- Phases and morphorlogy of CuFeS2 films prepared by electrodeposition

Ming Ji, Kegao Liu* and Nianjing Ji

School of Materials Science and Engineering, Co-Innovation Center for Green Building of Shandong Province, Shandong Jianzhu University, Fengming Road, Jinan 250101, China

This work reports one

low-priced ways for production of CuFeS2 films on conductive glass

surface. CuFeS2 films were prepared by electrodeposition and

post-sulfurization treatment at 220 oC for 30 h in N2

atmosphere for the first time. CuFeS2 films were prepared by

electrodeposition with sulfate, ascorbic acid, complexing agent sodium citrate

as raw materials. When the deposition potential is -1.0 V and the

deposition time is 20 min, CuFeS2 thin films with good phrase

formation can be obtained at pH 4 and 0.02M Na2S2O3·H2O.

The phase of samples were characterized using X-ray diffraction (XRD). The

morphology of samples were characterized via scanning electron microscopy

(SEM). The composition of samples were characterized by energy dispersive

spectrometer (EDS). The crystallinity of CuFeS2 thin films prepared

under these conditions are relatively good. The microcosmic morphology of the

samples is flaky crystal. It is shows that post-sulfurization method is helpful

for the phase formation of CuFeS2 films electrodeposited.

Keywords: CuFeS2, Thin film, Photoelectric, Electrodeposition, Solar energy

Recently, Chalcopyrite CuFeS2 was classified as

indispensable and multi-functional materials [1] due to their abundance [2],

their higher conversion efficiency [3], higher absorption

coefficients [3] and lower toxicity [2, 3] compared with other

semiconducting materials. It was found to be a semiconductor with a zero or

narrow band gap [4]. It has been considered as a prospective material

with wild applications including energy storage, solar

energy generation [5-8]. The preparation methods of optoelectronic materials

including chemical co-reducton [9], vacuum evaporation

[10], solution-chemical method [11-13], hydro-thermal

method [3, 5, 8, 14], electrodeposition [15], flash evaporation technique [4],

high energy ball milling [16, 17], thermal-injection synthesis [2] and so on.

Se Hoon Kim studied the influence of surface roughness on

the efficiency of a flexible organic solar cell [18]. At the same time,

Cuan-Lin Chiu researched the influence of doping iron ions into Cu(In,Ga)Se

films [19]. Thin-film batteries also has been studied for a long time. Kegao

Liu has prepared many kind of absorption layer films, such as CuInSe2

[20], CuInS2 [21] and ZnS [22] successfully, for example. As a kind

of ternary optoelectronic material, CuFeS2 has strict technological

requirements in the preparation process, and the process parameters of

electrodeposition have great influence on the properties of CuFeS2

preparation [15], so it is necessary to explore an optimum techno- logical condition.

Eelectrodeposition method has the advantages of non-vacuum

and low cost, the deposition process can be carried out at room temperature,

and a uniform and dense film can be prepared [15]. The thin film can be

crystallized by the sulfurization treatment, and the film is

crystal structure of chalcopyrite. The electrodeposited CuFeS2

is often prepared by sulfurization treatment to improve the composition and

crystallization, thus improving the photoelectric performance of the film.

This work used CuSO4·5H2O, (NH4)2Fe(SO4)·6H2O,

and Na2S2O3·H2O as the basic raw

material, CuFeS2 thin films were prepared by using the constant

potential method. The effects of the pH value and the con- centration of Na2S2O3·H2O

on the phase formation and morphology of the

films were investigated and characterized.

Solution preparation: 0.01 M CuSO4·5H2O,

0.01 M (NH4)2Fe(SO4)·6H2O,

0.01 M ascorbic acid, 0.01 M complexing agent sodium citrate and a

certain con- centration of Na2S2O3·H2O.

The CuFeS2 thin films were electrodeposited at different pH and

concentra- tions of Na2S2O3·H2O

on the FTO-coated glass surface. The deposition time was 20 min and

deposition potential was -1.0 V. The films were prepared via using

electrodeposition and post-sulfurization at 220 oC for

30 h in an N2 atmosphere. The electrodeposition of thin films

was obtained via the PARSTAT 2273 electroche-mical workstation. All the experiments can be guaranteed

to be variable unique.

