- Influence of substrate surface-grinding on surface roughness of zirconia coatings fabricated by room temperature spray processing

Jeong Jun Kim and Jong Kook Lee*

Department of Advanced Materials and Engineering, Chosun University, Gwangju 61452, Korea

Zirconia ceramics used for

dental implants have low bioactivity. Their surface roughness needs to be

enhanced for improved bone-bonding ability and cell adhesion. Zirconia implants

in the gums with low surface roughness have a probability detachment over time.

In this study, a zirconia substrate zirconia was coated by a powder via spray

processing at room temperature (25 oC) to increase its surface

roughness. In addition, we investigated the morphology of the as-produced rough

substrate, including microstructural evolution. Four types of zirconia

substrates with different surface texture were fabricated via surface-grinding

by silicon carbide (SiC) abrasive papers (#220, #400, #800) after sintering.

Room temperature spray processing was carried out using a commercial zirconia

powder after thermal treatment. The as-produced zirconia coatings showed dense

microstructure and uniform thickness. Surface roughness of zirconia substrate

was greatly enhanced depending on the surface texture of the substrate. Surface

texture by substrate grinding affected coating morphology; however, it did not

increase the surface roughness of the substrate or the coatings. High-roughened

coatings and thick coating layer could be obtained from the as-sintered

substrate owing to its high surface roughness.

Keywords: Zirconia substrate, Room temperature spray processing, Surface roughness

3 mol% yttria-stabilized tetragonal zirconia polycrystals

(3Y-TZP) exhibits superior mechanical properties such as high

fracture toughness (~10 MPa·m-1),

high flexural strength (~1,300 MPa), elastic

modulus (~210 GPa), and abrasion

resistance (~1,200 Hv) [1-4]. It also characterized

by biological and optical properties, for example, good biocompatible

properties, i.e., corrosion resistance, non-toxicity,

minimal ion release, low affinity to bacterial colonization,

and good esthetics [5, 6]. The mechanical, biological

and optical properties of zirconia dental implants are related to the ionic and

phase composition, hydrophilicity, and surface roughness, which depend on the

bulk composition as well as the surface treatment of the implants [7, 8]. Even

though 3 mol% yttria-stabilized tetragonal zirconia (3Y-TZP) is the most

commonly used material, yttria content of zirconia bulk materials can vary from

3 to 5 mol% [9, 10].

Most of zirconia implants are fabricated by the milling

of ceramic block using a computer‐aided design and computer‐aided manufacturing

(CAD/CAM) system, after post-sintering [11]. Shaping of zirconia blocks by cutting

or grinding creates several invisible microcracks on the

machined implant surface that might induce microstructural

disintegration or failure after implantation, limiting the

use of this material as a dental implant [12, 13]. Fabrication of zirconia

implants by CAD/CAM and sintering usually results in a relatively smooth

surface, that reduces its bone-bonding ability and cell adhesion [14, 15].

The surface treatment of zirconia dental implants is

diverse and has not been thoroughly studied. Several efforts have been made to

roughen the zirconia implant surface to improve its

osseointegration. Numerous surface modifications are currently

being applied, such as sandblasting and acid etching to enhance the surface

roughness of CAD/CAM machined zirconia implants [16, 17]. Zirconia particles

are also used as an effective coating material, and surface coating is a

frequently used method to improve the surface roughness and bone-bonding

ability of dental zirconia implants [18, 19].

In this study, we applied a zirconia coating on zirconia

substrate to obtain a highly roughened zirconia surface by spray processing at

room temperature (25 oC), to improve the bone-bonding ability

and osseointegration of the implant. We also investigated

the effect of substrate texturing and

roughness on coating morphology, including microstructural

evolution, surface roughness, and coating thickness.

Materials

Commercial 3Y-TZP powder was used as the raw material to

fabricate the zirconia coating and substrate. To match the

processing condition for room temperature spray

processing, 3Y-TZP powder was heat-treated at 1,100 oC for 2 h

to enlarge the particle size and weight. After calcination, attrition-milling

was performed for 24 h. After drying, the powder was sieved to prevent the

nozzle from clogging during coating.

Dense zirconia substrate 1 cm in diameter was fabricated

by uniaxial pressing and sintering at 1,450 oC for 2 h. Surface

microstructure and roughness of substrate were investigated via field emission

scanning electron microscopy (FE-SEM) and atomic force microscopy (AFM). To

change the surface texture of the zirconia substrate, abrasive milling was

performed using the three types of silicon carbide (SiC) paper (#220, #400,

#800).

Coating

The 3Y-TZP substrate was coated with zirconia particles

by spray processing at room temperature. A few preliminary experiments were

performed to determine the optimum

coating parameters as described in our previous study [20].

