- Fabrication and dielectric properties of CCTO/PF dielectric composites: CCTO with different particle size

Yang Zhaoa, Yuzhen Zhaoa, Yuhua Niub, Yongming Zhanga and Zongcheng Miaoa,*

aKey Laboratory of Organic Polymer Photoelectric Materials, School of Science, Xijing University, Xi’an, 710123, Shaanxi, People's Republic of China

bKey laboratory of Auxiliary Chemistry & Technology for Light Chemical Industry of Ministry of Education, Shaanxi University of Science & Technology, Xi’an, 710021, Shaanxi, People's Republic of China

Calcium copper titanate (CaCu3Ti4O12,

CCTO) particles with three types of particle size (CCTO–i, CCTO–ii,

CCTO–iii) are prepared by wet chemical method. And then the dielectric

composites based on CCTO particles and Phenol formaldehyde resin (PF) are

fabricated by mixing and mould pressing. This paper mainly studies the

microstructure and dielectric properties of CCTO/PF dielectric composites

(CCTO–i, CCTO–ii and CCTO–iii composites). XRD, FTIR and

SEM indicate that the CCTO particles are dispersed in the polymer matrix. In

addition, the effect of particle size on the dielectric properties of CCTO/PF

composites is also discussed. By comparing the CCTO/PF composites with

different particle sizes, it is found that the CCTO–i composite has a

high maximum dielectric constant and low loss at room temperature of 100 Hz,

while the CCTO volume fraction was 0.5 in the measurement frequency range,

which shows a very weak frequency dependence. On this basis, the CCTO–i

composite with relatively small particle size has excellent dielectric

properties, which may imply that the effect of interface will be changed by

smaller particle size.

Keywords: CCTO particles, PF, Particle size, Dielectric property

In the past decades, ceramic/polymer dielectric composites

exhibited high dielectric properties, good processability,

owing to the combination of the advantage of the

ceramic and polymer. The composite could be used in the fields of the high

density capacitors, embedded microcapacitors, artificial muscles and so on.

Recently, trends for these electronic devices require functionality, high-speed

performance, miniaturization and lower cost. Therefore, developing new types of

ceramic/polymer dielectric composites with relatively high dielectric

properties to satisfy requirement of miniaturization and multifunctionality of

electronic devices become an important subject in the area of the engineering

and technology [1-7].

Currently, among the ceramic/polymer dielectric composites,

the ceramics of BaTiO3 (BT), Ba0.6Sr0.4TiO3

(BST),

Pb(Zr, Ti)O3(PZT), and Pb(Mg1/3Nb2/3)O3–PbTiO3 (PMN–PT) exhibit relatively high

dielectric permittivity [8-11]. These ceramics would be used as inorganic

filler which mixed with the polymer matrix to form the ceramic/polymer

dielectric composites. However, such

ceramics always exhibit strong electro-

mechanical effects (such as

piezoelectric effect), which limits the reliability of the devices [12, 13].

Recently CaCu3Ti4O12(CCTO) with environment

friendly, giant permittivity, low loss tangent and better temperature stability

is introduced as ceramic fillers to further increase the dielectric constant of

the composites [14, 15]. What’s more,

Polyimide (PI), Poly (polyvinylidene–trifluoroethylene) (P(VDF–TrFE)), Epoxy resin,

Silicone resin, Polyvinylidene

fluoride (PVDF), and Polyaniline (PU), especially Phenol formaldehyde resin

(PF) that exhibit high mechanical strength, good insulativity and heat

resistance, are selected as polymer matrix [16-21]. To summarize, new types of

CCTO/polymer composite have been investigated. Dang et al. [22] fabricate a CCTO/PI

composite film (with 40 vol. % ceramic filler) with a dielectric permittivity

of about 49 at 100 Hz and room temperature, which is approximately 6 times

larger than that of pure PI. Babu et al. [23] report the permittivity of

CCTO/silicone resin composite is about 13 at 1 kHz and room temperature, which

would reach a maximum value by filling with CCTO volume fraction at 50 vol. %

and is about 4 times larger than silicone resin. Srivastava et al. [24] also

report the dielectric behaviors of CCTO/PVDF composite. The dielectric constant

of the CCTO/PVDF composite with 10 wt% of ceramic loading is about 8.2 at 1 Hz

and 300 K. However, the grain sizes of CCTO filler of these composites

mentioned above are prepared by several methods that could range from a few to

tens of micrometers. In some theoretical models [25], the large dielectric constant of CCTO/polymer dielectric

composite may contribute to the

morphology and the particle size of the ceramic powder. In addition, the

smaller CCTO particles exhibit the larger surface area, which also could

influence the dielectric properties. Therefore, ceramic/polymer composite containing different particle sizes

of CCTO that exhibit various dielectric properties, and then extraordinary properties of this

composite are obtained.

In this study, different sizes of CCTO particles are synthesized

by the sol–gel method, and then the composites are fabricated by

mixing and mould pressing. These composites, composed of CCTO

particles and PF matrix, are studied by varying the filler content and particle

size of the fillers. Finally, the variation of dielectric properties of CCTO/PF

dielectric composite with certain range of temperature and frequency are

measured.

Materials

Copper nitrate (99%), calcium nitrate (99%), tetrabutyl titanate

(≥98%), ethanol (≥99.7%), acetic acid (≥99.5%), ammonium

hydroxide (25%), phenol (99%), formaldehyde (37%),

oxalic acid (99.5%) and hexamethylenetetramine (≥99%) are

purchased from Sinopharm Chemical Reagent Co., Ltd., China. All

materials are used without further purifications.

Preparation

of CCTO particles

CCTO particle is synthesized by the sol–gel method as

follow: copper nitrate, calcium nitrate, and tetrabutyl titanate in the

stoichiometric ratio are dissolved ethanol separately.

The above solutions are mixed with continual stirring,

and then dilute ammonia solution is dripped dropwise into this solution to

adjust the pH to 1.0-2.0. The gel is formed at room temperature with several

hours. After that the powder is obtained by dried and ground, and then these

powder is calcined at 700, 800, 900 °C for 10 h to form the CCTO

particles which exhibit different particle size. These

particles are abbreviated as CCTO–i, CCTO–ii and CCTO–iii.

Preparation

of CCTO/PF dielectric composite

CCTO/PF dielectric composite are prepared by mixing

and mould pressing that the material contains different volume of CCTO–i,

CCTO–ii and CCTO–iii particles. The CCTO powders are

ultrasonically dispersed in mixed solution of phenol and formaldehyde for

several hours with stoichiometry (n(C6H5OH):n(HCHO)

= 1:0.85) in order to form a stable suspension. After that,

addition of oxalic acid as catalyst, the sample is obtained with polymerization

reaction for 3 h at 90 °C. The sample are filtrated, dried at 120 °C

in an oven and then ground into powders. Finally, these powders are well–mixed

and molded by hot pressing to obtain the dielectric composite. The final

samples with a disk shape are 15 mm in diameter and about 3 mm in thickness.

