- A novel method: mixed matrix membrane – An overview

R Umapriyaa,*, J Rohanb, S Manisha Vidyavathyc, Thenmuhild and G Arthanareeswarane

aDepartment of Chemical Engineering, Erode Sengunthar Engineering College, Perundurai, Tamilnadu 638407, India

bDepartment of Chemical Engineering, Adhiyamaan Engineering College, Hosur, Tamilnadu 635109, India

cDepartment of Ceramic Technology, Alagappa College of Technology, Anna University, Chennai, Tamilnadu 600025, India

dDepartment of Ceramic Technology, Alagappa College of Technology, Anna University, Chennai, Tamilnadu 600025, India

eDepartment of Chemical Technology, National Institute of Technology, Trichirapalli, Tamilnadu 620015, India

The development of India into

a modern country is slow but the population growth is rapid. Pure air, water

and soil are the three important things for a day to day life in the current

scenario. Pure form of these three is must. Nowadays many water resources,

soils and air in the environment are polluted due to massive increase in

population growth, industrialization and modern Urbanization. The heavy metals,

dyes, pesticides etc., are mainly polluting the water bodies. In current

scenario the world is in the need of treating water bodies, wastewater and sea

water to reduce the water scarcity level. All wastewater and water treatment

processes possess at least one separation process in the treatment units.

Membrane separation process is playing a main role in the treatment process. In

this study, the different types of conventional and advanced treatment

processes were discussed. Membrane treatment techniques, Types of membranes,

materials which can be used for membrane preparation, advantages and

disadvantages of each materials, performance of organic membrane (polymeric

membrane), performance of inorganic membrane (ceramic membrane) and membrane

fabrication methods were also discussed in this study. To overcome the

drawbacks, the new innovative idea was derived and discussed.

Keywords: Polymeric membrane, Inorganic membrane, Mixed matrix membrane

General

Population growth rate of the world was reported as a 75

million annually [1]. The world population was reported as 3.4 billion in 2009

and it was grown by 30% approximately between the year 1990 and 2010 according

to the UN population statistics. If this situation continues,

there is the possibility of having the population as 6.3

billion in 2050 [1]. In this, India’s growth rate was reported as 350 million.

Parallel to this population growth, the world is moving with

rapid industrialization and

urbanization too. Apart from the basic requirements (Food, Cloth

and Shelter), pure air, water and soil are also added in the basic requirements

due to this rapid growth of world. In most of the cases the air and water

purification are considered as a major problem. The need of deriving pure fresh

water from different water sources and domestic and industrial

effluent is increased due to this growth. This paper

discusses the new innovative membrane process for treating the water and

suggests new material and method for the membrane preparation.

Water and wastewater Treatment

Due to the water scarcity and pollution, the water and

wastewater should be treated and reused. The treatment generally consists of

the following conventional treatment methods [2].

1. Primary Treatment (Mixing,

Equalization, Screening and Clarification)

2. Secondary Treatment (Sedimentation or

Clarifloc- culation,

Filtration and Advanced treatment methods like

adsorption, Ion exchange, and membrane filtration).

3. Tertiary treatment (Nitrogen and

phosphorous removal treatment methods and disinfection, etc.)

Initially the wastewater is mixed and equalized to get a

homogeneous solution. The water from the equalizer is fed to the screen chamber

for removing large size materials and followed by oil trap for removing oil,

fat and grease. This water is then subjected to sedimentation

tank or flash mixing chamber based on the intensity of the solids.

Coagulants (such as lime, alum, polyelectrolyte, etc.) are

added with the water in the flash mixing tank. Then it is processed through

Clariflocculator to create high densed flocs. This floc contained

water is sent to a settling tank for the settlement of the impurities

(suspended matters) present [2].

Most of the processes in chemical industry involve at

least one separation or purification to remove foreign matters or to recover

the water [3]. The separation process is generally divided into as

equilibrium governed process and rate governed process.

Equilibrium governed process includes distillation, absorption,

Adsorption, drying etc., Most of the membrane-based processes are rate governed

process. It includes Osmosis, Reverse Osmosis, Dialysis, etc., These

processes are carried over by the

gradient of chemical potential (i.e., concentration gradient,

pressure gradient, temperature gradient and electrochemical potential gradient)

[3]. In this paper particularly membrane filtration was discussed.

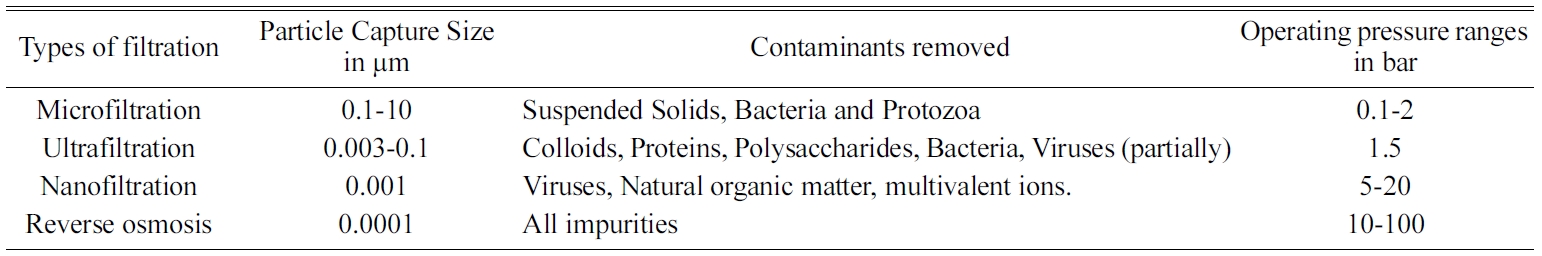

Table 1

Initially the membrane separation process was started in

laboratory scale. Later it started growing to the industrial pilot plant level

with proper technical and commercial requirements. The reasons to choose for

membrane technology are: fast process with short residence time, less component

specific [4]. The basic principle of Membrane processes are

the mechanisms of impaction, diffusion, electrostatic interaction, hydrophobic

property, and adsorption [5]. The transport selectivity of the

membrane, high efficiency, Low capital cost and operating cost, ease of

operation and lower energy requirements and low time for the

completion of processes are also the

main advantages of the membrane separation processes.

The gas separation and liquid separation by membranes is a growing field in the

current scenario [4, 5].

The wide research spectrum subjects to modulation and

improvement in search of better prototypes development.

Types

of membrane filtration

The main part or heart of the membrane process is nothing

but the membrane itself. To get the best efficiency in the removal, the

identification of the new membrane materials that can be with the expected requirements

is strongly growing in the current research field.