Pressure difference between aerosol and deposition chambers was maintained at 1

atm under the nitrogen gas flow rate of 5 L/min. The distance

between the nozzle and the substrate, termed as spraying

distance, was set at 5 mm. Aerosol of 3Y-TZP particles in the deposition

chamber was formed by the injection of nitrogen gas and severe vibrations at

approximately 600 rpm. The 3Y-TZP particles carried via nitrogen

flow into the deposition chamber were rapidly impacted onto

the substrate and deposited as the coating layer. To obtain a

thick coating on the substrate, coating cycle was repeated

a maximum of 40 times in succession, using a slit nozzle with a size of

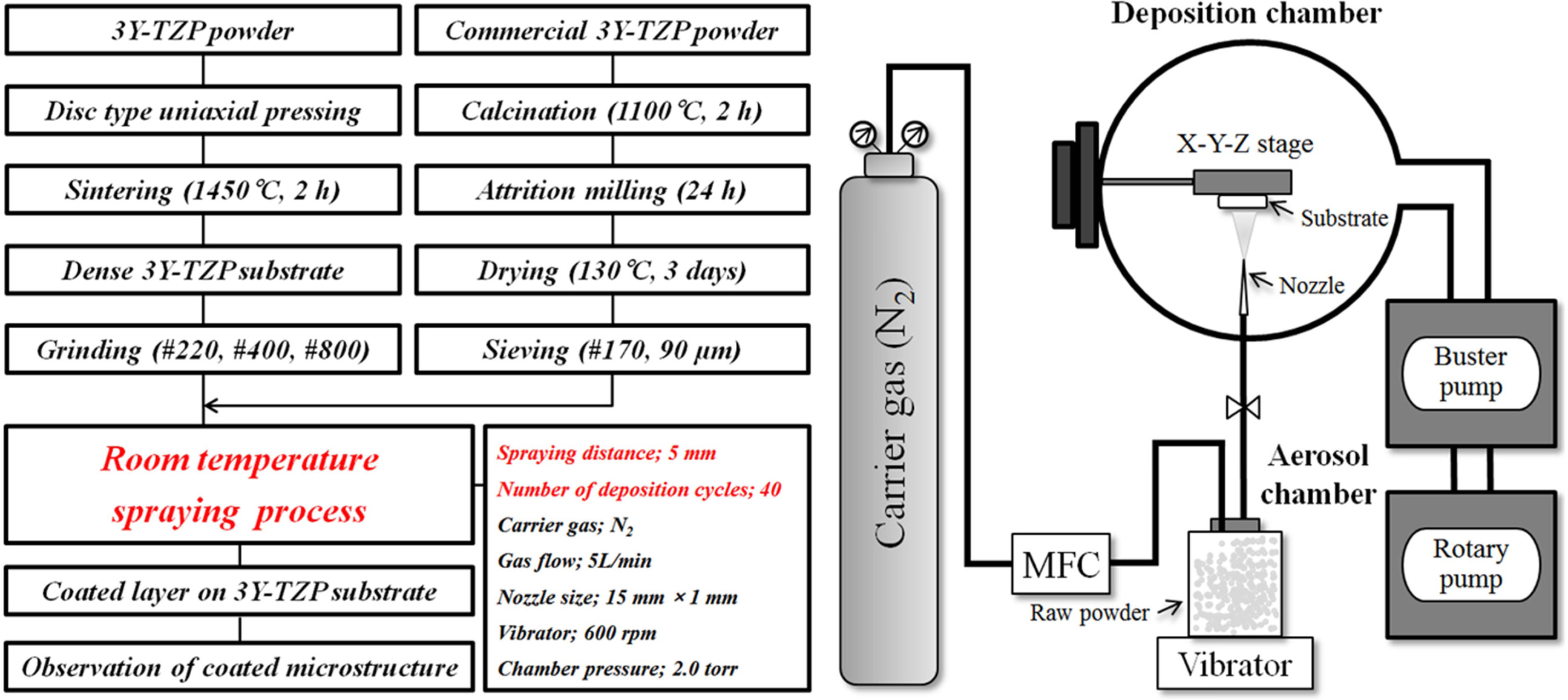

15 × 1 mm2. Detailed experimental procedure for the

preparation of substrate and room temperature spray processing is indicated in

Fig. 1.

Characterization

The change in the color of the coating with deposition

cycle was observed using optical microscope, and its phase composition was

analyzed by X-ray diffraction (XRD). The morphology and

microstructure of the coated layer were investigated both on planar and

perpendicular surfaces using an FE-SEM. Coating thickness was

measured as a function of the deposition cycle and the values were compared

based on the degree of surface-grinding. Surface morphology and microstructure

of the 3Y-TZP coating were observed by SEM and AFM and investigated with

respect to the deposition cycle and surface-grinding type. From the AFM image,

the roughness parameter (Ra; centerline average roughness) was measured, and

the relation between coating properties and processing parameters was analyzed.

|

Fig. 1 Schematic for the preparation of 3Y-TZP coating powder and substrate, and the room temperature spray processing. |

