- Preparation and characterization of hexaferrites Ba0.40Sr0.60-xNdxFe12.00-xZnxO19 by the solid-state reaction route

Yujie Yang*, Xiansong Liu, Shuangjiu Feng, Xucai Kan, Qingrong Lv, Feng Hu, Jiangli Ni, Chaocheng Liu and Wei Wang

Engineering Technology Research Center of Magnetic Materials, School of Physics & Materials Science, Anhui University, Hefei 230601, P. R. China

The microstructural, spectral, magnetic and electric properties of hexaferrites Ba0.40Sr0.60-xNdxFe12.00-xZnxO19 (0.00 ¡Â x ¡Â 0.30) synthesized by the solid-state reaction route have been studied. XRD results confirmed that the hexaferrites with Nd-Zn content (x) of 0.00 ¡Â x ¡Â 0.24 were single M-type phase, and the hexaferrite with x = 0.30 exhibited the M-type phase and impurity phase. The remanence (Br) increased with x from 0.00 to 0.06, and then decreased when x ¡Ã 0.06. The intrinsic coercivity (Hcj) and magnetic induction coercivity (Hcb) decreased with x from 0.00 to 0.30. Br indicated a linear decreasing behavior with increasing temperature from 20 oC to 140 oC. Hcj raised linearly with increasing temperature from 20 oC to 140 oC. The value of aBr basically remained constant with Nd-Zn content (x). The value of aHcj increased with x from 0.00 to 0.12, and began to decrease when x ¡Ã 0.12. The electrical resitivity (¥ñ) presented a decreasing trend with x from 0.00 to 0.30.

Keywords: M-type hexaferrites, Solid-state reaction route, X-ray diffraction, Magnetic measurements

Hexagonal ferrites have received considerable attention

of researchers and engineers since the discovery of the ferrite in the 1950s.

Although not as powerful as the newest NdFeB or SmCo5 magnets, they

still have a large market share in the market of magnetic materials, because of

their perfect chemical stability, high Curie temperature, high

performance-price ratio, and easy methods of production [1, 2]. In addition,

M-type hexaferrites can be widely utilized as microwave devices,

permanent magnetic materials, radar communication and microwave

devices [3-5]. Many preparation techniques have been

used to prepare the M-type hexaferrites such as hydrothermal method [6],

three-step calcination method [7], co-precipitation method [8], standard

solid-state reaction route [9], molten flux calcination method [10], sol-gel

method [11], pulsed laser deposition method [12], and extrusion-based three-dimensional

(3D) printing [13]. In the above-mentioned methods, the solid-state reaction

route was used to fabricate the hexaferrites because of a few several

profitable factors, for example controllable grain size, low manufacturing

cost, simple technology and high productive.

In order to modify the intrinsic magnetic properties of

M-type hexaferrites, the M-type hexaferrites been doped with rare-earth metals

and transition metals, or the combination of these [14-36]. Singh et al.

reported the rare-earth substitution (La3+, Nd3+ and Sm3+

) doped strontium ferrite (Sr-M), and the results exhibited that the

magnetization moment (Ms) and remenance (Mr)

decrease with increasing rare-earth ions substitution, while the

enhancement of Hc values may be due to higher

magnetocrystalline anisotropy [15]. The Nd-substituted strontium

hexaferrites prepared by hydrothermal synthesis have been

reported by Wang et al. [17], and it is found that Nd substitution with a Nd-Sr

ratio of 1/8 enhances the coercivity without causing any

significant deterioration in either the saturation

magnetization or the remanence. Shekhawat et al. synthesized the La-Sm

substituted Sr-hexaferrite SrAl4(La0.5Sm0.5)xFe8-xO19

(0.0 ≤ x ≤ 1.5) nanomaterials by the auto combustion method and found

that the remanence magnetization increases while intrinsic

coercivity decreases with substitution [18]. The Zn-doped Ba hexaferrite single

crystals have been synthesized, and it is found that Zn substitution significantly

influences the coercivity and magnetization of Ba

hexaferrite while the Curie temperature was nearly constant over the range of

doping [23]. Zhang et al. reported the Nd-Co doped strontium hexaferrites Sr1-xNdxFe12-xCoxO19

(0.0 ≤ x ≤ 0.4) fabricated by sol-gel autocombustion method, and the

results showed that Nd-Co substitution can improve the saturation magnetization

and coercivity and reaches a maximum at x=0.2 [33]. Liu et al.

prepared the Ce-Zn co-substituted M-type strontium hexaferrites by the

ceramic method, and the results showed that Ms and Hc

can be improved significantly [36].

In this article, in order to enhance

the magnetic properties, we have selected a combination of Nd3+ and

Zn2+ ions to substitute in the M-type Ba-Sr hexaferrites. The

hexaferrites Ba0.40Sr0.60-xNdxFe12.00-xZnxO19

(0.00 ¡Â x ¡Â 0.30) were successfully synthesized by the

solid-state reaction route. Impact of Nd-Zn co-doping on the

microstructural, spectral and electric properties was analyzed. Subsequently,

the magnetic properties of hexaferrites with different Nd-Zn content

(x) were systematically investigated under

different temperatures from room

temperature (20 oC) to 140 oC. The novelty of this work is doing a study on the temperature coefficient of remanence (Br) (aBr), and

temperature coefficient of intrinsic coercivity (Hcj) (aHcj) for the Nd-Zn co-doped hexaferrites.

The hexaferrites Ba0.40Sr0.60-xNdxFe12.00-xZnxO19

(0.00 ≤ x ≤ 0.30) were prepared via the solid-state reaction route

[37]. Barium carbonate (BaCO3), strontium carbonate

(SrCO3), metallic oxides (Nd2O3, Fe2O3

and ZnO) were weighted in stoichimetric ratio. And then, the raw materials were

thoroughly mixed together in water for 10 h in a ball mill in order to obtain

finely mixed powder. Further, the as-mixed powder was dried, and pressed into

circular pellets with Φ30 × 16 mm. Subsequently, the pellets

were calcined in a muffle furnace at 1,260 oC for

2.0 h. The calcined pellets were shattered in a vibration mill, and suitable

additives (CaCO3 0.8 wt%, SiO2 0.2 wt% and Al2O3

0.2 wt%) were added, then the mixture was wet-milled in a ball-mill for

16 h. This procedure guarantees a narrow particle size distribution with the

mean size of around 0.75 μm. The fine milled hexaferrite slurry was pressed

into circular pellets with Φ30 × 16 mm in a magnetic field of 1.2 T. In

order to measure the DC electrical resitivity, the fine milled hexaferrite

slurry was dried, and then pressed into circular pellets with Φ20 × 8

mm. Finally, all green pellets were sintered in a muffle furnace at 1,185 oC

for 1.5 h.

The phase identification and structural characterization of

synthesized samples were performed by X-ray diffraction (XRD,

Rigaku Smartlab). The surface morphology of the hexaferrites was detected by a

field emission scanning electron microscopy (FE-SEM, HITACHI S-4800). The

magnetic properties were measured at different temperatures from room

temperature (20 oC) to 140 oC

using a Hysteresis graph meter (NIM-2000HF, National

Institute of Metrology of China). (Resistivity testing system, Ningbo rooko

FT-353) was used to measure the DC electrical resitivity (ρ) of

the hexaferrites at room temperature.

