- The effect of transition metal oxide doping on the sintering behaviour of yttria-stabilised tetragonal zirconia

H.C. Alexander Cheea, R.S.K. Singha,b and K.Y. Sara Leec,*

aFaculty of Engineering, University of Malaya, 50603 Kuala Lumpur, Malaysia

bFaculty of Engineering, Universiti Teknologi Brunei, Tungku Highway, Gadong BE1410, Brunei Darussalam

cTunku Abdul Rahman University College, Faculty of Engineering & Technology, Department of Mechanical Engineering, 53300, Kuala Lumpur, Malaysia

The effect of small amounts

(0.2 wt% and 0.5 wt%) of transition metal oxide (CuO) doping on the

sintering behavior of 3 mol% yttria-stabilized zirconia (Y-TZP) was

investigated over the temperature range of 1250 oC to

1500 oC. Sintered samples were characterized to determine the

phase present, relative density, microstructural evolution and Vickers

hardness. The studies revealed that the addition of 0.2 wt% CuO dopant was

most effective in enhancing the densification of the Y-TZP in particularly at

low temperatures below 1350 oC. The phase analysis revealed

that the tetragonal phase was disrupted as evident from the high monoclinic

phase formation in the 0.5 wt% CuO-doped zirconia. This phenomenon was

associated with mechanism involving transient liquid phase which believed to

have destabilized the tetragonal structure. Nevertheless, the study revealed

that compared to the undoped Y-TZP, the sample with addition of 0.2 wt%

CuO resulted in enhanced hardness and finer grain sizes when sintered at

relatively low temperatures.

Keywords: Y-TZP, Copper oxide, Doping, Sintering additives, Vickers hardness

Yttria-stabilized tetragonal zirconia polycrystals or

Y-TZP is known to exhibit attractive properties such as high

fracture toughness, strength and good wear properties suitable

for many industrial and biomedical applica-

tions. This has been attributed to its unique ‘self-healing’

mechanism known as transformation toughening. In this

mechanism, the energy of an advancing crack through the matrix is absorbed by

the tetragonal grains in the vicinity of the crack front and transform to a

monoclinic symmetry. This phase transformation is accompanied

by 3-5% volume expansion which induced a local compression

surrounding the crack tip; as a result more energy would be required for crack

pro- pagation and hence enhancing the

strength [1-3].

The widespread use of Y-TZP, however is hampered by the

undesirable tetragonal to monoclinic phase transformation when exposed to steam

environment at temperatures 60 oC to 500 oC, a

phenomenon known as hydrothermal ageing or low temperature degradation (LTD)

[4-8]. This devastating effect of zirconia was initially observed by Kobayashi

et al. [4], and the ageing process was documented to induce formation of

networks of micro- and macro-cracking, thus leading to deterioration of

mechanical properties. According to this study, when the Y-TZP was exposed to

humid environment at temperatures between 150 oC

and 400 oC, isolated tetragonal grains or

nuclei at the surface begin to transform to the monoclinic

symmetry by incorporating the hydroxyls in the oxygen

vacancies of the zirconia lattice. This induces localized residual stresses

which subsequently destabilized the tetragonal structure [7-10].

A nucleation and growth mechanisms have been proposed to

explain the ageing kinetics although a consensus on the nature of the

transformation in the interior of the sample i.e. whether the transformation

proceed linearly or exponentially with time and/or reached a saturation limit

after a certain depth have not been unequivocally resolved [11-15].

Nevertheless, factors such as grain sizes and the chemistry of the grain

boundaries have been associated with the LTD phenomenon [16-19]. For instance,

Hallmann et al. [17] reported that Y-TZPs with average grain size less than

0.3 μm was resistant against the ageing-induced phase transformation. The

authors also found that grain boundary modification using dopants such as alumina,

ceria and iron oxide were beneficial in suppressing the LTD in Y-TZP. Zhang et

al. [19] investigated the influence of 0.25 wt% alumina

addition and incorporating yttria coating of zirconia starting

powder on the LTD behavior of the ceramics when exposed in an autoclave

containing steam at 134 oC and 0.2 MPa up to 40 h.

Their TEM analysis revealed that the Y/Zr ratio of the yttria coated zirconia

was higher at grain boundary regions when compared to the grain core. Zhang et

al. suggested that the improved ageing resistant observed for their Y-TZP was

attributed to both, the segregation of Al3+ and the heterogeneously

distributed of Y3+ at the grain boundaries.

Improvement in the sintering conditions has been

demonstrated in the literatures to be viable in order to improve the

densification and properties of Y-TZP as well as to control the LTD in

zirconia. This includes using non-conventional sintering processes and the

manipulation of the sintering conditions such as field-assisted

sintering [20], hot-isostatic pressing [21], spark-plasma

sintering [22], cold sintering [23], two-step fast firing [24], microwave

sintering [25] and laser sintering [26]. All these methods have shown to be

effective in enhancing the properties of zirconia, however this improvement is

at the expense of high cost associated with the equipment used for powder

consolidation. A more economical approach would be to aid the conventional

sintering process using low melting sintering additives

or dopants, added to the zirconia during powder processing and subjecting the

doped powders to conventional sintering at low temperatures. This strategy has

been demonstrated to yield highly dense bodies in several ceramic systems

[27-33].

The present work aims to examine the effect of small

additions of transition metal copper oxide (0.2 wt% and 0.5 wt%)

on the mechanical properties and microstructural development

of Y-TZP ceramics prepared by the pressureless sintering method.