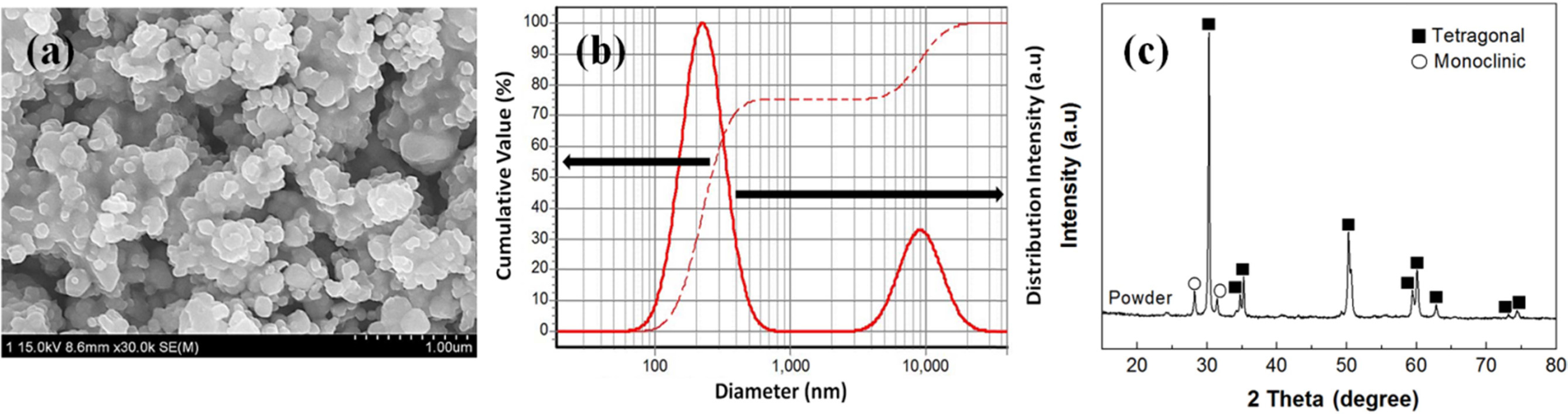

Heat treatment of the 3Y-TZP powder at high temperature is

essential to obtain the powder that is suitable for spray coating at room

temperature; it also provides sufficient impaction energy to the particles for collision

[21, 22]. All 3Y-TZP particles after calcination showed an

equiaxed shape with uniform agglomeration as shown in Fig. 2(a). From the

analysis of particle size distribution (Fig. 2(b)), calcined 3Y-TZP powder had

primary and secondary agglomerate sizes of 287 nm and 3.3 µm, respectively, and

composed of 75 vol% primary and 25 vol% secondary agglomerates. Calcined

and milled 3Y-TZP powder was characterized as the main tetragonal phase with a

trace of monoclinic phase as per the XRD analysis (Fig. 2(c)), indicating

partial phase transformation by heat-treatment and attrition milling.

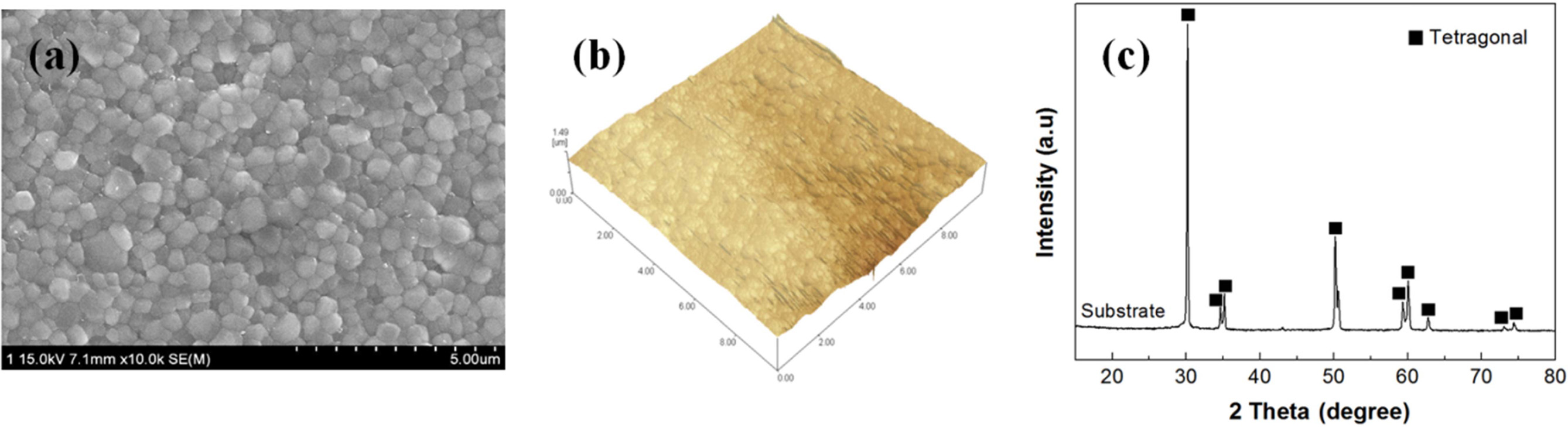

Surface microstructure and morphology of the as-sintered

3Y-TZP substrate observed by SEM and AFM are shown in Fig. 3, indicating that

the specimen has homogeneous microstructure composed of all

tetragonal grains of 500 nm, and 0.28 µm surface roughness (Ra)

