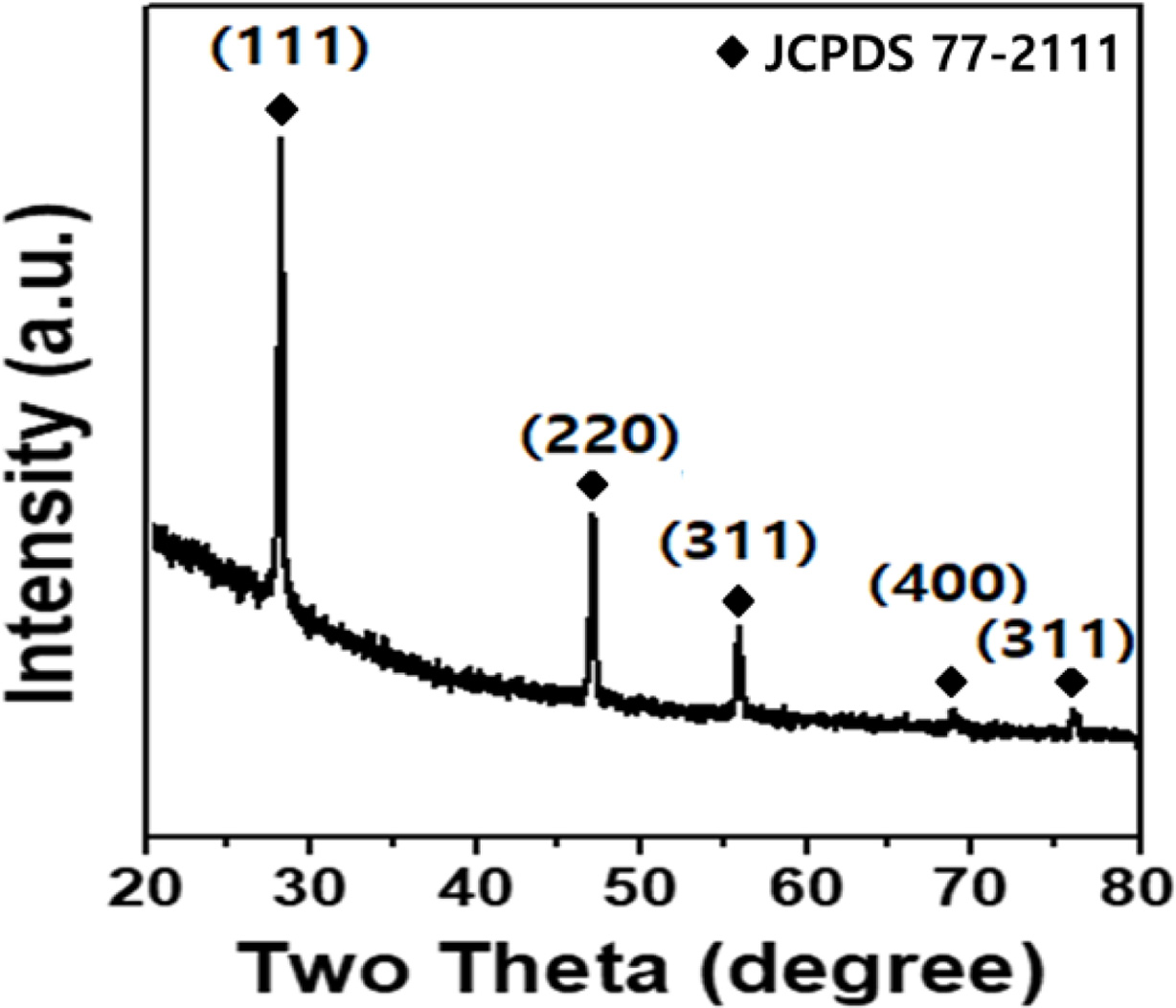

Fig. 1 shows the results of the XRD analysis of the SiOx

used in this experiment. The diffraction of the (111), (220), (311), (400) and

(331) planes appeared at 28.4o, 47.3o, 56.1o, 69.1o

and 76.3o, and these results are identical to those of JDPDS Card

JCPDS No. 77-2111.

