- Enhanced TE performance of FeVSb1-xSnx half-heusler matrices using zirconia vial

Rahidul Hasana,b, Kyu Hyoung Leeb and Soon-Chul Ura,*

aDepartment of Materials Science and Engineering / ReSEM, Korea National University of Transportation (KNUT), Chungju, Chungbuk 27469, Republic of Korea

bElectronic Device and Materials Laboratory (EDML), Yonsei University, Seoul 03727, Republic of Korea

Thermoelectric and transport

properties of FeVSb1-xSnx (0.015

Keywords: Thermoelectric, X-ray Diffraction, Lattice Thermal Conductivity, Scanning Electron Microscope, Mechanical Alloying

Mechanical alloying (MA) process is a well-known high

energy milling technique that can produce ultrafine

microstructures which can be controlled during the progress of the milling [1].

It has superior advantages over other traditional processes; for instance, it

may help to produce alloys that are difficult to produce applying

conventional metallurgical techniques, namely casting and

forging [2, 3]. Regarding this, MA can be utilized for elements with a low

melting point which may suffer from sublimation during processing.

Despite these benefits, there are few drawbacks of the MA process

which may generate problems during the synthesizing process. One important

effect that we suffered previously was the contamination of the

foreign elements from stainless-steel vial during the milling

[4]. It made the desired half-Heusler (HH) system unstable,

causing a negative doping effect. To overcome such

problems, zirconia vial was used in order to prevent the incorporation of

foreign elements from the vial.

Thermoelectric (TE) generators open a feasible way to

reduce the dependency of fossil fuels and greenhouse gas

emissions by converting waste heat into electricity [5, 6]. However, the

large-scale applications were not possible yet because of

moderate conversion efficiencies and high cost of the materials [7,

8]. Generally, the TE material performance is derived from, ZT = (α2σT)/(κlat.+κel.)

= (PF/κ)T . It is

obvious that an efficient TE material should have high α (Seebeck

coefficient), σ (electrical conductivity) but low κ

(thermal conductivity), κlat. (lattice

thermal conductivity) and κel. (thermal conductivity

due to electronic contribution) at the applicable temperature, T.

However, it is highly challenging to get high ZT because of

the inter-relation of these ZT parameters [9].

Half-Heusler (HH) alloys are the new addition in renewable

energy materials and could become an appropriate candidate for TE devices. HH

materials have advantages over other TE materials because of its

high-temperature strength, cheap ingredients and ease of synthesis process. HH

alloys showed improved TE efficiency from intermediate to high-temperature

waste heat conversion [10]. Generally, HH has considerable PF at 300 K. It is

the major merit point of getting high efficiency. Till today, the best TE

efficiency was observed from the HH alloys of ZrNiSn, ZrCoSb, and NbFeSb in the

range of ZT = 1~1.5 [11-15]. Ferluccio et al. showed that NbCoSb HH

also produced ZT ≈ 1 when it occupied vacancies at the Nb site [16].

Zhu et al. revealed that TE efficiency in HH alloys was limited due to large

lattice thermal conductivity (κlat.) around

10~13 Wm-1K-1

at 300 K [17]. Recently, FeVSb HH alloy has gained research

interest owing to its high PF value though it had a relatively high κ

value around 8~10 Wm-1K-1 [18].

Hence, the reduction of κ is one of the main objectives to get high ZT in FeVSb

alloys. For achieving optimum efficiency, doping in the FeVSb

HH system may reduce the thermal conductivity barrier [19]. Mass

scattering process may be one of the efficient ways

to reduce thermal conductivities in the HH system which may

reduce the κlat. around 4~5 Wm-1K-1

[20]. Recently, Zou et al. stated that κ could be reduced by

boundary scattering engineering [21]. Stadnyk et al. studied the Fe1-xCuxVSb

matrix and found metallic conductivity at elevated temperature owing to a

sequential-shift in Fermi level to the conduction band [22]. Some of the

previously reported highly efficient thermoelectric materials are p-type

ZrCoBi0.65Sb0.15Sn0.20 half-Heusler

(ZT ≈ 1.42 at 973 K) [23], p-type endoaxially

nanostructured PbTe (ZT ≈ 2.2 at 915K) [24], Bismuth-doped GeTe

(ZT ≈ 1.8 at 722 K) [25], Skutterudite DDyFe3CoSb12 (ZT > 1.3

at 773 K) [26] and Bismuth Chalcogenides, Bi2Te3/Sb2Te3

super-lattice (ZT≈2.4 at 300 K) [27].

For the investigation of the TE properties of FeVSb1-xSnx (0.015

FeVSb1-xSnx HH systems were

synthesized by MA process using the stoichiometric powder mixtures of Fe (63

µm), V (75 µm), Sb (45 µm) and Sn (63 µm) and all the powders were 99.9% pure.

MA process was carried out using a zirconia vial in a vibratory mechanical

mill for 6 h. The Speed of the mill was kept constant at 1,080 rpm throughout

the process. 5 mm diameter zirconia ceramic balls were used to

avoid contamination. A 325-mesh dry sieve was used for the sieving of

MAed powders. Consolidation of the MAed powders was carried out using VHP at 70

MPa pressure and at 1173K temperature for 2 h. Every process was carried out

under Ar-atmosphere to avoid contamination.

A particle size analyzer (PSA) was applied to get the

particle size and the data were confirmed by SEM. Phase transformation of MAed

powders and VHPed samples were studied by XRD. A scanning electron microscope

(SEM) was employed to analyze the microstructures of

the specimens. α and σ were measured by the 4-probe

method using ZEM-3. 3×3×10 mm3 rectangular samples were prepared for

conducting properties measurement and 10Φ×1 mm spherical disk was for

thermal diffusivity measurements. Heat transfer was captured by a laser flash

instrument using a TC-9000H. The density of the specimens was calculated on the

basis of the Archimedes principle. Hall measurements were taken

by the instrument Modified Keithley 7065 (USA) using

the Van der Pauw method. Rietveld refinement plot was produced using the py-GSAS-II program.