Generally, the criteria for selecting materials for membrane separation are too

difficult. Based on the purpose of utilization, the materials and pore size of

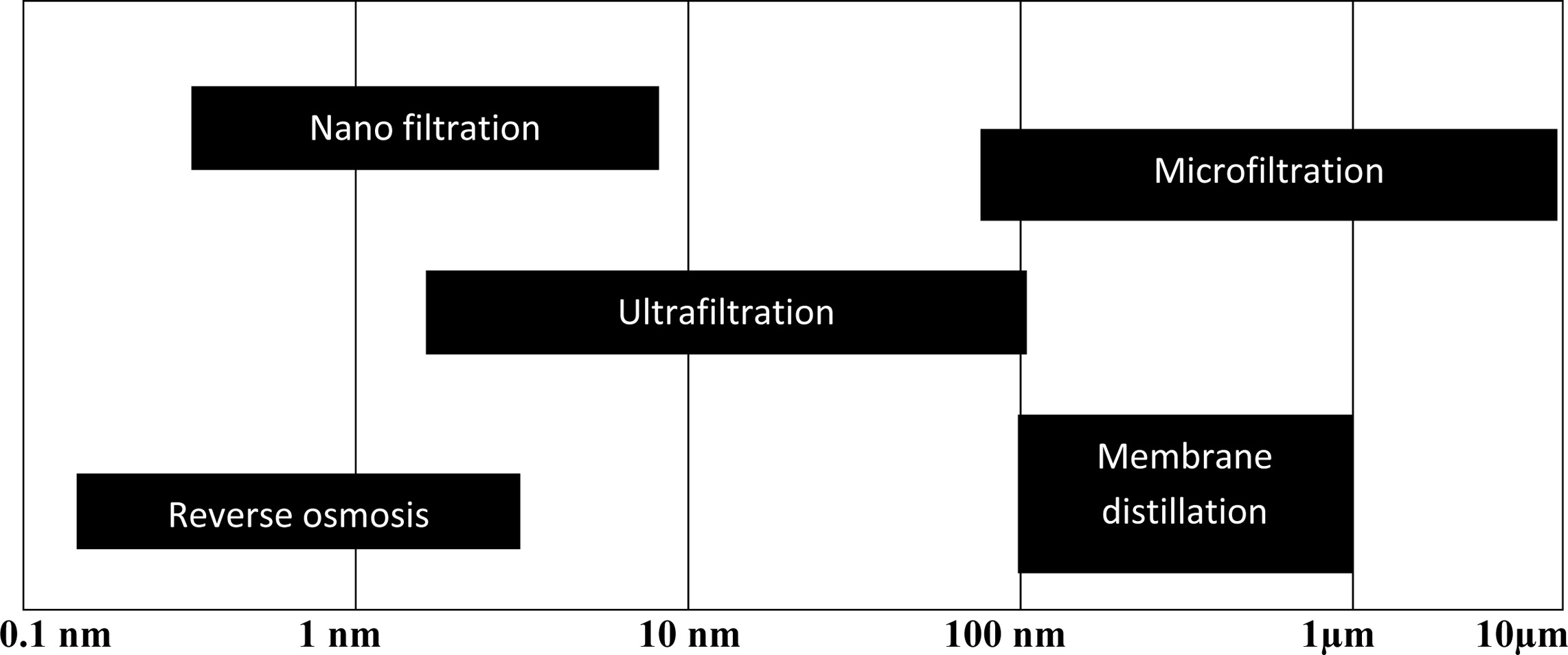

the membranes will be selected. Fig. 1 represents the average

pore size requirement for membranes for different water treatment processes

[6].

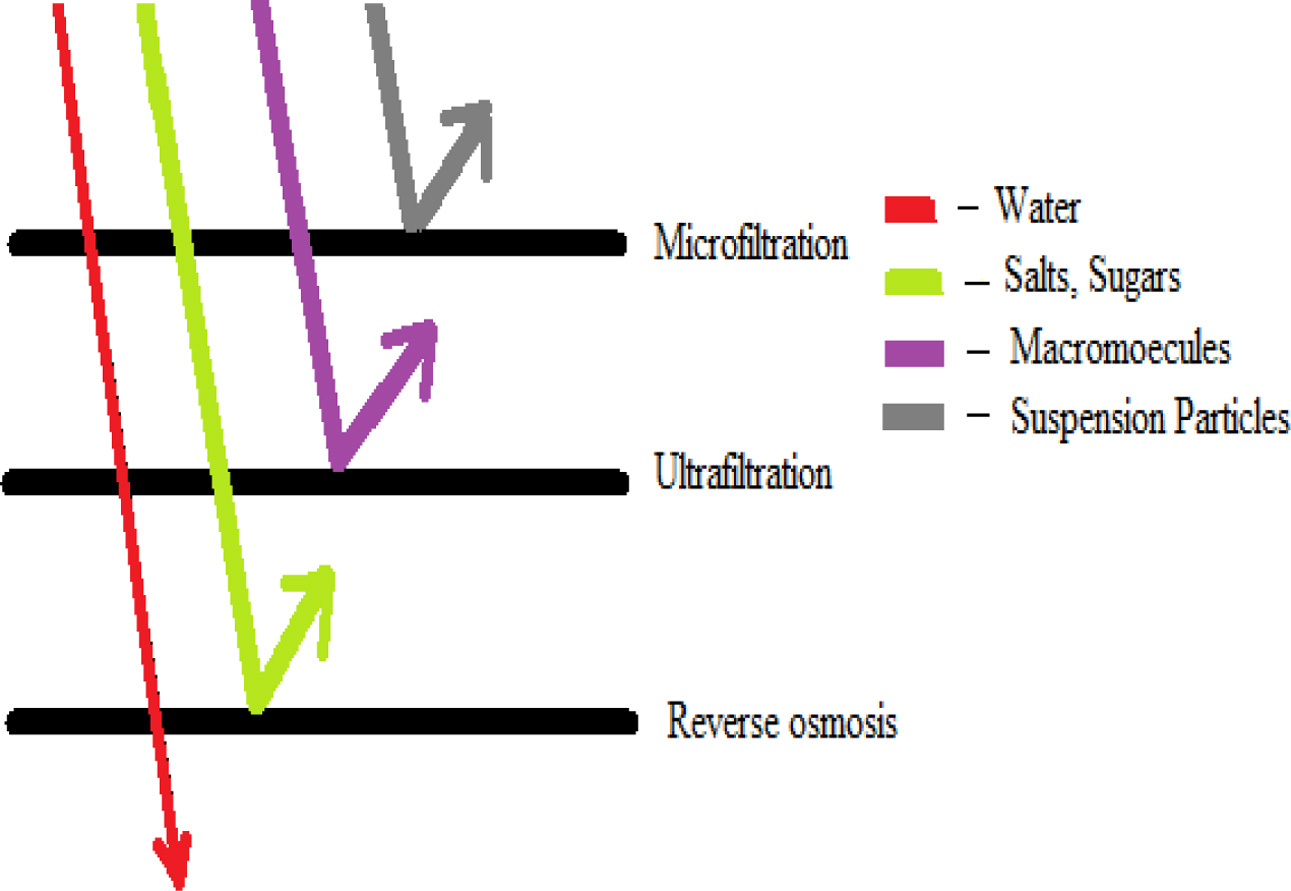

There are four main types of membrane system commonly used

in industry [7] based on pore size: (a) Microfiltration (MF) is

widely applied in particulate removal process and maintains degreasing. (b) Ultra filtration (UF) is generally

used for oil, water and emulsion separations; paint recovery; and the separation of

fats, oils or greases in the food industry. (c)

Reverse osmosis (RO) and (d) nanofiltration (NF) are used extensively for water

purification and desalination. Membrane Distillation is one of the developing

techniques to treat saline water [8, 9]. Fig. 2 shows the

differences of membrane system.

Materials

of membrane

Two types of materials are used generally in the membrane

preparation. First one is organic membrane (polymeric membrane) and the other

one is inorganic membrane (ceramic membrane). Membranes are made from different

materials based on the application. They are manufactured in different forms to

produce optimal hydrodynamic conditions for separation. Complete

systems comprise arrangements of modules and control systems

needed to integrate them into the various process configurations.