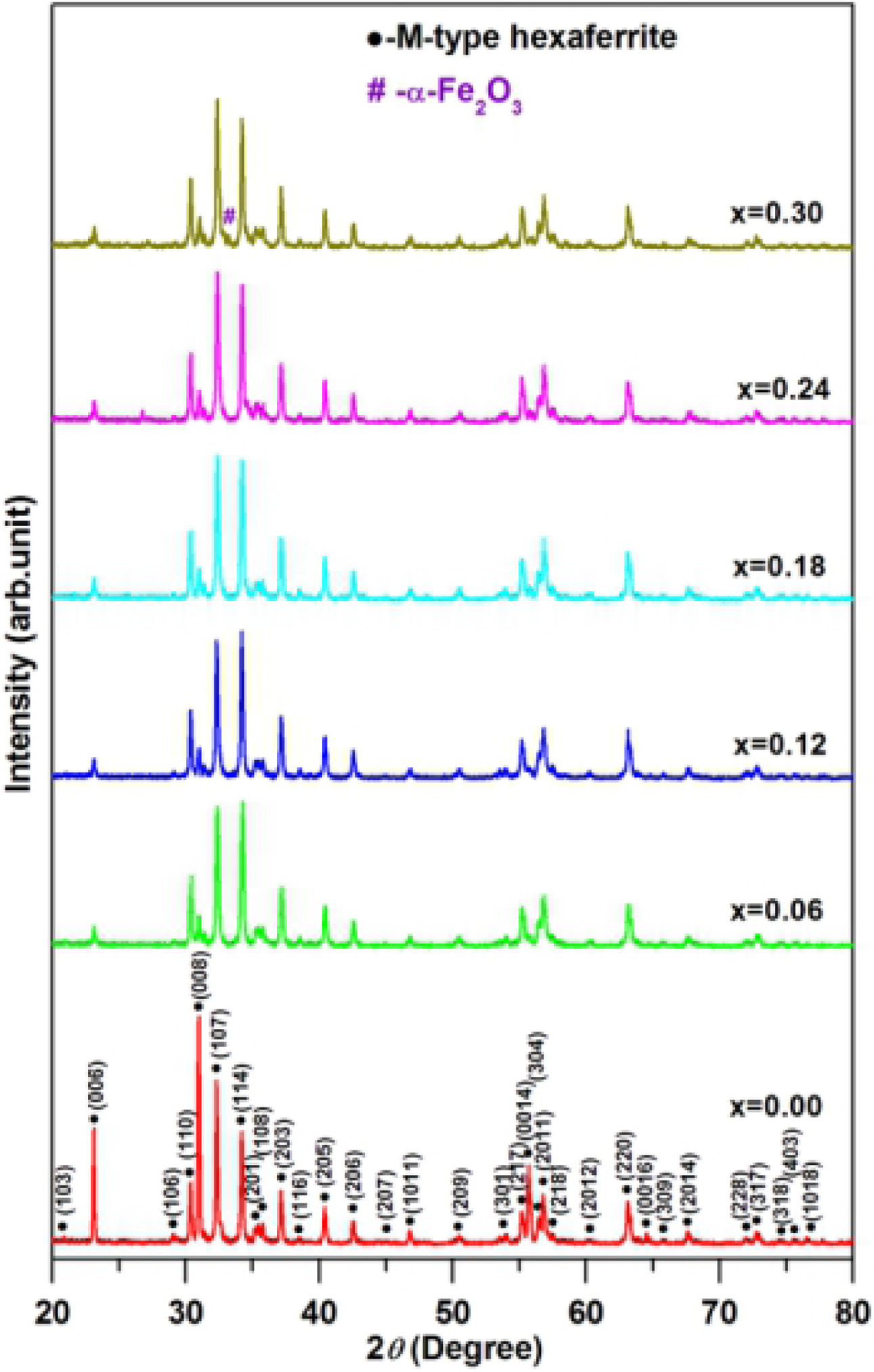

Fig. 1 presents the XRD patterns of hexaferrites Ba0.40Sr0.60-xNdxFe12.00-xZnxO19

with different Nd-Zn content (x). The characteristics

peaks were compared with the M-type hexaferrite ICCD card No.

51-1879. It can be observed that the hexaferrites Ba0.40Sr0.60-xNdxFe12.00-x ZnxO19 with

Nd-Zn content (x) ≤ 0.24 belonged to M-type hexagonal crystal structure. The

presence of hematite (α-Fe2O3) (ICCD card no. 89-0599)

detected for the hexaferrite with Nd-Zn content (x) = 0.30 might be due the

incomplete reaction under the preparing conditions. These show that the maximum

doped content of Nd-Zn co-doping can not exceed x = 0.24.

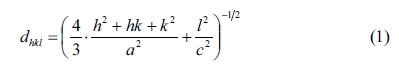

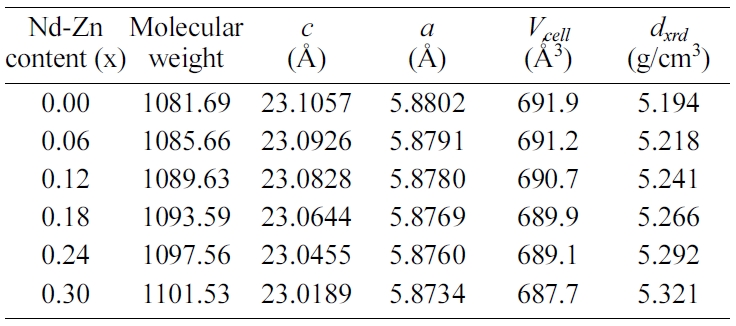

The lattice parameters c and a of the

hexaferrites Ba0.40Sr0.60-xNdxFe12.00-xZnxO19

were calculated using to the following formula [38].

In the given relation, dhkl is the

interplaner spacing of the lines in XRD pattern and h, k and l

are the Miller indices. The values of lattice parameters c and a

for the hexaferrites Ba0.40Sr0.60-xNdxFe12.00-xZnxO19

with different Nd-Zn content (x) are listed in Table 1. The values

of c and a decrease with increasing Nd-Zn content (x) from 0.00

to 0.30. The possible explanation for the decrease of c and a

with increasing Nd-Zn content (x) can be attributed to the difference in the

ionic radii (Δr) of the metal ions and the number of ionic substitutions

of each species. Substitution of Sr2+ (r = 1.180 Å) by Nd3+

(r = 0.983 Å) makes a negative difference in the ionic radii of Δr

= -0.197 Å. Substitution of Fe3+ (r = 0.645 Å) by Zn2+ (r

= 0. 740 Å) makes a positive difference in the ionic radii of Δr =

+0.095 Å. As in the case of Nd-Zn content (x) = 0.12, the lattice parameter

c and a are decreased.

The unit cell volume (Vcell) of the

hexaferrites Ba0.40Sr0.60-xNdxFe12.00-xZnxO19

was calculated from the following equation [38]:

And its values are summarized in Table 1. It is clearly

seen that the unit cell volume (Vcell) decreases with Nd-Zn

content (x) from 0.00 to 0.30. The decrease in the Vcell is

due to the decrease of lattice parameters c and a with increasing

Nd-Zn content (x) as shown in Table 1. The X-ray density (dxrd)

has been calculated by using the below formula [39]:

where Z is the number of

molecular per unit cell, M is the molecular weight, NA

is Avogadro’s number and Vcell is unit cell volume. And the

values dxrd are listed in Table 1. It noticed that the value

of dX-ray enhances from 5.194 g/cm3 at x = 0.00 to

5.321 g/cm3 at x = 0.30. The enhancement of dxrd

with increasing Nd-Zn content (x) can be attributed to the larger molecular

weight and decreasing trend of unit cell volume (Vcell) for the Nd-Zn co-doped

hexaferrites displayed in Table 1.

