- Properties of ceramic fabricated of synthetic carbon and organoclay based on carbon particle size

Agus Edy Pramonoa,*, R. Sugeng Mulyonoa, R. Grenny Sudarmawana, Muhammad Zaki Nuraa, Haolia Rahmana and Nanik Indayaningsihb

aDepartment of Mechanical Engineering, Politeknik Negeri Jakarta, Jln. Prof. Dr. G.A. Siwabessy, Kampus UI. Depok 16425, Jawa-Barat, Indonesia

bResearch Centre for Physics, Indonesian Institute of Sciences, Kawasan Puspiptek, Gd. 440-442, Tangerang Selatan, Banten 15310, Indonesia

The electrical and thermal

conductivity properties of ceramics fabricated from carbon powder and clay have

been studied. This study was designed by varying the particle size of carbon

powders of mesh 150; 200; 250; 300; 350, with a carbon-organoclay ratio of 30:

70% by weight, 200 bar compacting, and sintering of 950; 1000; 1050 °C.

Electrical conductivity, thermal conductivity, specific wear rate,

density/porosity, and ceramic morphology have been studied. The thermal

conductivity follows the tendency of electrical conductivity, because of the

effect of carbon particle size. Increased sintering temperatures tend to

decrease wear resistance. The smaller the particle size of carbon powder, it

tends to increase the wear rate and the density of carbon-ceramic experiences

relatively small changes. Porosity tends to follow density, even though the

size of carbon particles gets smaller. The occurrence of porous and cracking is

more due to the irregular shape of carbon and matrix particles.

Keywords: electrical conductivity, thermal conductivity, carbon-ceramic, carbon particle size, organoclay

This study has succeeded in fabricating carbon-ceramic

from coconut coir organic waste materials as electrically conductive carbon

synthetic which is distributed in the organoclay as a ceramic matrix.

Organoclay is a ceramic matrix that is a local material from

Plered, Purwakarta, West Java, Indonesia. Synthetic carbon is

produced from organic coir coconut waste carbonized at

high temperatures (900 oC), producing the carbon

which is electrically conductive. The electrical conductivity properties,

mechanical properties of wear rate, physical properties of density

and porosity, thermal conductivity properties, and morphology of carbon-ceramic

composites have been studied. The relationship between

these properties has been analyzed and studied. The need

for friction mechanical parts that are resistant to wear and are electrically

conductive is the solution that will be offered from the results of the study.

The objectives of the research are development of alternative

types of electrically conductive of carbon-ceramic, developing geometric

alternatives and dimensions of conductor carbon particles for electrically

conductive ceramics, developing techniques and engineering pro- cesses for carbon-ceramic materials based on

coconut coir waste and clay, increasing the technological value of organic

waste coconut fiber, and clay, which are local ingredients. For decades, other

researchers have carried out research on ceramic that is electrically

conductive. Clay is an important component in making ceramic mixtures, because

of its plasticity, ease of use, strength and final properties obtained by heat

treatment [1, 2]. As a study conducted in 2015, developing carbon

black material from agricultural waste using the pyrolysis method at varied

carbonization temperatures and used as an amplifier in polymer composites [3].

The design of activated carbon-clay composites for waste decontamination made

from clay and carbon has been carried out. Fluesorb B was chosen as activated

carbon while a-sepiolite is a magnesium silicate clay used as an agglomerator

to achieve rheological charac-

teristics when mixed with activated carbon and water to confirm

ingredients in a monolithic, solid or tubular form [4]. Research on the

engineering of the use of coconut fiber into carbon-ceramic composites with

electrically conductive properties has been carried out. This research was

carried out experimentally based on coconut fiber with an

organoclay matrix. The properties of electrical conductivity, thermal

conductivity, and physical properties have been studied. This study

focuses on engineering carbon-ceramic composites with a clay matrix

[5]. New engineering, biochar with clay particles implanted

on the surface of carbon in the biochar pore has been successfully developed

[6]. The conductive aggregate type is prepared by calcining a ceramic matrix

and dispersed graphite powder. The conductive aggregate prepared was used in a

mortar containing carbon fiber, and the electrical resistivity and

piezoresis- tivity of the

specimen were studied [7]. Poly nano- composites

(ε-caprolactone) (PCL) with carbon nanotube particles

supported by clay loam (Clay-CNT) in concentration by weight were made by

mixing melt. The mechanical, structural and thermal properties of

nanocomposites are studied [8]. The 2015 study was to compare the fatigue

behavior and oxidation resistance of CC composites (carbon) derived from metals

with CC/ceramic composites (carbon/ceramics) obtained by impregnation of CC

composites with polysiloxane-based preceramic and subsequent heat treatment

[9]. This paper evaluates the effect of carbon nanotubes on the mechanical

properties and flame resistance of Homra / OPC blends; Homra is a solid waste

produced from the clay brick industry in Egypt [10]. Semi-finished

ceramic composites are consolidated with various starches and sintered at

different temperatures in the argon atmosphere. Electrical measurements, carbon

content and Raman analysis of carbon structures determine

the optimal sintering temperature of 1700 oC, which causes the

formation of a uniform conductive graphite network.

This carbon network produces porous composites that have high

electrical conductivity, which depends on the type of starch and porous

properties [11]. The composition of the ceramic material is prepared by

inserting up to 20 wt % of waste into two types of clay. The raw materials

used in this work are (a) one type of steel-making electric furnace waste to be

combined, and (b) two types of clay that significantly differs as a matrix.

The raw material is characterized by mineralogical

composition, chemical composition, and particle size distribution [12]. Carbon

fiber with hydrophilic surface modification is added to the mortar cement

through ultrasonic treatment. The mechanical and electrical properties of

carbon fiber cement mortar cement were tested to test the carbon fiber

strengthening effect [13]. A new ceramic of structured hybrids of nanocarbon

formed from organoclays during pyrolysis has been fabricated. It functions as a

reinforcement filler and binder for carbon/carbon (C/C) composites. The heat pressing

on the organoclay itself forms black monolithic sheets with

high thermal stability [14]. The nature of wear resistance and electrical

conductivity fabricated from the dispersion of coconut coir waste powder in the

organoclay matrix have been investigated [15], the study does not consider

carbon particle size as an electrically conductive filler. The

study is oriented mainly to the electrically conductive

properties, the composite wear resistance properties, the physical properties

of density and porosity, and composite elements. Carbon powder from coconut fibers

mixed with organoclay clay, with variations in composition 10:90, 20:80, and

30: 70% by weight. Composite molds are carried out by hydraulic machines in

tablet form [16]. Research on the use of sludge wastewater from industrial

uniform laundry as raw material combined with kaolin clay for the production of

white ceramics and the development of composites and

laboratory-level sustainable technology to produce white ceramics

has been carried out [17]. Based on studies of research on carbon-ceramic

composites that have been carried out by many other researchers, there has been

no research on carbon-ceramic composites with measurable powders, from

electrical conductivity carbon of coconut coir waste, and

organoclay as a matrix for ceramics with electrically conductive

and wear-resistant properties. State of the art of the research are:

Utilization of coconut fiber waste fiber as synthetic carbon material; The use

of organoclay clay as a matrix material of carbon-ceramic;

Engineering of ceramic based on waste materials and local

materials for wear-resistant and electrically conduc- tive materials; The repyrolysis

sintering process is a high-temperature combustion process to obtain two

ceramic characters, simultaneously in one process, electrically conductive and

wear-resistant. The process of sintering to form organoclay into ceramics,

while the repyrolysis process to form carbon becomes electrically conductive.

The pyrolysis is a repyrolysis process, because the filler is already in the

form of synthetic carbon from organic waste; The repyrolysis sintering process

is carried out in a tightly closed reactor tube, without inert gas (nitrogen or

argon). The two-process experiments also contributed to the technology of

carbon-ceramic fabrication processes.

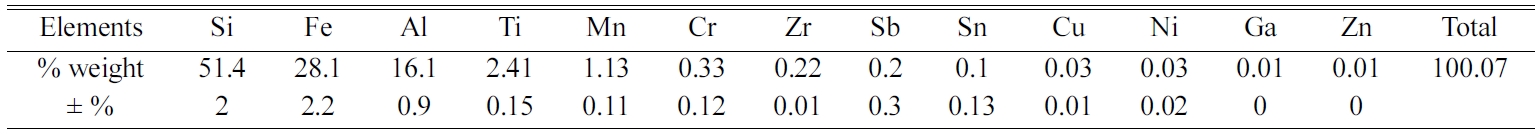

Material

preparation

Organoclay

is a local material as a ceramic matrix. Synthetic carbon powder is carbonized

at 900 oC from organic coir coconut waste. Organoclay elements

were examined by an X-ray Fluorescence

Analyzer TORONTECH TT - EDXPRT, the main element of the organoclay was silica

(51.4%), the same thing was done by other researchers with silica element (an

average of 50.5%) [18], 61.1% SiO2 element [19]. The results of testing the

organoclay elements are shown in Table 1.

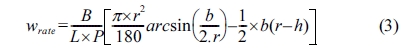

Fig. 1 shows the X-ray diffraction of the organoclay, at

an angle of 2 thetas, between 20-30°, the position of the highest peak of

intensity (> 1000), showing the silica element contained in the

organoclay. The same characteristic graph of clay was also shown by other studies,

[20, 15, 16, 21-23].

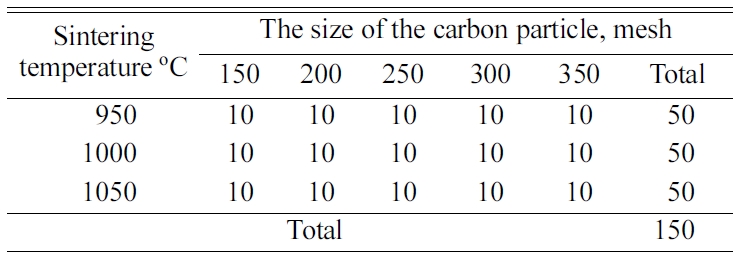

Fabrication

of specimens

The coconut coir pyrolysis process is carried out in a

furnace with an airtight tube. Milling is conducted with a crusher to reach a

mesh size of 150; 200; 250; 300; 350, was sieved with a sieve vibrator. Mixing

carbon powder with organoclays for the formation of mixed plasticity, with a

composition ratio of carbon powder and clay mixture designed 30:70, produced 30

green compact specimens. Compaction was carried out with a hydraulic press

machine with a pressure of 200 bar, resulting in

a green compact tablet with a size of 40 mm in diameter ×

10 mm thick. Repyrolysis sintering was carried out in a furnace with an

airtight reactor tube, at temperatures varying from 950; 1000; 1050 oC,

with a temperature velocity of 2 oC/min, carbon-ceramic is

produced with electrically conductive properties. The total specimens are shown

in Table 2.

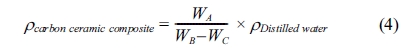

Electrical

conductivity test

Electrical conductive properties were tested using the

two-point probe method, with a modification of the copper plate electrode

instead of the probe. Measure- ments

were made against the DC electric current resistance

using a digital multitester, specimen diameter, and

thickness of carbon-ceramic specimens. The measure- ment of electrical

conductivity follows the ASTM D257 standard [15, 16, 5, 24, 25]. The testing

method is shown in Fig. 2.

Measurements were made of electrical resistance, specimen

thickness, and cross-sectional area of specimens for

electricity. Electrical static resistance is calculated by the equation,

The amount of electrical conductivity is determined by the

equation,

Note: r = static

electricity resistance [Ωm]; R = electrical resistance [Ω];

A = cross-sectional area of specimens [m2]; l = length

of current path [m]; s = electrical

conductivity of specimens [1/Ωm] or [S/m].

Thermal

Conductivity test

Testing of thermal conductivity to determine thermal

physical properties, especially heat conductivity, of carbon-ceramic to heat

flow. This test refers to the ASTM E1530 standard for evaluating resistance to

thermal transmission of materials through the protected heat

flow meter technique [5]. This test method includes a

steady-state technique in determining resistance to thermal transmission. Two

solid samples were prepared with a diameter of 50 mm and a thickness of

4 mm and 2 mm from each sample.

Note: l and k refer to the thickness of the sample and

thermal conductivity respectively. Subscripts a and b show two different sample

thicknesses.

