- Effect of the ratio of eggshell and rice husk as starting materials on the direct synthesis of bioactive wollastonite by solid state thermal method

Sazia Sultana, Md. Maksudur Rahman, Zenefar Yeasmin, Samina Ahmed* and Farzana Khan Rony

Institute of Glass and Ceramic Research and Testing (IGCRT), Bangladesh Council of Scientific and Industrial Research (BCSIR), Dhaka-1205, Bangladesh

This paper describes the effect

of the ratio of two starting materials, eggshell (ES, source of Ca) and rice

husk (RH, source of silica) on the direct synthesis of wollastonite

via a facile two-step solid state method, i.e. ball milling of the raw

materials followed by calcination of the mixture at 1,000 oC.

The investigation was focused on optimizing the ratio of ES and RH to maximize

the formation of wollastonite. Keeping the wt.% of RH constant, four different

ratios of RH and ES (10:2.6, 10:3.0, 10:3.3 and 10:3.7) were used and the

observed result revealed that the initial ratio of RH and ES plays a key role

in controlling the formation of wollastonite as the major phase which was

confirmed by x-ray diffraction (XRD) and Fourier Transform Infrared (FT-IR)

techniques. The bioactive property of this wollastonite was studied in

simulated body fluid at 37 oC while the time dependent growth

of hydroxyapatite (HA) on the surface of wollastonite was examined by SEM and

XRD. Observed data supported the bioactive nature of wollastonite as

biomaterial.

Keywords: Wollastonite, Eggshell, Apatite, Bioactive

Wollastonite, a dazzling white to gray or brown coloured

calcium meta silicate (CaSiO3) has received enormous attention to

the researchers. The application of wollastonite in traditional ceramics e.g.

porcelain [1], heat insulating ceramics [2], concrete [3] and cement [4] is

quite well known due to its various notable properties (fluxing

characteristics, low shrinkage behavior and

better strength). However, in the arena of advanced ceramics, pure wollastonite

has been categorized as an innovative material which has proved its

potentiality to be used as a bone regenerative bioceramic material [5] and

presently it continues to be an eye-catching research field [6-11]. Furthermore,

composite format of wollastonite, is also developed for biomedical

applications [12]. However, the prime reason for the bioactivity of

wollastonite, is the ability to form Si–OH bond on its surface upon exposure in

simulated body fluid (SBF). Concerning the significance

of wollastonite as biomaterial, researchers have already developed many routes,

namely sol-gel [6, 9-11, 13-15], hydrothermal [16-18] solid

state [19-21], ultrasonic irradiation [5] microwave assisted solid

state [22] and wet chemical precipitation method

[23] etc. to synthesize CaSiO3.

Being a non-toxic, solvent free and environment friendly

method, hitherto, solid-state approach has ranked to be

preferable.

Nevertheless, in addition to the synthesis route, the

precursors used as calcium and silica sources are also important. Different combinations

of the starting materials have been used by

different researchers e.g. Udduttula et al. [6], Lakshmi et al. [9] and

Wang et al. [13] used [Ca(NO3)]2.

4H2O and tetra ethyl orthosilicate (TEOS) as calcium and silica sources respectively; Anjaneyulu et al.

[10] choice was eggshell and TEOS; eggshell and diatomite

were chosen by Puntharod et al. [16] while snail shell and rice husk ash (RHA)

were used by Phuttawong et al. [19]. The researchers of Vichaphund’s group

prepared wollastonite from eggshell and commercial grade (98%) silica [22]. In

combination with [Ca(NO3)]2. 4H2O researcher

also used Na2SiO3.9H2O as silica source [11].

However, researchers still continue

to explore different combination of

the raw materials to be used as the source of calcium and silica and numerous

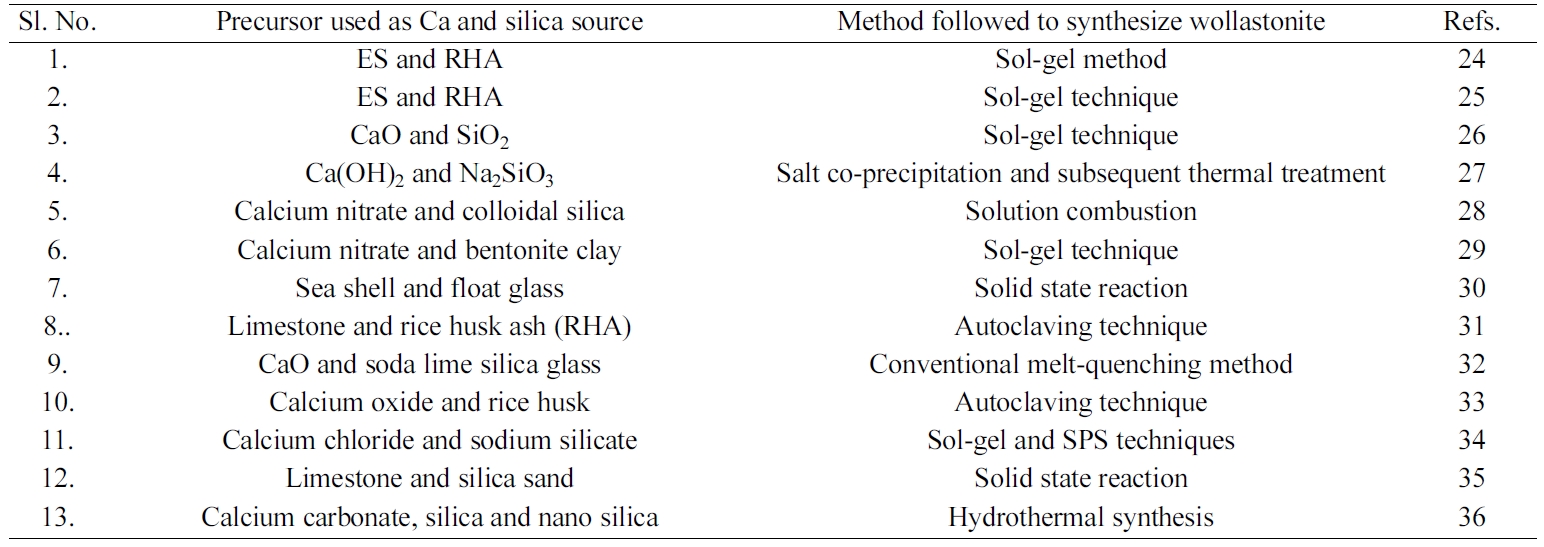

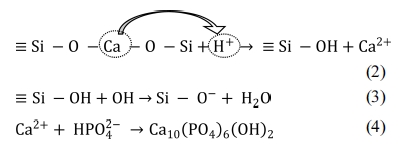

recipes used to synthesize wollastonite [24-36] are summarized in Table 1.

In this era of globalization, scientists across the globe are

paying more and more attention to resolve environmental pollution problems and

this has led them to be concerned in developing new synthetic routes as well as

in utilizing waste materials. Keeping this view in mind, we have used waste ES

(as Ca source) and RH (as silica source) together to

synthesize wollastonite via solid state thermal treatment method.

RH, though categorized as waste/by-product but it

contains cellulose (38.3%), hemicellulose (31.6%), lignin (11.8%) and silica

(18.3%). Heat treatment or combustion of RH produces about 20-25 wt% of rice

husk ash (RHA), which contains more than 90% silica. [37]. On the other hand,

ES is enriched with CaCO3 (94-97%) [38]. Hence these two agro-wastes

are being getting the attention of the researchers to be used as the source of

silica and Ca respectively in synthesizing biomaterials and or ceramic

materials. Concerning the significance of RH and ES, to the

best of our knowledge, for the first time, we have studied

the effect of the ratio of ES:RH to synthesize CaSiO3

even though individually either ES or RHA was used as calcium

or silica source material in many previous studies

[10, 16, 19, 22, 33].

Bangladesh is categorically considered as Agriculture

or Agro based country having an annual production of 4-4.5 million

metric tons (MT) of paddy which gives about 9.0 million tons of RH as waste

product [39]. On the other hand, in Bangladesh the production of egg

is 10168 million per annum [40] and consequently every year ~113000 tons of ES

are thrown away to the environment. Hence, utilization of ES and RH will be beneficial

in two ways: (i) synthesized wollastonite will be cost

effective bioceramic material for biomedical applications, and (ii) it will be

an effective material-recycling pathway for waste management.

|

Table 1 Summary of the recepies used to synthesize wollastonite by different methods. |

Materials

and their processing

RH and ES were collected from rice mill and local

restaurant and used as the source of silica and calcium respectively. Prior to

using as source materials, RH was processed following a previously described

method [13]. Briefly, RH was soaked in water for 5 minutes,

maintaining the water to RH ratio at 20 L/kg. Then the mixture was kept

undisturbed for couple of minutes to allow the unwanted materials to be settled

down at the bottom. After that, RH was collected carefully from the upper

portion of the mixture using a sieve of 60-mesh. The cleaned RH was then dried

overnight in an oven at 100ºC followed by treating with 0.2 M H2SO4

(acid to RH ratio was 10 L/kg) at 100ºC for 2 hrs. After cooling and filtering,

the RH was washed with copious amount of water to remove any trace of sulphuric

acid and finally dried at 100 oC [1]. Entire

processing steps resulted about 40% weight loss of RH. On the

other hand, collected ES was washed thoroughly with tap water. Then the inner

shell membrane was removed from ES and boiled in water for 30 min. Finally, the

boiled ES was dried at 100 oC [2].