In the present work, 3 mol% yttria stabilized

zirconia powder from Kyoritsu Japan was used and the different amounts of high

purity CuO (0.2 wt% and 0.5 wt%) were mixed in an attritor-mill

contained zirconia beads (1 mm in diameter) as the milling media and

ethanol as the mixing medium. The speed of the rotation was kept constant at

600 rpm and each milling was carried out for 30 mins. After the

mixing process, the slurries were separated from the milling media by

filtration and then dried overnight in an oven at 60 oC.

Finally, soft, ready to press powders, were obtained by sieving through

212 µm mesh sieve. For the study, green disc samples (20 mm

diameter, 5 mm thick) were uniaxially compacted using a

metal mold and subsequently subjected to cold isostatic pressing at

200 MPa.

Powder consolidation was accomplished by pressureless

sintering under ambient conditions in a box furnace. The sintering was carried

out at different temperatures ranging from 1250 oC to

1500 oC at a ramp rate 10 oC/min and holding

time 2 h. The sintered samples were ground

successively on one face by using silicon carbide paper of

120 (rough), 240, 600, 800 and 1200 (fine) grades, followed by polishing using

6 µm and 1 µm diamond paste to obtain an optical reflective surface.

The bulk densities of sintered samples were determined by

the water immersion method based on the Archimedes principle, and the relative

densities were calculated by taking the theoretical density of tetragonal

zirconia as 6.07 g/cm3. Vickers Hardness (Hv) was measured

on polished samples using Vickers indention method. The

indention load was kept constant at 10 kgF with a loading time of 10

s. Phase analysis was conducted by X-ray diffraction (XRD) (Geiger-Flex,

Rigaku Japan) under room temperature conditions using Cu-Kα

as the radiation source. The fraction of monoclinic phase was determined using

the method of Toraya et al. [34]. The effect of temperature on the

microstructure evolution of the ceramic was examined by using scanning electron

microscope (SEM). The average grain size of the polished samples was

deter-mined by using the line

intercept method [35].