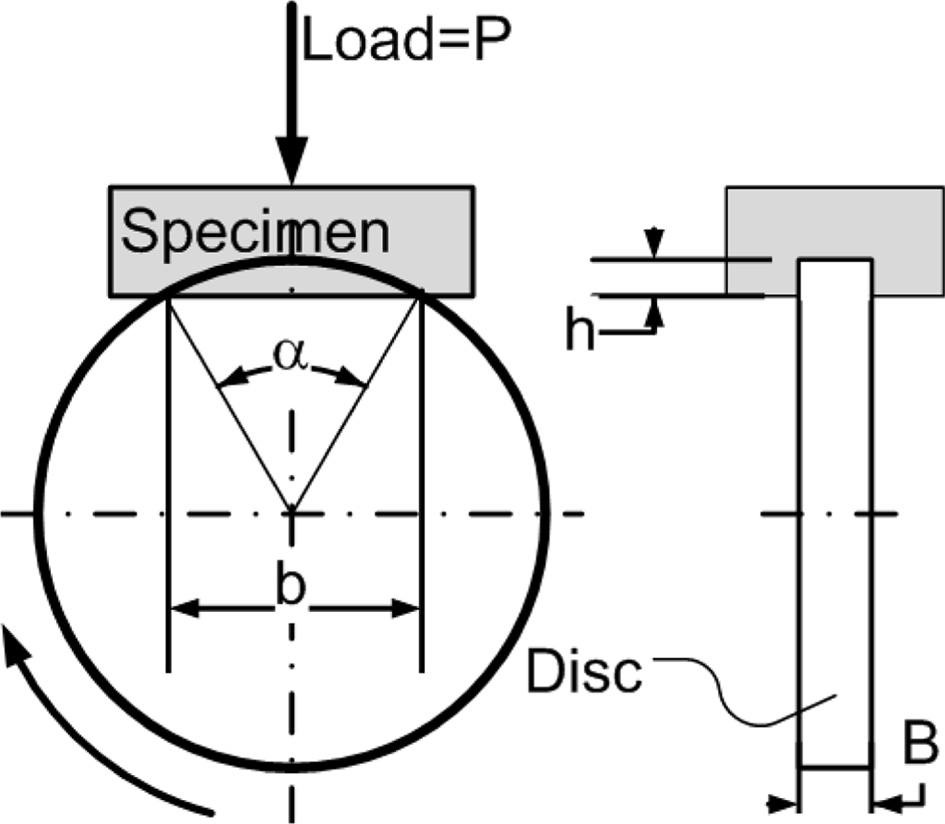

Wear

resistance test

Wear rate testing is carried out to determine the

resistance of carbon-ceramic to friction using a disc wear tester. Different

studies use the wear resistance test method with the ball-on-disk method [26].

Another study uses the pin-on-disk method, to test the

wear rate [27, 28]. In this study, wear rate testing follows ASTM C1243-93

(2015) standards [29, 30], with a disc-wear testing machine. Shown in Fig. 3.

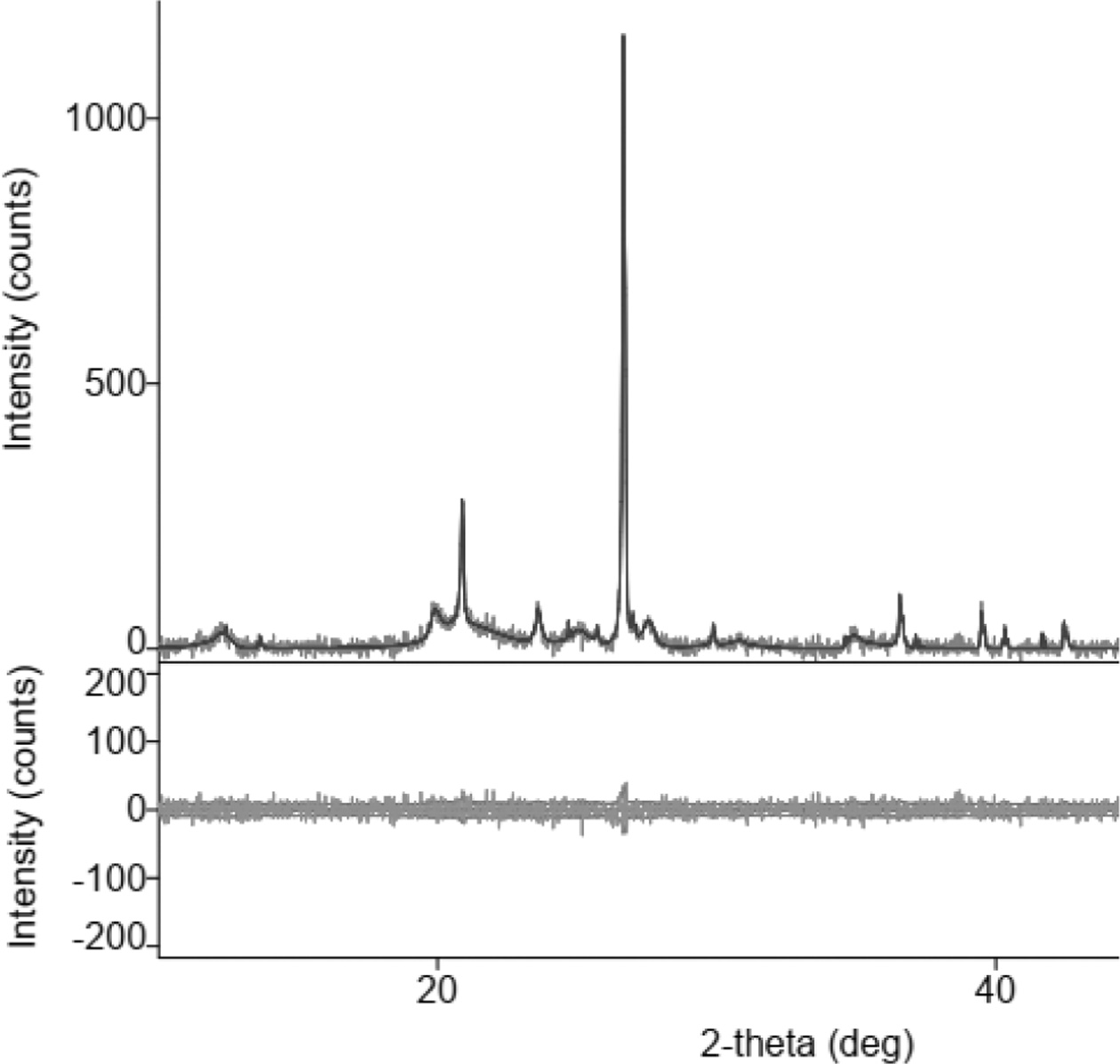

The specific wear rate is calculated by the equation,

Note: Wrate = specific wear rate [mm3/Nm];

b = trace length [mm]; L = distance [m]; P = test

load [N]; r = disk radius [mm]; B = trace

width [mm]; h = trace depth [mm].

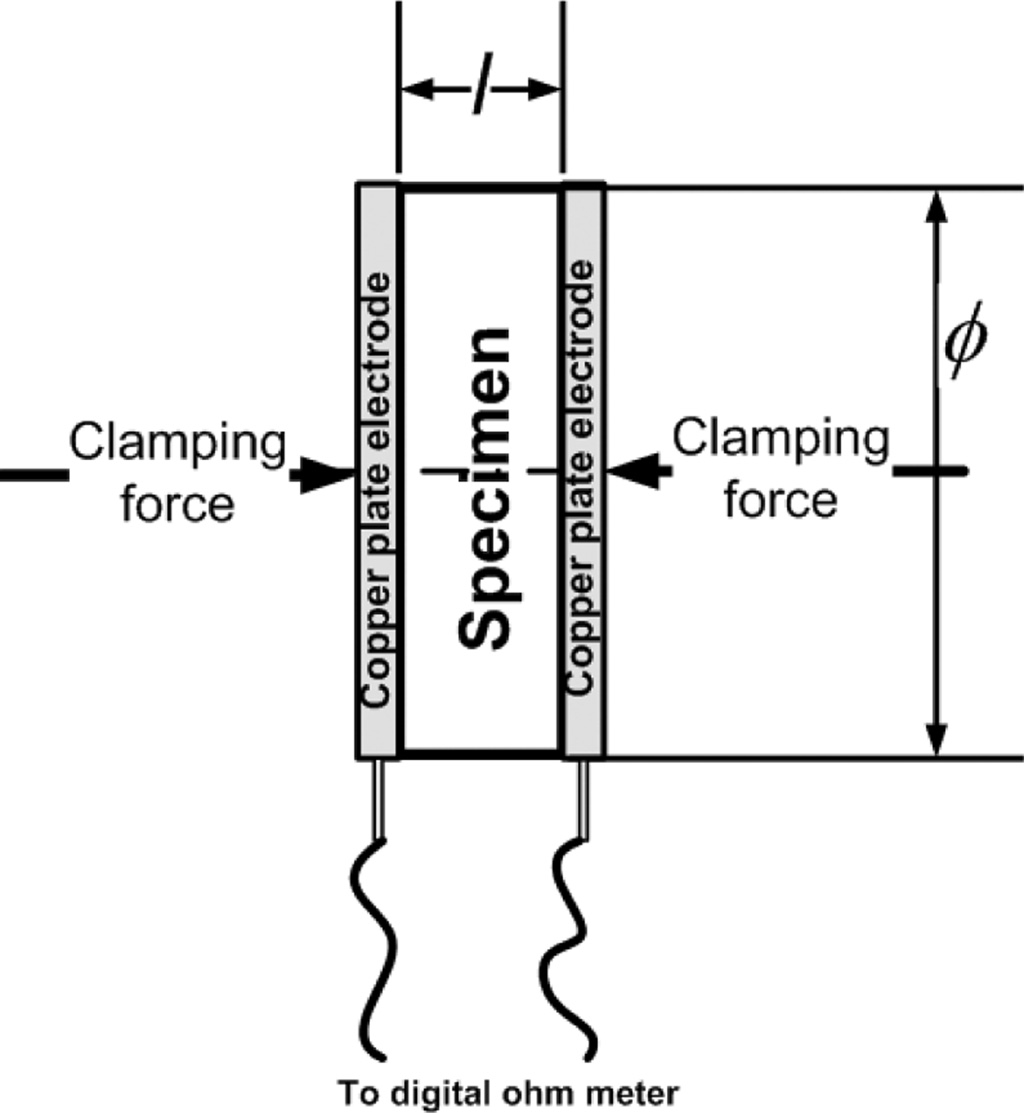

Density

test

A density test is conducted to determine the density level

of carbon-ceramic. Another study determined the density by weighing the

specimen weights then divided by the volume of the specimen [14]. This study,

the density test was conducted experimentally using the Archimedes

method based on the ASTM D792 standard [16, 31, 32, 11, 33, 34,

35]. The density of carbon-ceramic is calculated by the equation,

Porosity

test

The porosity test is to determine the percentage of voids

and voids contained in the carbon-ceramic volume. The

porosity test applies the Archimedes method following

the ASTM C20 - 00 (2015) standards [16, 11 33, 36, 37]. Porosity is

calculated as follows,

Note: WA = dry weight [gram]; WB = saturated

weight of water in the air [gram]; WC = saturated

weight of water in the water [gram]; rcomposite

= composite density [g/cm3];

rdistilled

water = the density of distilled water 0.992

[g/cm3]

Morphological

tests

This test was conducted to determine the morpho- logical conditions of carbon-ceramic on a

micro-scale. Based on the morphology of carbon-ceramic, the geometric shape of

the particles can be identified, both matrix and carbon particles, the

interface bond between the particles can be known, and the appearance of

cavities that cause porosity of the ceramic can be identified. Morphological

tests were conducted with Hitachi SU 3500 microscopic scanning electron.