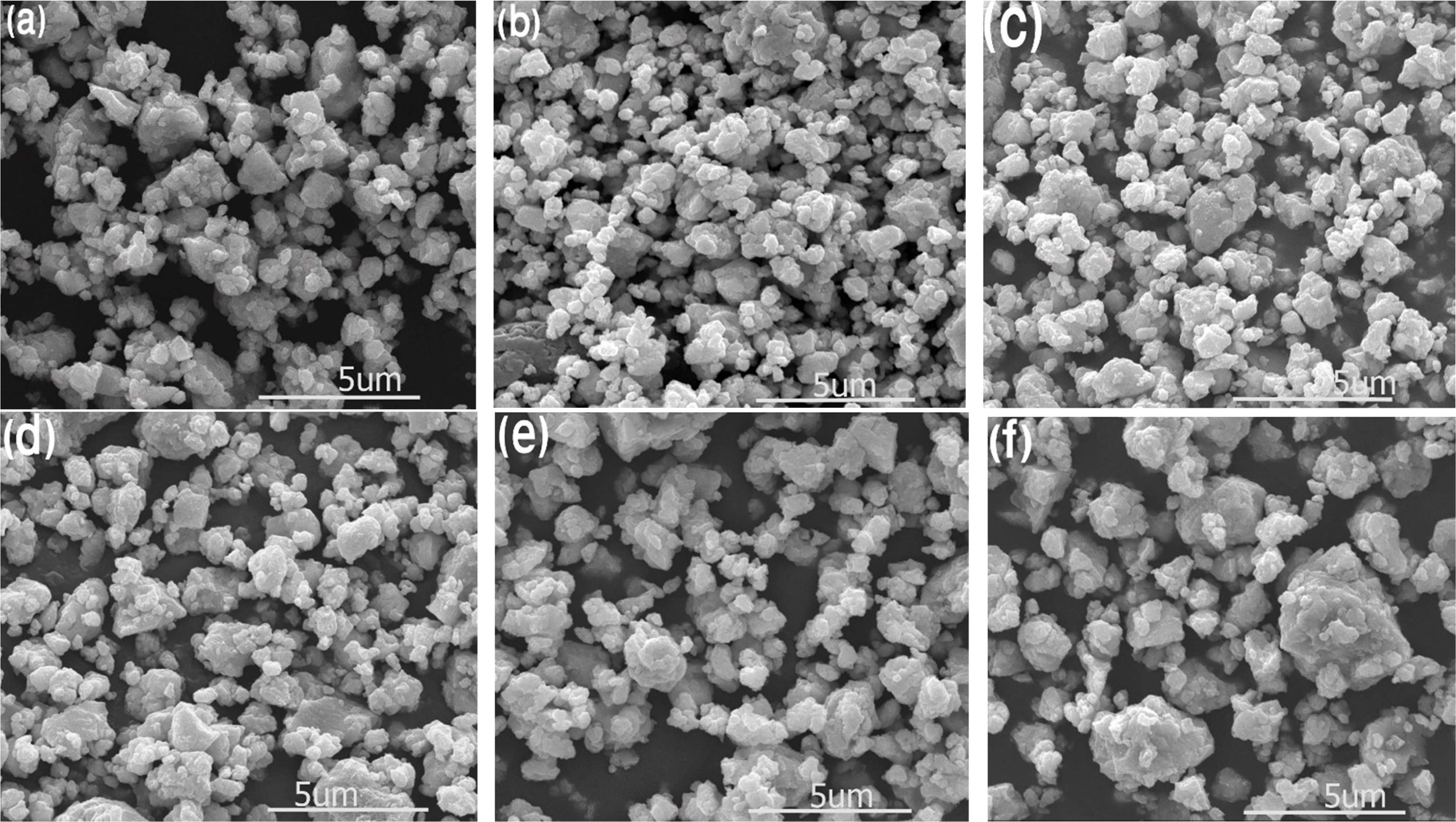

Generally, the particle size of a sample decreases when

doped with elements of a smaller ionic radius, which replaces the larger ions

from the specimen [28]. As-MAed powders are shown to be

near-spherical shape as in typical MA process and approximated particle

sizes are found to be less than 10 µm (Fig. 1). There is no considerable change

of particle morphology that might be due to the use of fractional

doping concentration.

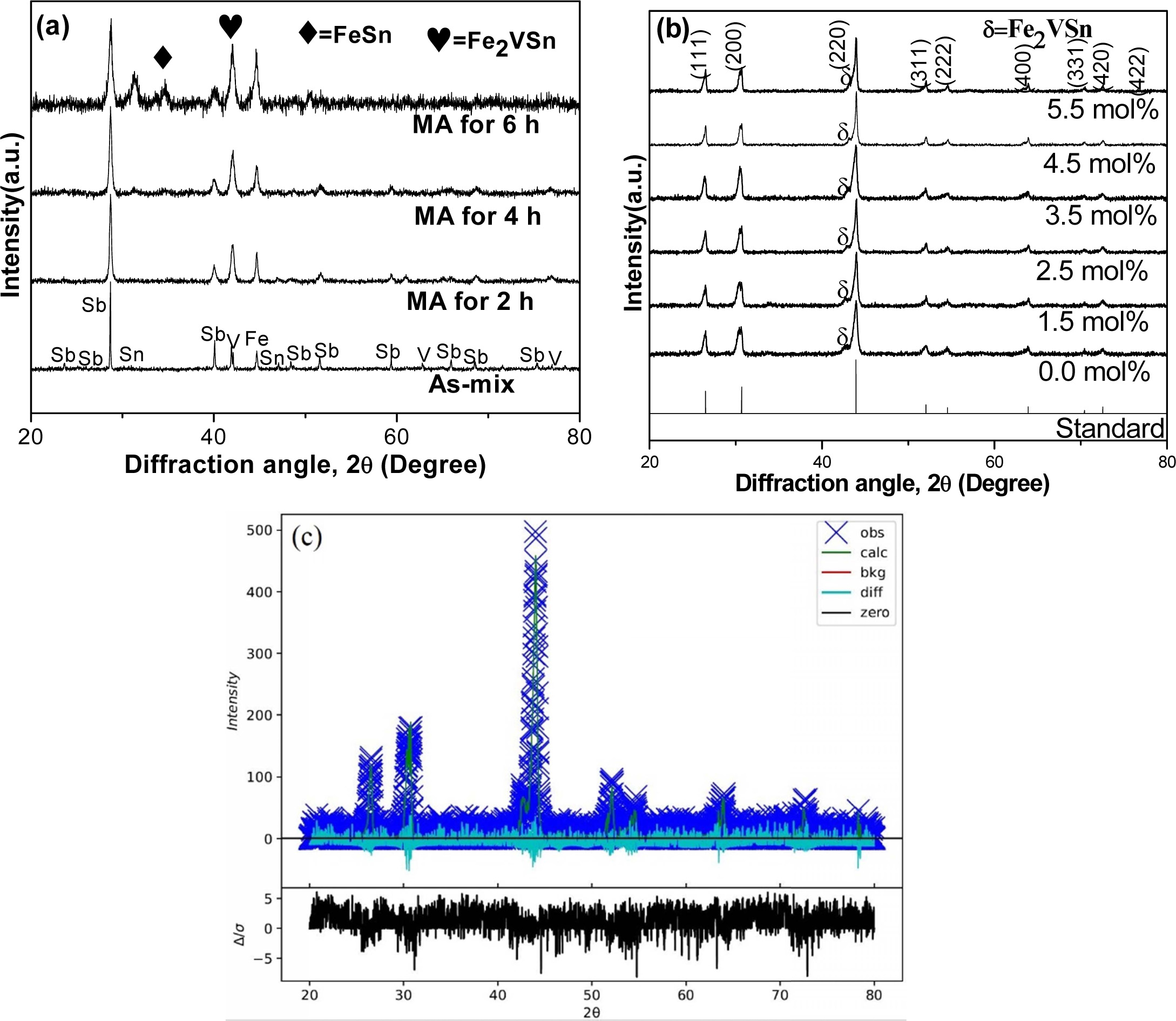

XRD patterns during milling are shown in Fig. 2(a) with

respect to time, and Fig. 2(b) shows the XRD curves of VHPed samples

synthesized by the MA process using zirconia vial. HH phases were coming out

after 4 h of milling and the remnant part of the HH phase developed during VHP

[29]. Two-second phases of FeSn and Fe2VSn were found in as-milled

powders. Among these second phases, FeSn disappeared; however,

Fe2VSn still remained after VHP. Near single HH phases

are dominating in VHPed samples though a fraction of the

second phase (Fe2VSn) remains, which is in agreement with our

previous study [4], (Fig. 2(b)). The Rietveld refinement of the bulk samples

(Fig. 2(c)) also confirms the presence of single-phase with F43m

symmetry.