The crystal structure of samples were analyzed by the

Bruker D8 Advance XRD system with Nifiltered Cu-Kα (λ=1.5059 Å).

The samples’ surface morphology were analyzed by using

scanning electron microscope (SEM) with a model of JSM-7610F made by Japan

Electronics Co., Ltd. The composition of the film was detected by using energy

dispersive spectrometer (EDS) with a model of JSM-7610F made by Japan

Electronics Co., Ltd. The resistivity was measured by Four Probe Resistivity

Meter.

The

effect of pH of system on phase formation and morphology of CuFeS2

thin films

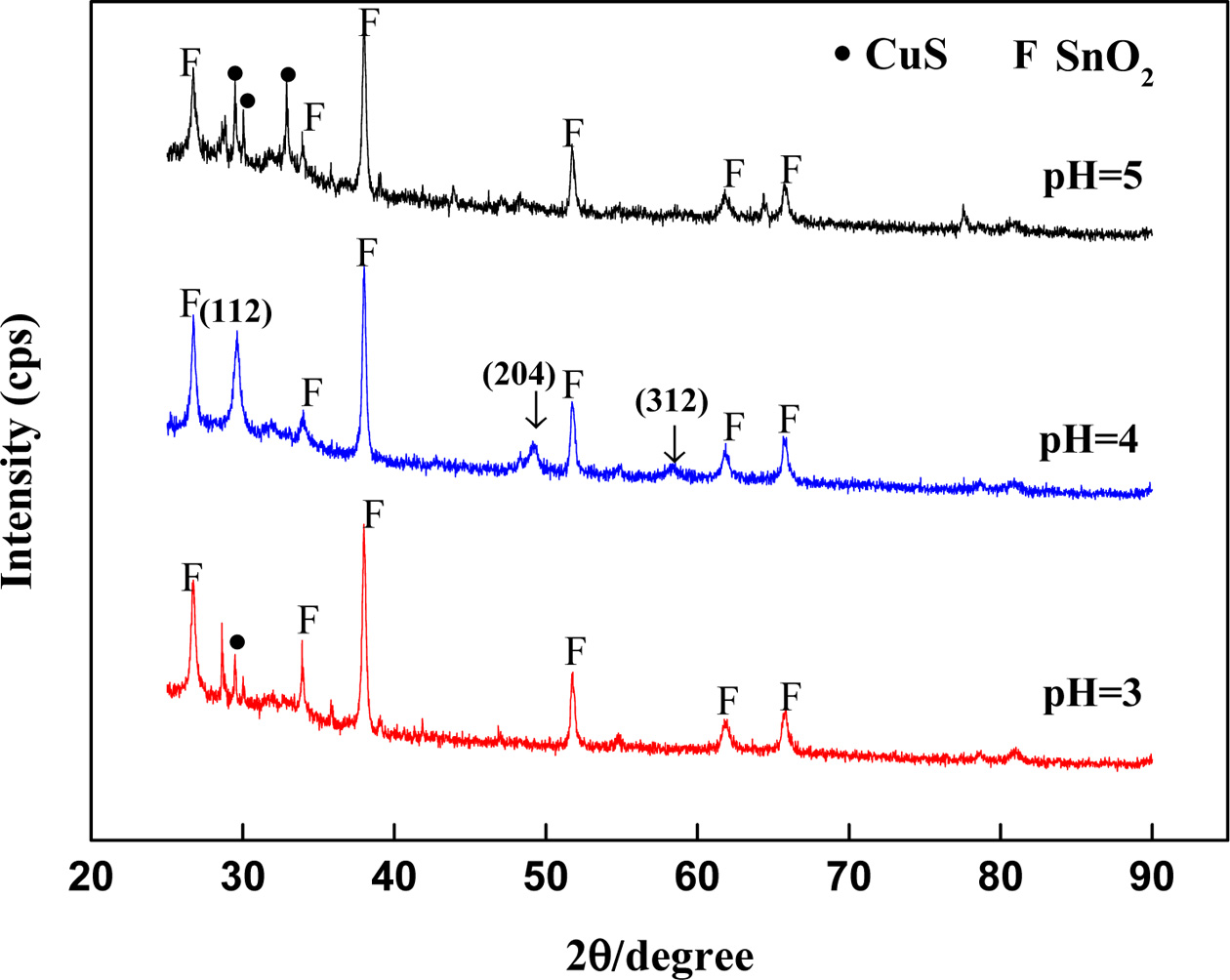

The crystal structures of the synthesized products were

characterized by XRD. Fig. 1 shows the XRD patterns of

CuFeS2 thin films deposited on FTO substrate. FTO

substrate is one kind of conductive glass. Through the phase retrieval, it can

be seen that there are three peaks at 2θ angles with 29°, 48° and 57°. These

three peaks are matched with the three strong peaks of copper iron sulfide. The

peaks correspond to (112), (204) and (312) crystal planes of the chalcopyrite

structured CuFeS2 (Card No.74-1737) at pH 4, which is in consistent

with other reports [5]. Additional peaks resulting from FTO (mostly SnO2,

Card No.46-1088) have been identified as F. Each phase of the sample contains a

glass substrate. It may account for the thickness of the film. It can also be

observed from the Fig. 1 that the impurity phase CuS (Card No.75-2233) appears

in the other samples except the sample with pH 4. Only at pH 4 can the pure

phase of the target product be obtained. Therefore, the optimal pH value of the

system is 4.