|

Fig. 1 X-Ray Diffractions of organoclay. |

|

Fig. 2 Two plate electrodes testing method. |

|

Fig. 3 Disc-wear testing method. |

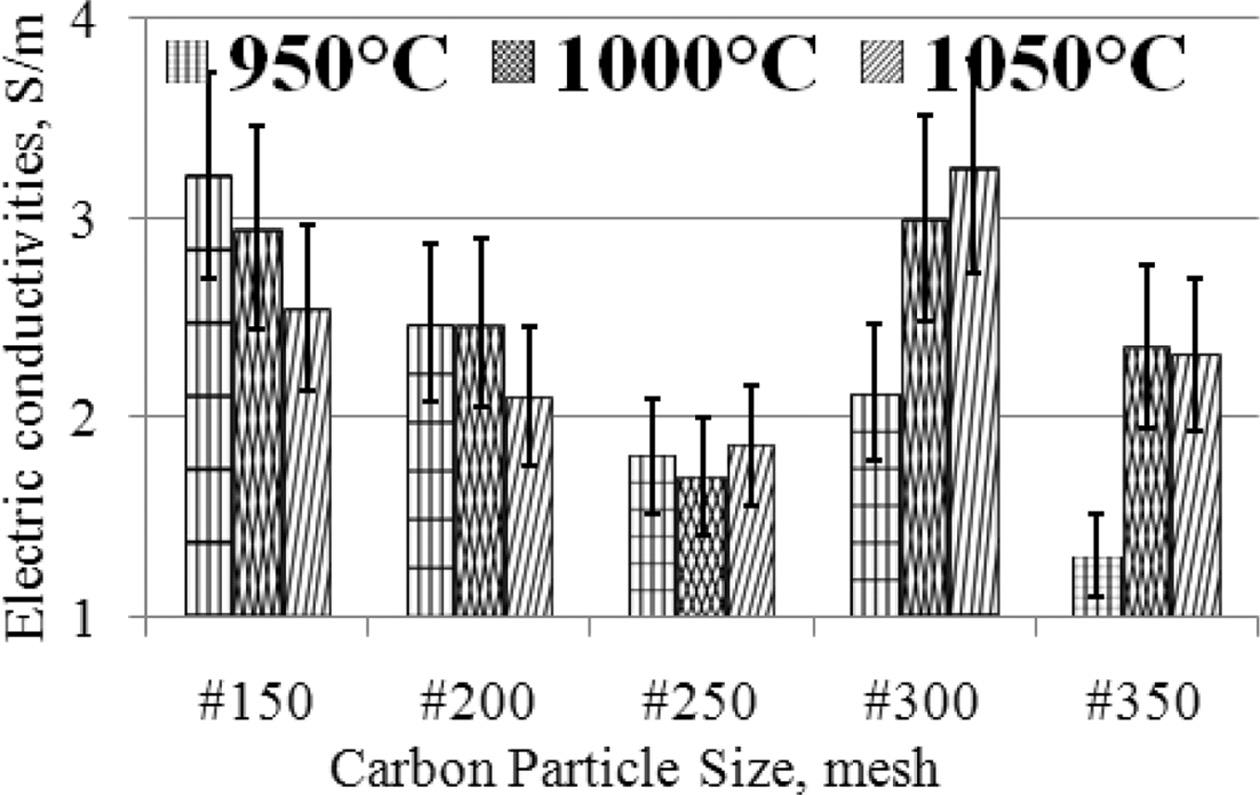

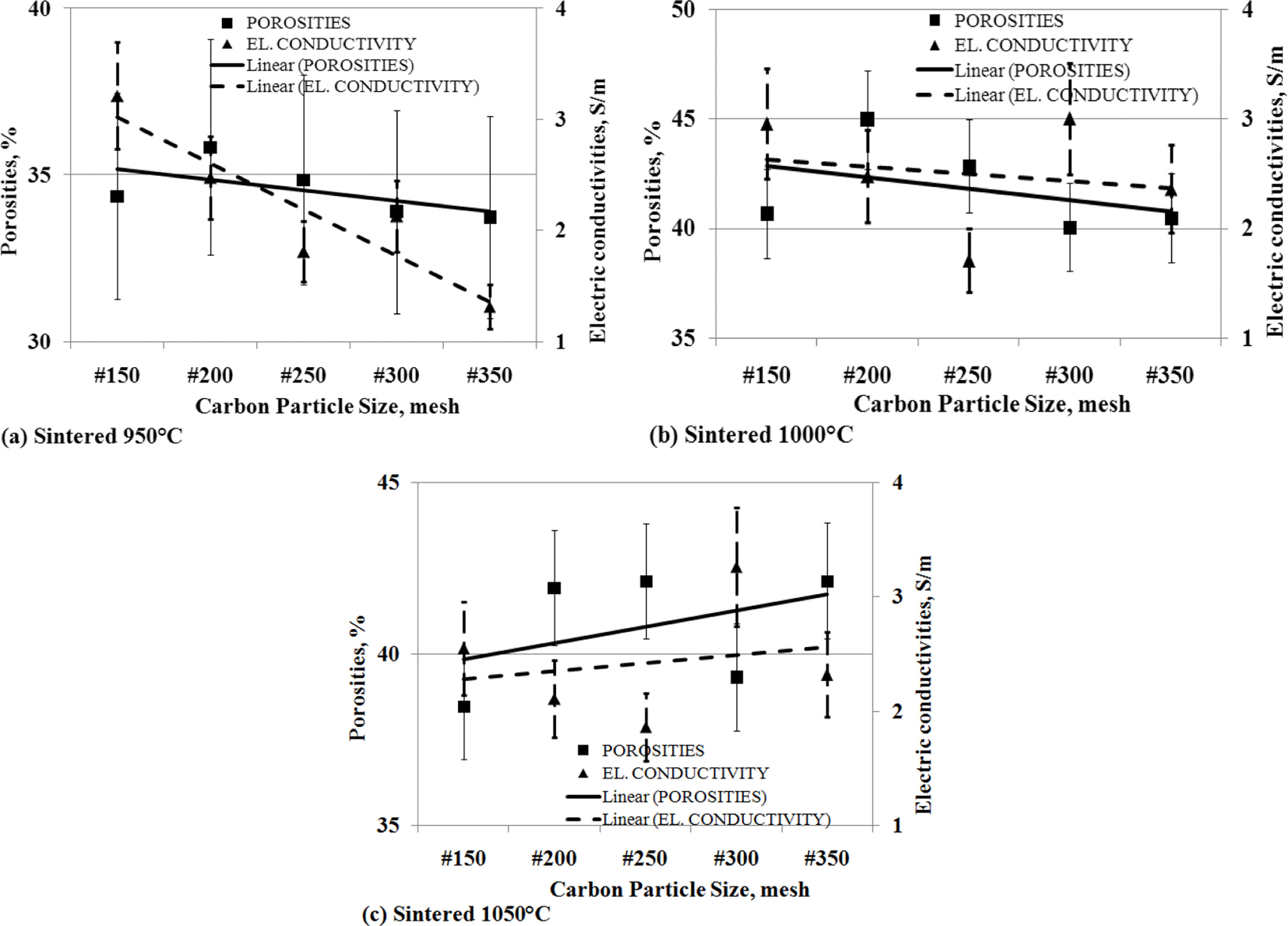

Electrical

conductivity

The purpose of measuring electrical conductivity is to

determine the highest electrical conductivity value of carbon-ceramic.

Electrical conductivity values are arranged in

graphical form, as shown in Fig. 4.

The highest electrical conductivity was produced by

specimens with carbon particle size #300, with a sintering

temperature of 1050 oC, an electrical conductivity

value of 3.26 [S/m]. Meanwhile, the lowest 1.31 [S/m] is produced by specimens

with carbon particle size #350 at a sintering temperature of

950 oC. The condition of the specimen with carbon

particle size # 150, when the sintering temperature increases, the electrical

con- ductivity

decreases, also experienced by carbon-ceramic with

particle # 200, whereas for samples with carbon particle # 250, the electrical

conductivity produced is relatively constant. Specimens with particle sizes

#300 and #350, when the sintering temperature is increased it tends to increase

the electrical conductivity of the specimens. In general, at mesh particle size

# 150; 200; 250, the electrical conductivity decreases further, when the

sintering temperature is raised, from 950 oC to 1050 oC.

In specimens with mesh particle sizes # 300 and # 350, and higher sintering

temperatures (from 950 oC - 1050 oC),

this will increase electrical conductivity. Factors

affecting DC conductivity in solids are current carrier concentration,

temperature, defective density and/or structural irregularities, and facilities

where ions can jump to adjacent empty locations [38, 2]. The particles in this

study are small carbon which is homogeneously dispersed which acts as a

conductive phase in the ceramic matrix [24]. The more carbon particles as a

conductor filler, and cling tightly to the ceramic matrix will result in good

interface contact, and this will increase the electrical conductivity the

better. When the carbon content is at the percolation limit, a continuous

electrically conductive path begins to form, that is, an electric current can

flow between adjacent carbon particles through direct contact or tunneling

effects, and so the resistance decreases. The conductor filler network is

formed by the relationship between the conductor fillers that are close

together and stick together. Based on the volume fraction of few-layer

graphene in multilayer composites, it produces electrical

conductivity from 1 × 10-14 to 1 × 10-4

[S/cm] [25]. Engineering ceramics from clay illite, the results of AC

electrical conductivity tests show values from 1 × 10-2 to

1 × 10-7 [S/m] [2]. The electrical properties of the

insulant appear to be very dependent on the chemical and mineralogical

composition of the clay used, and the soaking period used. The study of the use

of clay from Indian Jammu, for insulant ceramics, produces

electrical conductivity of around 0.5 to 2 × 10-8

[mhos/cm] [39]. The electrical properties of aluminum nitride ceramics show

electrical resistance from 1 × 1010 to 1 × 1014

[Ω cm] [40].

