- Synthesis of zinc substituted cobalt ferrites via standard double sintering ceramic technique: A study on their structural, magnetic and dielectric properties

Tamanna Mariama,b, I. N. Eshab, M. N. I. Khanc, Shamima Choudhuryb and Kazi Hanium Mariab,*

aDepartment of Physics and Astronomy, University of Toledo, Toledo, Ohio, USA

bDepartment of Physics, University of Dhaka, Dhaka-1000, Bangladesh

cMaterial Science Divisions, Atomic Energy Centre, Dhaka-1000, Bangladesh

A series of Co1-xZnxFe2O4

ferrites with x = 0.0, 0.1, 0.2, 0.3, 0.4, 0.5 were synthesized

using the standard double sintering ceramic technique. The single-phase cubic

spinel structure of the samples was confirmed from the X-ray diffraction

patterns and the sharp high intensity peak revealed that the samples are in

good crystalline form. The lattice parameters were observed to increase with

the increasing of Zn concentration. By increasing the concentration of Zn

content, a significant increase in the density and a subsequent decrease in

porosity and grain size were observed. The dielectric constant (ε′) of the

sample is found to decrease with the increase in frequency. Dielectric relaxation

peaks were observed for the frequency dependence of dielectric loss curves. The

dc resistivity at different temperatures was studied and all the samples were

of semiconductor nature. The saturation magnetization was found to be reduced

as the Zn substitution was increased and consequently permeability decreases.

Keywords: X-ray diffraction, SEM, Permeability, Dielectric, Anisotropy Constant

The spinel ferrite, MFe2O4 (M=Co,

Mn, Ni, Zn etc.) with general formula (MδFe1−δ)[M1−δFe1+δ]O4

where, δ represents degree of inversion [1, 2] have remarkable

electrical and magnetic properties that can be tuned by ion substitution. Such

materials are considered as promising candidates for microwave and

magneto-optic devices, high-frequency catalysis, magnetic drug delivery,

magnetic resonance imaging (MRI), radio-frequency hyperthermia and high-density

recording medium [1-3]. Cobalt ferrite (CoFe2O4)

has a high cubic magneto-crystalline anisotropy, high coercivity and moderate

saturation magnetization [3]. These properties of cobalt ferrite

can be tuned by substituting various metal ions in the ferrite lattice.

Substitution of small amount of non-magnetic Zn ions generates cation

redistribution in the octahedral [B] and tetrahedral [A] sites of the spinel

structure which makes changes in the saturation magnetization and coercivity of

the materials [4]. In CoFe2O4 ferrites Co2+

ions occupy octahedral [B] sites and Fe3+ ions are equally

distributed between tetrahedral and octahedral sites. It is reported that Zn2+

can continuously migrate to tetrahedral and octahedral positions which has

significant impact on the magnetic and electrical properties of ferrites [4].

Therefore, sub- stitution of Zn2+

in CoFe2O4 makes it a hard magnetic material

with high Curie temperature and good chemical stability

[5]. Co-Zn ferrite is suitable in high frequency magnetic applications,

magnetic recording applications (audio–video tapes) and high-density digital

recording disks etc. [6] because of its high electrical resistivity and

negligible eddy current losses. There are many reports on Co-Zn ferrites

synthesis in the literature. A. Khan et al. [7] by ceramic method, S. Singhal

et al. [8] by sol-gel-route, S. Tapdiya and A.K. Shrivastava [9], M.T.

Jamil et al. [10] by chemical co precipitation method, R. Rani et al. [11] by

solution combustion method, S.T. Alone and K.M. Jadhav, [12] by wet chemical

co-operation technique prepared the samples. In this paper, Co1-xZnxFe2O4(x=0.0-0.5)

ferrites are synthesized by cost effective double sintering solid state

reaction method [7] which involves amalgamating the powdered particles together

through solid state diffusion process at an elevated temperature below the

melting points of the constituents. This is a two-step process

where the pre-sintering stimulates phase formation and

sintering expedites grain growth with densification. As such, the prepared

samples are less porous, denser, harder and has greater

flexural strength [7, 13]. Thus, the sintering

process gives a microstructure of the samples with conductive grains and

improves grain boundaries. But the temperature and duration need to be chosen carefully in order to

attain the particular characteristics of the samples.

Moreover, sintering process prevents

deformation and cracking of samples. Here, we have

carried out direct substitution of nonmagnetic Zn2+ for Co in cobalt

ferrite by double sintering process in order to investigate the effect on

magnetic behavior. Zn2+ substitution is likely to affect the

cation distribution and thereby significantly alter the magnetic

properties.

All ferrite samples were synthesized by double sintering

ceramic process. The materials used in this study were CoO, Fe2O3

and ZnO and mixed together to form the composition of Co1-xZnxFe2O4(x = 0.0-0.5)

where “x” is the Zn concentration in CoFe2O4 ceramic

compound. Mixtures of these raw materials were grinded into extremely fine

powder for 4 hours. The prepared powder was kept in programmable furnace for

calcination process. The calcination temperature was 750 oC

and it was calcined for 3 hours. After calcination, they were

grinded again. Finally, the pellets were made from the powders using hydraulic

pressure. Then the samples were sintered for 2 hours at 1050 oC.

Characterization

The crystalline and cubic spinel structure of the ceramic

samples was studied by an X-ray Diffracto-

meter (XRD) using PHILLIPS PRO XRD SYSTEM in the 2θ range from 20o

to 70o. The specimens were exposed to CuKα

radiation of wavelength, λ = 1.54178 Å with a

primary beam of 40 kV and 30 mA with a sampling pitch of 0.02o

and time for each step data collection was 1.0 sec. The lattice parameter

of the synthesized samples was estimated using the relation [2]

where, q

is the Bragg’s angle [14].

The X-ray densities of the samples were estimated using

the relation [2]

where Z is the number of molecules per unit cell of spinel

lattice, M is the molecular weight of the samples, N is the Avogadro’s number

and a is the lattice parameter of the samples.

The bulk density of the samples was calculated by using

the formula

And we have measured the porosity of the samples using the

formula given below,

The surface morphology and compositional features were

studied using a scanning electron microscope (FEI SEM). dielectric and

permeability measurements were conducted by Impedance Analyzer (WAYNE KERR

PRECISION-6500B). The real part of dielectric constant was calculated using the

formula,

Here, C is the capacitance of the pellet, L is the

thickness or height of the pellet, A is the area of cross-section of the flat

surface of the pellet, ![]() is the

dielectric constant at free space.

is the

dielectric constant at free space.

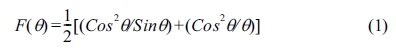

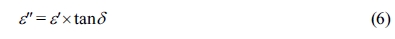

The imaginary part of the dielectric constant is,

with tand

being the loss tangent.

The quality factor was measured using the formula

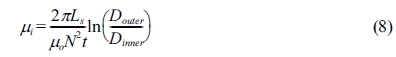

The initial permeability was measured by using the formula

[15]

Where, Ls is the inductance in Henry, N is the

number of turns of copper wire in the torroid, Douter indicates the

outer diameter and Dinner stands for the inner diameter of the

torroid.

To determine the temperature dependent resistivity,

“KEITHLEY 6514 SYSTEM ELECTROMETER” a small oven and a thermocouple-based

thermometer had been used.

The resistivity was calculated using the formula,

Where, r

denotes the specific resistance, L is the length of the specimen and A

indicates the area of cross section.

Magnetic properties of the samples were measured by a

Vibrating Sample Magnetometer (EV9 MICROSENSE VSM). All

the hysteresis magnetic measurements were carried out at room temperature.

Anisotropy constant has been calculated by using the formula,

with Hc is Coercive field and Ms

denotes Saturation Magnetization.