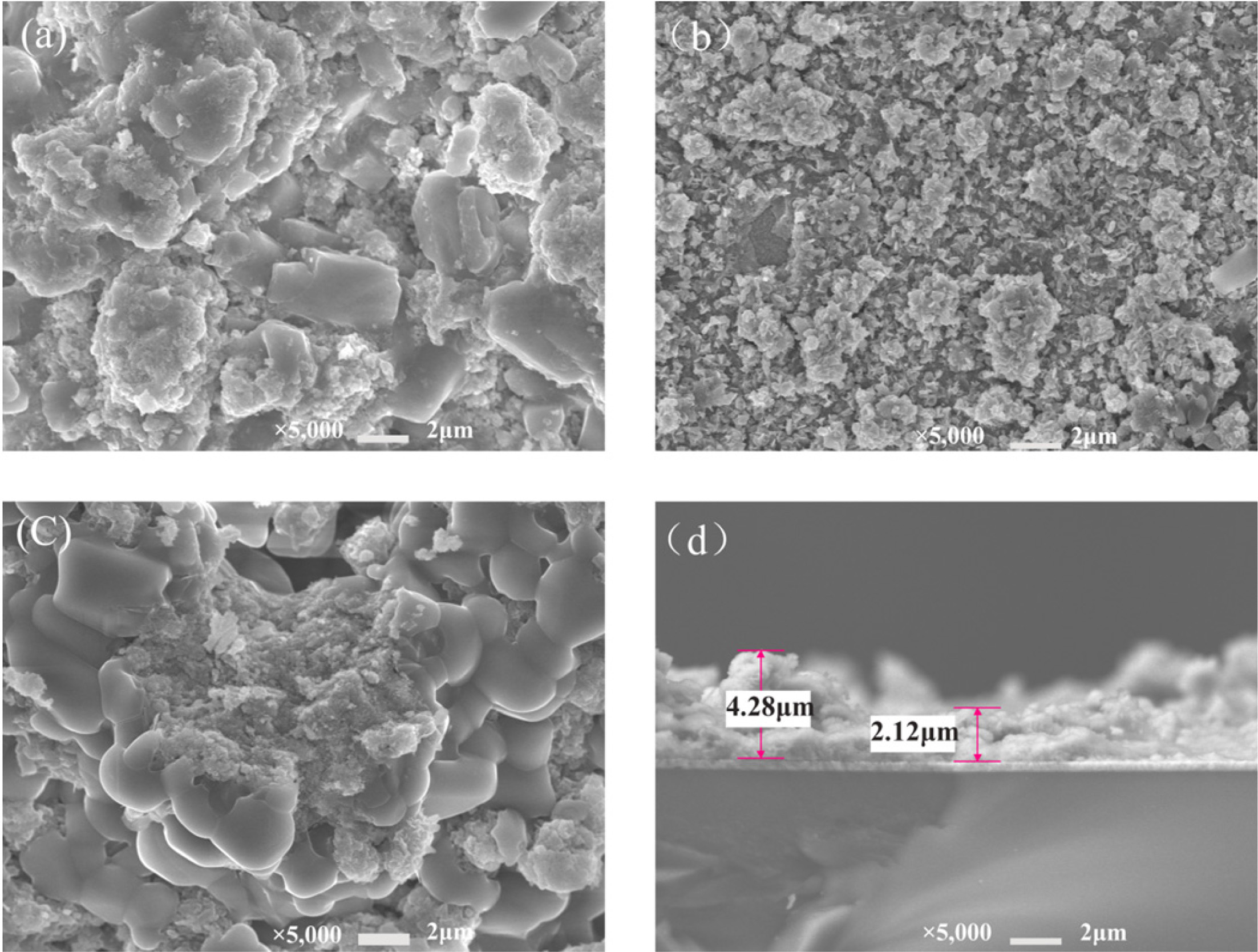

Fig. 2 shows the morphology of the synthetic CuFeS2

prepared by electrodeposition after sulfurization. It was found that the

surface of the film was relatively uniform, the degree of crystallization was

relatively good, and the particles were relatively small at pH 4. It can be

seen the microcosmic morphology of the samples is flaky crystal. The thickness

of the thin film varied from 1 to 5 μm.

For the above study, it is concluded that the structure

and morphology of films depend on pH mostly.