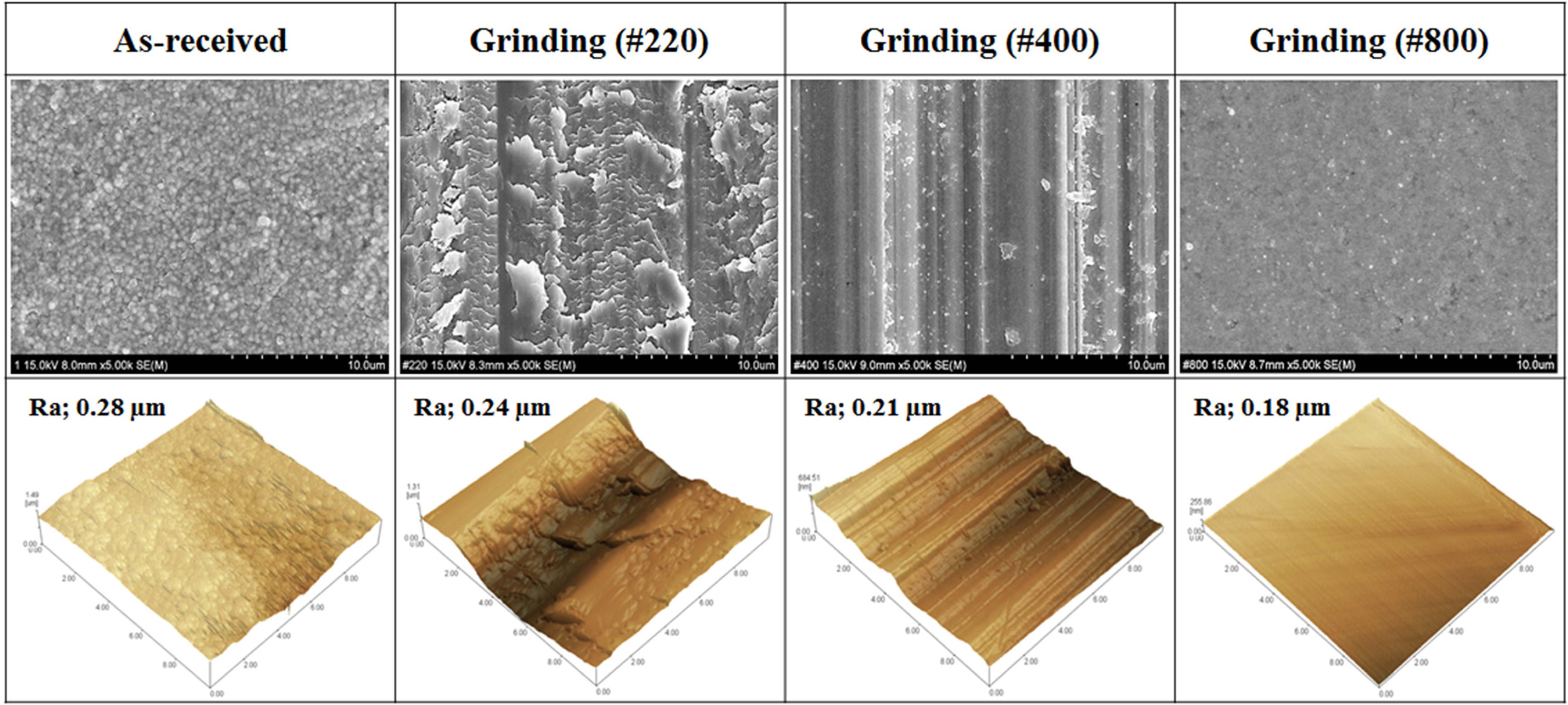

measured from AFM image. Fig. 4 shows the surface morphology and roughness of

the 3Y-TZP substrate after surface-grinding by three types of SiC abrasive.

Several scratches in vertical direction were observed from the SEM

photographs, but the scale and frequency of scratches

were dependent on the type of the SiC abrasive. Surface-grinding by

coarse SiC abrasive (#220) induced large scale scratches on

the substrate surface with relatively low frequency. In contrast,

surface-grinding by fine SiC abrasive (#800) greatly reduced the scratch mode

on the substrate surface, resulting in low surface

roughness (Ra). Even though large scratches were

formed on the substrate surface by surface-grinding it caused a

decrease in the roughness value (Ra) from 0.28 µm (as-sintered substrate) to

0.18 µm (#800 SiC abrasive).

