- Effect of gas condition on graphene synthesized by rapid thermal chemical vapor deposition

Yang Soo Leea,†, Dong In Jeonga,†, Yeojoon Yoonb,†, Byeongmin Baekc, Hyung Wook Choid, Seok Bin Kwona, Do Hun Kimc, Young Joon Honge, Won Kyu Parkf, Young Hyun Songg, Bong Kyun Kangc, Dae Ho Yoona,* and Woo Seok Yangc,*

aSchool of Advanced Materials Science and Engineering, Sungkyunkwan University, Suwon 440-746, Republic of Korea

bDepartment of Environmental Engineering, Yonsei University, Wonju-si, Gangwon-do, Republic of Korea

cNano Materials and Components Research Center, Korea Electronics Technology Institute, Seongnam-si, Gyeonggi-do 13509, Republic of Korea

dSKKU Advanced Institute of Nanotechnology (SAINT), Sungkyunkwan University, Suwon 16419, Korea

eDepartment of Nanotechnology and Advanced Material Engineering, Sejong University, Seoul 05006, Republic of Korea

fNano Material Division, Cheorwon Plasma Research Institute, Cheorwon, Gangwon, 24047, Republic of Korea

gLighting Design & Component Research Center, Korea Photonics Technology Institute, Gwangju 61007, Republic of Korea

Graphene was synthesized using

rapid thermal chemical vapor deposition (RT-CVD) equipment designed to produce

large-area graphene at high speed. The effects of methane (CH4),

argon (Ar), and hydrogen (H2) gases were investigated between 800 oC

and 1,000 oC during heating and cooling in the graphene

synthesis process. The findings reveal that multilayer domains increased due to

hydrogen pretreatment with increase in temperature. Furthermore, when

pretreated with the same gas, it was confirmed that the post-argon-treated

sample cooled from 1,000 oC to 800 oC had a

higher ID/IG value than that of the other samples. This

result was consistent with the sheet resistance properties of graphene. The

sample prepared in methane atmosphere maintained during both the pre-treatment

and post-treatment demonstrated the lowest sheet resistance of 787.49 Ω/sq. Maintaining the methane gas atmosphere in the

high-temperature region during graphene synthesis by RT-CVD reduced the defects

and improved the electrical property.

Keywords: Graphene, Rapid thermal chemical vapor deposition, Gas condition

The progress in information and communication technology

has led to the rapid development of electronic materials

industry [1]. With the growing popularity of smart devices, research on high

performance and light- weight

products has rapidly increased in the last several years.

Carbon materials (carbon nanotube, graphene, g–C3N4) have

attracted tremendous attention as high value-added materials due to their

lightweight, higher strength, good chemical, and thermal stability

properties compared to other materials [2, 3]. In addition, its

excellent electrical properties and chemical stability

makes a potential candidate for energy storage, batteries and

electrode materials [4-6].

Especially, graphene, sp2-hybridized carbon

atoms, has superior electronic, optical, thermal, and mechanical

properties [7, 8].

To effectively apply the various excellent properties of

graphene to electronic materials, it is necessary to study the conditions of

graphene synthesis process [9]. Chemical vapor deposition (CVD) is a suitable

method for producing large-scale single-layer graphene [10, 11]. Graphene

synthesized by CVD is a polycrystalline material, in which several

micrometer-scale domains consisting of carbon, grow in two dimensions. Also,

CVD method has been conducted to achieve uniform growth of single and large

area carbon films on the transition metal surface at relatively low process

costs [11-13]. During CVD synthesis of graphene, the synthetic

conditions such as gas used, temperature, and pressure, affect the characteristics

of the graphene synthesized. Therefore, investigating the synthesis mechanism

of large-area and high-quality graphene is necessary to effectively apply the

excellent properties of graphene to transparent electrodes and various

electronic devices [5, 14].

However, thin film synthesis in conventional thermal CVD

(T-CVD) equipment is time consuming, hindering the

commercialization of monolayer graphene. Thus, the rapid thermal chemical vapor

deposition (RT-CVD, RHP400V, NPS Corporation) equipment is suitable for

graphene synthesis on the surfaces of large-area metal catalysts [15].

Furthermore, the RT-CVD could synthe-

size the graphene film about 7 times faster than the conventional T-CVD

equipment [15]. Since the RT-CVD equipment is not widely available, there have

been limited studies on the suitable process conditions for high-speed graphene

synthesis. To investigate the properties of synthesized graphene using the

RT-CVD, have been analyzed such as the crystal structure, defects,

optical properties, and electrical properties [16, 17].

Process conditions such as temperature, gas, and pressure

affect the properties of chemical-vapor-deposition materials

[18-20]. The optimum ratio of hydrocarbon gas to hydrogen gas promotes the

synthesis of low-defect monolayer graphene on copper foils, which was

determined by the interaction between graphene growth and etching [21].

Especially, hydrogen plays an important role in the growth process of graphene

by CVD as an activator for size-limited graphene domain growth and carbon

adsorption on the surface of copper foils [21, 22]. Furthermore, the synthesis

of graphene using a high purity methane precursor was reported at 800 oC,

which is lower than the typical temperature for graphene synthesis [23].

In this study, the graphene was synthesized in various gas

conditions and growth temperatures (800 oC ~ 1,000 oC)

by RT-CVD. In addition, to understand the effect of methane (hydrocarbon

precursor), hydrogen, and argon (inert gas) on graphene synthesized by RT-CVD process,

the synthetic processes were divided into 5 steps. The characteristics of

graphene on various growth conditions was investigated.