Structural

Properties

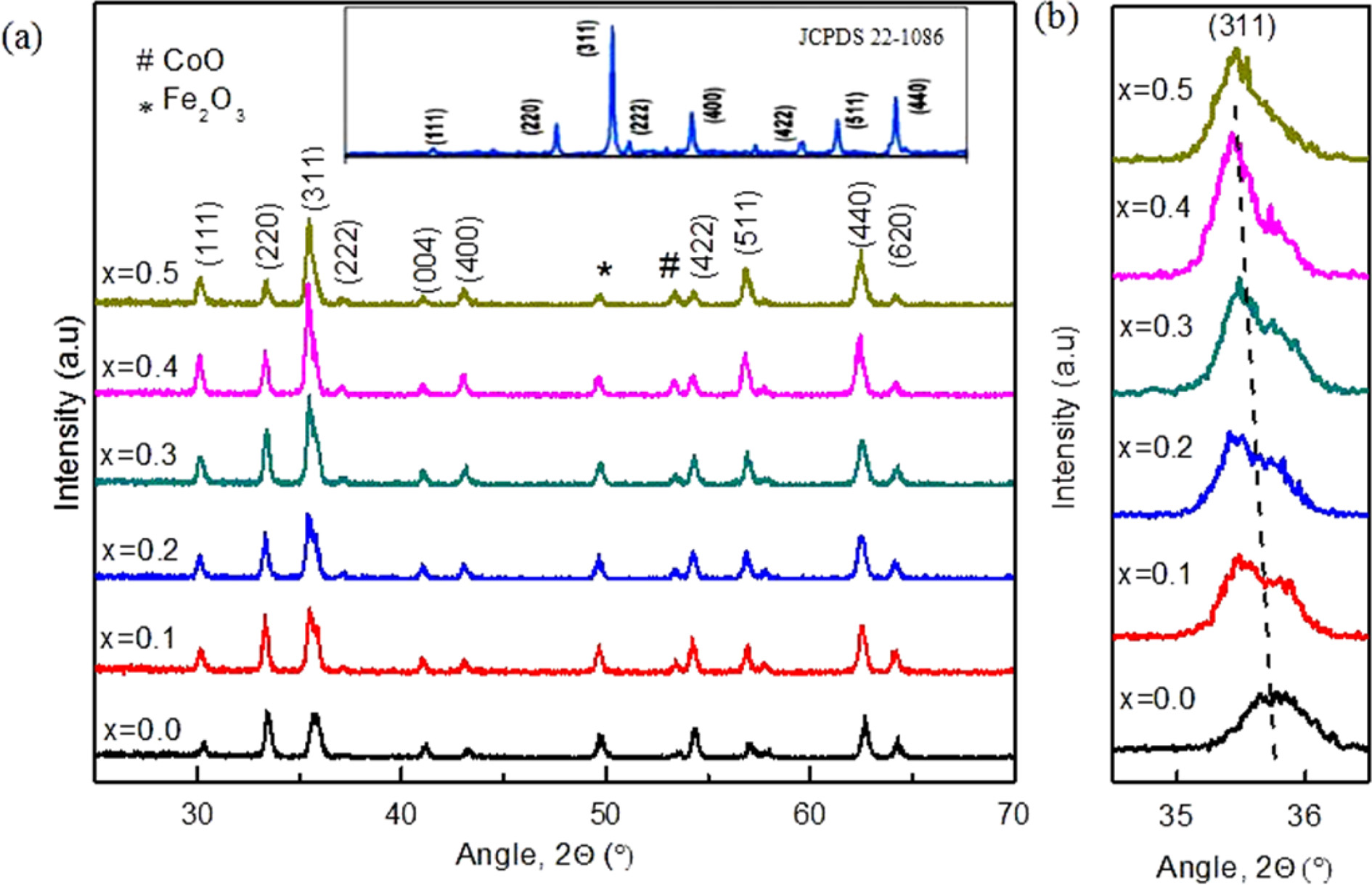

The structural characteristics of Zn doped Cobalt ferrites

with compositions of Co1-xZnxFe2O4(x = 0.0-0.5)

were measured by X-ray diffraction technique shown in Fig. 1. The miller

indices were indexed according to JCPDS card no 22-1086 [16].

The fundamental reflections from the planes of (220), (311),

(511), (440) are charac-

terizing the single-phase cubic spinel structures [17]. The

sharp peak reveals that the samples are in good crystalline form. Reflection

from the other planes (400), (422) has also been observed

with weak intensities. Impurity peaks for Fe2O3 and

CoO were detected which suggests the occurrence

of a few unwanted chemical reactions at the time of sintering.

In this sample, it is observed that the highest intensity peak was shifted to

lower angle with the increase of Zn content (Fig. 1(b)). This shifting

of highest intensity peak towards lower angle is attributed to have higher

inter-planar distance and increase in cell volume. The intensity of the highest

peak is found to increase with increase of Zn content which indicates the

crystalli- zation and spatial position

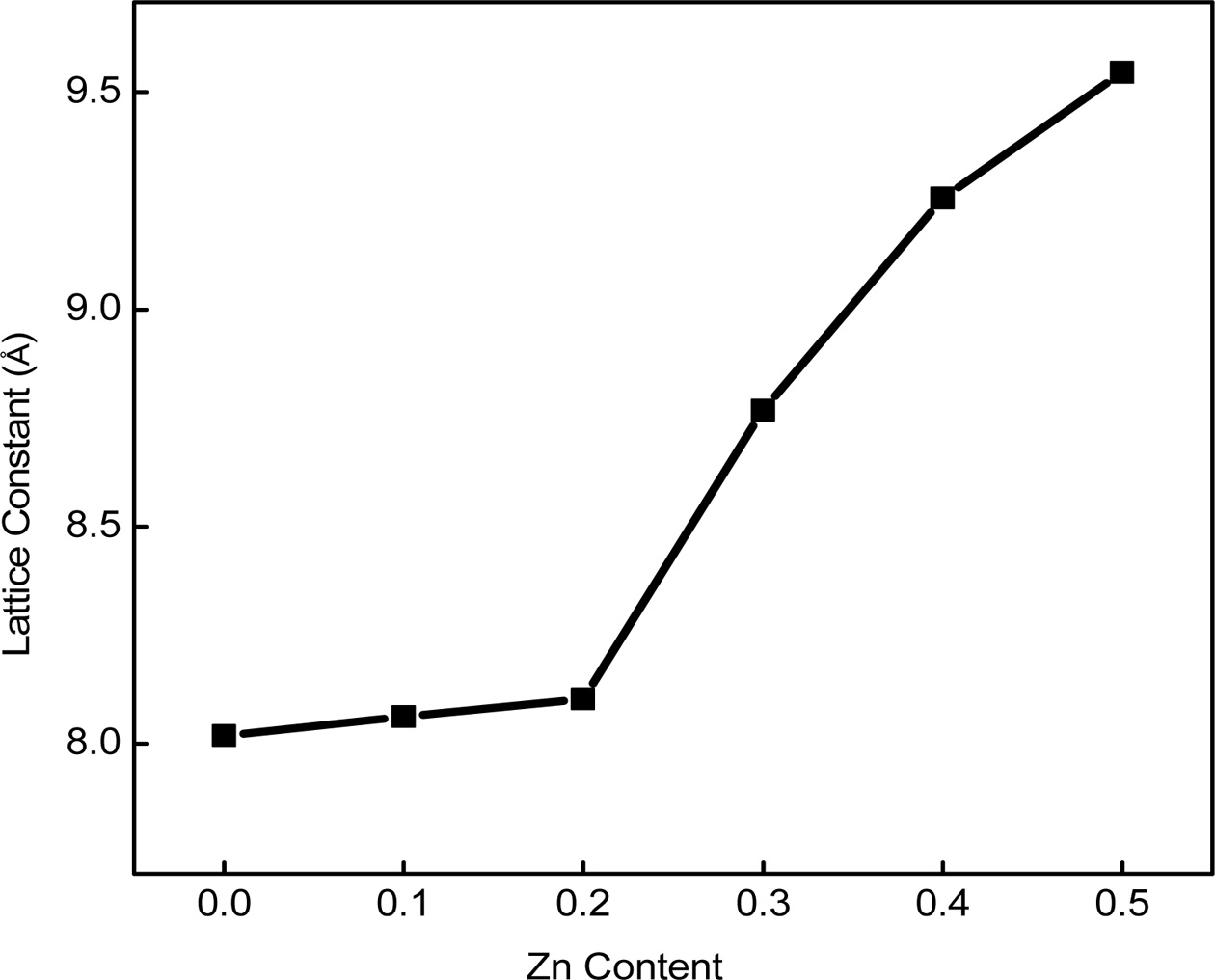

of the substituted atom. To determine the exact value of lattice parameter,

Nelson-Riley (N-R) extrapolation method was used [2]. The effect of Zinc substitution

on the lattice constant is shown in Fig. 2. From this figure, it is found that

the lattice parameter enhances with the increasing Zn content. This increment

may be related to the replace- ment of

Co2+ ion with smaller ionic radius (0.745 Å) [18] by Zn2+

ion with larger ionic radius (0.82 Å) [19]. During the crystallization

process, the unit cell expands to assemble

the substituted large Zn2+ ions. Thus, the addition of Zn2+ in the Cobalt ferrite is expected to

increase the lattice parameter. Similar trend has been reported in

Zn-Mg-Cu [20]; Zn-Mg [21] and Ni-Zn [22] and Cu-Zn [2] ferrites.