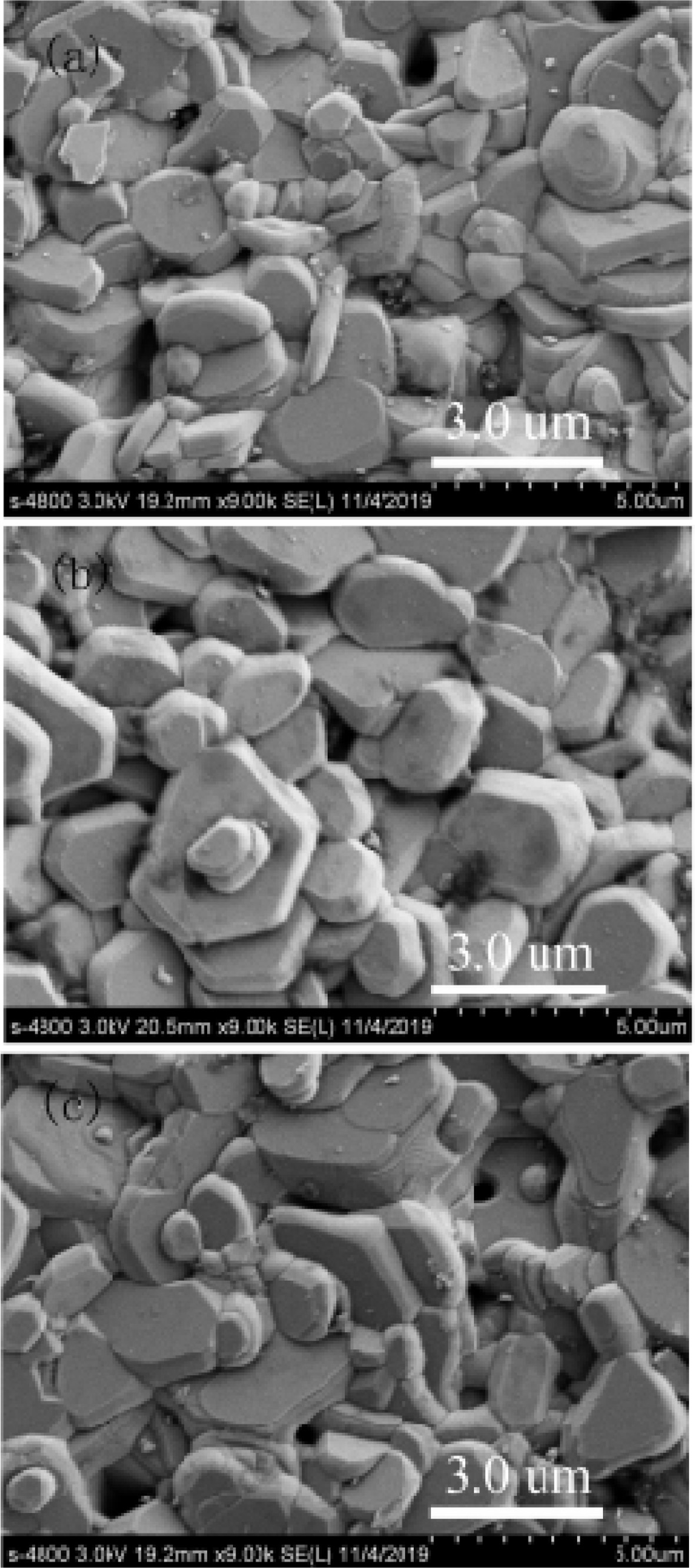

Fig. 2 shows the FE-SEM images of the hexaferrites Ba0.40Sr0.60-xNdxFe12.00-xZnxO19

with x = 0.00, x = 0.12, and x = 0.24. This

indicates that the grains in the hexaferrites are homogeneous

distribution with hexagonal plate like shape. The average grain

size increases from 1.8 μm at x = 0.00 to 3.2 μm at

x = 0.24.

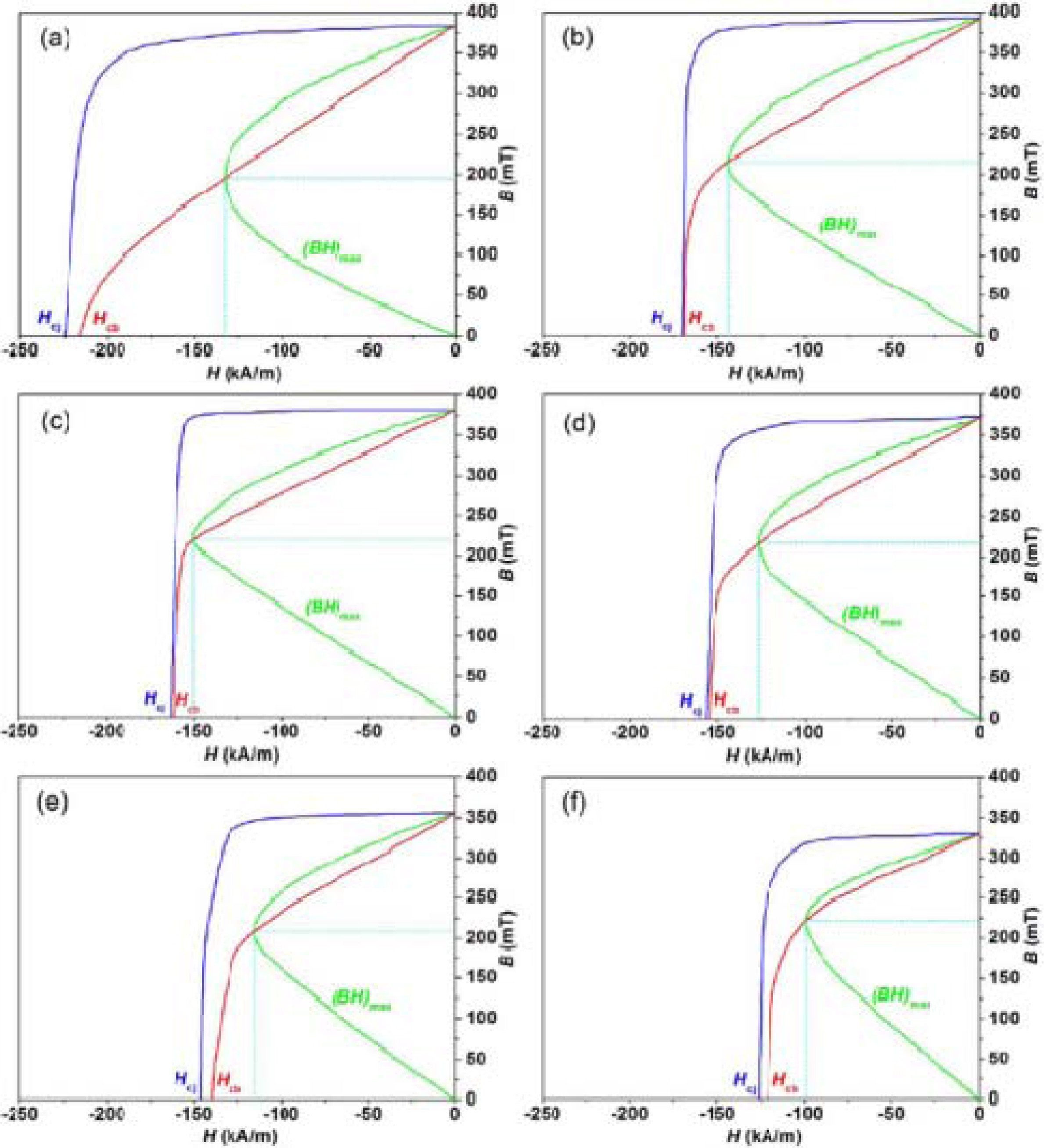

Fig. 3 represents the room temperature demagnetizing curves

of the hexaferrites Ba0.40Sr0.60-xNdxFe12.00-xZnxO19

with different Nd-Zn content (x). As revealed by the demagnetizing curves, the

magnetic properties of the hexaferrites are greatly influenced by the

substitution of Sr2+ ion by Nd3+ ion and Fe3+

ion by Zn2+ ion. The remanence (Br), magnetic

induction coercivity (Hcb), and intrinsic coercivity (Hcj)

at the room temperature are derived from the demagnetizing curves of the

hexaferrites samples with different Nd-Zn content (x).