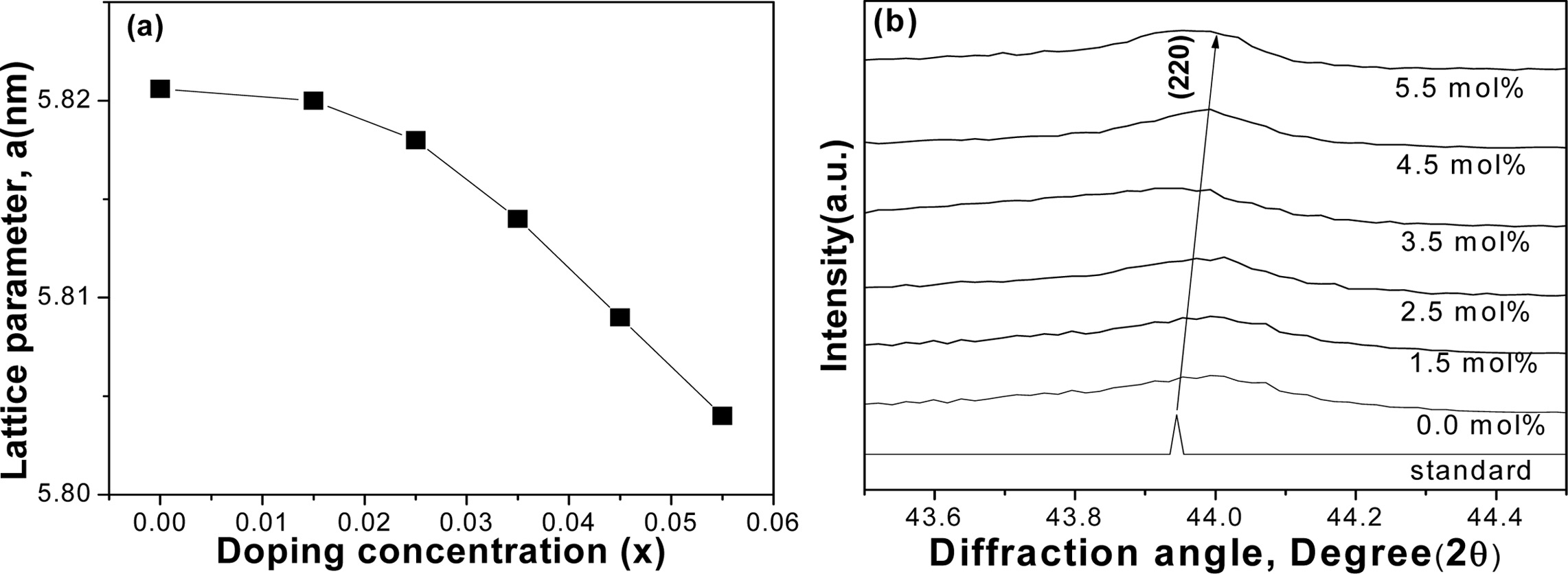

Lattice parameters of the various compositions are

depicted in Fig. 3(a). It is quite evident that the lattice parameters were

slightly decreased with the increase of Sn concentrations. Generally,

decreasing of lattice parameters could shift the diffraction peak (220) to the greater

angle [21]. The substitution of smaller Sn+4 (0.69 Å)

from the larger Sb+3 (0.76 Å) might be responsible for this effect,

as shown in Fig. 3(b). The second phase might have

played a role to decrease the lattice constant with the

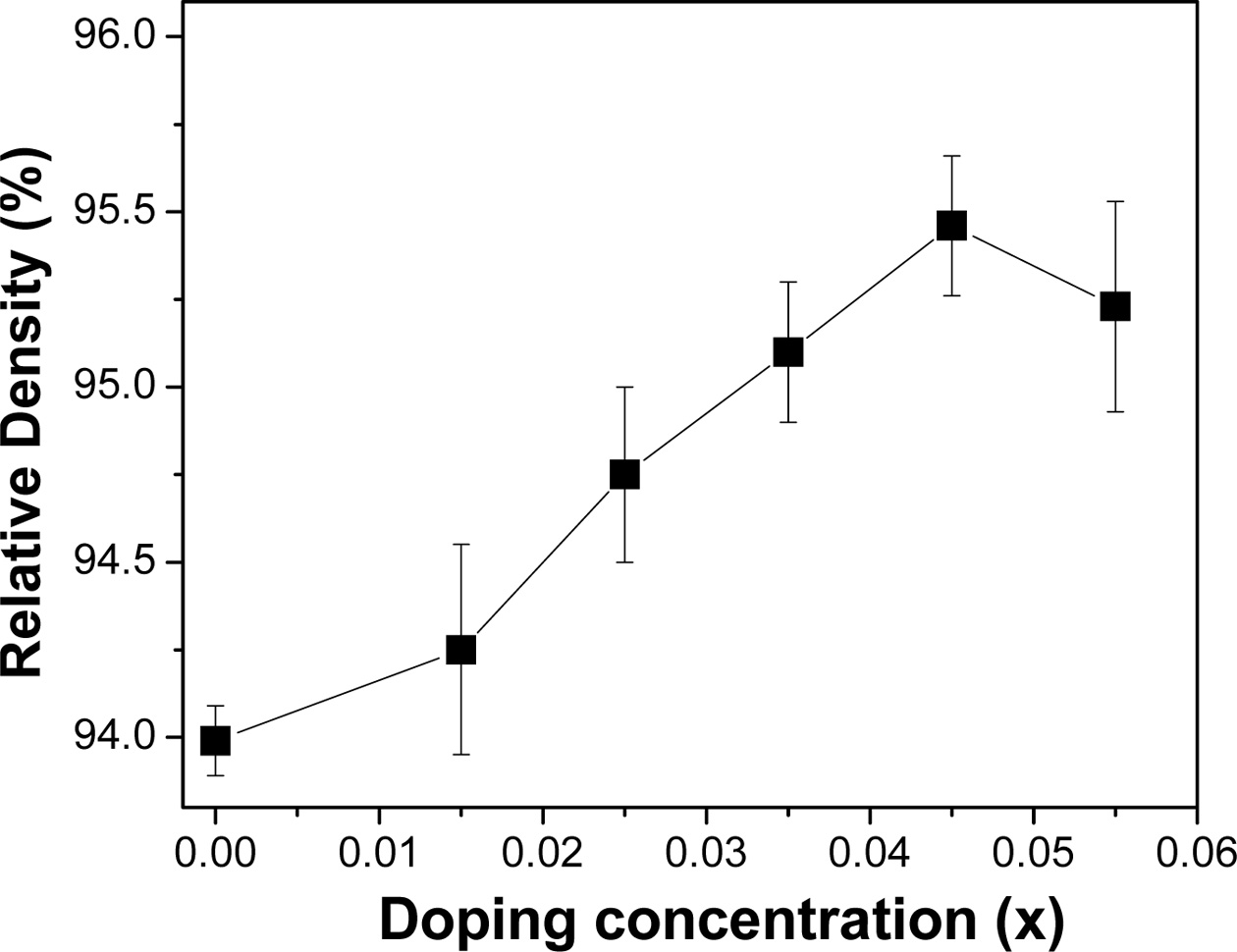

increase of Sn concentration [30]. The relative density is found to be quite

lower than our expectation (~95%, Fig. 5.). It might be due to the formation of

a small fraction of voids during hot-consolidation.

