- Effects of alloy ratio and coating thickness on temperature distribution of thermal barrier coatings

Can Ozturka and Tolga Demircanb,*

aDepartment of Mechanical Engineering, Faculty of Engineering, Kırıkkale University, Kırıkkale, Turkey

bDepartment of Mechanical Engineering, Faculty of Engineering, Kırıkkale University, Kırıkkale, Turkey

Pistons on internal combustion

engines that are constantly subjected to high pressure and temperature should

be light, resistant to heat, resistant to corrosion and have adequate hardness

to work more efficiently and to have longer lifecycles. For this purpose,

piston surfaces are coated with thermal barrier that increases resistance

against heat and corrosion. In this study, temperature distribution on piston

surfaces were numerically analysed for ceramic coating on a piston. For this

purpose, it is assumed that 100 μm NiCrAl coating is applied as bond coat

on piston upper surface. This coating was coated with MgZrO3+NiCrAl

alloy with different alloy ratios for different coating thicknesses. MgZrO3+NiCrAl

alloy thickness was changed between 200 µm and 600 µm. For all

analysed coating thicknesses, MgZrO3 ratio in the alloy was changed

between 100 to 10% and simulations were repeated for different alloy rates. As

a result of these analysis, it was determined that as MgZrO3 ratio

in the alloy decreased, piston upper surface temperature decreased as well. For

all alloy ratios, maximum temperature was observed on piston upper surface.

Additionally, it was determined that as piston upper surface coating thickness

increased, piston upper surface temperature increased as well.

Keywords: Functional ceramic coating, Thermal barrier coating, Coating thickness, Coating alloy ratio

As ceramic materials have high resistance, and can conduct

heat and electricity at high levels, this material is commonly used in

engineering applications to increase efficiency and durability.

One of these materials is known as zirconium dioxide. ZrO2

is used in aviation industry, gas turbines, and certain engine components. In

this study, the purpose was to apply Magnesium ZrO3, which is a

zirconium-based ceramic on piston surface in graded way. The purpose of using

different functional graded materials on a piston is to increase piston

resistance, enable upper surface of piston to achieve higher temperatures,

thus, increase overall efficiency. For this purpose, in this study, different

coating ratios and thickness with MgZrO3 (Magnesium zirconium oxide)

and connection layer that will be applied on the upper surface of a designed

diesel engine piston was calculated numerically. After the analysis, maximum

and minimum temperature changes were obtained for diesel engine piston. Some of

the studies in the literature regarding piston ceramic coating were given

below.

Cerit and Çoban [1] numerically analysed thermal

properties of an aluminium alloy piston coated with ceramic in a diesel engine.

Authors compared tem- perature values

for coated and uncoated piston by using finite element analysis. Authors stated

that temperature values of coated piston surface was higher than

uncoated piston surface. Büyükkaya [2]

analysed thermal behaviours of functional graded

aluminium-silicon alloy piston and steel pistons with package program. Author

compared temperature values of piston coated with AlSi allow and uncoated

piston. As a result, author found that piston surface value of FGM coated AlSi

piston was 28% higher than uncoated piston surface temperature. It was observed

that surface temperature of steel piston increased 17%. Büyükkaya and Cerit [3]

conducted numerical 3 dimensional thermal analysis on ceramic coated diesel

engine piston. MgO, ZrO, and AlSi alloy coated pistons and uncoated pistons

were simulated. It was observed that maximum surface temperature of steel

piston was higher than AlSi alloy piston.

Gehlot and Tripathi [4] evaluated thermal analysis of

holes that are created to coat ceramic to the piston of a diesel engine.

Analysis were conducted for piston geometries with 1.5 mm, 2 mm, and

2.5 mm radius holes. Authors observed that as radius of holes

increased, temperature of upper surface (coated

surface) increased, and when coats had holes, upper surface

temperature levels of piston significantly increased. Cerit et al. [5] analysed

effect of partially ceramic coated piston use in spark ignition engine on HC

emission. For engine tests, both standard piston and coated piston was selected.

Authors observed that with coating, surface temperature

of piston increased up to 100 oC. Robinson and Palaninathan [6]

conducted thermal analysis for piston cast by using three dimensional finite

element method. Authors determined that the thinnest part solidifies in one

second while middle part solidifies after sixty seconds.

Kummitha and Reddy [7] numerically analysed thermal

effect of using different materials on winged cylinder block. Authors

determined that heat transfer speed of the material was linked with

thermal conductivity of material.

Dudareva et al. [8] analysed microarc oxidation (MAO)

coating application for thermal protection of internal combustion engine piston

upper surface. Tests were conducted for 76 and 106 μm MAO coating thicknesses

and it was determined that piston temperatures decreased

by 45 and 78 oC respectively. Dhinest et al. [9] numerically

and experimentally analysed thermal properties of coated diesel engine that

works with nano biofuel. For this purpose, engine piston, valves and cylinder

head was coated with YSZ (Yttria-stabilised zirconia) coating. As a result, it

was determined that average temperatures of these components increased, harmful

emission decreased and engine thermal efficiency increased

by 1.75% compared to conventional engines. Yao et al. [10] analysed effects of

thermal barrier coating on a diesel engine on combustion and resulting

emissions. For this purpose, simulations are conducted for two different engine

loads (6 bar IMEP and 17.9 bar IMEP). Results of their study showed that

thermal barrier applications have the ability to decrease thermal transfer

losses on piston walls and this might increase engine thermal efficiency. Lu et

al. [11] analysed effects of diesel engine YSZ thermal barrier coating

application on thermal behaviour. Authors reported that coating application

significantly affected piston peak temperature distribution. It

was observed that as coating thickness increased, piston upper

surface temperature increased and coating and piston mid-surface

temperature decreased. Authors stated that this might lead lower

thermal loss in combustion chamber and increased thermal efficiency.

Muthusamy et al. [12] experimentally analysed effect of

engine piston thermal barrier coating (8YSZ-TiO2-Al2O3)

application on engine efficiency and resulting emissions. For same operating

conditions, it was observed that thermal efficiency increased 5.99% for thermal

barrier coating practice compared to uncoated condition. On the other hand,

specific fuel consumption decreased by 0.06 kg/kWh. It was also noted that

combustion caused HC and CO emission decreased as well. Cerit [13] analysed

effects of coating thickness and size of a ceramic coated internal combustion

engine piston on temperature and stress distribution. As coating

thickness increased, it was observed that coating surface

temperature increased as well. With increasing coating thickness, it was noted

that normal stress on piston surface decreased and shear stress slightly

increased. For analysed coating thickness, optimal coating thickness value was

identified as 1 mm. Sachit et al. [14] numerically analysed thermal

effects of Cr2O3 coating on diesel engine piston upper

surface. Their study showed that Cr2O3

coating on piston surface increased surface temperature

compared to uncoated condition.

Yao and Qian [15] investigated effects of nano-ceramic

coated piston use in natural gas engine on piston

temperature distribution. Authors compared these results with

uncoated piston. For those parameters, piston upper surface temperature of

coated piston had approximately 44% higher average temperature than uncoated piston

and piston coating bottom average temperature decreased approximately 12%.