Characteristics

as a function of the amount of conductive material of in the anode electrode

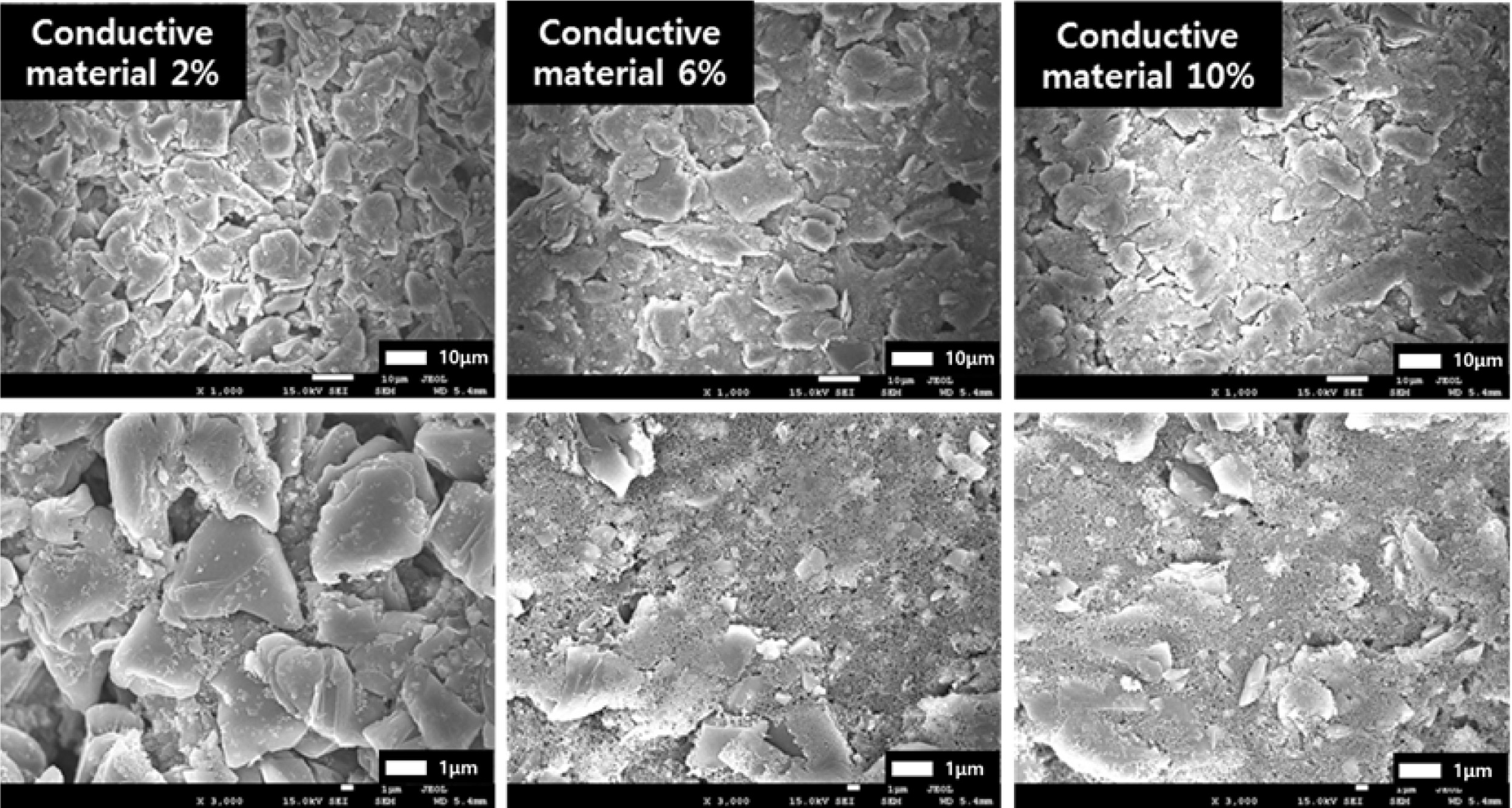

Fig. 2 depicts FE-SEM images of the anode electrodes

as a function of the amount of conductive material, The conductive material is

uniformly distributed in the space between the artificial graphite and the SiOx

particles and around the particles as the content of the conductive material

which has a structure in which 20 to 30 nm particles are connected to one

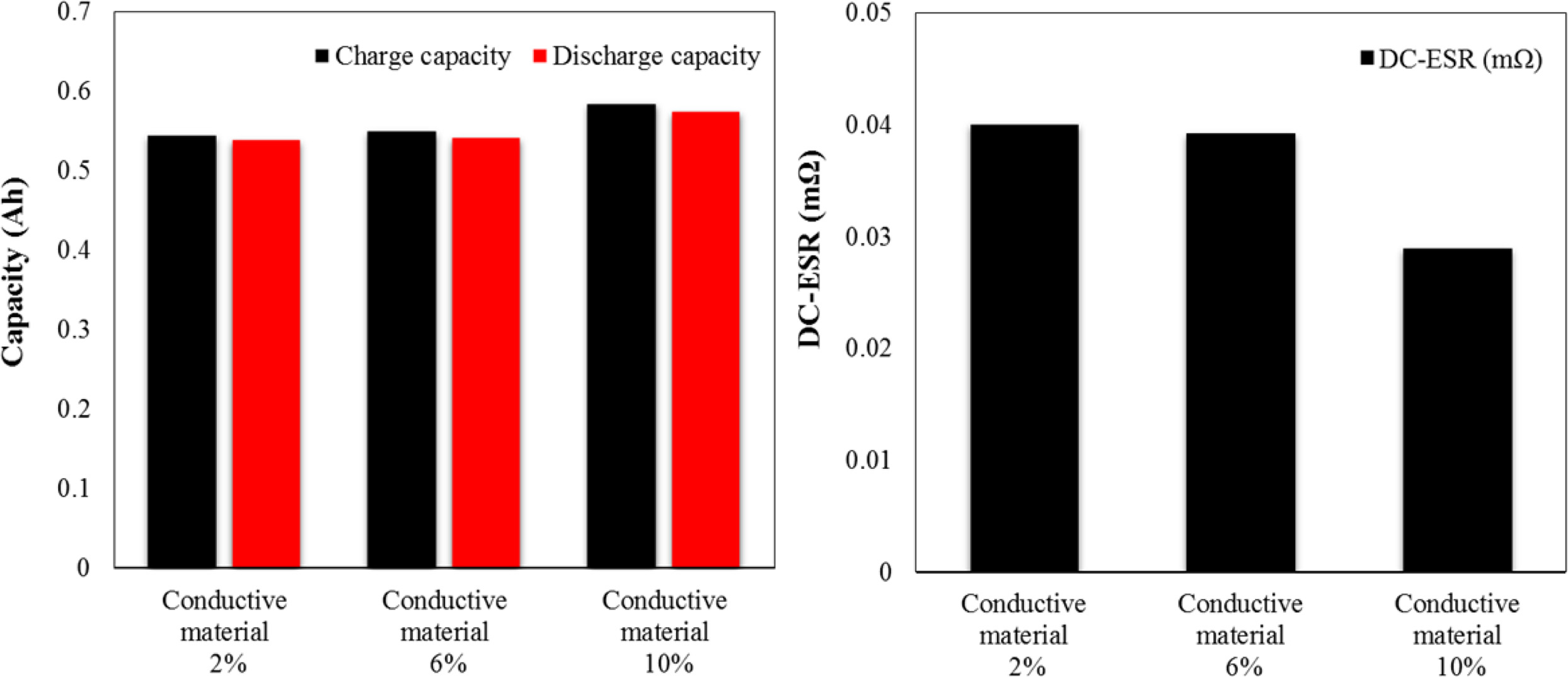

another like chains is increased. Fig. 3 shows the results of

measuring electrical characteristics as a function of the

conductive material content by performing charge/discharge at 1C. The charge

capacity and the discharge capacity show a tendency to increase as the amount

of conductive material increases. The DC-equivalent series resistance is

as low as 0.028 Ω when the content of the conductive

material is 10%. We obtained the result for the charge/discharge capacity and

DC-equivalent series resistance characteristics because the conductive

material, Which had high conductivity was uniformly distributed in the space

between the active materials as confirmed by the FE-SEM image of the anode

electrode in Fig. 2, thereby facilitating the migration of lithium ions to the

artificial graphite and the SiOx active material.