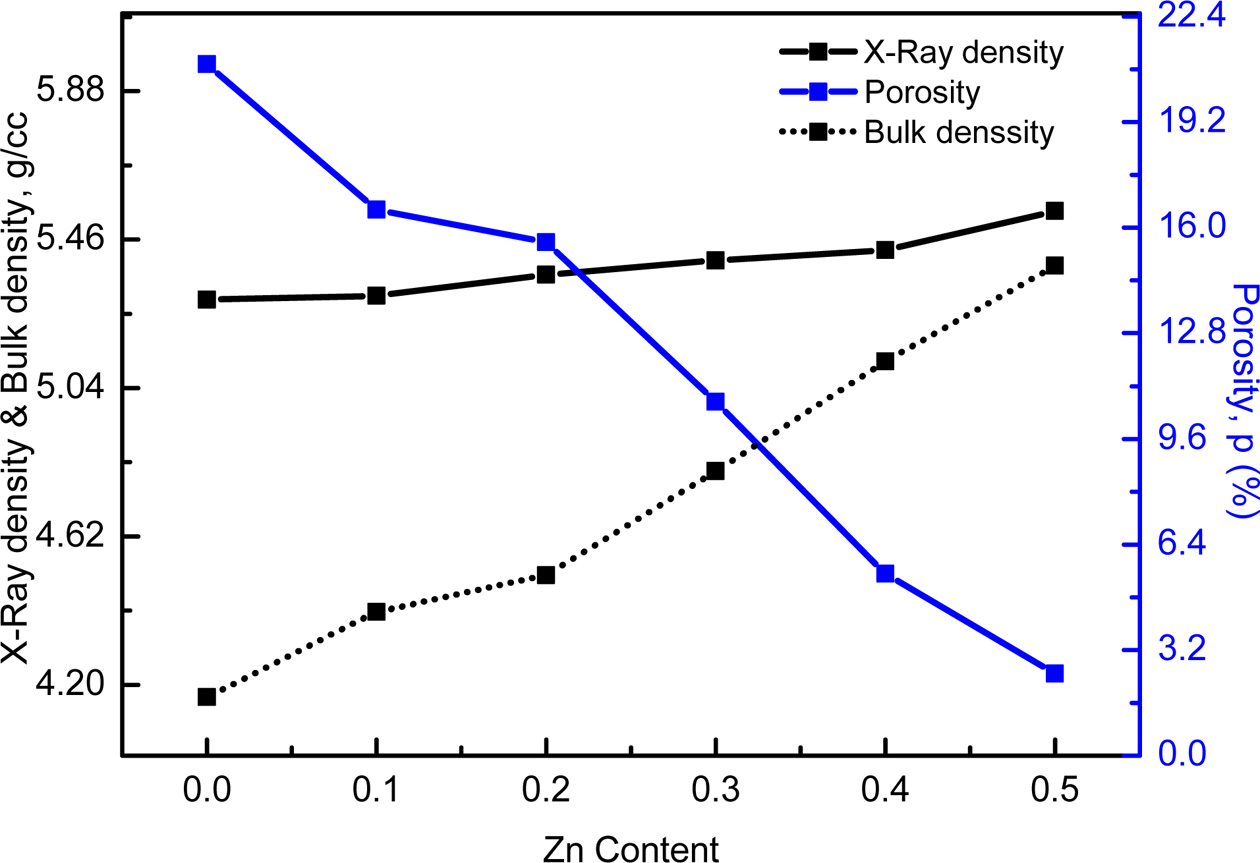

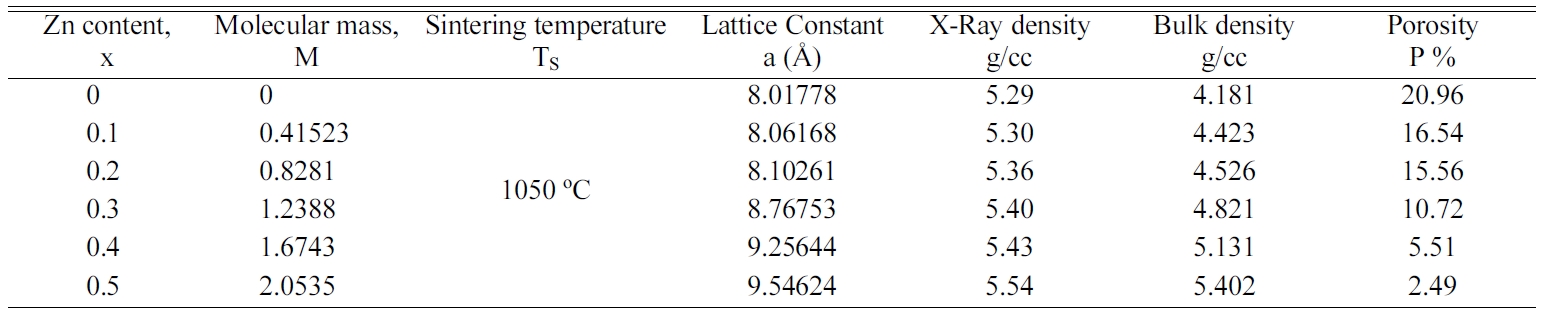

The effect of Zn substitution on lattice parameter, X-ray density,

Bulk density and porosity is shown in Table 1.

It is observed from Fig. 3 that the X-ray density, ρx

and bulk density, ρB increase increase with increasing Zn

content. The increase in X-ray and bulk density may be due to the increase in

molecular weight of the various compositions of Co-Zn ferrites.

Generally, the homo- geneous

distribution of any element in other element may increase the

density. This significant increase of the density can be explained by the

introduction of Zn ions through sintering and lattice diffusion. The lattice

diffusion increases the diffusion path length which in turn accelerates the

rate of cation inter-diffusion in the samples [23]. As a result, the density

increases with the introduction of Zn content. It is also observed from this

figure that the X-ray density is higher than the bulk density. This might be

evolved with the existence of pores on the macroscopic scale and vacancies in

the lattice on atomic scale during the sintering process or at the time of

sample preparation [13]. The smaller value of bulk density, ρB compared

to the X-ray density, ρx might be due to the presence of

inter-granular porosity. On the other hand, porosity exhibits completely

opposite trend as shown in Fig. 3. The porosity is found to decrease with the

increase in Zinc content as the samples become denser. Similar

results were observed in several ferrites [3, 13, 24, 25].

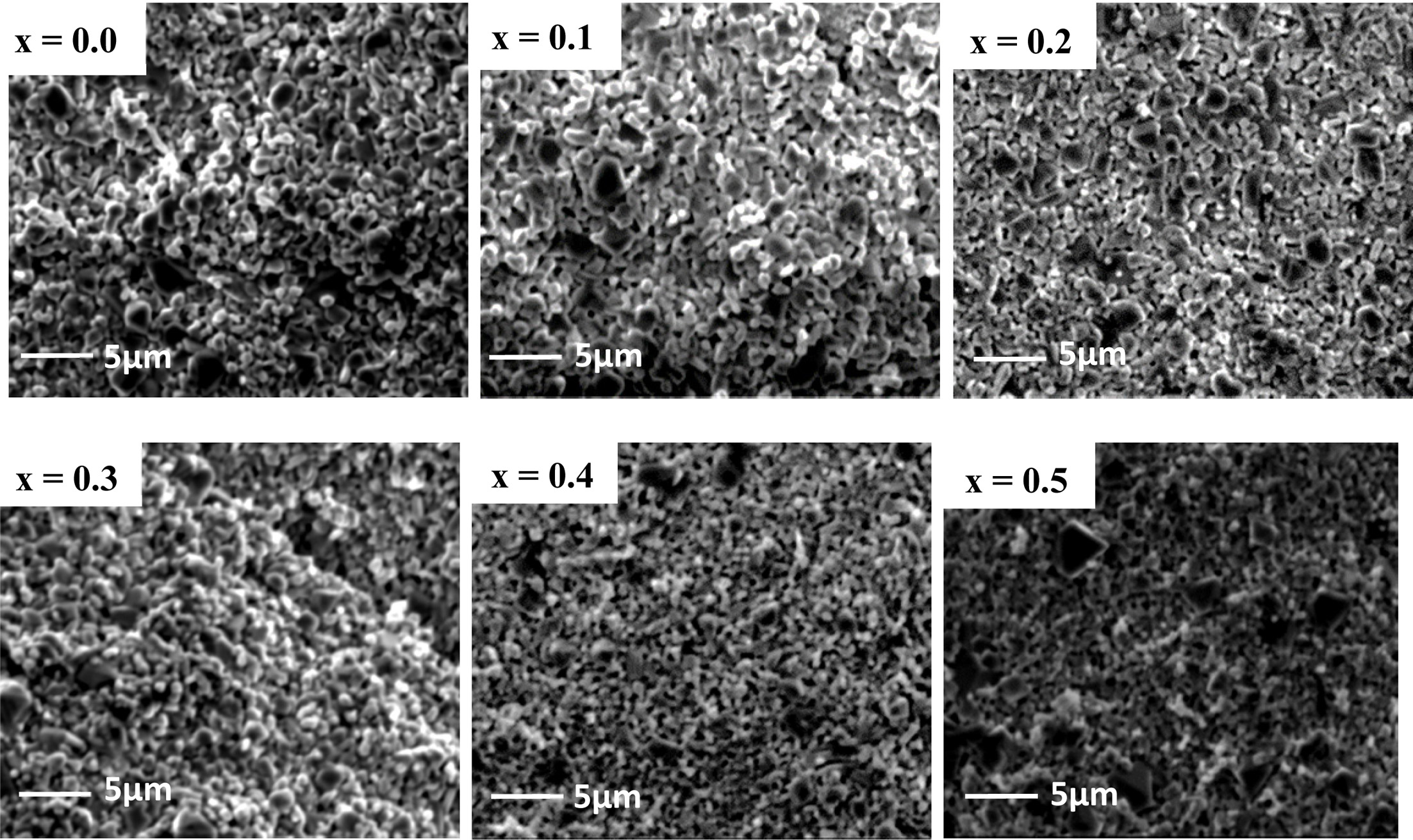

The microstructures of the investigated materials are

given in Fig. 4. The grain size remained almost same for the lower

Zinc substitution (x = 0 to 0.3) but for higher

Zn content (x = 0.4, 0.5), the grain size was found to decrease as

ZnO hinders the grain growth during sintering to stabilize the crystallization.

The grain growth amplifies the migration of the

pores to the grain boundary and hence, increases the sintered density. Grain

boundaries expand over the pores during the sintering which might produce the

denser material by reducing the pores volume [25]. The pores located at the

grain boundaries impede the domain wall move-

ment and impact on permeability and resistivity [26]. It has been

reported that Zn2+, Cd2+, Zn2+, Ti4+,

Nd2+ substitution do not favor the grain growth [27-29].