Mahade et al. [16] analysed effects of YSZ coating thickness in gadolinium

zirconate/YSZ couple on resistance. To determine thermal conductivity and

thermal shock lifecycle of Thermal Barrier Coating, experiments were conducted

for different gadolinium zirconate (GZ) and YSZ thicknesses. Minimum thermal

conductivity was observed for thinnest YSZ coating. Additionally, it was reported

that as YSZ thickness increased, thermal shock lifecycle

decreased. Garud et al. [17] analysed effects of a diesel engine piston surface

thermal barrier coating (YSZ) application on engine

performance and combustion properties. For this purpose,

piston upper surface was coated with 250 micron thick YSZ (Y2O3

& ZrO2) ceramic material with plasma spraying technique. As a

result, it was observed that piston upper surface YSZ thermal barrier coating

increased engine break thermal efficiency by 1.4% compared to uncoated

condition.

Yao et al. [18] experimentally and numerically analysed

Nano PYSZ Thermal Barrier Coating on temperature and thermal

load distribution. For this purpose, aluminium allow piston

surfaces were coated with Nano PYSZ thermal barrier. As a result, it was

observed that Nano PYSZ coated piston lower layer temperatures

decreased by 16% compared to uncoated piston.

It was determined that piston upper surface temperature approximately

increased 52%. Authors reported that this could increase

engine combustion chamber temperature and engine efficiency. Venkadesan and

Muthusamy [19] experi- mentally

analysed Al2O3/8YSZ and CeO2/8YSZ alloy

coating of diesel engine piston surfaces on engine performance and emission

properties. For this purpose, aluminium piston upper surface was first coated with

CoNiCrAlY bonding layer. These layers were coated with two different coating

material as 20%Al2O3/80%8YSZ and 20%CeO2/80%8YSZ and experiments were

conducted. Results showed that CeO2/8YSZ based coating had better

thermal cycle behaviour compared to Al2O3/8YSZ based

coating. For both thermal coating material, it was reported that break thermal

efficiency increased and fuel consumption decreased for uncoated condition.

Additionally, it was reported that HC, CO and smoke decreased and NOx emission

increased.

Moon et al. [20] investigated the effects of plasma

spraying ZrO2 based thermal barrier coating on the phase change for

different thermal cycles. For this purpose, ZrO2-8Y2O3

and ZrO2-25CeO2-2.5Y2O3 materials

were subjected to heat treatment at 1300 oC and 1500 oC

for 100 hours and cooled down with 4 different cooling methods. As a

result, it was found that the amount of oxygen gap was the main factor for

phase change behaviour and had a strong correlation with cooling ratio. Lee et

al. [21] studies on the effect of coating thickness of thermal barrier coatings

(TBCs) on contact fatigue and abrasion behaviour. Bond coat material thickness

was kept constant at 250 μm and thermal barrier coating (TBC) material

thickness was changed as 200, 400 and 600 μm. As a result, it was found

that TBC coating thickness change had a significant effect on the mechanical

behaviour of gas turbine operation. Cho et al. [22] gas turbine were coated

with yttrium stabilized zirconia (YSZ) and thermal and mechanical behaviours of

the coated thermal barriers were investigated. NiCrCoAlY was used as the

binder. Thermal barrier layer thermal resistance was determined with thermal

annealing and hardness measurements. As a result, it was observed that pre-heat

treated thermal barrier coating offered advantages in thermal and mechanical

resistance.

Lee et al. [23] analysed nano-structured SiC reinforced

zirconia-based thermal barrier coatings. For this purpose, ZrO2-25CeO2-2.5Y2O3

(CYSZ) coatings were investigated. As a result, it was determined that the

friction coefficient decreased with SiC reinforcement. Kim et al. [24] analysed

residual stresses and thermal conductivity values of 3YSZ/LaPO composite

thermal barrier coating (TBC) prepared by atmospheric plasma spraying method.

It was determined that the thermal conductivity of the coating layers had lower

values than sintered materials. Yao ve Li [25] applied thermal barrier coating

to an aluminium alloy piston with PYSZ (TBC Nano yttria partially stabilized

zirconia) material and investigated the piston microstructure and thermal

behaviour. As a result, when the ceramic coating thickness was increased from

0,1 mm to 1.4, TBC applied piston maximum temperature increased from

399 oC to 665 oC. It was determined that

aluminium alloy sub-layer maximum temperature decreased from 336 oC

to 241 oC. It was observed that thermal insulation

performance increased as the ceramic layer thickness increased. Caputo et al.

[26] experimentally and numerically investigated the effects of a thermal

barrier coating on a diesel engine piston on fuel consumption and emission. The

results of the study showed that when TBC is applied to the pistons, fuel

consumption decreased approximately by 1% and thermal transfer decreased by 6%.

However, due to increased surface graining, a relative decrease in engine

efficiency was determined.

Reghu et al. [27] numerically and experimentally

investigated the effects of 8YPSZ coating on Al-Si alloy on the

thermal barrier. For different layer thicknesses,

temperature decrease was determined along the upper surface and lower layers of

the thermal barrier coating. In this experiment, for coating thickness of

100 mm, 250 mm and 500 mm, maximum 57 oC,

170 oC and 248 oC temperature decrease were

observed. Numerical analysis was conducted for the same parameters and it was

reported that the obtained results are in line with the experimental results.

Ramaswamy et al. [28] developed a model to predict the effects of thermal barrier

coating (TBC) thickness inconsistencies applied to internal combustion engine

pistons. The results obtained from this model were verified with the

experimental study and it was determined that this model was reliable.

Yerrennagoudaru and Manjunatha [29] conducted a numerical combustion analysis

for platinum coated and uncoated states of a piston modified from a diesel

engine. The results showed that the thermal stress of the modified piston was

lower than the conventional piston. The upper surface tem- perature of the platinum coated piston was

observed to have a higher temperature vale than the uncoated piston. It is

stated that coating the piston with platinum might help combusting fuels with

lower Centene value.

In this study, temperature distribution on piston surfaces

were numerically analysed with Ansys package program for

ceramic thermal barrier coating on diesel engine piston. Material of diesel

engine was selected as aluminium silicon. Piston coating was selected as NiCrAl

alloy. Additionally, MgZrO3+NiCrAl alloy was applied to the upper

surface of the piston as functional graded material. Based on change of

functional graded coating rates and thicknesses, analysis were conducted and

changes in piston temperature distribution were evaluated.