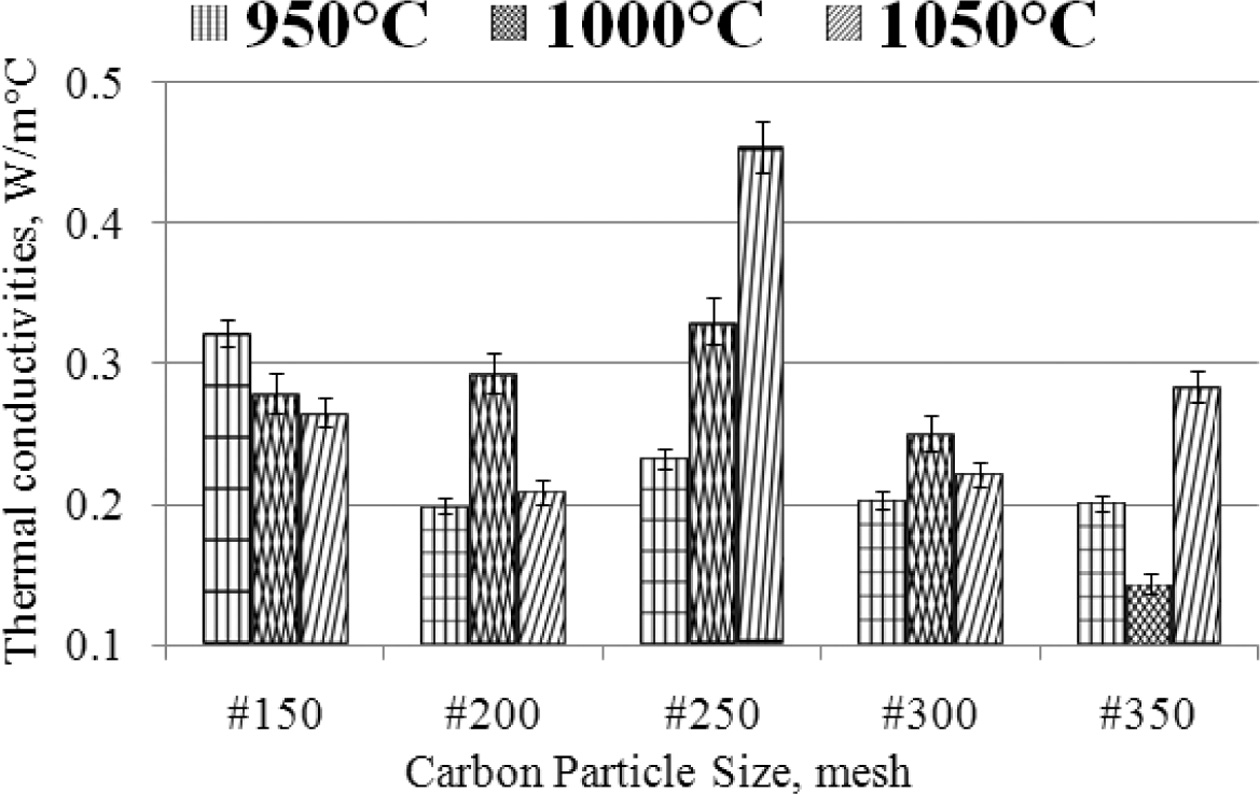

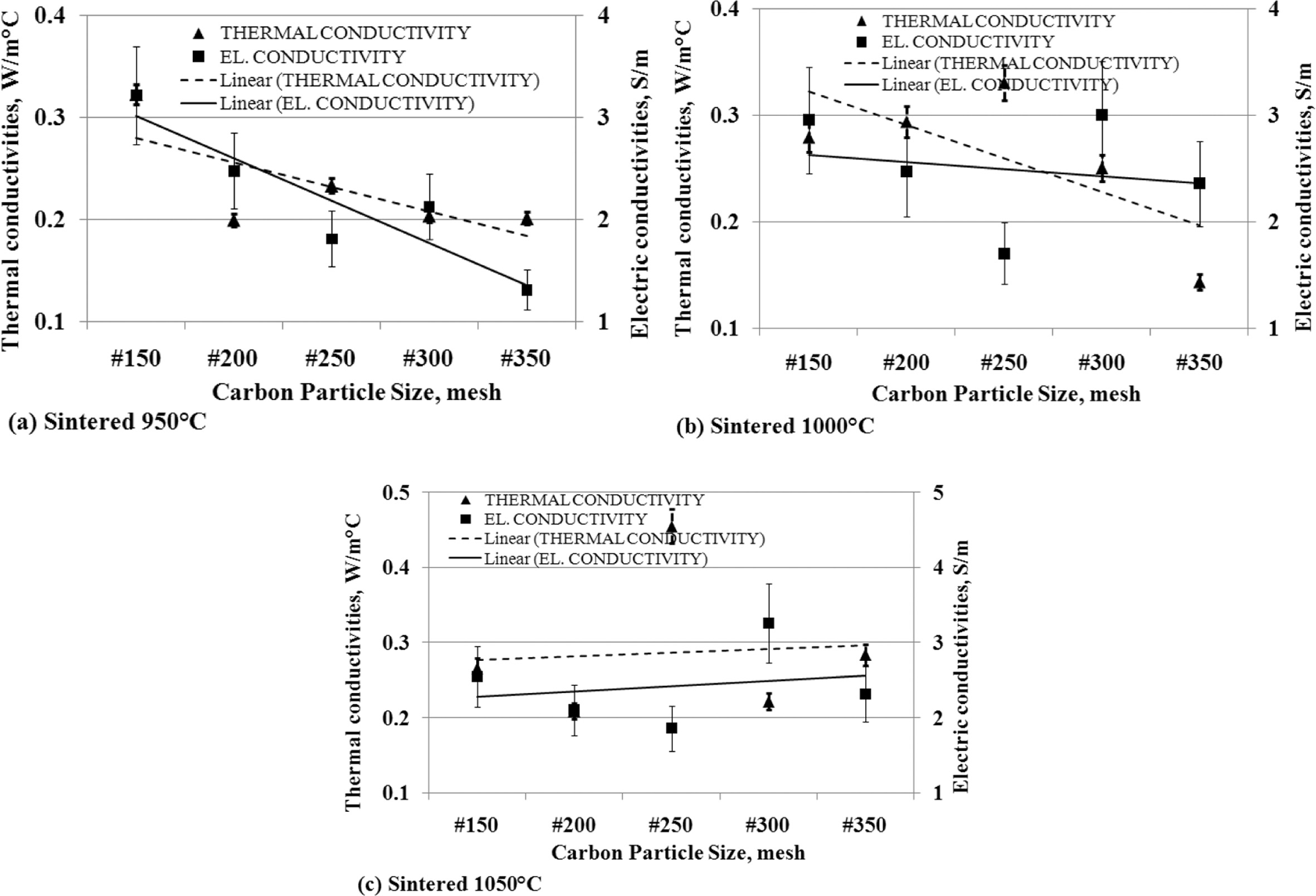

Thermal

conductivity

Testing of thermal conductivity to determine thermal

physical properties, especially heat conductivity, of carbon-ceramic to heat

flow. Thermal conductivity testing has also been carried out in other studies,

with different methods, [41, 42, 43, 44, 45]. The highest thermal

conductivity is ± 0.45 [W/moC], produced from

specimens with carbon particle size # 250, in the sintering process of

1050 oC. The lowest thermal con- ductivity is ± 0.1 [W/moC],

produced from carbon-ceramic with particle # 350, at sintering temperatures of

1000 oC. This is shown in Fig. 5, the deviation values

of each sample variant are shown, with an average deviation value not higher

than 10%.

The smaller the particle size of carbon, the smaller the

thermal conductivity produced by carbon-ceramic. This occurs at sintering

temperatures of 950 oC and 1000 oC.

Meanwhile, at a sintering temperature of 1050 oC,

indicating that the smaller the particle size, the increase in

thermal conductivity. The effect of sintering temperature

on the thermal conductivity of carbon-ceramic also shows an unequal tendency.

As shown in Fig. 5, the mesh size # 150 shows that the higher the sintering temperature,

the lower the thermal conductivity. Mean-

while, samples with mesh # 200 to mesh # 350 show increased

thermal conductivity, when the sintering temperature is increased from 950 to

1050 oC. In com- parison, other studies have also produced

thermal con- ductivity, which is shown

as follows. Allegreta studied the thermal conductivity

values of kaolin samples with kaolinitic clay

(kaolinite = 58%, ilite = 18%, smectite = 2%,

quartz = 22%, rutile and anatase in the trace). The highest thermal

conductivity value is ± 0.68 [W/mK] produced by kaolin samples with

tempering tempera- tures up to

1000 oC, and the lowest is ± 0.28 [W/mK] [46]. The raw

material used in this study is kaolin powder which is marketed by the company

Denain-Anzin-Minéraux (France). When the temperature inc- reases, the

sintering process implies better material consolidation

due to the decomposition of clay particles in the

mullite phase and amorphous flux which is rich in silica. This study produced a

thermal conductivity of 0.28 to 0.63 [W/mK] [47]. The clay-based ceramics

investigated in this study were made of clay, sand, and water. Clay is

extracted as a batch in a clay mine to ensure

homogeneity. Clay-based ceramics produce thermal

conductivity of 1.07 [W/mK] [43]. Three commercially available soil-based

plasters, widely used for interior wall base systems in several European

countries, selected for experimental testing. The thermal conduc- tivity of the sample disk made from the soil

plaster material examined is measured. This study yields thermal conductivity

of 0.74 to 1.16 [W/mK] [48]. The clay material supplied by Ceradel company

(Saint Amand en Puisaye, France) is a mixture of extruded clay that is used for

making pots. To ensure good homogeneity, the raw material is first mixed in

water. This study yields thermal conductivity of ± 0.4 to 1.8 [W/mK] [49].

Clay-based materials which exhibit high pore volume fractions and low thermal

conductivity suitable for thermal insulation have been studied. This study

shows a thermal conductivity of 0.063 to 0.130 [W/mK] [44].

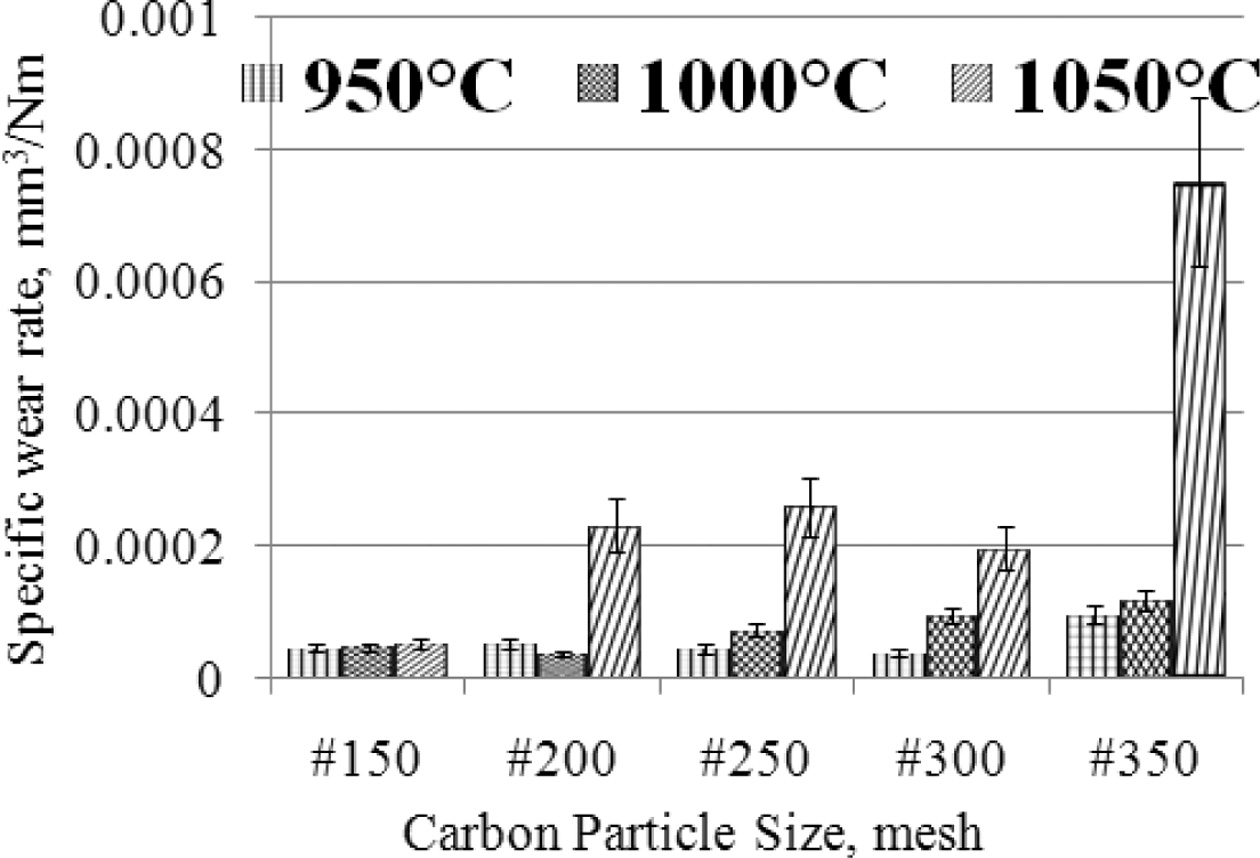

Specific

wear rate

Wear rate testing is performed with a disc wear tester, by

measuring the variables of wear depth, wear trail length, wear trail width,

load, rotational speed, distance traveled. The lowest wear rate is produced by

carbon-ceramic with carbon particle size # 200, at a sintering temperature of

1000 oC, which is 3.59827 × 10-05 [mm3/Nm],

in this condition this material shows the highest hardness compared

to other specimens, of the size different carbon particles.

The softest specimens in this study produced the highest wear rate, 0.000752239

[mm3/Nm], this was demonstrated by specimens with carbon particle

size #350, at sintering temperatures of 1050 oC, as shown in

Fig. 6. The graph shows that the higher the sintering temperature the higher

the wear rate produced, the condition shows that the increase in sintering

temperature tends to decrease the wear resistance properties, in other words,

the softer the specimens. Carbon-ceramic tend to show relatively stable wear

rates at particle size # 150, even though the sintering temperature is raised

to 1050 oC. This specimen shows the harshest

mechanical character. Likewise, the smaller the particle

size of carbon powder tends to increase the wear rate, meaning that

carbon-ceramic is softer, and is not resistant to mechanical friction. Wear

rate is one of the mechanical properties of carbon-ceramic; this mechanical

property can also represent the level of hardness of the material.

Indirectly can also show the level of strength of the

carbon-ceramic. The concept is, the lower the wear rate, the higher the level

of hardness of the ceramic, and thus the higher the tensile strength of the

specimens, with the structure of the material being isotropic. As in this study,

this carbon-ceramic is designed isotropic, therefore using

powder-shaped filler. The weakness of the mechanical properties of this

material is thought to be caused by porous cavities formed in carbon-ceramic,

although the fabrication process of carbon-ceramic tablets applies a pressure

of 200 bars, with a hydraulic press.