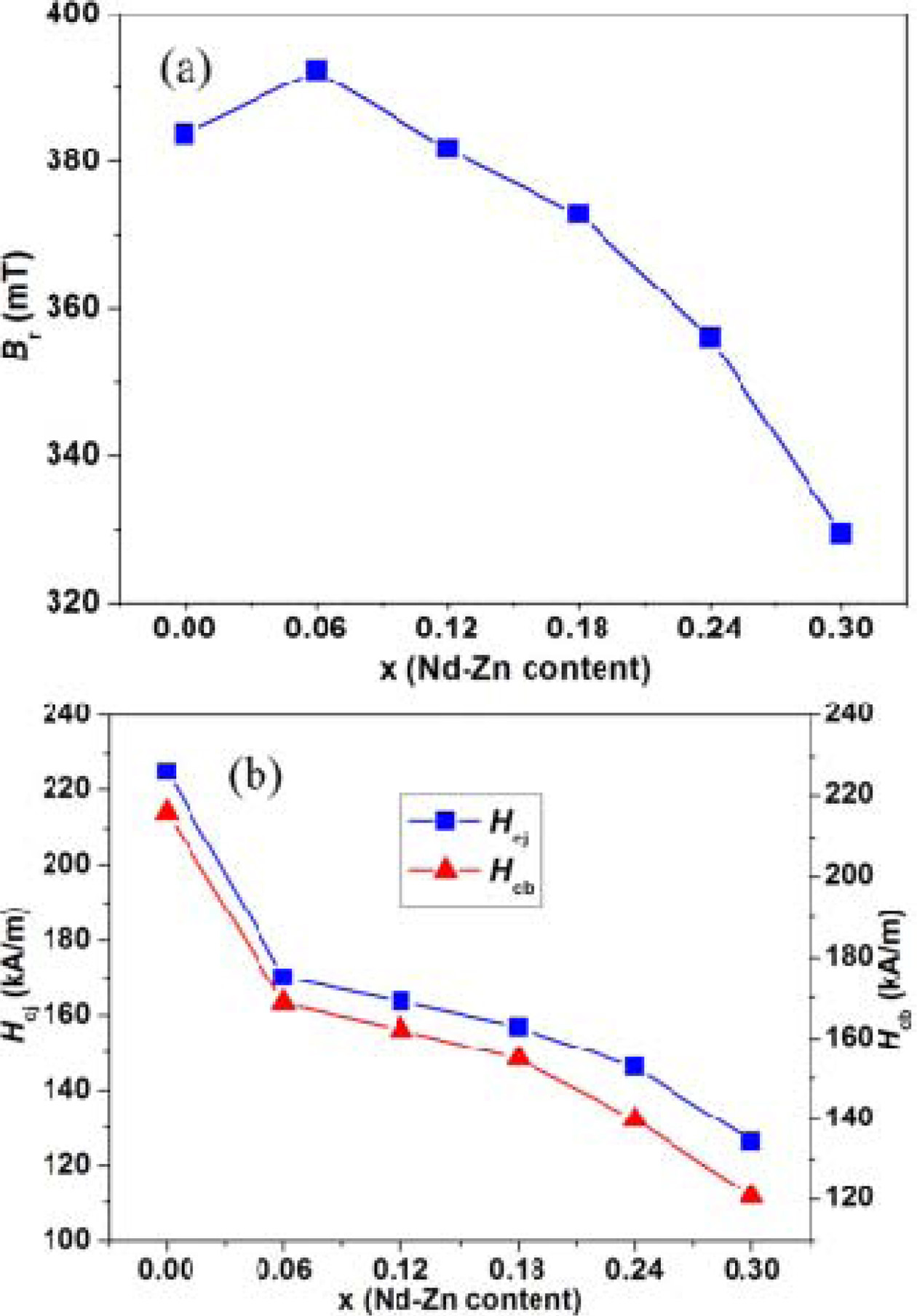

The remanence (Br) of the hexaferrites

Ba0.40Sr0.60-x NdxFe12.00-xZnxO19

as a function of Nd-Zn content (x) is plotted in Fig. 4(a). It is clearer

that a suitable amount of Nd-Zn substitution can increase the remanence (Br)

of the hexaferrites. In Fig. 4(a), with increasing Nd-Zn content

(x), Br first increases and reaches to the maximum

value of 386.0 mT at Nd-Zn content (x) = 0.06, and then decreases when Nd-Zn

content (x) ≥ 0.06. The changing trend of remanence (Br)

can be explained on the basis of the occupation of the substituted ions and the

impurity phase. M-type hexaferrites belong to P63/mmc space group,

and have five crystallographic sublattices, such as three kinds of octahedral

sites (2a, 12k, 4f2), one tetrahedral site (4f1)

and one bipyramidal site (2b). The 2a, 12k and 2b

sites have upward spin direction, and the 4f1 and 4f2

sites have downward spin direction [37, 40]. Herme et al. [41]

have reported that in the M-type hexaferrites, Nd3+ ions substitute

the Sr2+ sites in the vicinity of 4f2 sites via

Mössbauer analysis. Lee et al. [42] have reported that Zn2+ ions

prefer to occupy the 4f1 and 2b sites of tetrahedral

sites in the M-type hexagonal structure by Mössbauer spectra. Zn2+ ion

is nonmagnetic. And the magnetic moment of Fe3+ ion is 5 μB.

Therefore, the increase of remanence (Br) for the

hexaferrites with increasing Nd-Zn content (x) from 0.00 to 0.06 is probably

due to the below factor. When Nd-Zn content (x) ≤ 0.06, the number of Zn2+

ions entering 4f1 sites (spin down) is

more than that of Zn2+ ions entering 2b sites (spin

up). This in turn decreases the negative magnetic moment of Fe3+ ions.

Consequently, according to equation (3), the whole magnetic

moment is enhanced. This leads to the increase of the

remanence (Br). When Nd-Zn content (x) ≥ 0.06, the

decrease of remanence (Br) for the hexaferrites may be

attributed to the below three reasons. Firstly, at Nd-Zn content (x) ≥ 0.06, Zn2+

ions substitute Fe3+ ions in 2b sites having spin-up.

According to equation (3), this in turn decreases the whole magnetic moment.

This results in the decrease of the remanence (Br).

Secondly, Zn2+ (0 μB) ions substituting magnetic Fe3+

ions (5 μB) weaken the super-exchange interaction

between metallic ions in the M-type hexaferrites, and then the

remanence (Br) is decreased. Thirdly, when Nd-Zn

content (x) = 0.30, as seen from Fig. 1, the impurity phase

(hematite: α-Fe2O3) leads to the decrease of

remanence (Br).

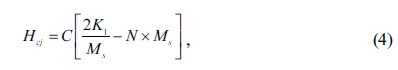

Fig. 4(b) shows the intrinsic coercivity (Hcj)

and magnetic induction coercivity (Hcb) of the hexaferrites

Ba0.40Sr0.60-xNdxFe12.00-xZnxO19

as a function of Nd-Zn content (x). As shown in Fig. 4(b), the values of Hcj

and Hcb show a decreasing trend with increasing Nd-Zn content

(x), and decrease from 225.0 and 215.9 kA/m at x = 0.00 to 126.2 and 120.7 kA/m

at x = 0.30, respectively. This proposes that Nd-Zn co-substitution can modify

the coercivity of M-type Ba-Sr hexaferrites. Yang et al. [43] have

reported that in the M-type hexaferrites, the ions at octahedral

4f2 site and bipyramidal 2b

site are known to be the main contributors to the magnetocrystalline

anisotropy. According to the Stroner-Wohlfarth theory, the

intrinsic coercivity (Hcj) of the M-type

hexaferrites which results from coherent rotation of

magnetization can be calculated by the following equation [44]:

where C is dimensionless constant of

material, K1 is the first anisotropy constant, and

N is the grain demagnetization factor. Therefore, according

to the equation (4), the decrease of Hcj with increasing

Nd-Zn content (x) from 0.00 to 0.30 could be due to the following two reasons.

Firstly, as seen from Fig. 2, the average grain size of M-type hexaferrite

increases with increasing Nd-Zn content (x) from 0.00 to 0.30. Thus, the value

of N increases with increasing Nd-Zn content (x). According to equation

(4), the value of Hcj is decreased. Secondly, the results of

Mössbauer spectra showed that Zn2+ ions prefer to occupy the 4f1

and 2b sites of tetrahedral sites in the M-type hexagonal structure

[42]. The decrease of Hcj with increasing Nd-Zn content (x)

may be related to the reduction of magnetocrystalline anisotropy

field as a result of Zn2+ substitution for Fe3+ ions at 2b

sites.

