- Influences of characteristics of the alkaline activator on the compressive strength and microstructure of the fly ash-based geopolymer pastes

Qingbo Tiana,*, Daquan Suna, Zeyu Gua and Zhijie Lvb

aSchool of Materials Science and Engineering, Shandong Jianzhu University, Jinan, China

bSchool of Mechanical and Electrical Engineering, Shandong Jianzhu University, Jinan, China

The effects of Na2O

content, water to binder (W/B) ratio, and the modulus (Ms) of

alkaline activator solution on a fly ash-based geopolymer paste (FGP) were

investigated. The microstructure of the pastes was observed and characterised

by Scanning electron microscope and X-ray diffraction. The results showed that

the increase of Na2O content and Ms resulted in an

increase in compressive strength: an increase in the W/B ratios led to a

decreased compressive strength. It was found that the high compressive strength

was achieved as Ms of the alkaline activator was 1.5, and the

content of this activator was 8.0-12.0% by the proportion of Na2O to

fly ash. The compressive strength of these pastes was between 26.5-39.6 MPa at

28 days when they were cured at 85 ºC for 1 h followed by curing under standard

conditions. OH- concentration, determined by Na2O content,

Ms, and water content, seemed to be a crucial parameter

influencing the compressive strength. There was an optimal OH- concentration range, in which the appropriate

strength of geopolymer paste would be achieved. An increased alkaline content

promoted the reaction between the mineral phases of the fly ash with the

alkaline activator and the formation of an additional sodium aluminosilicate

hydrate (N-A-S-H) gel.

Keywords: Fly ash-based geopolymer pastes (FGP), Geopolymers, Alkaline activation, Compressive strength, OH- concentration

Geopolymers are synthesised using an aluminosilicate

raw material and an alkaline activator solution (AAS) [1-6]. Compared to

ordinary Portland cement (OPC), geopolymer materials are known for their

excellent properties, such as comparable or better mechanical properties [3],

thermal and chemical stability [4], and impact resistance [7], and are

considered as potential alternatives to OPC [8]. In particular, waste materials

that are not currently reused in other industrial sectors can be used as

precursors to geopolymer materials. Therefore, geopolymers have

received increasing attention among those

trying to reduce the consumption of natural raw

materials and their environmental impact.

Fly ash is a by-product derived from the combustion of

coal powder in thermal power plants. It becomes an important material for

geopolymeric precursor due to its containing suitable components of amorphous

silica and alumina [4, 5]. Therefore, fly ash-based geopolymer

products have attracted much interest and studies have been undertaken

therewith in recent years [9-18]. In the fabrication of geopolymers, a strong

alkaline medium is necessary to increase the dissolution of silica and alumina

in precursor materials, in which, alkaline solutions such

as sodium hydroxide, and sodium silicate, are most commonly adopted.

Fernández-Jiménez and Palomo [13] investigated

the effects of NaOH content on the properties thereof: at NaOH contents of 5,

6, 7, 8, and 10% (by mass of binders),

compressive strengths of 9 MPa, 21

MPa, 30 MPa, 31 MPa, and 50 MPa at 28 days ensued, respectively. Palomo et al. [14] also observed that the

concentration of the activator affected the compressive strength and stiffness

of fly ash-based geopolymers (other results also confirm this [15-17]):

however, some authors reported that the ratios of SiO2/Na2O

or Al2O3/Na2O exerted greater influences on

the strength than NaOH content alone [10, 13, 17]. Palomo et al.

[14] investigated an alkaline activated fly ash mortar: the compressive

strength reached almost 70 MPa at SiO2/Al2O3

and Al2O3/Na2O ratios of 3.95 and 2.62. As the

SiO2/Al2O3 and Al2O3/Na2O

ratios were changed to 3.87 and 3.13, the strength decreased to 54.5 MPa. Ryu

et al. [18] also examined the effects of SiO2/Al2O3

and Al2O3/Na2O ratios in fly ash-based

alkaline activated pastes. At SiO2/Al2O3 ratio

of 4.13, the compressive strength was reduced with the increase of Al2O3/Na2O

ratio.

Besides, the water content also played crucial roles in

the reactivity and strength development of the FGPs [2, 13, 19-23]. As the W/B

ratio was 0.47, the compressive strength was 50 MPa. When the ratio decreased

to 0.42, 0.31 and 0.26, the strength increased to 63.5 MPa,

82.5 MPa and 96.0 MPa, respectively [3], indicating that the rises of water

content greatly decreased the strength. Fang et al. [23] observed that a large

portion of water was entrapped in discontinuous gel pores, this might be the

cause to impair the strength of the paste. In addition, the effects of the curing

processes on the properties of FGP has been generally recognised.

Palomo et al. [14] studied a FGP cured at 65 ºC and 85 ºC

respectively for 2-24 h. The compressive strength was 30

MPa in the binder cured at 65 ºC for 5 h; while as cured at

85 ºC for only 2 h, the compressive strength could arrived at 31.6 MPa. As

the curing time attained 24 h, the strength of 68.7 MPa would reached in

the binders cured at 85 ºC. In another FGP, 28-day compressive strength

was 24.4 MPa in the binder cured for 24 h at 40 ºC; it

increased by 96.7%, 104.1% and 145.8% as the curing temperature rose to

70 ºC, 80 ºC and 100 ºC, respectively

[16]. However, it was found that there was a crucial

curing temperature and time in the geopoly-

merisation of FGPs and the optimal curing

processes varied with different FGP systems [15, 24, 25]. In fact, all parameters,

including the concentration of the activator,

the SiO2/Na2O or Al2O3/Na2O

ratio, the water content, and pH, and the curing processes, seem to play roles

in the synthesis of FGPs. However, the influences thereof are complex and it is

difficult to predict which one is more important [13, 17, 21, 26]. In addition,

the optimum conditions are different in fly ash based geopolymers due to the

differences in fly ash resource and its

characteristics [5, 20, 27-30]. Here, a fly ash with high iron content was used

as the precursor to fabricate

geopolymer pastes. The roles of the contents of the alkaline activator, the ratios of SiO2/Al2O3,

Al2O3/Na2O, and W/B, especially the effects of

OH-

concentration, on the properties and microstructure of FGPs are

discussed.

