- Enhanced ionic conductivity and suppressed electronic conductivity of an Al- and Mn-added ceria solid electrolyte

Ji Young Park*

Department of Materials Science and Engineering, University of Seoul, Seoul 02504, Korea

Gd-doped ceria (GDC) is a

promising solid electrolyte for intermediate temperature solid oxide fuel cells

(IT-SOFCs) due to its high oxygen-ion conductivity. However, commercialization

is limited due to high grain boundary resistance and electronic conduction in

reduced conditions. In this work, Al- and Mn-added GDCs were designed to

overcome their weaknesses. GDC and Al- and Mn-added GDC powders were prepared

using spray pyrolysis and then sintered using spark plasma sintering technique

to obtain dense ceramic pellets. Additives enhanced the sinterability of the

ceria leading to an increase in ionic conduction. More importantly, electronic

conduction in GDC with the additives was suppressed under reduced conditions.

This demonstrates that Al- and Mn-added GDC is a possible candidate as a solid

electrolyte for IT-SOFCs.

Keywords: GDC, Additives, Ionic conduction, Electronic conduction

SOFCs (Solid oxide fuel cells) electrochemically generate

power in an environmentally friendly and efficient way by

directly converting the chemical energy of fuel gas into electric energy [1-3].

Compared to other types of fuel cells, SOFCs use relatively

inexpensive materials, have a

relatively high tolerance to fuel impurities, enable hybrid

operation, and have high efficiency. However, SOFCs operate at a high

temperature (> 700 oC), and therefore high temperature

alloys or expensive ceramic materials that can withstand high

temperature conditions are used in SOFCs [4-6].

Additionally, due to high temperature operation, the durability of materials

used in the manufacture of SOFCs degrades; therefore, many

studies have been conducted on fuel cells that operate at low temperatures. The

operating temperature of a SOFC depends greatly on the properties of the solid

electrolyte used [7-10].

Doped ceria, which has higher oxygen-ion conductivity

than that of doped zirconia has been intensively studied to replace doped

zirconia, a popular solid electrolyte [8-11]. However, it is known that the

reduction reaction is caused under low oxygen partial pressure (Po2)

condition (fuel condition in fuel cells) and causes the problem

of electron conduction [12, 13]. An equilibrium potential

(open circuit voltage, OCV) associated with power output, is a function of the

ionic transference number (ti = sion/(sion + selectron),

OCV = tiCln(P1/P2)

where C is a temperature-dependent constant, and P1

and P2 oxygen partial pressure on cathode and anode sides). When the

electronic conductivity is substantially lower than the ionic conductivity, ti

is 1; while high electronic conductivity leads to ti < 1,

and OCV decreases; this reduction in OCV degrades the power output of the fuel cell. In addition

to electronic conduction in a reducing environment, many cracks are generated

due to lattice expansion by Ce4+ ® Ce3+ [14].

Such a mechanical weakness in reducing

conditions has also prevented its commercialization as a solid electrolyte for

SOFCs. Therefore, it is necessary to develop doped ceria with high ti

and mechanical stability (note that electronic

conduction is related to mechanical properties in reduced conditions because the electronic charge carrier is produced

by Ce4+ ® Ce3+).

In this study, we have produced Al- and Mn-added ceria

with high ti. Ceria powders were synthesized using

ultrasonic spray pyrolysis (USP), a simple method for synthesizing

multi-component materials, and the samples were

quickly sintered using spark plasma sintering (SPS).

The preparation of a starting precursor solution to

synthesize Gd0.8Ce0.2O2 (GDC) powders was

carried out by mixing gadolinium nitrate (Gd(NO3)3 × 9H2O,

Aldrich, 99.9%), cerium nitrate (Ce(NO3)2 × 6H2O,

99%, Aldrich), ethylene glycol (Reagent

plus, > 99%, Aldrich) and citric

acid (Citric acid monohydrate, 99.5%, Daejung Chemical.

Co.) in pure water. The concentration was fixed at 0.1 M. The solution for

GDC-Al2O3-Mn2O3 (GDCAM,

GDC : Al2O3 : Mn2O3 = 97 vol % : 2

vol % : 1 vol %) nano-powder was mixed in the same manner.

Aluminum nitrate (Al(NO3)3×9H2O, Alfa, 98%)

and manganese nitrate (Mn(NO3)2×6H2O, Kanto,

98%) were added to the starting solution for GDC to prepare GDCAM. The solution

mists were generated at a frequency of 1.6 MHz in an ultrasonic atomizer with

transducer operation and were carried into a furnace preheated at a given

temperature (900 oC). After the powder was collected, the spark

plasma sintering technique was carried out to make high-density pellets of GDC

and GDCAM. Each powder was filled with a cylindrical graphite die of 5 mm

radius, heated to 1400 oC at a rate of 100 oC/min

while a pressure of 80 MPa was applied, and sintered for 5 min.