Dielectric

Properties

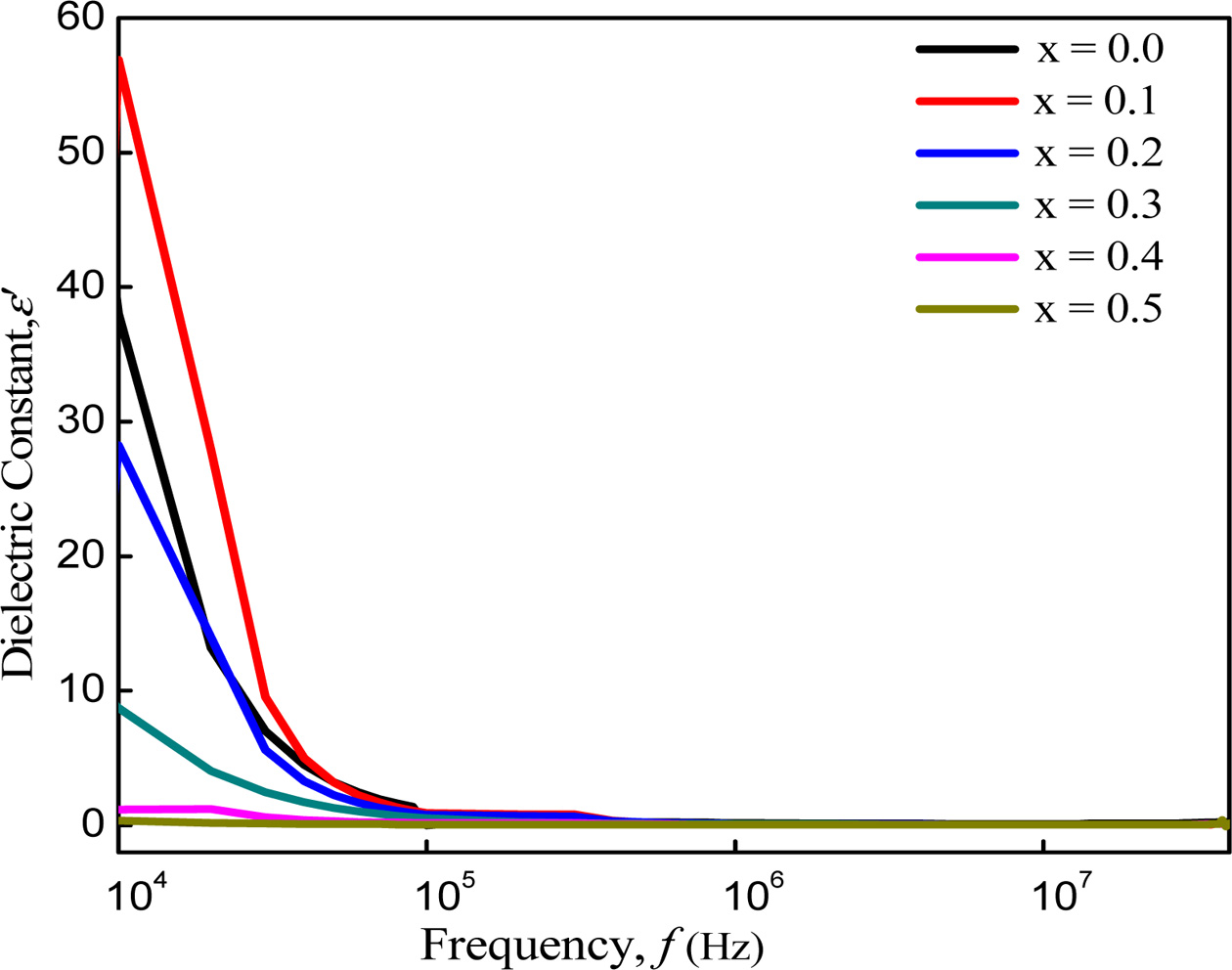

The variation of the real part (e ')

of dielectric constant with frequency from 10 kHz to 40 MHz at room

temperature are shown in Fig. 5. The dielectric constant (e ') decreases with increasing

frequency, which is rapid at lower frequencies and slower at higher

frequencies. At much higher frequency it is very small and becomes independent

of frequency. Similar dielectric behavior is observed in Mg-Cu-Zn ferrites

[30], Ni-Cu-Zn ferrites [31] and Cu-Zn ferrites [32]. All the samples have high

value of dielectric constant in the order of 103-105 at

low frequencies. Maxwell-Wagner interfacial type of polarization can describe

these higher values at lower frequency region [33, 34, 13] for the

inhomogeneous double layer dielectric structure. This is normal dielectric

behavior observed in most of the ferromagnetic materials in room tem- perature. Sintering temperature and time or

atmosphere including grain structure can influence the Fe2+ ions

concentration which is a characteristic property of a ferrite material. Fe2+

ions availability allows the electron to exchange between the +2 and +3

valance states of Fe ions and creates the local displacement of charges in the

direction of the applied electric field. This in turn causes the dielectric

polarization of the ferrites. The electron exchange was assumed to

increase with the increased concentration of Fe2+/Fe3+

ions pairs on B-site. However, as the frequency of the alternating field is

increased, the electron exchange between Fe2+ and Fe3+ ions

cannot follow the alternating field beyond a certain frequency and then the

dielectric constant becomes constant [28, 32].

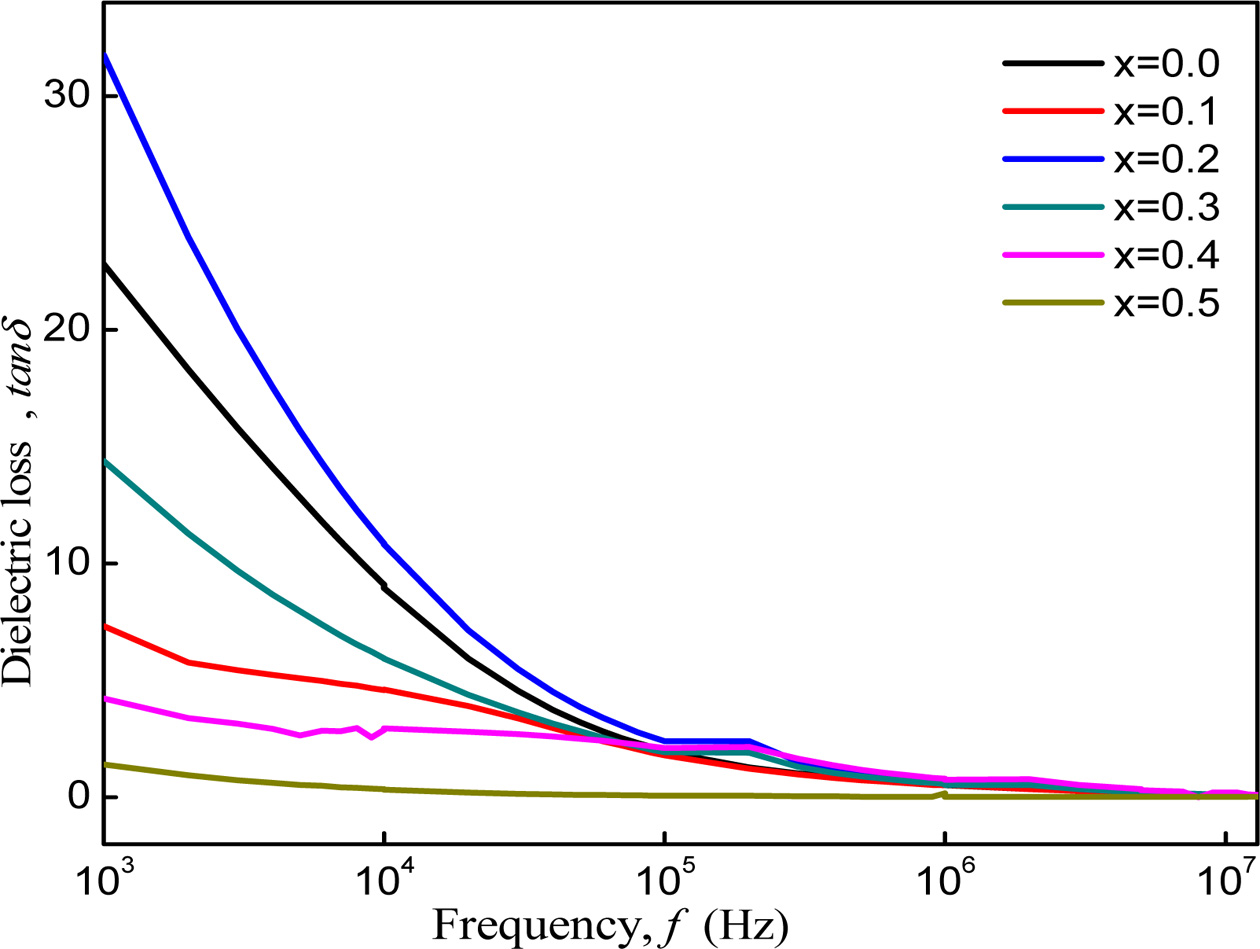

Fig. 6 shows that dielectric loss decreases rapidly with

increasing frequency and becomes constant at higher frequency range. In the

high frequency the conduction in between Fe2+ and Fe3+ ions

increases which corresponds to low resistivity and small energy is required for

electron exchange at the octahedral site results in lower value of dielectric

loss [32].