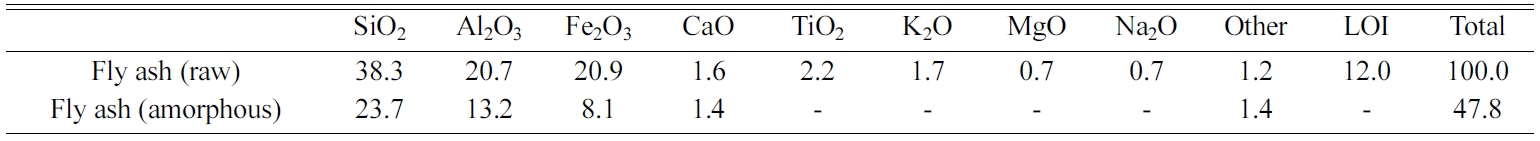

Precursor

material properties

The fly ash used in the study was supplied from Guizhou

Alumina Corporation, Guiyang, China. The chemical composition of the fly ash,

obtained by X-ray fluorescence (XRF) on a ZSX Primus II X-ray spectro- meter, is summarised in Table

1. The reactive amounts in fly ash, which were estimated by a combined

dissolution of fly ash in NaOH solution by following extraction with HCl

solution [31], are also listed in Table 1. The fly ash was found to have 47.8%

amorphous material, comprising 23.7% SiO2, 13.2% Al2O3,

8.1% Fe2O3, 1.4% CaO, and 1.4% other elements.

Preparation

of the AAS

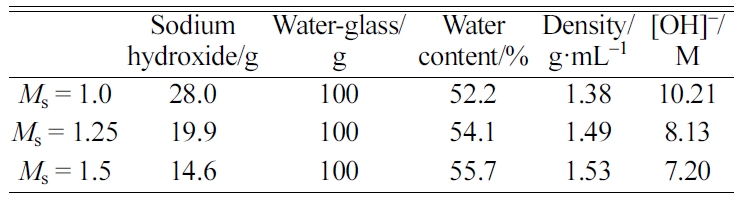

Analytical sodium hydroxide pellets (99 wt %) were

dissolved in distilled water, and then mixed with glass-water solution (30.4%

SiO2, 9.6% Na2O, and 60.0% H2O by mass). Three

different moduli (Ms) of SiO2/Na2O

(mol) were adopted to explore the effect of Ms on the

geopolymer pastes. The mix proportions of sodium hydroxide and water-glass

solution for the AAS are summarised in Table 2.

Preparation

of the FGPs

The pastes were prepared by stirring the fly ash and AAS

together. The equivalent sodium oxide content in the AAS was set to 6, 8, 10,

and 12% by mass of the fly ash binder, respectively. The appropriate amount of

water was added to adjust the W/B ratios to 0.38, 0.49, and 0.57. After being

stirred thoroughly, the pastes were cast in 40 mm × 40 mm × 160

mm metal moulds, vibratory compacted, wrapped in thin plastic film and cured

for 24 h at 80 ºC, then cured under standard curing conditions. The curing

temperature of 80 ºC was selected as it provided the required energy

guaranteeing the reaction between the fly ash and activating solution [30,32].

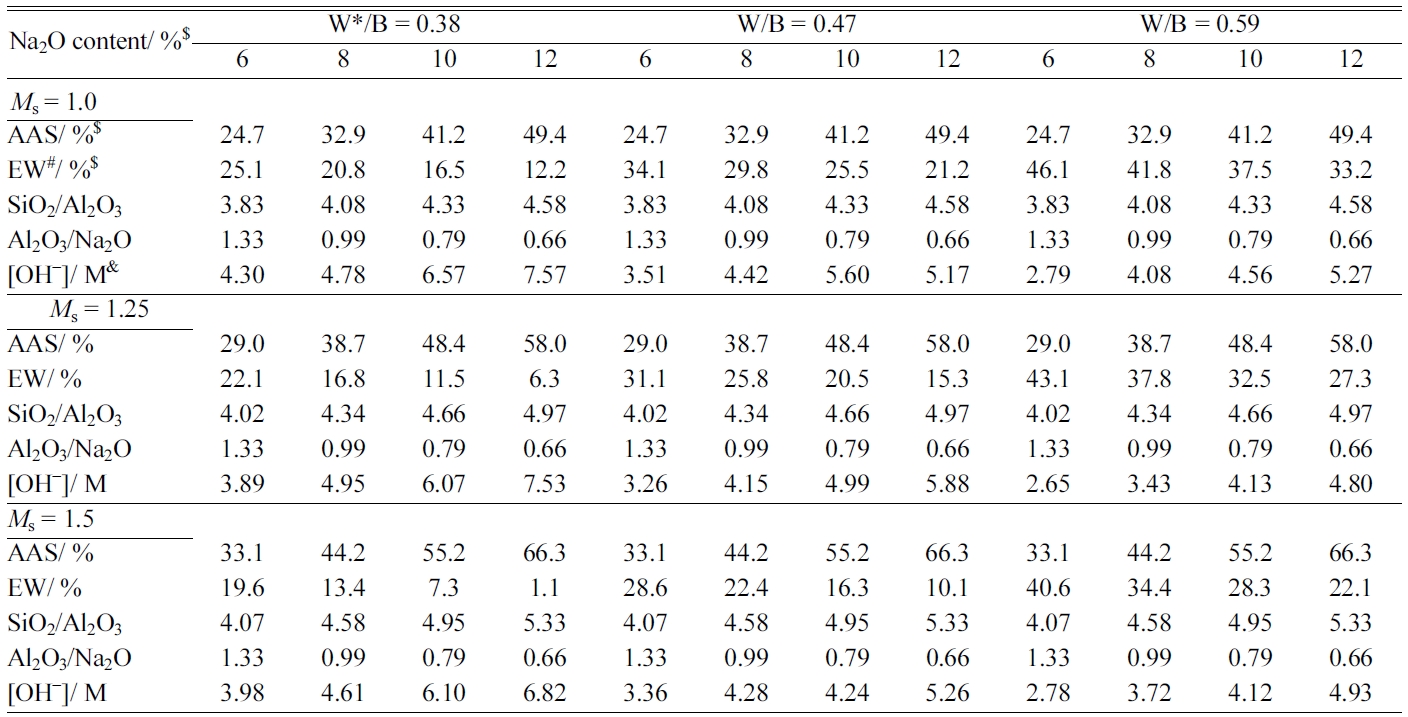

The mix proportions of AAS, extra water, the molar ratios of SiO2/Al2O3,

Al2O3/Na2O, and the OH- concentration for preparing

FGPs are summarised in Table 3.