The CCTO/PF dielectric composites with the CCTO–i, CCTO–ii and

CCTO–iii particles are named as CCTO–i composite, CCTO–ii

composite and CCTO–iii composite respectively.

Characterization

techniques

The particle size distributions of CCTO–i, CCTO–ii

and CCTO–iii are measured by Laser Particle Size Analyzer. X-ray

diffraction patterns are obtained at room temperature with a Cu tube at 40 kV

and 100 mA by X-ray diffraction (XRD). The infrared spectra are recorded

in the 400-4000 cm-1

range by Fourier Transform infrared spectrometer (FTIR). The

morphology of composite is examined by

scanning electron microscopy (SEM).

For electrical measurement, the surfaces of CCTO/PF dielectric composites are

sputtered by silver paste to form electrodes. The permittivity and loss tangent

of these composites are measured by Agilent 4294A impedance analyzer in a

frequency range from 100 Hz to 1 MHz

over the temperature range of 25-75 °C.

Characterization

of CCTO particles

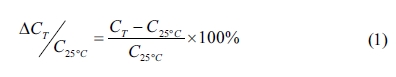

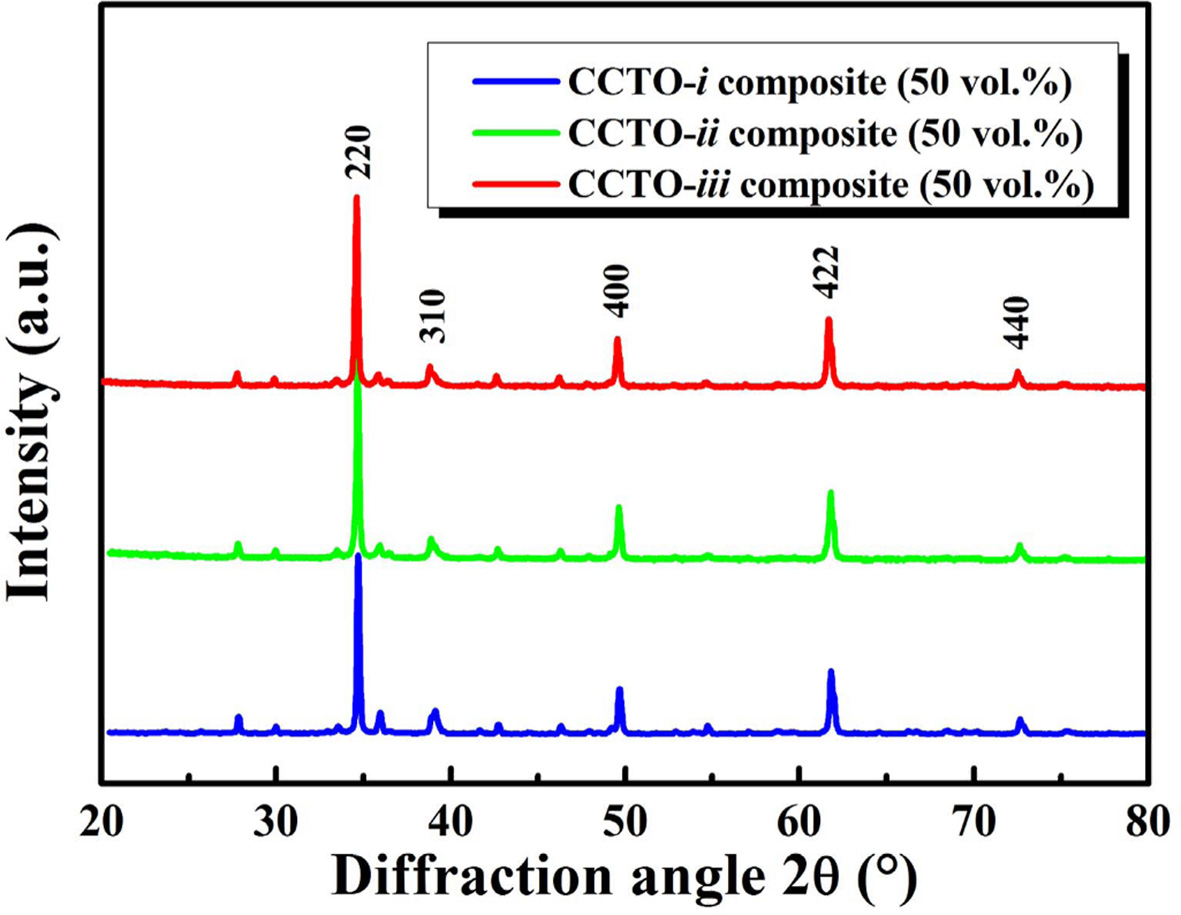

The X–ray diffraction patterns of CCTO particles (CCTO–i,

CCTO–ii and CCTO–iii) are shown in Fig. 1(a). The main

diffraction peaks of three kinds of CCTO particles are matched to the JCPDS

patterns of CaCu3Ti4O12 for identification

[26]. It shows that these particles have a cubic perovskite-related structure

(group: Im3). Some minor diffraction peaks of CaTiO3, CuO and TiO2

are detected in these particles, which are consistent

with previous literature [27]. CCTO–i particles with low calcining

temperature exhibit the lower diffraction

intensity peak than the CCTO–iii particles (the calcine temperature is

900 °C). And the FTIR spectrum of CCTO particle (CCTO–i) is shown in

Fig. 1(b). A peak appears at 458 and 571 cm-1

are attributed to the stretching vibration of Ti–O of CCTO–i particles.

From the XRD and FTIR, the CCTO particles are successfully prepared by the

sol–gel method with different calcine temperatures.