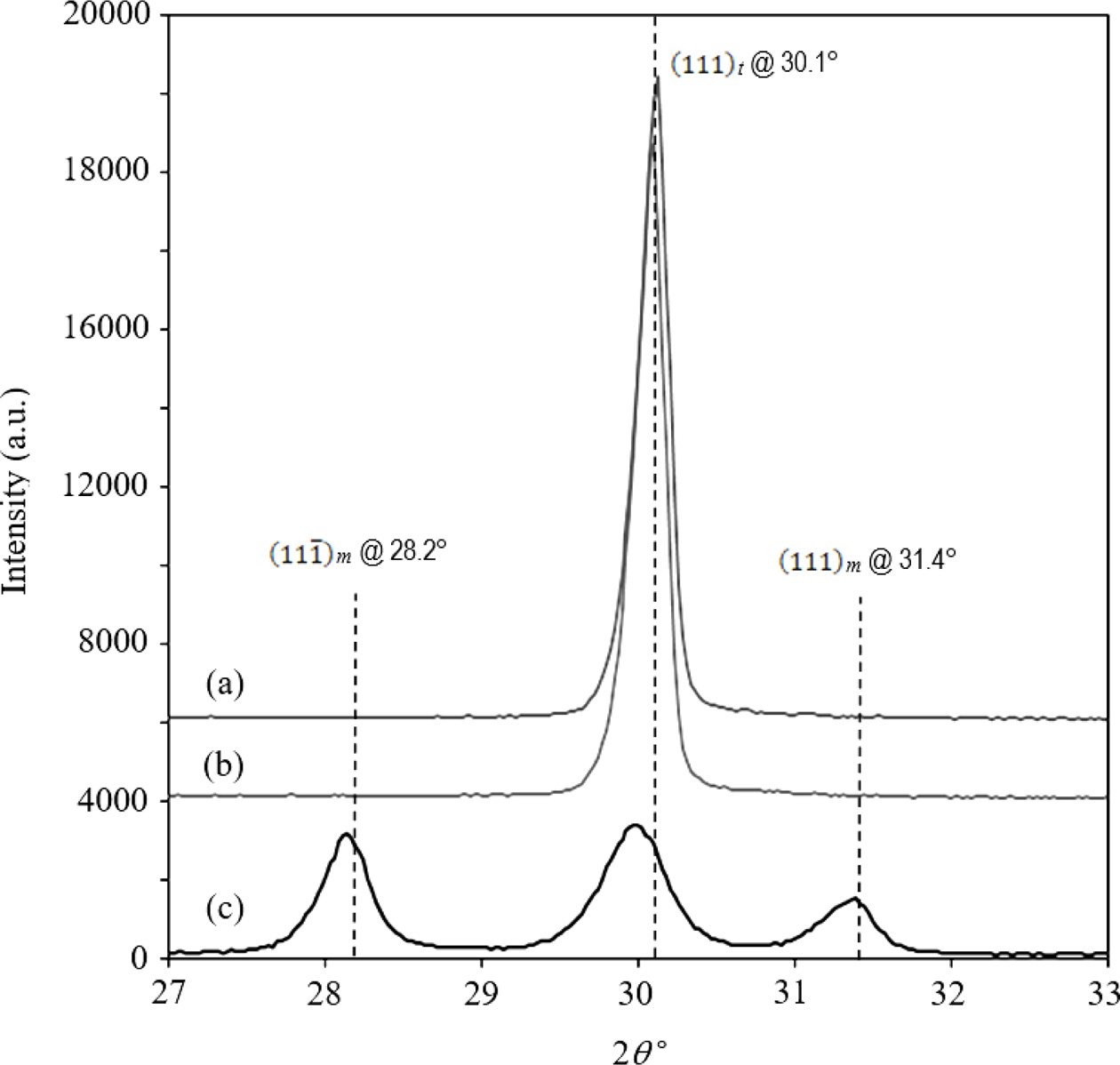

A typical XRD trace of the undoped and CuO-doped Y-TZP

sintered at 1400 oC is shown in Fig. 1. A similar trend was

observed at all temperatures. The undoped and 0.2 wt% CuO doped zirconia

exhibited a fully tetragonal structure, however, the XRD analysis indicated

that the addition of 0.5 wt% CuO has disrupted the tetragonal phase stability

of the Y-TZP throughout the sintering regime employed. A high percentage of

monoclinic phase was measured for the 0.5 wt% CuO addition. It

is believed that the addition of high amounts of dopant

could have developed excessive transient liquid phase

during sintering which caused the depletion of yttria

stabilizer from the zirconia lattice at around 1180 oC and on

cooling destabilised the tetragonal structure [36, 37]. It was determined that

the mono- clinic phase content for the

0.5 wt% CuO-doped zirconia samples varied between 50 to 55% as the

sintering temperature increased from 1250 to 1500 oC. In

addition, the tetragonal peaks at 2θ = 30.1° for this sample

shifted slightly to the left by about 0.10-0.13° when compared to the undoped

zirconia as shown by the inset picture in Fig. 1. This is an indication that

the high amount of CuO had affected the stability of the tetragonal zirconia

lattice.

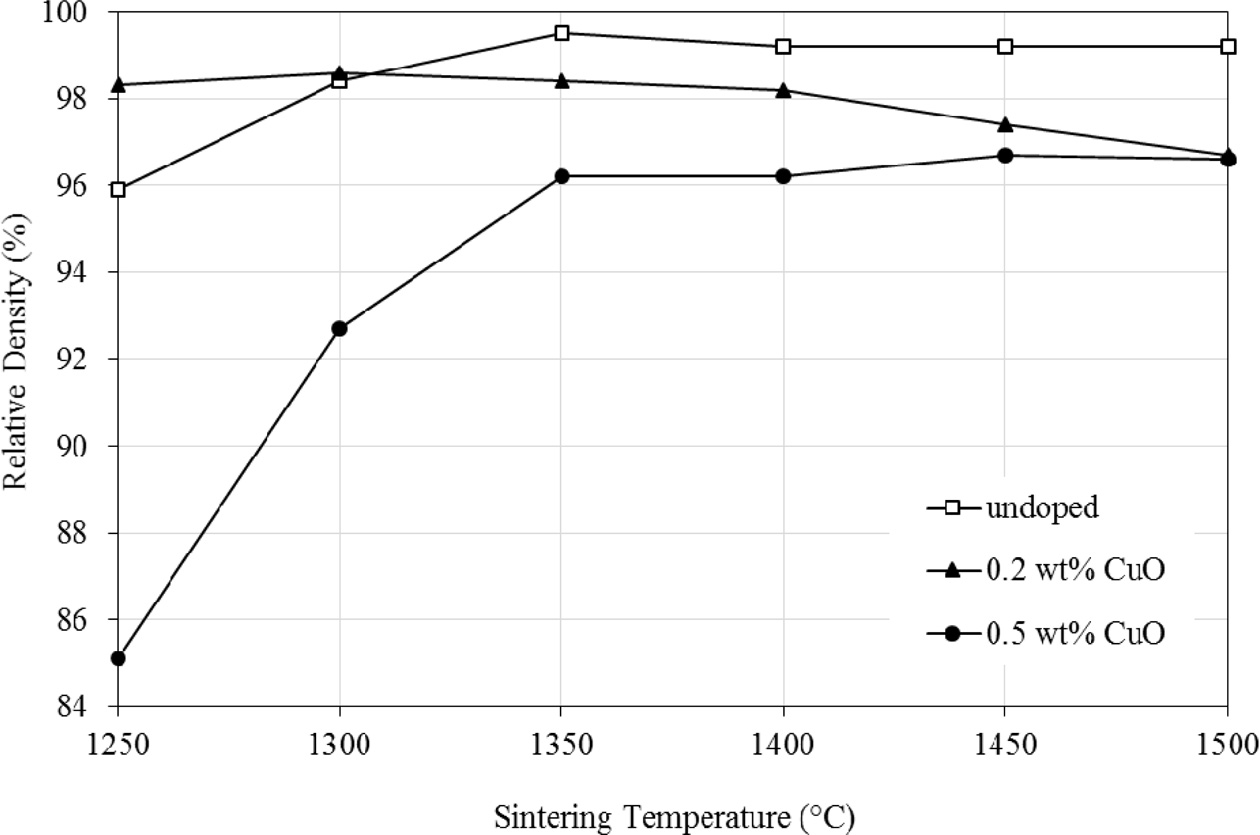

The effect of sintering temperature on the relative

density of undoped and CuO-doped zirconia is shown in Fig. 2. The result shows

that the addition of 0.2 wt% CuO was beneficial in enhancing the density

of Y-TZP sintered below 1350 oC. This sample

exhibited > 98% relative density when sintered at 1250 oC

when com- pared to 96% for the undoped

zirconia. However, the relative density of the undoped Y-TZP started to

increase and maintained above 98% as the temperature raised to 1350 oC

and above. In contrast, the 0.5 wt% CuO doped Y-TZP

exhibited the lowest density regardless of sintering temperature. It

started low at 85% dense @ 1250 oC and increased steadily to

96% at 1350 oC and then remained almost constant with further

increased in temperatures. This observation is in good agreement with the high

monoclinic content observed for the sintered body.