Synthesis

of wollastonite by indirect method

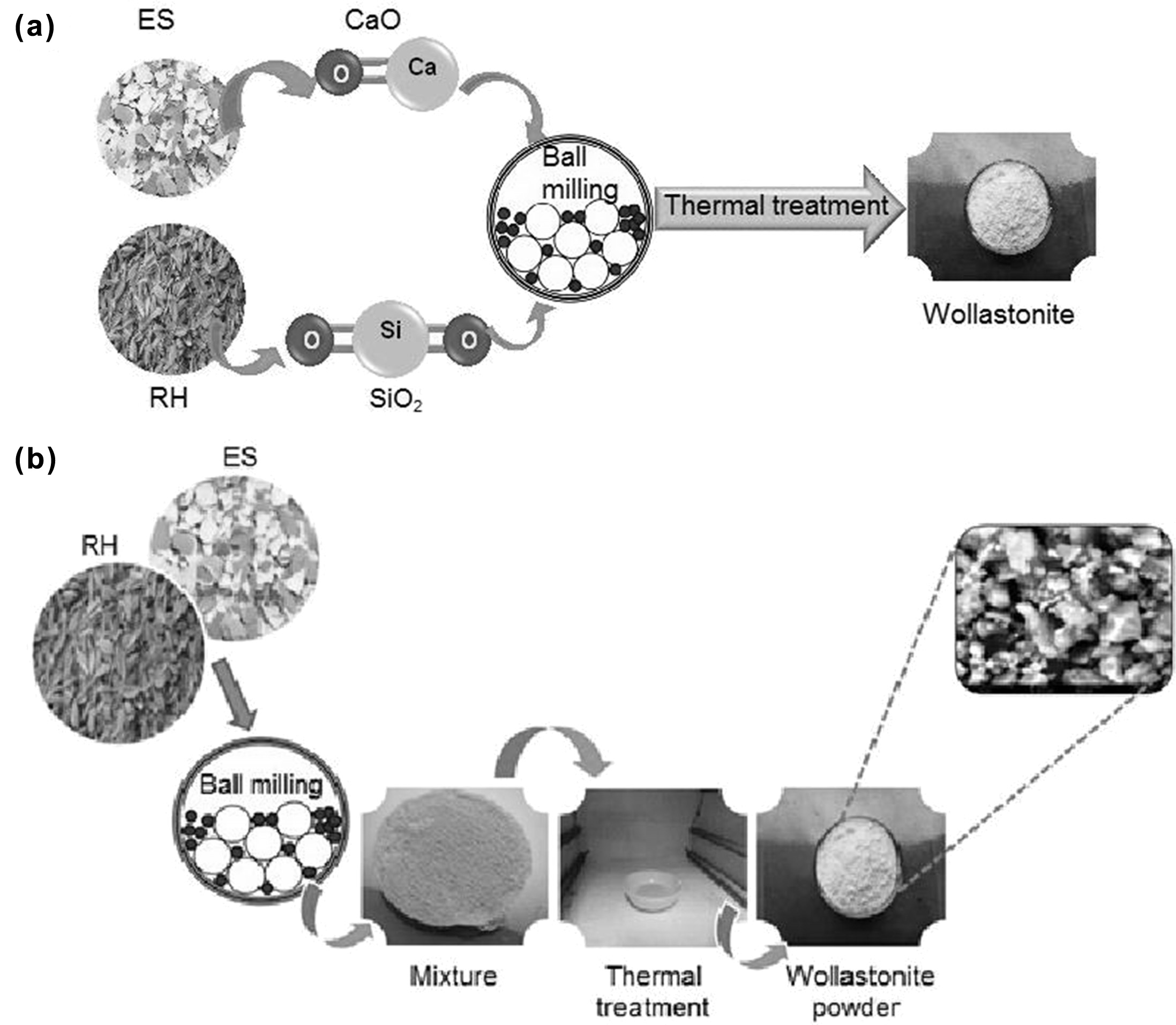

In order to synthesize wollastonite using RH and ES as the

starting materials, at first an indirect calcination method [21]

was followed which was then scaled up by developing the direct sintering

approach. Since theoretically the wt% of CaO and SiO2 in

wollastonite is 48% and 52% respectively [1-2], so to determine the exact wt.%

of CaO and SiO2 in ES and RH our primary attempt was confined with

the indirect method as adopted by Hossain et al. [21]. In the indirect method,

SiO2 was extracted from treated RH following the previously

described methods [1,21] but extending the

calcination temperature up to 1,000 oC. On the other

hand, 3 hours thermal treatment (at 1,000 oC) of ES resulted

the formation of CaO [21]. Then stoichiometric amount of

CaO and SiO2 were mixed homogeneously for 30 minutes at 1,000 rpm

using a high-energy ball mill (Model: MSK-SFM-1 QM 3SP2) followed by thermal

treatment at 1,000 oC for 3 hrs.

which facilitated the formation of desired wollastonite.

Synthesis

of wollastonite by direct calcination of RH and ES

In the direct method, a series of ratio of powdered RH and

ES (10:2.6, 10:3.0, 10:3.3 and 10:3.7) were chosen as the starting materials

and each selected proportion was straightaway ball milled for 30 minutes at

1,000 rpm to get the mixture in homogeneous form. Then the desired wollastonite

was produced by sintering the mixture in a muffle furnace at 1,000 oC

for 3 hrs. The schematic representations of the indirect and direct synthesis

process are displayed in Fig. 1.

Characterization

of synthesized wollastonite

Synthesized wollastonite was characterized by various

techniques e.g. X-ray diffractometer (XRD), Fourier transform

infrared spectrophotometer (FT-IR), Scanning electron

microscopy (SEM) and Thermogravimetric (TG/DTA) analyses.

The respective phases of wollastonite were identified by

the XRD (PANalytical X’Pert PRO XRD PW 3040). Intensity

data were collected by fixing scanning range, 2q = 10o – 75o

using Cu Kα radiation (λ = 1.5406 Å) with a step scan of 4o/min.

To confirm the presence of desired phases, recorded data were compared with

standard JCPDS files.

The presence of the functional group was explored by

recording the FT-IR spectrum using (Prestige 21; SHIMADZU) a FT-IR

spectrophotometer. The sample-to-KBr ratio was 1:100 while the scanning range

was 4000 to 400 cm-1

and the resolution was 4 cm-1 with

32 scanning.

The thermogravimetric analysis (TGA) was carried out on an

EXSTAR TG/DTA 6300 with alpha-alumina powder as a reference sample from 30 to

1,000 oC in nitrogen atmosphere (flow rate 50 nmL/min). The

heating rate was 20 oC/min. The surface morphology and

microstructural features of the synthesized material were observed by SEM

(Phenom Pro) applying an accelerating voltage of 15 kV.