Characteristic

material properties

The compressive strength of FGPs was determined using

a SANS machine (MTS CDT 1305-2) at a maximum load of

300 kN. The average of three measurements was calculated. The images of

the FGPs were captured by scanning electron microscopy (SEM:

Hitachi SU8010, Japan) method on a fractured section and a thin

film of Au was sputter-coated onto the specimen surface before

observation. The mineral phases of fly ash and alkaline activated binders were

identified by X-ray diffraction (XRD: Bruker D8 ADVANCE, Germany) on

powdered samples.

|

Table 2 Mix proportions of sodium hydroxide and water-glass for the AAS and its properties |

|

Table 3 Mix proportions for fly ash-based binder pastes and their characteristics. |

Note: $, percentage relative to fly ash; #, Extra water; *, Water includes water from water-glass and extra water; &, OH− concentration was measured by acid-base titration. |

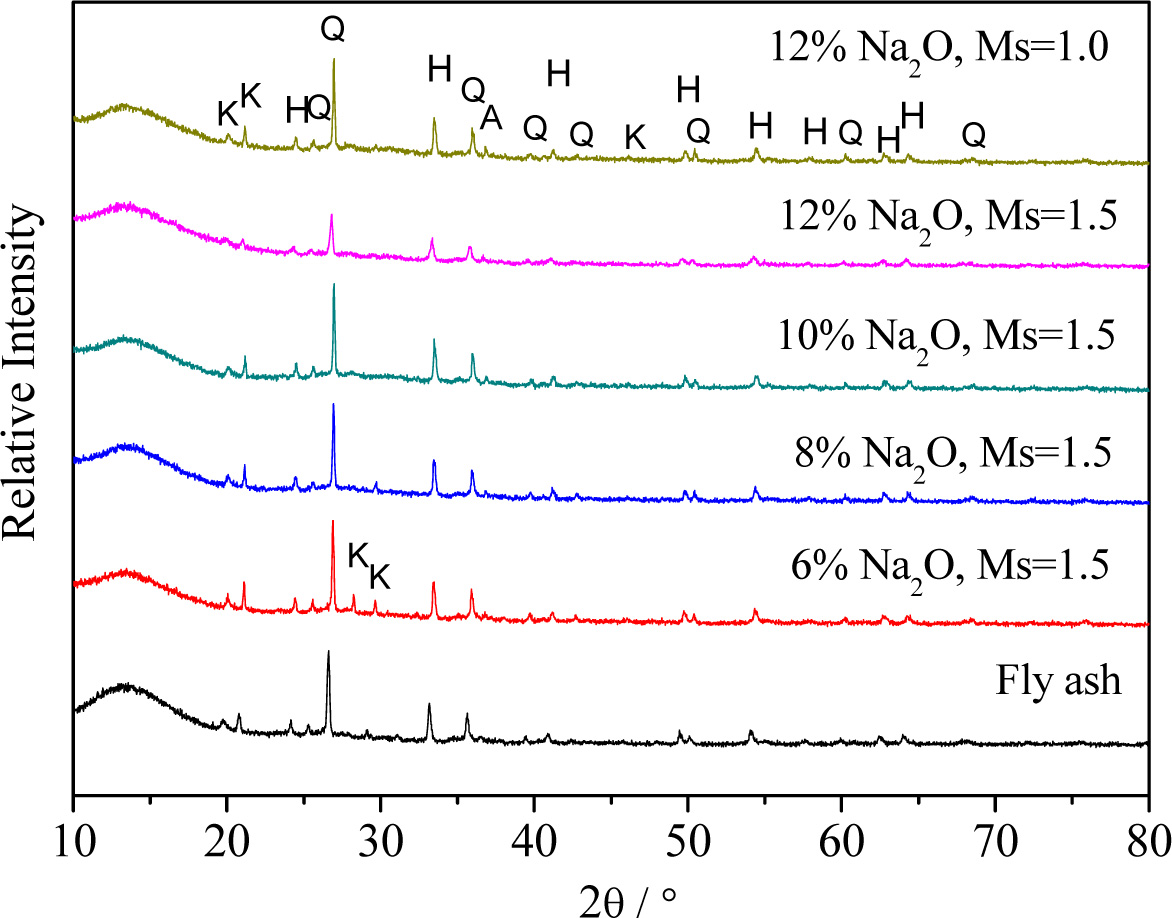

Fig. 1 shows XRD patterns of fly ash and geopolymer

pastes developing at various Na2O contents and values of Ms.

The fly ash shows different mineral peaks related to the presence of quartz (Q,

SiO2), hematite (H, Fe2O3), and kyanite (K, Al2SiO5)

mineral phases. Besides, the broad diffuse hump at about 10-20º indicates

that it contains a certain amount of amorphous material

[33]. After alkaline activation, the mineral phases in the pastes are not

significantly altered from those found in the fly ash. The predominant phases

in the fly ash are also found in all pastes, however, as the Na2O

content increased, the diffraction peaks of quartz, hematite, and kyanite

gradually decreased in amplitude, indicating that the mineral phases present in

the fly ash were reacting with AAS. In particular, diminished peak intensities

in the XRD spectra are seen at a Na2O content of 12% and Ms

= 1.5. Meanwhile, an albite phase (A, NaAlSi3O8) is

gradually formed in the alkaline activated pastes. This albite phase is

associated with the strong Na-Al-Si hydrated bonds which can be considered to

play major effects to the strength of such geopolymers [34]. In addition, a

slight shift in the peak for the binder was observed, implying that a new amorphous phase formed [19]. When alkaline

activator solution was added, Na+ was accommodated within the cavities of -Si-O-Al- networks as a charge

balancer to form sodium aluminosilicate gel (N-A-S-H). The formation of the gel also contributed to the development of

compressive strength [35-38].