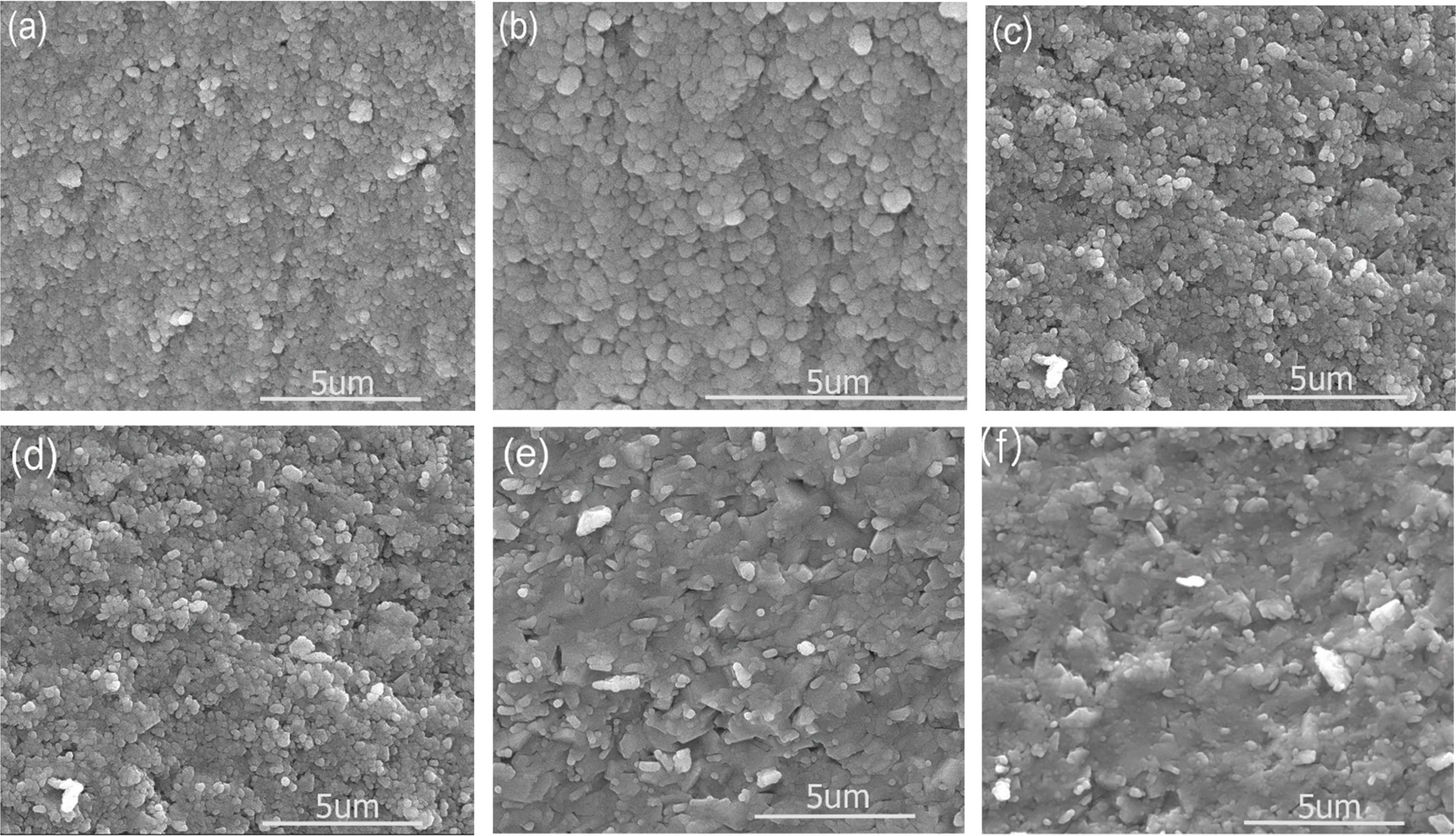

SEM images for VHPed samples are represented by Fig. 4.

Generally, the MA process gave rise to ultrafine microstructure [1]. In this

study, the average grain size could not be detected accurately from

the microstructures. However, the microstructures showed

that the approximate grain/particle size could be less than 10 µm, which

is a usual feature of MA and VHP [31]. From the SEM images, it

can be presumed to be prior particle boundaries or grain

boundaries present in the samples but we are not sure which one it is in this

set of experiments. Since the doping concentration used was very low, it didn’t

show any significant change in grain morphology as well.