Bioactivity

studies

In-vitro bioactivity response is the evaluation of

apatite-forming ability (mainly hydroxyapatite, HAp), on the surface of

bio-material in simulated body fluid (SBF). A previously published

method [1] was followed for this

purpose. About 0.2 g of synthesized wollastonite powder was

immersed into 30 ml SBF at 37 oC. The growth of HAp

was monitored at different time intervals (1, 3 and 7

days). To investigate the formation of HAp on the surface of wollastonite

powder, first the SBF solution was drained out carefully then the powder was

gently rinsed with deionized water to remove excess SBF followed by drying at

50 oC. The formation of apatite layers was examined by XRD and

SEM.

|

Fig. 1 Schematic representation of the synthesis of wollastonite (a) Indirect method, (b) Direct method. |

XRD

analysis

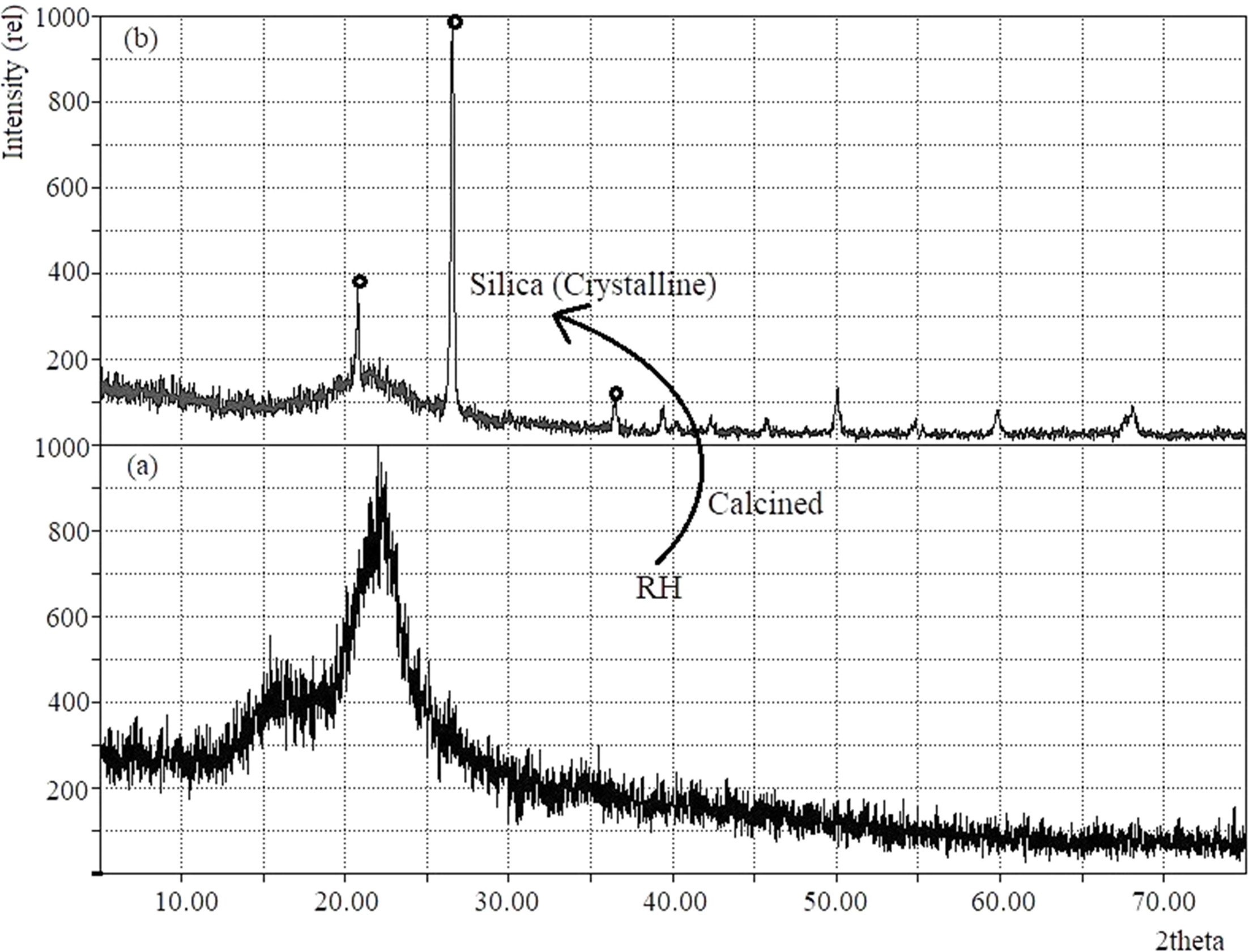

Given in Fig. 2 is the x-ray diffratogram of as received

RH and after calcination at 1,000 oC. The XRD pattern of SiO2

(Fig. 2b) having 2θ values of 21.9o, 26.6o and 36.0o

indicates that the silica formed in crystalline nature as expected. Because, it

is well known that the presence of amorphous silica, crystalline silica or both

phases strictly depends on the calcination temperature [41, 42]. The

characteristic peaks of tridymite (2θ = 21.6o) and cristobalite (2θ = 21.8o)

phases coincides giving a single peak at 21.9o. This could be due to

the melting of the surfaces of ash silica particles followed by formation of

bonding of the particles together [41, 42].

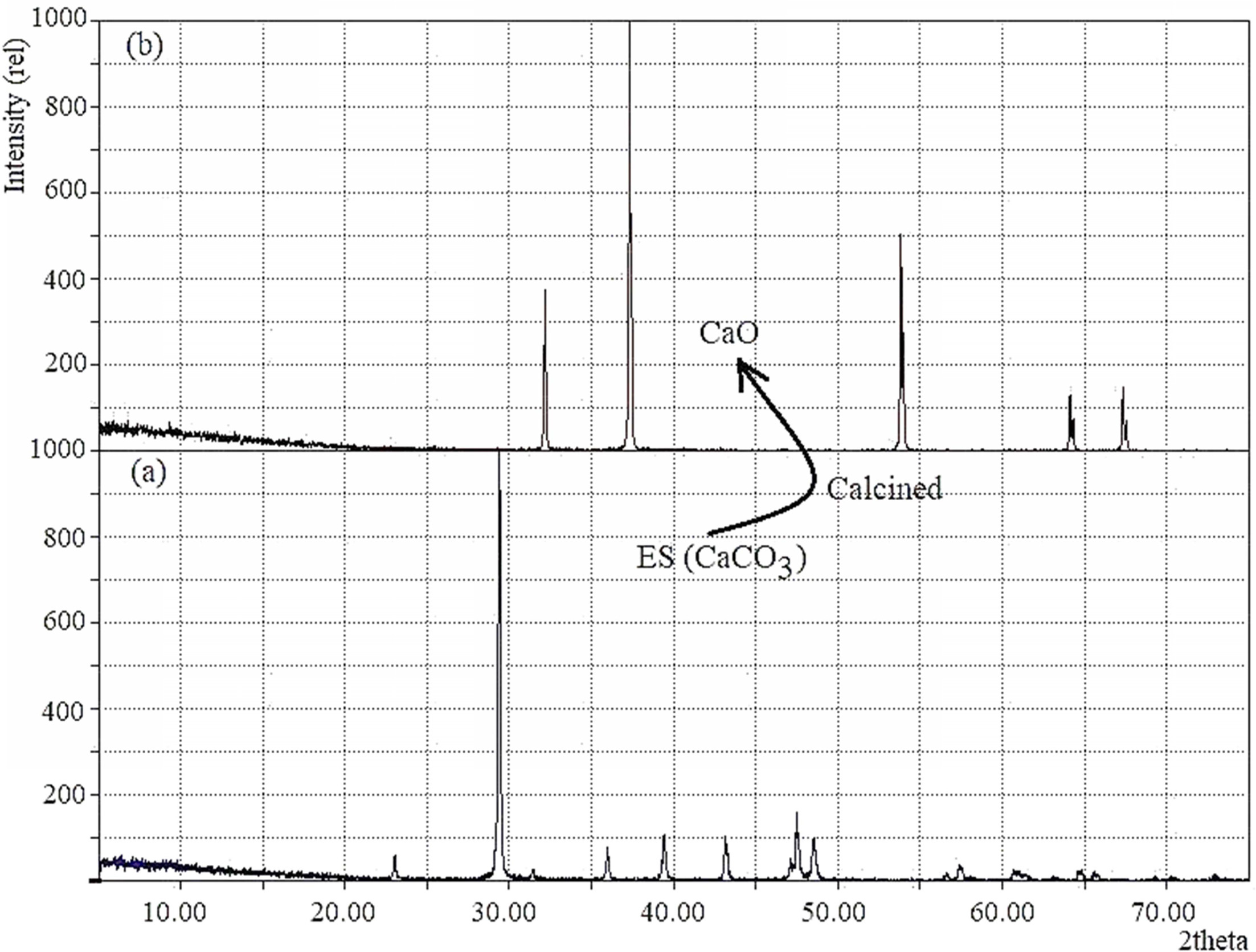

The XRD patterns of the ES before and after calcination

are displayed in Fig. 3(a, b). It is apparent from the

recorded diffraction data (Fig. 3a) that the ES without being

thermally treated shows the usual characteristic peaks for rhombohedral calcite

(File # 5-0586). The characteristic peak detected at 2θ position 29.485o

(1 0 4) plane coupled with several peaks at 23.07o,

36.06o, 39.48o, 43.26o, 47.64o and

48.6o confirmed the mineral phase of egg shell as

calcite and no other crystalline phase was observed.

Conversely, after calcination (Fig. 3b) of ES, existence

of the distinctive peak at 2θ position 37.09o (2 0 0) plane supports

the formation of CaO. Moreover, the calcined sample showed no peak at 2θ = 29.48o

which indicates that CaCO3 has completely changed to CaO [43].