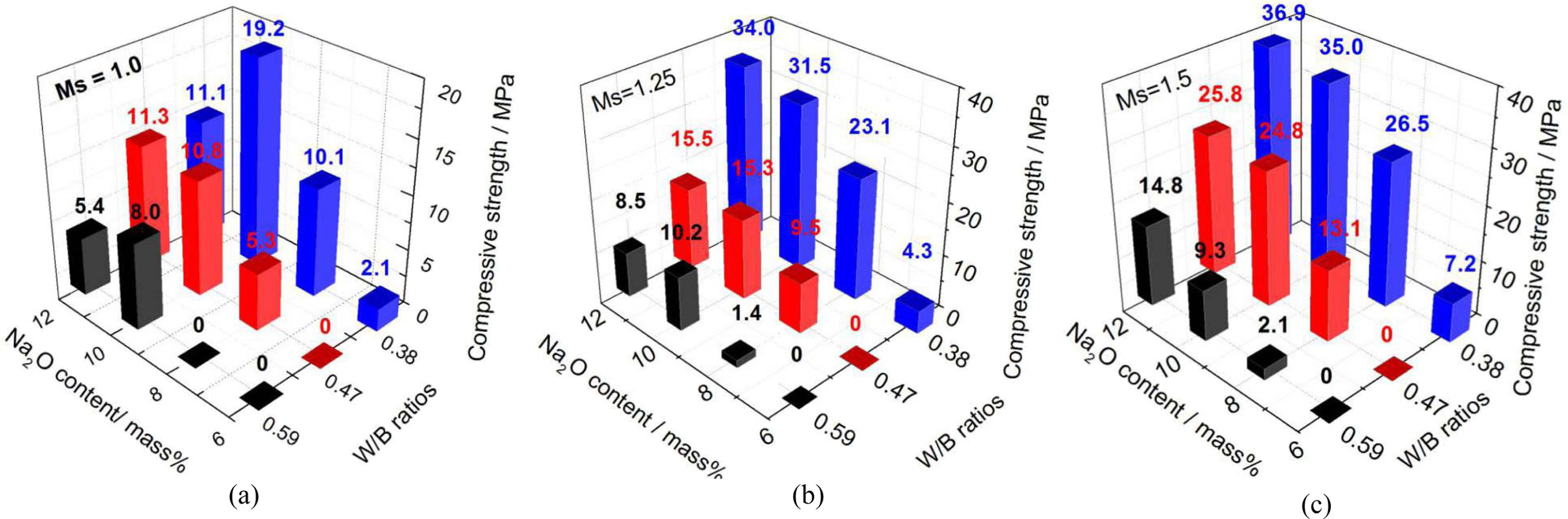

The effects of Na2O percentage to binder, W/B

ratios, and Ms on the compressive strength of FGPs are shown

in Fig. 2. As Ms is 1.0 (Fig. 2(a)), the strength at 28 days

is negligible in pastes with 6.0% Na2O content (2.1 MPa) at a W/B

ratio of 0.38. As the Na2O content was increased, the strength

gradually developed at 28 days for the pastes tested here. Compressive

strengths of 10.1 MPa and 19.2 MPa in the paste samples with Na2O

contents of 8% and 10% were achieved (increased 3.8 and 8.1

times, respectively, compared with that at 6% Na2O

content). When the W/B ratios were increased to 0.47 and

0.59, a similar trend was observed. The compressive strength of pastes was low

at low Na2O content, and increased therewith;

however, the difference was also observed in that the

strength decreased with increasing W/B ratios at the same Na2O

content. At a Na2O content of 8%, the strength decreased to

5.3 MPa and to almost zero from 10.1 MPa, when the W/B ratio was increased

to 0.47 and 0.59 from 0.38. As the Na2O content was 10%, the

compressive strength of the paste was decreased by 43.4% and 58.3% when the W/B

ratio was increased to 0.47 and 0.59, respectively.

The alkaline activation of fly ashes leads to the

formation of an alkaline aluminosilicate of amorphous nature[39]. Alkali

activator solutions play an important role to dissolve Si and Al oxides in fly

ash. In a low alkaline activator solution, the silica and alumina are filtered

less [40] and a weak chemical reaction will occur [13, 26, 28, 39, 41, 42]. It

is undoubtedly that a low compressive strength would be attained in a

low-alkalinity solution. With the increase in Na2O content, the

higher reactivity of the fly ash would be expected [21]. Thus, a

higher compressive strength was anticipated. It has been

reported that there is a threshold alkaline activator

content [7, 15, 20, 41]. Bakharev [15] reported that the

strength developed rapidly at 8% Na2O concentration in a geopolymer material. Cho

et al. [16] observed that the strength at 28 days increased as the Na2O

content increased from 4.0% to 6.0%; however, when Na2O content

further increased beyond 6.0%, the rate of strength

development decreased. Steveson et al. [35] found that the optimum compressive

strength of geopolymer materials could be achieved when the

Na2O content in AAS is between 7% and 9% by mass of fly ash. From

our experimental results, an 8%-10% Na2O content in the fly ash was

a critical value range able to activate the fly ash efficiently. As the Na2O

content was less than 8%, regardless of any adjustment of Ms

and W/B ratio, the compressive strength of the pastes did not exceed 10 MPa

(Figs. 2(a)-(c)).

As the Na2O content was further increased to

12%, no obvious increase in the strength, and even a decrease

therein, was observed: this may have been caused by free OH- present in the

alkali-activated matrix [27] (as also observed elsewhere [26, 35, 41]). Table 3

also lists the OH-

concentration changes of the AAS at various W/B ratios, Na2O

contents, and Ms. The W/B ratios, Na2O contents,

and Ms exerted significant influences on the OH- concentration.

With the increase in W/B ratios, the water content increases and dilutes OH- at the same Ms

and Na2O content so the OH- concentration

decreased accordingly. On the contrary, the OH- concentration

increased with increasing Na2O content. The influences of Ms

on the OH-

concentration are mutual: on one hand, more NaOH was needed to obtain an AAS

with lower Ms (Table 2), thus, with a larger Ms

in the AAS, a lower NaOH content resulted, causing the decrease in OH- concentration. On the other

hand, as water-glass was mixed with NaOH, more NaOH was generated through

the hydrolysis of sodium silicate, further increasing the OH- concentration [13, 18, 43]

(Table 3).