Polymeric membranes

Polymeric membranes are drawn the attention for its use in

many applications such as wastewater treatment, food

industries, etc., Due to its pore forming mechanism in a

straightforward manner, higher flexibility, low installation

cost and low manufacturing cost, the polymeric membrane

turned the attention. Some important criteria (good filtration flux, low energy

consumption) are considered in a selection of membrane to get a high quality

[10]. Though, polymeric membrane has many advantages, it has some challenges

such as relationship between selectivity and permeability and its resistance

for the membrane fouling [10].

Polymeric membranes are very competitive in both

performance and cost wise. The polymers must exhibit appropriate properties for

specific applications. They offer low binding affinity in case of biotechnology

applications. They show good fabrication properties for that fabricating

process. The polymeric materials used for making into membrane are

cellulose acetate, cellulose nitrate, polyamide, polysulfone,

polycarbonate, poly (ether sulfone), polyimide, poly (vinylidene fluoride),

polyacrylonitrile (PAN), polyphenols, polytetrafluoro- ethylene, etc., These

membranes have many applications such as effluent filtration,

dialysis, pervaporation, gas separation, etc., [11].

Advantages of polymeric membranes:

• They have excellent heat resistance and

chemical compatibility [12],

• They have good mechanical properties and high modifying

abilities [73-78]. Disadvantages of polymeric membranes

• It suffers from biofouling, mineral

scaling, abrasion, metal oxide fouling,

• It has low stability and low rejection [6, 13].

- They have low surface hydrophilicity, low

porosity and low permeability [73].

Ceramic membranes

Ceramic membranes are used in water treatment, fermentation

industries, food industries, dairy industries, paper

industries and petrochemical industries. The out promising

advantages of ceramic membranes are extended lifetime,

constant quality, excellent separation ability, reduced energy requirements,

high permselectivities. The disadvantages of ceramic membranes are higher

density, higher production cost, lower surface area per unit volume,

complicated synthesis process [16].

The materials used for the preparation of ceramic

membranes are alumina, zirconia, silica and titania [24]. Ceramic membranes

consist of three layers.

Inner porous support layer-provides good mechanical

strength. Intermediate layer-coated upon support layer and has lower pore size.

Top layer-separation takes place Based on structure. Ceramic membranes can be

classified as porous and dense membranes. The porous membranes may

be symmetric or asymmetric. Asymmetric configuration gives high

permeability property [23]. Ceramic membranes are prepared in various geometric

configurations – plate and frame, tubular, capillary, hollow fibre [19].

Advantages of ceramic membranes [14]

1) They possess extremely high chemical, thermal,

mechanical and physical stability.

2)

Long working life.

3)

Good separation characteristics.

4)

Ecologically friendly

5)

No additives are required

6)

No phase transformation

7)

Running costs can is less

8)

They have high abrasion resistance.

Disadvantages

of ceramic membrane [14]

1)

Production cost is little high.

2)

Low membrane surface area.

3)

High density when compared with polymers.

4)

Fabrication process is complicated

Mixed matrix membranes

To overcome the drawbacks of polymeric membranes,

the novel technique with high stability and high ions rejection was developed.

Mixed Matrix Membranes (MMM) consist of organic and

inorganic particle phases. In this

continuous phase is polymeric phase and dispersed phase is

inorganic particles.

Mixed matrix membranes have

higher selectivity, permeability. MMMs improve the mechanical [51], thermal

[52], magnetic [53], and electrostatic [54]. So generally, to improve

hydrophilicity in the polymeric membrane surface modification, hydrophilic

polymer coatings, grafting, composite structure formations can be done. In the

recent days the MMM is widely used in the gas separation process, textile

effluent treatment, oil removal, desalination, etc..

|

Fig. 1 Average pore size of the membranes used in different membrane process. |

|

Fig. 2 Use of membrane systems to separate of different sized molecules |

Polymeric

membrane

The selection of method for the fabrication of membrane is

highly dependent on the type of polymer and the geometry of the membrane to be

designed. The methods commonly used for fabrication are [6]

• Phase inversion

• Interfacial polymerisation

• Stretching

• Track – etching

• Electrospinning

Phase inversion

This process is also known as de-mixing process. Here,

the homogeneous polymer solution is transformed from liquid

state into solid state in a controlled manner [13]. This transformation

involves five ways [55]:

a) Immersion precipitation

b) Thermally induced phase separation

c) Evaporation induced phase separation

d) Vapour induced phase separation

Among these immersion precipitation and thermally induced

phase separation methods are the most commonly used methods [11, [56].

Interfacial polymerization

It is a common method for the fabrication of thin-film

composite (TFC) membranes for nano-filtration and reverse osmosis. The first

interfacially polymerised thin-film composite membrane was developed by Cadotte

et al. [57] and they are used for many RO and NF applications [58].

Stretching

This method is suitable to produce microporous membranes

which are commonly used in applications such as microfiltration,

ultrafiltration, etc., This process is first developed in 1970s. This process

does not use any solvent. The polymer is heated above its melting point and

extruded into thin films. Then it is stretched to make it porous [59-61].

Track-Etching

Here, irradiation of a nonporous polymeric membrane

using energetic heavy ions. This leads to the formation of damaged tracks

linearly in the irradiated polymeric film. This technique is more

advantageous for its control on the pore size distribution [62].

Electrospinning

It is a new technique where a drop of polymer is made into

a liquid jet by applying a high potential between the droplet and the ground

collector. The droplet gets converted into liquid jet when the potential

becomes greater than the surface tension of the droplet [63-65].