However, the total percentage of

silica (SiO2) and CaO formed due to calcination of RH and ES at 1,000 oC were found to be 20% and 55% respectively. Following earlier studies

[14, 15, 19], our indirect approach used an equal ratio of these two calcined products (i.e. CaO and SiO2) to synthesize wollastonite. But as our

intention was to investigate the impact of the ratio of RH and ES on the direct

synthesis of wollastonite, we explored a facile pathway where blend of RH and

ES (at different ratios, 10:3.7; 10:3.3; 10:3.0 and 10:2.6)

were straight away calcined to get the desired wollastonite.

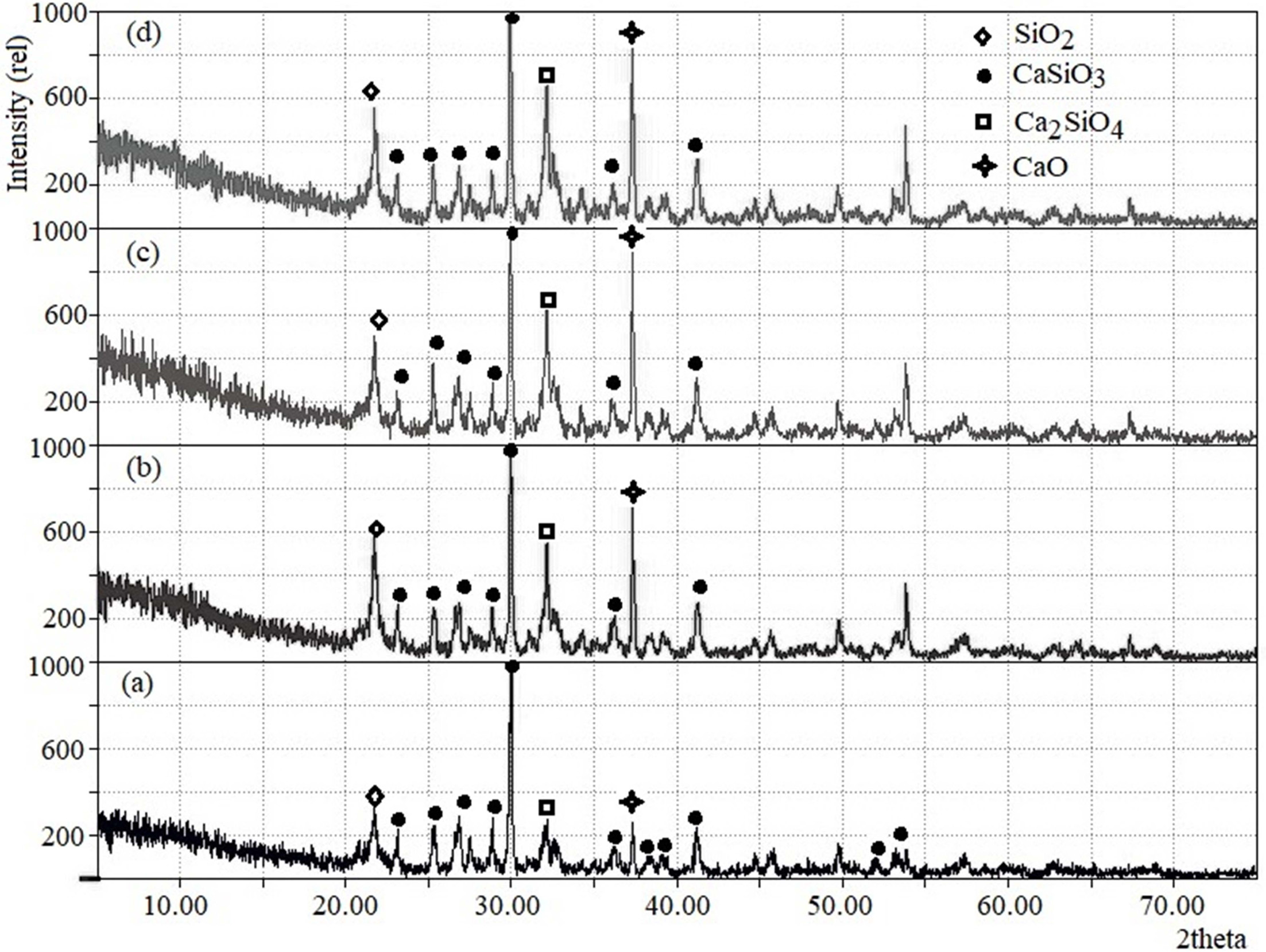

Fig. 4 demonstrates the corresponding x-ray diffractograms of

wollastonite as synthesized using the above-mentioned ratios of RH

and ES. It is clearly evident from Fig. 4 that the initial ratio of RH and ES

plays a key role in controlling the formation of wollastonite as the major

phase. Although the four chosen proportions of RH and ES effectively produced

wollastonite (consistent with the JCPDS file no. 043-1460) [10] but together

with wollastonite, larnite (Ca2SiO4) as well as unreacted

CaO and SiO2 were also indexed [13]. The wollastonite phase

(ICDD number: 00-043-1460) [10, 31] was recorded

in Fig. 4(a-d) at 2 theta positions 23.1, 25.4, 26.9, 28.9, 30.0, 36.2, 38.2,

39.2, 41.3 showed a good match with previous investigations [10, 31] while

calculated lattice parameters (a = 15·46, b = 7·33 and c =

7·19 Å) were also found to be in good agreement [10, 31].

Obviously, the formation of wollastonite with mixed phases

strictly depends on the fraction of RH and ES used. The characteristic peaks

for CaO, SiO2 and larnite were very prominent (as shown in Fig. 4b,

4c and 4d) when the ratios of RH and ES were 10:3.0, 10:3.3 and 10:3.7. On the

other hand, these three peaks appeared in suppressed state making the

wollastonite phase as predominant when the RH:ES ratio was fixed at 10:2.6

(Fig. 4a). As it has been observed from the XRD data that among the four

combinations of RH to ES ratios, better result was obtained at RH:ES ratio

10:2.6, we further proceeded with the FT-IR analysis of wollastonite

synthesized using this ratio of RH:ES.