The beneficial effects of transition metal oxides such as

copper oxide and manganese oxide (MnO2) in promoting densification

and improvement in other properties were also observed in other ceramic systems

such as alumina [38], cadmium [39] as well as SnO2 [40] and ternary

based ferroelectrics [41]. It is known that ceria and the tantalates are not

easy to densify at moderate temperatures without sintering at elevated

temperature above 1500 oC. Shimada et al. [42] de- monstrated that 3 wt% MnO-doped LiTaO3

promoted densification at low temperatures of 1125-1190 oC.

They obtained a relative density of 85-90% when compared to 60-62% for the

undoped ceramic but at the expense of grain coarsening. The authors believed

that the enhancement in densification in these ceramics could be linked to the

reactive Mn-based liquid formation at low temperatures. In another research,

Corker et al. [43] studied the effect of CuO doping on the sintering of PZT and

they found the addition of 3 wt% of Cu2O/PbO with the eutectic ratio

of Cu2O : PbO (1 : 4) was effective in reducing the densification

temperature considerably by about 67%, from 1260 oC down to

850 oC. The authors attributed this remarkable improvement to

the presences of a Cu2O-PbO eutectic liquid at about 680 oC.

This finding was supported by TEM studies [44] which showed the formation of a

CuO-PbO rich grain boundary phase at 900 oC and the

crystallization of nanosized CuO precipitates near grain boundary regions after

sintering.

Zhang et al. [45] investigated the effect of transition

metal oxide (MnO2) doping in ceria and found that the addition of up

to 1.5 wt% MnO2 accelerated the densi- fication rate of ceria when sintered at low

temperatures. They went on to suggest the formation of a very thin Mn-amorphous

layer during heating could have facilitated particle

rearrangement thus leading to rapid consoli-

dation during the early-stage of sintering. Similar observation on the

effect of manganese oxide in aiding the sintering of zirconia was also reported

in the literatures [46, 47]. These studies concur that the presence

of a reactive liquid phase involving the transition metals during

sintering was responsible for the improve-

ment in sintered density. More recently, Watson et al.

[41] concluded that CuO actively reacted with PbO to form a reactive eutectic

liquid phase during sintering of PIN-PMN-PT ceramics, which reduces the

activation energy for sintering to proceed at temperatures as low as 790 oC

and hence retaining a fine grain micro-

structure on cooling. There have been different views on the sintering

mechanism involving CuO as additive. For instance, Nie et al. [48] who studied

the effect of CuO on the sintering of TiO2 ceramics inferred that

the enhancement in densification of CuO-doped TiO2 at low

temperatures was due to sub-eutectic activated sintering, rather than

liquid-phase sintering.

The fact that the melting point of copper oxide (1150 oC)