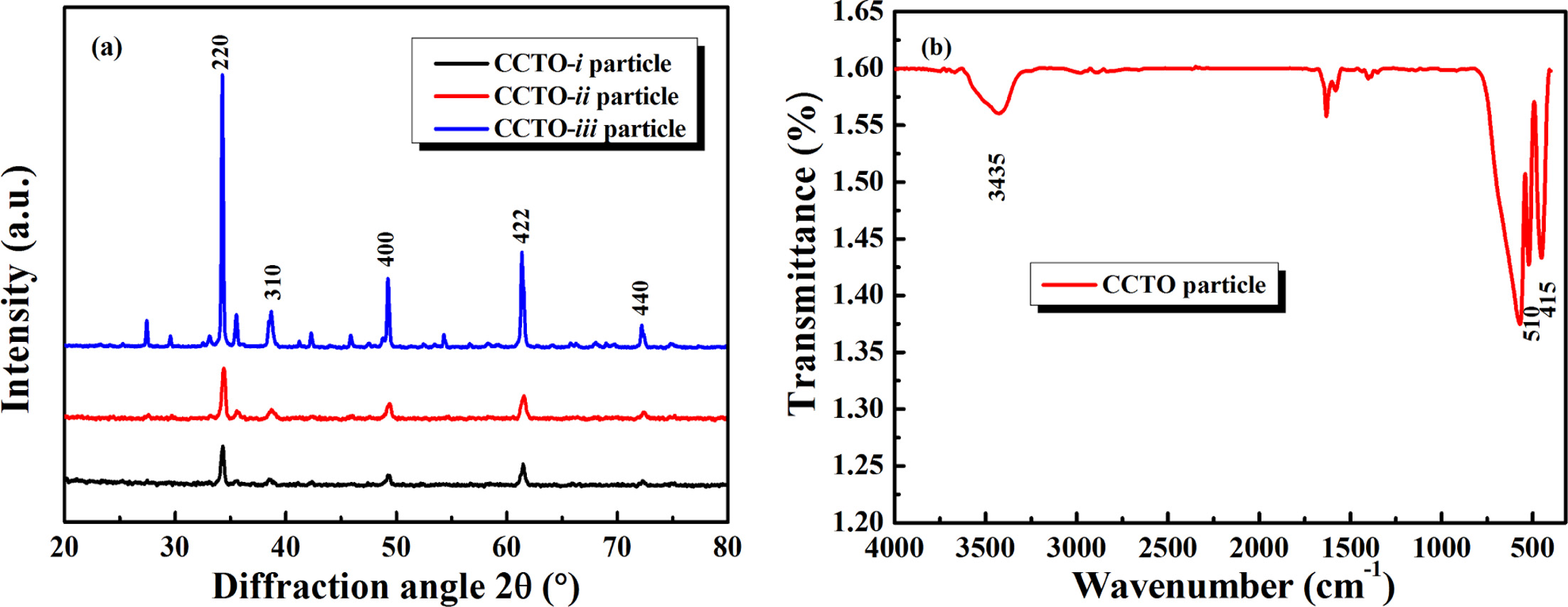

Particle size distribution of CCTO particles (CCTO–i,

CCTO–ii and CCTO–iii) is shown in Fig. 2. The Particle size of

CCTO powders are prepared by sol–gel method and increased as the calcining

temperature rises, and the effective diameter of CCTO particles is a few

hundreds of nanometers. The effective diameter is 310 nm for CCTO–i

particle, which is much lower than the value of 520 nm for CCTO–iii

particle. CCTO–i particle with the lower calcining temperature exhibit

small particle size, which due to lower crystallization temperature. Moreover,

the small powder size of CCTO–i particle exhibit low diffraction

intensity peak, which is consistent with particle size distribution of CCTO–i

particle.

The

structure of CCTO/PF dielectric composites

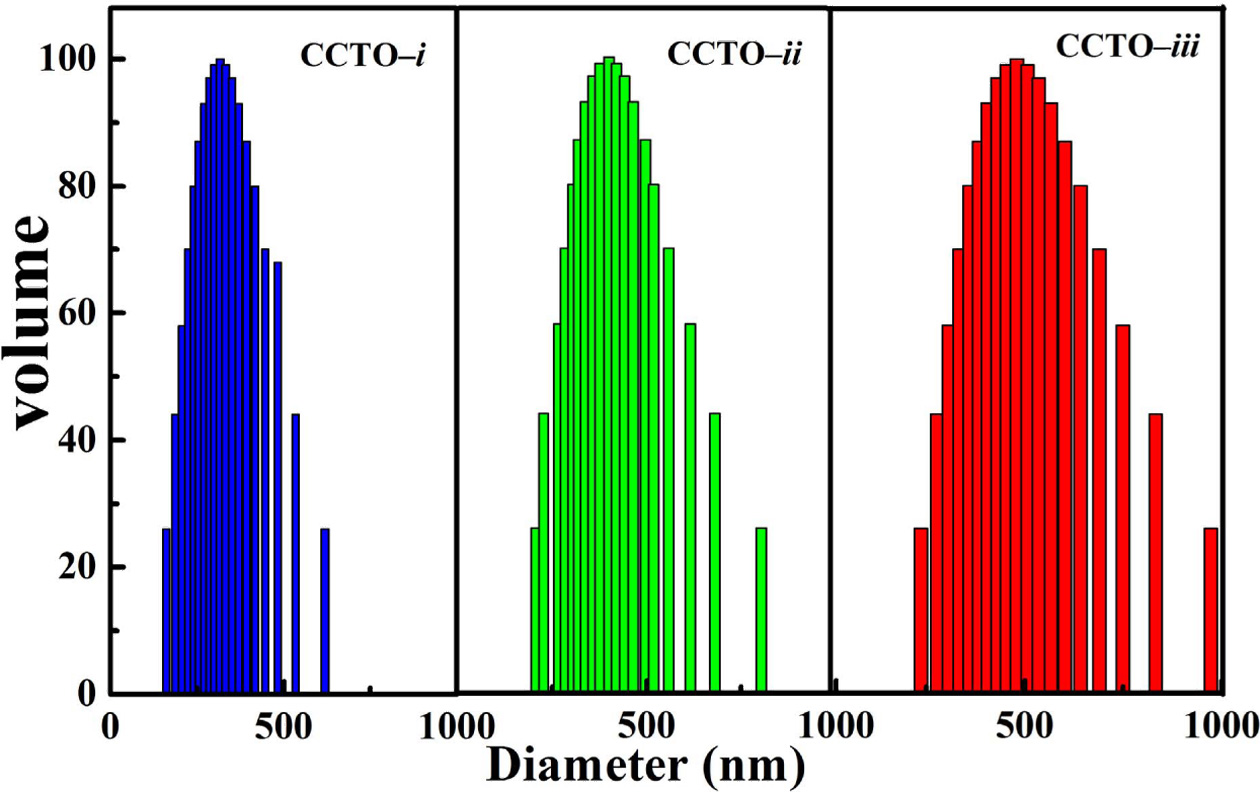

The FTIR spectra of CCTO/PF dielectric composites with 50

vol. % CCTO–i particles, 50 vol. % CCTO–ii particles and 50 vol.