Ceramic

membrane

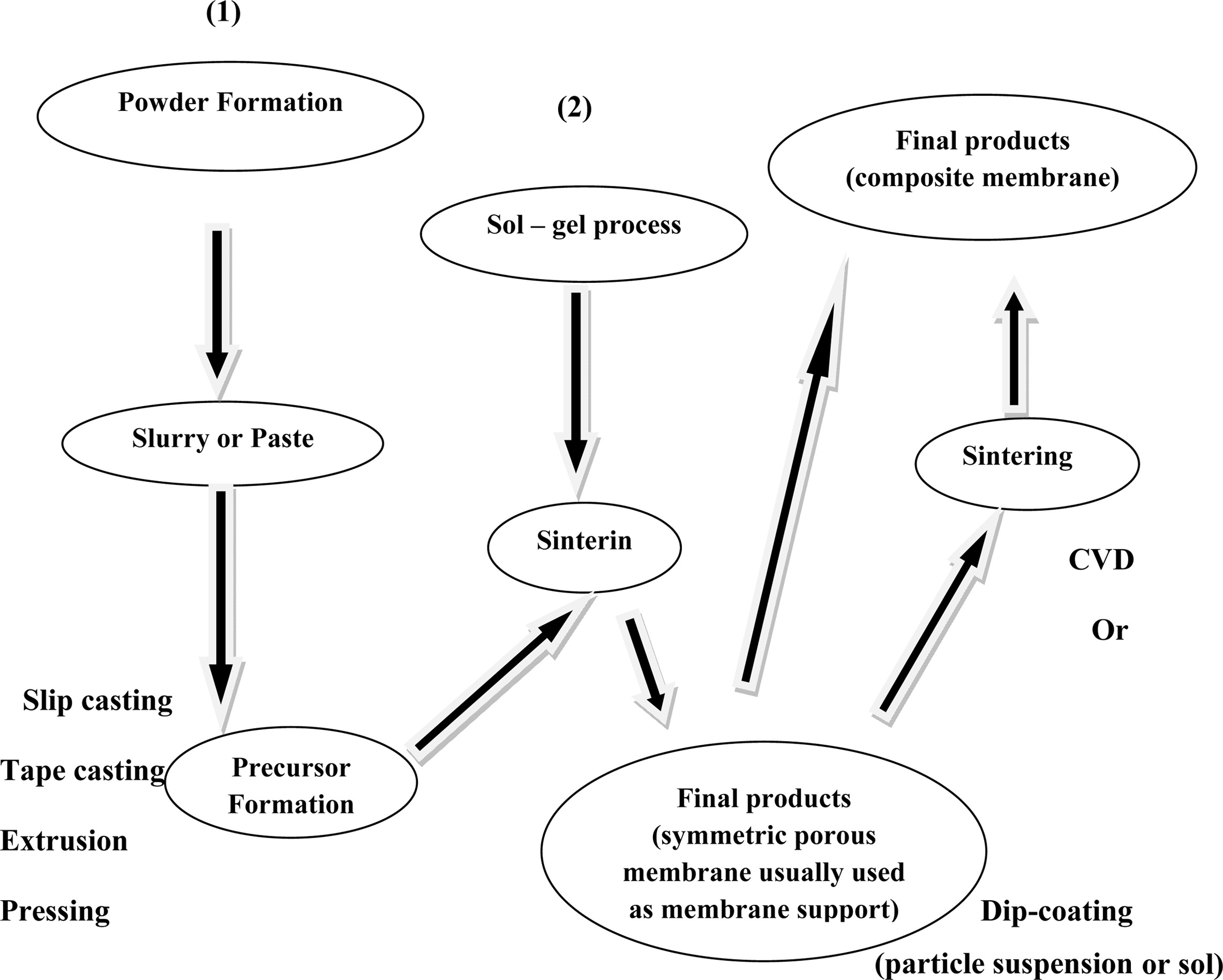

The steps involved in the synthesis of ceramic membranes

are, suspension preparation, forming and heat treatment.

There are various methods available for ceramic membrane

synthesis. They are slip casting, sol gel, dip coating, extrusion, pressing,

anodic oxidation, solid state process, pressing, tape casting and freeze

casting [16]. The required membrane structures and the application

are the major considerations for the selection of appropriate membrane

preparation method.

Slip casting method

The most common method for ceramic membrane fabrication is

the slip casting method. Fig. 3 shows the schematic diagram of slip casting

method. The major disadvantages of this method are that the control of wall

thickness is difficult, and it requires long time. The mold is filled with

powder suspension and the diffusion of solvent into pore takes place. Hence gel

formation occurs by precipitation followed by rapid condensation to prevent the

penetration of particles into pores [17, 18]. Some of the membranes prepared by

this method are alumina [19], zirconia [20], and perovskite [21], BaCo0.7Fe0.2Nb0.1O3-δ

[22].

Sol gel

Sol gel is an important method for synthesis of ceramic

membranes. This method gives a good control over the pore size and pore size

distribution. They are of two categories – colloidal route and polymer route

[16].

In colloidal route, the hydrolysis of dissolved metal

alkoxide in alcohol is done by addition of acid or water.

Maintaining the precipitate formed as a hot solution for long

time results in stable colloidal solutions. It is then cooled and coated on the

support surface followed by sintering process [23, 24]. His route is

mainly used for the synthesis of silica [25, 26] and alumina membranes [27].

In the polymeric route, partial hydrolysis of metal

alkoxides dissolved in alcohol is done by addition of excess of water to for

inorganic polymer. The polymer formed is coated on the surface, dried and

sintered [28]. This procedure is adopted for the manufacturing of

titania [29] and zirconia membranes [30].

Dip coating

Thin membranes can be obtained by this method [16].

This method involves the dipping of the supports in the sols followed by drying

and calcining. This method is utilized in the preparation of silica membranes

[25], alumina membranes [33, 34], titania [30], zirconia [35].

Extrusion

It is importantly used for production of ceramic tubes. A

paste is formed by mixing raw materials. A mould is extruded from the paste,

dried, calcined and sintered. The preparation of porous alumina ceramics by

extrusion method is carried out using poly vinyl acetate as pore former. The

remaining solvent is evaporated [36]. Usually,

the diameter of the membrane formed is greater than 2 mm

and the thickness is greater than 0.5 mm [16]. Ba0.5Sr0.5Co0.8Fe0.2O3-d

hollow fibre membrane synthesis by extrusion method involves EDTA

–citrate complex as starting powders [37].

Freeze casting

This process involves the formation of slurry with ceramic

powders, dispersant and deionised water. Then, it is

poured in the mould and solidified. After complete solidification, specimens

are lyophilized and dried. Finally, they are sintered. This procedure was

adopted for the synthesis of yttria – stabilized zirconia

membranes [38]. Freeze casting method is also

employed to fabricate porous tubular mullite membranes

[39]. Maintenance of constant cooling rate in this method produces porous alumina

membrane with improved mechanical properties [22].

Mixed

matrix membranes

According to recent study, wet phase inversion method was

suggested to prepare the MMM [73, 74, 78]. Common procedure for preparing MMM

is:

1. Polymer solution was prepared by dissolving the

required amount of polymer in N- methyl-2-pyrrolidone (NMP) solvent.

2. Mixture should be stirred for 24 h at 60 oC

to get a homogeneous polymer solution.

3. Desired amount of Inorganic material dispersed

in NMP will be added.

4. Mixture should be stirred for 24 h at 60 oC

to get a uniform dispersion of inorganic material in polymer solution.

5. This casting solution will be deposited on a

clean glass plate pasted with adhesive material on both sides.

6. Glass plate will be allowed at room temperature

for 30s and then it will be immersed in the non solvent bath until the complete

phase inversion.

7. After complete phase inversion, the membrane

will be peeled, washed thoroughly with water.

8. Clean membrane will be stored in

slightly chlorinated distilled water.

|

Fig. 3 Slip casting method. |

Polymeric

membrane

Polyamide membranes being hydrophilic material do not

require a wetting agent. This membrane is mainly used for microfiltration and

reverse osmosis [66].

Polyimide has excellent heat resistance; chemical

compatibility and resistance over wide range of pH are widely used

in high temperature fuel cells and separation membranes

[74].

Polysulphone membranes were more commonly used in the

process of ultrafiltration of wastewater because of its

mechanical robustness and chemical and structural stability.

Since it is a low hydrophilic in nature, it is modified by

blending it with SiO2, ZrO2, and TiO2 which

are hydrophilic nanoparticles to increase its hydrophilic properties.

This blending process improved the separation performance

of the membrane, its thermal and chemical resistance

and its adaptability to wastewater environments [67].

PVDF (Polyvinylidene fluoride) membranes were used in

wastewater purification and desalination in many trials. It has the advantage

of good separation performance and mechanical stability. Qi Zhang et al. [68],

fabricated membrane with PVDF and PVC (Polyvinyl Chloride) by phase

inversion method. The polymer ratios were varied as 1%, 5%, 10%, 20%, and 50%

and its influence on the structure and performance of the membranes were

investigated. Among these, the membrane with 5% of PVC had high porosity, high break

strength and water flux. The membrane with small wt% of PVC

had better performance and increased the applications of PVDF [68].