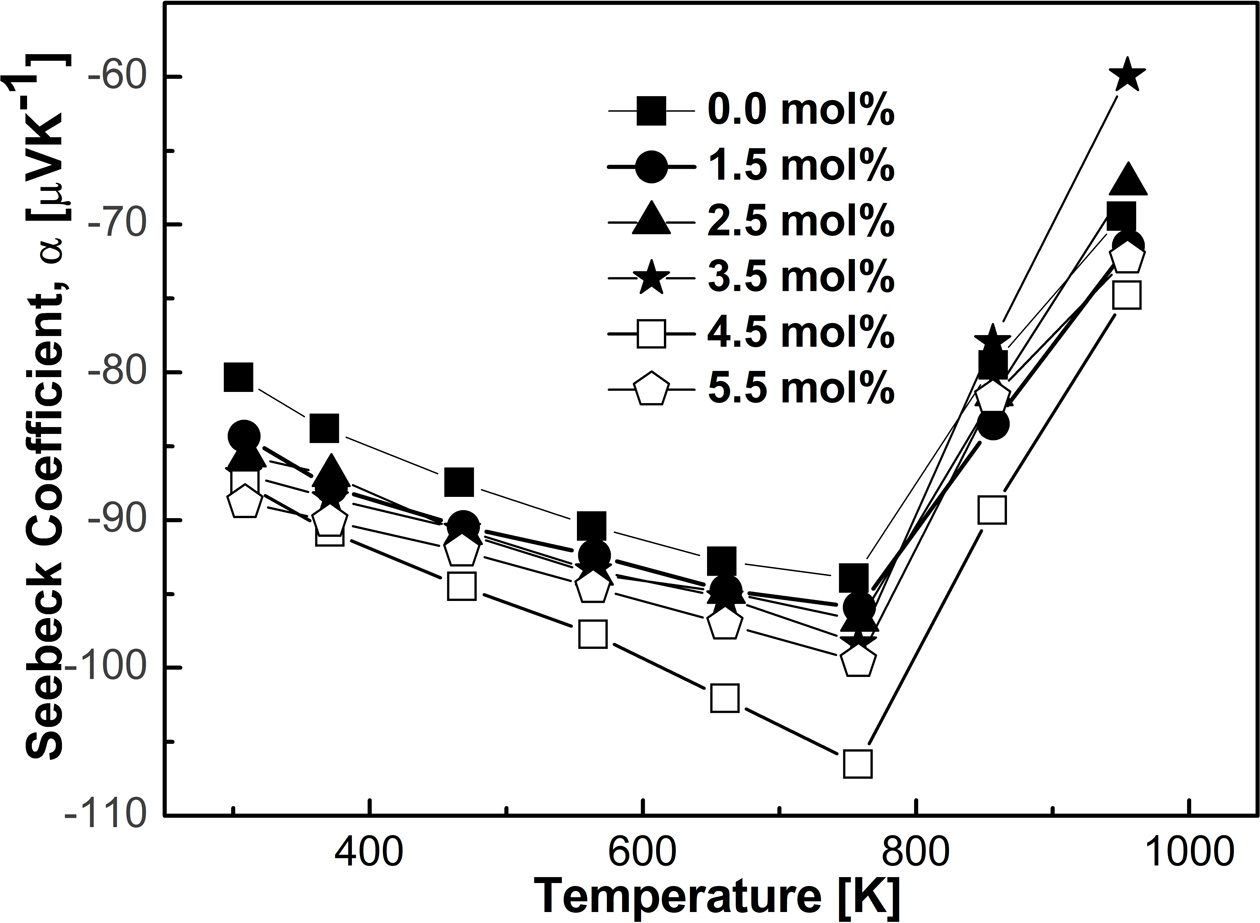

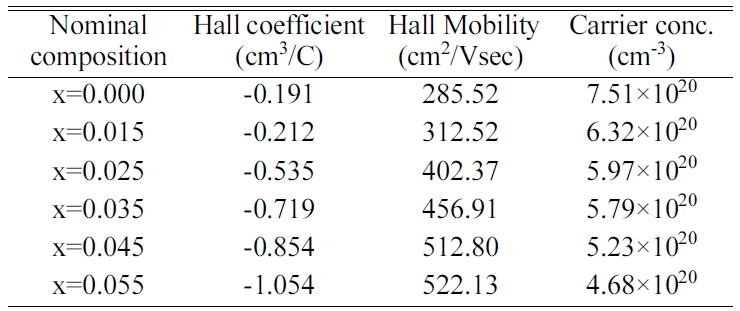

Fig. 6 illustrates the Seebeck coefficient of the VHPed

samples produced by the MA process using zirconia vial. The values of α

were detected negative in sign, which in turn reveal that the present charge carriers

were electrons. Notice that, the absolute value of α increases with

increasing doping concentration at 300 K in the MA process using zirconia vial.

The Hall measurement data from Table 1 also supports this increase in the

absolute value of α. Generally, α increases with the decrease of

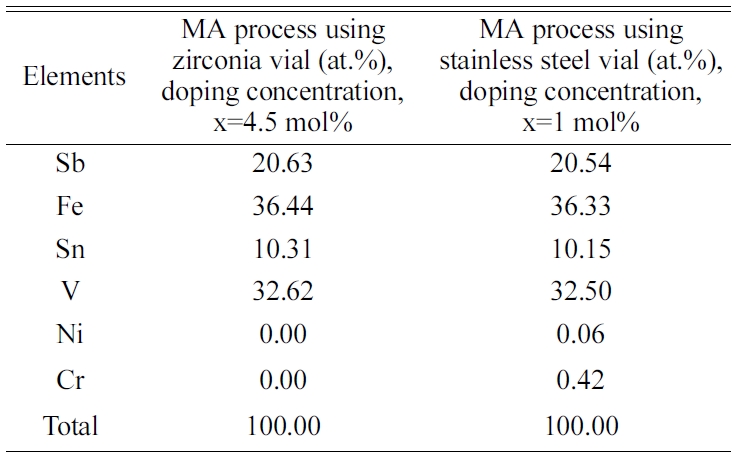

carrier concentration. On the contrary, the absolute value of α

decreased with increasing Sn contents during milling, possibly due to the

undesired incorporation of vial composition in the MA process using

stainless-steel vial [4], which was confirmed by EDS analysis. Shashanka and

Chaira et al. also reported such incorporation in their work [32]. There

was no evidence of incorporation of the foreign elements from vial found in

controlled MA process using zirconia vial in this study, which is shown in Table

2. Moreover, the absolute value of α was increased with

increasing T and with doping concentration in the controlled MA process

using zirconia vial possibly owing to the intrinsic excitation of the bands

[33, 34]. The highest absolute value of α was found to be 106 µVK-1

at 758 K, which was observed for 4.5 mol% in the MA process using zirconia vial

indicated well-controlled composition of HH phase.