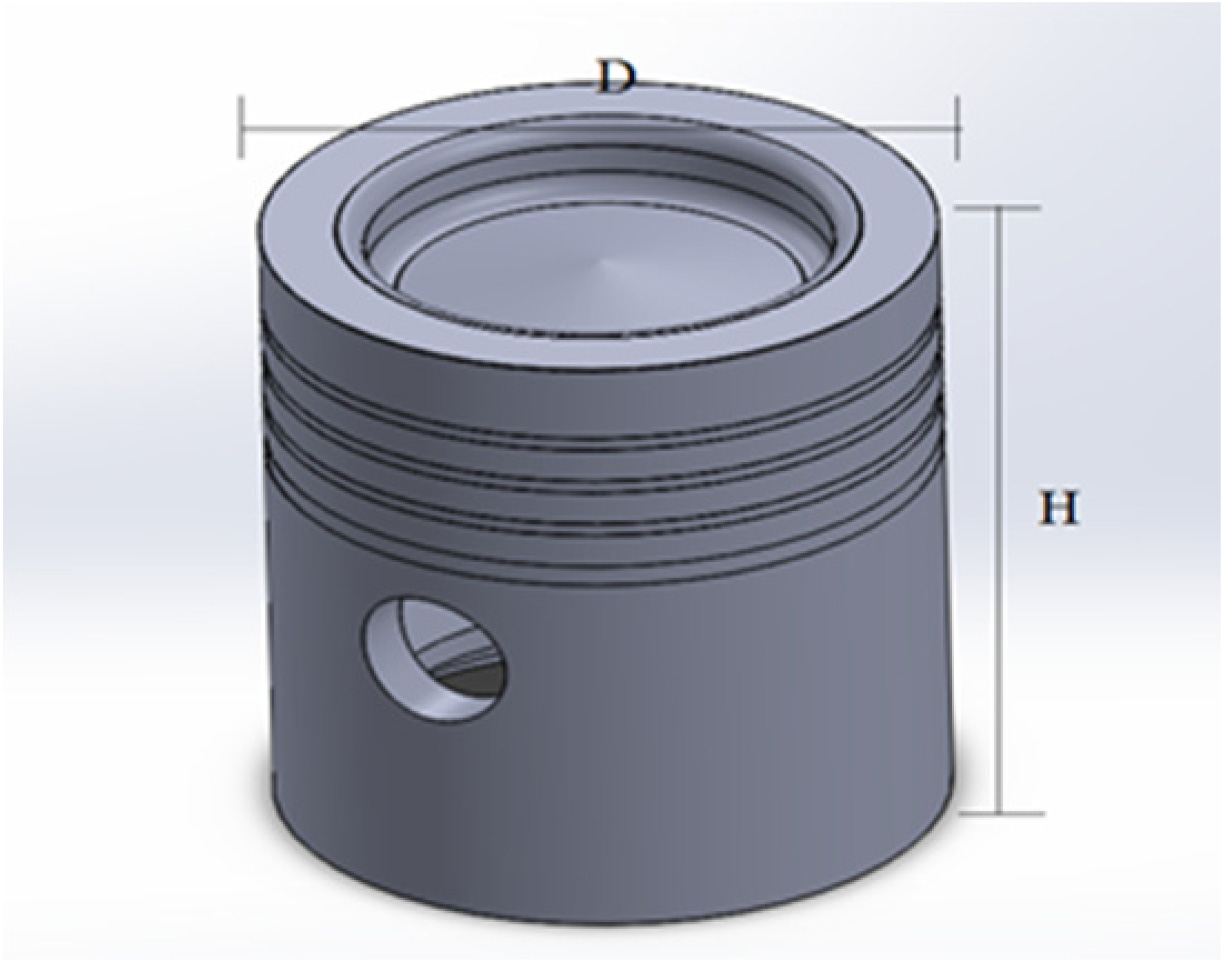

In this study, temperature distribution on piston surfaces

were numerically analysed for ceramic coating on diesel engine piston. Adopted

piston geometry was presented in Fig. 1. As seen from the figure, piston

evaluated in this study had diameter of D = 130 mm, and piston

length of H = 147.76 mm. 100 micrometre thick NiCrAl coating was

applied as bond coat on the upper surface of the piston. On this coating,

graded MgZrO3+NiCrAl alloy with 200, 300, 400, 500 and 600

micrometre thicknesses were applied for different alloy ratios. In graded

coated sections of piston, simulations were repeated for 100%, 90%, 70%, 50%,

30%, and 10% MgZrO3.

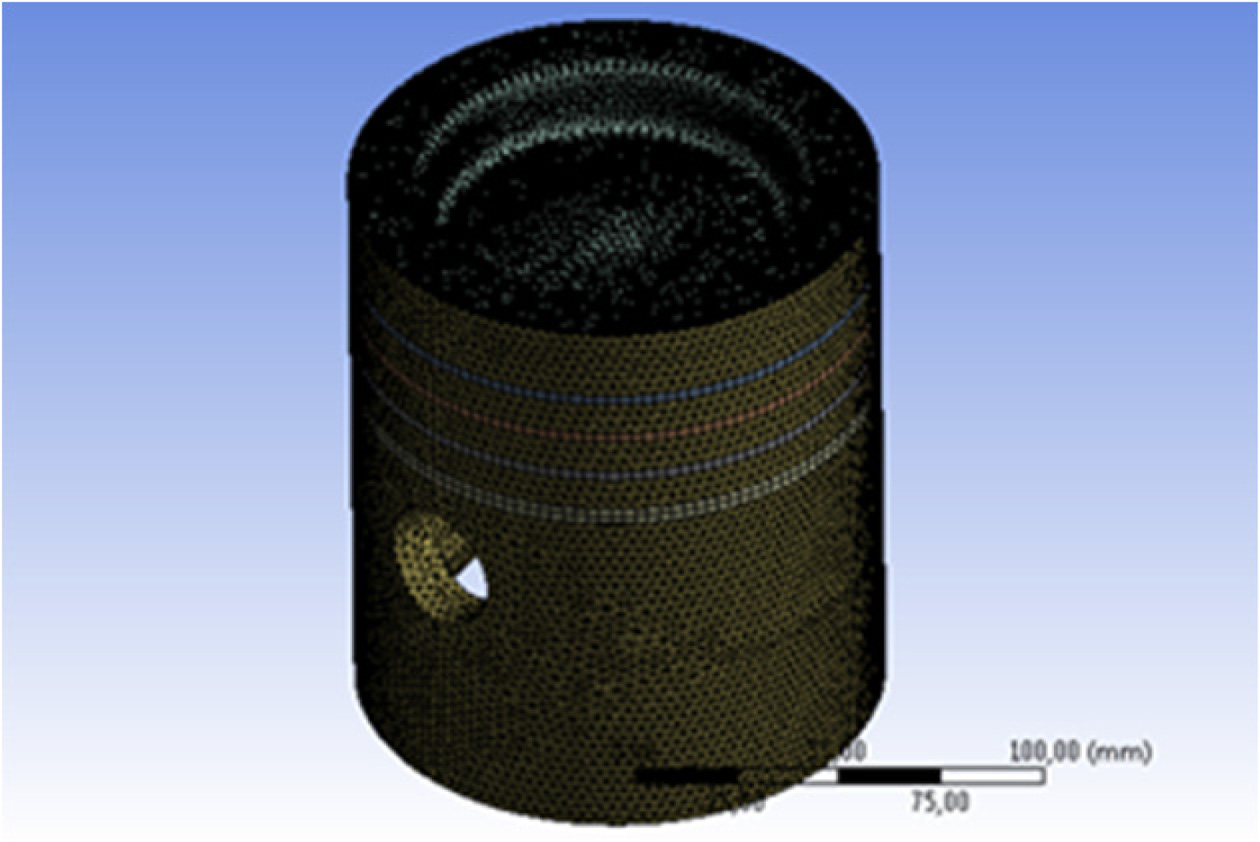

Mesh

Structure

Mesh structure of the piston analysed in this study was

presented in Fig. 2. To determine optimum mesh structure,

analysis were repeated for mesh structures with different node numbers. Based

on the obtained results, optimum node number was determined as about 570000,

and all analysis were conducted based on optimum mesh structure.