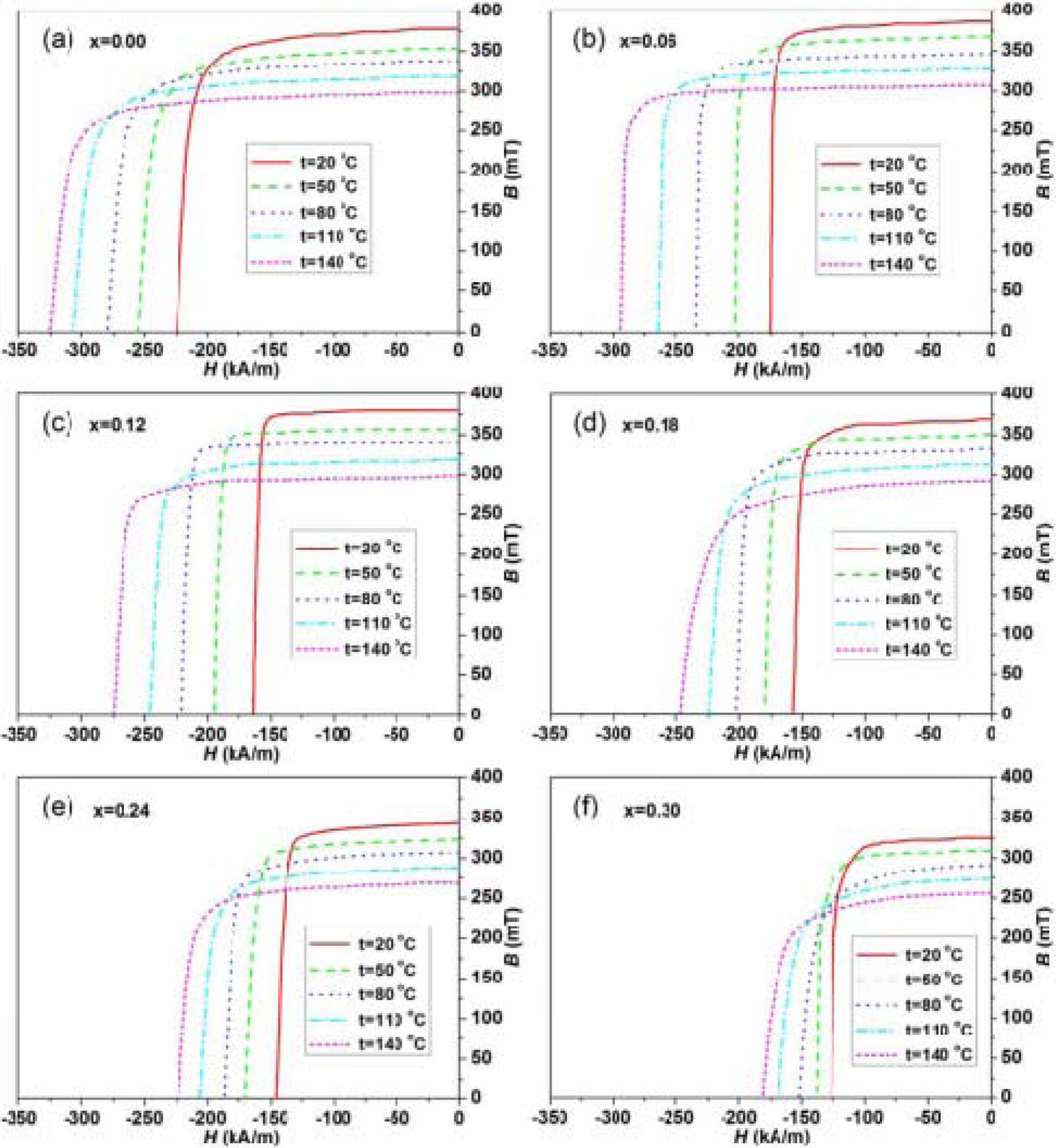

The temperature dependent demagnetizing curves of the

hexaferrites Ba0.40Sr0.60-xNdxFe12.00-xZnxO19

with different Nd-Zn content (x) are presented in Fig. 5. The changing trend of

the demagnetizing curves measured at different temperatures is in agreement

with that reported by T.D.K. Corporation [45] and A. Goldman et al. [46]. The

values of the remanence (Br), and intrinsic coercivity (Hcj)

at different temperatures are calculated from the demagnetizing curves for the

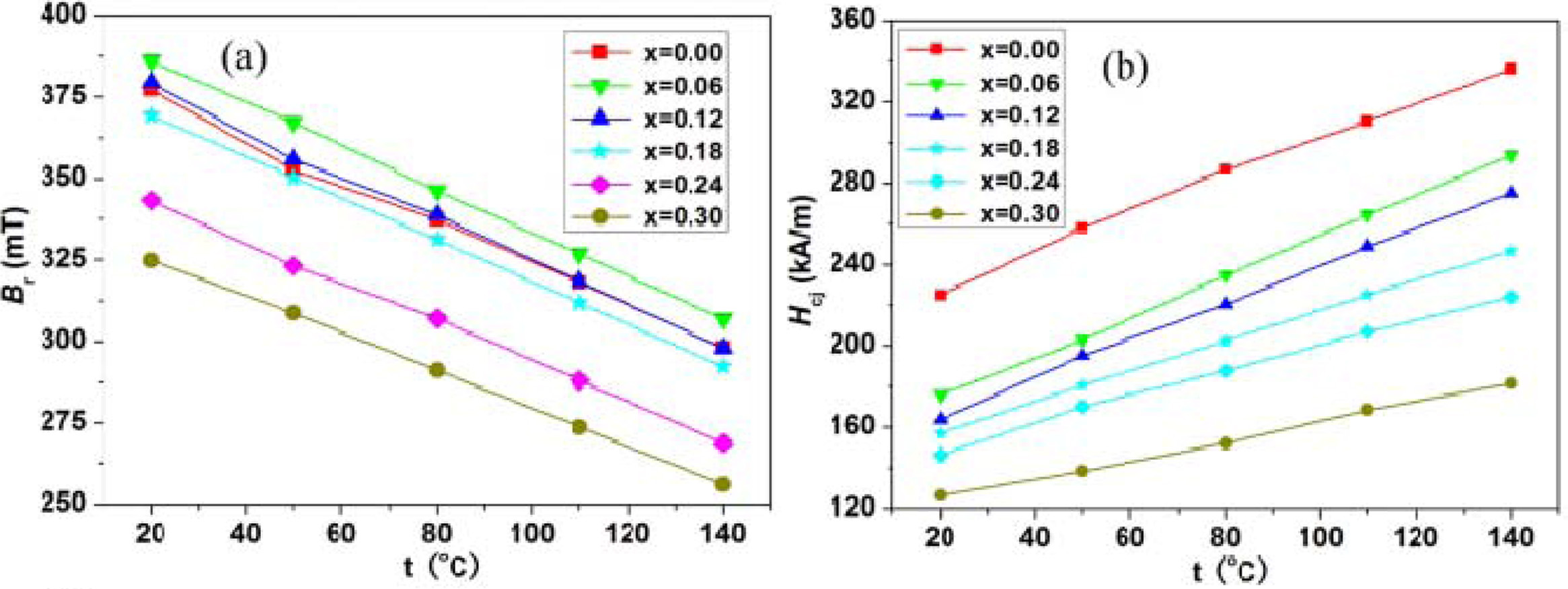

hexaferrites with different Nd-Zn content (x). Fig. 6(a) presents the

temperature dependent remanence (Br) between 20 oC

and 140 oC for the hexaferrites with different Nd-Zn content (x). As

seen from Fig. 6(a), for the hexaferrites with different Nd-Zn content (x), the

values of remanence (Br) have a linear decreasing behavior

with increasing temperature from 20 oC to 140 oC.

This is in agreement with the results reported by Zhou et al. [47]. The

variations of the intrinsic coercivity (Hcj) between 20 oC

and 140 oC for the hexaferrites Ba0.40Sr0.60-xNdxFe12.00-xZnxO19

with different Nd-Zn content (x) are shown in Fig.

6(b). It is observed that for the hexaferrites with different Nd-Zn

content (x), the values of intrinsic coercivity (Hcj) raise

linearly with increasing temperature from 20 oC to 140 oC.

This agrees with the changing trend reported by W. Zhou [48] and T.D.K. Corporation

[49].