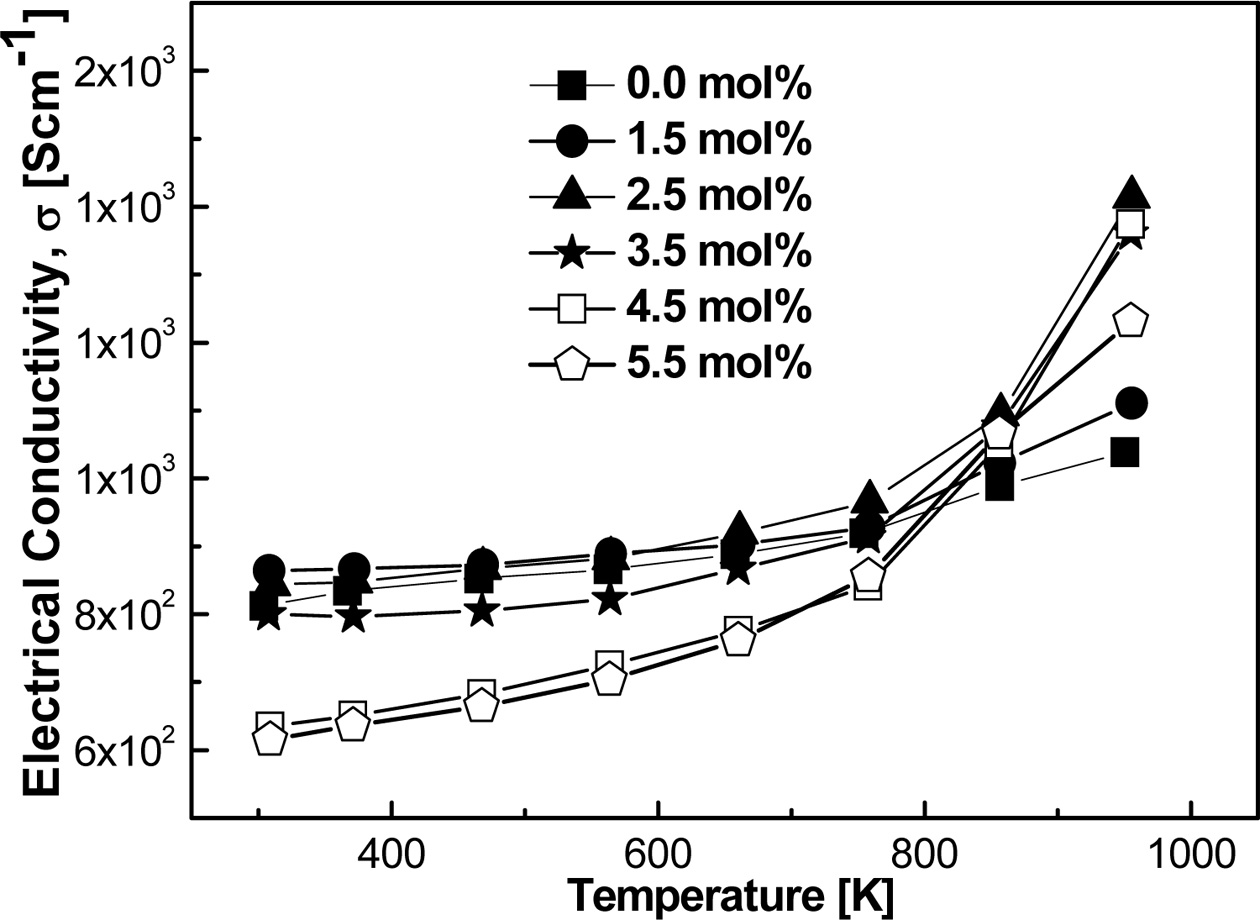

Fig. 7 showed the measured σ for controlled MA

process. The values of σ showed a similar trend to our previous work [4]

after adding dopants. σ was found to be decreased in the MA process

using both zirconia and stainless-steel vial with increasing Sn contents.

In both

cases, σ increased with increasing T, which indicated the inherent semi-metallic behavior.

This increasing trend of σ might have forced the Fermi band to the higher conduction band by the thermal

excitement of charge carriers within

the bandgap [35].

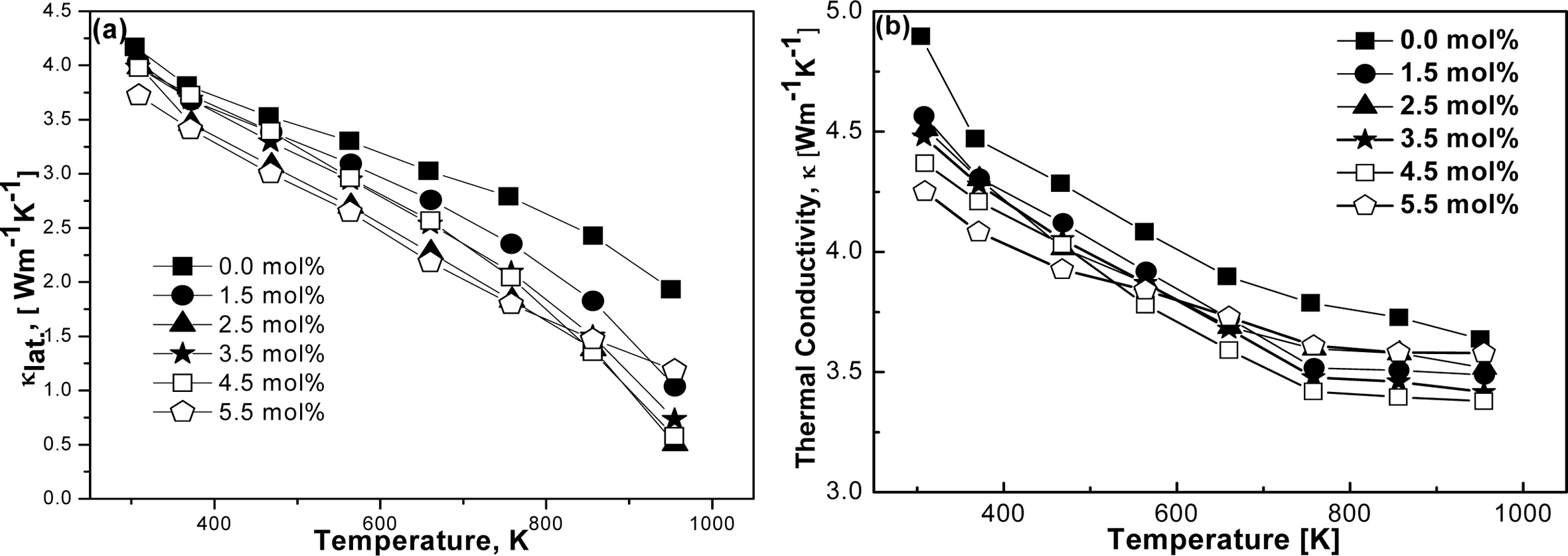

Fig. 8(a) and 8(b) represent κlat. and

κ with respect to time and doping elements.

Thermal energy is transferred by the thermalized electrons in the

conduction band and lattice vibration (phonon). The total thermal conductivity

of a material system can be expressed by the following equation, κ = κlat.

+ κel. Both κ and κlat.

of FeVSb1-xSnx were found to be decreased significantly with

increasing Sn contents. Possibly, enhanced phonon scattering

could play a major role in this decrease of κ and κlat.

[36]. Additionally, highly dense grain boundaries

might form because of the expected small grain size (~10 µm) [37].

Consequently, the scattering of phonon could take place at grain boundaries

which might produce a favorable path to the reduction of κlat..

A similar tendency was experienced for κ of all FeVSb1-xSnx

HH samples. There is a slight difference found between κ and κlat.

due to the very low value of κel. of FeVSb1-xSnx

HH alloys. Though κlat. is found considerably low; however,

it cannot be ignored for good TE devices. A portion of the second phase could

also be responsible for this decreasing value of κ [38]. The origin of

the cause in the differences of thermal conductivity

and lattice thermal conductivity might be the reduction

of the acoustic phonon bandwidth, consequently lowering the acoustic phonon

group velocities [39], which might decrease the lattice thermal conductivity.