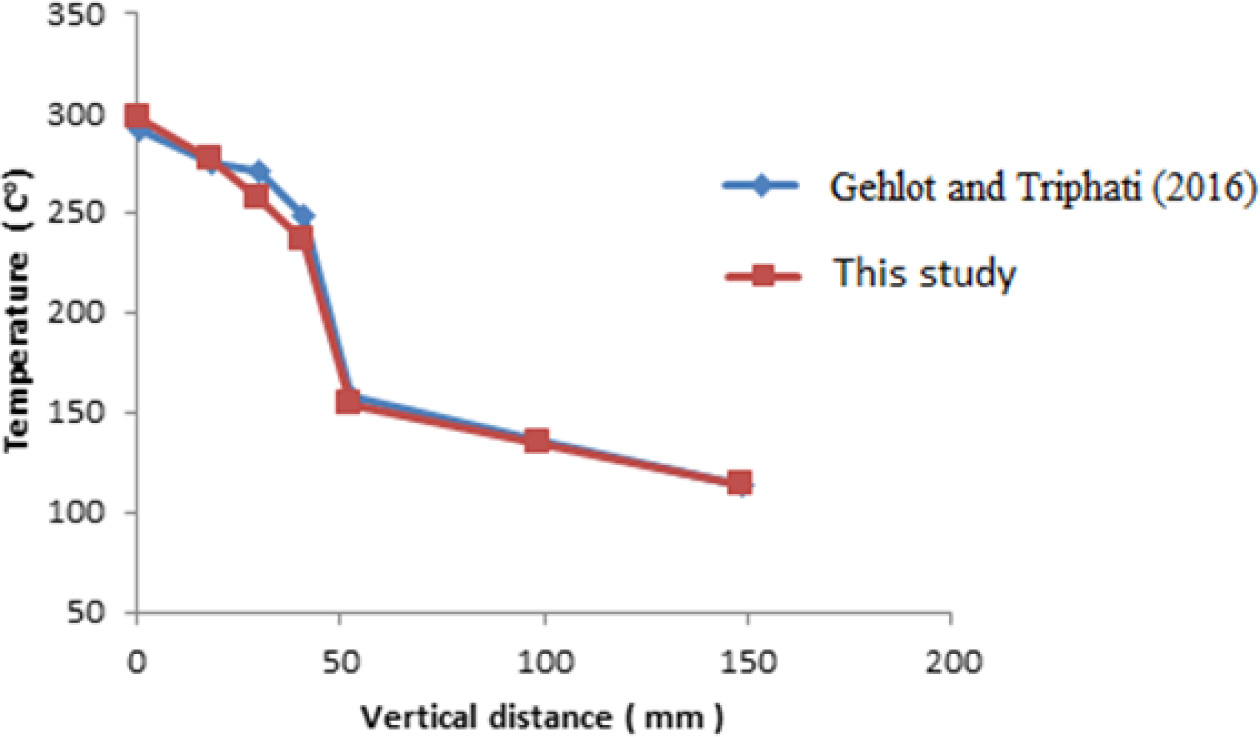

Validation

of numerical method

To determine whether numerical results are within reliable

region, these results should be compared with other studies accepted as

reliable. For this purpose, geometry and boundary conditions of previous

studies in the literature were repeated in simulation. Obtained results and

sample results from literature [4] were presented in Fig. 3.

In Fig. 3, change of surface temperature along piston side

surfaces were presented for both studies. As seen from the figure, surface

temperature curves for both studies are similar. Therefore, it could be said

that results obtained from numerical methods employed in this study are

reliable.

|

Fig. 1 Piston Geometry. |

|

Fig. 2 Mesh structure of problem. |

|

Fig. 3 Comparison of piston outer side surface temperature change with literature. |

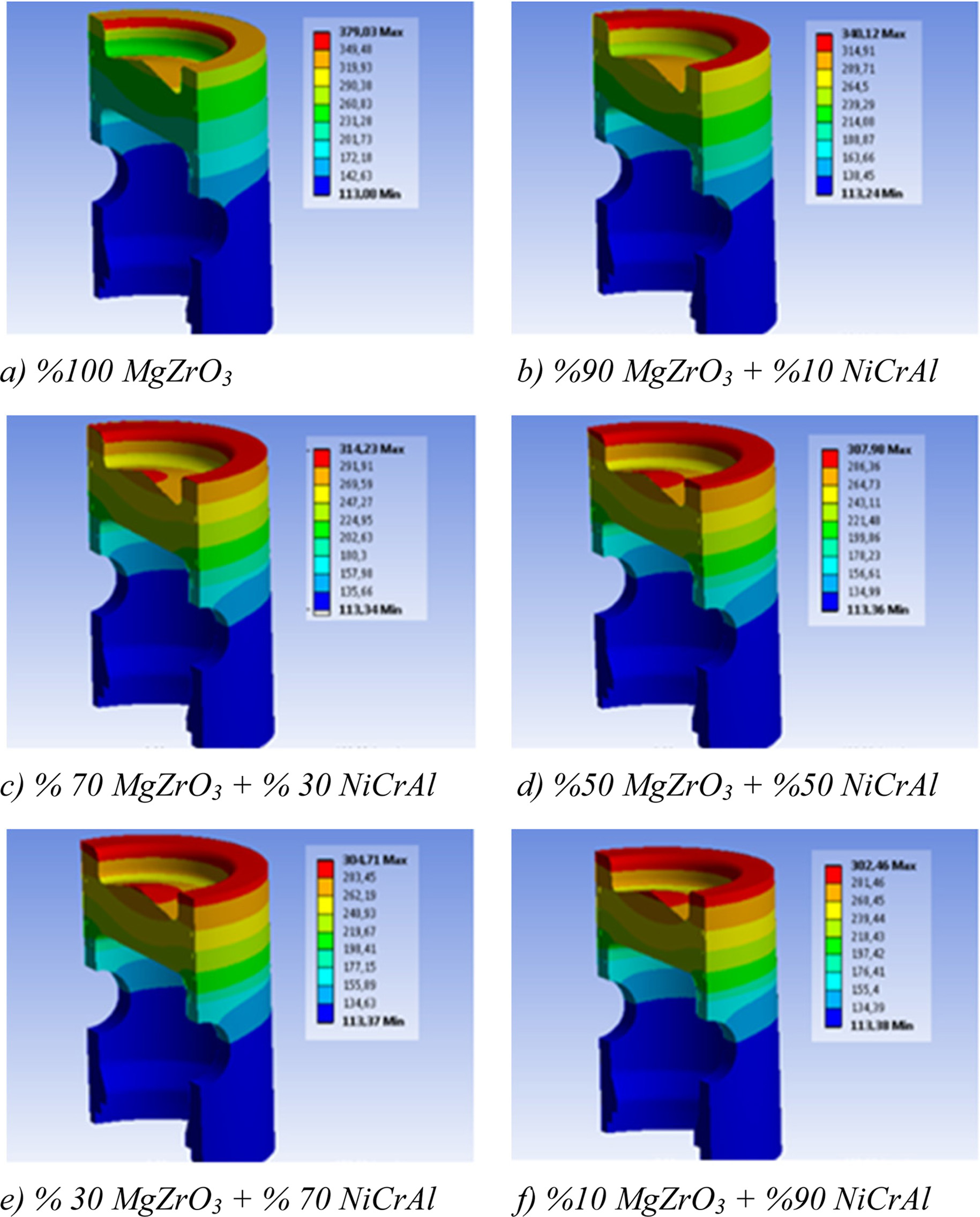

In this study, functional graded ceramic coating applied

on a designed diesel engine and temperature distribution on piston upper

surface based on bond coating were numerically evaluated for maximum and

minimum temperature changes on piston volume. For this purpose, upper surface

of piston was coated with ceramic to have bond coat thickness of micrometre,

and graded coat thickness of 100, 200, 300, 400, 500 and 600 micrometre. Graded

coating was applied as MgZrO3 and NiCrAl alloy. Piston bond coat was

kept constant as 100 micrometre NiCrAl alloy, and on this layer, graded MgZrO3

was applied with 100%, 90%, 70%, 50%, 30%, and 10% ratio, and

numerical simulations were repeated for graded coating. Some of the

analysis results were presented below.