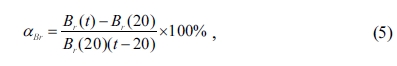

When the ambient temperature ¡Â 400

oC, the remanence (Br)

of hexaferrites BaFe12O19 deareases linearly with increasing temperature [50]. The temperature

coefficient of remanence (Br)

can be approximated as a constant in a certain temperature range. Therefore,

the average temperature coefficient of Br (aBr) of

hexaferrites can be defined as the below relation [48]:

where Br(20)

is the value of remanence (Br) measured at 20 oC,

Br(t) is the value of remanence (Br)

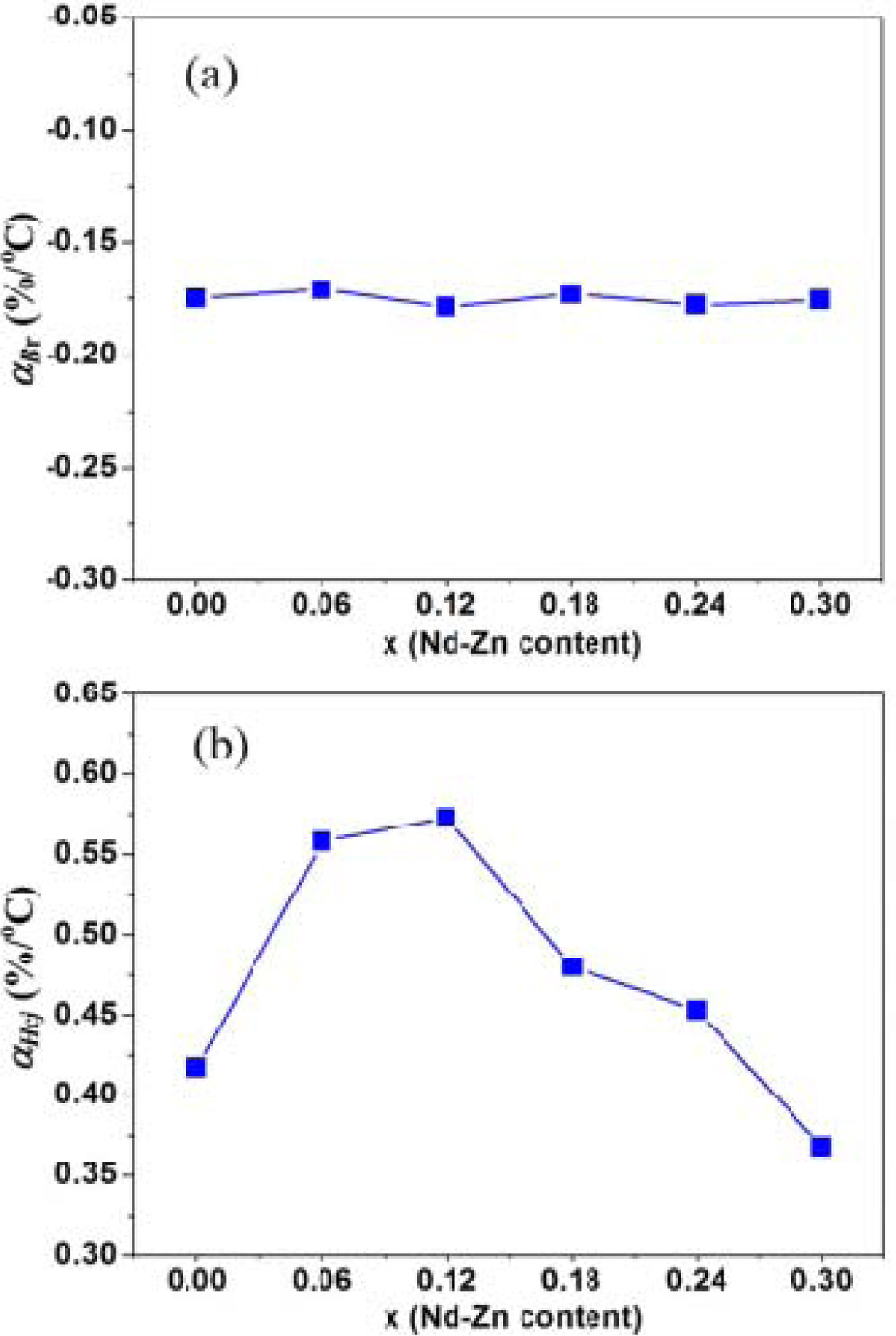

measured at temperature of t oC. Fig. 7(a) represents the variation

of aBr of

the hexaferrites Ba0.40Sr0.60-xNdxFe12.00-xZnxO19

as a function of Nd-Zn content (x). It is clear from Fig. 7(a) that the

value of aBr basically remains constant around -0.175 %/oC.

The value of aBr is in agreement with that reported by T.D.K.

Corporation [45]. This indicates

that the Nd-Zn substitution have not big impact on the average temperature coefficient of remanence

(Br) (aBr) of the

hexaferrites Ba0.40Sr0.60-xNdxFe12.00-xZnxO19.

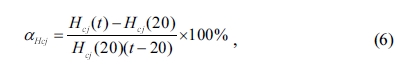

As shown in Fig. 6(b), the values of

intrinsic coercivity (Hcj)

have a linear behavior with temperature from 20 oC to 140 oC.

The temperature coefficient of intrinsic coercivity (Hcj) is

also approximated as a constant in a certain temperature range [49]. Thus, the

average temperature coefficient of Hcj (aHcj) can be calculated using the following equation [43]:

where Hcj(20)

is the value of intrinsic coercivity (Hcj) measured at 20 oC,

Hcj(t) is the value of intrinsic coercivity (Hcj)

measured at temperature of t oC. The influence of Nd-Zn content (x) on the average temperature coefficient of intrinsic coercivity (Hcj)

(aHcj) of the hexaferrites Ba0.40Sr0.60-xNdxFe12.00-xZnxO19

is plotted in Fig. 7(b). It is noted that the value of aHcj firstly increases from 0.417 %/oC at x=0.00 to

0.573 %/oC at x = 0.12, and then decreases when Nd-Zn content (x) ¡Ã

0.12. This shows that Nd-Zn content

(x) can significantly affect the

values of aHcj.

The values of aHcj are larger

than that reported by T.D.K. Corporation [49], which should the values of intrinsic coercivity (Hcj)

in this study are lower than that in TDK Products Catalog [49].