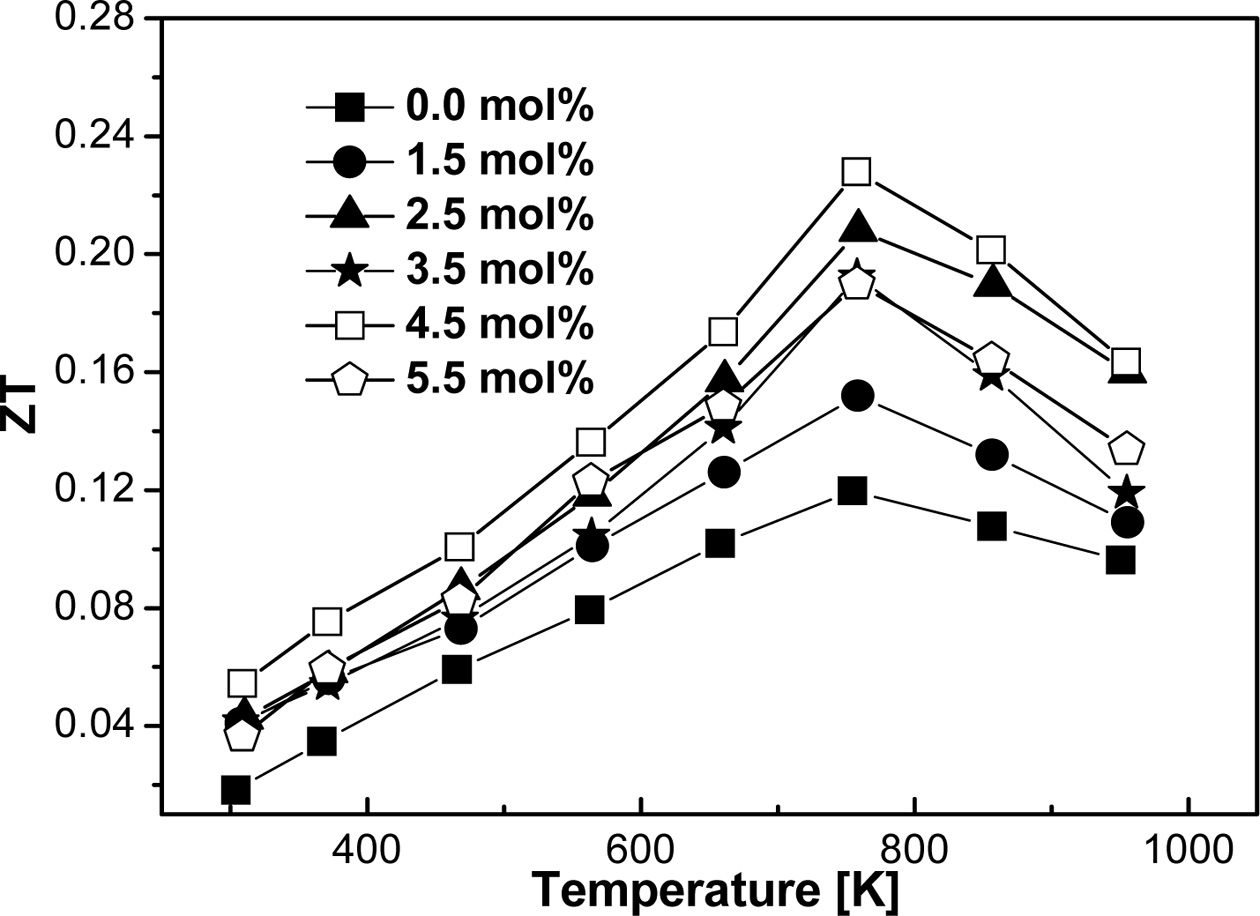

Fig. 9. indicates the ZT value calculated from α, σ,

and κ for the MA process using zirconia vial. Comparing the

MA process between zirconia vial and stainless-steel vial, the former produced

a much higher ZT compared to ref. [4], which is clearly seen from the figure.

Generally, a sample with high relative density possesses the maximum ZT and

that is evident for FeVSb0.955Sn0.045 at 757 K.

The corresponding ZTmax≈0.23 was

calculated because of relatively high α and low κ, which suggest

that ZT can be further improved by careful tuning of appropriate dopant. If κ

might have reduced further by applying multiple substitutions and/or small

grain formation, ZT could be enhanced to unity which is in good accordance with

Codrin et al. [25].

|

Fig. 1 Microstructures of powder specimens mill for 6 h; (a) 0 mol%, (b) 1.5 mol%, (c) 2.5 mol%, (d) 3.5 mol%, (e) 4.5 mol%, and (f) 5.5 mol%. |

|

Fig. 2 (a) XRD patterns for FeVSb0.945Sn0.055 during milling which represents other samples, (b) FeVSb1-xSnx (x=0.0~0.055) HH phases applying MA process using zirconia vial, and (c) representative Rietveld refinement of bulk sample x=4.5 mol%. |

|

Fig. 3 Crystal structure variations of VHPed samples; (a) lattice parameter, and (b) peak shifting to the greater diffraction angle. |

|

Fig. 4 Scanning electron microscope images of the various Sn-doped VHPed samples: (a) 0 mol%, (b) 1.5 mol%, (c) 2.5 mol%, (d) 3.5 mol%, (e) 4.5 mol%, and (f) 5.5 mol%. |

|

Fig. 5 The relative density of the bulk FeVSb1-xSnx HH systems against the doping concentration |

|

Fig. 6 The Seebeck coefficient of FeVSb1-xSnx HH systems as a function of T, processed by MA process using zirconia vial |

|

Fig. 7 Temperature dependence of σ values as a function of T for the MA process using zirconia vial |

|

Fig. 8 Calculated (a) κlat., (b) κ of the VHPed samples produced by MA process using zirconia vial. |

|

Fig. 9 Calculated ZT of VHPed FeVSb1-xSnx specimens for the MA process using zirconia vial. |

|

Table 1 Measured Hall data of the bulk FeVSb1-xSnx HH systems at room temperature synthesized by using zirconia vial. |

|

Table 2 EDS analysis of the VHPed samples synthesized by the MA process using zirconia and stainless-steel vial. |

FeVSb1-xSnx (x=0.015~0.055) HH

compositions were fabricated by the MA process using zirconia vial. A

subsequent VHP was required to consolidate the powders. After MA and VHP, all

the compositions produced near single HH phases. In this study, TE properties

of the MAed materials processed using zirconia vial and stainless-steel vial

were evaluated as a function of doping concentration and T and compared between

them. It was found that the incorporation of foreign elements from

stainless-steel vial reduced the absolute value of α and increased the κ

by negative doping effect. On the other hand, α was not being affected

by impurities in the MA process using zirconia vial, leading to a relatively

higher absolute value of α of 106 µVK-1 at 758 K for

the optimum composition. κ reduced comprehensively for the MA process

using zirconia vial, possibly due to enhanced phonon scattering

due to doped with Sn and second phase interaction. It was observed that

Sn-doping in FeVSb HH phases synthesized by the MA process using zirconia vial

reduced κ to its lowest value of 3.38 Wm-1K-1 from

intrinsic FeVSb (~8 Wm-1K-1).

A ZTmax of 0.23 was being calculated for FeVSb0.955Sn0.045

at 757 K using zirconia vial, which is a

much-improved value compared to the MA process using

stainless-steel vial [4]. The lower κlat. and relatively high

magnitude of α played the main part to reach this ZTmax.

Further improvements in TE efficiency it might be possible by the multi-doping

technique.

This research was supported by the Korea Basic Science

Institute grant funded by the Ministry of Education (grant no.

2019R1A6C1010047).

- 1. S.-C. Ur, H. Choo, D.B. Lee, and P. Nash, Metals and Materials. 6[5] (2000) 435-440.

-

- 2. M. Blair and T.L. Stevens, in “Steel Castings Handbook” (ASM International, Ohio, USA, 1995) p.71.

- 3. E.P. DeGarmo, J.T. Black and R.A. Kohser, in “Solution Manuals to Accompany-Materials and Process in Manu- facturing” (John Wiley and Sons Ltd, 2003) p.122.

- 4. R. Hasan and S.-C. Ur, J. of Trans. Electr. Electron. Mater. 19[2] (2018) 106-111.

-

- 5. D.M. Rowe, in “Thermoelectrics and Its Energy Harvest- ing” (CRC Press, 2012) p.80.