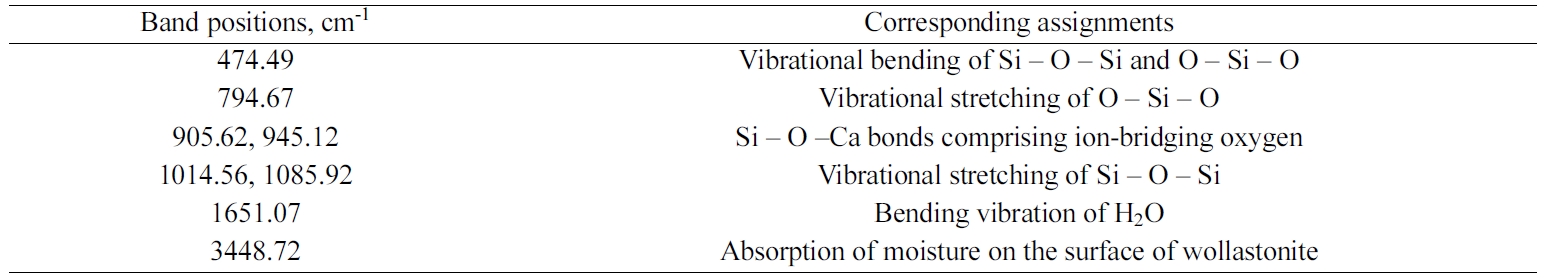

FT-IR

analysis

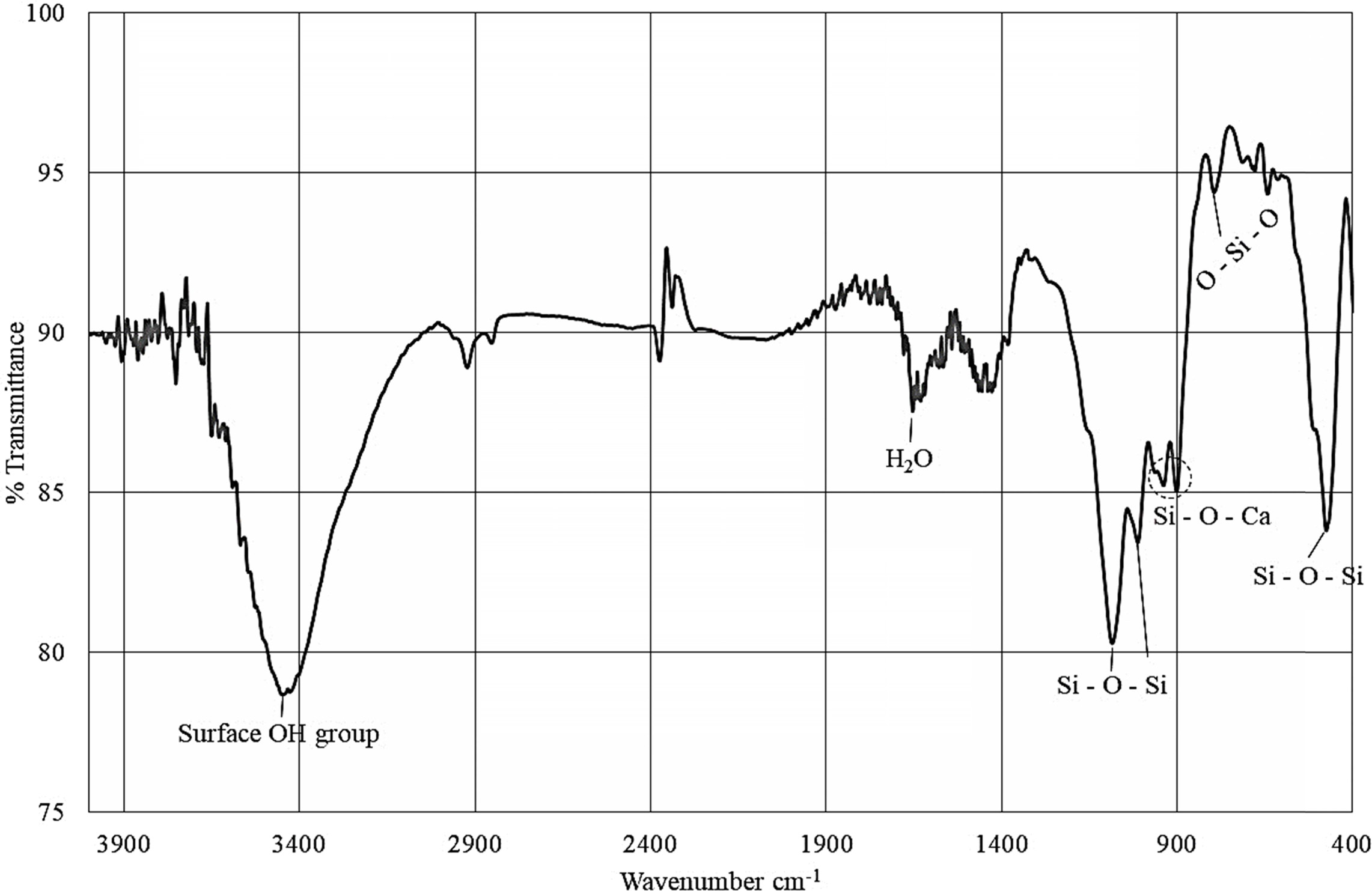

Fig. 5 represents a typical FT-IR spectrum of the synthesized

wollastonite. Recorded FT-IR band positions as

tabulated in Table 2, were fairly consistent with previous studies

[6, 10, 14]. Noticeably, the band position

observed around 476 cm-1

represents the vibrational bending mode of Si – O – Si bond while the

vibrational stretching mode of O – Si – O bond is positioned at 792.74 cm-1.

Si – O –Ca bond having ion-bridging oxygen is noticed at band positions 905-945

cm-1.

Vibrational stretching mode of Si–O–Si bond was observed in

the range of 1,014 to 1,091 cm–1. The bands

around 1,639 and 3,400 cm–1 are responsible for the moisture content

present in the sample.

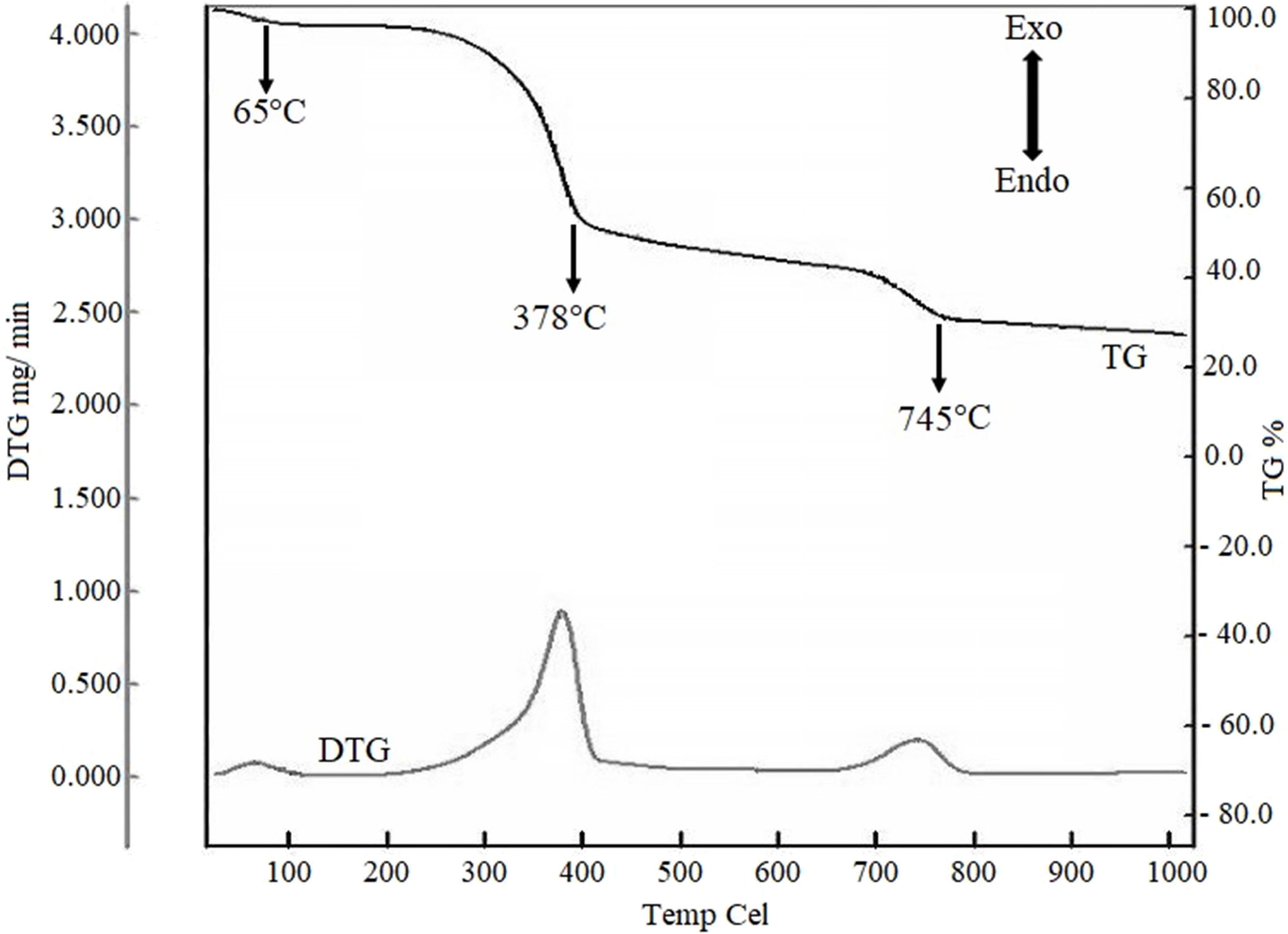

Thermogravimetry

analysis

Since the RH and ES mixture of 10:2.6 ratio was the best

combination for synthesizing wollastonite by direct calcination,

further investigation was focused on the thermogravimetric analysis of this

mixture in raw state (i.e. without calcination). Given in Fig. 6 are the TG and

DTG behavior of RH and ES (10:2.6) blend which can be described consequently

depending on different stages. It is apparent from the Fig. 6 that there are

three visible endothermic peaks at 65, 378 and 745 oC. The

first weight loss (~4%), as shown in TGA starts from ambient temperature to

65 oC, is responsible for the release of the moisture from the

sample during heating. The major decomposition occurred at 378 oC

where approximately 47% weight was lost. This is due to the degradation of

chemically bound water, cellulose, hemicelluloses and lignin from RH [44].

Finally, an endothermic peak at 745 oC is due to

high-temperature decarbonation i.e. due to the decomposition of calcium

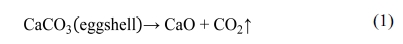

carbonate from ES according to the reaction (1) [45]. The weight was constant

after 800 oC. Observed TG profile is in

line with many previous studies where such three steps

weight loss behaviour was well documented [33, 46-48].