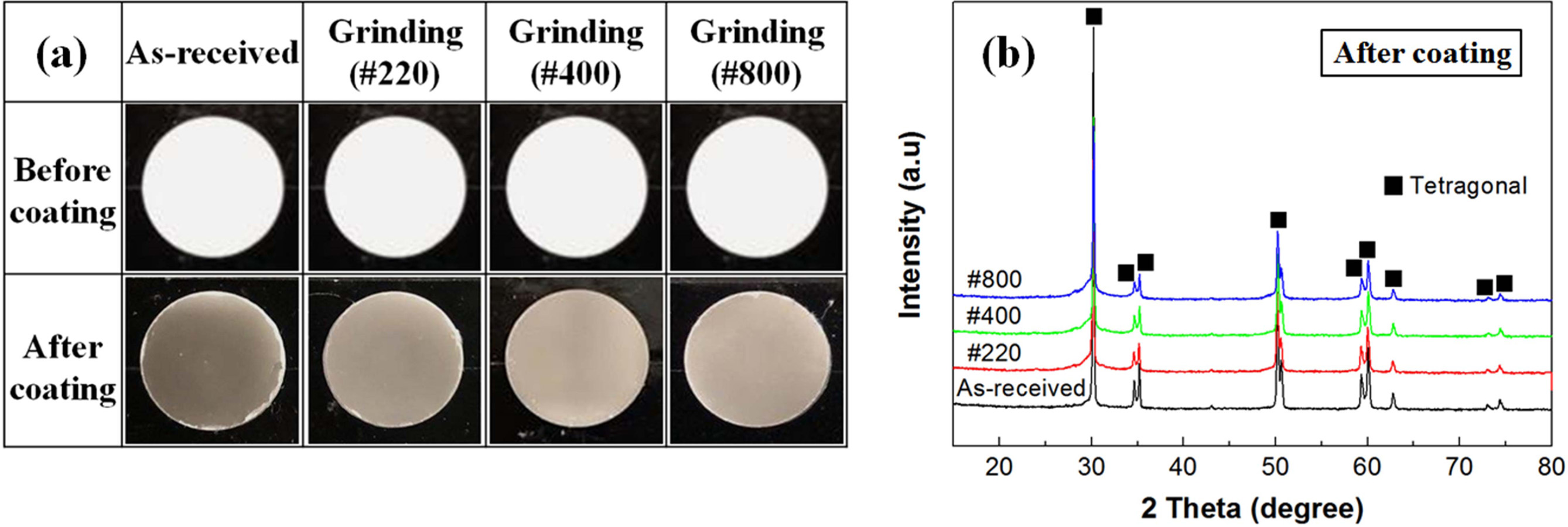

Surface color of the as-sintered 3Y-TZP substrate

corresponds to that of the ivory, which is the typical color of 3Y-TZP. After

the coating of zirconia substrate by 3Y-TZP particles the color of the former

changed to gray-black

as shown in Fig. 5(a), depending on the deposition cycle and the type of

surface-grinding. In a previous study [23]

dark gray or black color was generally

observed in thick coating layer, and the color change was influenced by the

carrier gas and the degree of coating thickness. The presence of gray-color on

the coating layer was caused by the discharging during the deposition,

which induced defects in the film and drastically decreased its transmittance

[24]. Coated zirconia layer was composed of

all tetragonal grains as indicated in Fig. 5(b), regardless of the type of

surface-grinding. Trace of monoclinic phase in starting zirconia powder was not

observed on coated zirconia layer, meaning that tetragonal grains were formed

by strong impaction and adhesiveness on substrate during the room temperature

spray processing.