Fig. 4 showed temperature distributions for graded coat

thickness 300 and different MgZrO3 alloy ratio. In this figure, 6

different states with 100%, 90%, 70%, 50%, 30%, and 10% MgZrO3 were

presented. As seen from figures, temperature distribution on pistons were similar

for all states. While maximum temperature was observed on the upper surface of

the piston, tem- peratures decreased

along the piston, and had minimum value at the bottom surface.

For constant coating thickness, decreased MgZrO3

alloy ratio decreased temperatures observed on all piston surfaces. Especially,

piston upper surface tem- perature

significantly decreased as MgZrO3 alloy ratio decreased. Piston

upper surface maximum temperature value was identified for 100% and 10% MgZrO3

alloy ratio as 379.03 and 302.46 oC respectively. As alloy

ratio of ceramic coating decreased, piston upper surface maximum

temperature approximately decreased 20.2%. For 6

different alloy ratio, piston bottom surface tem- perature was approximately 113 oC.

Therefore, piston bottom surface temperature was not significantly

affected from MgZrO3 alloy ratio.

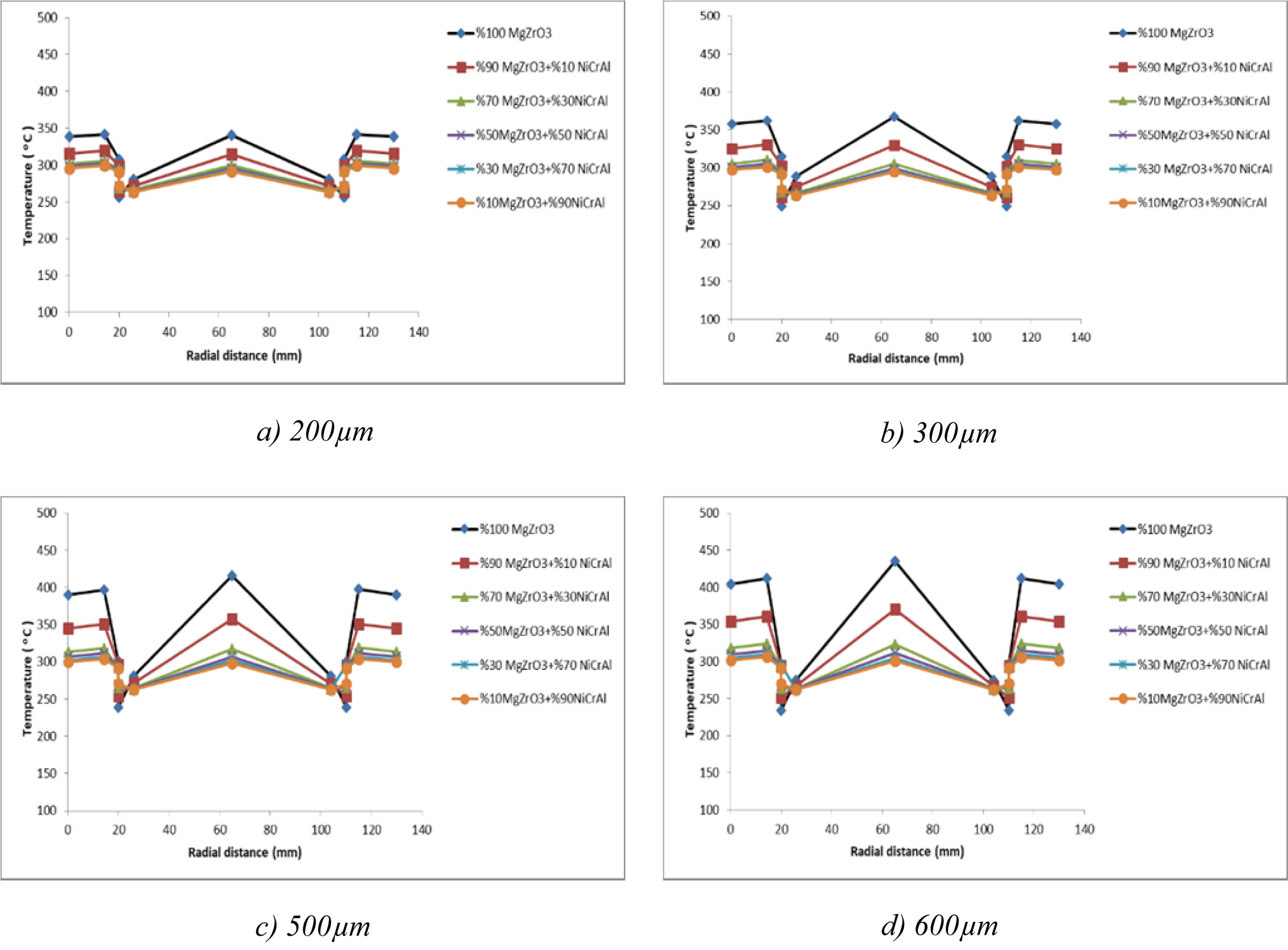

For different alloy ratios, graphics that show radial

piston upper surface temperature change were plotted for 200, 300, 500 and

600 µm coating thickness. These graphs are presented in Fig. 5. These

figures show radial piston upper surface temperature change along piston

diameter. For constant coating thickness, curves plotted for all alloy ratios

had similar structure. All curves present a symmetrical structure compared to

piston centre. Temperature level slightly changes for first 20 mm distance

from piston outer surface to centre. From this distance, temperature values

suddenly decrease and reach minimum level. Temperature values increase around

piston centre. At the central point of the piston, temperature levels reach

maximum level. This is similar for all analysed alloy ratio and coating thicknesses.

As seen from this figure, for all coating thicknesses,

piston upper surface temperatures are at maximum level when alloy ratio was

100%. With decreases alloy ratio, piston upper surface temperature decreased as

well. When alloy ratio was 90%, piston upper surface temperatures decreased.

When alloy ratio was between 70-10%, temperatures obtained for these ratios had

similar structure. For four coating thickness in the figure, there is similar

structure. Therefore, for constant coating thickness, as ceramic coating MgZrO3

alloy ratio increased, it can be stated that piston upper surface temperature

value increased. Especially when MgZrO3 ratio in coating was 70% or

higher, these ratios have significant effect on piston upper surface

temperature distribution. Additionally, curves for alloy ratio of 70% of lower

were slightly effected from coating thickness increase. Temperatures are at

similar level. However, temperature values for alloy rate of 70% or higher

increases as coating thickness increases. These values

reach maximum value for coating thickness of

600 µm. Therefore, with increasing coating thickness,

temperature difference between 70% and 100% alloy curves increase.

