- Preparation and thermodynamic equilibrium analysis of neodymium disilicate via sol-precipitation and sintering

Shanjun Kea, Yanmin Wanga,*, Zhidong Pana,b,* and Heping Zenga

aSouth China University of Technology, Guangzhou 510640, China

bFoshan Oceano Ceramics Co. Ltd., Foshan 528138, China

Neodymium disilicate powders

were synthesized via a sol-precipitation method with different

precipitants (i.e., ammonia, ammonium bicarbonate and urea) and subsequent

sintering. The samples were characterized by X-ray diffraction. In addition, a

theoretical relationship between neodymium ion concentrations in different

precipitation equilibrium solutions was also investigated and analyzed based on

thermodynamic equilibrium calculation. The results show that the precipitant

type has an impact on the phase compositions of the precursors and the sintered

products. In the synthesis, neodymium ions can be completely precipitated as

amorphous neodymium hydroxide with ammonia as a precipitate at pH 8~9. For

ammonium bicarbonate as a precipitate, the precursor type is related to both

carbon concentration and pH value. The excessive hydroxide forms neodymium

hydroxycarbonate in a heated urea solution. The possible formation mechanism of

silicon sol in the presence of different precipitants was discussed.

Keywords: Precipitant, Precursor, Neodymium disilicate, Thermodynamis

Inorganic pigments are widely used in the field of ceramic

decoration [1-3]. As is known, the coloring ions of ceramic pigments are from

mainly transition metal elements. However, some ceramic pigments contain a

certain amount of heavy metal elements, which are strictly controlled due to

the corresponding environmental protection issues [4-7]. Due to special

structure and low toxicity, rare-earth ions are also widely used as colorants

in ceramic pigments [8, 9]. In addition, some functional ceramic

pigments are reported, such as effect pigments [10, 11],

luminescent pigments [12, 13], phosphorescent pigments [14, 15] and

near-infrared reflective pigments [16-19]. Moreover, recent work [20, 21]

revealed that neodymium disilicate (i.e., Nd2Si2O7)

powder can be applied as a functional ceramic pigment with allochroic effect

under various illuminants. Nd2Si2O7 powder has

a violet red color under an incandescent lamp, while presents a blue

color under a fluorescent lamp. The mechanism of color change

under different illuminations was discussed in detail in a previous work [22].

Solid-state reaction and sol-gel methods are the main preparation

routes for Nd2Si2O7 pigment [20-22]. However,

solid-state reaction usually requires harsh reaction con- ditions, such

as high temperatures and/or long treatment time [23,

24]. Although sol-gel method can achieve a low-temperature preparation, it

needs long-reaction time and precursors with severe agglomeration during

drying, leading to the formation of a poor dispersibility of the resultant

powder. In a previous study [25], Nd2Si2O7

powder was synthesized via a sol-precipitation method

with different precipitants. This sol-precipitation method is a

relatively simple way for the synthesis of Nd2Si2O7

pigment. However, different precipitants have a greater

impact on the phase composition of the precursor and

the final product. The relevant reasonable explanations

on the precipitation process of the precursor powder with

different precipitants are not reported so far.

As is well known, thermodynamic equilibrium analysis

is an effective method for describing the precipitation process

of ceramic materials. Many studies [26-28] reported that

the thermodynamic equilibrium calculation could

establish the equilibrium diagram to provide a theoretical guide for the

precipitation reaction. Li et al. [29] investigated the precipitation process

of silicate species in (NH4)2WO4-(NH4)2CO3-NH3-H2O

system by thermodynamic analysis. Their experimemtal results consisted with the

theoretical calculation.

In this paper, neodymium disilicate powders were synthesized

via a sol-precipitation method with different precipitants

(i.e., ammonia, ammonium bicarbonate and urea) and

subsequent sintering. The phase compositions of the

precursors and the sintered products with different precipitants were

discussed. In addition, the thermodynamic equilibrium parameters of precursors

in different precipitation equilibrium solutions were also calculated and

discussed based on the thermodynamic data and mass conservation.

The main ingredients include neodymium nitrate tetraethyl

orthosilicate (TEOS, C8H20O4Si, 98 wt.%,

Guangzhou Chemical Reagent Factory, China) and hexahydrate (Nd(NO3)3·6H2O,

99.5 wt.%, Ganzhou Ruihua Rare-earth Co. Ltd., China). Ammonia (NH4OH, 25

wt.%), ammonium bicarbonate (NH4HCO3, analytical

grade) and urea ((NH2)2CO, 99.0 wt.%) as precipitants were

purchased from Tianjin Fuchen Chemical Reagent Factory,

China. Polyethylene glycol (PEG-10000, analytical grade) was

used as a surfactant. Absolute ethanol (C2H5OH, 99.7%)

and deionized water were obtained from Guangzhou Qianghui Bose Instrument Co.