% CCTO–iii particles respectively are shown in Fig. 3. The

characteristic peaks at 1101 cm-1

and 3384 cm-1

are attributed to stretching vibration of C–C and –OH of benzene

ring. A peak appears at 1225 cm-1

which is attributed to the stretching vibration of –CO–. The

characteristic peaks at 458 and 571 cm-1

are attributed to the stretching vibration of Ti–O of CCTO particles in spectra

a, b and c. The characteristic peaks of C–C, –OH, –CO– and Ti–O

become extremely weak in CCTO/PF dielectric composite, which are

owing to the fact that the CCTO particles fill in the PF and change the

original structure of polymer matrix. These characteristic peaks appear in

spectra a, b and c which are an indication that interaction between CCTO and

polymer chain to form the CCTO/PF dielectric composite.

Fig. 4 shows the X–ray diffraction pattern of CCTO/PF

dielectric composites which contain 50 vol. % CCTO–i particles, 50 vol.

% CCTO–ii particles and 50 vol. % CCTO–iii

particles respectively. The XRD analysis for three

types of CCTO/PF dielectric composites shows the predominance of CCTO phase. It

could be seen that all the major diffraction peaks can been indexed as a body

centered cubic perovskite-related structure of space group Im3 according to

JCPDS #75-2188 and diffraction peak of the PF could not be detected, indicating

that CCTO particles dispersed in the PF might have an important effect on the

structure of the molecular aggregation of the PF polymer and destroy the

ordered structure of the polymer matrix.

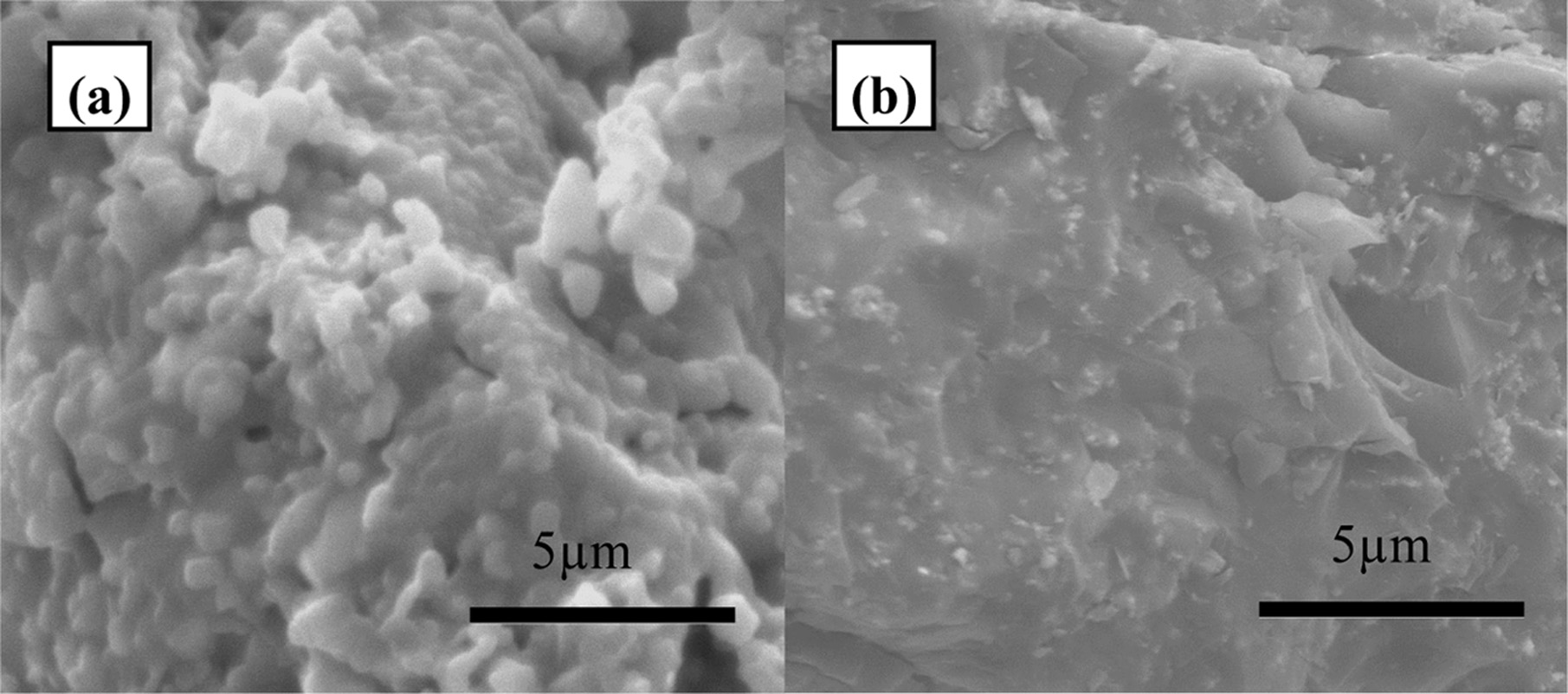

To further make clear the morphology of CCTO powders and

CCTO/PF composite, SEM images of CCTO–i particles and CCTO–i

composites are presented in Fig. 5(a) and (b) respectively.

The result shows that CCTO–i particles are in non-spherical shape and

with an average diameter of 310 nm, which is in accordance with the results of

particle size distribution. Fig. 5(b) shows the surface morphology of CCTO–i

composites. CCTO particles are homogeneously dispersed in PF matrix to form a

composite.

According to the FTIR spectra, X–ray diffraction pattern

and SEM image, it would be indicated that CCTO particles disperse into the PF

to form a ceramic/polymer dielectric composite.