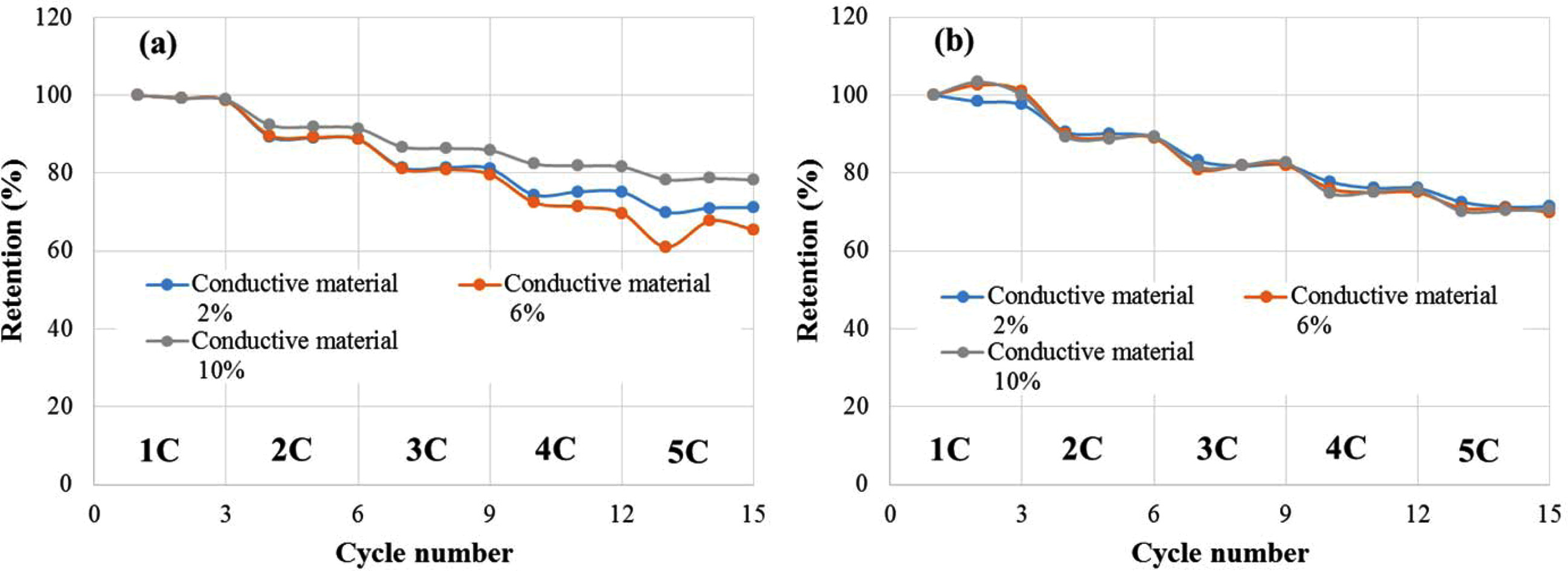

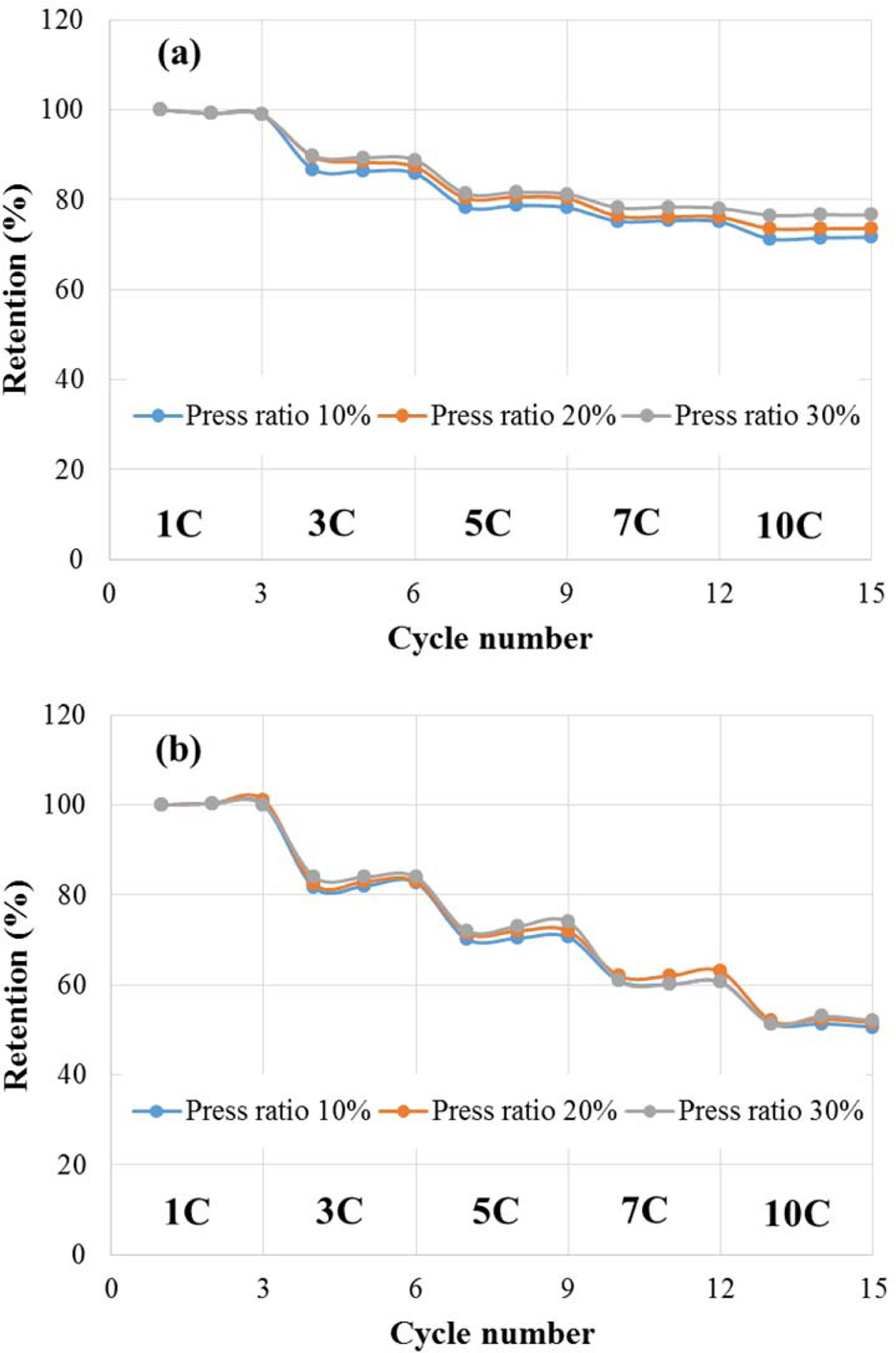

Fig. 4 shows the results obtained by charging the cell at

1C to 5C-rate, and then maintaining for 10 seconds in the CV region, and then

discharging at the same current as the charge current and measuring the C-rate

for each three cycles. The results of the C-rate mea- surement indicated that the capacity

retention increased as the content of the conductive material content

increased and that the lithium ion battery fabricated using the

electrode with a conductive material of 10% had a discharge capacity retention

of 78% at 5C compared to 100% at 1C. The DC-equivalent series resistance did

not significantly change according to the change in the conductive

material content, while the discharge capacity did.

Characteristics

as a function of the anode electrode

The delamination between the Cu foil (current collector)

and the coating layer when a cell is fabricated using

lithium secondary battery electrodes influences the fabrication process and

reliability characteristics. In the anode electrode experiment we performed as

a function of the conductive material content, the press ratio was set at 10%

and the delamination between the Cu foil (current collector) and the coating

layer was measured

as a function of the conductive material content.

In the result, average adhesion forces of 0.0627, 0.0128 and 0.01 kgf appeared at conductive material contents of 2, 6

and 10%. The results of the experiment performed as a function of the

conductive material content indicated that with an electrode with a

conductive material content of 10%, which showed the best charge/discharge

characteristics and C-rate characteristics,

a problem arose: The adhesion force between the current collector and the

coating layer decreased.