Cellulose acetate is one of the first polymer membrane

used for separation process and is used in both RO and UF

applications. This material is generally used because it is

naturally available, has high mechanical strength and it has high hydrophilic

property. R. Saranya et al. [93], used the composite membrane of chitosan and

cellulose acetate membrane for the removal of copper ions from the wastewater.

It showed a retention of 81.03% for copper ions. The results of the

studies carried out with Cellulose acetate is the one of the most important

polymeric material [69]. It is having high hydrophilicity

and easy processability. But it was having excessive

fouling, lower pH, and thermal stability.

Ceramic

membranes

Silica membranes

Silica membranes showed higher permeability with small

molecules. Silica membranes can be prepared with low defect concentrations [31,

32]. They were employed for energy efficient separation processes

under industrial conditions. They were also

used for dehydration and hydrogen process [40]. When compared to other

oxides such as alumina, zirconia and titania, silica involves easier

preparation as ultra or microporous thin layers. Unsupported silica membranes

prepared from the sol obtained by hydrolysis with acid catalyst and

condensation of tetra ethyl ortho silicate followed by calcination is

microporous in nature and showed a significant permeability to helium and

hydrogen. At the same time, the permeability of N2, Ar, O2,

C3H6, C3H8, nC4H10,

i-C4H10 was very small. At 303 K, hydrocarbon permeation

was 2 times that of helium [26]. Hydrophobic nature is

being observed from the silica membrane prepared by the repeated dip coating of

supported γ-alumina membranes in silica sol

solution followed by drying and calcining. Hydrophobicity was due to the added

methyl tri ethyl silicate. The obtained membrane has a pore diameter of 0.7 nm

and a thickness of 60 nm. The hydrophobicity was 10 times more than that of

ordinary silica membrane [31]. A double layered silicate

coated membrane on γ-alumina was synthesized by sol gel

dip coating using surfactant template silica as intermediate layer. Cheong et

al., 1999 stated that the dual layered membrane showed

improvement in flux and stability [25]. Sols were prepared from tetra

ethoxy silane and octyl-,

dodecyl-

and octadecyltriethoxysilane to fabricate silica membranes on γ-alumina

coated α-alumina tube. Micropores were obtained in size range of 0.3-0.4 nm

when calcined at 600 °C. Mesopores formed during the gelation step [42].

Alumina membranes

Alumina membranes have been used for both liquid and

gaseous separations [43]. The alumina membranes had high resistance to

temperature, pressure, oxidation, solvents, hot acids and caustic solutions

[44]. They are back flushable and can be sterilized by steam [19].

It has an excellent thermal, chemical and mechanical strength

[17]. Non supported mesoporous γ-alumina membrane

prepared from boehmite sols were with a pore radius of

2.2. nm when calcined at 600 °C. Membranes with α-alumina support were

with a pore radius of 2.5 nm [27]. Supported -alumina membrane were prepared by

dipping into boehmite sols also observed that the layer thickness decreased

with increase in the pore size of the support [33]. Mesoporous γ-alumina

membranes on cordierite honeycombs were prepared by the method of dip

coating into boehmite with addition of HNO3 to bring

the pH to 4.0 [34]. Preparation of alumina membranes from aluminium

secondary butoxide reveals that the transition of 7-AlOOH to 7-Al2O3

takes place at 390 °C [33]. γ-alumina

nanofiltration membranes with pore diameter greater than 5 nm

were prepared from boehmite at low sintering temperature of

about 540 °C. Boehmite can be obtained by the precipitation

of complete hydrolysis of aluminium alkoxide [45].

Titania membranes

Titania membranes have unique structure and surface

properties. Titania membranes show high resistance towards corrosion at strong

acidic pH [46]. Titania membranes when calcined at high temperatures results in

phase transformation to anatase and hence the structure collapses. Sekulic et

al., 2004 reported that the membranes were of high chemical stability at wide pH ranges [29]. Titania

membranes exhibit higher permeability to

propylene. Asymmetric titania membranes

were prepared by wang et al., 2008 from stable titania suspensions with a pore

size in the range of 0.1-0.12 microns

[46]. He used sol gel technique for the synthesis of titania nanofiltration membranes. Membrane with top layer of anatase

– TiO2 fired at 300 °C is with low crystallinity and at a pH of

2, the molecular weight cut off increased to 800 from 200 [35]. Microporous

titanic membranes layers of pore size lesser than or equal to 0.8 nm are

synthesized on mesoporous γ-alumina and titania/zirconia coated substrates by

polymeric sol gel route [29]. Non supported titania membranes were prepared by

dip coating in colloidal dispersions of titania. Supported titania membranes

are prepared by slip casting with the same solution. The membrane is of 3-6

micron thick and with an average pore diameter of 3-4 nm [30].

Zirconia membranes

Zirconia membranes show higher rejection rates towards

polyvalent ions and lower rejection rates towards monovalent

ions [47]. Zirconia membranes possess superior stability in aqueous solutions

[48]. At low and high pH values, zirconia membranes were preferred due to its

chemical stability under these conditions [35]. Yttria stabilized the zirconia

membranes prepared from polymeric sol gel method with zirconium

tetra-n-propoxide and yttrium nitrate. The chelating agent used here is

acetylacetone [49]. Yttria stabilized zirconnia membranes prepared by freeze casting

method has a compressive strength of 23.57 to 63.86 MPa and they exhibit non

catastrophic failures [38]. Nanofiltration zirconia membranes prepared by sol

gel technique from synthesized zirconia sols were having average particle size

of about 8.6 nm [50]. Membranes with molecular weight cut

off less than or equal to 300 for nanofiltration and per

evaporation purposes were produced with α-alumina support prepared by slip

casting method, yttria doped zirconia interlayer and

zirconia top layer prepared by dip coating method [35].

MMM-desalination

The freshwater resources are getting dried. Water

desalination has been increased and got an important role in supplying

freshwater [70-72]. In the todays trend, the polymeric membrane is preferred

for the filtration more than the conventional treatment to get better salt

rejection and high-water flux. But in all the polymeric

membrane processes the water flux was stated as low due

to low permeability. Currently, polymeric, ceramic and mixed matrix membranes

are used in desalination. Polymeric membranes are widely used in this field.

Bio-fouling, poor thermal and chemical stability are the main challenges for

the polymeric membrane. Ceramic membranes show excellent thermal

and chemical stability that make them a possible alternative to be used in

water desalination process.

Combination of polymer with inorganic such as Graphene,

carbon nanotubes and various nano particles such as

silica, titania and zirconia MMM were produced to improve

the performance of membrane. Low loading rate, poor dispensability,

hydrophilicity are the major issues in the MMM. In the membrane filtration

polysulfone based membranes were used. It had good resistance over the wide

range of pH. But it was having the hydrophobic nature. By improving the

hydrophilic nature of the membrane, the productivity will be increased.

The blending of the polymer with hydrolysed poly

isobutylene-alt-maleic anhydride is the promising method to improve the

hydrophilicity [3]. High salt rejection and good hydrophilicity can be achieved

by blended polymer membrane with surface midified poly isobutylene-alt-maleic

anhydride [4]. Functionalised inorganic material in the membrane

preparation also gives the increased hrdrophilicity [5, 6].