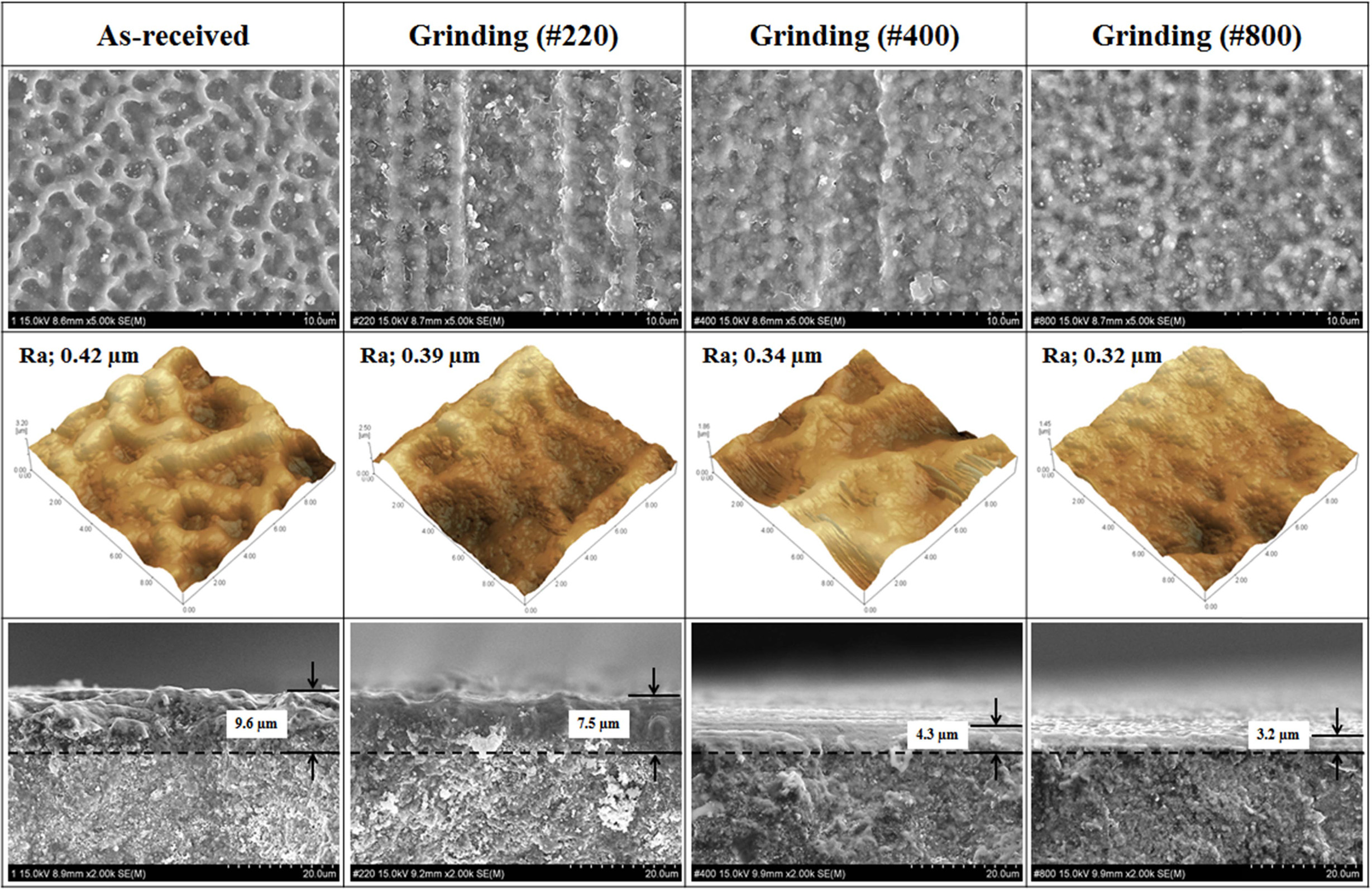

Fig. 6 shows the surface microstructure and morphology

of the coating layers fabricated by room temperature spray processing as a

function of surface-grinding. No delamination or micro-cracks were observed in

the coating layer or at the interface between the coating and substrate. All

coating layers were composed of nanoscale 3Y-TZP particles in the range of 50

to 200 nm. Homogeneous surface microstructure and coating thickness was

obtained for all substrates, but coating morphology and thickness were

dependent on the texture of the substrate surface after grinding. Coated

microstructure showed a three dimensional network or a wave-like pattern in the

as-sintered specimens as well as those obtained by fine grinding by

#800 SiC abrasive; however, large difference in surface roughness

were noted between the two coating layers. From the analysis of AFM images,

maximum value of Ra (0.42 µm) was obtained for the coating layer of the

as-sintered substrate; in contrast, minimum value of Ra (0.32 µm) was obtained

from the coating layer of the specimen obtained by fine surface-grinding using

#800 SiC abrasive.

Vertical lines were observed in the coated layers of the

substrates with large scale scratches fabricated using #220, #400

SiC abrasive. In these specimens, coated morphology was similar to the vertical

patterns on the substrate surface. The Ra of the coated layers gradually

decreased from 0.42 µm to 0.32 µm with a decrease in the surface roughness of

the substrate, indicating that highly roughened substrate is the main factor

for obtaining a highly roughened coating layer.