From the results (Fig. 2), the W/B ratios played an

important role as described elsewhere [12-14, 42]. Palomo et al. [14] note that

the roled of the added water must be taken into account when investigating the

properties of a geopolymer material. Firstly, enough water was necessary to

ensure the workability of the mixtures [11], or a high strength was

difficult to achieve: however, when excess water was added, there was

sufficient mobility of ions in the mixtures for the solid to dissolve, causing

a low level of unreacted material and a low strength [9]. This is attributed to

the increase of porosity in the binder matrix [35].

At Ms of 1.25 or 1.5, similar trends in

the compressive strength of the pastes along with the Na2O

content and W/B ratio were observed (Figs. 2(b) and 2(c)). That is: the

compressive strength increased with increasing Na2O content

(relative to fly ash) and decreased with increasing

W/B ratio. The compressive strength increased at larger Ms

at the same Na2O content and W/B ratio. At Ms

of 1.25 and 1.5, the compressive strength increased to

31.5 MPa and 35.0 MPa from 19.2 MPa, respectively, with 10% Na2O

content and a W/B ratio of 0.38; while, the strength

increased by 27.6% and 46.4%, respectively, with 8%

Na2O content and a W/B ratio of 0.38. The maximum strength of 36.9

MPa was achieved in that geopolymer paste with 12% Na2O content at Ms

= 1.5.

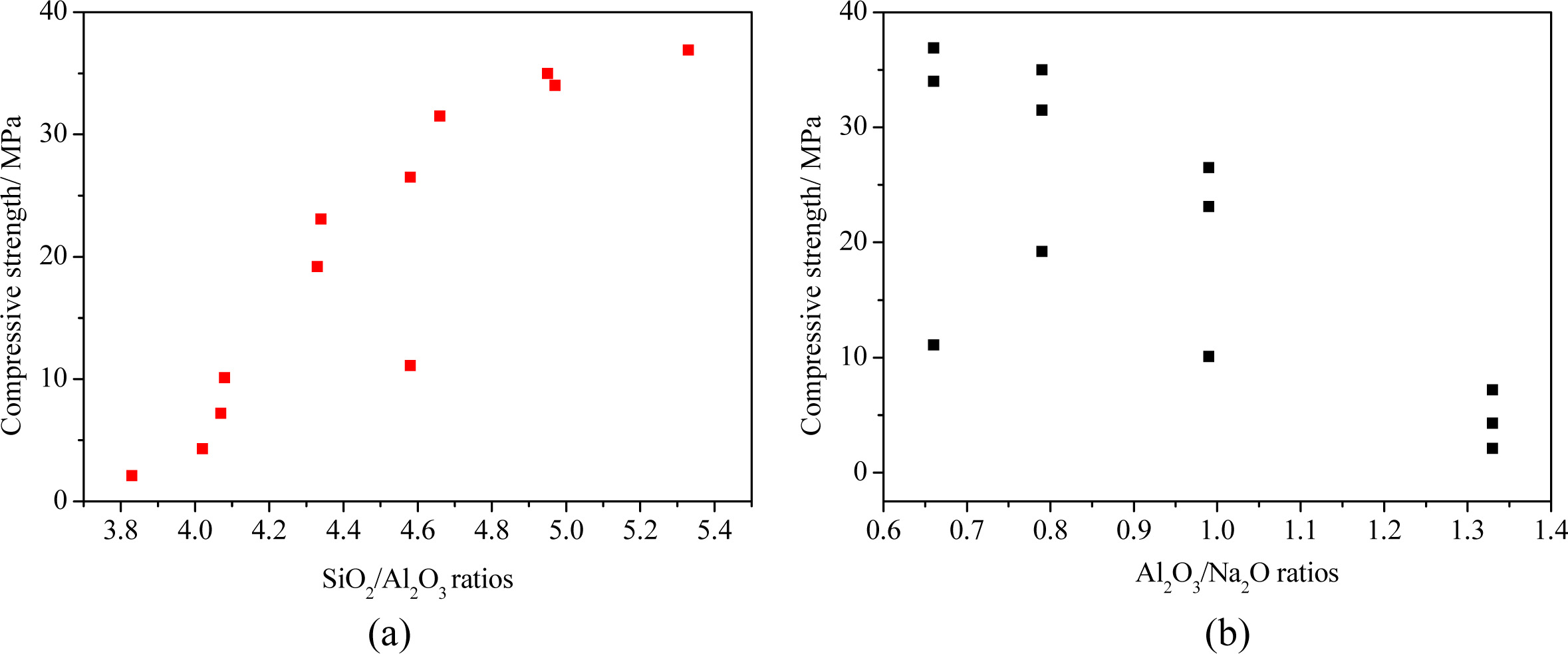

In fact, the changes in Ms and Na2O

content also changed the SiO2/Al2O3 and Al2O3/Na2O

ratios, which are important parameters in geopolymer synthesis [18]. Fig. 3

plots the results of the effects of the SiO2/Al2O3

and Al2O3/Na2O ratios on the compressive

strength of pastes at a W/B ratio of 0.38. The strength increased as the SiO2/Al2O3

ratio was increased from 3.83 to 5.33 (Fig. 3(a)): because the

active SiO2 content was relatively low (23.7%)

in the fly ash used in the present study, the larger Ms, led

to the higher SiO2 content in the AAS and the binder matrix, thus

increasing the compressive strength of fly ash-based geopolymers. The strength

values were scattered with the change in Al2O3/Na2O

ratio, however, a high strength could be attained only with an Al2O3/Na2O

ratio of less than 1.0 (Fig. 3(b)). According to these results, the strength at

28 days is improved by more than 1.6 times at SiO2/Al2O3

= 4.58, compared to that at SiO2/Al2O3 = 4.08

at the same Al2O3/Na2O ratio of 0.99; while, a

strength greater than 30 MPa at 28 days could be achieved with an Al2O3/Na2O

ratio of less than 0.80. These indicated the roles of SiO2/Al2O3

and Al2O3/Na2O ratios to strength development in the geopolymers.