Allegedly, when printing green compact, there are air

cavity bubbles trapped inside, so that during the sintering process the air

cavity forms porous in a carbon-ceramic. Some elements of the organoclay are

thought to have also burned during the high-tem- perature sintering process; this will form a

porous in the material. As explained in the analysis of relation- ships of porosity and composite wear rates.

This study tested the wear rate using the two-body abrasive wear test method,

which was carried out using a pin on disc tool. This study shows the wear rate

based on weight loss from the material being tested [29]. Other

researchers applied specific wear rate testing to the ASTMG99-95a

standard producing specific wear rates with values from

5 × 10-7 to 1.5 × 10-5 [mm3/Nm]

[50]. The wear rate of the C/C-SiC composite produces a specific rate

of 2.5 × 10-4 to 5 × 10-4 [mm3/Nm]

[51]. The engineering of carbon-ceramic composites from other studies shows

testing the wear rate based on the level of hardness of the composite [28].

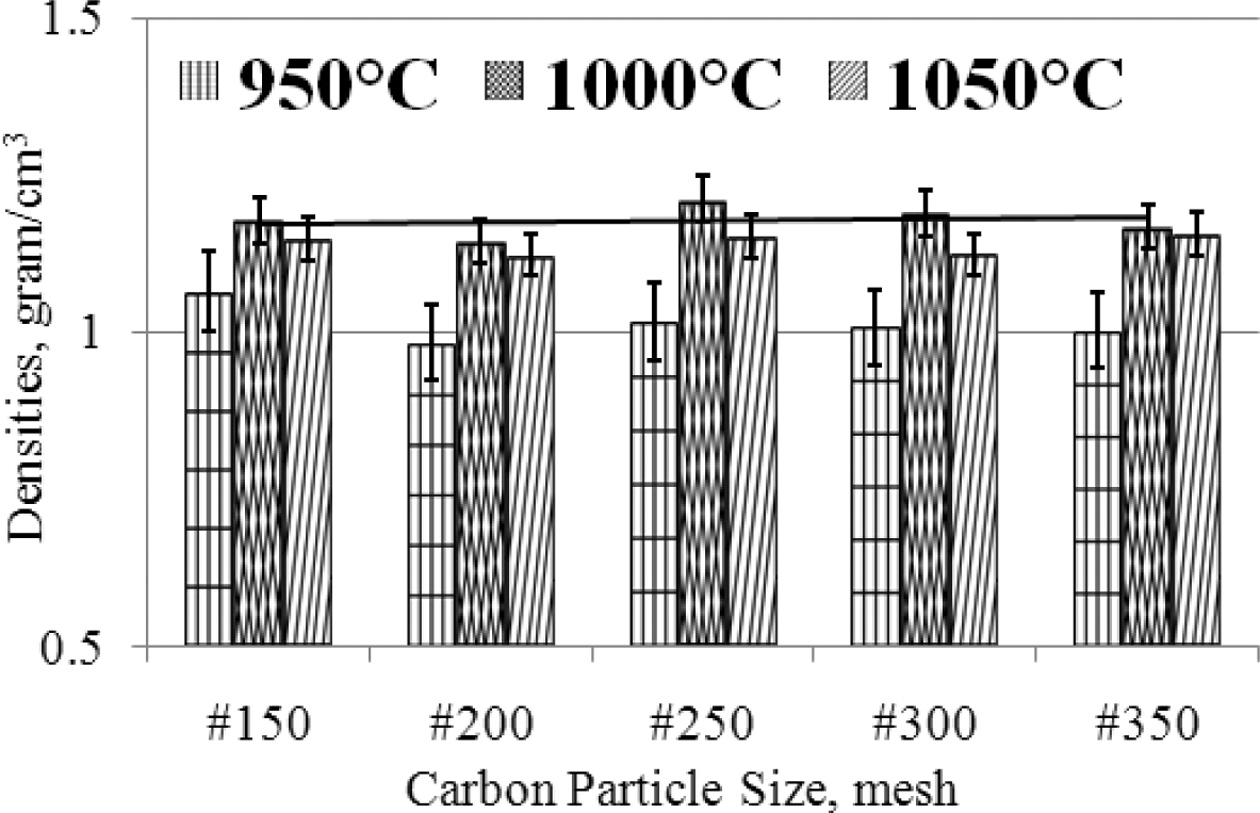

Carbon-ceramic

density

Density testing is carried out to determine the level of

density of carbon composites. This test was carried out experimentally using

the Archimedes method based on the ASTM D792 standard [30, 34, 35, 37]. The

condition of the density will indicate the degree of porosity of the specimens.

The lower the densities level of the carbon-ceramic, the

higher the porosity of the specimens.

This will affect the level of electrical conductivity and

ceramic wear resistance. The density of carbon-ceramic is arranged in graphical

form as shown in Fig. 7. The engineering of carbon-ceramic shows the physical

properties of relatively stable densities between 1-1.2

[gram/cm3]. In detail, it can be proven that there is an increase in

density when the sintering temperature is increased, but an increase in density

of about 0.2 [gram/cm3], when observing the deviation value, the

value of increasing density is not significant. Changes in carbon particle size

from #150 - #350 also do not make significant changes in densities.

As shown in Fig. 7. The smaller the particle size of carbon, the density is

relatively unchanged. As a comparison to the results of other studies,

explained as follows. This researcher utilizes kaolin for compacting and

sintering with temperature variations from 980 - 1200 oC,

producing densities of 2.55 to 2.9 [grams/cm3], and porosity of 6.3

to 35.4% [47]. A study of ceramics fabricated from kaolin,

bentonite, and sand. To investigate the evolution of

electrical resistivity of various layers of kaolinite dominant clay, in terms

of soil composition, due to moisture content and dry density

changes. This research resulted in a composite density

between 0.72 to 1.87 [gram/cm3] [52]. A

carbon-ceramic composite fabricated from fly ash,

carbon fiber, and other particles, compacted 200

[kg/cm2], heated to 1000 oC, has produced densities

between 1.65 to 1.87 [gram/cm3] [28].

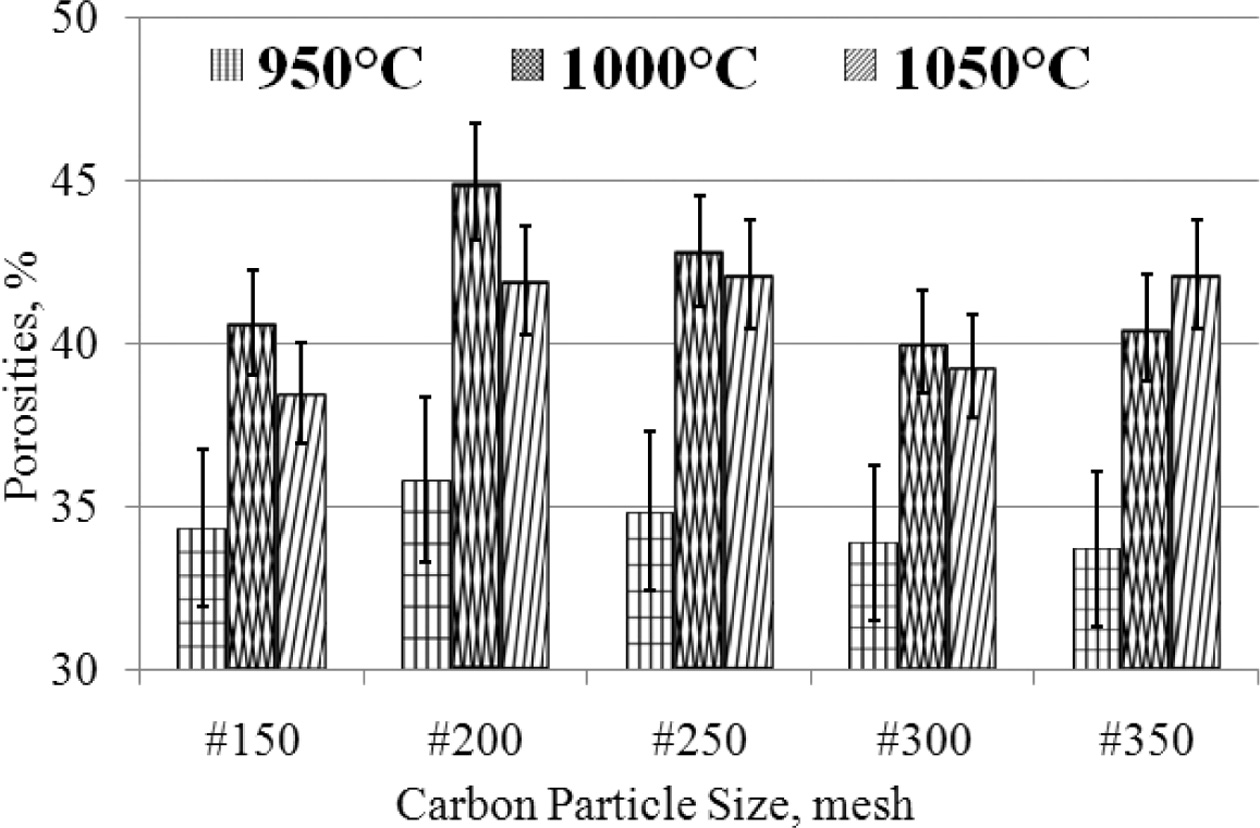

Carbon-ceramic

porosity

The porosity test applies the Archimedes method following

the ASTM C20 - 00 (2015) standards [16, 11, 33, 37]. Carbon-ceramic

shows relatively high porosity, between 33 - 42%

porosity. Based on considera- tion

of the deviation of carbon-ceramic in the 950 oC sintering

process shows the percentage of porosity that is relatively stable, between

33 - 36%, even though the particle size gets smaller, from mesh #

150 - # 350, while carbon-ceramic with the same mesh particle size (#

150 - # 350) which is processed by sintering 1000 oC,

producing porosity between 40 - 45%, while carbon-ceramic processed

by sintering at temperatures of 1050 oC show porosity between

38 - 42%, with a mesh size change of # 150 - # 350. The

porosity of carbon-ceramic is even greater when the sintering process

temperature is raised from 950 - 1050 oC, with an

equal composition ratio of 70: 30%, as shown in Fig. 8. This condition is

thought to be due to the fact that most organoclay matrices turn to carbon when

sintering is processed at high temperatures. This increases the volume of

carbon in the carbon-ceramic, and carbon has a high absorption of water when

testing porosity.

Broadly speaking, the smaller the size of carbon particles

in carbon-ceramic, the porosity contained by carbon-ceramic

is relatively stable, there is no significant change. In

comparison, several researchers, using the same method, produced the porosity

described below. Because the particles grow irregularly, the ability of the

particles to bear the external force decreases when an external load is

applied. The compressive strength of the sample is reduced due to an increase

in porosity, which is caused by a pile of compressed particles between the

particles, this study produces a porosity of 70 to 80%

[53]. Another study showed the real porosity of the K1

and K2 specimens calculated according to the Archimedes principle, each

equivalent to 21.9 and 19.9%. Thus, round silica solids show lower porosity,

that is, denser microstructure [36]. This study shows the results of porosity

testing of various types of ceramic specimen particle sizes and produces

porosity between 14 to 43% [54]. This researcher utilizes bentonite as a

mixture for clay and silica ceramics producing porosity from 10 to 50% [37].