This was because the amount of the conductive material

with a nano-scale size and a large specific surface area increased, and thus

the area caught by the binder increased. In order to increase the adhesion

force between the current collector and the coating layer, we set the

composition as shown in Table 1 and performed pressing using a press at press

ratios of 10, 20 and 30%, and then we examined the adhesion force and

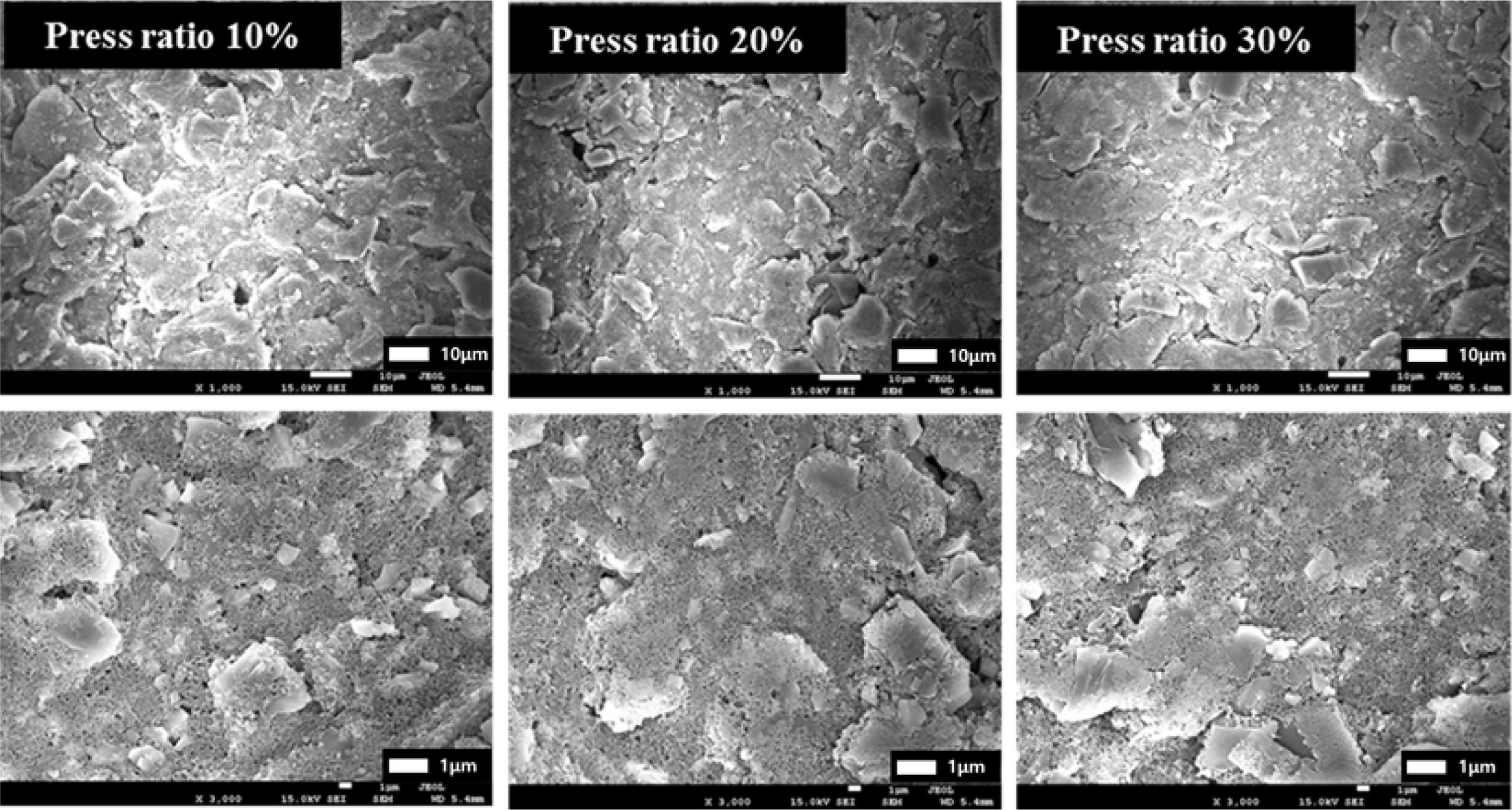

electrical characteristics. Fig. 5 depicts FE-SEM images as a function of the

pressure ratio: As the press ratio increases, particles are pushed and pores

decrease. We thought that the distance between the current collector and the

coating layer decreased because of the increase in the press rate, and the

active material and the conductive material were closely connected to each

other.

We fabricated lithium ion battery unit cells and compared

the amount of impregnated electrolyte with press ratios. The amount of

impregnated electrolyte decreased to 6.63, 6.23 and 5.77 g at press ratios of

10, 20 and 30%, respectively. From the FE-SEM images and the experiment on the

amount of impregnated electrolyte, we confirmed that the

pores in the electrolyte decreases as the press ratio

increased.