Ltd., China.

Nd(NO3)3·6H2O and TEOS

with a molar ratio of 1:1 were dissolved in 400 ml alcohol-water solution. 2.5

g PEG-10000 was firstly added into the mixture solution above, and then the

mixture was added in dropwise into the precipitant solution (2 mol/L NH4OH

or NH4HCO3) to keep the solution pH values 8-9 under

vigorous stirring at room temperature. After 12 h, the resultant suspension was

filtered and washed for three times with deionized water, and dried at 60

oC for 24 h. For (NH2)2CO as a precipitant, the

concentration ratio of (NH2)2CO and the total metal ions

was 15:1. The mixture solution was heated to 95 oC and kept at this temperature

for 6 h. The precipitate was filtered, washed and dried by

using the same procedure above. The dried precipitates were ground in an agate

mortar and calcined at 1,200 oC for 5 h, respectively.

The phase compositions of the precursor and sintered

product were determined by a model PW-1710 X-ray diffractometer

(XRD, Philips Co. Ltd., The Netherlands), using Cu Kα

radiation.

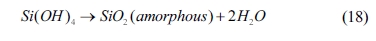

Fig. 1 shows the XRD patterns of the synthesized samples

with different precipitants. The precursor obtained with

NH4OH is amorphous Nd(OH)3 phase (JCPDS No. 83-2035).

When the sintering temperature reaches 1,200 oC, the tetragonal

Nd2Si2O7 (JCPDS No. 22-1177) is the main

crystalline phase for the sample synthesized with NH4OH (see Fig.

1(a)). For the precursor obtained with NH4HCO3, there are

some obvious diffraction peaks in the XRD pattern, which coincides with a

unknown phase of Nd2(CO3)3·xH2O. In

some previous studies [30, 31], the precursor obtained

with (NH4)2CO3 as a precipitant could be Nd2(CO3)3· 2.5H2O, Nd2(CO3)3·4H2O

or Nd2(CO3)3·8H2O. After the

precursor produced with NH4HCO3 is sintered at

1,200 oC, the main crystalline phases are Nd4Si3O12

(JCPDS No. 42-0171), Nd2SiO5 (JCPDS No. 40-0284) and Nd2O3

(JCPDS No. 43-1023) (see Fig. 1(b)). The XRD pattern for the precursor obtained

with (NH2)2CO is in agreement with that for NdOHCO3 (JCPDS

No. 27-1296). The main crystalline phases of the precipitate sintered at 1,200 oC

are also Nd4Si3O12, Nd2SiO5

and Nd2O3 (see Fig. 1(c)). After sintering, the phase compositions of the precursors prepared with

different precipitants are inconsistent, indicating a poor element (i.e., Si

and Nd) homogeneity of the precursors. In order to explain the result

above, the reaction processes of the systems with different precipitants should

be further analyzed based on thermodynamic equilibrium calculation.

For the prepared precursors, the neodymium element is

precipitated as different precipitates. Two variables such as temperature and

pressure are usually constants for the precipitation process in the solution.

Therefore, in this study, the diagram of the precipitated ion concentration and

pH value at different precipitation equilibrium solutions are drawn for further

discussion.