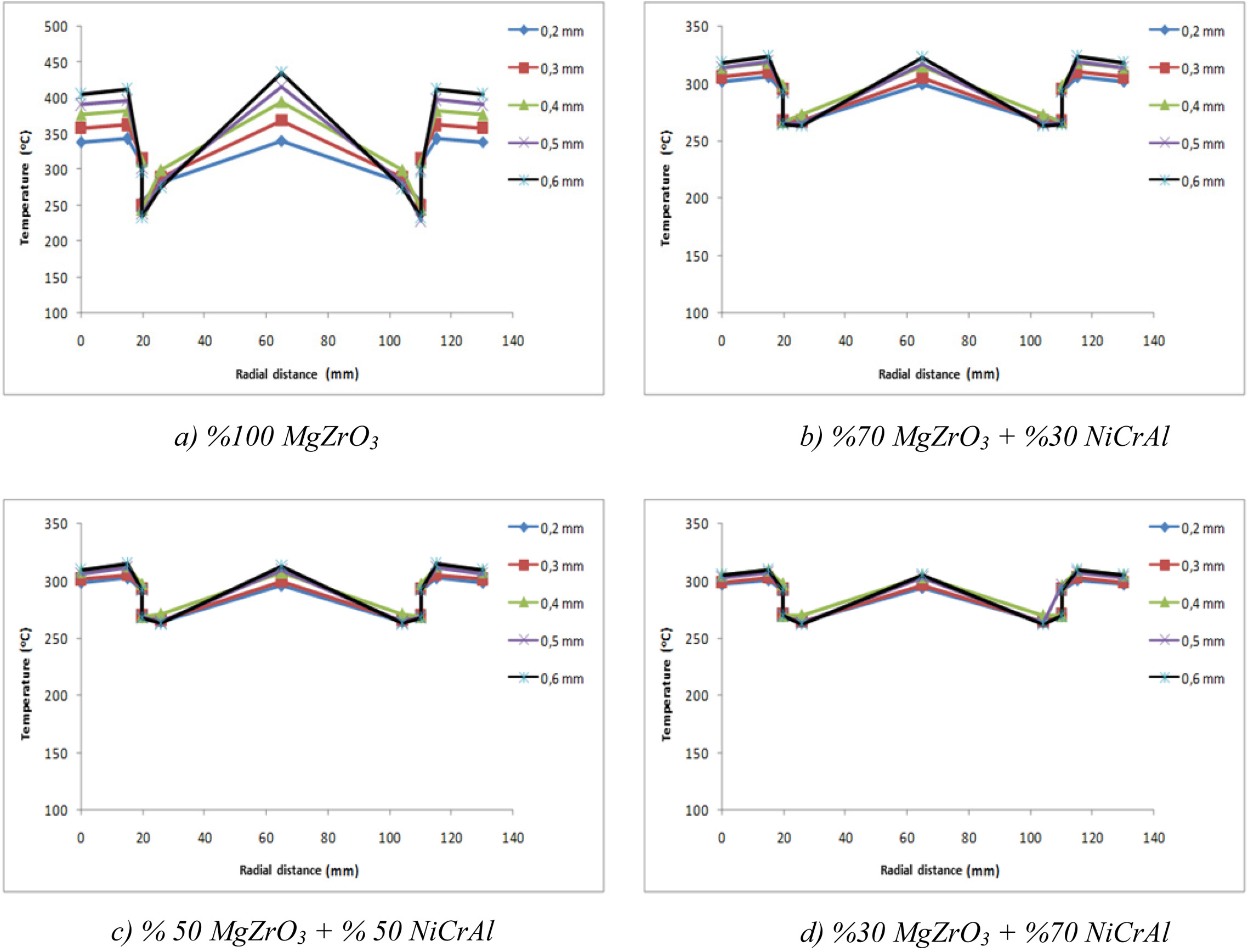

For different coating thickness, graphics that show radial

piston upper surface temperature change were plotted for 100%, 70%, 50% and 30%

ceramic coating alloy ratio. These graphs are presented in Fig. 6. These

figures show radial piston upper surface tem-

perature change along piston diameter. For constant coating thickness,

curves plotted for all alloy ratios had similar structure. All curves present a

symmetrical structure compared to piston centre. As seen from the figure,

for constant alloy rates, increased coating thickness increases

piston upper surface temperature. Especially when coating alloy ratio was 100%

MgZrO3, increased coating thickness can significantly increase

piston upper surface temperature. With decreasing alloy ratio, effect of

coating thickness on temperature distribution decreases as well. Small alloy ratios

has similar temperature curves for all analysed coating thicknesses.