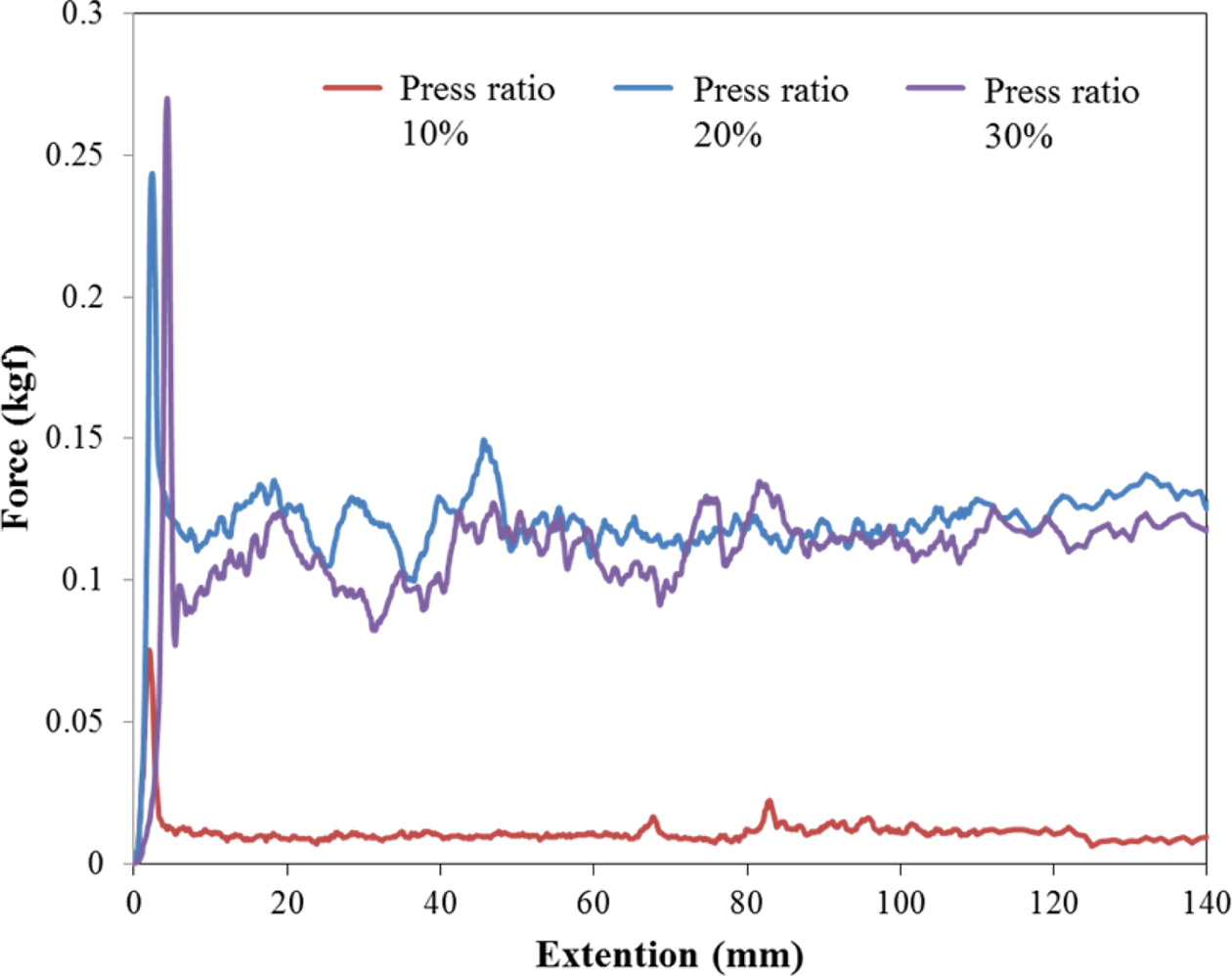

Fig. 6 shows the results for the measurement of the

adhesion force between the Cu current collector and the coating layer as a

function of the press ratio. The average adhesion forces are 0.01, 0.117 and

0.095 kgf at press ratios of 10, 20 and 30%, indicating that the highest occurs

at a press ratio of 20%.

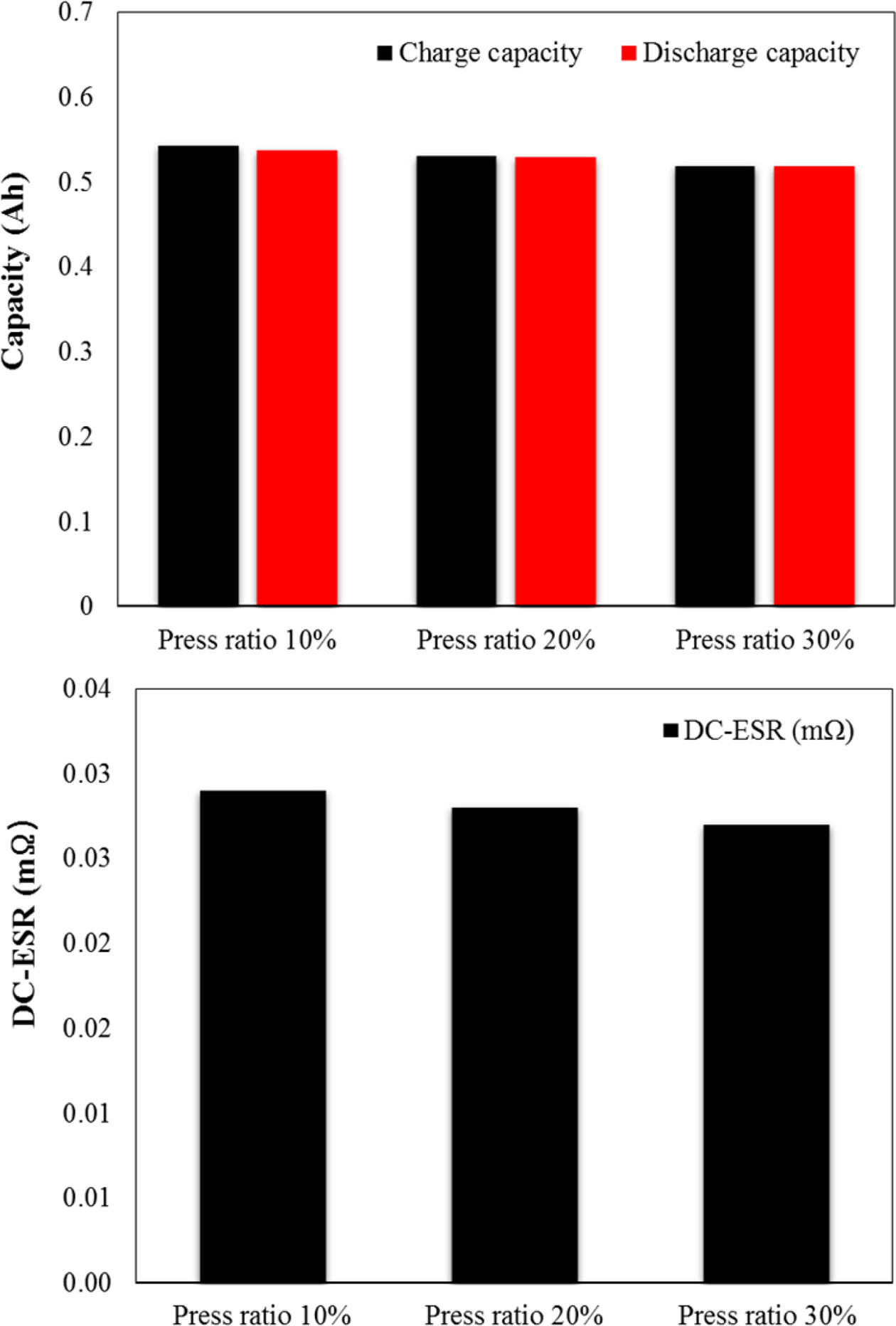

Fig. 7 shows the measurement results for the electrical

characteristics as a function of the press ratio with the performance of

charge/discharge at 1C. The charge/discharge capacities and the DC-equivalent

series resistance show a tendency to decrease. We believe considered that the

decrease in the charge/discharge capacities was due to the decrease in the amount

of impregnated electrolyte and that the decrease in the DC-equivalent series

resistance was because of the decrease in the distance between the current

collector and the coating layer due to the increase in the press ratio rather

than the influence of the amount of impregnated electrolyte and because of the

compact connection between the active material and the conductive material.