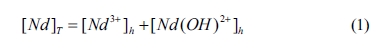

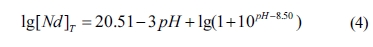

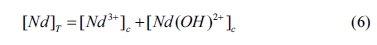

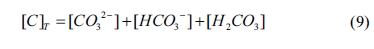

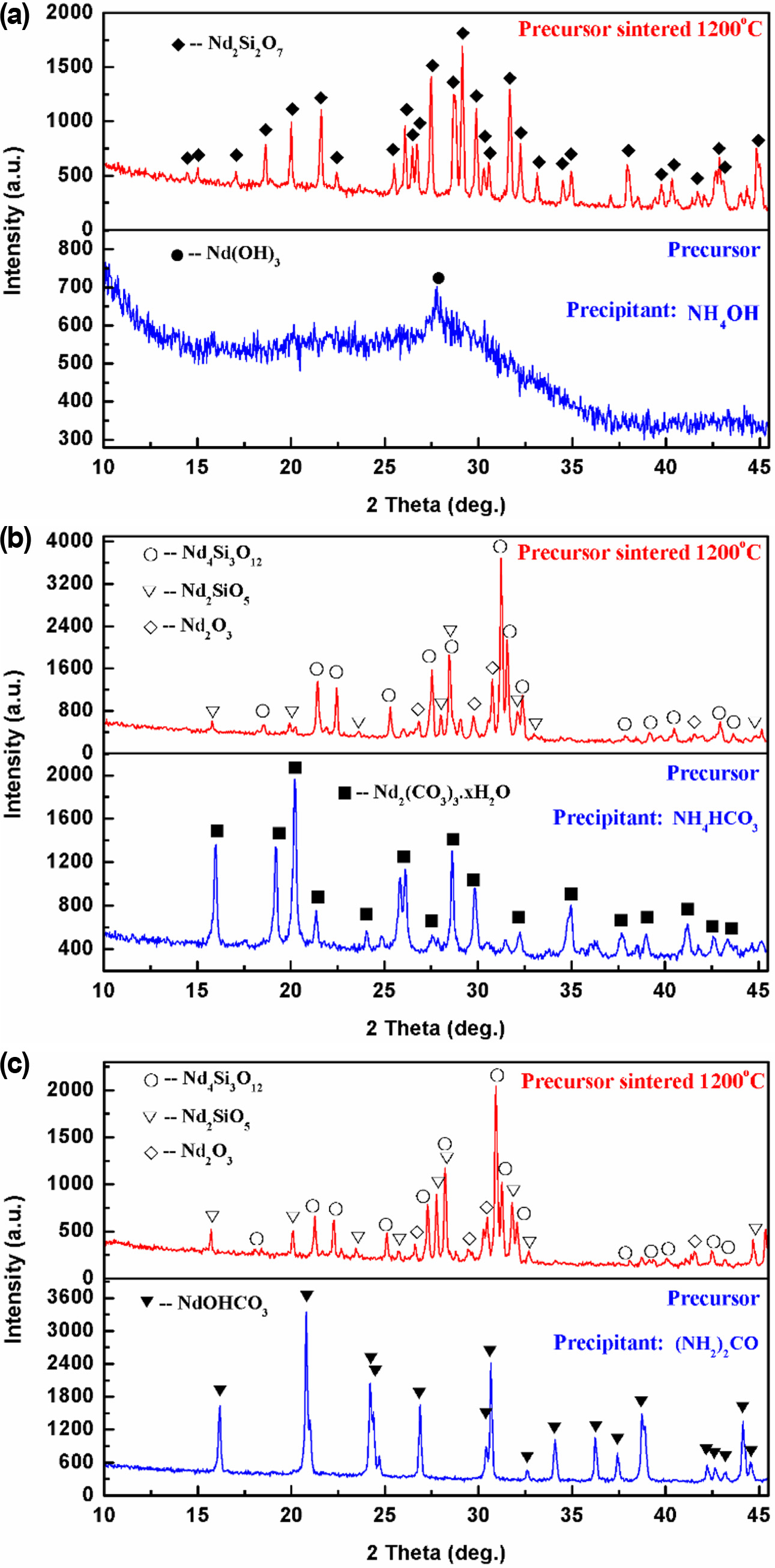

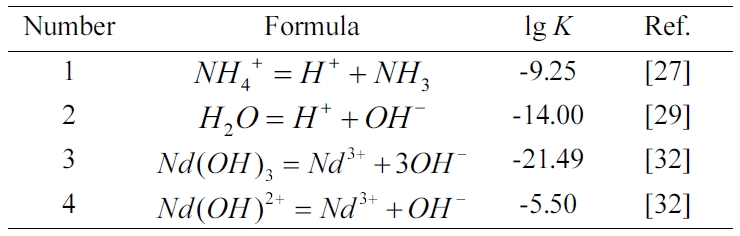

In the system of Nd3+-NH4OH-H2O

(NH4OH as a precipitant), the relevant reactions are shown in Table

1. Based on the principle of mass balance, the mathematical model of lg[Nd]T

vs pH value can be deduced, where [Nd]T is the

total concentration of Nd in equilibrium solution. The concentration is used instead

of the activity for the calculation. The total concentration of Nd can be

obtained by

where [Nd 3+]h

and [Nd(OH)2+]h are the

concentration of Nd 3+ and Nd(OH)2+,

respectively.

The mathematical relationships of [Nd 3+]h

and [Nd(OH) 2+]h can be

expressed as follows:

where [OH-] is the

concentration of OH- in the equilibrium solution. According

to Eqs. (2) and (3), Eq. (1) can be re-written as

The diagram of lg[Nd]T vs pH

can be proposed according to Eq. (4), as shown in Fig. 2. Clearly, in the whole

pH value range, the concentration of Nd in the equilibrium

solution sharply decreases with the increase of pH value,

which is attributed to the formation of Nd(OH)3 (see Fig. 1(a)).