Dielectric

properties of CCTO/PF dielectric composites

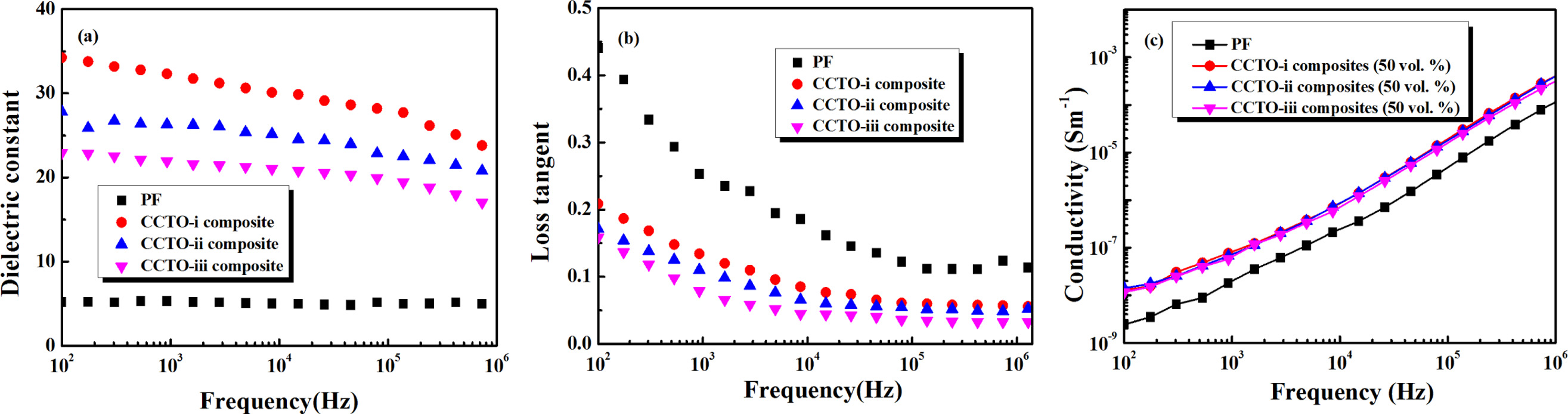

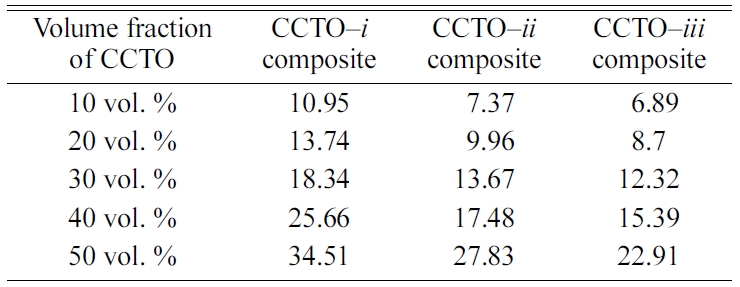

Frequency dependences of dielectric constant of CCTO–i,

CCTO–ii and CCTO–iii composites at room temperature are shown in

Fig. 6(a). It is found that dielectric constant increase gradually with the

particle size of CCTO increase. And in the frequency of 100 Hz to 1 MHz, the

decrease in the dielectric constant with increase in frequency is owing to the

fact that the dipole orientation polarization and interfacial

polarization could not keep up with the alternating field when

the frequency is raised. For the CCTO–i composite with 50 vol. % ceramic

particles, the dielectric constant of this composite is 34.51, which was about

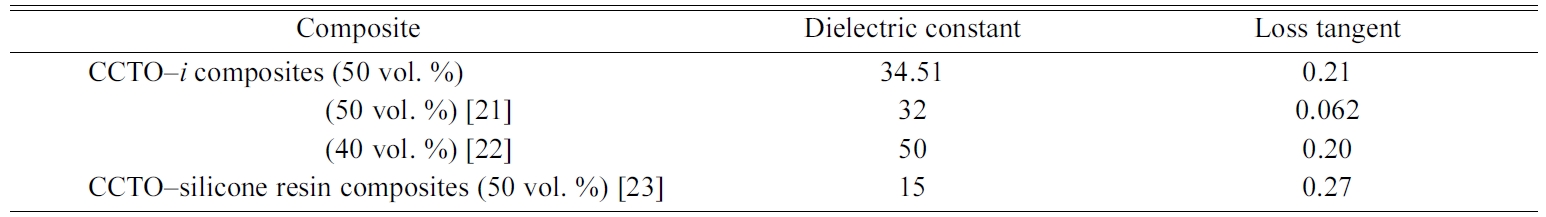

10 times higher than that of pure PF. From the Table 1 it is found that dielectric

constant increased gradually with the increase of

the content of CCTO, and the permittivity of CCTO–i

composite with 50 vol. % ceramic particles reach a maximum value, which is much

higher than those of CCTO–ii composite and CCTO–iii

composite. Moreover, it could be seen that the CCTO/PF

dielectric composites with three types of particle size

are independent in the total range of the measuring frequencies.

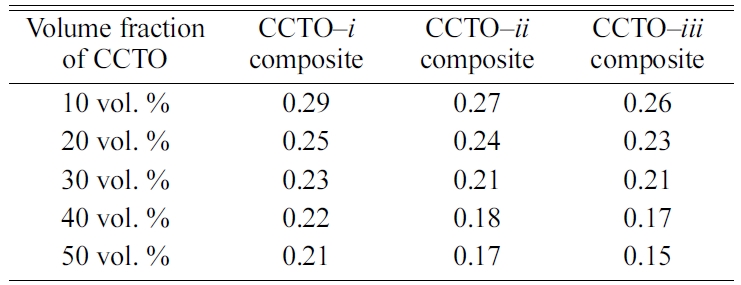

The loss tangent of CCTO/PF dielectric composite measured

in the frequency range from 100 Hz to 1 MHz at room temperature is shown in

Fig. 6(b). With the adding of inorganic filler CCTO, the dielectric loss of

three types of composites could be effectively reduced. For the CCTO–i

composite with 50 vol. % CCTO, the loss tangent decreased to 10-2 which

was lower than that of polymer matrix (10-1).

At the same time, the frequency stability of CCTO/PF dielectric composite is

improved by the addition of CCTO. From the Table 2, it is noticed that when

volume fraction increase, loss tangent of these composites decrease. This drop

of the loss tangent is due to the addition of CCTO to a

certain extent which pins the dipole orientation, thus

reduced the dielectric loss of composite.

Among the three types of ceramic/polymer dielectric

composites, the CCTO–i composite with a smaller particle size exhibit

excellent dielectric properties that could be influence by different particle

sizes. As it could be seen in Fig. 6(c), with the CCTO concentration

is 50 vol. %, the conductivity of CCTO–i composite is only 10-7 S · m-1

at 100 Hz and room temperature and it increase with an increase in the

frequency. It is confirm that insulating layer existed in CCTO/PF dielectric

composite and was consistent with the variation of dielectric permittivity.