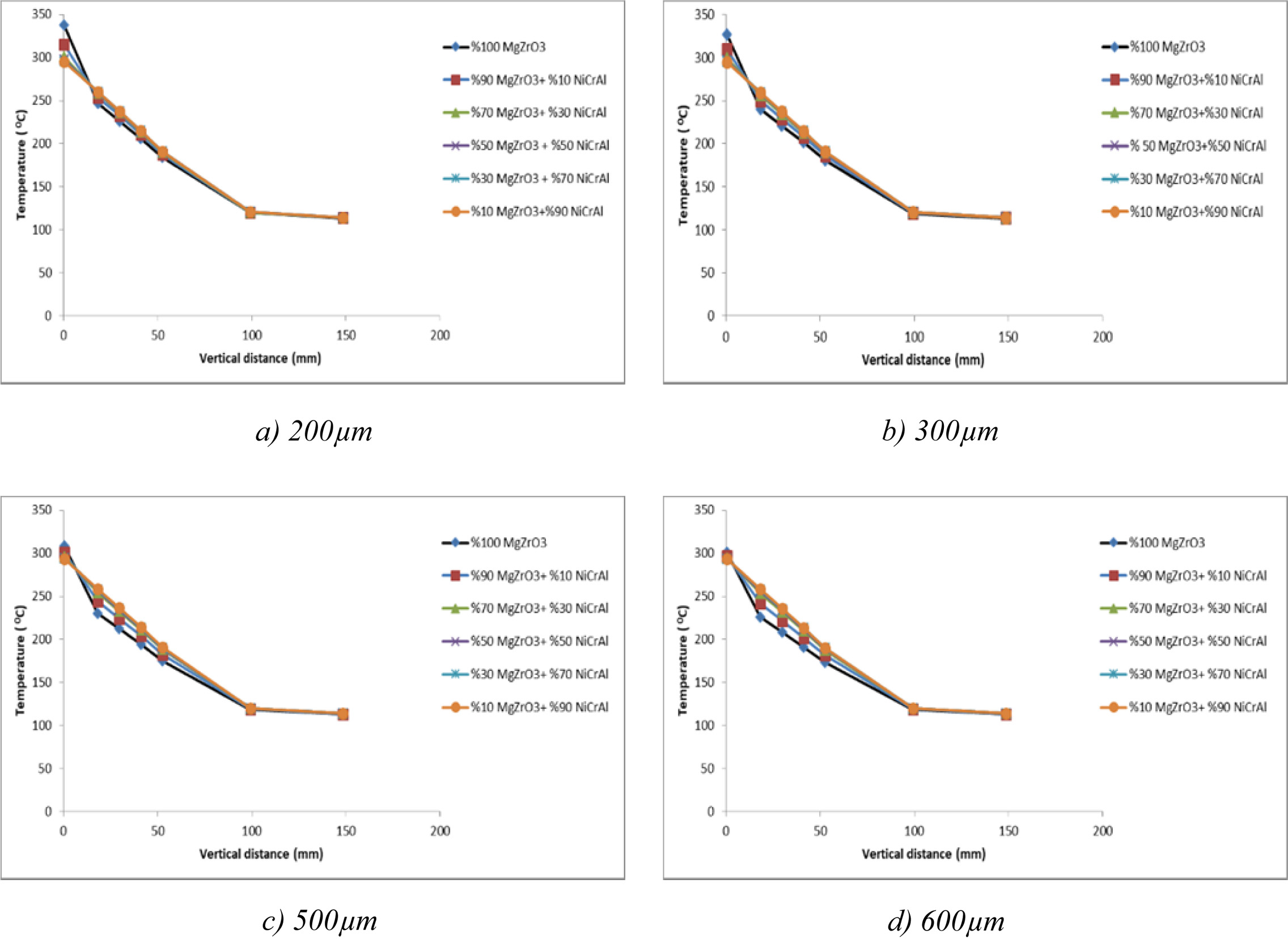

In Fig. 7, piston upper surface temperature changes

for different alloy rates are presented for 200 µm, 300 µm,

500 µm and 600 µm coating thickness. These figures show piston outer surface

temperature change from piston upper surface to piston bottom surface along

vertical axis. When this figure was analysed, for all alloy ratios, upper

surface of the piston showed maximum temperature, and temperatures

decreased along the piston to minimum level. Maximum temperature

on the upper surface of the piston was observed in 100% MgZrO3 alloy

model. With decreased MgZrO3 alloy ratio, piston upper temperature

decreased as well. However, this changed approximately 15mm after the upper

part of the piston and reverse states were observed. While maximum temperature

in that region was observed for 10% MgZrO3 alloy, temperatures

decreased with increased alloy ratio. Especially with increasing

coating thickness, temperature values observed in this region

are effected from coating alloy rate changes. 100 mm after the upper part

of the piston, alloy ratio on the piston had almost no significant effect on

temperature change, and all curves have similar structure in piston skirt. This

is similar for all analysed coating thicknesses.

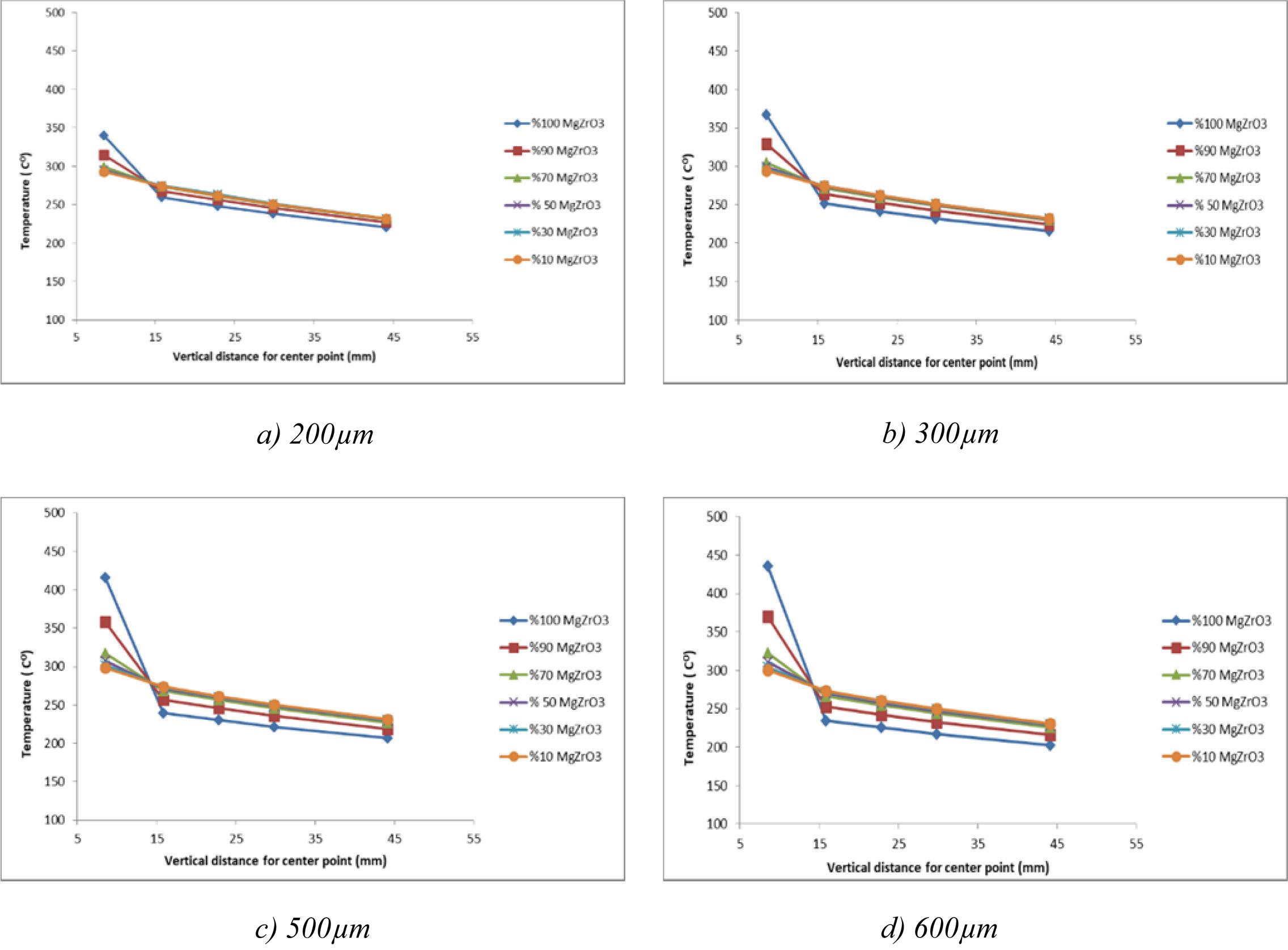

In Fig. 8, piston central axis temperature changes for

different alloy rates are presented for 200 µm, 300 µm, 500 µm

and 600 µm coating thickness. These figures show piston central axis

temperature change from piston upper surface to piston bottom surface along

vertical axis. When this figure was analysed, for all alloy

ratios, upper surface centre of the piston showed maximum

temperature, and temperatures decreased along piston central axis and reached

minimum level. For piston upper surface centre, maximum temperature was

observed for 100% MgZrO3 alloy coating model and minimum temperature

was observed for 10% MgZrO3 alloy coating model. MgZrO3 alloy

ratio decreased, piston upper central temperature decreased as well. However, this

changed approximately 10-15 mm after the upper part of the piston and reverse

states were observed. From this point, temperature decreases with

increasing alloy rate. While maximum temperature was

observed for 10% MgZrO3, minimum temperature was observed for 100%

MgZrO3. This case was similar along piston central axis. For all

analysed coating thicknesses, temperature curves show similar structure. Additionally,

for 200 µm coating thickness, temperature curves for

different alloy rates have similar levels. However, these curves diverge with

increasing coating thickness.