The SiO2/Al2O3 and Al2O3/Na2O

ratios cannot reflect the role of water on the compressive strength, as they

were kept constant as the W/B ratio was changed (Table 3). The OH- concentration, which

reflected the comprehensive effects of parameters such as the Na2O

content, W/B ratio, and Ms, represented parameter that could

be used to characterise the compressive strength of FGA. From Table 3, it can

be seen that OH-

concentration are influenced by the W/B ratio, Na2O content, and Ms.

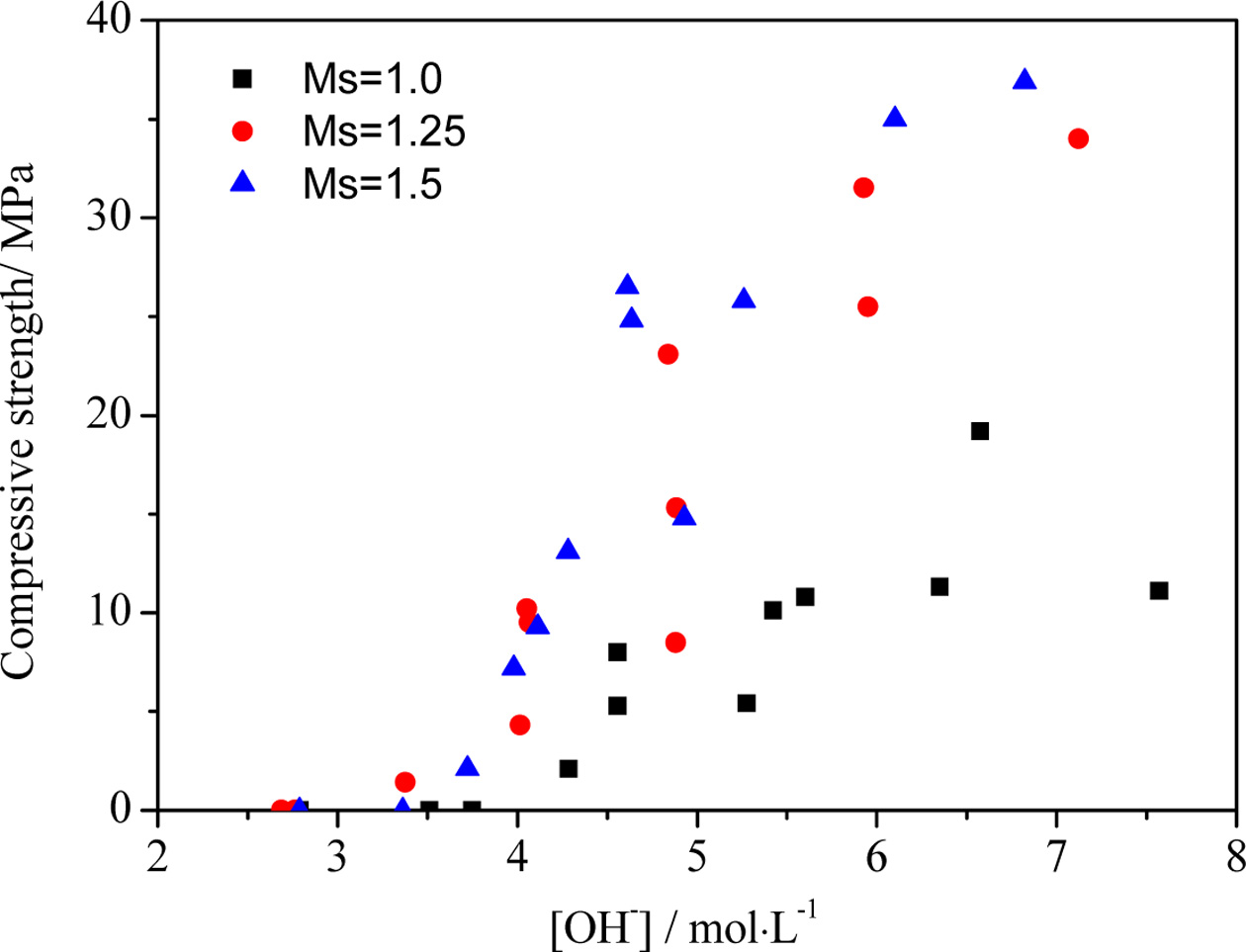

The variation in OH-

concentration, which influences the chemical reaction of AAS with fly ash,

would affect the final strength of these geopolymers as also demonstrated by

our results. Considering the mutual effects of W/B ratio and Na2O

content, the influences of OH-

concentration on the compressive strength were as shown in Fig. 4. Regardless

of the effects of Ms, the compressive strength could not be

detected as the OH-

concentration was initially below its critical threshold value: it then

generally increased at greater OH-

concentrations, and finally decreased at an excessive OH- concentration. The critical

values of OH-

concentration inducing the turning point in the compressive strength were

similar, although the strength varied with Ms. When the OH- concentration was less than