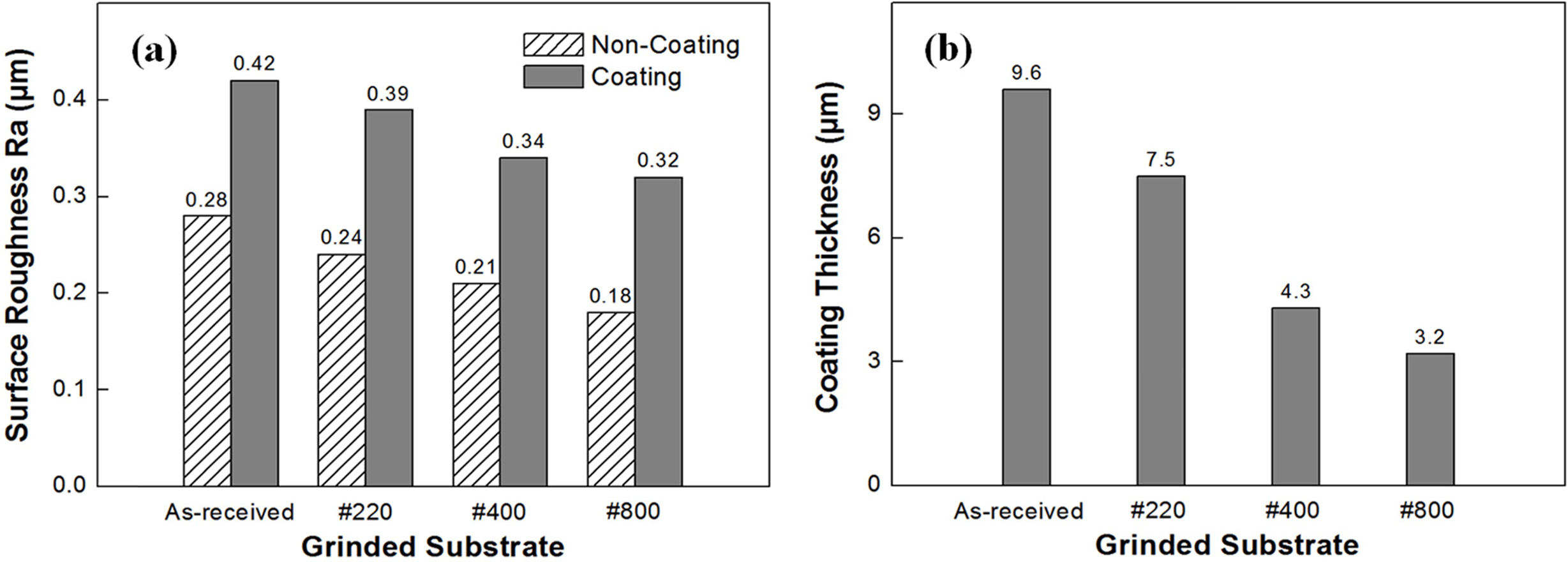

Fig. 7 shows the coating thickness and the surface

roughness of the coated layer. The Ra of the coating layer can be calculated

from the average value of the linear roughness data along the horizontal and

vertical lines in the AFM map [25]. Coating thickness and surface

roughness of the coated layer were also dependent on the substrate roughness

based on the type of surface-grinding. Maximum coating thickness of 9.6 µm was observed

for the coating layer of the as-sintered substrate. Conversely,

minimum coating thickness of 3.2 µm was obtained for the coating layer of the

substrate ground using #800 SiC abrasive.

|

Fig. 2 Characterization of coating powder after calcination; (a) particle morphology, (b) agglomeration size distribution and (c) phase composition. |

|

Fig. 3 Characterization of the as-sintered 3Y-TZP substrate before surface-grinding; (a) surface microstructure as per SEM, (b) surface morphology as per AFM, and (c) phase composition. |

|

Fig. 4 Planar microstructure by SEM and surface morphology by AFM of 3Y-TZP substrates after surface-grinding. |

|

Fig. 5 Optical photographs and phase analysis of 3Y-TZP coatings as a function of deposition cycle and the type of surface-grinding; (a) color of coated layer and (b) phase composition. |

|

Fig. 6 Characterization of coated 3Y-TZP morphology by room temperature spray processing observed by SEM and AFM with respect to the type of substrate surface-grinding. |

|

Fig. 7 Variations in (a) surface roughness determined via AFM images and (b) coating thickness determined from perpendicular images of SEM. |

Zirconia substrate was coated by zirconia particles by

spraying process at room temperature to improve the bone-bonding ability and

cell adhesion of zirconia dental implants by enhancing the surface roughness of

the as-obtained specimens. The influence of substrate surface-grinding

on the surface roughness of the coating surface was also

investigated. Large and small scratches were induced on the

zirconia substrate through surface-grinding by SiC abrasive,

but the process resulted in decreased substrate roughness. Dense and

homogeneous coatings composed of tetragonal zirconia grains were formed on the

zirconia substrate by room temperature spray processing and coating morphology and

thickness were dependent on the substrate roughness and surface

texture obtained by abrasive grinding. Maximum Ra of 0.42 µm and film thickness

of 9.6 µm of the coated layer was obtained for the as-sintered substrate

with maximum substrate roughness, indicating that a

highly roughened coating layer adhered to the highly

roughened substrate. In contrast, minimum surface roughness

(Ra; 0.32 µm) and film thickness (3.2 µm) of the coated layer were obtained

from the fine grinded substrate with minimum substrate roughness.