is lower than the sintering temperature employed in the

present work and based on the literature findings as well as the results

obtained, it is envisaged that a transient liquid phase mechanism was in

operative. The results indicated that the addition of 0.2 wt% CuO was the

optimum amount required to form sufficient reactive Y2O3/CuO-rich

transient liquid phase which facilitated particle rearrangement and coalescence

at low temperatures, below 1350 ºC. As the doping level increased to

0.5 wt%, the excess amount of Cu-rich liquid proved to be detrimental as

this has an effect to draw out too much of yttria from the zirconia matrix,

resulting in phase transformation upon cooling from sintering as evident from

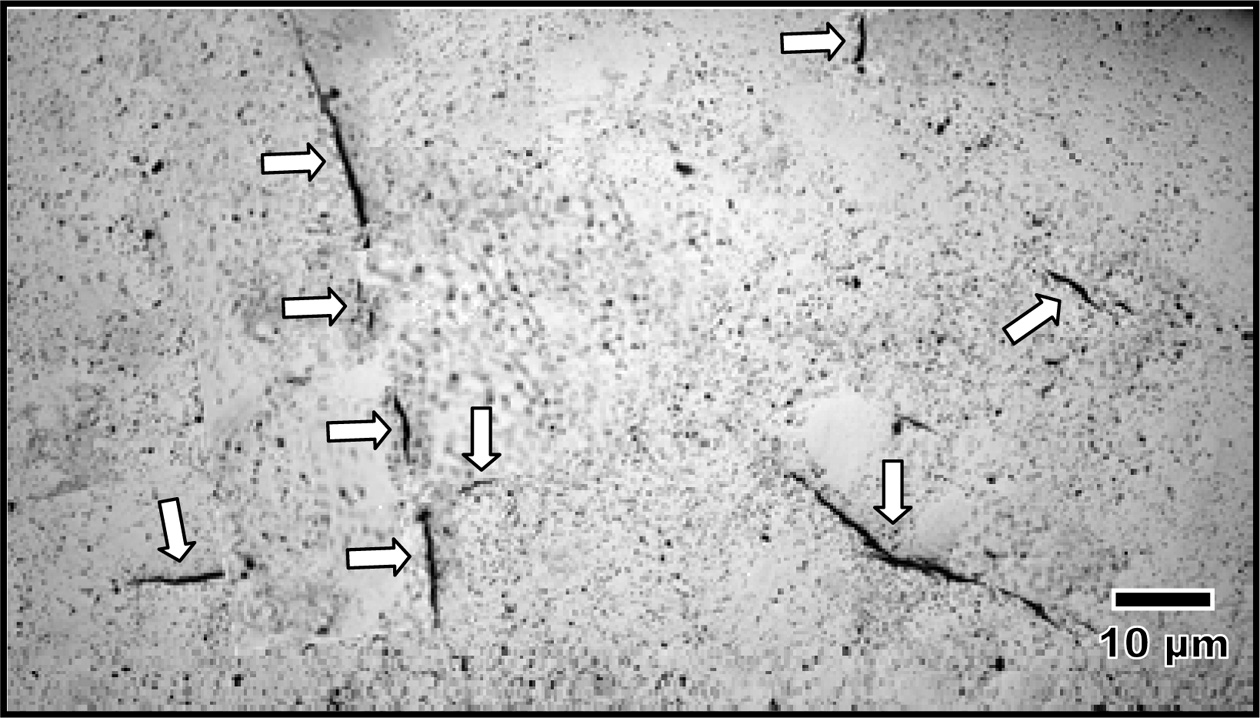

the XRD analysis. This tetragonal to monoclinic phase transformation was

accompanied by micro-and macro-cracking observed on the free surface of the

samples as typically shown in Fig. 3.

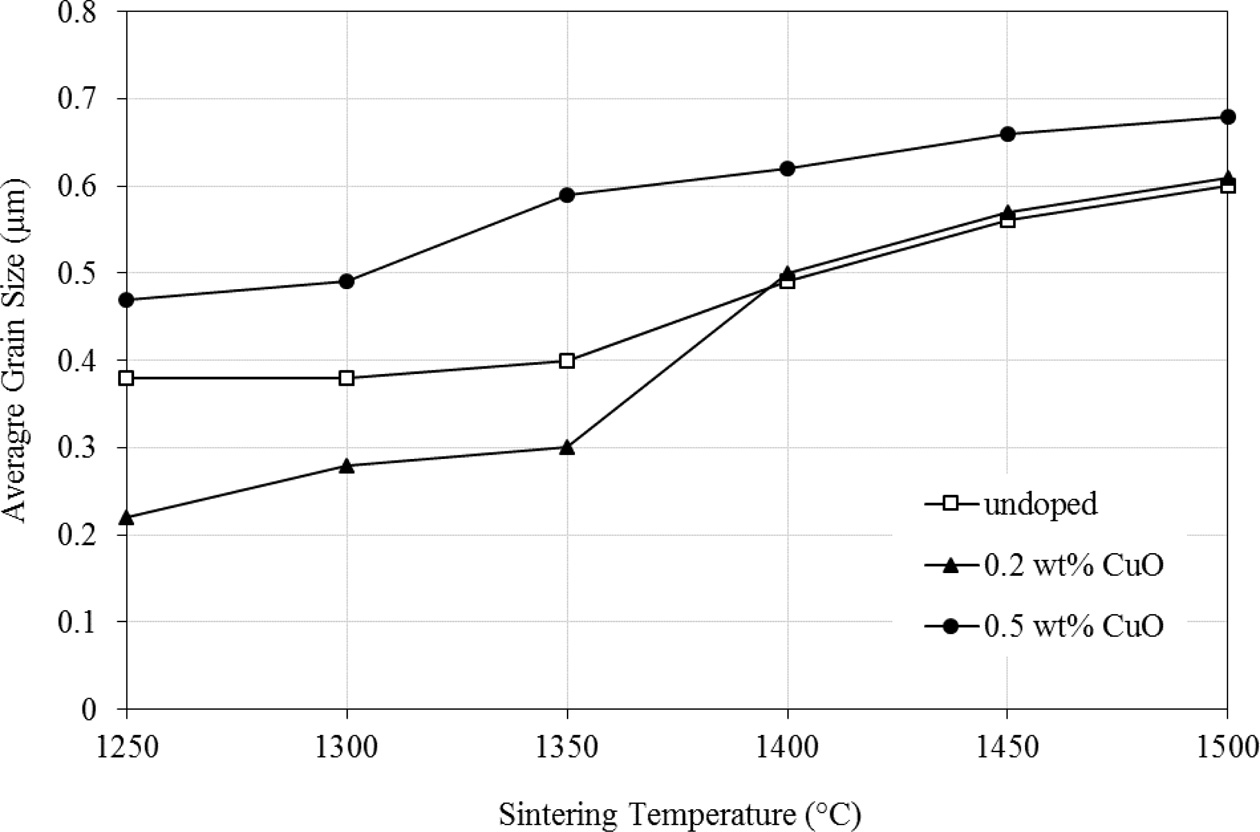

The effect of sintering and dopant addition on the average

grain size of Y-TZP is shown in Fig. 4. The general trend is that the grain

size increases with increasing sintering temperature for all samples. The

results showed that the 0.5 wt% CuO exhibited larger grain size when

compared to the 0.2 wt% CuO and undoped samples for all temperatures

investigated. The grain size of the 0.2 wt% CuO-doped zirconia was smaller

(below 0.3 µm) than the undoped when sintered at

1350 oC and below.