The

crystal structure of the as-synthesized powders and sintered pellets was

characterized by X-ray diffractometer (XRD,

Rigaku, D-2500). The morphology and microstructures of nanopowders were characterized by field

emission scanning electron microscopy (FE-SEM, Hitachi S-4800). The

distribution of elements was detected using energy dispersive X-ray analysis

spectroscopy (EDS).

The relative density of the sintered samples was determined

by the Archimedes method. Bending strength tests for

the sintered samples were also conducted. For electrical measurements, platinum

ink was painted on either side of the pellet and heated at 800 °C for 2 h

to act as an electrode as well as an electric current

collector. The electrical resistance was measured using two-probe

ac techniques as a function of temperature under air and reducing atmosphere (5

% H2/N2-balance). In order to ensure sufficiently fast

oxygen exchange at the interface of the sample, resistance was measured twice

with increasing and decreasing temperature in the temperature range of

230-550 °C at a fixed Po2. For the reducing environment test,

the temperature was swept two times in a range of

230-550 °C. The first experiment was conducted within 12 h

under reducing condition (short-term test where the swept temperature was 230 oC ® 550 oC ® 230 oC). In the

second-time experiment, the resistance of the specimen

already exposed under the reducing environment for 12 h was measured again in

the same environment for 12 h (long-term test where the swept temperature was

230 oC ®

550 oC ®

230 oC). As another test, resistance was examined as a function of

time under the reducing condition (5 % H2/N2-balance gas

was used) to determine whether the Al- and Mn- added sample prevents electronic

conduction in a reduced atmosphere.

AC impedance spectra were obtained in the frequency

range of 1 Hz to 10 MHz using an impedance analyzer (Material

Mates 7260), and the Z-view program (Scribner Associates)

was used for the fitting of data.

The solid state reaction, precipitation and sol-gel methods

are representative ceramic processing techniques used for the

synthesis of solid electrolytes of SOFCs [15, 16]. However, it is difficult to

achieve optimal powder characteristics for multi-component materials with these

methods, because the materials must be subjected to subsequent calcination and

mixing steps. Moreover, the multi-component materials obtained by such methods

can be unintentionally agglomerated without even distribution; these phenomena

deteriorate as particle sizes decrease to nanoscale. By

implementing USP, a simple and versatile synthetic method, GDC

powders were obtained.