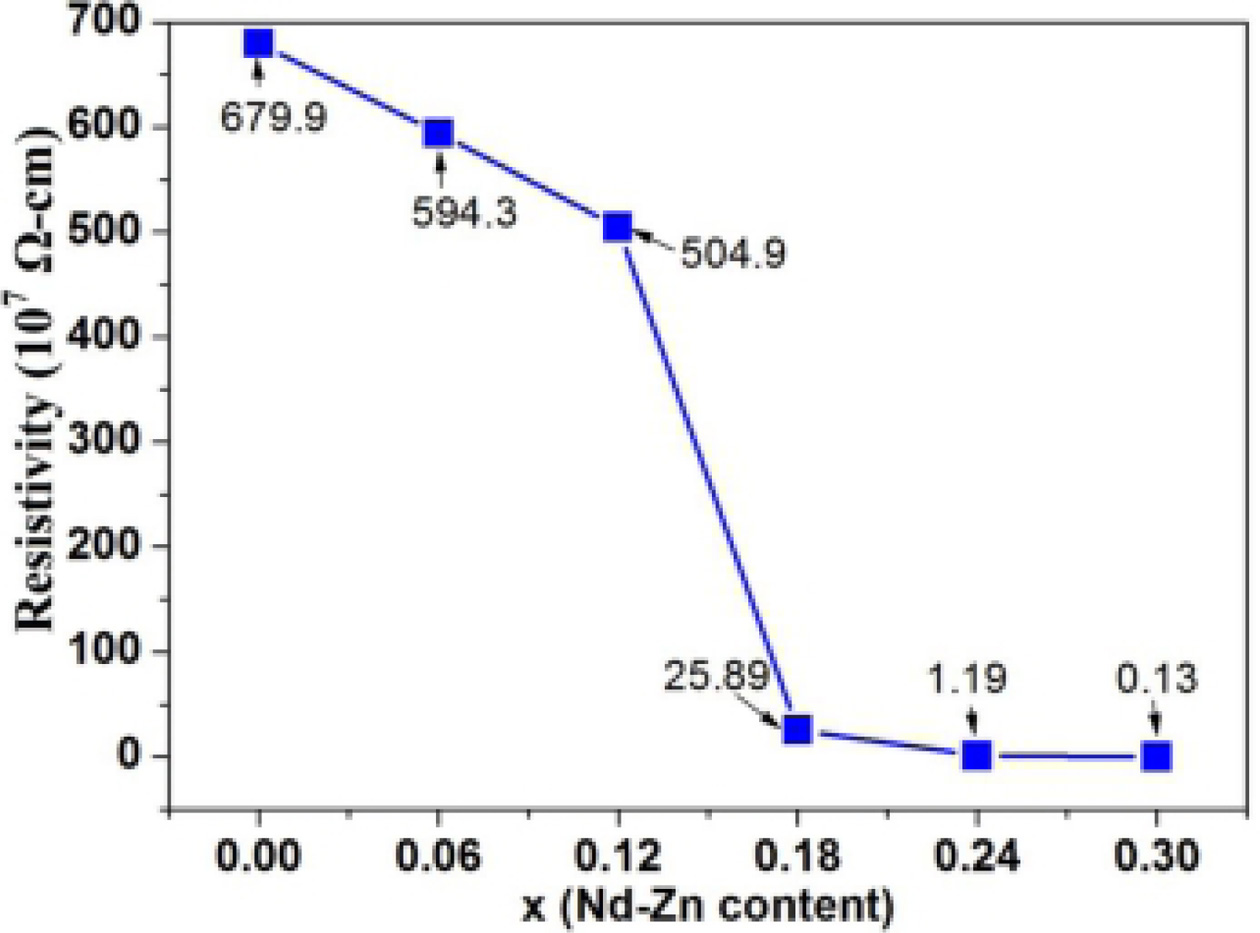

Fig. 8 illustrates the impact of Nd-Zn content (x) on the

DC electrical resistivity (ρ) of the hexaferrites Ba0.40Sr0.60-xNdxFe12.00-xZnxO19.

It is clear that the electrical resistivity (ρ)

is strongly affected by Nd-Zn content (x). It is observed that the

value of electrical resitivity (ρ) decreases from 679.9 × 107

Ω-Cm at x = 0.00 to 0.13 × 107 Ω-Cm at x = 0.30. The

mechanism of conductivity in the hexaferrites is attributed to the hopping of

electrons between Fe3+ and Fe2+ ions at the octahedral

sites [50]. Van Diepen et al. have reported that the substitution of La3+

for Ba2+ or Sr2+ in M-type ferrites is associated with a

valence change of Fe3+ to Fe2+ at 2a or 4f2

site [51]. Thus, as Nd3+ ions substitute Sr2+ ions and Zn2+

ions substitute Fe3+ ions, some Fe3+ ions

will change into Fe2+ ions. This increases the number

of Fe2+ ions which leads to the increase of the hopping probability

between the Fe3+ and Fe2+ ions. Thus, the above reasons

result in the decrease of electrical resitivity (ρ).

|

Fig. 1 XRD patterns of the hexaferrites Ba0.40Sr0.60-xNdxFe12.00-xZnxO19 with different Nd-Zn content (x). |

|

Fig. 2 FE-SEM images of the hexaferrites Ba0.40Sr0.60-xNdxFe12.00-xZnxO19 with (a) x=0.00, (b) x=0.12, and (c) x=0.24. |

|

Fig. 3 Room temperature demagnetizing curves of the hexaferrites Ba0.40Sr0.60-xNdxFe12.00-xZnxO19 with (a) x = 0.00, (b) x = 0.06, (c) x = 0.12, (d) x = 0.18, (e) x = 0.24, and (f) x = 0.30. |

|

Fig. 4 (a) Remanence (Br), and (b) Intrinsic coercivity (Hcj) and magnetic induction coercivity (Hcb) of the hexaferrites Ba0.40Sr0.60-xNdxFe12.00-xZnxO19 as a function of Nd-Zn content (x). |

|

Fig. 5 Measuring temperature dependent demagnetizing curves of the hexaferrites Ba0.40Sr0.60-xNdxFe12.00-xZnxO19 with (a) x=0.00, (b) x=0.06, (c) x=0.12, (d) x=0.18, (e) x=0.24, and (f) x=0.30. |

|

Fig. 6 (a) The temperature dependent remanence (Br), and (b) The temperature dependent intrinsic coercivity (Hcj) of the hexaferrites Ba0.40Sr0.60-xNdxFe12.00-xZnxO19 with different Nd-Zn content (x) from x=0.00 to x=0.30, obtained from demagnetizing curves. |

|

Fig. 7 (a) The average temperature coefficient of remanence (Br) (aBr), and (b) The average temperature coefficient of intrinsic coercivity (Hcj) (aHcj) of the hexaferrites Ba0.40Sr0.60-xNdxFe12.00-xZnxO19 as a function of Nd-Zn content (x). |

|

Fig. 8 DC electrical resistivity (ρ) of the hexaferrites Ba0.40Sr0.60-xNdxFe12.00-xZnxO19 as a function of Nd-Zn content (x). |

|

Table 1 The values of molecular

weight, lattice parameters (c and a), unit cell volume (Vcell),

X-ray density (dxrd), and bulk density (dbulk)

for the hexaferrites Ba0.40Sr0.60-xNdxFe12.00-xZnxO19

with different Nd-Zn content (x). |

The solid-state reaction route was

used to synthesize the Nd-Zn substituted

M-type hexaferrites with nominal

compositions Ba0.40Sr0.60-xNdxFe12.00-xZnxO19

(0.00 ¡Â x ¡Â 0.30). The X-ray diffraction patterns show that the hexaferrites

with Nd-Zn content (x) of 0.00 ¡Â x ¡Â 0.24 were single M-type phase, while the

hexaferrites with Nd-Zn content (x) = 0.30 exhibited the M-type phase and

impurity phases. FE-SEM images proposed that all the particles were regular

hexagonal platelet-like shape and the average particle size increased with

increasing Nd-Zn content (x). Br increased with Nd-Zn content

(x) from 0.00 to 0.06, and then started to decrease when Nd-Zn content (x) ¡Ã

0.06. Hcj and Hcb decreased with Nd-Zn

content (x) from 0.00 to 0.30. Br indicated a linear

decreasing behavior with increasing temperature from 20 oC to

140 oC. Hcj raise linearly with increasing

temperature from 20 oC to 140 oC. The value of aBr basically

remained constant with Nd-Zn content (x). The value of aHcj firstly increased with x from 0.00 to 0.12, and then

decreased when x ¡Ã 0.12. The electrical resitivity (¥ñ) presented a

decreasing trend with x from 0.00 to 0.30.

This work was supported by the National Natural Science

Foundation of China (Nos. 51872004, 51802002), Education

Department of Anhui Province (Nos. KJ2013B293, KJ2018A0039), Key Program of the Science

and Technology of Anhui Province (Grant No. S201904a09020074).

- 1. S.V. Trukhanov, A.V. Trukhanov, V.A. Turchenko, An.V. Trukhanov, E.L. Trukhanova, D.I. Tishkevich, V.M. Ivanov, T.I. Zubar, M. Salem, V.G. Kostishyn, L.V. Panina, D.A. Vinnik, S.A. Gudkova, Ceram. Int. 44 (2018) 290-300.

-

- 2. L.A. Trusov, E.A. Gorbachev, V.A. Lebedev, A.E. Sleptsova, I.V. Roslyakov, E.S. Kozlyakova, A.V. Vasiliev, R.E. Dinnebier, M. Jansen, P.E. Kazin, Chem. Commun. 54 (2018) 479-482.

-

- 3. T.T. Loan, T.T.V. NGA, N.P. Duong, S. Soontarnon, T.D. Hien, J. Electron. Mater. 46 (2017) 3396-3405.

-

- 4. I. Ali, M.U. Islam, M.S. Awan, M. Ahmad, J. Electron. Mater. 43 (2014) 512-521.

-

- 5. R. Valenzuela, in “Magnetic ceramics” (Cambridge University Press, 1994) p.191.

-

- 6. D. Makovec, D. Primc, S. Šturm, A. Kodre, D. Hanžel, M. Drofenik, J. Solid State Chem. 196 (2012) 63-71.

-

- 7. S. Mahadevan, S.B. Narang, P. Sharma, Ceram. Int. 45 (2019) 9000-9006.

-

- 8. N. Tran, H.S. Kim, T.L. Phan, D.S. Yang, B.W. Lee, Ceram. Int. 44 (2018) 12132-12136.

-

- 9. J. Dho, E.K. Lee, J.Y. Park, N.H. Hur, J. Magn. Magn. Mater. 285 (2005) 164-168.

- 10. C. Serletis, G. Litsardakis, E. Pavidou, K.G. Efthimiaadis, Physica B. 525 (2017) 78-83.