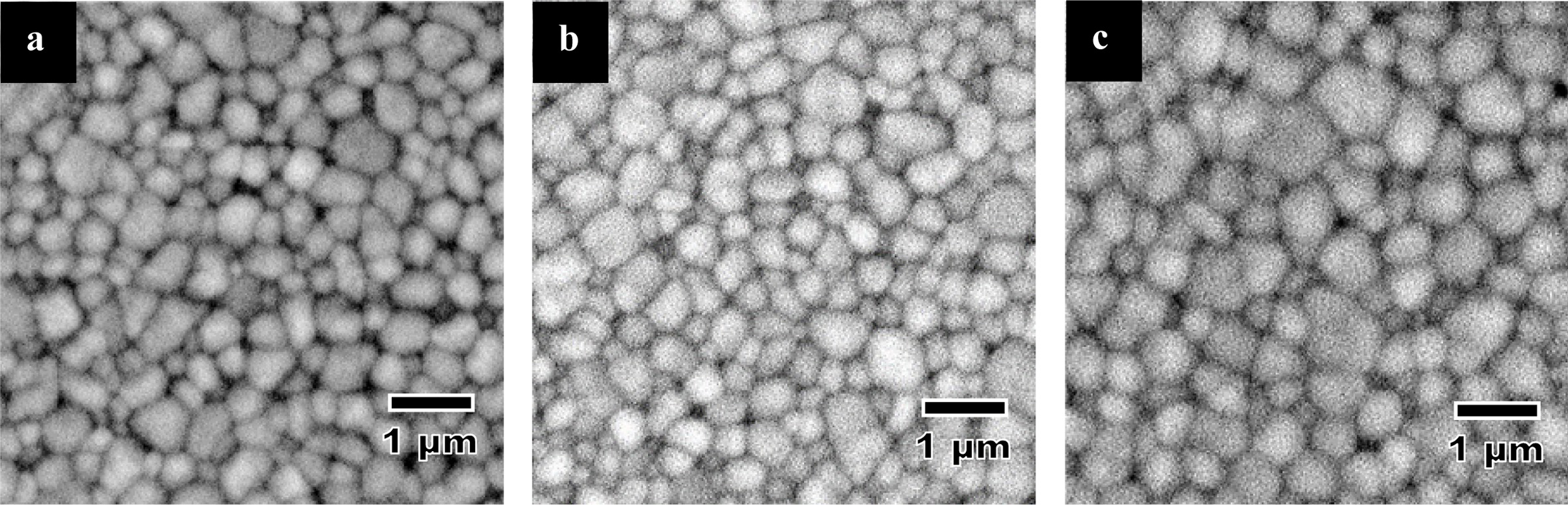

A typical SEM microstructure of the samples sintered

at 1450 oC is shown in Fig. 5. An equiaxed grain morphology was

observed for all samples regardless of dopant additions. The general

observation made was that the grain size increased with increasing CuO content.

This phenomenon of grain coarsening has also been noted by other researchers.

For instance, the effect of copper oxide doping on the electrical and

micro- structural properties of SnO2-based

varistors (SCNCr) was studied by Mahmoudi et al. [40]. The authors found

that the grain growth kinetics of the ceramic increased when the doping level

exceeded 0.25 mol%. This grain growth was accompanied by a reduction in

the activation energy from 594 kJ/mol (undoped) to 364 kJ/mol

(0.25 mol% CuO-doped). They suggested that a solute drag force was the

controlling mechanism of grain growth for samples with a low CuO content

(< 0.25 mol%) and this growth

mechanism changed to the Sn4+ solution-precipitation in CuO-rich

liquid phase for higher CuO doping. On the contrary, Kim et al. [49] who

studied the effect of CuO on the properties of (K,Na,Li)(Nb,Ta)O3 ceramics showed that the exaggerated grain growth observed for the CuO-doped ceramics

could be avoided by manipulating the sintering para- meters.

The authors initially performed normal sintering at temperatures above 900 oC and obtained an in inhomogeneous microstructures, consisting of a

bimodal distribution of small

(several microns) and exaggerated grains (20-40 µm). However, when a

two-step sintering (920-930 oC for 0 h in the first step and

880 oC for 1-12 h in the second step) was used, this

resulted in a homogeneous

fine-grained microstructure without com-promising on the piezoelectric properties of the

ceramics.

The variation in Vickers hardness as a function of

sintering temperature and dopant addition is shown in Fig. 6. The results show

that both the 0.2 wt% CuO-doped and undoped zirconia exhibited a similar

trend with increasing temperature. However, in all cases, the hardness of the

0.2 wt% CuO-doped was higher than the undoped ceramic and this agrees with

the density trend. The hardness of the 0.2 wt% CuO-doped zirconia

was > 13 GPa when sintered at 1350 oC and below.

Similar observation on the effect of CuO in enhancing the mechanical properties

of Sm-doped CeO2 ceramic was reported by Lu et al. [50]. The

researchers found that the addition of CuO lowers the densification

sintering temperature and enhances mechanical strength. They also

noted that the hardness dramatically increases from 4.9 ± 0.5 to

8.8 ± 0.4 GPa after doping with only 0.5 mol% CuO which was

attributed to a fracture transformation from intergranular to transgranular, as

well as enhanced density. In the present work, however, the hardness of the

0.5 wt% CuO was low regardless of sintering temperature. The sintered body

attained a maximum value of about 10 GPa when sintered at 1500 oC.