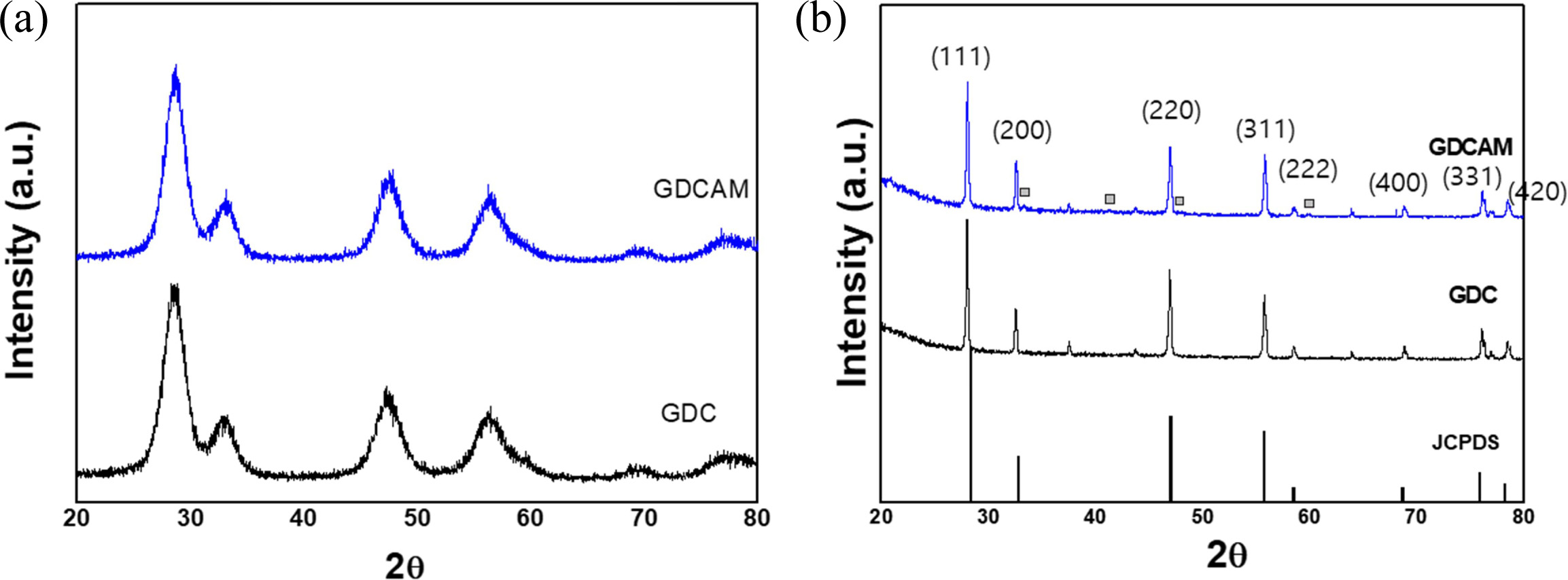

Fig. 1 shows the XRD patterns of (a) as-synthesized

powders and (b) sintered pellets of GDC and GDCAM. As seen, the

detected peaks for both cases were matched with JCPDS

peaks of CeO2, indicating that the desired fluorite cubic-crystal

structure (space group : Fm3 ̅m) was well formed. However, the peaks of

as-synthesized powders are not sharp but broad. This peak broadening is

attributed to the nano crystal size of the powder, ~ 10 nm, which was

calculated from Sherrer’s equation with the

broadening. Additional peaks detected in the sintered pellet

of GDCAM were GdAlO3, which is a well-known secondary

phase formed in ceria and alumina composites [17].

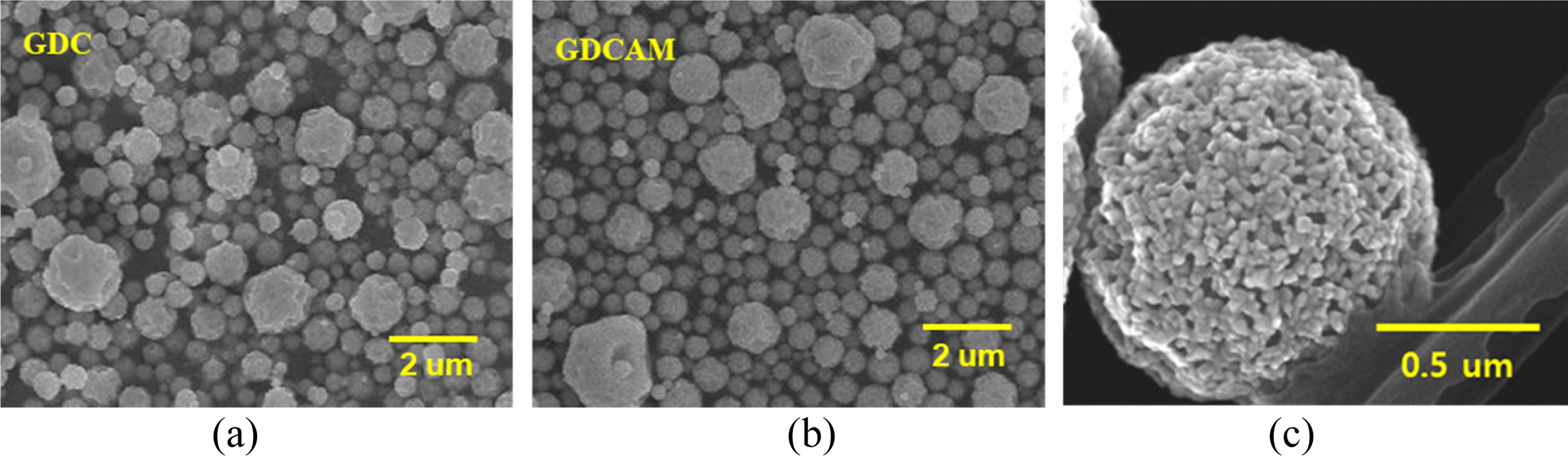

The microstructures of the ceria powders were investigated

using SEM, as seen in Fig. 2. As-prepared powders had near-spherical

morphologies with an average size of

~ 0.95 mm. The spherical powders are the secondary particles consisting of primary nanoparticles. They were pelletized and then quickly sintered

at 1,400 oC using SPS (the relative densities of the green

samples were in the range of 45~50%).

After sintering, the relative

densities of GDC and GDCAM, measured by the Archimedean method, were ~ 94% and 96%, respectively. The obtained densities were

relatively high compared with the reported results prepared by

conventional solid-state reaction

[9]. In particular, GDCAM was highly

sintered (note that this high density

is reported to be achieved above 1,500 oC) [9]. The

microstructure and element distribution of the sintered body of GDC and GDCAM

were also investigated by SEM and EDS (the atomic percentages of Ce, Gd, Al and

Mn were 78.4, 18.3, 1.9 and 1.4, respectively), and high density and homogeneous element distribution

were shown. Furthermore, the presence

of this high density and secondary

phase in GDCAM enhances the mechanical

properties of ceria. The measured bending strength of GDC and GDCAM were

~ 90 MPa and ~ 115 MPa, respectively.