Moreover, a high pH value of equilibrium solution is beneficial for the

precipitation of Nd ions. When the pH value is 8~9, the concentration

of Nd ions is the range of 10-3~10-6

mol/L. In this experiment, the pH value of the equilibrium solution is 8.72

before the precursor is filtered, which can be defined as an almost complete

precipitation. Zhu et al. [33] found that Nd(OH)3 nanoparticles with

different morphologies can be synthesized using a microemulsion-precipitation

method with NH4OH as a precipitant in the presence of cetyltrimethyl

ammonium bromide. Arunachalam et al. [34] also reported that a facile chemical

precipitation method was used to prepare Nd(OH)3

nanopowder at an ambient temperature without the addition

of any surfactants.

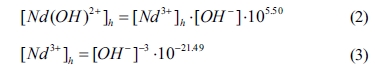

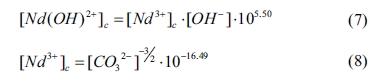

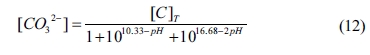

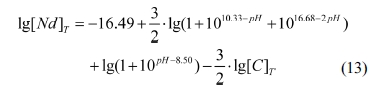

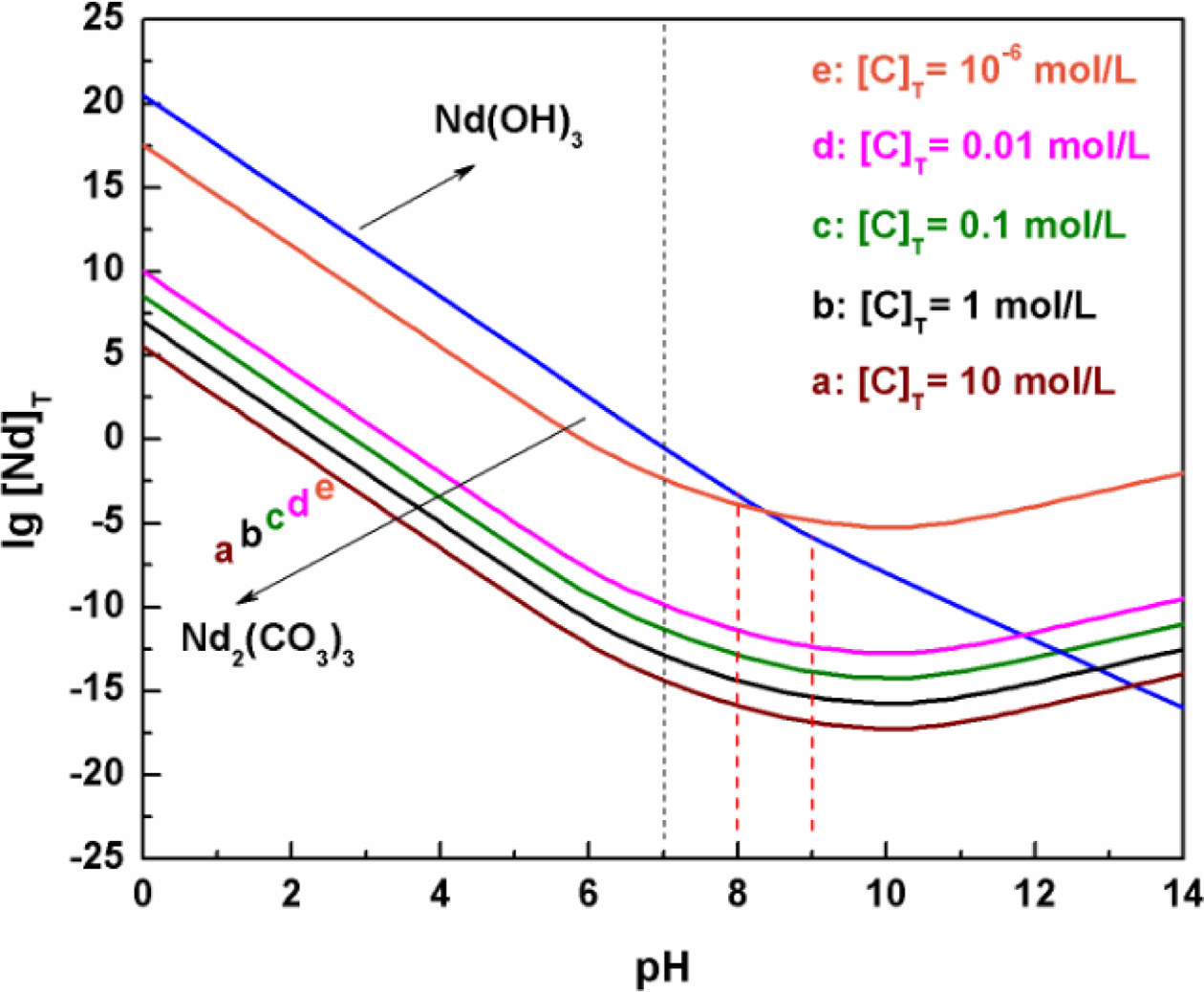

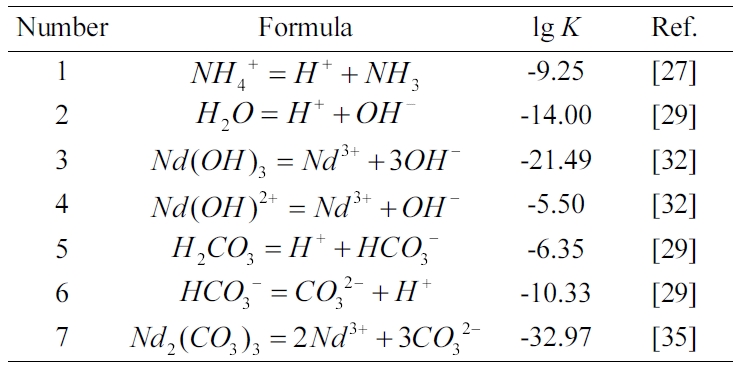

In the system of Nd3+-NH4HCO3-H2O

(NH4HCO3 as a precipitant), the hydrolysis equation of NH4HCO3

can be expressed by

The other relevant reactions are listed in Table 2. Based

on the principle of mass balance, the mathematical model of lg[Nd]T

vs pH value is deduced, where [Nd]T is the

total concentration of Nd ions in the equilibrium solution. The concentration

is used instead of the activity for the calculation. The total concentration of

Nd ions can be expressed by

where [Nd 3+]c

and [Nd(OH)2+]c are the

concentration of Nd 3+ and Nd(OH)2+,

�respectively. The mathematical relationships of [Nd 3+]c

and [Nd(OH) 2+]c can be

obtained as follows:

where [OH-] and [CO32-] are the

concentrations of OH- and CO32- in the

equilibrium solution, �respectively.

According to the mass balance of the system, the concentrations of OH-

and CO32- can be established by

where [C]T

is the total concentration of C in the equilibrium solution. Moreover, [CO32-], [HCO3-] and [H2CO3]

are the concentrations of CO32-, HCO3- and

H2CO3, respectively. The mathematical

relationships of [HCO3-] and [H2CO3]

can be obtained as follows:

Based on Eqs. (10) and (11), Eq. (9) can be rearranged

by