This was expected due to the lower bulk density as well as the high monoclinic

phase content measured in the sintered bodies as discussed earlier.

|

Fig. 1 XRD trace of Y-TZPs sintered at 1400 oC: (a) undoped, (b) 0.2 wt% CuO and (c) 0.5 wt% CuO. Note the shifting of the peaks resulting from copper doping. |

|

Fig. 2 The effect of sintering temperature on the relative density of Y-TZP. |

|

Fig. 3 Typical optical view of the free surface of the as-sintered 0.5 wt% CuO-doped Y-TZP revealing the presences of micro- and macro-cracks (as indicated by the arrows) associated with the tetragonal to monoclinic phase transformation upon cooling from sintering. |

|

Fig. 4 Average grain size variation as a function of sintering temperature and CuO doping. |

|

Fig. 5 Typical SEM microstructure of Y-TZPs sintered at 1400 oC: (a) undoped, (b) 0.2 wt% CuO and (c) 0.5 wt% CuO doped samples, respectively. |

|

Fig. 6 The effect of sintering temperature on the Vickers hardness of Y-TZPs. |

In this present work, the effect of small amounts of

transition metal oxide i.e. CuO addition as a sintering aid on the

densification and properties of Y-TZP ceramics were investigated. The results

revealed that the addition 0.2 wt% CuO was beneficial in aiding

densification with improved hardness when sintered at low temperatures, below

1350 oC when compared to the undoped ceramics. The tetragonal

phase stability was also not affected by the 0.2 wt% doping and the

sintered grain sizes were below 0.3 µm when sintered at lower temperature

regime. In contrast, the addition of 0.5 wt% CuO was found to be

detrimental as this excess liquid formation during sintering has disrupted the

tetragonal phase stability and resulted in lower hardness and low relative

density. This phase trans- formation

on cooling to room temperature was also accompanied by micro- and

macro-cracking thus rendering the material unfit for application.

Nevertheless, this study has shown the viability of aiding low

temperature sintering of Y-TZP through doping with low amounts of copper oxide.

- 1. R.C. Garvie, R.H. Hannink, and R.T. Pascoe, Nature 258 (1975) 703-704.

- 2. I. Birkby, and H. Hodgson, Proceedings of the 3rd European Symposium on Engineering Ceramics, edited by F.L. Riley (Elsevier Applied Science, Ltd., 1991) p.167.

- 3. M. Xue, S. Liu, X. Wang, and K. Jiang, Mater. Chem. Phys. 244 (2020) 122693.

-

- 4. K. Kobayashi, H. Kuwajima, and T. Masaki, Solid State Ionics 3-4 (1981) 489-493.

-

- 5. S. Ramesh, and C. Gill, Ceram. Int. 27 (2001) 705-711.

-

- 6. J. Chevalier, S. Deville, E. Münch, R. Jullian, and F. Lair, Biomater. 25 (2004) 5539-5545.

-

- 7. S. Ramesh, K.Y. Sara Lee, and C.Y. Tan, Ceram. Inter. 44 (2018) 20620-20634.

-

- 8. M. Cattani-Lorente, S. Durual, M. Amez-Droz, H.W.A. Wiskott, and S.S. Scherrer, Dent. Mater. 32 (2016) 394-402.

-

- 9. T. Sato, and M. Shimada, J. Am. Ceram. Soc., 68 (1985) 356-356.

-

- 10. G.K.R. Pereira, M. Amaral, P.F. Cesar, M.C. Bottino, C.J. Kleverlaan, and L.F. Valandro, J. Mech. Behav. Biomed. Mater. 45 (2015) 183-192.

-

- 11. H.Y. Lu, H.Y. Lin, and S.Y. Chen, Ceram Int, 13 (1987) 207-214.

-

- 12. S. Lawson, and P.A. Smith, J. Am. Ceram. Soc. 76 (1993) 3170-3172.

-

- 13. L. Gremillard, J. Chevalier, T. Epicier, S. Deville, and G. Fantozzi, J. Eur. Ceram. Soc. 24 (2004) 3483-3489.

-

- 14. M. Cattani-Lorente, S.S. Scherrer, P. Ammann, M. Jobin, and H.W.A. Wiskott, Acta Biomater. 7 (2011) 858-865.

-

- 15. M. Keuper, K. Eder, C. Berthold, and K.G. Nickel, Acta Biomater. 9 (2013) 4826-4835.

-

- 16. C.H. Ting, S. Ramesh, N. Lwin and U. Sutharsini, J. Ceram. Proc. Res. 17 (2016) 1265-1269.

- 17. L. Hallmann, P. Ulmer, E. Reusser, M. Louvel, and C.H.F. Hämmerle, J. Eur. Ceram. Soc. 32 (2012) 4091-4104.

-

- 18. S.M. Kwa, S. Ramesh, L.T. Bang, Y.H. Wong, W.J. Kelvin Chew, C.Y. Tan, J. Purbolaksono, H. Misran, and W.D. Teng, J. Ceram Proc. Res. 16 (2015) 193-198.

- 19. F. Zhang, K. Vanmeensel, M. Inokoshi, M. Batuk, J. Hadermann, B. Van Meerbeek, I. Naert, and J. Vleugels, J. Eur. Ceram. Soc. 34 (2014) 2453-2463.

-

- 20. K. Eltayeb, W. Hong, F. Chen, Y.-H. Han, Q. Shen, and L. Zhang, J. Ceram. Proc. Res. 18 (2017) 1-9.

- 21. X. Hu, X. Jiang, S. Chen, Q. Zhu, M. Feng, P. Zhang, J. Fan, B. Jiang, X. Mao, and L. Zhang, Ceram Int. 44 (2018) 2093-2097.

-

- 22. N. Obradović, and F. Kern, Ceram. Int. 44 (2018) 16931-16936.