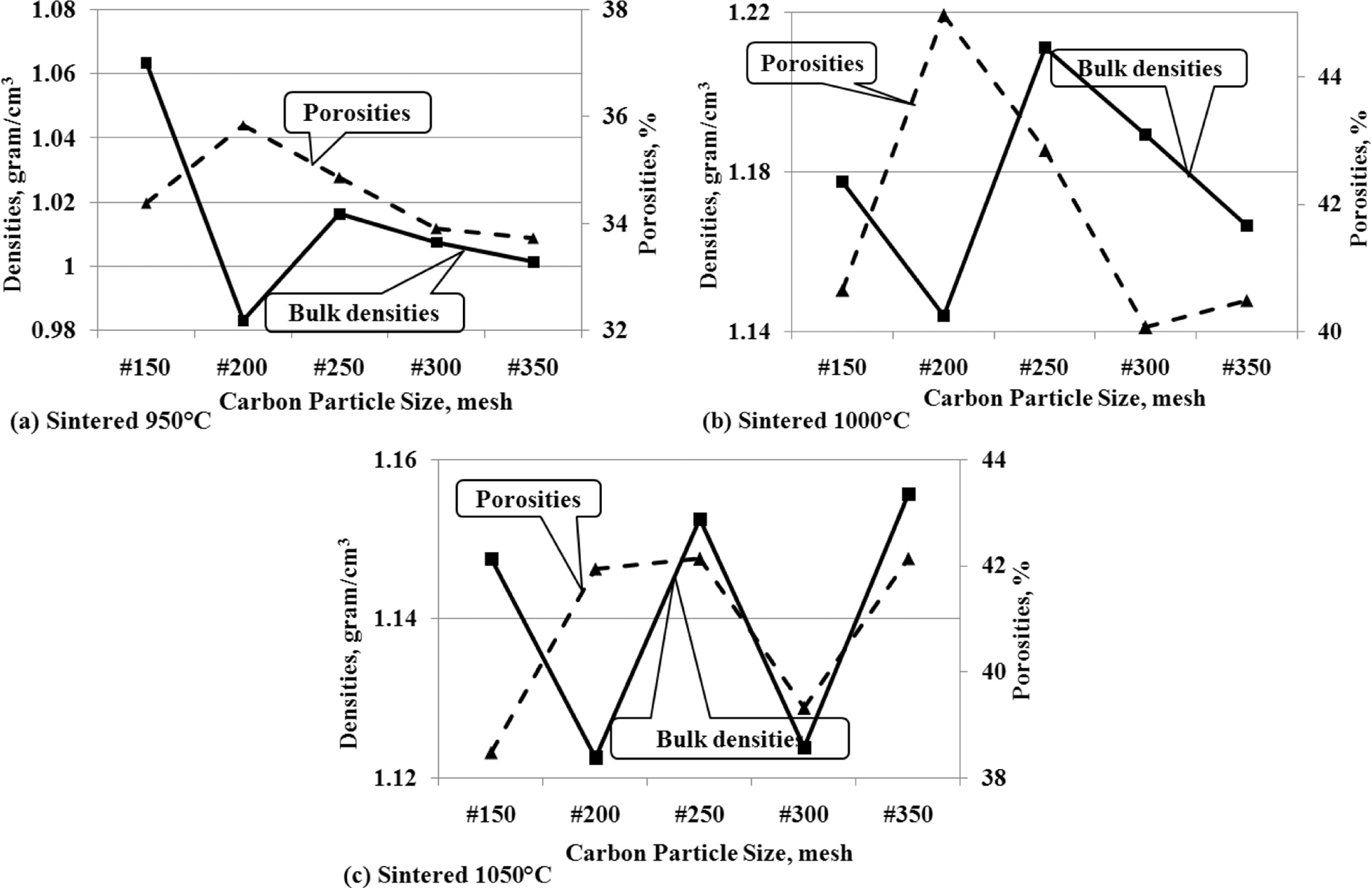

The

relationship of density to porosity

This analysis is to show the interdependence between density

and porosity. The concept which states that when density increases, porosity

will decrease, does not apply significantly in the facts of this study. Figure

9 (a); 9 (b); and 9 (c) show that when the carbon particle size gets smaller

the density shows a decrease, followed by a decrease in the percentage of

porosity volume. This occurs relatively similarly at all sintering temperatures.

Fig. 9 (a) shows the same tendency between density and

porosity of carbon-ceramic composites which are processed by sintering at

950 oC.

The fact that relatively similar trends are also shown by

carbon-ceramic by sintering at temperatures of 1000 oC, as

shown in Fig. 9 (b), when the size of carbon particles decreases, the density

also decreases and is followed by decreasing porosity. The same relative thing

is also shown in Fig. 9 (c), the density increases and is followed by increased

porosity as well, at the particle size reduction of mesh #150 - #350, at a

sintering temperature of 1050 oC. The fact that happens is,

porosity tends to follow density, even though the size of carbon particles gets

smaller.

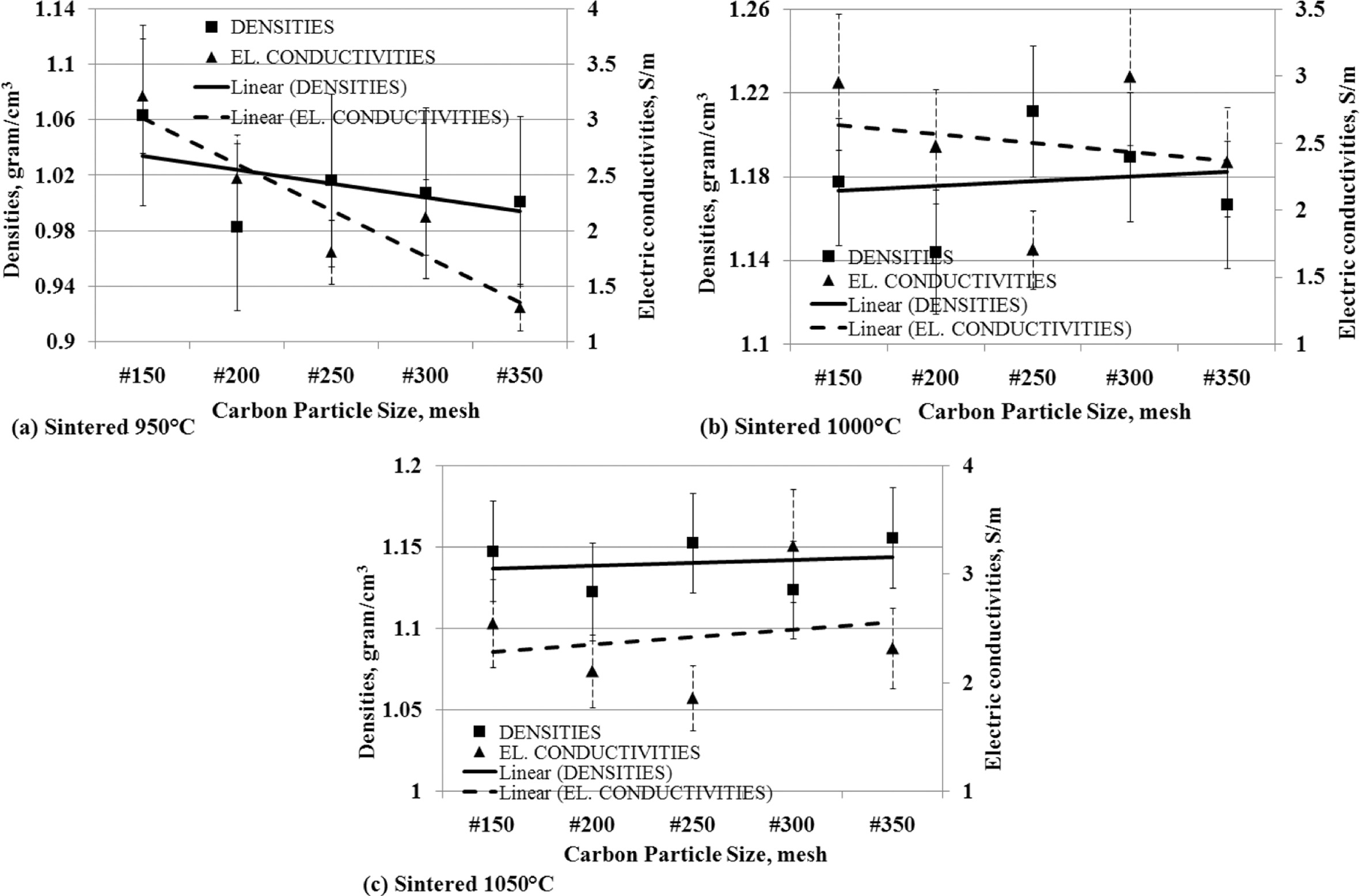

The

effect of the density to electrical conductivity

Density is a physical property that shows a specific level

of material weight in units of volume, it can be named density. The fact that

occurs in the fabrication of carbon-ceramic shows that the density affects the

electrical conductivity, as shown in Fig. 10. Fig. 10 (a) is a fact of

carbon-ceramic with a sintering process at a temperature

of 950 oC, which shows the smaller particle

size carbon spread in the specimens makes electrical conductivity decreases,

following the decrease of the density.

Carbon-ceramic with a 1000 oC sintering

process shows a different fact, the smaller the size of carbon particles,

indicating an increase in the density of the carbon-ceramic, but conversely,

the electrical conduc- tivity actually

decreases, as shown in Fig. 10 (b). The decrease in carbon particle size in the

specimens gives an increase in the density of the carbon-ceramic and is

followed by an increase in electrical conductivity shown by carbon-ceramic by

sintering at temperatures of 1050 oC, as shown in Fig. 10 (c).

In general, an increase or decrease in carbon-ceramic density based on carbon

particle size is followed by an increase or decrease in

the electrical conductivity of carbon-ceramic.

The

effect of the porosity to electrical conductivity

The level of porosity of carbon-ceramic will affect the

level of electrical conductivity.

Porosity is cavities formed in ceramic due to compaction.

Cavities formed on carbon-ceramics cause connectivity between carbon

conductivity particles to be disrupted and become a barrier to the flow of electricity.

This study shows that the smaller the change in the

particle size of carbon powders, the lower the porosity volume of

carbon-ceramics followed by a decrease in electrical conductivity.

This is experienced by carbon-ceramic at sintering

temperatures of 950 oC, as shown in Fig. 11 (a). Likewise,

carbon-ceramic with a sintering temperature of 1000 oC

experienced the same decrease between the porosity volume and the electrical

conductivity of the specimens, as shown in Fig. 11 (b). Different charac- teristics are shown in carbon-ceramic with

sintering temperatures of 1050 oC, the smaller the particle

size of carbon, the greater the percent porosity volume, and followed by an

increase in electrical conductivity of carbon-ceramic. This is shown in Fig. 11

(c).