4.5 mol/L, it could not induce an efficient reaction, thus a

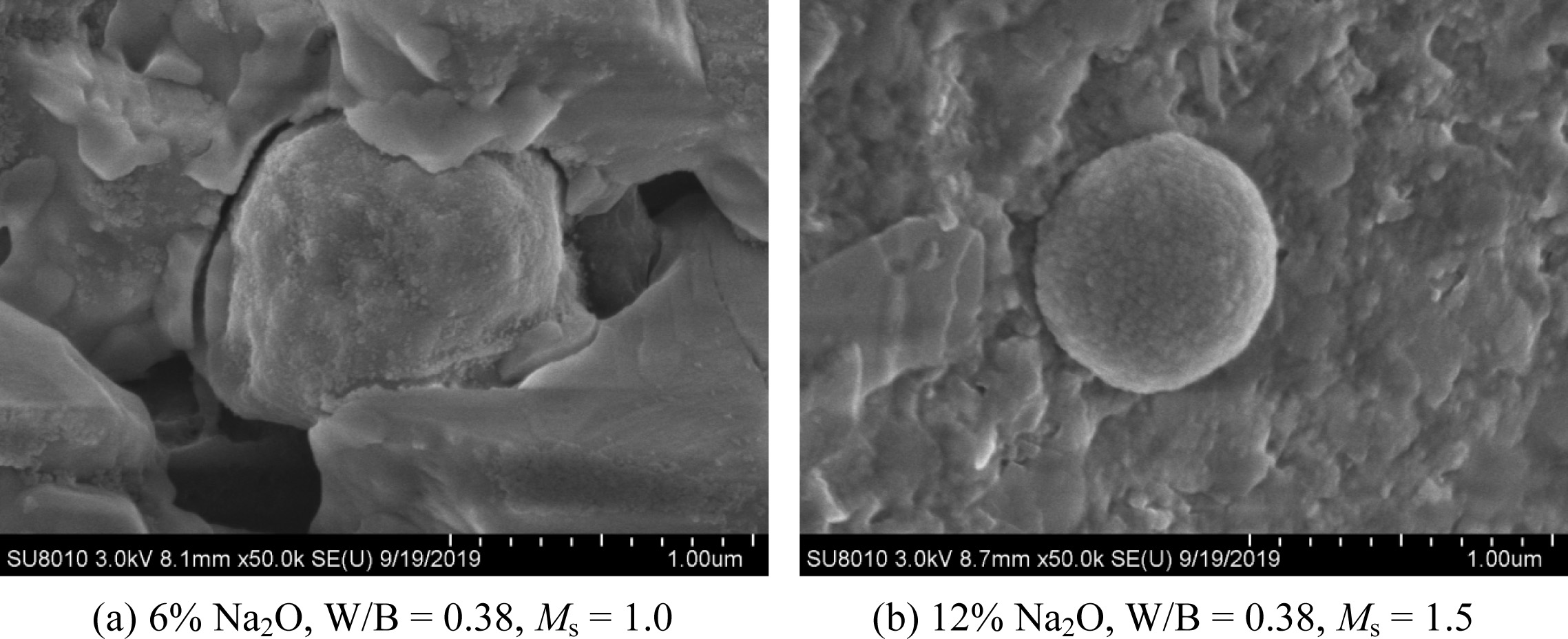

low-strength product ensued. From the SEM image of the sample

with [OH-] of 4.30, the unreacted fly ash particles were

visible (Fig. 5). In addition, the presence of voids and cracks along the

surface of fly ash particle was found, which may have impaired the compressive

strength (Fig. 5(a)). At an OH-

concentration greater than 7.0 mol/L, a high strength could not be reached due

to the free OH-

in the pastes, causing efflorescence from the binder [44].

An OH-

concentration of between 4.5-7.0 mol/L was able to

induce the chemical reaction so as to produce a high strength product using the

fly ash system adopted here [13, 18, 43]. From the microstructure as imaged

under an SEM (Fig. 5(b)), the material was less void and more well

development, compared with that seen in Fig. 5(a). This also

indicated the higher degree of polymerisation and the presence of N-A-S-H gel

[33], as evinced by XRD results. The compressive strength of geopolymer pastes

at Ms = 1.5 was higher than that at Ms

values of 1.25 and 1.0 at the same OH-

concentration: this may have been caused by the higher SiO2/Al2O3

ratio (Table 3).

|

Fig. 1 XRD patterns of fly ash and geopolymer pastes at various conditions. |

|

Fig. 2 Influences of Na2O content, W/B ratio and Ms on compressive strength of FGAs (a) Ms = 1.0, (b) Ms = 1.25 and (c) Ms = 1.5. |

|

Fig. 3 Influence of SiO2/Al2O3 and Al2O3/Na2O ratios on the compressive strength at W/B=0.38. |

|

Fig. 4 Effects of [OH−] in AAS on the compressive strength of pastes. |

|

Fig. 5 SEM image of paste with different [OH−] concentrations of (a) 4.30 and (b) 6.82. |

The influences of variables, such as Na2O

content, W/B ratio, and Ms of alkaline activator solution, on

the compressive strength of a FGA were investigated. There was a critical value

of the OH-

concentration of the alkaline activator required for optimal compressive

strength development, as influenced by the W/B ratio, Ms, and

Na2O content. At an OH-

concentration of less than 4.5 mol/L, the compressive strength was less than 20

MPa due to the low OH-

concentration having induced an low reaction of fly ash with

alkaline activator: however, at OH-

concentrations greater than 7.0 mol/L, free OH-

was present in the binder, and the compressive strength reached

a plateau or decreased. Only at an OH- concentration of

between 4.5-7.0 mol/L, could the compressive strength have reached between

20.0-36.0 MPa. The ratios of SiO2/Al2O3

and Al2O3/Na2O affected the compressive strength. According to the

results, the increase in SiO2/Al2O3 values

over the range of 3.83-5.33 promoted the increase of compressive strength; whilst, it was possible to achieve a high strength only when the Al2O3/Na2O

ratio was less than 1.0. As the

alkali content was increased to 12%

(relative to the mass to fly ash), the reaction of the mineral phases in the fly ash with the alkali

activator was strengthened, which

induced the formation of N-A-S-H gel, thus increasing the compressive strength.

This research was financially supported through the

National Natural Science Foundation of China (Grant No. 51375281).

- 1. M. Asadi, R. Naghizadeh, A. Nemati, K. Arzani, and R. Nassiri, J. Ceram. Process. Res. 13[4] (2012) 425-428.

- 2. T. Luukkonen, Z. Abdollahnejad, J. Yliniemi, P. Kinnunen, and M. Illikainen, Cem. Concr. Res. 103 (2018) 21-34.

-

- 3. K. Neupane, Mech. Mater. 103 (2016) 110-122.

-

- 4. J. Feng, R. Zhang, L. Gong, Y. Li, W. Cao, and X. Cheng, Mater. Des. 65 (2015) 529-533.

-

- 5. Y. Kim and T. Chae, J. Ceram. Process. Res. 19[5] (2018) 378-382.

- 6. P. Duxson, J.L. Provis, G.C. Lukey, and J.S.J. van Deventer, Cem. Concr. Res. 37 (2007) 1590-1597.

-

- 7. M. Khandelwal, P.G. Ranjith, Z. Pan, and J.G. Sanjayan, Arabian J. Geosciences 6[7] (2013) 2383-2389.

-

- 8. H.A. Abdel-Gawwad, and S.A. Abo-El-Enein, HBRC Journal 12[1] (2016) 13-24.