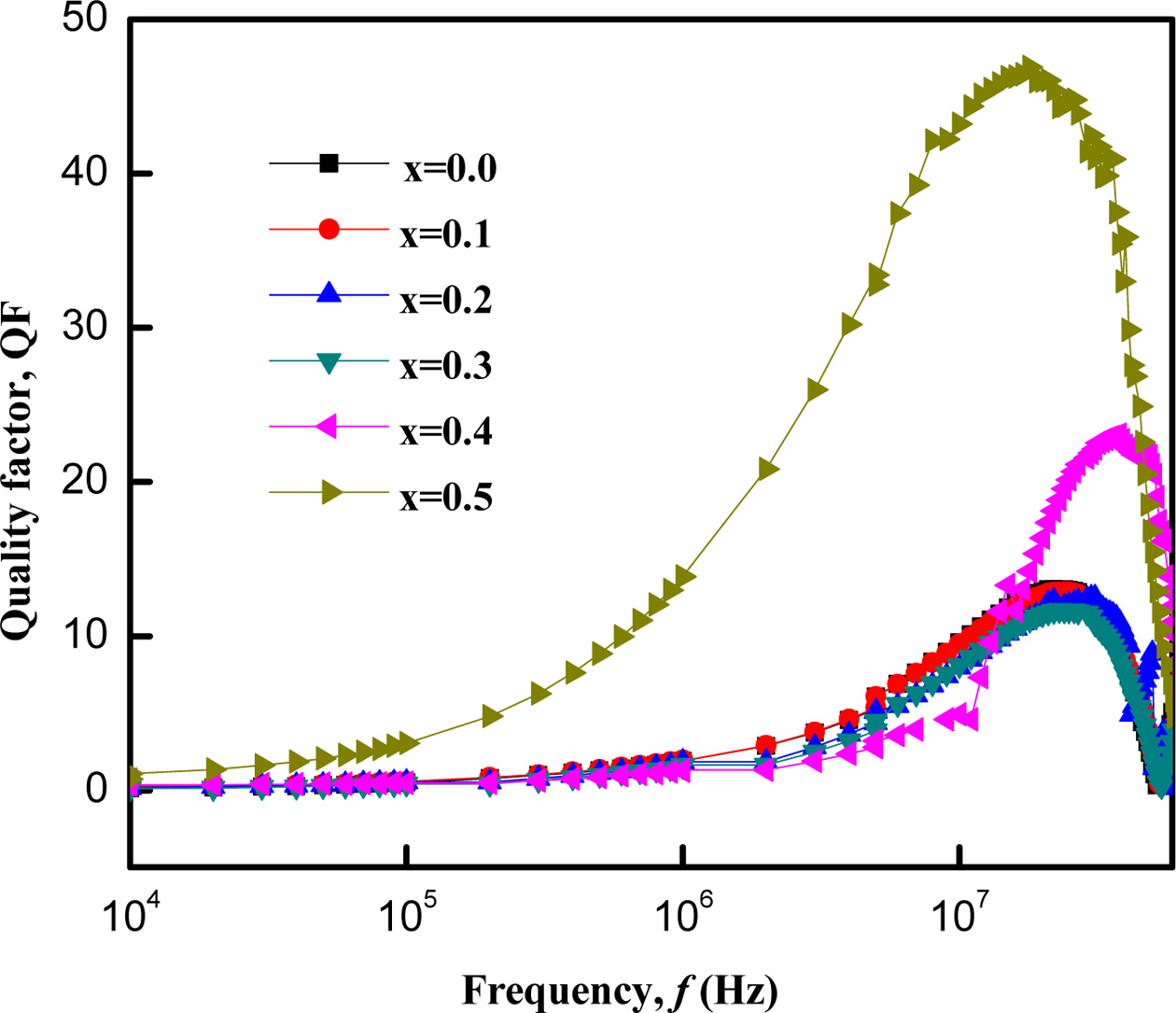

Fig. 7 shows the variation of Q factor with frequency as

log f for the samples. All the samples show a maximum at a certain

frequency. The appearance of a maximum can be described by the relaxation

formula, wt = 1,

where, w = 2pfmax

and relaxation time, t = 1/2p,

p is the hopping probability per unit time [35]. As stated by this

relaxation relation, a maximum can be appeared when the hopping frequency of

electron between Fe2+ and Fe3+ ions at the adjacent

B-sites and the frequency of applied AC field exactly match with each other

[28, 32]. It is also observed that fmax or the hopping probability

per unit time increases for the samples with Zn content. Therefore, the

concentration of the Fe2+ ions on the B-sites increases

in these samples which is also consistent with the resistivity

data.

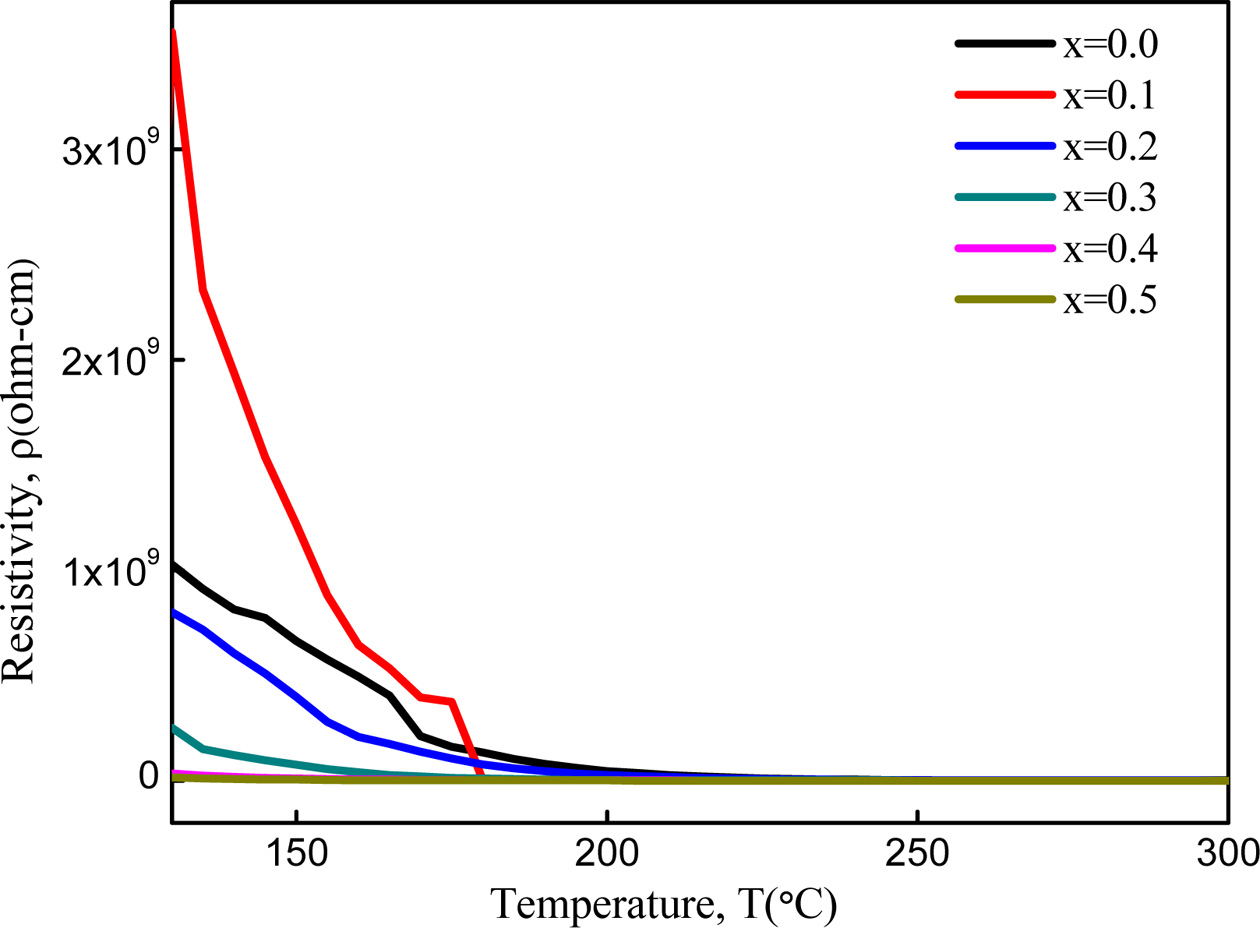

Fig. 8 shows that the DC resistivity decreases with the

increase in temperature for the samples which is the normal ferromagnetic

behavior. Generally, the hopping of electrons between

Fe2+ and Fe3+ ions at adjacent B-sites starts to get

thermally activated with the increase in temperature and produce local

displacement in the direction of the applied AC field. In the low tem- perature region,

the resistivity, r starts to decrease gradually because the thermal energy

breaks the localized dipoles and starts orienting themselves in the low temperature region. The orientation of these dipoles becomes more significant with

the increase of temperature, as

the exchange of charge carriers between the Fe3+ and Fe2+

ions on octahedral sites [34, 36] increases and this exchange decreases the resistivity of the samples. The intensified chaotic thermal oscillations at high temperature are responsible for this negligible

small resistivity [36].

It is observed that for x = 0.1, the dielectric

constant as well as the value of resistivity are greater than the pure Cobalt

ferrite. This sample may have higher dielectric properties and low eddy current

loss than the other samples.