- 6. T.M. Tritt, Annu. Rev. Mater. Res. 41[1] (2011) 433-448.

-

- 7. M. Zebarjadi, K. Esfarjani, M.S. Dresselhaus, Z.F. Ren, and G. Chen, Energy Environ. Sci. 5[1] (2012) 5147-5162.

-

- 8. W.S. Liu, Q. Jie, H.S. Kim, Z.F. Ren, Acta Mater. 87 (2015) 357-376.

-

- 9. G.J. Snyder and E.S. Toberer, Nature Materials. 7[2] (2008) 105-114.

-

- 10. S.A. Barczak, J. Buckman, R.I. Smith, A.R. Baker, E. Don, I. Forbes, and J.W.G. Bos, Materials. 11[4] (2018) 536.

-

- 11. L. Chen, S. Gao, X. Zeng, A.M. Dehkordi, T.M. Tritt, and S.J. Poon, Appl. Phys. Lett. 107[4] (2015) 041902.

-

- 12. M. Gurth, G. Rogl, V.V. Romaka, A. Grytsiv, E. Bauer, and P. Rogl, Acta Mater. 104 (2016) 210-222.

-

- 13. X.A. Yan, G. Joshi, W.S. Liu, Y.C. Lan, H. Wang, S. Lee, J.W. Simonson, S.J. Poon, T.M. Tritt, G. Chen, and Z.F. Ren, Nano Lett. 11[2] (2011) 556-560.

-

- 14. E. Rausch, B. Balke, T. Deschauer, S. Ouardi, and C. Felser, APL Mater. 3[4] (2015) 105.

-

- 15. C.G. Fu, S.Q. Bai, Y.T. Liu, Y.S. Tang, L.D. Chen, X.B. Zhao, and T.J. Zhu, Nature Communications. 6[1] (2015) 6888.

-

- 16. D.A. Ferluccio, R.I. Smith, J. Buckman, and J.W.G. Bos, Phys. Chem. Chem. Phys. 20[6] (2018) 3979-3987.

-

- 17. T.J. Zhu, C.G. Fu, H.H. Xie, Y.T. Liu, and X.B. Zhao, Adv. Energy Mater. 5[19] (2015) 1500588.

-

- 18. A. Yamamoto and T. Takeuchi, J. of Elec. Materi. 46[5] (2017) 3200-3206.

-

- 19. H. Hohl, A.P. Ramirez, C. Goldmann, G. Ernst, B. Wolfing, and E. Bucher, J. Phys.: Condens. Matter. 11[7] (1999) 1697-1709.

-

- 20. L.D. Zhao, S.H. Lo, Y.S. Zhang, H. Sun, G.J. Tan, C. Uher, C. Wolverton, V.P. Dravid, and M.G. Kanatzidis, Nature. 508[7496] (2014) 373-377.

-

- 21. M. Zou, J.F. Li, and T. Kita, J. of Sol. Stat. Chem. 198 (2013) 125-130.

-

- 22. Y. Stadnyk, A. Horyn, V. Sechovsky, L. Romaka, Y. Mudryk, J. Tobola, T. Stopa, S. Kaprzyk, and A. Kolomiets, J. Alloys Compd. 402 (2005) 30-35.

-

- 23. H. Zhu, R. He, J. Mao, Q. Zhu, C. Li, J. Sun, W. Ren, Y. Wang, Z. Liu, Z. Tang, A. Sotnikov, Z. Wang, D. Broido, D.J. Singh, G. Chen, K. Nielsch, and Z. Ren, Nature Communications. 9[1] (2018) 2497.

-

- 24. K. Biswas, J. He, I. D. Blum, C.-I. Wu, T.P. Hogan, D.N. Seidman, V.P. Dravid, and M.G. Kanatzidid, Nature 489[7416] (2012) 414-418.

-

- 25. J. Li, Z. Chen, X. Zhang, Y. Sun, J. Yang, and Y. Pei, NPG Asia Mater. 9[3] (2017) e353.

-

- 26. G. Rogl, A. Grytsiv, R. Anbalagan, J. Bursik, M. Kerber, E. Schaflur, M. Zehetbauer, E. Bauer, and P. Rogl, Acta Mater. 159 (2018) 352-363.

-

- 27. R. Venkatasubramanian, E. Siiviola, T. Colpitts, and B. O’Quinn, Nature. 413[6856] (2001) 597-602.

-

- 28. I.-H. Kim, J.-C. Kweon, Y.-G. Lee, M.-S. Yoon, S.-L. Ryu, W.-G. Kim, and S.-C. Ur, Mater. Sci. Forum. 658 (2010) 33-36.

-

- 29. E. Yuasa, T. Morooka, M. Tsunoda, and J. Mishima, J. of the Japan Soc. of Powd. and Powd. Metall. 42[2] (1995) 171-174.

-

- 30. K.D. Codrin, T. Yamada, A. Yamamoto, R. Sobota, M. Matsunami, and T. Takeuchi, Jpn. J. Appl. Phys. 56[11] (2017) 111202.

-

- 31. P. Jozwik and Z. Bojar, Archives of Metallurgy and Materials. 52[2] (2007) 321-327.

- 32. R. Shashanka and D. Chaira, in “Ball Milled Nano-Structured Stainless-Steel Powders-Fabrication and Characterization” (Educreation Publishing, 2011) p.8.

- 33. H.J. Goldsmid, in "Electronic refrigeration" (Pion, 1986).

- 34. T. Xing, R. Liu, F..Hao, P. Qiu, D. Ren, X. Shi, and L. Chen, J. Mater. Chem. C, 5[47] (2017) 12619-12628.

-

- 35. D.P. Young, P. Khalifah, R.J. Cava, and A.P. Ramirez, J. of Appl. Phys. 87[1] (2000) 317-321.

-

- 36. J.J. Gong, A.J. Hong, J. Shuai, L. Li, Z.B. Yan, Z.F. Ren, and J.-M. Liu, Phys. Chem. Chem. Phys. 18[24] (2016) 16566-16574.

-

- 37. R. Hasan and S. C. Ur, Elect. Mater. Lett. 14[6] (2018) 725-732.

-

- 38. J. Cui, G. Cai, and W. Ren, RSC Adv. 8[38] (2018) 21637-21643.

-

- 39. H. Euchner, S. Pailhès, V. M. Giordano, and M. de Boissieu, Phys. Rev. B. 97[1] (2018) 014304.

-

This Article

This Article

-

2020; 21(3): 319-325

Published on Jun 30, 2020

- 10.36410/jcpr.2020.21.3.319

- Received on Nov 7, 2019

- Revised on Mar 6, 2020

- Accepted on Mar 9, 2020

Services

Services

- Abstract

introduction

experimental procedure

results and discussion

conclusions

- Acknowledgements

- References

- Full Text PDF

Shared

Correspondence to

Correspondence to

- Soon-Chul Ur

-

Department of Materials Science and Engineering / ReSEM, Korea National University of Transportation (KNUT), Chungju, Chungbuk 27469, Republic of Korea

Tel : +82-43-841-5385 - E-mail: scur@ut.ac.kr

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.