-

- 9. W. Zhou, C. Yan, P. Duan, Y. Liu, Z. Zhang, X. Qiu, and D. Li, Mater. Des. 95 (2016) 63-74.

-

- 10. M. C. Bignozzi, S. Manzi, M. E. Natali, W. D.A. Rickard, and A. van Riessen, Constr. Build. Mater. 69 (2014) 262-270.

-

- 11. J. Temuujin, A. van Riessen, and K.J.D. MacKenzie, Constr. Build. Mater. 24 (2010) 1906-1910.

-

- 12. S. Lee, A. van Riessen, and C.M. Chon, Materials 9[7] (2016) 598-608.

-

- 13. A. Fernández-Jiménez and A. Palomo, Cem. Concr. Res. 35 (2005) 1984-1992.

-

- 14. A. Palomo, M.W. Grutzeck, and M.T. Blanco, Cem. Concr. Res. 29 (1999) 1323-1329.

-

- 15. T. Bakharev, Cem. Concr. Res. 35 (2005) 1224-1232.

-

- 16. Y.K. Cho, S.W. Yoo, S.H. Jung, K.M. Lee, and S.J. Kwon, Constr. Build. Mater. 145 (2017) 253-260.

-

- 17. A.S. de Vargas, D.C.C. Dal Molin, A.C.F. Vilela, F.J. da Silva, B. Pavãoe, and H. Veit, Cement Concr. Compos. 33[6] (2011) 653-660.

-

- 18. G.S. Ryu, Y.B. Lee, K.T. Koh, and Y.S. Chung, Constr. Build. Mater. 47 (2013) 409-418.

-

- 19. S. Kumar, R. Kumar, T.C. Alex, A. Bandopadhyay, and S.P. Mehrotra, Adv. Appl. Ceram. 106[3] (2007) 120-127.

-

- 20. S. Kumar, R. Kumar, and S.P. Mehrotra, J. Mater. Sci. 45[3] (2010) 607-615.

-

- 21. M. Palacios, M.M. Alonso, C. Varga, and F. Puertas, Cement Concr. Compos. 95 (2019) 277-284.

-

- 22. H. R. Gavali, A. Bras, P. Faria, and R.V. Ralegaonkar, Constr. Build. Mater. 215 (2019) 180-191.

-

- 23. Y. Fang, and O. Kayali, Constr. Build. Mater. 39 (2013) 89-94.

-

- 24. F. Winnefeld, A. Leemann, M. Lucuk, P. Svoboda, and M. Neuroth, Constr. Build. Mater. 24 (2010) 1086-1093.

-

- 25. D. Hardjito, S.E. Wallah, D.M.J. Sumajouw, and B.V. Rangan, ACI Mater. J. 101 (2004) 467-472.

- 26. M. Soutsos, A.P. Boyle, R. Vinai, A. Hadjierakleous, and S.J. Barnett, Constr. Build. Mater. 110 (2016) 355-368.

-

- 27. Y.K. Cho, S.H. Jung, and Y.C. Choi, Constr. Build. Mater. 204 (2019) 255-264.

-

- 28. L. Assi, S. Ghahari, E. Deaver, D. Leaphart, and P. Ziehl, Constr. Build. Mater. 123 (2016) 806-813.

-

- 29. J.S. Tenepalli and D. Neeraja, J. Build. Eng. 19 (2018) 42-48.

-

- 30. G. Görhan and G. Kürklü, Composites: Part B 58 (2014) 371-377.

-

- 31. K.U.A. Sanalkumar, M. Lahoti, and E. Yang, Constr. Build. Mater. 225 (2019) 283-291.

-

- 32. J.G.S. van Jaarsveld, J.S.J. van Deventer, and G.C. Lukey, Chem. Eng. J. 89[1-3] (2002) 63-73.

-

- 33. A. Mehta and R. Siddique, Constr. Build. Mater. 141 (2017) 325-334.

-

- 34. A. Mehta, R. Siddique, B. Singh, S.Aggoun, G. Lagod, and D. Barnat-Hunek, Constr. Build. Mater. 150 (2017) 817-824.

-

- 35. M. Steveson and K. Sagoe-Crentsil, J. Mater. Sci. 40[16] (2005) 4247-4259.

-

- 36. C.E. White, J.L. Provis, A. Llobet, T. Proffen, and J.S.J. van Deventer, J. Am. Ceram. Soc. 94[10] (2011) 3532-3539.

-

- 37. P.V. Krivenko, and G.Y. Kovalchuk, J. Mater. Sci. 42[9] (2007) 2944-2952.

-

- 38. A. Palomo, A. Fernández-Jiménez, G. Kovalchuk, L.M. Ordoñez, and M.C. Naranjo, J. Mater. Sci. 42[9] (2007) 2958-2966.

-

- 39. F. Puertas, S. Martı́nez-Ramı́rez, S. Alonso, and T. Vázquez, Cem. Concr. Res. 30 (2000) 1625-1632.

-

- 40. P. Chindaprasirt, C. Jaturapitakkul, W. Chalee, and U. Rattanasak, Waste Manage. 29[2] (2009) 539-543.

-

- 41. X. Guo, H. Shi, and W. A. Dick, Cement Concr. Compos. 32 (2010) 142-147.

-

- 42. Z. Xie and Y. Xi, Cem. Concr. Res. 31 (2001) 1245-1249.

-

- 43. J.W. Phair, J.S.J. Van Deventer, and J.D. Smith, Appl. Geochem. 19[3] (2004) 423-434.

-

- 44. Z. Zuhua, Y. Xiao, Z. Huajun, and C. Yue, Appl. Clay Sci. 43[2] (2009) 218-223.

-

This Article

This Article

-

2020; 21(3): 358-364

Published on Jun 30, 2020

- 10.36410/jcpr.2020.21.3.358

- Received on Oct 16, 2019

- Revised on Apr 23, 2020

- Accepted on May 4, 2020

Services

Services

- Abstract

introduction

materials and methods

results and discussion

conclusion

- Acknowledgements

- References

- Full Text PDF

Shared

Correspondence to

Correspondence to

- Qingbo Tian

-

School of Materials Science and Engineering, Shandong Jianzhu University, Jinan, China

Tel : +86 131 53128675

Fax: +86 531 86367282 - E-mail: tqb11@sdjzu.edu.cn

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.