Fig. 8 shows the results obtained for charging the cell at

1C to 10C-rate, and then maintaining it for 10 seconds in the CV region, and

then discharging it at the same current as the charge current and measuring the

C-rate for each three cycles. The results of the C-rate measurement indicated

that the discharge capacity retention at a press ratio of 30% was 76.6% at 10C compared

to 100% at 1C. Unlike the discharge capacity, the

DC-equivalent series resistance did not significantly change

according to the change in the amount of conductive material.

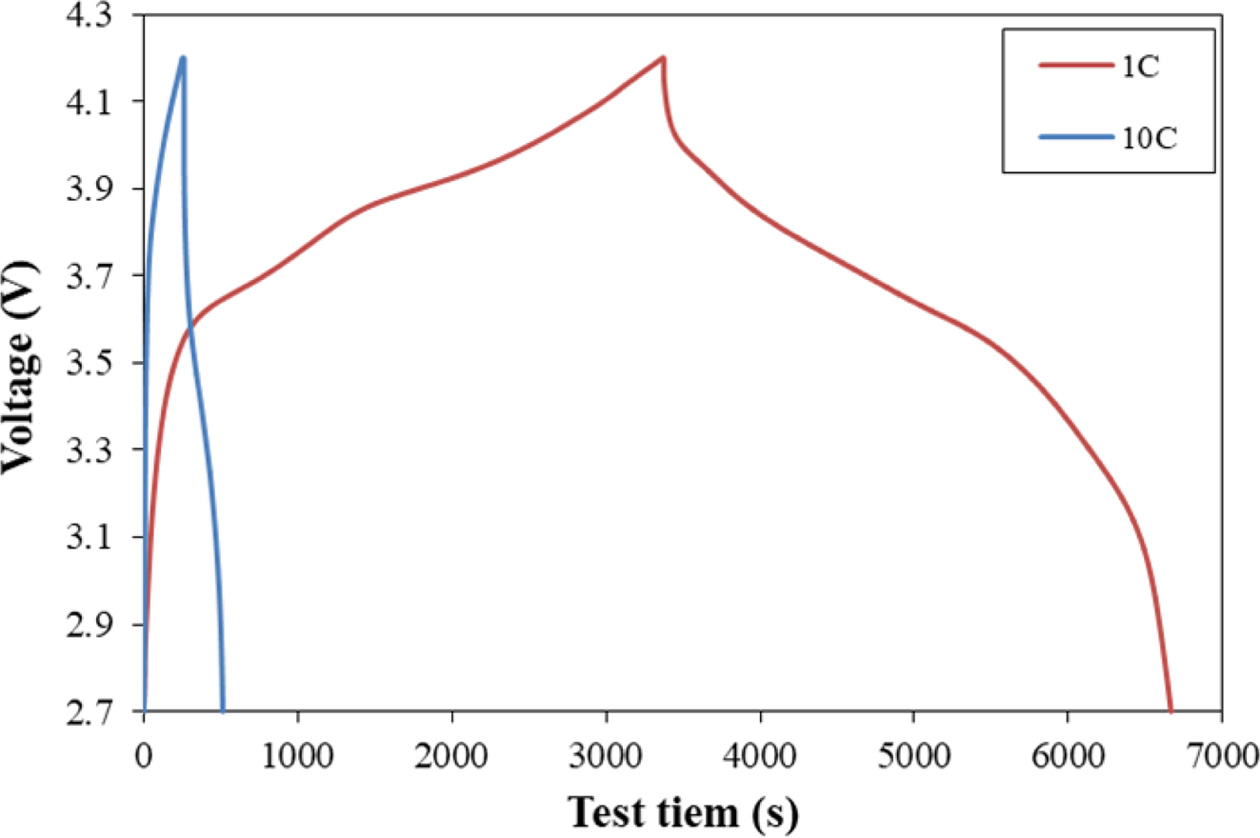

The charge/discharge curve of the cell at a press ratio of

30% as a function of current rate is shown Fig. 9. The charging and discharging

time at 1C was 6664 seconds, and the charging and discharging time at 10C was

513 seconds. The discharge capacity at 10C was 76.6% while it was 100% at 1C.

|

Fig. 1 Results of the XRD measurement of SiOx |

|

Fig. 2 FE-SEM images of anode electrodes as a function of the amount of conductive material. |

|

Fig. 3 Capacity and DC-ESR as a function of the amount of conductive material. |

|

Fig. 4 C-rate as a function of the amount of conductive material: (a) capacity retention. (b) DC-ESR retention. |

|

Fig. 5 FE-SEM images of anode electrodes as a function of the pressure ratio. |

|

Fig. 6 Adhesion force of anode electrodes as a function of the

press ratio. |

|

Fig. 7 Capacities and DC-ESR as a function of the press ratio of

the anode electrode. |

|

Fig. 8 C-rate as a function of press ratio: (a) capacity retention, (b)

DC-ESR retention. |

|

Fig. 9 The charge/discharge curve of cell with press ratio 30% as

a function of current rate. |

In this study, in order to develop a lithium secondary

battery, that is capable of charging/discharging even at high current rates,

using SiOx as an anode active material, we evaluated the

electrical characteristics as a function of the amount of conductive material

and the press ratio. We adjusted the content of the conductive material to 2, 6

and 10 wt% and evaluated the electrical characteristics were evaluated. We

found that as the content of the conductive material increased, the capacity

increased and the resistance decreased. The c-rate was measured at 1 to 5C, and

the cell with a conductive material content of 10 wt% showed the best capacity

retention according to the change in charge current.