This work was supported by a National Research Foundation

of Korea (NRF) grant funded by the Korea government (MEST) (Grant No.

2018-019041).

- 1. H. Nishihara, M.H. Adanez, and W. Att, J. Prosthodont. Res. 63[1] (2019) 1-14.

-

- 2. H. Tong, C.B. Tanaka, M.R. Kaizer, and Y. Zhang, Ceram. Int. 42[1] (2016) 1077-1085.

-

- 3. C. Gautam, J. Joyner, A. Gautam, J. Rao, and R. Vajtai, Dalton. Trans. 45[48] (2016) 19194-19215.

-

- 4. A. Apratim, P. Eachempati, K.K.K. Salian, V. Singh, S. Chhabra, and S. Shah, J. Int. Soc. Prev. Community. Dent. 5[3] (2015) 147-156.

-

- 5. E.S. Elshazly, S.M. El-Hout, and M.E.S. Ali, J. Mater. Sci. Technol. 27[4] (2011) 332-337.

-

- 6. I. Denry, and J.A. Holloway, Mater. 3[1] (2010) 351-368.

-

- 7. Y.R. Fonseca, C.N. Elias, S.N. Monteiro, H.E.S dos Santos, and C. Santos, Mater. 12[16] (2019) 2529.

-

- 8. F. Rupp, L. Liang, J. Geis-Gerstorfer, L.Scheideler, and F. Hüttig, Dent. Mater. 34[1] (2018) 40-57.

-

- 9. Z. Özkurt, and E. Kazazoğlu, J. Oral. Implantol. 37[3] (2011) 367-376.

-

- 10. M. Andreiotelli, H.J. Wenz, and R.J. Kohal, Clin. Oral. Impl. Res. 20[4] (2009) 32-47.

-

- 11. P.F. Manicone, P.R. Iommetti, and L. Raffaelli, J. Dent. 35[11] (2007) 819-826.

-

- 12. R. Depprich, C. Naujoks, M. Ommerborn, F. Schwarz, N.R. Kübler, and J. Handschel, Clin. Implant. Dent. Relat. Res. 16[1] (2014) 124-137.

-

- 13. Y. Zhang, and B.R. Lawn, J. Biomed. Mater. Res. Part B Appl. Biomater. 72B[2] (2005) 388-392.

-

- 14. G. Soon, B. Pingguan-Murphy, K.W. Lai, and S.A. Akbar, Ceram. Int. 42[11] (2016) 12543-12555.

-

- 15. M.R. Towler, I.R. Gibson, and S.M. Best, J. Mater. Sci. Lett. 19[24] (2000) 2209-2211.

-

- 16. L. Le Guéhennec, A. Soueidan, P. Layrolle, and Y. Amouriq, Dent. Mater. 23[7] (2007) 844-854.

-

- 17. M. Guazzato, M. Albakry, L. Quach, and M.V. Swain, Biomaterials. 25[11] (2004) 2153-2160.

-

- 18. K. Pardun, L. Treccani, E. Volkmann, P. Streckbein, C. Heiss, G.L. Destri, G. Marletta, and K. Rezwan, Mater. Sci. Eng. C. 48 (2015) 337-346.

-

- 19. O.E. Ogle, Dent. Clin. North Am. 59[2] (2015) 505-520.

-

- 20. H.J. Kim, J.J. Kim, and J.K. Lee, J. Nanosci. Nanotechnol. 19[10] (2019) 6285-6290.

-

- 21. D. Hanft, J. Exner, M. Schubert, T. Stöcker, P. Fuierer, and R. Moos, J. Ceram. Sci. Technol. 6[3] (2015) 147-182.

-

- 22. J. Akedo, Mater. Sci. Forum. 449-452 (2004) 43-48.

-

- 23. Y. Imanaka, and J. Akedo, in Proceedings of the 54th Electronic Components and Technology Conference, April 2004, edited by IEEE (Institute of Electrical and Electronics Engineers, 2004) p. 1614.

-

- 24. J. Akedo, J. Therm. Spray. Technol. 17[2] (2008) 181-198.

-

- 25. D.W. Lee, and S.M. Nam, J. Ceram. Process. Res. 11[1] (2010) 100-106.

This Article

This Article

-

2020; 21(S1): 68-73

Published on May 31, 2020

- 10.36410/jcpr.2020.21.S1.s68

- Received on Dec 16, 2019

- Revised on Apr 16, 2020

- Accepted on May 4, 2020

Services

Services

- Abstract

introduction

experimental details

results and discussion

conclusions

- Acknowledgements

- References

- Full Text PDF

Shared

Correspondence to

Correspondence to

- Jong Kook Lee

-

Department of Advanced Materials and Engineering, Chosun University, Gwangju 61452, Korea

Tel : +82-62-230-7202

Fax: +82-62-608-5402 - E-mail: jklee@chosun.ac.kr

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.