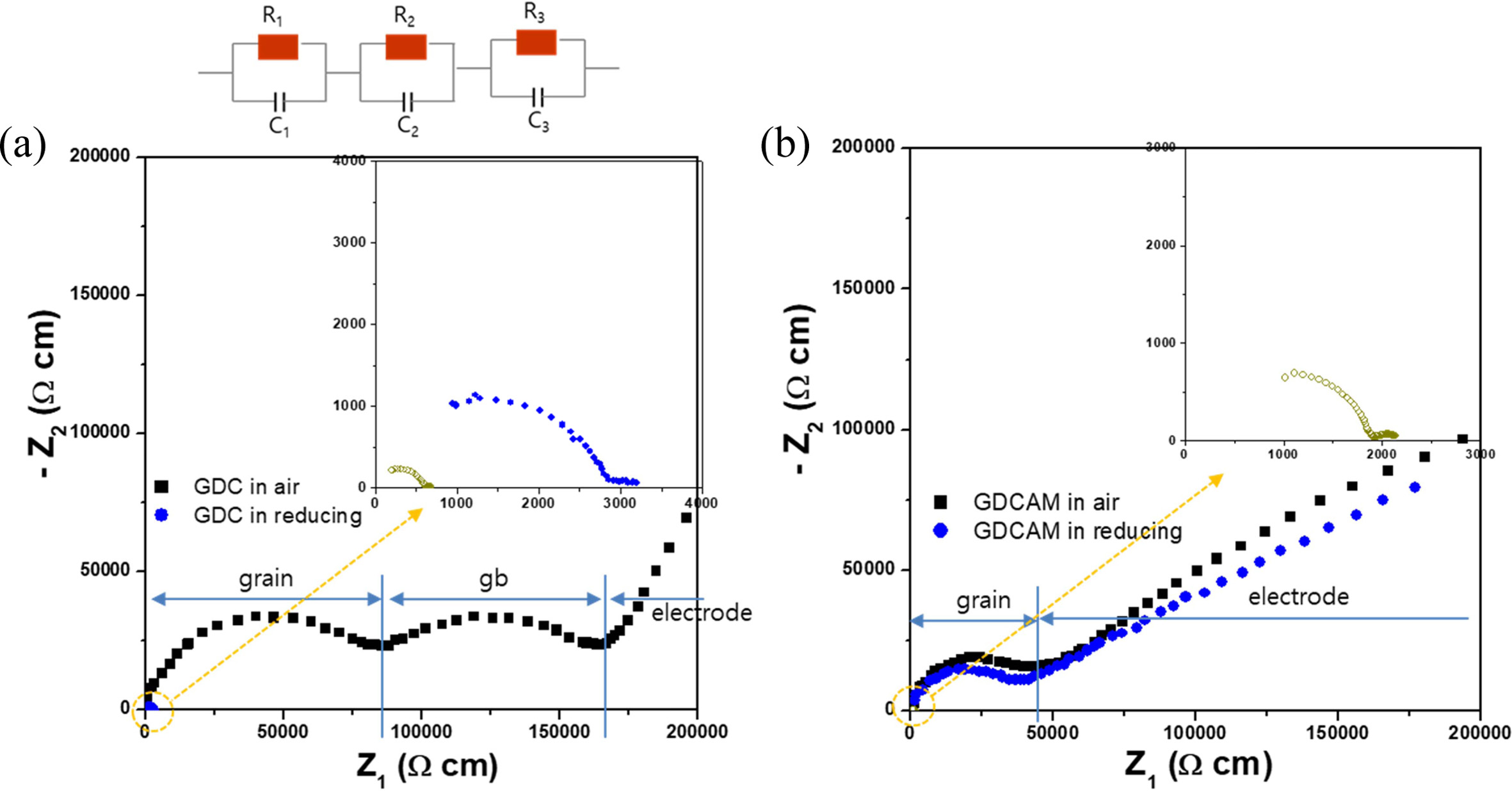

Electrical characteristics of GDC and GDCAM were investigated

as follows. Fig. 3 shows their representative impedance

data measured in air and reduced conditions (short term and long term),

respectively. As seen in the figure, typical impedance spectra of

conducting ceramics were observed. In Fig. 3(a), the spectrum consists

of three parts corresponding to the grain, grain boundary (gb), and electrode,

in that order, as indicated (note that the arcs corresponding to the grain and

gb are almost semicircular, and the signals corresponding to the electrode are

also imperfect arcs, but partially shown). Those parts are generated from the

three respective resistances and capacitances (R1C1-R2C2-R3C3,

series equivalent circuit) of grain, gb and electrode. From the impedance

patterns and equivalent circuits, the grain and gb resistances (Rgrain,

Rgb) were obtained (R1C1 and R2C2

were estimated for the grain and the gb by fitting the impedance

spectrum using a corresponding equivalent circuit

based on a bricklayer model: R1 = Rgrain, R2

= Rgb). The total resistance of GDC, the summation of the

grain and gb resistances, was also calculated. A notable point is that the arcs

of the grain and gb of GDC became small in reduced condition, showing that the

resistances of the grain and gb greatly decreased. When the sample was exposed

in reduced condition for a long time, the arcs shrank further (the inset figure

shows the pattern of GDC in reduced conditions). On the other

hand, the pattern of GDCAM remained almost unchanged

for a while, as shown in Fig. 3(b), even though it eventually shrank after long-time

exposure (inset figure). Decreasing the size of the arc means less resistance,

which is attributed to the generation of electronic conduction by Ce4+

® Ce3+ under a

reducing environment in ceria.