According to Eqs. (7), (8) and (12), Eq. (6) can be

deduced as

For the given values of [C]T at a

certain pH value, the diagram of lg[Nd]T vs pH

value can be obtained from Eq. (13) by a computer software named Origin 8.0.

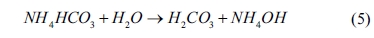

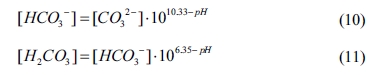

The lg[Nd]T vs pH value

diagram of the Nd3+- NH4HCO3-H2O

system with different total carbon concentrations at equilibrium is shown in

Fig. 3. Clearly, the patterns of the lg[Nd]T vs

pH curves with different total carbon concentrations are similar. The

concentration of Nd ions sharply decreases with the increase of pH value in the

range of 7~10, which is attributed to the formation of Nd2(CO3)3.

A further increase of pH value results in the increase of Nd ion concentration

due to the partial dissolution of Nd2(CO3)3.

In fact, precipitates with a low solubility are preferentially

precipitated in the equilibration solution [29]. That is, the lower position of

the curve is beneficial to the formation of the precipitate in the lg[Nd]T

vs pH value diagram. According to the theoretical calculation, the

precipitate may be Nd2(CO3)3 or Nd(OH)3,

when NH4HCO3 is used as a precipitant. When the [C]T

value is 10-6

mol/L, the precipitate is Nd2(CO3)3 in the pH

value range of 7.0~8.3. The precipitate is Nd(OH)3 in the pH value

range of 8.3~14.0. Moreover, the pH value range of Nd2(CO3)3

presence becomes greater with the increase of [C]T

value. In this experiment, the [C]T value exceeds 0.01

mol/L. The precipitate is thus Nd2(CO3)3 for

the equilibrium solution in the pH value range of 8~9.

Due to the special structure of Nd element, neodymium

carbonate generally exists as hydrated carbonates.

Liu et al. [36] found that neodymium carbonate with an

orthorhombic system was synthesized using NH4HCO3 as a

precipitant, which contained a certain amount of

water. Zhu et al. [37] reported that Nd2(CO3)3· 8H2O with various

morphologics and sizes was synthesized using a

microemulsion-assisted solvothermal method in the

presence of Na2CO3. In addition, there also can be formed

poorly-ordered nanoparticulate precursors, as

termed amorphous amorphous neodymium carbonate [38].