No

significant weight change was observed in TG curve after 800 oC. Surprisingly, the DTG

curve also featured three exothermic peaks

at 65, 378 and 745 oC. The exothermic hump at 65 oC could be the

repre- sentative for the elimination

of physically adsorbed humidity water. The

2nd exothermic signal at 378 oC is comparatively strong than

the other two exothermic peaks. This is probably due to the burning of organic

matter from ES and RH [21]. The 3rd exothermic peak recorded at around 750 oC could be due to the formation

of CaSi2O4 and

CaSiO3 crystalline phases [13]. It should be

mentioned here that Sreekanth et al. [48] also obtained an exothermic peak of the DTA at 890 oC,

which is the preparatory temperature for the crystallization of CaSiO3.

In-vitro Bioactivity

Response of wollastonite synthesized using RH:ES ratio 10:2.6

The wt % ratio of RH and ES appeared significant in

producing the desired wollastonite. When the combinations

of RH and ES were 10:3.0, 10:3.3 and 10:3.7, formation of larnite

(Ca2SiO4) became significant with

wollastonite. Additionally, CaO and SiO2 were also present with the

desired product. On the other hand, formation of wollastonite as major phase

was visualized when the RH:ES ratio was fixed at 10:2.6 while

larnite formation was suppressed. Since, wollastonite shows

high biocompatibility as compared to other silicate based

ceramics, so it is presumed that wollastonite synthesized using this optimum

ratio will show better bioactive properties as larnite

formation was suppressed in this case. However, further

investigation in this direction is yet to be explored.

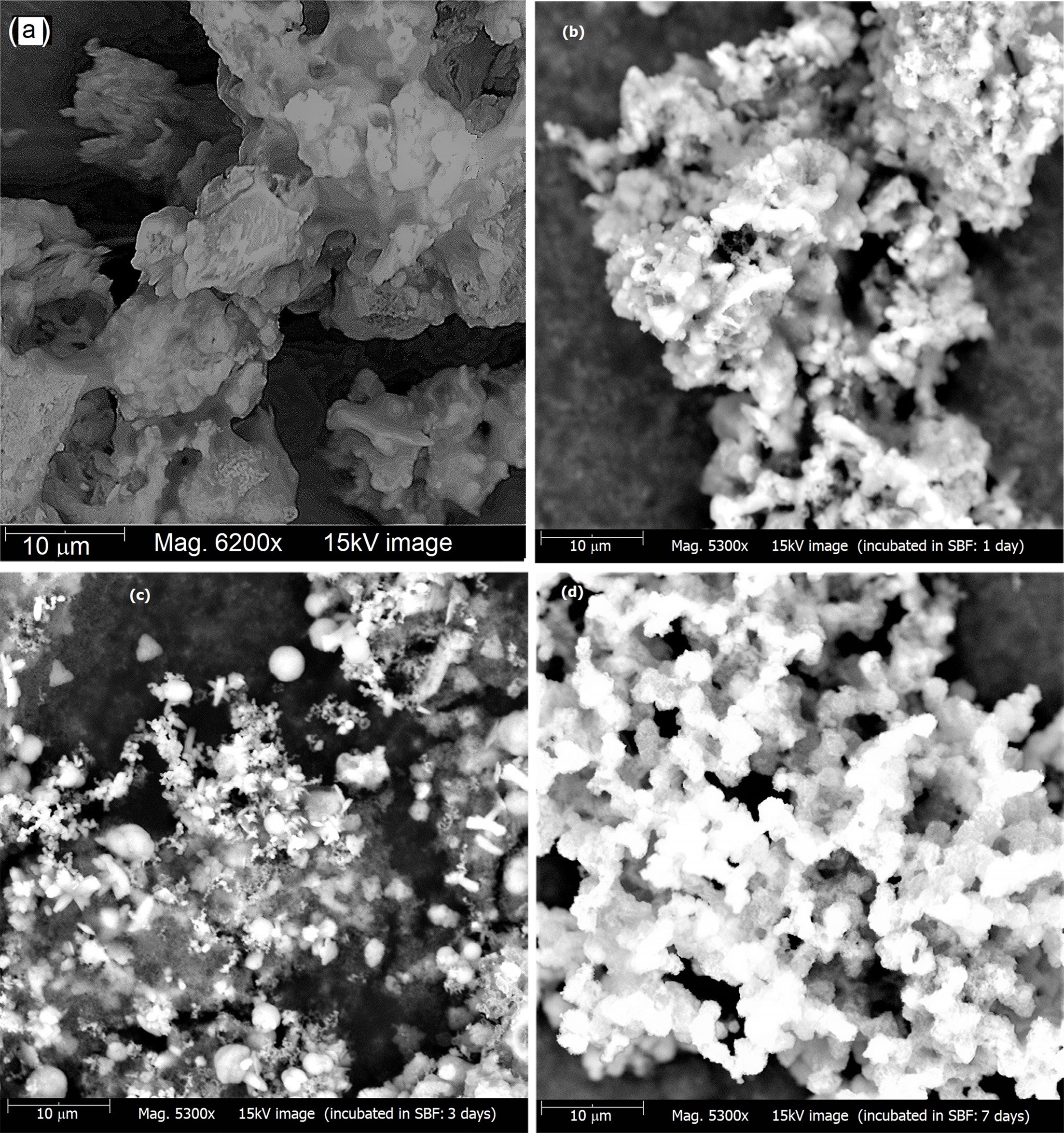

SEM images of wollastonite powder showing the in-vitro

bioactivity response i.e. the apatite forming ability are depicted in Fig.