|

Fig. 4 Temperature distributions for a piston with different graded MgZrO3 coating ratios a) 100%, b) 90%, c) 70%, d) 50%, e) 30%, f) 10%. |

|

Fig. 5 Radial change of piston upper surface temperature for different MgZrO3 ratio a) 200 μm, b) 300 μm, c) 500 μm, d) 600 μm. |

|

Fig. 6 Radial change of piston upper surface temperature for different coating thickness a) %100 MgZrO3, b) %70 MgZrO3, c) %50 MgZrO3, d) %30 MgZrO3. |

|

Fig. 7 Temperature change along outer edge vertical length of piston for different alloy ratios a) 200 μm, b) 300 μm, c) 500 μm, d) 600 μm. |

|

Fig. 8 Temperature change of piston central axis along with vertical length for different alloy ratios a) 200 μm, b) 300 μm, c) 500 μm, d) 600 μm. |

In this study, temperature distribution on piston surfaces

were numerically analysed for ceramic thermal barrier coating on diesel engine

piston. 100 micrometre thick NiCrAl coating was applied as bond coat on the

upper surface of the piston. On this coating, graded MgZrO3+NiCrAl

alloy with 100, 200, 300, 400, 500 and 600 micrometre thicknesses were applied

for different alloy ratios. In graded coated sections of piston, simulations

were repeated for 100%, 90%, 70%, 50%, 30%, and 10% MgZrO3.

As a result of the analysis, it was determined that for all alloy

ratios, upper surface of the piston showed maximum temperature, and

temperatures decreased along the piston to minimum level at piston skirt

region. Maximum temperature on the upper surface of the piston was observed in

100% MgZrO3 alloy model. MgZrO3 alloy ratio decreased,

piston upper temperature decreased as well. In skirt region of the piston, it

was observed that alloy ratio had no significant effect on

temperature values. Minimum upper surface temperatures were

determined for alloy ratio between 70-10% and it was observed that these temperatures

were similar. All these coating thicknesses showed

similar behaviour. For constant alloy ratio, increased coating thickness also

increased piston upper surface temperature. As a result,

using different functional graded materials on a piston

increases piston resistance, enables upper surface of piston to achieve higher

temperatures, thus, increases overall thermal efficiency. Considering this

factors, it could be stated that 600 µm thickness and 100% MgZrO3

alloy coated piston model was the best state for analysed problem.

Preliminary work of this paper are presented as abstract

proceeding in Engineers of the Future International Student Symposium-EFIS2017

organised in Zonguldak, Turkey between 07-09 June 2018.

- 1. M. Cerit and M. Çoban, Int. J. Therm. Sci. 77 (2014) 11-18.

-

- 2. E. Büyükkaya, Surf. Coat. Tech. 202[16] (2008) 3856-3865.

-

- 3. E. Büyükkaya and M. Cerit, Surf. Coat. Tech. 202 (2007) 398-402.

-

- 4. R. Gehlot and B. Tripathi, J. Case Stu. Therm. Eng. 8 (2016) 291-299.

-

- 5. M. Cerit, V. Ayhan, A. Parlak, and H. Yasar, J. App. Therm. Eng. 31[2-3] (2011) 336-341.

-

- 6. D. Robinson and R. Palaninathan, Int. J. Fin. Elem. Analy. Des. 37[2] (2001) 85-95.

-

- 7. O.R. Kummitha and B.V.R. Reddy, J. Mater. T. 4[8] (2017) 8142-8148.

-

- 8. N.Y. Dudareva, R.D. Enikeev, and V.Y. Ivanov, Proc. Eng. 206 (2017) 1382-1387.

-

- 9. B. Dhinesh, Y.M.A. Raj, C. Kalaiselvan, and R. Krishna- Moorthy, Energy Conv. Man. 171 (2018) 815-824.

-

- 10. M. Yao, T. Ma, H. Wang, Z. Zheng, H. Liu, and Y. Zhang, Energy. 162 (2018) 744-752.

-

- 11. G.X. Lu, L.J. Hao, C. Liu, and F.X. Ye, Mater. Sci. Tech. 30[11] (2014) 1273-1282.

-

- 12. J. Muthusamy, G. Venkadesan, and U. Krishnavel, Therm. Sci. 20[4] (2016) S1189-S1196.

-

- 13. M. Cerit, Surf. Coat. Tech. 205[11] (2011) 3499-3505.

-

- 14. T.S. Sachit, R.V. Nandish, and Mallikarjun, Mater. T. Proc. 5[2] (2018) 5074-5081.

-

- 15. Z. Yao and Z. Qian, J. Alloy Comp. 768 (2018) 441-450.

-

- 16. S. Mahade, N. Curry, K.P. Jonnalagadda, R.L. Peng, N. Markocsan, and P. Nylén, Surf. Coat. Tech. 357 (2019) 456-465.

-

- 17. V. Garud, S. Bhoite, S. Patil, S. Ghadage, N. Gaikwad, D. Kute, and G. Sivakumar, Mater. T. Proc. 4[2] (2017) 188-194.

-

- 18. Z. Yao, K. Hu, and R. Li, J. Alloy Comp. 790 (2019) 466-479.

-

- 19. G. Venkadesan and J. Muthusamy, Cer. Int. 45[3] (2019) 3166-3176.

-

- 20. J. Moon, H. Choi, and C. Lee, J. Ceram. Process. Res. 1[1] (2000) 69-73.

- 21. D.H. Lee, B. Jang, C. Kim, and K.S. Lee, J. Ceram. Process. Res. 20[5] (2019) 499-504.

- 22. J.H. Cho, T.W. Kim, Y.G. Jung, K.D. Lee, J. Ceram. Process. Res. 10[3] (2009) 344-350.

- 23. J.W. Lee, C.H. Lee, H.J. Kim, J. Ceram. Process. Res. 2[3] (2001) 113-119.

- 24. S.H. Kim, Z.Y. Fu, K. N, and S.W. Lee, J. Ceram. Process. Res. 12[2] (2011) 126-131.

- 25. Z. Yao and W. Li, J. Alloy Comp. 812 (2020) 152162.

-

- 26. S. Caputo, F. Millo, G. Boccardo, A. Piano, G. Cifali, and F.C. Pesce, J. App. Therm. Eng. 162 (2019) 114233.

-

- 27. V.R. Reghu, A. Basha, K. Lobo, S. Shivakumar, P. Tilleti, V. Shankar, and P. Ramaswamy, Mater. T. Proc. 19 (2019) 630-636.

-

- 28. P. Ramaswamy, V. Shankar, V.R. Reghu, N. Mathew, and S. Manoj Kumar, Mater. T. Proc. 5 (2018) 12623-12631.

-

- 29. H. Yerrennagoudaru and K. Manjunatha, Mater. T. Proc. 4[2] (2017) 2333-2340.

-

This Article

This Article

-

2020; 21(4): 433-441

Published on Aug 30, 2020

- 10.36410/jcpr.2020.21.4.433

- Received on Jan 21, 2020

- Revised on Apr 4, 2020

- Accepted on Apr 7, 2020

Services

Services

- Abstract

introduction

definition of problem and mathematical formulation

findings and discussion

results

- Note

- References

- Full Text PDF

Shared

Correspondence to

Correspondence to

- Tolga Demircan

-

Department of Mechanical Engineering, Faculty of Engineering, Kırıkkale University, Kırıkkale, Turkey

Tel : +90 3183574242 / 1057

Fax: +90 3183572459 - E-mail: tolgademircan@gmail.com

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.