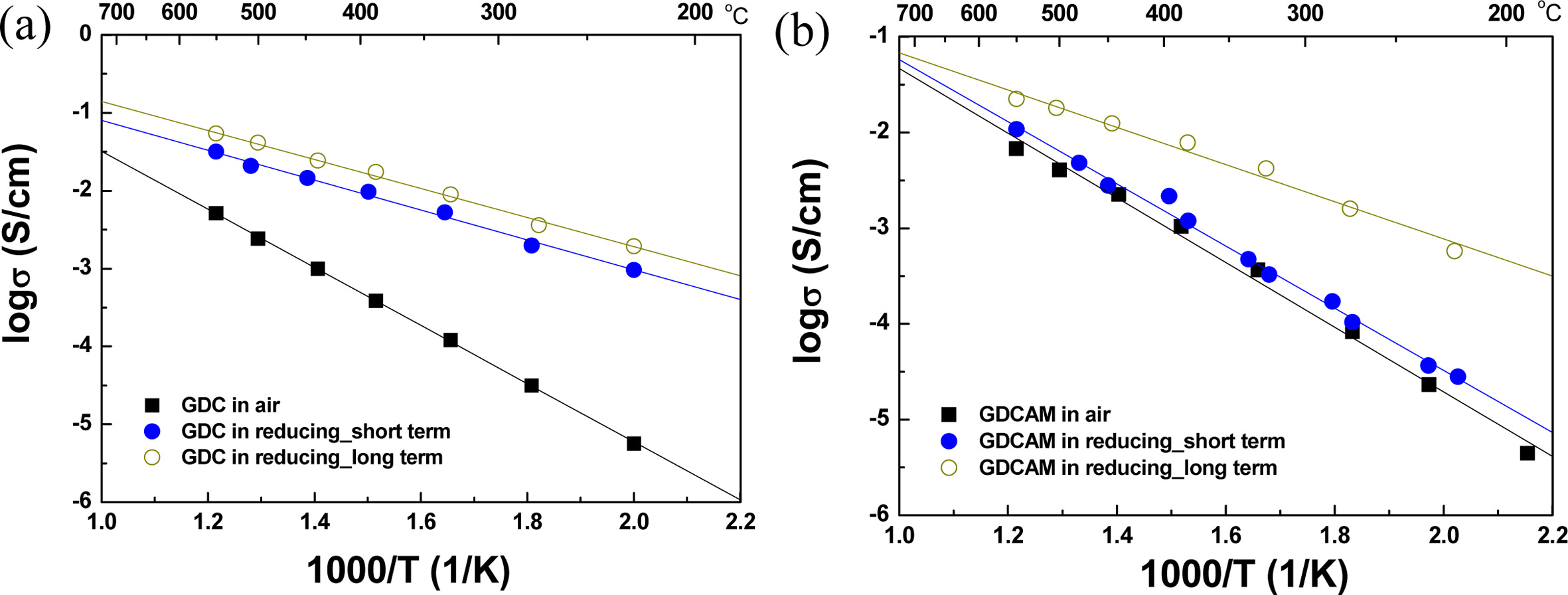

The temperature dependences of the

total conductivities (stotal =1/( Rgrain + Rgb)¡¿L/A,

L and A being the length and area of the specimen) computed from the resistances are exhibited in Fig. 4(a) and (b). In this figure,

the solid rectangular symbol represents the stotal of GDC in air. The activation energy (Ea)

is about 0.74 eV, indicating that the main charge carrier is the oxygen ion

[18]. As expected from the impedance patterns, the stotal of GDC greatly increased in reduced conditions (solid blue

symbol). After long-time exposure (open circle symbol), it increased further;

on the other hand, in the short term, stotal (GDCAM) in the reducing environment was very similar to that in an air atmosphere (see Fig.

4b). This means that even in a reducing environment, ionic conduction is still a dominant charge

carrier for the short term, and thus even in a reducing environment, the ionic

transference number (ti) is near 1. However, stotal eventually greatly changed after long-time exposure in reducing conditions, showing that GDCAM can suppress the electronic conduction

generated by cerium reduction (Ce4+ ® Ce3+) for a limited time. One

interesting thing is that the stotal of

GDCAM is still lower than the stotal of

GDC, even though it is greatly changed after

the long-term exposure. This

means that the additives (Mn or Al) play a role in preventing cerium reduction.