7(a-d). Fig. 7(a) illustrates the surface morphology of bare wollastonite which

is in agglomerated form. However, in comparison with this sample, it is clearly

evident from Fig. 7(b, c, d) that as a result of immersing in SBF

the surface of wollastonite samples come to be covered by newly

formed apatite (HAp) layers and a continuous deposit of dense apatite takes

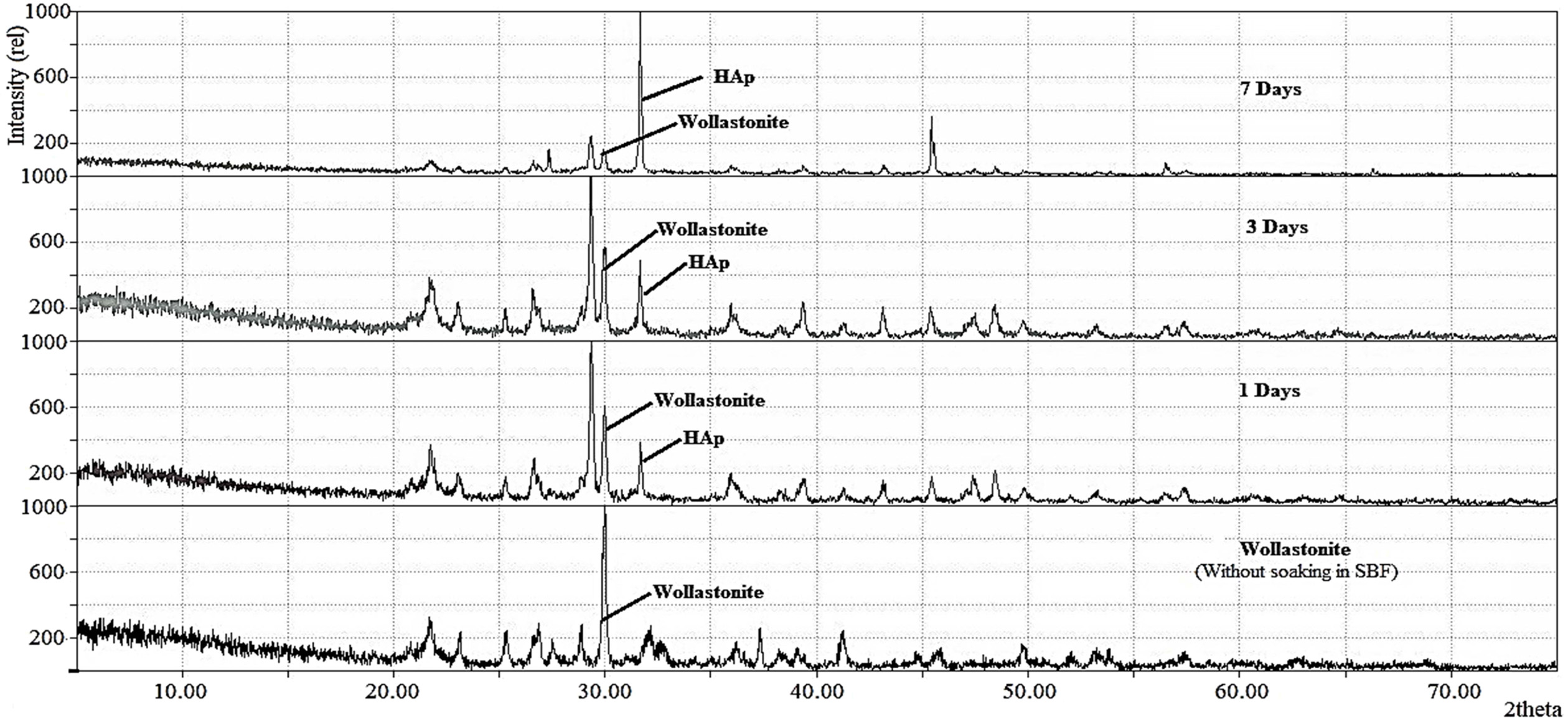

place with time. This was further validated by XRD data. The

stacked XRD diffractograms of wollastonite before and after soaking in SBF are

shown in Fig. 8. In SBF treated wollastonite, coupled with wollastonite peak,

the characteristic peak of HAp representing the (2 1 1) plane is also detected

at 2θ position 31.79o and this observation is in good agreement with

earlier studies [11,49]. Supporting the SEM observation, it is evident that as

more and more apatite forms, intensity of this freshly formed peak goes toward

the upward direction with the course of time. On the other hand, the intensity

of wollastonite peak gradually declines. This result supports that the

wollastonite synthesized by thermal treatment of two waste

materials e.g. RH and ES shows bioactive properties by inducing direct bone

ingrowth while incubated in physiological environment.

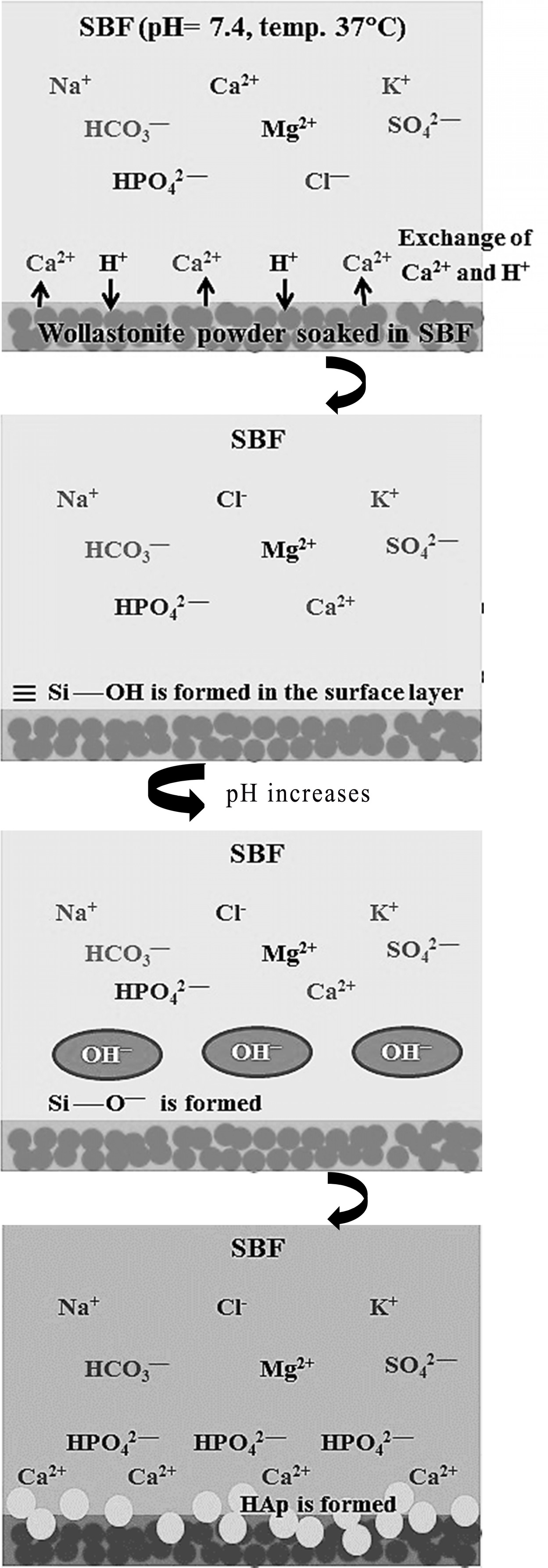

Mechanism of HAp formation

The bioactive response of wollastonite is accredited to

the nucleation of hydroxyapatite (HAp) and this phenomenon becomes activated by

the dissolution of calcium and silicate ions. Hence, the mechanism of HAp

formation on the surface of wollastonite powder soaked in SBF can be elucidated

following previous studies [6, 15, 49, 50]. Briefly, according

to Equation 2, due to immersion in SBF, Ca2+ present in wollastonite

tends to exchange with existing H+ of SBF forming silanol (Si – OH)

in the surface layer. This process increases the pH at wollastonite-SBF

interface and consequently a negatively charged surface having functional group

(Si – O–) is formed (Equation 3). The Ca2+ ions present

in SBF solution are firstly attracted to the solid - liquid interface which

causes the ionic activity product (IP) of apatite to be high enough at the

interface. Such an environment favours the growth of apatite on wollastonite

surface. Once the apatite begins nucleation, spontaneous growth occurs with the

aid of calcium and phosphate ion consumption from the mother SBF solution

(Equation 4). Fig. 9 depicts the pictorial representation of HAp formation

mechanism on wollastonite surface.

|

Fig. 2 XRD pattern of (a) treated RH and (b) silica obtained from RH treated at 1,000 oC. |

|

Fig. 3 XRD pattern of (a) ES and (b) CaO obtained from ES treated at 1,000 oC. |

|

Fig. 4 XRD pattern of RH-ES powders calcined at 1,000 oC. RH:ES = (a) 10:2.6. (b) 10:3.0. (c) 10:3.3 and (d) 10:3.7. |

|

Fig. 5 FT-IR spectrum of the wollastonite synthesized by calcining the mixture of RH and ES (ratio = 10:2.6) at 1,000 oC for 3 hrs. |

|

Fig. 6 TGA and DTG representation for the TGA for RH and ES (10:2.6) mixture |

|

Fig. 7 SEM images of (a) bare wollastonite samples and (b, c, d) after soaking in SBF for 1, 3 and 7 days respectively |

|

Fig. 8 XRD diffractograms of bare wollastonite samples and after soaking in SBF for 1, 3 and 7 days. |

|

Fig. 9 Schematic representation of apatite formation on wollastonite surface in SBF. |

|

Table 2 FT-IR band positions of wollastonite synthesized at RH:ES ratio 10:2.6. |

The

research work reported here in particular demonstrated

the influence of initial ratio of the raw materials, RH and ES in synthesizing

wollastonite directly by solid state method. Although different combinations of the starting materials have been

used by different researchers, but effect of the ratio of ES and RH has not

been explored yet. Hence the purpose of this research work was to develop a

protocol to synthesize wollastonite

from RH and ES and to the best of our knowledge, for the first time we have

investigated such effect on the

formation of wollastonite using RH and ES. Our approach revealed that the

initial ratio of RH and ES plays a

key role in controlling the formation

of wollastonite as the major phase. The optimum ratio of RH: ES to synthesize

wollastonite as the major phase was found to be 10:2.6 which was confirmed by x-ray diffraction (XRD) and Fourier Transform

Infrared (FT-IR) techniques.

Moreover, the bioactive response of the wollastonite synthesized using above

mentioned ratio of RH:ES showed excellent in-vitro bioactive properties. Such

observation revealed its suitability to be used as biomaterials.

Since, it is well-known that fine particles of the

ingredients speed up the diffusion reaction for the phase transition during

calcination and also helps to get the product in pure form thus further

advancement of our research focuses on investigating the effect of particle

size (ranging from fine to course) of the raw materials in synthesizing

wollastonite.

This research work was supported by BCSIR through R&D

project (Ref. 39.02.0000.11.014.007.2017/848, Dated 26/09/2017). Sazia Sultana

and Md. Maksudur Rahman also acknowledges BCSIR for ‘Nurul Abser Khan’ Post

Graduate Fellowship. Thanks to Dr. M. A. Gafur,

Principal Scientific Officer, Pilot Plant & Process

Development Centre, BCSIR, Dhaka for providing TGA facilities.

- 1. S. Ke, X. Cheng, Y. Wang, Q. Wang, and H. Wang, Ceram. Int. 39[5] (2013) 4953-4960.

-

- 2. M. Felipe-Sesé, D. Eliche-Quesada, and F.A. Corpas-Iglesias, Ceram. Int. 37[8] (2011) 3019-3028.

-

- 3. P. Kalla, A. Misra, R.C. Gupta, L. Csetenyi, V. Gahlot, and A. Arora, Constr. Build. Mater. 40 (2013) 1142-1150.