Magnetic

Properties

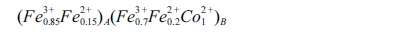

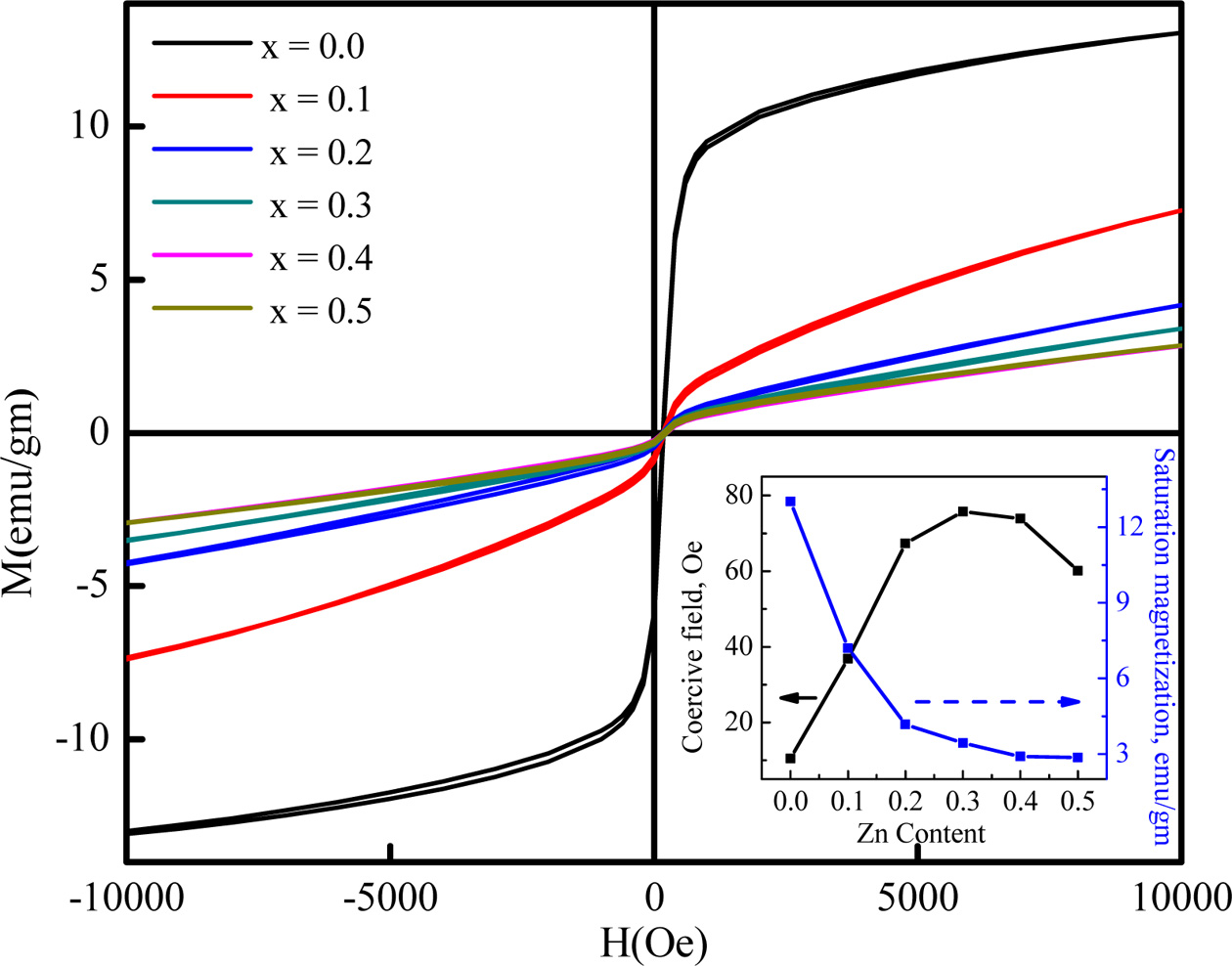

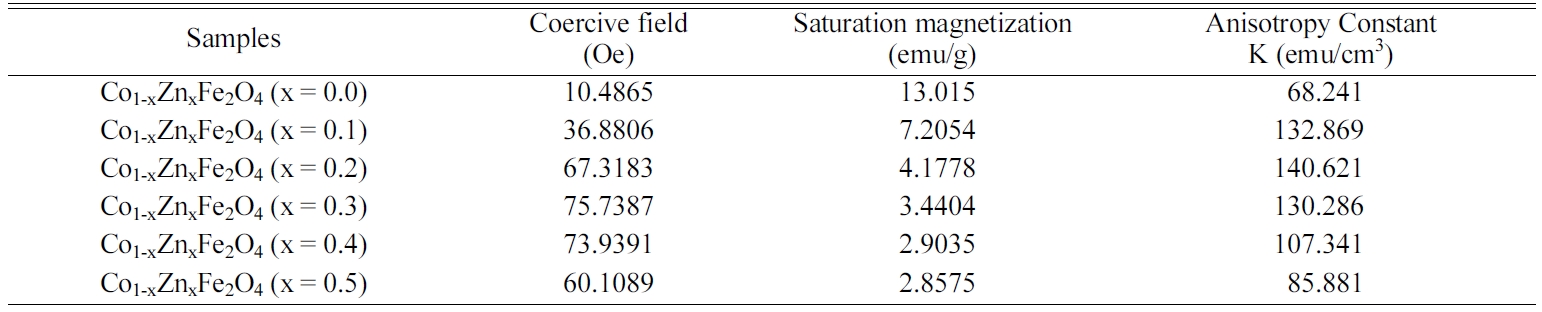

Figure 9 shows that the saturation magnetization decreases

with Zn content. Table 2 shows the variation of coercive

field, saturation magnetization and anisotropy constant

with increasing Zn content in Cobalt ferrites. According to

Néel's sublattice model, resulting magneti-

zation depends on the difference between B and A-site magnetization,

provided that the sites are collinear and antiparallel to each other. In Co-Zn

ferrite, Fe3+, Fe2+, Co2+ and Zn2+

elements have magnetic moment of 5 µB, 4 µB, 3 µB and

0 µB respectively which is coming from ‘d’

orbital electron distribution [25]. All the elements can

migrate to both A- and B-sites. The possible cation distribution

of CoFe2O4 can be presented as:

In case of CoFe2O4, most of the Fe3+

and a smaller part of Fe2+ take place on the A sites, and remaining

Fe3+, Fe2+, Co2+ goes to the B sites. For Co1-xZnxFe2O4,

the non-magnetic ion Zn2+ takes places to the

octahedral site along with the magnetic ion, Co2+.

Basically, the Zn2+ and Co2+ replace the Fe2+

and Fe3+ in octahedral sites, forcing a migration of

Fe2+ and Fe3+ to the tetrahedral sites [4].

The presence of large magnetic moments (caused by

the Fe3+ and Fe2+ ions) on the A-sites increases

the A-site magnetization which in turn leads to a decrease of

overall magnetization. The saturation magneti-

zation was found to decrease significantly from 13.015

emu/g to 2.85 emu/g with Zn substitution.

Here, from the inset of Fig. 9, the coercivity is noticed

to increase with the enhanced concentration of zinc ions while the saturation

magnetization behaves completely opposite which can be described by Browns

relations [25]. The high coercive force confirms that the cobalt ferrite

becomes hard from soft ferrite after Zn substitution. Anisotropy constant

represents the energy required to deflect the domains from the “easy” to

“hard” positions. The interaction between spin magnetic moment of

each atom and crystal lattice determine the easy and hard alignments of the

compounds. The change in anisotropy constant is similar to the change in

coercive field. It is observed from the change of anisotropy constant with

increasing Zn contents that cobalt ferrite behaved as “soft” magnet at the

lower concentration of Zn (x = 0.1,0.2). At x = 0.3-0.5,

the ferrite showed the characteristics of “hard” magnet.