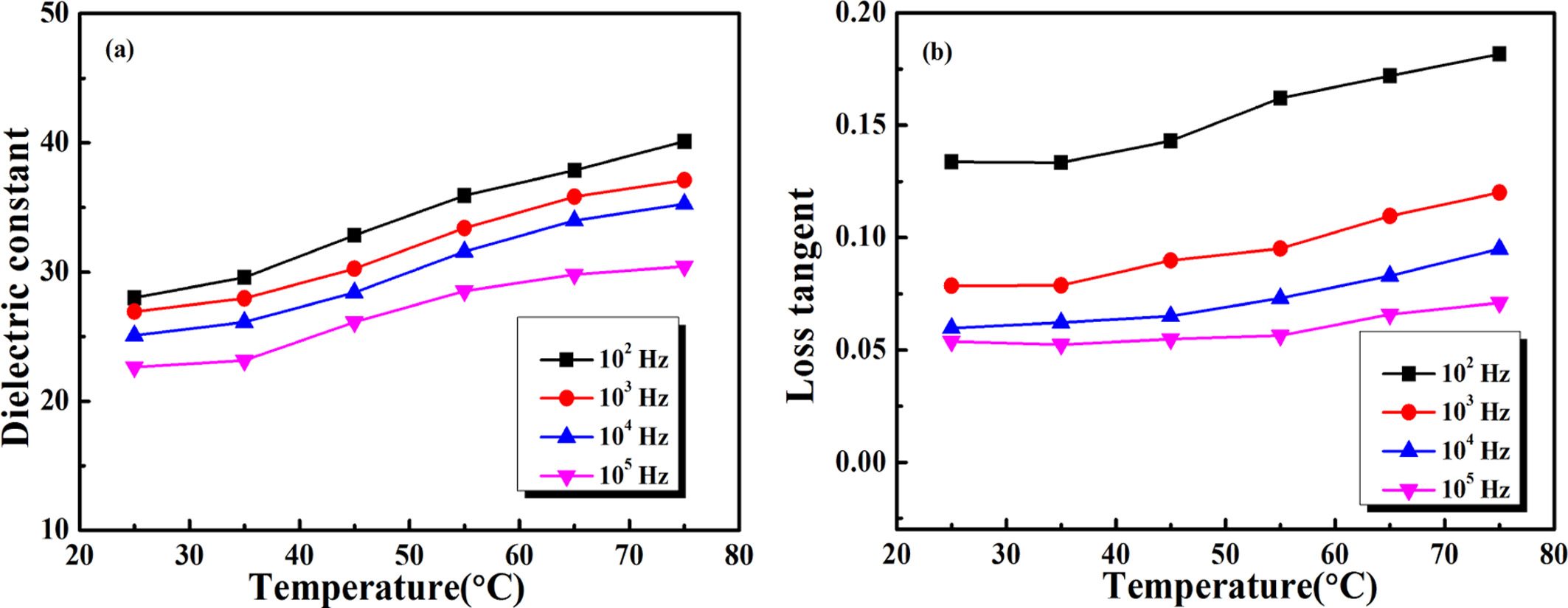

The temperature dependence of dielectric properties is determined for

CCTO/PF dielectric composite. Although the dielectric constant of the CCTO/PF

dielectric composites with three types of

particles was different, all the composites show the same dependence of the dielectric constant and loss on the

temperature. A typical result is shown in Fig. 7, where the temperature dependence of CCTO–i composites with 50

vol. % CCTO particles is measured at various frequencies. As shown in Fig. 7,

the dielectric constant and loss tangent of the CCTO–i composites that

containing 50 vol. % CCTO–i particles increase slightly with

temperature, exhibiting relatively good temperature stability in the measured

temperature range from 25 °C to 75 °C at different measured frequencies.

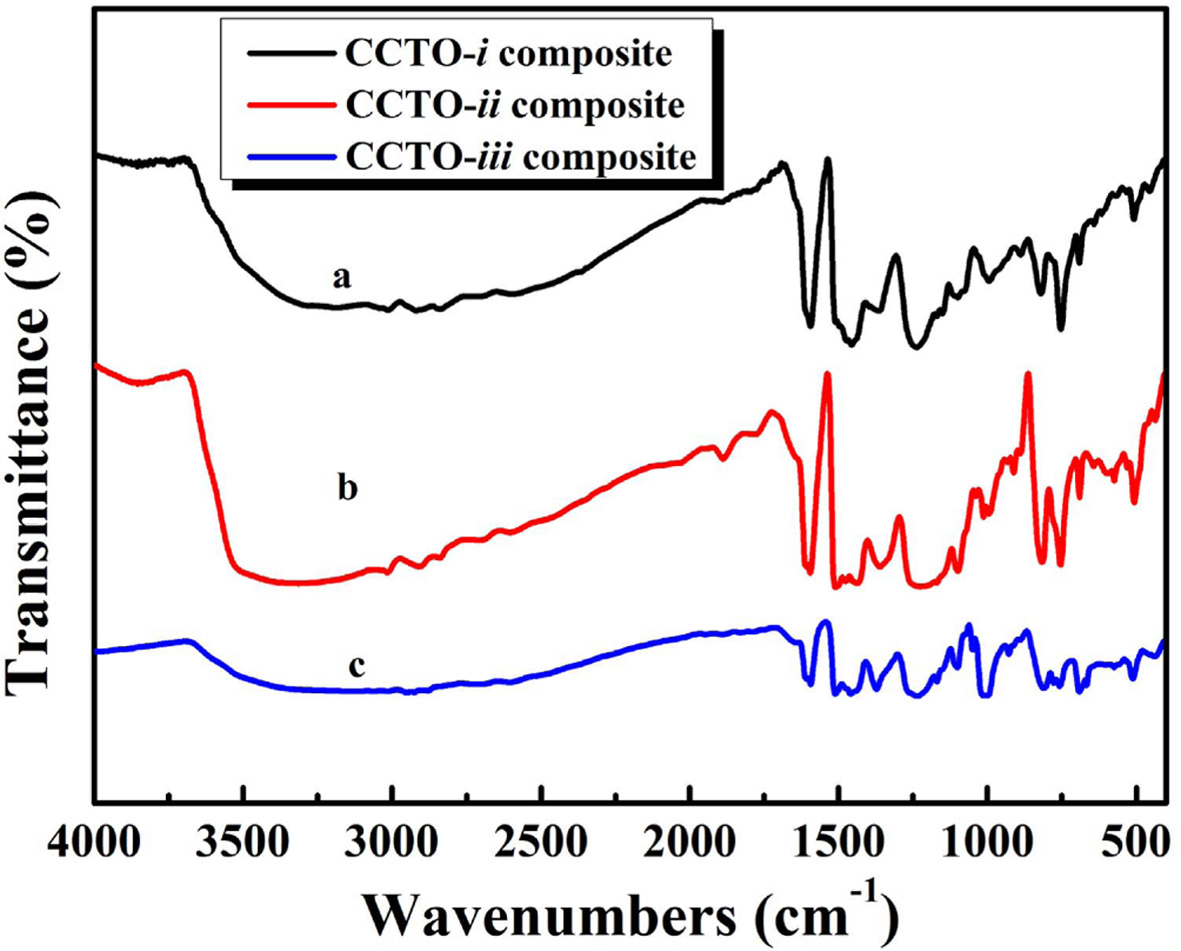

Temperature stability of dielectric constant is expressed as ΔCT/C25°C

and calculated by the Eq. (1).

Where ΔCT/C25°C is temperature

stability, C is capacitance. The temperature coefficient of CCTO–i

composite is -3% to 10% from 25 to 75 °C at 100 Hz.

In short, according to the results from the Figs. 6, 7 and

Tables 1, 2, we can make a conclusion that the CCTO–i composite possess

relative high dielectric constant, low loss tangent, as well

as the weak frequency and temperature dependence of

dielectric constant. From the Table 3, comparing with the existing

ceramic/polymer dielectric composites, the dielectric properties of

CCTO–i composite are comparable to these composites.