-

- 4. M.R.F. Gonçalves, C.K. Fillipeto, J. Vicenzi, and C.P. Bergmann, Constr. Build. Mater. 25[1] (2011) 320-327.

-

- 5. M. Mehrali, S.F.S. Shirazi, S. Baradaran, M. Mehrali, H.S.C. Metselaar, N.A.B. Kadri, and N.A.A. Osman, Ultrasonics Sonochemistry 21[2] (2014) 735-742.

-

- 6. A. Udduttula, S. Koppala, and S. Swamiappan, Trans. Ind. Ceram. Soc. 72[4] (2013) 257-260.

-

- 7. H. Begam, S. Mandal, J. Mukherjee, and S. K. Nandi, Trans. Ind. Ceram. Soc. 73[4] (2014) 284-292.

-

- 8. K. Maji and S. Dasgupta, Trans. Ind. Ceram. Soc. 73[2] (2014) 110-114.

-

- 9. R. Lakshmi, V. Velmurugan, and S. Sasikumar, Combust. Sci. Technol. 185[12] (2013) 1777-1785.

-

- 10. U. Anjaneyulu and S. Sasikumar, Bull. Mater. Sci. 37[2] (2014) 207-212.

-

- 11. R. Morsy, R. Abuelkhair, and T. Elnimr, Silicon 9[4] (2017) 489-493.

-

- 12. R. Morsy, R. Abuelkhair, and T. Elnimr, Silicon 9[4] (2017) 637-641.

-

- 13. H. Wang, Q. Zhang, H. Yang, and H. Sun, Ceram. Intl. 34[6] (2008) 1405-1408.

-

- 14. N. Tangboriboon, T. Khongnakhon, S. Kittikul, R. Kunanuruksapong, and A. Sirivat, J. Sol-Gel Sci. Technol. 58[1] (2011) 33-41.

-

- 15. H. Ismail, R. Shamsudin, M.A.A. Hamid, and R. Awang, J. Aust. Ceram. Soc. 52[2] (2016) 163-174.

- 16. R. Puntharod, C. Sankram, N. Chantaramee, P. Pookmanee, and K.J. Haller, J. Ceram. Proc. Res. 14[2] (2013) 198-201.

- 17. K. Yanagisawa, X. Hu, A. Onda, and K. Kajiyoshi, Cement and Concrete Research, 36[5] (2006) 810-816.

-

- 18. A.Yazdani, H.R. Rezaie, H. Ghassai, and M. Mahmoudian, J. Ceram. Proces. Res. 14[1] (2013) 12-16.

- 19. R. Phuttawong, N. Chantaramee, P. Pookmanee, and R. Puntharod, Adv. Mater. Res. 1103 (2015) 1-7.

-

- 20. S. Chehhlatt, A. Harabi, H. Oudadesse, and E. Harabi, Acta Physica Polonica A 127[4] (2015) 925-927.

-

- 21. S. S. Hossain and P. K. Roy, J. Asian Ceram. Soc. 6[3] (2018) 289-298.

-

- 22. S. Vichaphund, M. Kitiwan, D. Atong, and P. Thavorniti, J. Euro. Ceram. Soc. 31[14] (2011) 2435-2440.

-

- 23. K. Xiong, H. Shi, J. Q. Liu, Z. Shen, H. Li, and J. Ye, J. Am. Ceram. Soc. 96[3] (2013) 691-696.

-

- 24. S. Palakurthy, K.V. Reddy, R.K. Samudrala, and P.A. Azeem, Mat. Sci. and Eng. C 98 (2019) 109-117.

-

- 25. S. Palakurthy, P.A. Azeem, and K.V. Reddy, Ceramics International Part B 45[18] (2019) 25044-25051.

-

- 26. F.A.A. Azam, R. Shamsudin, M.H. Ng, A. Ahmad, M.A.M. Akbar, and Z. Rashidbenam, Ceramics International 44[10] (2018) 11381-11389.

-

- 27. A.P. Solonenko, A.I. Blesman, and D.A. Polonyankin, Ceramics International 44[18] (2018) 17824-17834.

-

- 28. I.V. de S.R. Nascimento, W.T. Barbosa, R.G. Carrodeguas, M.V.L. Fook, and M.A. Rodŕıguez, International Journal of Chemical Engineering, Article ID 6213568 (2018) 1-8.

-

- 29. L.A. Adams, E.R. Essien, and E.E. Kaufmann, J. Asian Ceram. Soc. 6[2] (2018) 132-138.

-

- 30. Heriyanto, F. Pahlevani, and V. Sahajwalla, J. Cleaner Production. 172 (2018) 3019-3027.

-

- 31. R. Shamsudin, F.A.A. Azam, M.A.A. Hamid, and H. Ismail, Materials 10[10] (2017) 1188.

-

- 32. K.A. Almasri, Hj. Ab A. Sidek, K.A. Matori, and M.H.M. Zaid, Results in Physics 7 (2017) 2242-2247.

-

- 33. H. Ismail, R. Shamsudin, and M.A.A. Hamid, Mat. Sci. and Eng. C 58 (2016) 1077-1081.

-

- 34. E.K. Papynov, O.O. Shichalin, E.B. Modin, V. Yu. Mayorov, A.S. Portnyagin, S.P. Kobylyakov, A.V. Golub, M.A. Medkov, I.G. Tananaev, and V.A. Avramenko, RSC Adv. 6[40] (2016) 34066-34073.

-

- 35. R. Shamsudin, M.A.A. Hamid, and A. Jalar, J. Asian Ceram. Soc. 2[1] (2014) 77-81.

-

- 36. A. Yazdani, H.R. Rezaie, and H. Ghassai, J. Ceram. Proc. Res. 11[3] (2010) 348-353.

- 37. D. Battegazzore, S. Bocchini, J. Alongia, and A. Frachea, RSC Adv. 4[97] (2014) 54703-54712.

-

- 38. S. Ahmed, F. Nigar, A.I. Mustafa, and M. Ahsan, Trans. Ind. Ceram. Soc. 76[4] (2017) 215-221.

-

- 39. S.J. Nipa and M.A. Hossain, Intl. J. Sci. & Engg. Res. 6[10] (2015) 387-391.

- 40. M.A. Hamid, M.A. Rahman, S. Ahmed, and K.M. Hossain, Asian J. Poult. Sci. 11[1] (2017) 1-13.

- 41. Y. Shinohara and N. Kohyama, Industrial Health 42[2] (2004) 277-285.

-

- 42. J.F. Saceda, R.L. de Leon, K. Rintramee, S. Prayoonpokarach, and J. Wittayakun, Quim. Nova 34[8] (2011) 1394-1397.

-

- 43. E.M. Rivera, M. Araiza, W. Brostow, V.M. Castaño, J.R. Díaz-Estrada, R. Hernández, and J.R. Rudriguez, Mat. Lett. 41[3] (1999) 128-134.

-

- 44. P.M.K. Reddy, S. Mahammadunnisa, B. Ramaraju, B. Sreedhar, and C. Subrahmanyam, Environ. Sci. and Poll. Res. 20[6] (2013) 4111-4124.

-

- 45. M.N. Freire and J.N.F. Holanda, Ceramica 52[324] (2006) 240-244.

-

- 46. D.S. Klimesch and A. Ray, Thermochimica Acta 306[1-2] (1997) 159-165.

-

- 47. R.P. S. Chakradhar, B.M. Nagabhushana, G.T. Chandrappa, K.P. Ramesha, and J.L. Rao, Materials Chemistry and Physics 95[1] (2006) 169-175.

-

- 48. S.K.S. Hossain and P.K. Roy, Boletín de la Sociedad Española de Cerámica y Vidrio 58[3] (2019) 115-125.

-

- 49. A. Harabi and S. Chehlatt, J. Therm. Anal. Calorim. 111[1] (2013) 203-211.

-

- 50. X. Liu, C. Ding, and P.K. Chu, Biomaterials 25[10] (2004) 1755-1761.

-

This Article

This Article

-

2020; 21(3): 285-295

Published on Jun 30, 2020

- 10.36410/jcpr.2020.21.3.285

- Received on Jun 25, 2019

- Revised on Sep 16, 2019

- Accepted on Sep 26, 2019

Services

Services

- Abstract

introduction

experimental details

results and discussion

conclusion

- Acknowledgements

- References

- Full Text PDF

Shared

Correspondence to

Correspondence to

- Samina Ahmed

-

Institute of Glass and Ceramic Research and Testing (IGCRT), Bangladesh Council of Scientific and Industrial Research (BCSIR), Dhaka-1205, Bangladesh

Tel : +8801817549816

Fax: +88-02-58613022 - E-mail: shanta_samina@yahoo.com

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.