The

effect of concentration of Na2S2O3·H2O

on phase formation and morphology of CuFeS2 thin films

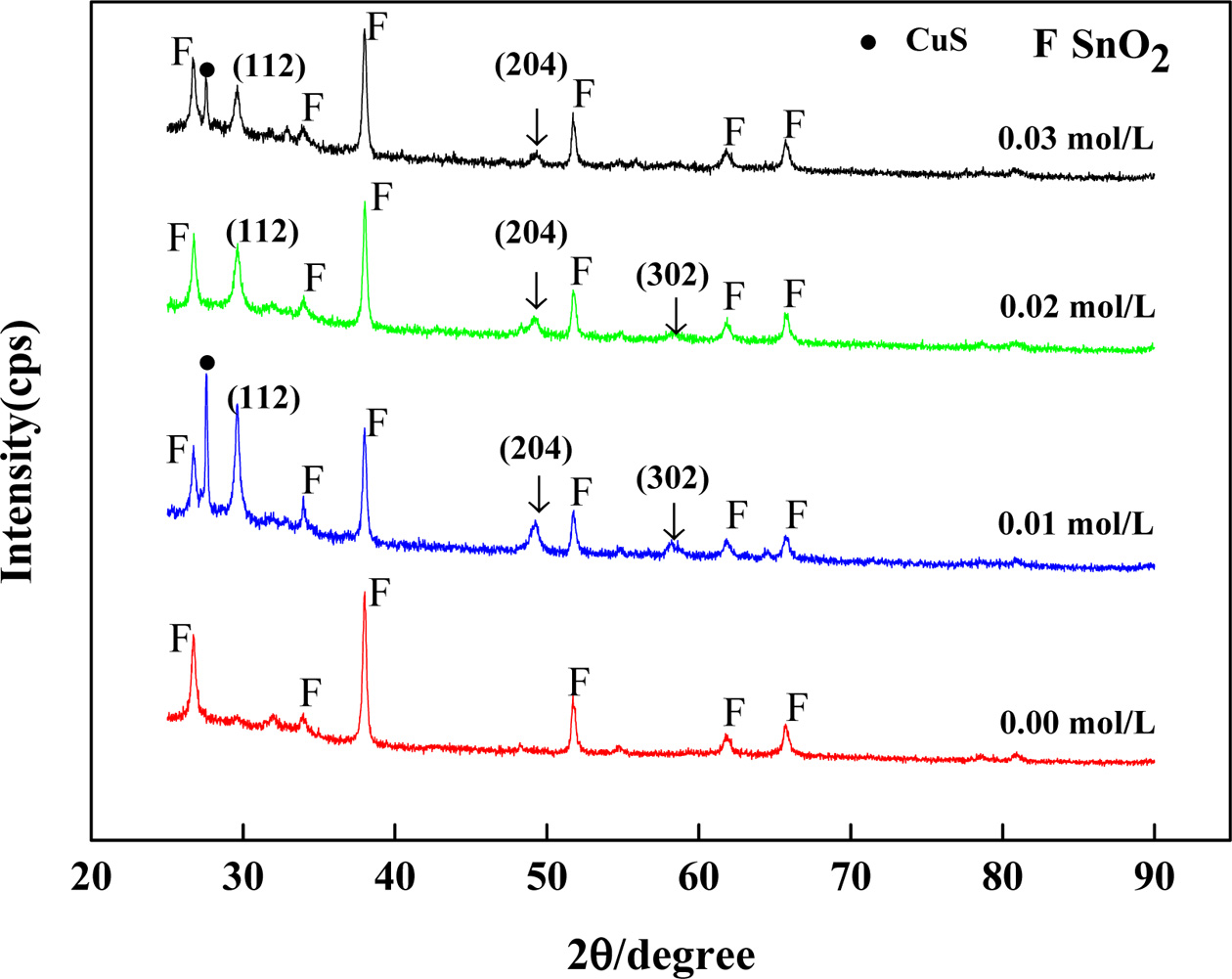

The crystal structures of the synthesized products were

characterized by XRD. Fig. 3 shows XRD patterns of CuFeS2

thin films with different concentration of Na2S2O3·H2O

after sulfurization. It can be seen that there are three diffraction peaks at 2θ

angles with 29°, 48° and 57°, except that the concentration of Na2S2O3·H2O

is 0.00 M. These three peaks are matched with the three

strong peaks of copper iron sulfide. The diffraction peaks correspond to (112),

(204) and (312) crystal planes of the chalcopyrite structured CuFeS2

(Card No.74-1737), additional peaks resulting from FTO (mostly SnO2,

Card No.46-1088) have been identified as F. It can also be observed from the

Fig. 3 that the impurity phase CuS (Card No.74-1234) appears in sample of

0.01 M and 0.03 M. It is concluded that the purity phase could be

prepared when sample’s concentration of Na2S2O3·H2O

is 0.02 M. Therefore, the optimal concentration of Na2S2O3·H2O

is 0.02 M.