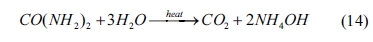

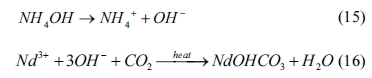

In the system of Nd3+-CO(NH2)2-H2O

(CO(NH2)2 as a precipitant), the hydrolysis of CO(NH2)2

can be expressed as follows:

The hydrolysate is similar to that of Eq. (5). However,

the hydrolysis process of CO(NH2)2 requires auxiliary

heating. In this experiment, the hydrolysis temperature is kept at 95 oC.

At this temperature, the relevant equilibrium constants are difficult to

obtain. According to the XRD result in Fig. 1(c), the precipitate

obtained in the presence of (NH2)2CO is neodymium hydroxycarbonate

(i.e., NdOHCO3). The main reactions for the

formation of NdOHCO3 can be expressed as follows:

From Table 2 (see No. 3 and No.7), the equilibrium

constant of Nd2(CO3)3 is smaller than that of

Nd(OH)3, indicating that Nd2(CO3)3

is preferentially precipitated. However, in the hydrolysis solution of (NH2)2CO,

hydroxide concentration is much higher than that of carbon dioxide. The

excessive hydroxide may thus cause the formation of NdOHCO3

in the heated equilibrium solution. In fact, a ultrafine

NdOHCO3 powder was also synthesized using (NH2)2CO

as a precipitant by a hydrothermal method [39]. Some

studies showed reaction temperature and pressure both have

important effects on the formation of NdOHCO3. Tahara et al. [40]

synthesized hexagonal and orthorhombic Nd(CO3)OH via a

hydrothermal reaction at 220 oC and different pressures.

Dentritic NdOHCO3 nanostructures were prepared using a facile

hydrothermal approach [41].

For the prepared precursors, the silicon element is

aggregated in the form of silicon sol, which is the result of hydrolysis and

condensation of TEOS. The hydrolysis reaction of TEOS in abbreviated form can

be given as

The condensation of silicon oxide can be expressed as

In the sol process of silicon alkoxide, generally, a homogeneous

catalyst is used to facilitate the hydrolysis reaction

since the reaction rate of hydrolysis is slow. Brinker et al. [42] proved that

all the hydroxyl groups of Si(OH)4 in hydrolysis reaction of TEOS

are derived from water. Iler et al. [43] also proposed the

mechanism for the basic hydrolysis of TEOS. The

hydrolysis process of TEOS can be affected by some parameters like pH

value, time and H2O/Si molar ratio as well [44-46]. Noted that in

general, the condensation reaction of silicon hydroxide is much faster than the

hydrolysis reaction of silicon alkoxide.

In alkaline solution, the hydroxyl anions attack Si

directly, leading to the abatement of Si-O bond and the acceleration

of -OC2H5 group cleavage [43]. In this work, three

reagents (i.e., NH4OH, NH4HCO3 or (NH2)2CO)

are selected as catalysts to promote the reaction of

hydrolysis of TEOS, respectively. When a catalyst is NH4OH,

the hydroxide ions formed by the ionization of ammonia water can effectively

attack Si, which is beneficial to the complete hydrolysis of TEOS. However, the

other reagents (i.e., NH4HCO3 and (NH2)2CO)

need to be hydrolyzed to form ammonia and then partially ionized, leading

to the incomplete hydrolysis reaction. Therefore, there is a

small amount of residual Nd2O3 that are not reacted due

to the lack of silicon element, when NH4HCO3 or (NH2)2CO

is a catalyst.

|

Fig. 1 XRD patterns of prepared samples with different precipitants, (a) NH4OH, (b) NH4HCO3 and (c) (NH2)2CO. |

|

Fig. 2 The lg[Nd]T vs pH value diagram of Nd3+-NH4OH-H2O system. |

|

Fig. 3 The lg[Nd]T vs pH value diagram of Nd3+- NH4HCO3-H2O system with different total carbon concentrations at equilibrium. |

Neodymium disilicate powders were prepared by a

sol-precipitation method with different precipitants (i.e., ammonia, ammonium

bicarbonate and urea) and subsequent sintering. The reaction processes of the

systems with different precipitants were analyzed based on thermodynamic

equilibrium calculation.

When NH4OH was used as a precipitate, the

precursor was amorphous Nd(OH)3. The precursor obtained

with NH4HCO3 was a unknown phase of Nd2(CO3)3·xH2O.