We performed the evaluation while changing the press ratio

of the electrode with a conductive material content of 10 wt%, and as a result,

the capacity and resistance decreased as the press ratio increased. The C-rate

was measured at 1 to 10C, and the cell with the highest press ratio (30%)

showed the best capacity retention (76.6%) at 10C compared to that of 1C, and

the adhesion force of the anode electrode was also excellent.

Our study confirmed that the lithium secondary battery

fabricated using SiOx achieved a capacity retention of 70% or

higher in rapid charge/discharge at 10C and had the potential as a lithium

secondary battery that is capable of rapid charging/discharging.

This work was supported by the Technology Innovation

Program (10080656, Development of ceramic/carbon convergence and integration

anode material for 10C fast charging Lithium ion battery) funded By the Ministry

of Trade, Industry & Energy (MOTIE, Korea).

- 1. C.P. Grey and J.M. Tarascon, Nat. Mater. 16 (2017) 45-56.

-

- 2. D. Larcher and J.M. Tarascon, Nat. Chem. 7 (2015) 19-29.

-

- 3. M. Armand and J.M. Tarascon, Nature. 451 (2008) 652-657.

-

- 4. X. Dong, Z. Guo, Z. Guo, Y. Wang, and Y. Xia, Joule 2 (2018) 902-913.

-

- 5. Y. Li, Y. Li, A. Pei, K. Yan, Y. Sun, C. Wu, L. Joubert, R. Chin, A.L. Koh, Y. Yu, J. Perrino, B. Butz, S. Chua, and Y. Cui, Science 358 (2017) 506-510.

-

- 6. P.G. Bruce, B. Scrosati, and J.M. Tarascon, Angew. Chem. Int. Ed. 47 (2008) 2930-2946.

-

- 7. N.-S. Choi, Z. Chen, S.A. Freunberger, X. Ji, Y.-K. Sun, K. Amine, G. Yushin, L.F. Nazar, J. Cho, P.G. Brucea, and Angew. Chem. Int. Ed. 51 (2012) 9994-10024.

-

- 8. J. Lee, D.A. Kitchaev, D.-H. Kwon, C.-W. Lee, J.K. Papp, Y.-S. Liu, Z. Lun, R.J. Clément, T. Shi, B.D. McCloskey, J. Guo, M. Balasubramanian, and G. Ceder, Nature 556 (2018) 185-190.

-

- 9. T. Chen, J. Wu, Q. Zhang, and X. Su, J. Power Sources 363 (2017) 126-144.

-

- 10. M. Ko, S. Chae, J. Ma, N. Kim, H.-W. Lee, Y. Cui, and J. Cho, Nat. Energy 1 (2016) 16113-16120.

-

- 11. D. Liu, Z. Liu, X. Li, W. Xie, Q. Wang, Q. Liu, Y. Fu, and D. He, Small 13 (2017) 1702000.

-

- 12. S. Chae, M. Ko, S. Park, N. Kim, J. Ma, and J. Cho, Energy Environ. Sci. 9 (2016) 1251-1257.

-

- 13. I.H. Son, J.H. Park, S. Kwon, J.W. Choi, and M.H. Rümmeli, Small 12 (2016) 658-667.

-

- 14. M.N. Obrovac and V.L. Chevrier, Chem. Rev. 114 (2014) 11444-11502.

-

- 15. K.L. Huang, Z.X. Wang, and S.Q. Liu, in “The Principle and Key Technology of Lithium Ion Battery”, (Beijing: Chemical Industry Press, 2008) p.38.

-

- 16. Y.P. Wu, J.Q. Ma, and X.B. Dai, in “Lithium Ion Battery: Application and Practice”, (Beijing: Chemical Industry Press, 2004) p.21.

-

- 17. X. Su, Q. Wu, J. Li, X. Xiao, A. Lott, W. Lu, B.W. Sheldon, and J. Wu, Adv. Energy Mat. 4 (2014) 1300882.

-

- 18. Z. Huang, K.D. Harris, and M.J. Brett, Adv. Mater. 21 (2009) 2983-2987.

-

- 19. H.H. Li, X.L. Wu, H.Z. Sun, K. Wang, C.Y. Fan, L.L. Zhang, F.M. Yang, and J.P. Zhang, J. Phys. Chem. C 119 (2015) 3495-3501.

-

- 20. B. Guo, J. Shu, Z. Wang, H. Yang, L.H. Shi, Y. Liu, and L. Chen, Electrochem. Commun. 10 (2008) 1876-1878.

-

- 21. Y. Ren, J. Ding, N. Yuan, and S. Jia, J. Solid State Electrochem. 16 (2012) 1453-1460.

-

This Article

This Article

-

2020; 21(5): 533-538

Published on Oct 31, 2020

- 10.36410/jcpr.2020.21.5.533

- Received on Mar 4, 2020

- Revised on Apr 16, 2020

- Accepted on May 4, 2020

Services

Services

- Abstract

introduction

experimental

results and discussion

conclusions

- Acknowledgements

- References

- Full Text PDF

Shared

Correspondence to

Correspondence to

- Jung-Rag Yoon

-

R&D Center, SAMWHA CAPACITOR, Yongin, South Korea

Tel : +82-31-330-5765

Fax: +82-31-332-7661 - E-mail: yoonjungrag@samwha.com

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.