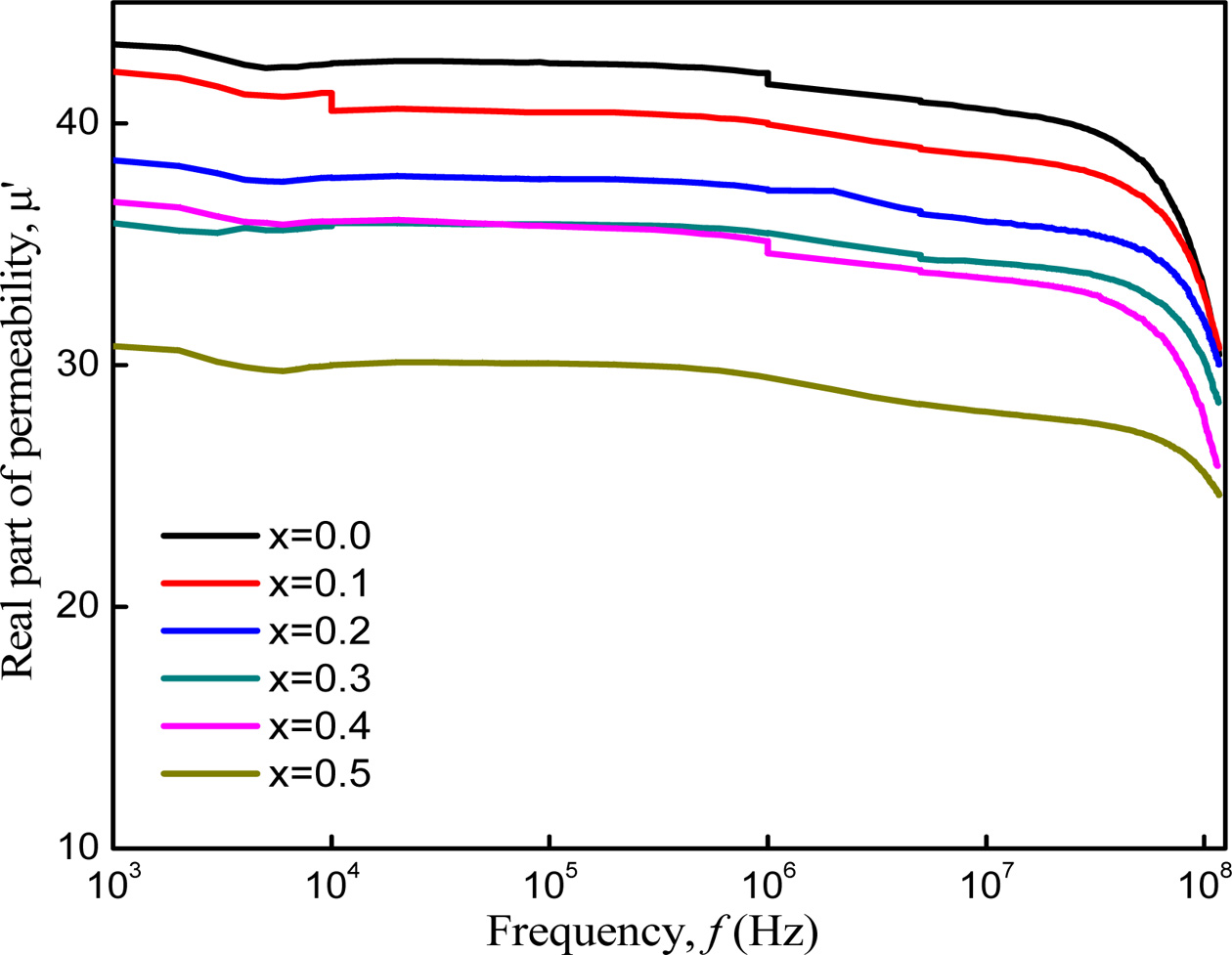

The complex permeability measurements on toroid shape

specimens have been carried out at room temperature for all the samples of

series Co1-xZnxFe2O4 (x = 0.0-0.5)

in the frequency range 1 kHz-100 MHz. The variation of μ' with frequency

is shown in Fig. 10. It is found that the value of initial permeability (μ')

shows flat profile up to a certain frequency (> 107 Hz)

indicating good low frequency stability and then it falls rapidly

to a very small value after a certain high frequency named as

Cut-off frequency. The permeability of polycrystalline ferrite is related to

spin rotation and domain wall motion. And Globus- Duplex model [28] says that

the permeability caused by wall motion is linearly dependent on the grain size.

From the micro- structure analysis of

this work, it is noticed that the grain sizes decrease with increasing Zinc

concentration and domain wall movement is influenced by grain size. Also, the

decrease of permeability is associated with the decrease in domain wall

movement. On the other hand, the saturation magnetization was found to be

decreased in our case, which decreases the number of domain walls within the

grain according to Globus relation [13, 37]. Therefore, the

permeability is expected to decrease with the addition of Zn

content. At high frequencies, the nonmagnetic impurities between intra-granular

pores influence both spin rotation and domain wall motion so that permeability

decreases at higher frequencies.

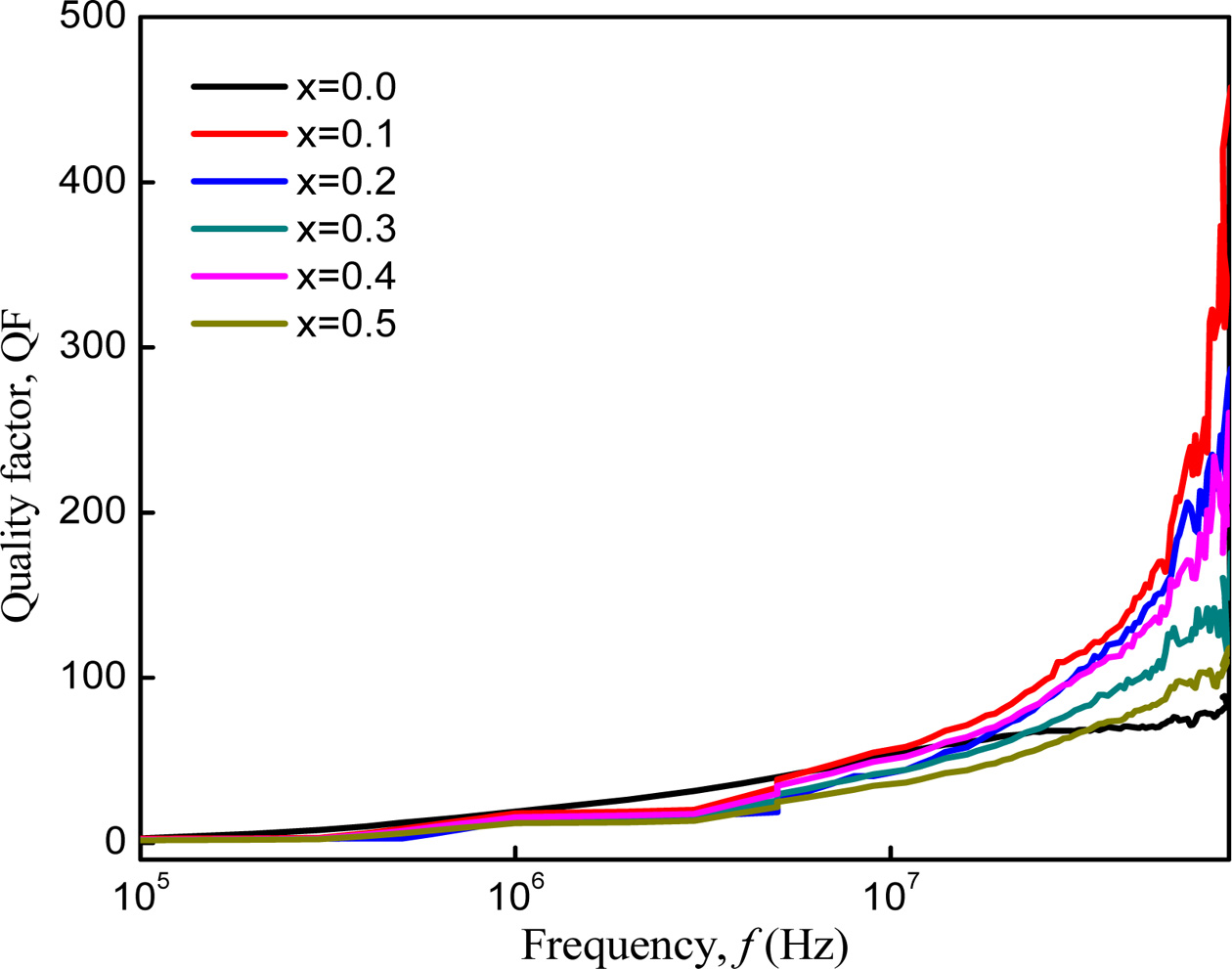

Fig. 11 shows the variation of Quality factor (QF) with

frequency of Co1-xZnxFe2O4 (x = 0.0-0.5)

that determines the efficiency of the magnetic materials. It increases with

increasing frequencies. The Q factor of Co-Zn ferrite samples increased for a

small amount of Zn2+ substitution and then decreased with addition

of Zn. Zn substituted sample has a higher value of QF than the unsubstituted

sample. This change of QF depends on magnetic loss and porosity of the samples [28]. Among the samples, Co-Zn ferrite with

x = 0.1 has the highest QF which indicates that this sample has the

lowest magnetic loss.

From the above discussion, it is claimed that the

polycrystalline Co-Zn ferrite is versatile ferrite, due to their high

resistivity and low eddy current losses. The adjustable

grain sizes and controllable magnetic properties make the

applicability of cobalt-zinc ferrite even more versatile. Cobalt-zinc ferrites

are suitable for magnetic recording applications such as audio and videotape

and high-density digital recording disks etc.

|

Fig. 1 (a) X-ray diffraction patterns for Co1-xZnxFe2O4 (x = 0.0-0.5) ferrites and (b) Phase shifting for the highest peak of (311). |

|

Fig. 2 Lattice parameter vs Zinc content of Co1-xZnxFe2O4 (x = 0.0-0.5) ferrites. |

|

Fig. 3 Variation of X-Ray density, bulk density and porosity of Co1-xZnxFe2O4 (x = 0.0-0.5). |

|

Fig. 4 Scanning Electron Microscope (SEM) images for Co1-xZnxFe2O4. |

|

Fig. 5 Variation of dielectric constant with increasing frequency of Co1-xZnxFe2O4 (x = 0.0-0.5). |

|

Fig. 6 Dielectric loss of Co1-xZnxFe2O4 (x = 0.0-0.5) as function of frequency. |

|

Fig. 7 Variation of quality factor, QF of Co1-xZnxFe2O4 (x = 0.0-0.5) with increasing frequency. |

|

Fig. 8 Variation of resistivity of Co1-xZnxFe2O4 (x = 0.0-0.5) as a function of temperature. |

|

Fig. 9 Hysteresis Loop with the inset of variation of coercive field and saturation magnetization of Co1-xZnxFe2O4 (x = 0.0-0.5) as function of Zinc content. |

|

Fig. 10 Variation of Permeability with increasing frequency of Co1-xZnxFe2O4 (x = 0.0-0.5). |

|

Fig. 11 Variation of quality factor, QF of Co1-xZnxFe2O4 (x = 0.0-0.5) with increasing frequency. |

|

Table 1 Lattice parameter, molecular mass, theoretical density, bulk density and porosity for the samples with the composition Co1-xZnxFe2O4 (x = 0.0-0.5) |

|

Table 2 Coercive field, Saturation magnetization and Anisotropy Constant for the samples with the composition Co1-xZnxFe2O4 (x=0.0-0.5) |