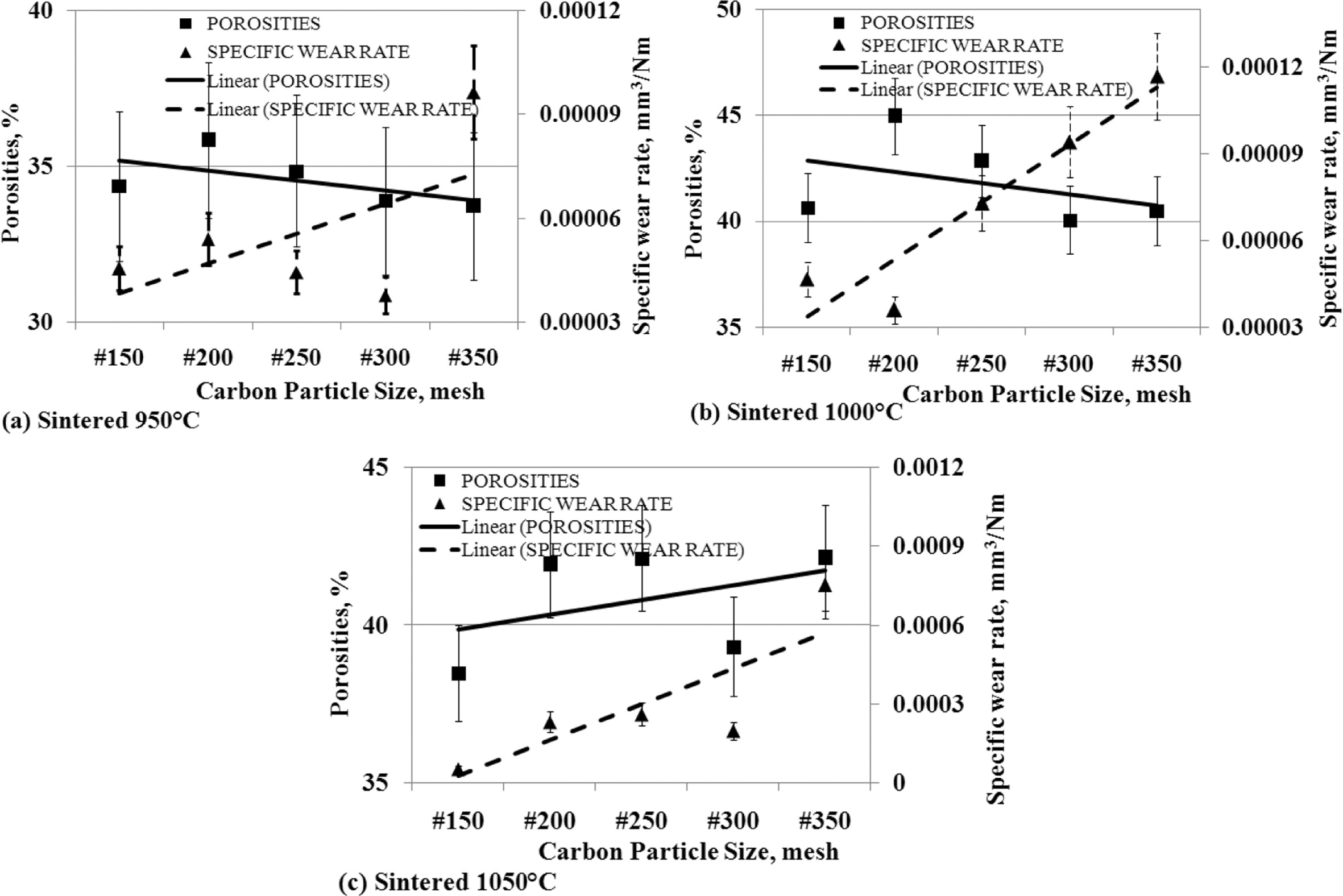

The

effect of porosity to specific wear rates

Cavities are formed in carbon-ceramics, which weaken the

mechanical bonding of filler particles and matrix particles, and between filler

particles and matrices. This fact is shown in Fig. 12. Theoretically, when the

percentage of porosity increases, it will form a weak bond between the

particles, producing a weak bond mechanically. The greater porosity percentage

indicates the number of cavity volumes in the specimen more and more, and the

bond between particles is mechanically weaker, so the wear rate gets higher, or

carbon-ceramic becomes softer, hardness decreases and easily wears out.

Conversely, a small percentage of porosity indicates a small number of cavities

in carbon-ceramics, and increases mechanical bonding between particles, both

fillers, matrices, and between matrices and fillers,

and thus strengthens the mechanical properties of these

specimens. This research does not always show the similarity of characteristics

with theoretical concepts. Carbon-ceramic with a sintering temperature of

950 oC shows the opposite character.

When the particle size of the carbon powder gets smaller,

resulting in a smaller percentage of porosity, but vice versa is followed by an

increase in higher wear rates, which means that this type of specimen exhibits

weaker mechanical bonding properties, its hardness decreases, as shown in Fig.

12 (a). Likewise, the characteristics shown by carbon-ceramics by the sintering

temperature process of 1000 oC, show the same character, this

is shown in Fig. 12 (b). Different characters are shown by carbon-ceramic with

sintering temperatures of 1050 oC, shown in Fig. 12 (c). The

study shows, the smaller the particle size of carbon powders results in greater

porosity percentages and is followed by the higher wear rate of the specimens.

This fulfills the concept that the more cavities in the carbon-ceramic will

weaken the mechanical bonding properties of the materials, and thus weaken the

mechanical properties, increasing the wear rate of carbon-ceramic.

The

relationship of thermal conductivity to the electric conductivity

Thermal conductivity has a relationship with electrical conductivity.

When thermal conductivity decreases, it is followed by reduced electrical

conductivity.

This is shown in Fig. 13 (a) and (b), which are produced

from carbon-ceramic with sintering temperatures of 950 oC and

1000 oC. The smaller the particle size of carbon, the value of

thermal and electrical conductivity decreases. Carbon-ceramic with the

sintering process of 1050 oC produces different tendencies, as

shown in Fig. 13 (c). The figure shows that the smaller the particle size of

carbon, the more thermal and electrical con-

ductivity increases. Based on the facts of the analysis, the tendency of

thermal conductivity will be followed by the tendency of electrical

conductivity.

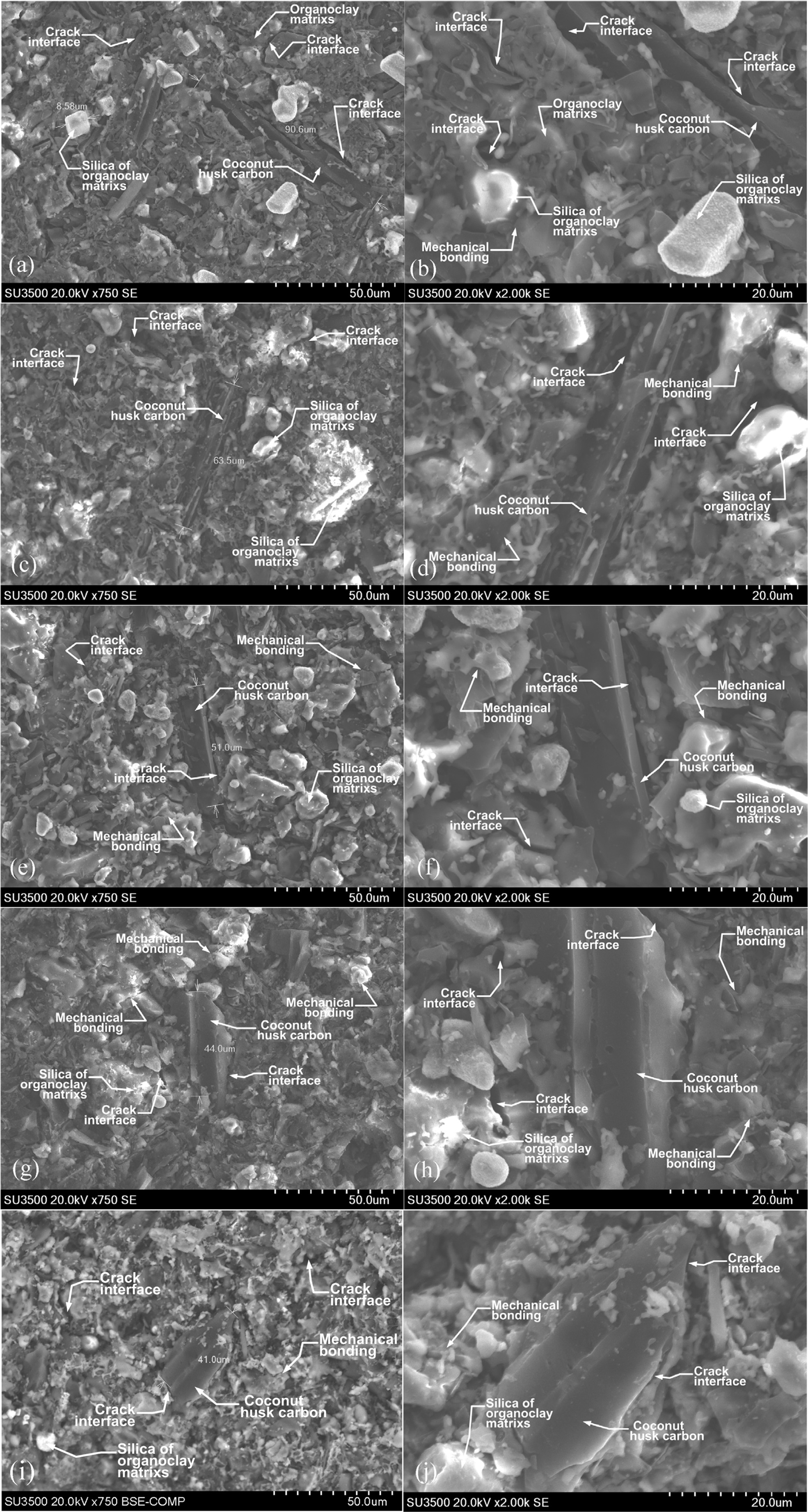

Morphology

of carbon-ceramic

Microphotographs from the scanning electron micro- scopic test cannot distinguish morphology

based on the ratio of composition between carbon and organoclay and also based

on sintering temperature, this test will show the size of carbon particles

scattered in the ceramic matrix of organoclays. The test was carried out with a

Hitachi SU 3500 scanning electron microscopic testing machine. The purpose of

this test is to look at the morphological state of carbon-ceramic. To see the

possibility of cavity formation on the specimens and the interface bond between

organoclay and carbon powder from coconut coir powder. Cavities formed in the

specimens will weaken the electrical conductivity and wear

resistance of the carbon-ceramic. Morphological are shown

in Fig. 14 (a) to 14 (j). The shape and geometric carbon powder, in general, is

elongated and irregular, and not granule or round in shape. The size of the

carbon powder is shown in the elongated micron size, 90 μm, shown by

carbon-ceramic with mesh size # 150, as shown in Fig. 14 (a). Based on the ASTM

wire mesh standard, the 90 μm particle size is relevant to the standard

mesh size number between 140 to 170. Fig. 14 (a) and (b) with magnifications of

750 and 2000 also shows the interface cracks between carbon particles

against organoclay matrix particles, silica particles from

organoclay matrices, mechanical bonding between particles

are also shown in the carbon-ceramic morpho-

logy. The smaller carbon particle size is shown in Fig. 14 (c), the

figure is the morphology of carbon-ceramic with carbon particle size # 200,

with an elongated particle size of 63.5 µm this particle size is relevant

to the ASTM standard wire mesh sieve chart numbers between 200 to 230. In

general, shapes and geometric carbon particles are elongated and irregular in

shape, and have dark features, as shown in Fig. 14 (c) and (d), with

magnifications of 750 and 2000. Also shown in the picture are silica particles

from the organoclay matrix, that are shown with bright white features, cracks

interface between carbon particles against the matrix, between particles of the

matrix, mechanical bonding between matrix and carbon particles. Carbon-ceramic

with mesh # 250 shows elongated geometric carbon particles measuring

51 µm. This dimension is relevant to the ASTM wire mesh standard between

numbers 270 to 325. At magnifications 750 and 2000, shown in Fig. 14 (e) and

(f) is the morphology of the interface cracks between carbon particles against

orga- noclay matrix particles, silica

particles of the matrix, mechanical bonding between particles.

The morphology of carbon-ceramic particles with mesh size # 300

is shown in Fig. 14 (g) and (h), at magnifications of 750 and

2000. The morphology shows the irregular geometric shape

of particles, both carbon particles, and organoclay matrix

particles. The measurement results of carbon particles show 44 μm, this is

relevant to the ASTM standard wire mesh sieve chart between numbers 325 to 400.

Interface cracks between carbon particles against the organoclay matrix are

also shown in the figure. The bright white feature indicates the content of

silica particles from the organoclay matrix. While the dark, irregular, and

elongated black features indicate carbon particles, or it is also suspected to

be very strong is the crack or porous of the specimens. The morphology of

carbon-ceramic with mesh size # 350 shows the carbon particle size of 41 μm, as

shown in Fig. 14 (i). The carbon particle size is relevant to the ASTM sieve

chart standard wire numbers between numbers 325 to 400. Fig. 14

(i) and 14 (j) show geometric irregular carbon particles and

matrices, showing mechanical bonds between particles, showing the interface

cracks between filler particles and matrices. The white and bright features in

the morphology indicate the silica content of the organoclay matrix. Meanwhile,

the dark morphological features indicate carbon particles and a very strong

suspicion is cracks or porous that occurs within the carbon-ceramic. This study

shows that compaction load of 200 bars and with smaller particle size apparently

cannot eliminate porous or cracks that occur in the specimens. The strong

suspicion of porous and cracking is caused more by the irregular shape of

carbon particles and matrix particles.