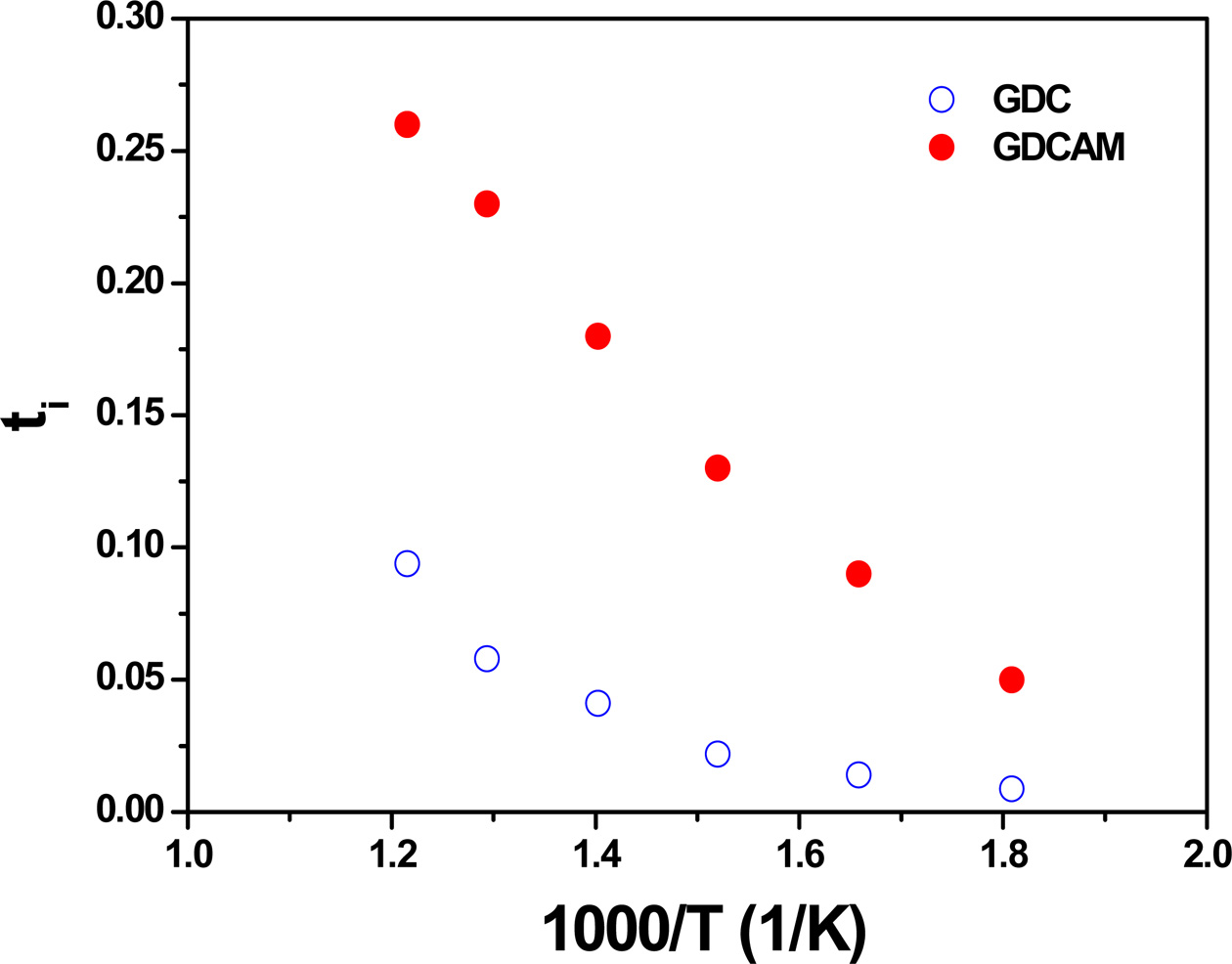

Based on conductivity in air and in reducing atmosphere

(long-time exposure), ti was calculated and is shown in Fig.

5. As seen in the figure, ti of GDCAM is higher than that of

GDC, showing that GDCAM suppresses electron conduction in reducing conditions.