Mainly polysulfone (Psf), polyether sulfones, poyimides, polyamides were used

in the MMM preparation [74].

Graphene oxide, Titania, silica and zirconia nanoparticles

Iron III oxides were used with polymeric membrane to improve the hydrophilicity

[2-5]. Ionic strength and pH of the solution also can induce agglomeration

between nanoparticles. These materials absorb very easily the hydroxyl groups

(OH-)

and they have high surface area and a very good antifungal and antibacterial

materials.

Bo Feng et al., 2017 used nanohybrid graphene oxide (GO)

and polyimide (PI) in the MMM preparation [74]. B.M Ganesh et al., 2013 used

the GO and Psf (polysulfone) for the MMM preparation [73]. Javed aslam

et al., 2013 used polyether sulfone with iron oxide

nanoparticles [78]. A derivative of graphene containing oxygen

rich functional groups leads the high hydrophilicity and high

water permeability in the membrane. In this GO has the strong interaction with

polymer chain. Mechanical strength, stability, water permeability, antifouling and salt rejection can be improved.

Wet phase inversion method was used

for the MMM preparation in this work.

B.M Ganesh et al., 2013 [73] used the GO and Psf in the

MMM to enhance the hydrophilic nature of the membrane. Wet phase inversion

method is used for the membrane preparation. He mentioned that the salt

rejection depends on pH. If the pH increases, the salt rejection

will be increased. Polysulfone based membranes are used

because of its excellent heat resistance, Chemical compatability and have good

resistance over the wide range of pH. Blending Psf with hydrolysed poly

isobutylene-alt-maleic anhydride increases the hydrophilicity. GO is preferred

due to its high surface area. GO is used due to its

outstanding electron transport and

mechanical properties, hydrophilic and pH sensitive behavior. In

this after GO doping the salt rejection was increased.

Polyether sulfone is used by javed aslam et al., 2013 for

the MMM preparation for desalination processes [78]. PES has

high glass transition temperature, thermal and chemical

stability. In this he doped the PES with iron III oxide nanoparticles. 15% Fe3O4

membrane gives the highest pure water flux, 10% Fe3O4

provides 10% salt rejection.

MMM

– Dye removal from textile industry effluent

Among the several separation techniques (impaction,

diffusion, adsorption and electrostatic interaction) [5], the

dye component of the textile effluent can be removed by

adsorption. The combination of adsorption and membrane

filtration is generally suggested for the textile effluent

treatment to enhance the membrane filtration. More number of research works are

carried out with activated carbon as an adsorbent material [85-88] due

to its large surface area [89] surface chemical deposition.

The effect of Activated Carbon on polysulfone and Polyether sulfone has been

studied thoroughly by Kusworo T.D. et al., 2010 [91] and Ballinas et al., 2004

[90] in their studies. With this Nanoparticles are also used

to improve the hrdophilic nature, filtration efficiency of polymeric

membrane. Nanoparticles of Iron oxide and Zero valent iron (ZVI) has high

surface area [92]. R.saranya et al., 2013 carried out the experiment with Cellulose

acetate+Activated carbon and Cellulose Acetate+Iron

Oxide combination [93]. They synthesised the different membranes and tested the filtration efficiency. High pure

water flux was achieved with the addition of 2.5%Activated Carbon and 0.5% Iron

oxide addition. They concluded that the addition of Activated carbon Activated

carbon influences the membrane permeability

and Iron oxide not. High rejection efficiency was obtained with no compromise in membrane permeability.

R.saranya et al., 2015 [94] used green synthesized zero

valent iron for the textile effluent treatment. They used ZVI for polymeric membrane

modification. The synergistic effect of permeation and adsorption

increases the use of ZVI/CA mixed matrix membrane for the textile

effluent treatment. Cellulose Acetate membrane was prepared with different mass

fractions of 0.5, 1.5 and 2.5 wt% of ZVI. Pure water permeability was increased

with 0.5% of ZVI nanoparticles addition. Physisorption was happened with this

filtration.

MMM

– Phenol and phenolic compounds removal

Most

of the chemical industries particularly petro- chemical industries produce phenol and

phenolic compounds which is very toxic and

carcinogenic [79, 80]. Continuous exposure to phenol gives eye irritation, skin

allergies, Mucous, headache, high blood pressure, liver and kidney damage.

Mixed matrix membrane is the better option

to remove Phenol from the effluent. RO membrane [81], Ultra filtration [82] and

nanofiltration are generally used in

the phenol removal. A novel technique, Nanoparticles doped MMM was nowadays

suggested as a better option to improve the removal percentage. Mixed matrix membrane of granular

alumina and Cellulose Acetate shows

flux enhancement [83]. Raka mukherjee 2014 [84] used doped alumina with

Cellulose Acetate Pthalate by phase inversion method. Various concentrations

membranes are prepared. 20 wt% alumina concentration membrane increases the

porosity and permeability.

MMM

– Proteins removal

Generally polymeric membrane with sulfone polymer

[75, 76], polysulfone, poly phenyl sulfone is used in the separation processes.

Polyethyl sulfone has the better properties than the polysulfone and polyether

sulfone [77]. Lawrence Arokiasamy dass et al., 2017 [78] fabricated the

sulfonated polyphenyl sulfone and Titania nanoparticles by phase inversion

method. With the 25.5% wt% the attained flux rate was high.

Thermal and mechanical properties also increased. Antifouling

properties of MMMs were enhanced. They concluded that fuctionalised

nanocomposite hollow fiber MMM will be the better promising membrane for the

proteins removal.

MMM

– Oilfield wastewater removal

Large quantities of oilfield wastewater are produced in

onshore and offshore exploitation. According to API 18bbl of

produced water were generated by US onshore operations

in 1995 [96]. Oilfield produced wastewater creates major environmental iisues [97].

Oil drilling produces large quantity of wastewater. Skimmer is the general

conventional treatment [98]. Polymeric and Ceramic membrane are used in the

removal of oil [99].

The necessity of the treatment of water was discussed in

this paper. In this paper, conventional treatment methods were discussed. Also,

particularly different types of membranes based on materials and pore size and

the factors affecting the Membrane processes were discussed. The mixed matrix

membranes are the combination of polymeric

and ceramic membranes. This MMM’s

hydrophilicity improving techniques were reviewed. Application of Mixed Matrix Membrane was also thoroughly

investigated. So that Mixed Matrix Membrane can be suggested as the novel

technique in the water and wastewater treatment. The future work can be carried

over with different material composition and with different inorganic particle

size composition to study the

performance behavior and other characteristics. Also, the work can be carried over with the derived inorganic and

organic materials from waste material so that the cost of the membrane will be

reduced. The wastes can also be recycled and reused.

- 1. J.-Bruinsma, in proceeding of Food and Agriculture Organisation of the United Nations Expert Meeting entitled How to Feed the world in 2050, Rome, Italy, (2009) 24-26

- 2. R. Umapriya, S.M. Vidhyavathy, G. Arthanareeswaran, and A. Vijayan, Int. J. Appl. Eng. Res. 10 (2015) 77-82.

- 3. S.-Ahuja, Sep. Sci. Tech. [4] (2003), 17-35

- 4. Hul, Jacob Peter vant, in “Membrane separation in Textile washing processes” (University of Twente Press, 1999) p.25-33.