NdOHCO3 was the crystal phase of the precursor obtained in the

presence of (NH2)2CO. In the system of Nd3+-NH4OH-H2O,

a high pH value for the equilibrium solution was beneficial for the

precipitation of Nd ions. In the system of Nd3+-NH4HCO3-H2O,

the precursor type was related to both carbon concentration and pH value. A low

pH value was beneficial to Nd2(CO3)3 formation,

while a high pH value was beneficial to Nd(OH)3 formation. In the

system of Nd3+-CO(NH2)2-H2O, the

excessive hydroxide could form NdOHCO3 in the heated equilibrium

solution. Only a precursor with NH4OH could transform to a single Nd2Si2O7

phase after it was sintered at 1,200 oC for 5 h, which was due

to the incomplete hydrolysis of TEOS in the presence of NH4HCO3

or (NH2)2CO.

This work was supported by the China Postdoctoral Science

Foundation (No. 2019M650196) and the Major Scientific and Technological

Projects of Foshan (No. 2016AG101415).

- 1. P. Lunáková, M. Trojan, J. Luxová, and J. Trojan, Dyes Pigm. 96[1] (2013) 264-268.

-

- 2. K.-R. Pyon, K.-S. Han, and B.-H. Lee, J. Ceram. Process. Res. 12[3] (2011) 279-288.

- 3. N. Gorodylova, V. Kosinová, Z. Dohnalová, P. Bělina, and P. Šulcová, Dyes Pigments 98[3] (2013) 393-404.

-

- 4. B. Tanisan and S. Turan, J. Ceram. Process. Res. 12[4] (2011) 462-467.

- 5. S. Akdemir, E. Ozel, and E. Suvaci, Ceram. Inter. 37[3] (2011) 863-870.

-

- 6. J.-H. Lee, H.-J. Hwang, J.-W. Kwon, J.-H. Kim, K.-T. Hwang, and K.-S. Han, J. Ceram. Process. Res. 20[2] (2019) 127-132.

-

- 7. Y.-Z. Halefoglu and E. Kusvuran, J. Ceram. Process. Res. 11[1] (2010) 92-95.

- 8. G. George, L.-S. Kumari, V.-S. Vishnu, S. Ananthakumar, and M.-L.-P. Reddy, J. Solid State. Chem. 181[3] (2008) 487-492.

-

- 9. K.-J. Sreeram, S. Kumeresan, S. Radhika, V.-J. Sundar, C. Muralidharan, B.-U. Nair, and T. Ramasami, Dyes Pigm. 76[1] (2008) 243-248.

-

- 10. B.-B. Topuz, G. Gündüz, B. Mavis, and Ü. Çolak, Dyes Pigm. 96[1] (2013) 31-37.

-

- 11. P.-M.-T. Cavalcante, M. Dondi, G. Guarini, F.-M. Barros, and A. Benvindo da Luz, Dyes Pigm. 74[1] (2007) 1-8.

-

- 12. H. Sameie, R. Salimi, A.-A. Sabbagh Alvani, A.-A. Sarabi, F. Moztarzadeh, and M. Tahriri, Physica B: Condensed Matter 405[23] (2010) 4796-4800.

-

- 13. S. Kunimi and S. Fujihara, Dyes Pigm. 91[1] (2011) 49-54.

-

- 14. S.-Y. Kaya and B. Karasu, Ceram. Inter. 38[4] (2012) 2757-2766.

-

- 15. A. Tucks and H.-P. Beck, Dyes Pigm. 72[2] (2007) 163-177.

-

- 16. M. Paraman and S. Muthiah, Sol. Energ. Mat. Sol. C. 174 (2018) 530-537.

-

- 17. S. Jose, A. Jayaprakash, S. Laha, S. Natarajan, K.G. Nishanth, and M.L.P. Reddy, Dyes Pigm. 124 (2016) 120-129.

-

- 18. S. Sameera, P.-P. Rao, V. James, S. Divya, and A.K.V. Raj, Dyes Pigm. 104 (2014) 41-47.

-

- 19. Q. Gao, X.-M. Wu, Y.-M. Fan, and Q. Meng, Dyes Pigm. 146 (2017) 537-542.

-

- 20. S.-J. Ke, Y.-M. Wang, and Z.-D. Pan, Dyes Pigm. 108 (2014) 98-105.

-

- 21. S.-J. Ke, Y.-M. Wang, Z.-D. Pan, and H.-P. Zeng, J. Ceram. Process. Res. 20[3] (2019) 264-269.

-

- 22. S.-J. Ke, Z.-D. Pan, Y.-M. Wang, C.-Y. Ning, S.-L. Zheng, and J. Huang, Dyes Pigm. 145 (2017) 160-167.

-

- 23. A.-C. Tas and M. Akinc, J. Am. Ceram. Soc. 77[11] (1994) 2968-2970.