At the same time, the CCTO–i composite is prepared with the small

particle size of the ceramic, which could make the CCTO/PF dielectric composite

attractive for practical applications.

A

mechanism to interpret the variation of dielectric properties of CCTO–i

composite

In this part, the CCTO–i composite is investigated

on the variation of dielectric properties that is similar to other composites.

Generally, the dielectric properties of CCTO/PF dielectric composite

significantly enhance, which attribute to fill the ceramic particles of CCTO with

giant dielectric properties. For the CCTO, the high dielectric properties are

derived from the specific structure, which is semiconducting

grains with insulating grain boundary. High dielectric

permittivity of ceramic/polymer dielectric composite originates from internal

interfaces effect that may be affected by the variation of interparticle

distance and interfacial area [28]. How to calculate the interparticle distance

and interfacial area? The assumption is that the ceramic particle is spherical

and uniformly distribute in the polymer matrix which is

shown in Fig. 8. For another, the interparticle distance of the CCTO/PF

dielectric composites is expressed by the equation (2):

Where d is interparticle distance, r is CCTO

particle radius and v is the volume fraction of CCTO particles. And the

interfacial area of composites could be calculated in certain volume of the 0-3

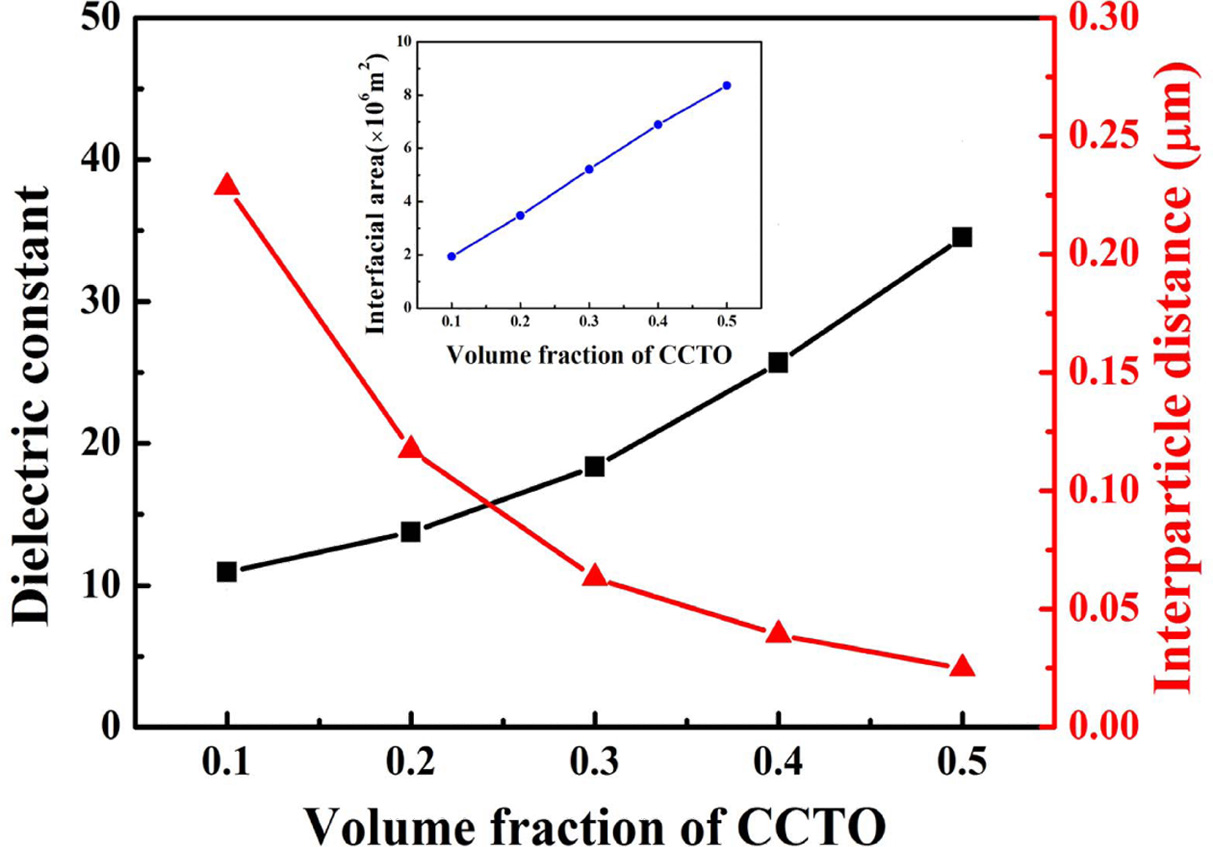

type composite (1 m3). As shown in Fig. 9, with the increase of

volume fraction of CCTO–i particles, interparticle distance decrease

dramatically, and interfacial area, dielectric constant becomes extremely large

at the frequency of 100 Hz and room temperature. With the increase the content

of ceramic powders, the increase of interfacial area of dielectric is

attributed to the reduction of interparticle distance, and then the dielectric

constant increase. The results thus clearly suggest that large interfacial

polarization mechanisms play a very important role in the

dielectric properties of CCTO/PF dielectric composite.

|

Fig. 1 XRD patterns of CCTO particles (a) and FTIR pattern of CCTO particle (b). |

|

Fig. 2 Particle size distribution of CCTO particles. |

|

Fig. 3 FTIR spectra of CCTO/PF dielectric composites. |

|

Fig. 4 XRD patterns of CCTO/PF dielectric composites. |

|

Fig. 5 SEM morphology of the CCTO–i particle (a) and SEM image of surface morphology of CCTO–i composite with 50 vol. % CCTO particle (b). |

|

Fig. 6 Frequency dependence of permittivity (a), loss tangent (b) and conductivity (c) of CCTO/PF dielectric composites with 50 vol. % CCTO particle at room temperature. |

|

Fig. 7 Temperature dependence of dielectric constant (a) and loss tangent (b) of CCTO–i composites with 50 vol. % CCTO particles is measured at various frequencies. |

|

Fig. 8 An illustration of CCTO particle fills in composite. |

|

Fig. 9 Variation of the interparticle distance, interfacial area (inset) and dielectric constant of CCTO–i composites with different volume fraction of CCTO. |

|

Table 1 The dielectric constant of CCTO/PF composites on the different fraction of CCTO at 100 Hz and room temperature. |

|

Table 2 The loss tangent of CCTO/PF composites on the different fraction of CCTO at 100 Hz and room temperature. |

|

Table 3 Dielectric properties of ceramic/polymer composites at 100 Hz and room temperature. |

CCTO/PF dielectric composites with three types of CCTO

particles have been investigated and discussed. For CCTO–i composite

containing smaller particle size of CCTO, the dielectric permittivity reach

about 34.5 with the volume fraction of CCTO–i particle was 0.5 at 100 Hz

and room temperature, while remains a low loss tangent about 0.063. The maximum

of dielectric constant of CCTO–i composite is much larger than that of

polymer matrix (PF) and that of other types of CCTO/PF dielectric composites

with the same volume fraction. The dielectric properties

of CCTO–i composite possess relatively high

permittivity, as well as exhibit good frequency and temperature stability. And

the experimental results show that the large enhancement in dielectric

permittivity may attribute to interface effect. It is believed that CCTO/PF

dielectric composite with high dielectric permittivity and relatively low loss

tangent could be applied in future high-technology fields.