-

- 11. Z.H. Hua, S.Z. Li, Z.D. Han, D.H. Wang, M. Lu, W. Zhong, B.X. Gu, Y.W. Du, Mater. Sci. Eng. A 448 (2007) 326-329.

-

- 12. J.E. Beevers, C.L. Love, V.K. Lazarov, S.A. Cavill, H. Izadkhah, C. Vittoria, R. Fan, G. van der Laan, S.S. Dhesi, App. Phys. Lett. 112 (2016) 082401.

-

- 13. X.X. Wei, Y.H. Liu, D.J. Zhao, X.W. Mao, W.Y. Jiang, S.Z. Sam Ge, J. Magn. Magn. Mater. 493 (2020) 165664.

-

- 14. J.F. Wang, C.B. Ponton, I.R. Harris, J. Alloys Compd. 403 (2005) 104-109.

-

- 15. A. Singh, S.B. Narang, K. Singh, O.P. Pandey, R.K. Kotnala, J. Ceram. Process. Res. 11[2] (2010) 241–249.

-

- 16. A. Thakur, R.R. Singh, P.B. Barman, J. Magn. Magn. Mater. 326 (2013) 35-40.

-

- 17. J.F. Wang, C.B. Ponton, I.R. Harris, IEEE Trans. Magn. 38 (2002) 2928-2930.

-

- 18. D. Shekhawat, A.K. Singh, P.K. Roy, J. Mol. Struct. 1179 (2019) 787-794.

-

- 19. Y.J. Yang, J.X. Shao, F.H. Wang, D.H. Huang, J. Ceram. Process. Res. 18[5] (2017) 394–398.

- 20. J.F. Wang, C.B. Ponton, I.R. Harris, J. Magn. Magn. Mater. 298 (2006) 122-131.

-

- 21. P.A. Pawar, S.S. Desai, Q.Y. Tamboli, S.E. Shirsath, S.M. Patange, J. Magn. Magn. Mater. 378 (2015) 59-63.

-

- 22. G. Litsardakis, I. Manolakis, C. Serletis, K.G. Efthimiadis, J. Magn. Magn. Mater. 316 (2007) 170-173.

-

- 23. D.A. Vinnik, A.S. Semisalova, L.S. Mashkovtseva, A.K. Yakushechkina, S. Nemrava, S.A. Gudkova, D.A. Zherebtsov, N.S. Perov, L.I. Isaenko, R. Niewa, Mater. Chem. Phys. 163 (2015) 416-420.

-

- 24. X.-S. Liu, L. Fetnandez-Garcia, F. Hu, D.-R. Zhu, M. Suárez, J.L. Menéndez, Mater. Chem. Phys. 133 (2012) 961-964.

-

- 25. M. Ghimire, S. Yoon, L. Wang, D. Neupane, J. Alam, S.R. Mishra, J. Magn. Magn. Mater. 454 (2018) 110-120.

-

- 26. D.A. Vinnik, A.Yu. Tarasova, D.A. Zherebtsov, L.S. Mashkovtseva, S.A. Gudkova, S. Nemrava, A.K. Yakushechkina, A.S. Semisalova, L.I. Isaenko, R. Niewa, Ceram. Int. 41 (2015) 9172-9176.

-

- 27. J. Qiu, Y. Wang, M. Gu, Mater. Lett. 60 (2006) 2728-2732.

-

- 28. I.A. Auwal, H. Güngüneş, A. Baykal, S. Güner, S.E. Shirsath, M. Sertkol, Ceram. Int. 42 (2016) 8627-8635.

-

- 29. A. Shayan, M. Abdellahi, F. Shahmohammadian, S. Jabbarzare, A. Khandan, H. Ghayour, J. Alloys Compd. 708 (2017) 538-546.

-

- 30. H.M. Khan, M.U. Islam, Y.B. Xu, M.N. Ashiq, I. Ali, M.A. Iqbal, M. Ishaque, Ceram. Int. 40 (2014) 6487-6493.

-

- 31. T.-Y. Hwang, J. Lee, H.-R. Lim, S.J. Jeong, G.-H. An, J. Kim, Y.-H. Choa, Ceram. Int. 43 (2017) 3879-3884.

-

- 32. L. Peng, L.Z. Li, X.X. Zhong, Y.B. Hu, S.M. Chen, J. Magn. Magn. Mater. 428 (2017) 73-77.

-

- 33. Z.Y. Zhang, X.X. Liu, X.J. Wang, Y.P. Wu, R. Li, J. Alloys Compd. 525 (2012) 114-119.

-

- 34. H.M. Khan, M.U. Islam, Y.B. Xu, M. Asif Iqbal, I. Ali, M. Ishaque, M.A. Khan, J. Sol-Gel. Sci. Technol. 75 (2015) 305-312.

-

- 35. Z. Lalegani, A. Nemati, J. Mater. Sci.: Mater. Electron. 26 (2015) 2134-2144.

-

- 36. C.C. Liu, X.C. Kan, F. Hu, X.S. Liu, S.J. Feng, J.Y. Hu, W. Wang, K.M. Ur Rehman, M. Shezad, C. Zhang, H.H. Li, S.Q. Zhou, Q.Y. Wu, J. Alloy. Compd. 785 (2019) 452-459.

-

- 37. Y.J. Yang, D.H. Huang, J.X. Shao, F.H. Wang, Chin. J. Phys. 57 (2019) 250-260.

-

- 38. A. Majeed, M.A. Khan, F. ur Raheem, A. Hussain, F. Iqbal, G. Murtaza, M.N. Akhtar, I. Shakir, M.F. Warsi, J. Magn. Magn. Mater. 408 (2016) 147-154.

-

- 39. V.N. Dhage, M.L. Mane, M.K. Babrekar, C.M. Kale, K.M. Jadhav, J. Alloys Compd. 509 (2011) 4394-4398.

-

- 40. Y.J. Yang, X.S. Liu, D.L. Jin, Y.Q. Ma, Mater. Res. Bull. 59 (2014) 37-41.

-

- 41. C. Herme, S.E. Jacobo, P.G. Bercoff, B. Arcondo, Hyperfine Interact. 195 (2010) 205-212.

-

- 42. S.W. Lee, S.Y. An, In-Bo Shim, C.S. Kim, J. Magn. Magn. Mater. 290-291 (2005) 231-233.

-

- 43. Z. Yang, C.S. Wang, X.H. Li, H.X. Zeng, Mater. Sci. Eng. B 90 (2002) 142-145.

-

- 44. B.K. Rai, S.R. Mishra, V.V. Nguyen, J.P. Liu, J. Alloys Compd. 550 (2013) 198-203.

-

- 45. TDK Electronics, in “TDK Products Catalog: Ferrite Magnets” (TDK Electronics, 2011) p.3.

- 46. A. Goldman, in “Modern Ferrite Technology” (Springer, 2006) p.235.

- 47. Z.G. Zhou, in “Ferrite Magnetic Materials” (Science Press, 1981) p.646.

- 48. W.Y. Zhou, in “Design Technology of Permanent Magnet Ferrite and Magnetic Fluid” (University of Electronic Science and Technology Press, 1991) p.34.

- 49. TDK Electronics, in “TDK Products Catalog: Ferrite Magnets” (TDK Electronics, 2014) p.4.

- 50. F. Aen, M.F. Wasiq, M.U. Rana, H.M. Khan, H.A. Khan, Ceram. Int. 42 (2016) 16077-16083.

-

- 51. A.M. Van Diepen, F.K. Lotgering, J. Phys. Chem. Solids 35 (1974) 1641-1643.

-

This Article

This Article

-

2020; 21(4): 416-424

Published on Aug 30, 2020

- 10.36410/jcpr.2020.21.4.416

- Received on Dec 28, 2019

- Revised on Apr 21, 2020

- Accepted on May 4, 2020

Services

Services

- Abstract

introduction

experimental details

results and discussion

conclusion

- Acknowledgements

- References

- Full Text PDF

Shared

Correspondence to

Correspondence to

- Yujie Yang

-

Engineering Technology Research Center of Magnetic Materials, School of Physics & Materials Science, Anhui University, Hefei 230601, P. R. China

Tel : +86 551 63861257

Fax: +86 831 63861257 - E-mail: loyalty-yyj@163.com

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.