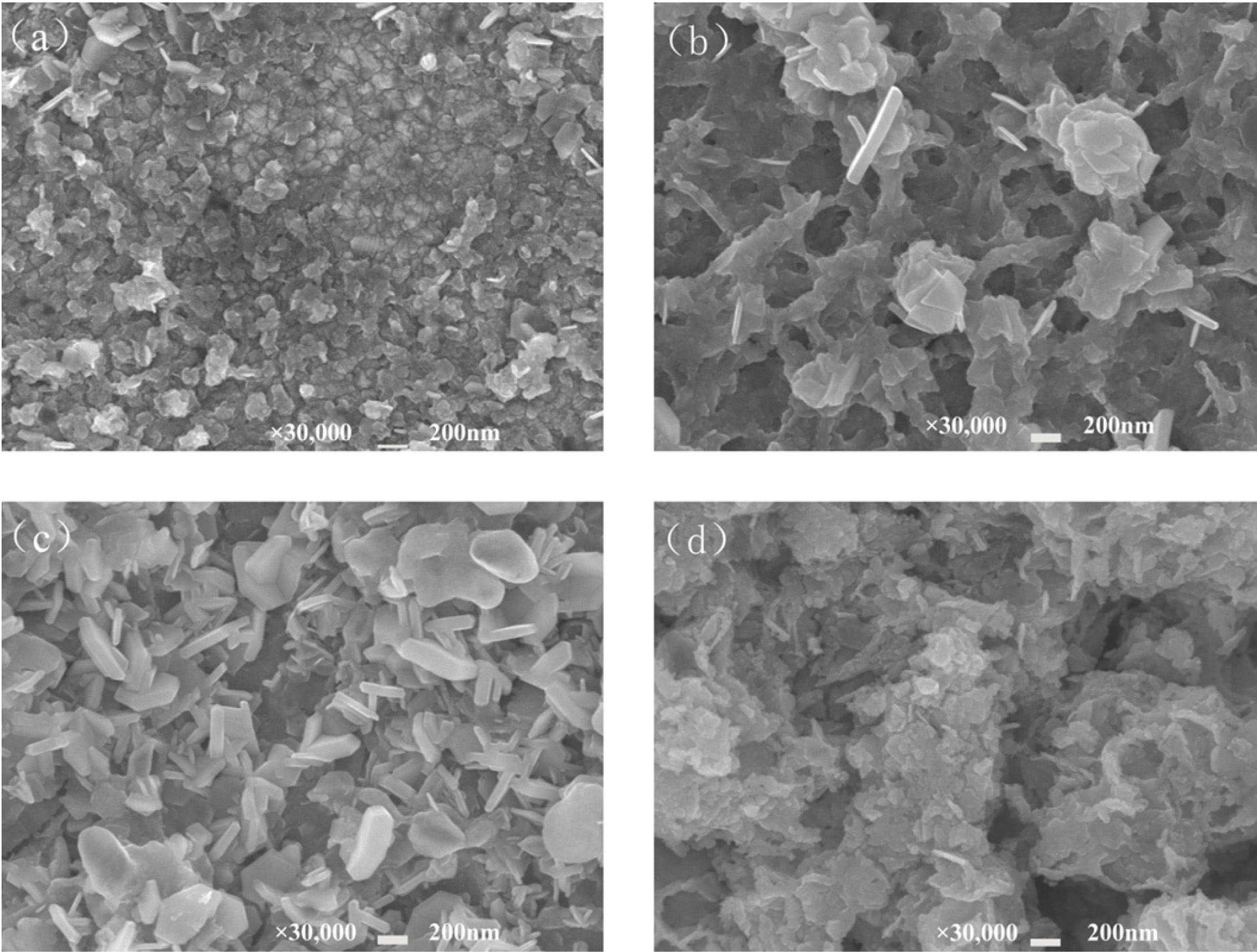

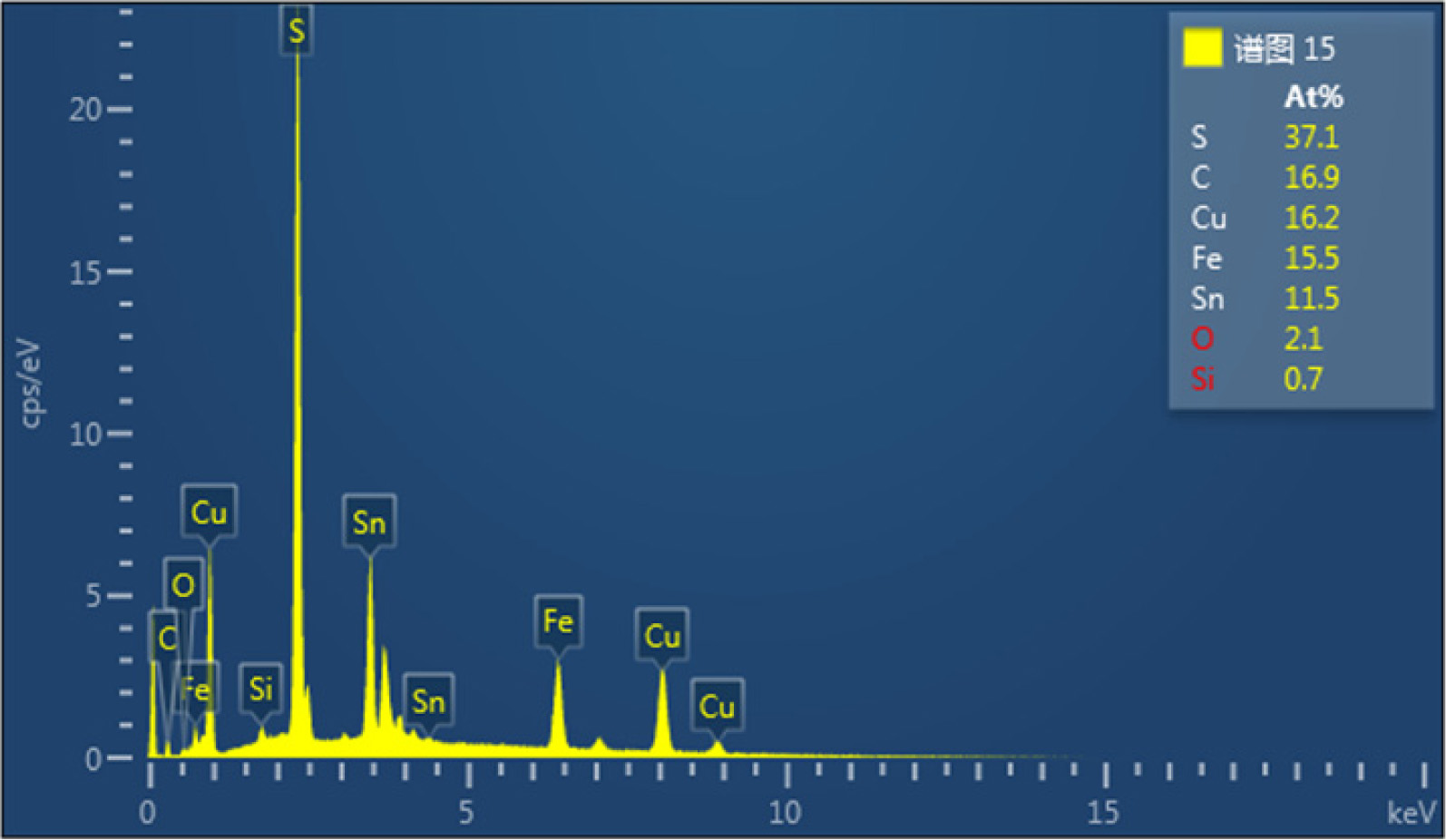

Fig. 4 shows the morphology of the synthetic CuFeS2

prepared by electrodeposition after sulfurization. It was found that all the

samples showed flake products except that the concentration of Na2S2O3·H2O

is 0.00 M. In order to determine the composition of the flake

product further, the energy spectrum of the flake target product was detected.

From Fig. 5, it was found that the ratio of copper - iron

- sulfur atom was roughly in accordance with the atomic ratio of the target

product 1:1:2. The thin film’s resistivity is 2.016 Ω·cm.

|

Fig. 1 XRD patterns of thin films prepared at pH 3-5 after sulfurization. |

|

Fig. 2 Morphology of samples prepared by electrodeposition after sulfurization. (a) pH = 3; (b) pH = 4; (c) pH = 5; (d) Cross section of thin film. |