The cavities formed are also thought to be a result of the

heating process in the sintering process, the particles forming the

carbon-ceramic bonds have non-uniform volume expansion coefficients, resulting

in pressing on each other and cracking even weaker particles mechanically. It

is also suspected that bonding between particles is only mechanical in nature,

relying only on the irregularity of the pairs of particles.

|

Fig. 4 The relationship of electric conductivities vs. carbon particle size vs. sintering temperature. |

|

Fig. 5 The relationship of thermal conductivity vs. carbon particle size vs. sintering temperature. |

|

Fig. 6 The relationship of specific wear rate vs. carbon particle size vs. sintering temperature. |

|

Fig. 7 The relationship between densities vs. carbon particle size vs. sintering temperature. |

|

Fig. 8 The relationship of porosities vs. carbon particle size vs. sintering temperature. |

|

Fig. 9 The relationship between densities vs. porosities vs. carbon particle size. |

|

Fig. 10 The relationship between densities vs. electric conductivities vs. carbon particle size. |

|

Fig. 11 The relationship of porosities vs. electric conductivities vs. carbon particle size. |

|

Fig. 12 The relationship of porosities vs. specific wear rate vs. carbon particle size. |

|

Fig. 13 The relationship of thermal conductivity vs. carbon particle size vs. electric conductivity. |

|

Fig. 14 Morphology of carbon-ceramic composite. |

At the carbon particle size of mesh #150; 200; 250, the

electrical conductivity decreases, when the sintering temperature is raised,

from 950 oC to 1050 oC. In mesh particle sizes

# 300 and # 350, and higher sintering temperatures (from 950 oC - 1050 oC),

this will increase electrical conductivity. The tendency of thermal con-ductivity follows the tendency

of electrical conductivity, from the effect of carbon particle

size. The higher the sintering temperature the higher the wear rate pro-duced, this condition shows

that the increase in sintering temperature

tends to decrease the wear resistance pro-

perties, in other words, the softer the carbon-ceramic. Likewise,

the smaller the particle size of carbon powder tends to

increase the wear rate, meaning that carbon-ceramic is softer, and is not

resistant to mechanical friction. The smaller the particle size of carbon, the density

of carbon-ceramic composites that occur relatively no change.

In general, the smaller the size of carbon particles in carbon-ceramic, the

porosity of carbon-ceramic is relatively stable. There is no significant

change. In fact, porosity tends to follow density, even though the size of

carbon particles gets smaller. In general, an increase or decrease in density

due to carbon particle size is followed by an increase or decrease in the

electrical conductivity of carbon-ceramic. Compaction of

200 bar and with smaller particle size apparently can not

eliminate porous or cracks that occur in the specimens. The occurrence of

porous and cracking is more due to the irregular shape of carbon particles

and matrix particles. Bonding between particles is only

mechanical in nature, relying only on the irregularity of the pairs of

particles.

The DIPA of Politeknik Negeri Jakarta, Scheme of the

Leading of Study Program Research has funded this study, Contract Number: 350 /

PL3.18 / PN.00.03 / 2019, Fiscal Year 2019.

The author thanks P3M, Politeknik Negeri Jakarta.

- 1. I. Štubňa, T. Húlan, T. Kaljuvee, and L. Vozár, Appl. Clay Sci. 153 (2018) 23-28.

-

- 2. Š. Csáki, J. Ondruška, V. Trnovcová, I. Štubňa, P. Dobroň, and L. Vozár, Appl. Clay Sci. 157 (2018) 19-23.

-

- 3. S. Ojha, S.K. Acharya, and G.J. Raghavendra, Appl. Polym. Sci. 132[1] (2015) 1-7.

-

- 4. M. Yates, M.A. Martín-luengo, L.V. Argomaniz, and S.N. Velasco, Microporous Mesoporous Mater. 154 (2012) 87-92.

-

- 5. A.E. Pramono, M.B.T. Firdaus, W. Ratriomasyo, M.Z. Nura, and J.W.M. Soedarsono, J. Ceram. Process. Res. 18[10] (2017) 748-753.

- 6. Y. Yao, B. Gao, J. Fang, M. Zhang, H. Chen, Y. Zhou, A. E. Creamer, Y. Sun, and L. Yang, Chem. Eng. J. 242 (2014) 136-143.

-

- 7. Y. He, L. Lu, S. Jin, and S. Hu, Constr. Build. Mater. 53 (2014) 131-137.

-

- 8. Z. Terzopoulou, D. Bikiaris, K.S. Triantafyllidis, G. Potsi, D. Gournis, G.Z. Papageorgiou, and P. Rudolf. Thermochim. Acta 642 (2016) 67-80.

-

- 9. T. Gumula, A. Rudawski, J. Michalowski, and S. Blazewicz, Ceram. Int. 41[6] (2015) 7381-7386.

-

- 10. M.S. Amin, S.M.A. El-gamal, and F.S. Hashem, Constr. Build. Mater. 98 (2015) 237-249.

-

- 11. R.L. Menchavez, M. Fuji, T. Shirai, and T. Kumazawa, J. Eur. Ceram. Soc. 34[3] (2014) 717-729.

-

- 12. C. Maurício, R. Sanchez, S.N. Monteiro, N. Lalla, and N. Quaranta, J. Mater. Res. Technol. 2[2] (2013) 88-92.

-

- 13. B. Han, L. Zhang, C. Zhang, Y. Wang, X. Yu, and J. Ou. Constr. Build. Mater. 125 (2016) 479-489.

-

- 14. 14. A. Wang, X. Gao, R.F.G. Jr, and D.D.L. Chung, Carbon N. Y. 59 (2013) 76-92.

-

- 15. A.E. Pramono, M. Zaki, J. Wahyuadi, M. Soedarsono, and N. Indayaningsih, J. Ceram. Process. Res. 20 (2019) 1-7.

-

- 16. A.E. Pramono, M.Z. Nura, J.W.M. Soedarsono, and N. Indayaningsih, J. Ceram. Process. Res. 20[4] (2019) 333-346.

-

- 17. V. Mymrin, C.F.G. Santos, K. Alekseev, M.A. Avanci, M.A. Kreusch, T. Borga, O. Graupmann, F.L. Cavalin, R.A. Monteiro, and V.A. Ruy Federal. Appl. Clay Sci. 155 (2018) 95-102.

-

- 18. F. Pardo, M.M. Jordan, and M.A. Montero, Appl. Clay Sci. 157 (2018) 158-164.

-

- 19. Z. Li, H. Zhang, P. Zhao, X. He, and X. Duan. J. Korean Ceram. Soc. 55[1] (2018) 36-43.

-

- 20. A. Mocciaro, M.B. Lombardi, and A.N. Scian, Appl. Clay Sci. 153 (2018) 90-94.

-

- 21. F.O. Aramide and A.P. Popoola, J. Ceram. Process. Res. 19[2] (2018) 87-94.

- 22. N. Belmokhtar, H.E. Ayadi, M. Ammari, and L.B. Allal, Appl. Clay Sci. 162 (2018) 1-9.

-

- 23. A. Miras, E. Galán, I. González, A. Romero-Baena, and D. Martín, Appl. Clay Sci. 161 (2018) 176-183.

-

- 24. Y. He, L. Lu, S. Jin, and S. Hu, Constr. Build. Mater. 53 (2014) 131-137.

-

- 25. K.B. Choi, J.Y. Kim, S.M. Lee, K.H. Lee, and D.H. Yoon, J. Korean Ceram. Soc. 54[3] (2017) 257-260.

-

- 26. W. Sun, P. Zhang, K. Zhao, M. Tian, and Y. Wang, Wear 342-343 (2015) 172-180.

-

- 27. G. Zheng, J. Zhao, and Y. Zhou, Wear 290-291 (2012) 41-50.

-

- 28. L.M. Manocha, G. Prasad, and S. Manocha, Mech. Adv. Mater. Struct. 21[3] (2014) 172-180.

-

- 29. N.C. Kaushik and R.N. Rao, Tribiology Int. 103 (2016) 298-308.

-

- 30. A.E. Pramono, J. Mater. Sci. Eng. B 3 (2013) 700-706.

-

- 31. D.S. Kim, J.S. Kim, and C.I. Cheon, J. Korean Ceram. Soc. 53[2], (2016) 162-166.

-

- 32. H.P.A. Alves, J.B. Silva, L.F.A. Campos, S.M. Torres, R.P.S. Dutra, and D.A. Macedo. Ceram. Int. 42[16] (2016) 19086-19090.

-

- 33. D.O. Obada, D. Dodoo-Arhin, M. Dauda, F.O. Anafi, A.S. Ahmed, and O.A. Ajayi, Appl. Clay Sci. 150 (2017) 175-183.

-

- 34. Z. Hongxia, D. Yongsheng, Y. Xiaowei, O. Shunli, and L. Baowei, J. Ceram. Process. Res. 18 (2017) 604-610.

- 35. C.H. Ting, S. Ramesha, C.Y. Tan, N.I. Zainal Abidin, W.D. Teng, I. Urriés, and L.T. Bang, J. Ceram. Process. Res. 18[8] (2017) 569-574.

- 36. J. Park, J.G. Yeo, S. Yang, and C.H. Cho, J. Ceram. Process. Res. 19 (2018) 20-24.

- 37. S.H. Mahdi, I.A. Hamad, and A.M. Ibraheim, Mesopotamia Environ. J. Mesop. 17 (2016) 10-17.

- 38. J. Ondruška, Š. Csáki, V. Trnovcová, I. Štubňa, F. Lukáč, J. Pokorný, L. Vozár, and P. Dobroň. Appl. Clay Sci. 154 (2018) 36-42.

-

- 39. S.N. Khosla, R.K. Bedi, and C.S. Gupta, Trans. Indian Ceram. Soc. ISSN 5456 (2014) 8-12.

-

- 40. J.-W. Lee, W.-J. Lee, and S.-M. Lee, J. Korean Ceram. Soc. 53[6] (2016) 635-640.

-

- 41. Y.K. Seo, Y.W. Kim, T. Nishimura, and W.S. Seo, J. Eur. Ceram. Soc. 36[15] (2016) 3755-3760.

-

- 42. Y.K. Seo, Y.W. Kim, K.J. Kim, and W.S. Seo, J. Eur. Ceram. Soc. 36[16] (2016) 3879-3887.

-

- 43. P.M. Nigay, T. Cutard, and A. Nzihou, Ceram. Int. 43[2] (2017) 1747-1754.

-

- 44. J. Bourret, A. Michot, N. Tessier-Doyen, B. Nait-Ali, F. Pennec, A. Alzina, J. Vicente, C.S. Peyratout, and D.S. Smith, J. Am. Ceram. Soc. 97[3] (2014) 938-944.

-

- 45. I. Allegretta, G. Eramo, D. Pinto, and A. Hein, Appl. Clay Sci. 135 (2017) 260-270.

-

- 46. I. Allegretta, G. Eramo, D. Pinto, and A. Hein, Thermochim. Acta 581 (2014) 100-109.

-

- 47. D. Buncianu, N. Tessier-Doyen, F. Courreges, and J. Absi, Eur. J. Environ. Civ. Eng. 21 (2017) 1270-1284.

-

- 48. L. Randazzo, G. Montana, A. Hein, A. Castiglia, G. Rodonò, and D.I. Donato, Appl. Clay Sci. 132-133 (2016) 498-507.

-

- 49. J. Bourret, N. Tessier-doyen, R. Guinebretiere, E. Joussein, and D.S. Smith, Appl. Clay Sci. 116-117 (2015) 150-157.

-

- 50. Y.P. Delgado, M.H. Staia, O. Malek, J. Vleugels, and P. De Baets, Wear 317[1-2] (2014) 104-110.

-

- 51. G. Byeong-Choon and C. In-Sik, Materials (Basel). 10[7] (2017) 701.

-

- 52. Q.A. AL Rashid, H.M. Abuel-Naga, E.C. Leong, Y. Lu, and H. Al Abadi, Appl. Clay Sci. 156 (2018) 1-10.

-

- 53. Z. Chu, C. Jia, J. Liu, R. Ding, and G. Yuan, J. Ceram. Sci. Technol. 8[4] (2017) 499-504.

- 54. B.M. Bishui and J. Prasad, Trans. Indian Ceram. Soc. (2014) 109-115.

-

This Article

This Article

-

2020; 21(4): 465-478

Published on Aug 30, 2020

- 10.36410/jcpr.2020.21.4.465

- Received on Feb 19, 2020

- Revised on Mar 22, 2020

- Accepted on Mar 24, 2020

Services

Services

- Abstract

introduction

experiments

result and discussion

conclusion

- Acknowledgements

- References

- Full Text PDF

Shared

Correspondence to

Correspondence to

- Agus Edy Pramono

-

Department of Mechanical Engineering, Politeknik Negeri Jakarta, Jln. Prof. Dr. G.A. Siwabessy, Kampus UI. Depok 16425, Jawa-Barat, Indonesia

Tel : +62 811 829 833 or +62 217863530

Fax: +62 217863530 - E-mail: agus.edypramono@mesin.pnj.ac.id

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.