- 5. H.J. Walther, S.D. Faust, O.M. Aly, Acta Hydroch. Hydrob. 16 (1998) 572.

- 6. B.S. Lalia, V. Kochkodan, R. Hashaikeh, and N. Hilal, Desalination 326 (2013) 77-95.

-

- 7. P. Aptel and C.A. Buckley, in “Water Treatment membrane processes” (McGraw-Hill, 1996) p.26.

- 8. M. Khayet and T. Matsumura, in “Membrane Distillation: Principles and Applications” (Elsevier, 2011) p.73.

- 9. E. Drioli and L. Giorno, in “Membrane operations: Innovative separations and transformations” (Wiley-VCH, 2009) p.80- 86.

-

- 10. L.Y. Ng, A.W. Mohammad, C.P. Leo, N. Hilal, Desalination 308 (2015) 15-33.

-

- 11. I. Pinnanu and B. D. Freeman, Formation and modification of polymeric membranes: overview. Desalination 278 (2011) 21-37.

- 12. J. Tong, L. Zhang, M. Han, K. Huang, J. Membr. Sci. 477 (2015) 1-6.

-

- 13. E. Drioli, L.Giorno, in “Membrane operations: Innovative separations and transformations” (Wiley-VCH, 2009) p.80-86.

- 14. L.C. Peng, in “Bimodal porous ceramic membrane via nano sized polystyrene templating: Syntesis, Characterisation and performanace evaluation” (Universiti Sains MalaysiaPress, 2008) p.75.

- 15. R.V. Kumar, A.K. Ghoshal, and G. Pugazhenthi, J. Membr. Sci. 490 (2015) 92-102.

-

- 16. S.K. Amin, H.A.M. Abdallah, M.H. Roushdy, and S.A. El-Sherbiny, Int. J. Appl. Eng. Res. 11[12] (2016) 7708-7721.

- 17. J.M. Benito, M. Conesa, A.F. Rubio, and M.A. Rodriguez, J. Eur. Ceram. Soc. 25[11] (2005) 1895-1903.

-

- 18. S. Schaffoner, L. Freitag, J. Hubalkova, and C.G. Aneziris, J. Eur. Ceram. Soc. 36[8] (2016), 2109-2117.

-

- 19. M. Barmala, A. Moheb, and R. Emadi, J. Alloys Compd. 485[1] (2009) 778-782.

-

- 20. F. Bouzerara, S. Boulanacer, and A. Harabi, Ceram. Int. 41[3] (2015) 5159 -5163.

-

- 21. D.D. Athayde, D.F. Souza, A.M.A. Silva, D. Vasconcelos, E.H.M. Nunes, J.C.D. Costa, and W.L. Vasconcelos, Ceram. Int. 42[6] (2016) 6555-6571.

-

- 22. Y. Zhang, L. Hu, J. Han, and Z. Jiang, Ceram. Int. 36[2] (2010) 617-621.

-

- 23. A.J. Burggraaf and L. Cot, in “Fundamentals of inorganic membrane science and technology-Chapter (7): Sol-gel chemistry and its application to porous membrane processing” (Elsevier Science, 1996) p.7.

-

- 24. A. Larbot, L. Gazagnes, S. Krajewski, M. Bukowska, and W. Kujawski, Desalination 168 (2004) 367-372.

-

- 25. H. Cheong, W.S. Cho, J.S. Ha, C.S. Kim, D.K. Choi, and D.S. Cheong, J. Alloys Compd. 290 (1999) 304-309

-

- 26. N.B. Nair J. Membr. Sci. 135[2] (1997) 237-243.

-

- 27. R.S.A. De Lange, Microporous Mater. 4[2] (1995) 169-186.

-

- 28. K. Li, in “Ceramic membranes for separation and reaction” (John Wiley & Sons, Inc., 2007) p.67.

- 29. J.J.E. Sekulic, T. Elshof, and D.H.A. Blank, J. Sol-Gel Sci. Technol. 31[1-3] (2004) 201-204.

-

- 30. V.T. Zaspalis, J. Mater. Sci. 27[4] (1992) 1023-1035.

-

- 31. R.M. de Vos, W.F. Maier and H. Verweij, J. Membr. Sci. 158[1] (1999) 277-288.

-

- 32. R.M. de Vos and H. Verweij, J. Membr. Sci. 143[1] (1998) 37-51.

-

- 33. A.F.M. Leenaars, K. Keizer, and A.J. Burggraaf, J. Mater. Sci. 19[4] (1984) 1077-1088.

-

- 34. S. Govender and H.B. Friedrich, Catalysts 7 (2017) 62.

-

- 35. T. Van Gestel, J. Membr. Sci. 214[1] (2003) 21-29.

-

- 36. T. Isobe, J. Eur. Ceram. Soc. 27[1] (2007) 61-66.

-

- 37. S. Liu and G.R. Georg, J. Membr. Sci. 246[1] (2005) 103-108.

-

- 38. K.H, Zuo, Y.-P. Zeng, and D. Jiang. Int. J. Appl. Ceram. Technol. 5[2] (2008) 198-203.

-

- 39. R. Liu, T. Xu, and C.-a. Wang, Ceram. Int. 42[2] (2016) 2907-2925.

-

- 40. L.H. Castricum, J. Mater. Chem. 18 (2008) 2150-2158.

-

- 41. M.A. Anderson, J.M. Gieselma, and Q. Xu, J. Membr. Sci. 39[3] (1988) 243-258.

-

- 42. K. Kusakabe, Sep. Purif. Technol. 16[2] (1999) 139-146.

-

- 43. C. Picard, A. Larbot, F. Guida-Pietrasanta, B. Boutevin, and A. Ratsimihety, Sep. Purif. Technol. 25[1] (2001) 65-69.

-

- 44. T. Masuda, H. Asoh, S. Haraguchi, and S. Ono, Materials. 8 (2015) 1350-1368.

-

- 45. L. Cot, A. Ayral, J. Durand, C. Guizard, N. Hovnanian, A. Julbe, and A. Larbot, Solid State Sci. 2[3] (2000) 313-334.

-

- 46. Y.H. Wang, X.Q. Liu, and G.Y. Meng, Mater. Res. Bull. 43[6] (2008) 1480-1491.

-

- 47. S. Benfer, U. Popp, H. Richter, C. Siewert, and G. Tomandl, Sep. Purif. Technol. 22 (2001) 231-237.

-

- 48. T. Tsuru, D. Hironaka, T. Yoshioka, and M. Asaeda, Sep. Purif. Technol. 25[1] (2001) 307-314.

-

- 49. X. Changrong, J. Membr. Sci. 162[1] (1999) 181-188.

-

- 50. H. Qi, J. Sol-Gel Sci. Technol. 62[2] (2012) 208-216.

-

- 51. A. Okada and A. Usuki, Mater. Sci. Eng. C3 (1995) 109.

-

- 52. J. W. Gilman, Appl.Clay Sci., 15, (1999), 31-49.

-

- 53. D. Godovski, Adv. Polym. Sci. 119 (1995) 135.

- 54. L.H. Li, J.C. Deng, H.R. Geng, Z.L. Liu, and L. Xin, Carbohydr. Res. 345 (2010) 994.

-

- 55. M. Mulder, in “Basic principles of membrane technology” (Kluwer Academic publishers, 1996) p.78.