|

Fig. 3 XRD patterns of thin films prepared with different of Na2S2O3·H2O after sulfurization. |

|

Fig. 4 Morphology of samples prepared by electrodeposition after sulfurization.(a) 0.00 M; (b) 0.01 M; (c) 0.02 M; (d) 0.03 M. |

|

Fig. 5 EDS spectrum showing the elemental composition of synthetic CuFeS2. |

In summary, CuFeS2 films has been prepared

successfully on conductive glass surface by two-step approach:

electrodeposition and post-sulfurization. CuFeS2

films were prepared by electrodeposition and post-sulfurization treatment at

220 oC for 30 h in N2 atmosphere. There are

four highlights in this work. The first one, when deposition potential is

-1.0 V and the deposition time is 20 min, CuFeS2 thin

films can be obtained at pH 4 and 0.02 M Na2S2O3·H2O.

Secondly, the crystallinity of CuFeS2 thin films prepared under

these conditions are relatively good. The microcosmic morphology of the samples

is flaky crystal by SEM. Furthermore, the sample’s phase has been confirmed as

chalcopyrite structure. At the same time, the ratio of copper - iron - sulfur

atom by EDS was roughly in accordance with the atomic ratio of the target

product. These results are meaningful for proving that post-sulfurization is a

useful measure for preparation of CuFeS2 films.

This work was financially supported by the National

Natural Science Foundation of China (No.51272140) and the Innovation Team of

the Co-Innovation Center for Green Building of Shandong Province in Shandong

Jianzhu University.