This result demonstrates again that Al and Mn additions are

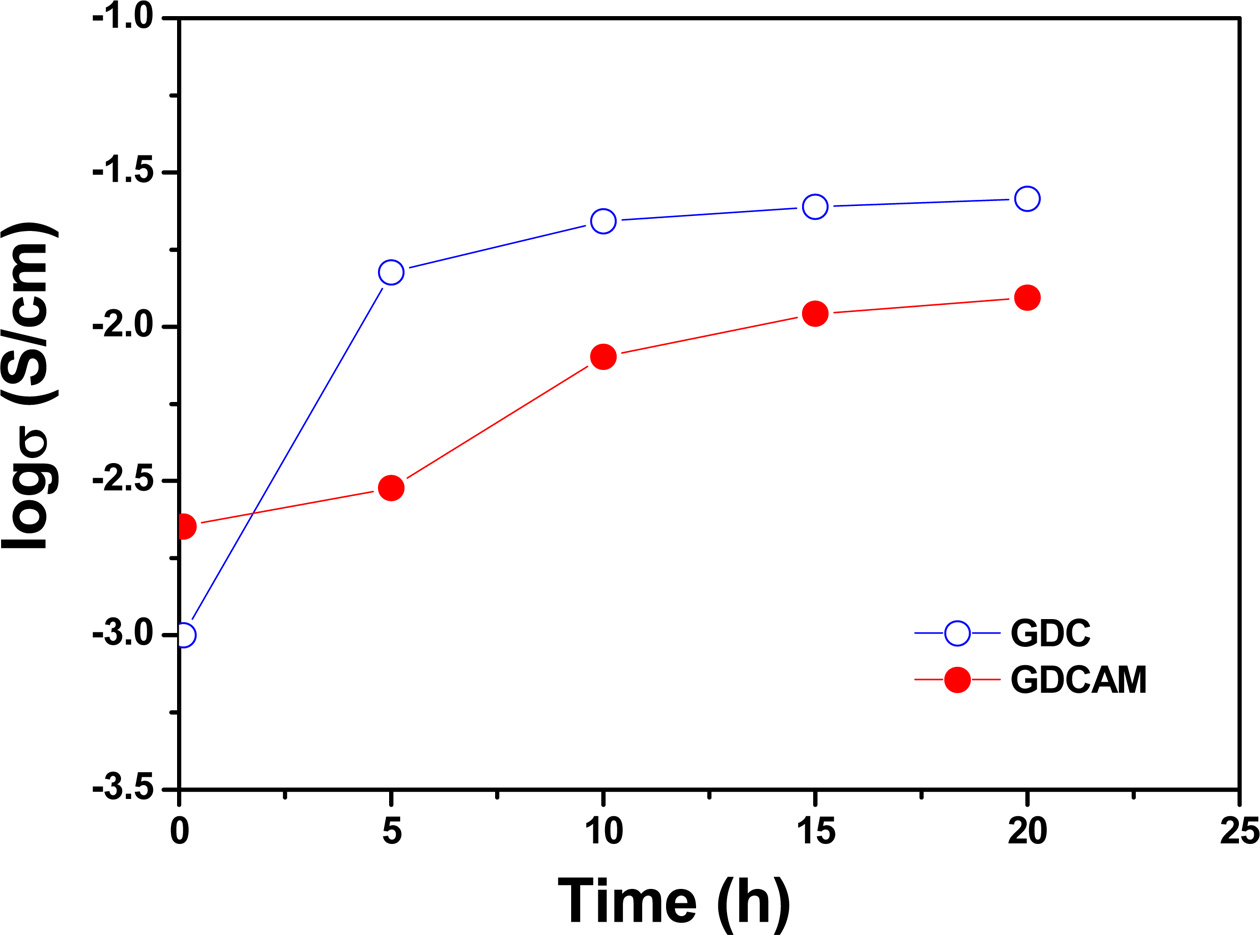

effective in reducing Ce-reduction. Fig. 6 shows the time

dependence of tis in GDC and GDCAM. The results confirm the

suppression of the electronic conduction of GDCAM in reducing conditions.

As another effect of adding Al and Mn

elements, stotal in

air is increased compared to purely that of GDC, showing improved oxygen ionic

conductivity (compare with totals of GDC (Fig. 4a) and GDCAM

(Fig. 4b)). The stotal of GDCAM in air is also competitive or higher than the reported ionic

conductivities. For example, the stotal of GDCAM at 500 oC is 0.004 S/cm and the reported values by S. Dikment et al. and H. Kim et

al. are ~ 0.0009 S/cm and 0.002 S/cm

at the same temperature and oxygen partial pressure [9, 11]. It is believed

that successfully synthesized nanoparticles using USP and multi-components (Al

and Mn) increase the sinterability of ceria. The sample fabricated using

conventional ceramic processing (solid-state reaction) shows a relative density

below 95 % [9]. In this study, it was observed that increasing sinterability

decreases grain and gb resistance (compare the gb resistances between Fig. 3a

and b). The relative densities of GDC and GDCAM are ~ 94% and 96%,

respectively.