-

- 23. H. Guo, T.J.M. Bayer, J. Guo, A. Baker, and C.A. Randall, Scripta Materialia 136 (2017) 141-148

-

- 24. Y. Wang, H. Huang, L. Gao, and F. Zhang, J. Ceram. Proc. Res. 12 (2011) 473-476.

- 25. S. Ramesh, N. Zulkifli, C.Y. Tan, Y.H. Wong, F. Tarlochan, S. Ramesh, W.D. Teng, I.Sopyan, L.T. Bang, and A.A.D. Sarhan, Ceram. Int. 44 (2018) 8922-8927.

-

- 26. F. Chen, J.-M. Wu, H.-Q. Wu, Y. Chen, C.-H. Li, and Y.-S. Shi, Int. J. Lightweight Mater. Manuf. 1 (2018) 239-245.

- 27. Z. Wu, N. Li, C. Jian, W. Zhao, and J. Yan, Ceram. Int. 39 (2013) 7199-7204.

-

- 28. S. Ramesh, S. Meenaloshini, C.Y. Tan, W.J.K. Chew, and W.D. Teng, Ceram. Int. 34 (2008) 1603-1608.

-

- 29. L. Holz, J. Macias, N. Vitorino, A.J.S. Fernandes, F.M. Costa, and M.M. Almeida, Ceram. Int. 44 (2018) 17962-17971.

-

- 30. A. Samodurova, A. Kocjan, M.V. Swain, and T. Kosmač, Acta Biomater. 11 (2015) 477-487.

-

- 31. Z. Feng, J. Qi, X. Guo, Y. Wang, X. Cao, Y. Yu, C. Meng, and T. Lu, J. Alloys Comp. 787 (2019) 254-259.

-

- 32. S.S. Mishra, D. Chaira, and S.K. Karak, Ceram. Int. 45 (2019) 20555-20565.

-

- 33. L. Fu, H. Engqvist, and W. Xia, J. Eur. Ceram. Soc. 38 (2018) 2110-2119.

-

- 34. H. Toraya, M. Yoshimura, and S. Somiya, J. Am. Ceram. Soc. 67 (1984) C-119-C-121.

- 35. M.I. Mendelson, J. Am. Ceram. Soc. 52 (1969) 443-446.

-

- 36. L. Lemaire, S. M. Scholz, P. Bowen, J. Dutta, H. Hofmeister, and H. Hofmann, J. Mater. Sci. 34 (1999) 2207-2215.

-

- 37. M.M. Khan, S. Ramesh, L.T. Bang, Y.H. Wong, S. Ubenthiran, C.Y. Tan, J. Purbolaksono, and H. Misran, J. Mater. Eng. and Perform. 23 (2014) 4328-4335.

-

- 38. H.R. Pasaribu K.M. Reuver, D.J. Schipper, S. Ran, K.W. Wiratha, A.J.A. Winnubst, and D.H.A. Blank, Inter. J. Refractory Metals & Hard Mater. 23 (2005) 386-390.

-

- 39. A.A. Menaze, A.M. Mostafa, and E.A. Al-Ashkar, Optical Mater. 100 (2020) 109663.

-

- 40. P. Mahmoudi, A. Nemati, and M.M. Shahraki, J. Alloys Comp. 770 (2019) 784-791.

-

- 41. B.H. Watson III, M.J. Brova, Y. Chang, S.T. Misture, M.A. Fanton, R.J. Meyer Jr., and G.L. Messing, J. Eur. Ceram. Soc. 39 (2019) 4719-4726.

-

- 42. S. Shimada, K. Kodaira, and T. Matsushita, J. Mater. Sci. 19 (1984) 1385-1390.

-

- 43. D.L. Corker, R.W. Whatmore, E. Ringgaard, and W.W. Wolny, J. Eur. Ceram. Soc. 20 (2000) 2039-2045.

-

- 44. Y.H. Kim, H. Ryu, Y.-K. Cho, H.-J. Lee, and S. Nahm, J. Am. Ceram. Soc. 96 (2013) 312-317.

-

- 45. T. Zhang, P. Hing, H. Huang, and J. Kilner, Mater. Lett. 57 (2002) 507-512.

-

- 46. N. Kimura, S. Abe, Y. Hayashi, J. Morishita, and H. Okamura, Sprechsaal 122 (1989) 341-343.

- 47. Y. Sakka, T. Ishii, T.S. Suzuki, K. Morita, and K. Hiraga, J. Eur. Ceram. Soc., 24 (2004) 449-453.

-

- 48. J. Nie, J.M. Chan, M. Qin, N. Zhou, and J. Luo, Acta Materialia 130 (2017) 329-338.

-

- 49. J.H. Kim, D.S. Kim, S.H. Han, H-W. Kang, H.-G. Lee, J.S. Kim, and C.I. Cheon, Mater. Letts. 241 (2019) 202-205.

- 50. Q. Lü, X. Dong, Z. Zhu, and Y. Dong, Ceram. Int. 40 (2014) 15545-15550.

-

This Article

This Article

-

2020; 21(4): 495-500

Published on Aug 30, 2020

- 10.36410/jcpr.2020.21.4.495

- Received on Mar 2, 2020

- Revised on Apr 7, 2020

- Accepted on Apr 14, 2020

Services

Services

Shared

Correspondence to

Correspondence to

- K.Y. Sara Lee

-

Tunku Abdul Rahman University College, Faculty of Engineering & Technology, Department of Mechanical Engineering, 53300, Kuala Lumpur, Malaysia

Tel : +(6)03-41450123

Fax: +(6)03-41423166 - E-mail: leeky@tarc.edu.my

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.