This work was supported by the National Natural Science

Foundation of China (Grant No. 51673157), the Natural Science Basic Research

Plan in Shaanxi Province of China (No. 2017JM5134, No. 2018JM5047

and No.2017JQ2037), Scientific Research Program Funded by Shaanxi Provincial

Education Department (Program No. 15JK2188).

- 1. C. Ehrhardt, C. Fettkenhauer, J Glenneberg, W. Münchgesang, H. S. Leipner, M. Diestelhorst, S. Lemm, H. Beige, and S. G. Ebbinghaus, J. Mater. Chem. A. 2[7] (2014) 2266-2274.

-

- 2. M. N. Feng, X. Huang, H. L Tang, and X. B. Liu, Colloids Surf. A. 441[3] (2014) 556-564.

-

- 3. K. Brandt, V. Salikov, H. Özcoban, P. Staron, A. Schreyer, L.A.S.A. Prado, K. Schulte, S. Heinrich, and G.A. Schneider, Compos. Sci. Technol. 72[1] (2011) 65-71.

-

- 4. P. Thomas, R.S.E. Ravindran, and K.B.R. Varma, J. Therm. Anal. Calorim. 115[2] (2014) 1311-1319.

-

- 5. P. Mishra, P. Kumar, Ceram. Int. 41 (2015) 2727-2734.

-

- 6. P. Mishra and P. Kumar, J. Alloys Compd. 617 (2014) 899-904.

-

- 7. M. Mikolajek, A. Friederich, C. Kohler, M. Rosen, A. Rathjen, K. Krüger, and J.R. Binder, Adv. Eng. Mater. 17 (2015) 1294-1301.

-

- 8. M. Bi, Y. Hao, J. Zhang, M. Lei, and K. Bi, Nanoscale 9 (2017) 16386-16395.

-

- 9. K. Osińska and D. Czekaj, J. Therm. Anal. Calorim. 113 (2013) 69-76.

-

- 10. H. Chen, X. Dong, T. Zeng, Z. Zhou, and H. Yang, Ceram. Int. 33 (2007) 1369-1374.

-

- 11. W. Sun and B. Lu, Mater. Sci. Eng. B 127 (2006) 144-149.

-

- 12. Z.M. Dang, J.K. Yuan, J.W. Zha, T. Zhou, S.T. Li, and G.H. Hu, Prog. Polym. Sci. 57 (2012) 660-723.

-

- 13. Y. Rao and C. P. Wong, J. Appl. Polym. Sci. 92 (2010) 2228-2231.

-

- 14. L.J. Romasanta, P. Leret, L. Casaban, M. Hernández, M.A. de la Rubia, J.F. Fernández, J.M. Kenny, M.A. Lopez-Manchado, and R. Verdejo, J. Mater. Chem. 22 (2012) 24705-24712.

-

- 15. A.P. Ramirez, M.A. Subramanian, M. Gardel, G. Blumberg, D. Li, T. Vogt, and S.M. Shapiro, Solid State Commun. 115 (2000) 217-220.

-

- 16. Y. Wang, X. Wu, C. Feng, and Q. Zeng, Microelectron. Eng. 154 (2016) 17-21.

-

- 17. L. Zhang, X.B. Shan, P.X. Wu, J.L. Song, and Z.Y. Cheng, Ferroelectrics 405 (2010) 92-97.

-

- 18. Y.C. Qing, W.C. Zhou, F. Luo, and D.M. Zhu, J. Mater. Chem. C 1 (2013) 536-541.

-

- 19. X. Yang, W. Huang, and Y. Yu, J. Appl. Polym. Sci. 120 (2011) 1216-1224.

-

- 20. W. Wan, J. R. Luo, C. Huang, J.Yang, Y. B. Feng, W. X. Yuan, Y. J. Ouyang, D. Z. Chen, and T. Qiu, Ceram. Int. 44 (2018) 5086-5092.

-

- 21. F.J. Wang, D.X. Zhou, and Y.X. Hu, Phys. Status Solidi A 206 (2009) 2632-2636.

-

- 22. Z.M. Dang, T. Zhou, S.H. Yao, J.K. Yuan, J.W. Zha, H.T. Song, J.Y. Li, Q. Chen, W.T. Yang, and J.B. Bai, Adv. Mater. 21 (2009) 2077-2082.

-

- 23. S. Babu, K. Singh, and A. Govindan, Appl. Phys. A 107 (2012) 697-700.

-

- 24. A. Srivastava, K. K. Jana, P. Maiti, D. Kumar, and O. Parkash, Mater. Res. Bull. 70 (2014) 735-742.

-

- 25. B.C. Luo, X.H. Wang, Y.P. Wang, and L.T. Li, J. Mater. Chem. A 2 (2014) 510-519.

-

- 26. S. Jesurani, S. Kanagesan, and K. Ashok, J. Sol-Gel Sci. Technol. 64 (2012) 335-341.

-

- 27. C. Yang, H.S. Song, and D.B. Liu, Composites Part B 50 (2013) 180-186.

-

- 28. Y. Yang, B.P. Zhu, Z.H. Lu, Z.Y. Wang, C.L. Fei, D. Yin, R. Xiong, J. Shi, Q.G. Chi, and Q.Q. Lei. Appl. Phys. Lett. 102[4] (2013) 042904.

-

This Article

This Article

-

2020; 21(3): 302-308

Published on Jun 30, 2020

- 10.36410/jcpr.2020.21.3.302

- Received on Oct 15, 2019

- Revised on Jan 18, 2020

- Accepted on Feb 7, 2020

Services

Services

- Abstract

introduction

experimental methods

results and discussions

conclusions

- Acknowledgements

- References

- Full Text PDF

Shared

Correspondence to

Correspondence to

- Zongcheng Miao

-

Key Laboratory of Organic Polymer Photoelectric Materials, School of Science, Xijing University, Xi’an, 710123, Shaanxi, People's Republic of China

Tel : +86-29-62307-012

Fax: +86-29-62307-012 - E-mail: zhao1983yang@hotmail.com

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.