-

- 24. L.-S. Chi, H.-Y. Chen, S.-Q. Deng, H.-H. Zhuang, and J.-S. Huang, Chinese J. Struct. Chem. 16 (1997) 177-180.

- 25. S.-J. Ke, Y.-M. Wang, and Z.-D. Pan, Dyes Pigm. 118 (2015) 145-151.

-

- 26. Y.-Q. Fan, C.-F. Zhang, J. Zhan, and J.-H. Wu, Trans. Nonferrous Met. Soc. China 18[2] (2008) 454-458.

-

- 27. C. Xiao and L. Zeng, Hydrometallurgy 178 (2018) 283-286.

-

- 28. C. Xiao, L.-S. Xiao, C.-J. Gao, and L. Zeng, Sep. Purif. Technol. 156 (2015) 582-587.

-

- 29. X.-B. Li, L.-T. Shen, X.-Y. Tong, T.-G. Qi, G.-H. Liu, Q.-S. Zhou, and Z.-H. Peng, Trans. Nonferrous Met. Soc. China 28[11] (2018) 2342-2350.

-

- 30. S. Sanuki, K. Matsushita, M. Nishiwaki, and H. Majima, Metall. Mater. Trans. B. 31[1] (2000) 5-13.

-

- 31. S. Sanuki, S. Matsushita, Y. Morita, and H. Majima, Hydrometallurgy 57[3] (2000) 253-261.

-

- 32. R.-S.Tobias and A.-B. Garrett, J. Phys. Chem. 80[14] (1958) 3532-3537.

-

- 33. W.-Q. Zhu, J. Ma, L. Xu, W.-Z. Zhang, and Y.-S. Chen, Mater. Chem. Phys. 122[2-3] (2010) 362-367.

-

- 34. S. Arunachalam, B. Kirubasankar, E.-R. Nagarajan, D. Vellasamy, and S. Angaiah, Chem. Select. 3[45] (2018) 12719-12724.

-

- 35. K. Binran-Kisohen II, and K. Nakata, in “Handbook of Chemistry” (Maruzen, Tokyo, 1993),p.170.

- 36. S. Liu, R.-J. Ma, R.-Y. Jiang, and F.-C. Luo, J. Crystal Growth 203[3] (1999) 454-457.

-

- 37. W.-Q. Zhu, J. Ma, X.-P. Xing, L. Xu, and Y.-S. Chen, Mater. Res. Bull. 46[6] (2011) 830-834.

-

- 38. B. Vallina, J.-D. Rodriguez-Blanco, A.-P. Brown, J.-A. Blanco, and L.-G. Benning, Nanoscale 7[28] (2015) 12166-12179.

-

- 39. Z.-Y. Xu, Y.-J. Zhang, Z.-Y. Fang, X.-B. Yin, and W. Zhu, Mater. Res. Bull. 45[1] (2010) 74-79.

-

- 40. T. Tahara, I. Nakai, R. Miyawaki, and S. Matsubara, Z Kristallogr 222 (2007) 326-334.

- 41. X.-F. Shang, W.-C. Lu, B.-H. Yue, L.-M. Zhang, J.-P. Ni, Y. Iv, and Y.-L. Feng, Crystal Growth Design 9[3] (2009) 1415-1420.

-

- 42. C.-J. Brinker, J. Non-Crystall. Solids 100[1-3] (1988) 31-50.

-

- 43. R.-K. Iler, in “The Chemistry of Silica” (Wiley, New York, 1979), p. 209.

- 44. S.-L. Chen, P. Dong, G.-H. Yang, and J.-J. Yang, Ind. Eng. Chem. Res. 35[12] (1996) 4487-4493.

-

- 45. E.-R. Pohl and F.-D. Osterholtz, in “Molecular characterisation of composite interfaces” (Plenum, New York, 1985), p. 157.

-

- 46. S.-H. Kim, B.-Y.-H. Liu, and M.-R. Zachariah, Langmuir 20[7] (2004) 2523-2526.

-

This Article

This Article

-

2020; 21(3): 386-391

Published on Jun 30, 2020

- 10.36410/jcpr.2020.21.3.386

- Received on Feb 24, 2020

- Revised on Mar 10, 2020

- Accepted on Mar 16, 2020

Services

Services

- Abstract

introduction

experimental

results and discussion

conclusions

- Acknowledgements

- References

- Full Text PDF

Shared

Correspondence to

Correspondence to

- Yanmin Wang a, Zhidong Pan a,b

-

aSouth China University of Technology, Guangzhou 510640, China

bFoshan Oceano Ceramics Co. Ltd., Foshan 528138, China

Tel : +86 20 87114883

Fax: +86 20 87110273 - E-mail: wangym@scut.edu.cn, wangym@scut.edu.cn

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.