- 56. N.F. Liu, A. Hashim, Y. Liu, M.R. Moghareh Abed, and K. Li, J. Membr. Sci. 375 (2011) 1-27.

-

- 57. J. Cadotte, R. Forester, M. Kim, R. Petersen, T. Stocker, Desalination 70 (1988) 77-88.

-

- 58. W.J. Lau, A.F. Ismail, N. Misdan, M.A. Kassim, Desalination 287 (2012) 190-199.

-

- 59. F. Sadeghi, presented in “Developing of Microporous poly- propylene by stretching” (Polytechnique Montreal, 2007) p.20.

- 60. W. Zhu, X. Zhang, C. Zhao, W. Wu, J. Hou, M. Xu, Polym. Adv. Technol. 7 (1996) 743-748.

-

- 61. K. Trommer, B. Morgenstern, J. Appl. Polym. Sci. 115 (2010) 2119-2126.

-

- 62. R.L. Fleischer, P.B. Price, and R.M. Walker, presented in “Nuclear tracks in solids, Principles and applications” (University of California Press, 1975) p.48.

- 63. J.A. Prince, G. Singh, D. Rana, T. Matsuura, V. Anbharasi, T.S. Shanmugasundaram, J. Membr. Sci. 397-398 (2012) 80-86.

-

- 64. B.S. Laila, E. Guillen-Burreiza, H.A. Arafat, R. Hashaikeh, J.membr.Sci. 428 (2013) 104-115.

-

- 65. R. Gopal, S. Kaur, Z. Ma, C. Chan, S. Ramakrishna, T. Matsuura, J.Membr. Sci. 281 (2006) 581-586.

-

- 66. A.K. Fard, G. McKay, A. Buekenhoudt, H.A. Sulaiti, F. Motmans, M. Khraisheh, and M. Atieh, Materials 11 (2018) 74.

-

- 67. H.L. Richards, G.L. Priscilla, Baker, and Emmanuel Iwuoha, J. Surf. Eng. Mater. Adv. Technol. 2 (2012) 183-193.

-

- 68. Q. Zhang, S. Zhang, Y. Zhang, X. Hu, and Y. Chen, Desalin. Water Treat. 51[19-21] (2013) 3854-3857.

-

- 69. A. Ghaee, M. Shariaty-Niassar, J. Barzin, T. Matsuura, and A.F. Ismail, Desalin. Water Treat. 57[31] (2015) 1-8.

- 70. M. Elimelech and W.A. Phillip, Science 333 (2011) 712-717.

-

- 71. M. Shanon, Nature 452 (2008) 301-309.

- 72. A. Cipollina, G. Micale, and L. Rizzuti, presented in “Seawater desalination: Conventional and renewable energy processes” (Springer, 2009), p.29.

- 73. B.M. Ganesh, M. Arun, Isloor, A.F. Ismail, Desalination 313 (2013) 199-207.

-

- 74. B. Feng, K. Xu, A. Huang, RSC Advances (2016) 164-169.

-

- 75. M. Sianipar, S.H. Kim, C. Min, L.D. Tijing, H.K. Shon, J. Ind. Eng. Chem. 34 (2016) 364-373.

-

- 76. H.G. Yuan, T.Y. Liu, Y.Y. Liu, X.L. Wang, Desalination, 379 (2016) 16-23.

-

- 77. A.W. Mohammad, Y.H. Teow, W.L. Ang, Y.T. Chung, D.L. Oatley-Radcliffe, N. Hilal, Desalination, 356 (2015) 226-254.

-

- 78. L.A. Dass, M. Alhoshan, J. Aslam, M.R. Muthumareeswaran, A. Figoli, and A.K. Shukla, Sep. Purif. Technol. 174 (2017) 529-543.

-

- 79. Canadian Environmental Protection Act, in “Priority Substances List Assessment Report: Phenol” (Health Canada, 1999) p.73.

- 80. R.J. Lifton, in “The Nazi Doctors” (Basic Books, 1986) p.254-268.

- 81. V.V. Goncharuk, D.D. Kucheruk, V.M. Kochkodan, V.P. Badekha, Desalination 143 (2002) 45-51.

-

- 82. M.K. Purkait, S. Das Gupta, S. De, Micellar, J. Colloid Interface Sci. 285 (2005) 395-402.

-

- 83. N.M. Wara, L.F. Francis, B.V. Velamakkani, J. Membr. Sci. 104 (1995) 43-49.

-

- 84. R. Mukherjee, S. De, Desalination 144 (2003) 51-59.

- 85. K.K.H. Choy, G. McKay, J.F. Porter, Resour. Conserv. Recy. 27[1-2] (1999) 57 - 71.

-

- 86. N. Kannan, M.M. Sundaram, Dyes Pigm. 51[1] (2001) 25-40.

-

- 87. C. Namasivayam, D. Kavitha, Dyes Pigm. 54 (2002) 47-58.

-

- 88. P.K. Malik, Dyes Pigm. 56[3] (2003) 239-249.

-

- 89. H. Marsh, F. Rodríguez-Reinoso, in “Activated Carbon” (Elsevier, 2006).

-

- 90. L. Ballinas, C. Torras, V. Fierro, R. Garcia-Valls, J. Phys. Chem. Solids. 65[2-3] (2004) 633-637.

-

- 91. T.D. Kusworo, A.F. Ismail, A. Mustafa, Budiyono, J. Sci. Eng. 1 (2010) 15-20.

- 92. W.X. Zhang, J. Nanopart. Res. 5 (2003) 323-332.

-

- 93. R. Saranya, Y. Lukka Thuyavan, and G. Arthanareeswaran, Journal Technology 20 (2013) 70-76.

- 94. R. Saranya, G. Arthanareeswaran, A.F. Ismail, D. Dionysios, and D. Paul, Journal Technology 26 (2015) 23-28.

- 95. K. Shams Ashaghi1, M. Ebrahimi, and P. Czermak, Open Environ. Sci. 1 (2007) 1-8.

-

- 96. API, in “Overview of Exploration and Production Waste Volumes and Waste Management Practices in the United States,” (ICF Consulting for the American Petroleum Institute, 2000) p.11.

- 97. Q. Li, C. Kang, C. Zhang, Proc Bio chem 40 (2005) 873-877.

-

- 98. F.E. Ciarapica, G. Giacchetta, presented in the Fifth Inter- national Membrane Science & Technology Conference, University of New South Wales, Sydney, Australia, (2003).

- 99. K. Shams Ashaghi, M. Ebrahimi, P. Czermak, Open Environ. Sci. 1 (2007) 1-8.

-

This Article

This Article

-

2020; 21(3): 309-318

Published on Jun 30, 2020

- 10.36410/jcpr.2020.21.3.309

- Received on Oct 15, 2019

- Revised on Jan 4, 2020

- Accepted on Jan 17, 2020

Services

Services

- Abstract

introduction

membrane filtration

membrane fabrication methods

polymeric, ceramic and mixed matrix membranes – an overview

mixed matrix membrane (mmm) – a novel separation technique - application

conclusion

- References

- Full Text PDF

Shared

Correspondence to

Correspondence to

- R Umapriya

-

Department of Chemical Engineering, Erode Sengunthar Engineering College, Perundurai, Tamilnadu 638407, India

Tel : +91 6383421616

Fax: +91 9994302399 - E-mail: btech.priya@gmail.com

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.