Conclusively, the addition of Al and Mn to ceria decreases

total resistance, the summation of the grain and gb resistance, and more

importantly, suppresses the electronic conduction in reducing atmosphere in

ceria, demonstrating that it can be a viable solid electrolyte for IT-SOFC.

|

Fig. 1 X-ray diffraction patterns of GDC and GDCAM (a) powders and (b) sintered pellets. In Fig. 1b, the square marks indicate the secondary phase (GdAlO3). |

|

Fig. 2 FE-SEM images of as-prepared powders of (a) GDC and (b), (c) GDCAM. |

|

Fig. 3 The complex impedance plots of (a) GDC and (b) GDCAM at 230 oC. Solid square symbols indicate the impedance patterns of GDC and GDCAM in air, and solid and open circles in the inset correspond those of GDC and GDCAM in reducing condition for short and long terms, respectively. |

|

Fig. 4 Arrhenius plots of the total conductivities of (a) GDC and (b) GDCAM in various atmospheres. |

|

Fig. 5 Ionic transference numbers of GDC and GDCAM as a function of temperature. |

|

Fig. 6 The total conductivities of GDC and GDCAM at 440 oC and in reducing condition as a function of time. |

In this study, Al- and Mn-added GDC was designed to

overcome some weakness of a ceria solid electrolyte such as low sinterability

and electronic conduction generation. GDC and Al- and Mn-added GDC powders were

synthesized using USP and then sintered using spark plasma sintering technique.

As a result, the successfully dense pellets were obtained. The addition of Al

and Mn components enhanced the relative density of the ceria leading to an

increase of the ionic conduction and mechanical strength. More importantly,

this addition suppressed the electronic conduction of ceria in

reducing atmosphere, which is a major problem in the

commercialization of ceria as a solid electrolyte for IT-SOFCs.

I am very grateful to Prof. Y. Choa and Prof. H. Park for

helping me synthesize powder and some experiments.

- 1. B.C.H. Steele and A. Heinzel, Nature 414 (2001) 345-352.

-

- 2. N.Q. Minh, J. Am. Ceram. Soc. 76 (1993) 563-588.

-

- 3. T. Suzuki, Z. Hasan, Y. Funahashi, T. Yamaguchi, Y. Fujishiro and M. Awano, Science 325 (2009) 852-855.

-

- 4. Z. Shao and S.M. Haile, Nature 431 (2004) 170-173.

-

- 5. W. Zhou, R. Ran and Z. Shao, J. Power Sources 192 (2009) 231-246.

-

- 6. H.J. Park, T.G. Kim, C. Kwak, D.W. Jung, S.M. Lee and K.H. Lee, J. Power Sources 275 (2015) 884-887.

-

- 7. Z. Tianshu, P. Hing, H. Huang and J. Kilner, Solid State Ionics 148 (2002) 567-573.

-

- 8. J.G. Cheng, S.W. Zha, J. Huang, X.Q. Liu and G.Y. Meng, Mater. Chem. and Phys. 78 (2003) 791-795.

-

- 9. H.N. Kim, H.J. Park and G.M. Choi, J. Electroceram. 17 (2006) 793-795.

-

- 10. L. Ge, R. Li, S. He, H. Chen and L. Guo, J. Power Sources 230 (2013) 161-168.

-

- 11. S. Dikmen, P. Shuk, M. Greenblatt and H. Gocmez, Solid State Sciences 4 (2002) 585-590.

-

- 12. R.T. Leah, N.P. Brandon and P. Aguiar, J. Power Sources 145 (2005) 336-352.

-

- 13. S. Wang, T. Kobayashi, M. Dokiya and T. Hashimoto, J. Electrochem. Soc. 147 (2000) 3606-3609.

-

- 14. B. Wang, B. Zhu, S. Yun, W. Zhang, C. Xia, M. Afzal, Y. Cai, Y. Liu, Y. Wang and H. Wang, NPG Asia Materials 11 (2019) 51.

-

- 15. A. Arabaci and M.F. Oksuzomer, Ceramics International 38 (2012) 6509-6515.

-

- 16. D. Kashyap, P. K. Patro, R. K. Lenka, T. Mahata and P.K. Sinha, Ceramics International 40 (2014) 11869-11875.

-

- 17. H. J. Park and G.M. Choi, Solid State Ionics 178 (2008) 1746-1755.

-

- 18. J.D. Nicholas and L.C. De Jonghe, Solid State Ionics 178 (2007) 1187-1194.

-

- 19. Y.J. Kang and G.M. Choi, Solid State Ionics 180 (2009) 886-890.

-

- 20. Y.J. Kang, H.J. Park and G.M. Choi, Solid State Ionics 179 (2008) 1602-1605.

-

This Article

This Article

-

2020; 21(S1): 63-67

Published on May 31, 2020

- 10.36410/jcpr.2020.21.S1.s63

- Received on Jan 28, 2020

- Revised on Apr 6, 2020

- Accepted on Apr 14, 2020

Services

Services

- Abstract

introduction

experimental

results and discussion

conclusions

- Acknowledgements

- References

- Full Text PDF

Shared

Correspondence to

Correspondence to

- Ji Young Park

-

Department of Materials Science and Engineering, University of Seoul, Seoul 02504, Korea

Tel : +82-2-6490-2400

Fax: +82-2-6490-2404 - E-mail: tojyp19@uos.ac.kr

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.