X-ray diffraction measurement confirmed the single-phase

cubic spinel structure of polycrystalline samples Co1-xZnxFe2O4

where x = 0.0-0.5, since no ambiguous reflections other than the

spinel structures were evidenced. The lattice parameter was observed to be

increased with Zn content substitution. From micro- structural study, it was observed that the

grain size remained almost the same with increasing Zn content. However, the

grain size decreased slightly for higher content of Zn. The dielectric constant

was found to decrease with increasing frequency, which was rapid at lower

frequencies and slower at higher frequencies. DC electrical resistivity

increased for 10% of Zn substitu- tion

then again decreased with Zn Content. The saturation

magnetization has been decreased and coercive field was increasing for up to

30% Zn content and then started to decrease with increasing Zn content.

Permea- bility decreased with Zn

content. From the Dielectric properties and Resistivity

measurement, it was observed that 10% of Zn

substitution in place of Cobalt increased the

dielectric properties and resistivity of the samples. Anisotropy constant is

enhanced for x = 0.1, 0.2 and then decreased with higher Zn content.

The authors acknowledge gratefully to Materials Science

Division, Atomic Energy Centre, Dhaka and Centre for Advanced Research of

Sciences, University of Dhaka, Dhaka, Bangladesh. Authors are sincerely

thankful to Nano and Advanced Materials Laboratory, Department of Physics,

University of Dhaka. The authors thank the Bose Centre for Advanced Study and

Research in Natural Sciences, University of Dhaka for partial support of this

work.

- 1. P.B. Belavi, G.N. Chavan, L.R. Naik, R. Somshekar, and R.K. Kotnala, Mat. Chem. And Phys. 132[1] (2012) 138-144.

-

- 2. K.H. Maria, S. Choudhury, M.A. Hakim, Int. Nano Lett. 42[3] (2013) 1-10.

-

- 3. Y. Kim, D. Kim, and C.S. Lee, Physica B 337[1-4] (2003) 42-51.

-

- 4. S.G.C. Fonseca, L.S. Neiva, M.A.R. Bonifácio, P.R.C. Santos, U.C. Silvad, and J.B.L. de Oliveira, Mater. Res. 21[3] (2018) e20170861.

-

- 5. A.V. Raut, R.S. Barkule, D.R. Shengule, and K.M. Jadhav, J. Magn. Magn. Mater. 358-359 (2014) 87-92.

-

- 6. S. Singhal, T. Namgyal, S. Bansal, and K. Chandra, J. Electromagn. Anal.Appl. 2[6] (2010) 376-381.

-

- 7. A. Khan, G.D. Al-Quaderi, M.A. Bhuiyan, K.H. Maria, S. Choudhury, K.M. Amjad Hossain, D.K. Saha, and S. Akhter, Biointerface Res. Appl. Chem. 10[3] (2020) 5665-5669.

-

- 8. S. Singhal, T. Namgyal, S. Bansal, and K. Chandra, J. Electromagnetic Analysis and Applications. 2[6] (2010) 376-381.

-

- 9. S. Tapdiya and A.K. Shrivastava, Int. J. Inno. Res. Sci. Eng. Tech. 5 (2016) 6681-6684.

- 10. M.T. Jamil, J. Ahmad, S.H. Bukhari, T. Sultan, M.Y. Akhter, H. Ahmad, and G. Murtaza, J. Ovonic Res. 13[1] (2017) 45-53.

- 11. R. Rani, G. Kumar, K.M. Batoo, and M. Singh, American J. Nanomaterials 1[1] (2013) 9-12.

-

- 12. S.T. Alone and K.M. Jadhav, Indian Academy of Sciences 70[1] (2008) 173-181.

-

- 13. I. N. Esha, Kazi Hanium Maria, Enayet Hossain, M. N. I. Khan, Md. Al-Amin, and F. T. Z. Toma, J. Ceram. Process. Res. 20[5] (2019) 530-539.

-

- 14. M.A. Ameer, and M. El-Hiti, J. Magn. Magn. Matter. 234[1] (2001) 118-125.

-

- 15. P. Puspitasari, Y. Yahya, N.A.M. Zabidi and N.A. Ahmad, J. Appl. Sci, 11[7] (2011) 1199-1205.

-

- 16. A. Poorbafrani, and E. Kiani, J. Magn. Magn. Mater. 416 (2016) 10-14.

-

- 17. A. Khan, M.A. Bhuiyan, G.D. Al-Quaderi, K.H. Maria, S. Choudhury, K.A. Hossain, S. Akther, and D.K. Saha, J. Bang. Aca. Sci, 37[1] (2013) 73-82.

-

- 18. R. Saravanan, in “Solid Oxide fuel cell materials” (Materials Research Forum LLC, 2018) p.134.

-

- 19. J. Smit, H.P.J. Wign, in “Ferrites” (John Willy & Sons, 1959) p.143.

- 20. S.M. Yunus, H. S. Shim, C.H. Lee, M.A. Asgar, F.U. Ahmad, and A.K.M. Zakaria, J. Magn. Magn. Mater. 232[3] (2001) 121-132.

-

- 21. B.P. Ladgaonkar, P.N. Vasambekar and A.S. Vaingankar, J. Magn. Magn. Mater. 210[3] (2000) 289-294.

-

- 22. M.M. Haque, K.H. Maria, S. Choudhury, M.A. Bhuiyan, and M.A. Hakim, J. Ceram. Process. Res. 14[1] (2013) 82-86.

- 23. T.K. Gupta, and R.L. Coble, J. Am. Ceram. Soc. 51[9] (1968) 521.

-

- 24. F.T.Z. Toma, I.N. Esha, Md. Al-Amin, M.N.I. Khan, and K.H. Maria, J. Ceram. Process. Res. 18[10] (2017) 701-710.

- 25. K.H. Maria, U.S. Akter, I.N. Esha, Md. S. Hossain, and M.N.I. Khan, J. Supercond. Nov. Magn. 33[7] (2020) 2133-2142.

-

- 26. T. Mariam, and S. Choudhury, J. Bangladesh Acad. Sci. 41[1] (2017) 85-93.

-

- 27. S.E. Jacobo, and P.G. Bercoff, Ceram. Int. 42[6] (2016) 7664-7668.

-

- 28. K.H. Maria, S. Choudhury, and M.A. Hakim, J. Bangladesh Acad. Sci. 34[1] (2010) 1-8.

-

- 29. S. Noor, M.A. Hakim, S.S. Sikder, S.M. Hoque, K.H. Maria, and P. Nordblad, J. Phys. Chem. Solids 73[2] (2012) 227-231.

-

- 30. Z. Yue, Z. Ji, L. Li, X. Wang and Z. Gui, Mater. Sci Eng B 86[1] (2001) 64-69.

-

- 31. Z. Yue, Z. Ji, Z. Gui and L. Li, J. Magn. Magn.Mat. 264[2-3] (2003) 258-263.

-

- 32. S.S. Bellad, and B.K. Choughule, J. Mater. Chem. Phys. 66[1] (2000) 58-63.

-

- 33. I.N. Esha, F.T.Z. Toma, Md. Al-Amin, M.N.I. Khan, and K.H. Maria, AIP Advances 8[12] (2018) 125207 (1-17).

-

- 34. F.G. Brockman, P.H. Dowliay and W.G. Stenneck, Phys. Rev. 77[1] (1950) 85-93.

-

- 35. M.A. Hakim, S.K. Nath, S.S. Sikder, and K.H. Maria, J. Phys. Chem. Solids 74[9] (2013) 1316-1321.

-

- 36. S.K. Gore, S.S. Jadhav, V. V. Jadhav, S.M. Patange, M. Naushad, R.S. Mane and K.H. Kim, Sci Rep. 7[1] (2017) 1-9.

-

- 37. S.K. Nath, K.H. Maria, S. Noor, S.S. Sikder, S. Manjura Hoque, and M.A. Hakim. J. Magn. Magn. Mater. 324[13] (2012) 2116-2120.

-

This Article

This Article

-

2020; 21(4): 442-449

Published on Aug 30, 2020

- 10.36410/jcpr.2020.21.4.442

- Received on Jan 27, 2020

- Revised on Apr 24, 2020

- Accepted on May 4, 2020

Services

Services

- Abstract

introduction

experimental details

results and discussion

conclusion

- Acknowledgements

- References

- Full Text PDF

Shared

Correspondence to

Correspondence to

- Kazi Hanium Maria

-

Department of Physics, University of Dhaka, Dhaka-1000, Bangladesh

Tel : +880-2-01711987595

Fax: +880-2-8615583 - E-mail: kazimaria@du.ac.bd

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.