- 1. N. Wu, Y. Li, M. Zeng, J. Gao, Y. Tang, Z. Zeng, Y. Zheng. J. Solid State Chem. 271(2019) 292-297.

-

- 2. E. Bastola, K.P. Bhandari, I. Subedi, N.J Podraza, Randy J Ellingson. MRS Commun. 8[3] (2018) 970-978.

-

- 3. S. Sil, A. Dey, S. Halder, J. Datta, P.P. Ray. J. Mater. Eng. Perform. 27[6] (2018) 2649-2654.

- 4. B. Korzun, A. Galyas. J. Electron. Mater. 48[5] (2019) 3351-3354.

- 5. K.M. Deen, E. Asselin. Electrochim. Acta. 297 (2019) 1079-1093.

-

- 6. Q. Jiang, R. Chen, X. Guo, Y. Zhu, W. Cheng, W. Li, X. Yang, H.C. Chen. Sol. Enrgy. 179 (2019) 59-66.

-

- 7. I.S. Lyubutin, C.-R. Lin, S.S.Y.-J. Siao, M.O. Shaikh, K.O. Funtov, S.C.S. Wang. ACTA Mater. 61[11] (2013) 3956-3962.

-

- 8. K.M. Deen, E. Asselin. Electrochimica. Acta. 212 (2016) 979-991.

-

- 9. K. Liu, J. Li, Y. Xu, H. Li, W. Gao. Results. Phys. 11 (2018) 749-754.

-

- 10. L. Barkat, N. Hamdadou, M. Morsli, A Khelil, J C Bernède. J. Cryst. Growth. 297[2] (2006) 426-431.

-

- 11. P. Kumar, S. Uma and R. Nagarajan. Chem. Commun. 49[66] (2013) 7316-7318.

-

- 12. Y.-H.A.Wang, N.Bao, A. upta. Solid State Sci. 12[3] (2010) 387-390.

-

- 13. D. Liang, J. Li, and G. Pang. J. Mater. Sci. 51[11] (2016) 5412-5420.

- 14. H. Yu, J. Xu, Y. Hu, H. Zhang, C. Zhang, C. Qiu, X. Wang, B. Liu, L. Wei, J. Li. J. Mater. Sci.: Mater. Electron. 30[13] (2019) 12269-12274.

- 15. J. Zhou, S. Yu, X. Guo, L. Wu, H. Li. Curr. Appl. Phys. 19[2] (2019) 67-71.

-

- 16. N. Poloko, G. Danha, T. Gaogane. Procedia Manufacturing. 35 (2019) 488-493.

-

- 17. A.O. Moghaddam, A. Shokuhfar, P. Guardia,Y. Zhang, A. Cabot. J. Alloy. Compd. 773 (2019) 1064-1074.

-

- 18. S.H. Kim, D.Y. Lee, Y.-J. Oh. J. Ceram. Process. Res. 21[1] (2020) 42-49.

- 19. C.-L. Chiu, T. Subburaj, S. Som, C.-Y. Ou, C.-H. Lu. J. Ceram. Process. Res. 18[10] (2017) 754-759.

- 20. K. Liu, Y. Xu, Q. Sun, H. Li, H. Wu. Results. Phys. 12 (2019) 766-770.

-

- 21. K. Liu, J. Li, Y. Xu, L. Shi, W. Gao. Cryst. Res. Technol. 53[2] (2018)1700203.

-

- 22. K. Liu, W. Song, Y. Xu, J. Li, Z. Wang. J. Ceram. Process. Res. 19[2] (2018) 146-149.

This Article

This Article

-

2020; 21(4): 456-459

Published on Aug 30, 2020

- 10.36410/jcpr.2020.21.4.456

- Received on Feb 6, 2020

- Revised on Mar 24, 2020

- Accepted on Apr 2, 2020

Services

Services

- Abstract

introduction

experimental details

results and discussion

conclusions

- Acknowledgements

- References

- Full Text PDF

Shared

Correspondence to

Correspondence to

- Kegao Liu

-

School of Materials Science and Engineering, Co-Innovation Center for Green Building of Shandong Province, Shandong Jianzhu University, Fengming Road, Jinan 250101, China

Tel : ++86 15610183153 - E-mail: liukg163@163.com

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.