Graphene synthesis was performed using a RT-CVD system

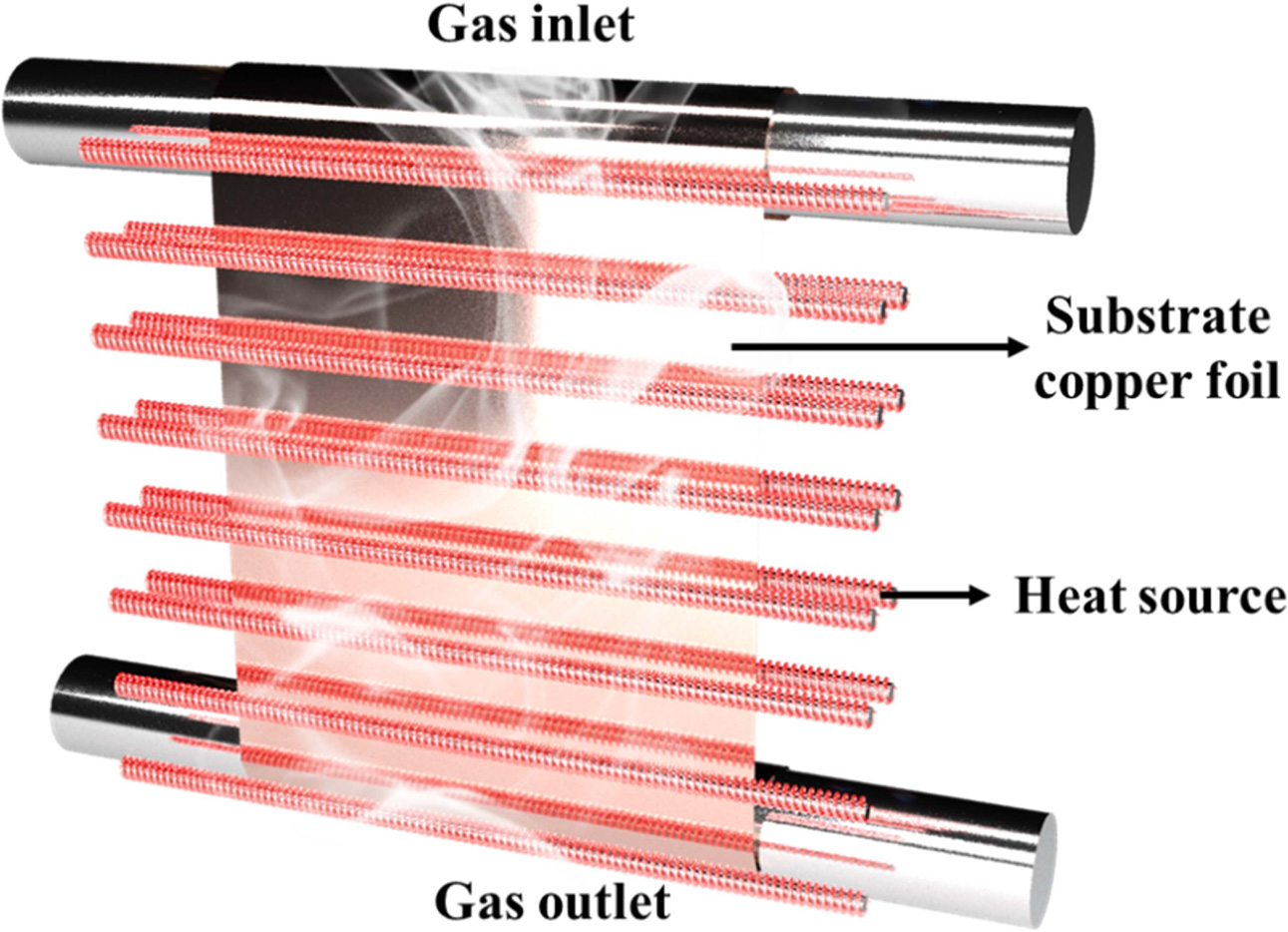

(RHP400V, NPS Corporation). Fig. 1 show the schematic of RT-CVD furnace. Since

the RT-CVD system is equipped with several linear heating elements,

it can heat up to over 7 times faster than a typical CVD furnace. Graphene was

grown on the surface of a rolled copper foil (Nippon Mining & Metals

Corporation, at least 99.9%) having a thickness of 0.035 mm, width of 350 mm,

and length of 480 mm.

Within the CVD equipment, the carbon precursor was

adsorbed on both sides of the copper foil. To obtain monolayer

graphene, the graphene grown on one side of the copper foil was etched with

oxygen plasma for 10 s at a pressure of 110 mTorr and with 50 W RF

power using reactive ion etching equipment (SciEnTech Co., Ltd.).

To prevent the tearing of graphene after the etching of the copper foil,

polymethyl methacrylate (PMMA) was spin coated on the graphene with a spin

coater at 4,000 rpm for 30 s. The PMMA coated graphene/Cu sample was thermally

cured at 180 oC for 1 min using a hot plate. A silicon wafer

coated with a 300-nm-thick oxide layer was sonicated in Standard Cleaning-1

(SC-1) solution (NH4OH:H2O2:H2O = 1:1:5). The

PMMA-coated thermally cured graphene/Cu samples were then

etched with ammonium persulfate (APS) solution for 8 h. The APS solution was

prepared by dissolving 32 g of APS powder in 2 L of deionized water. The

PMMA-coated graphene film was washed with DI water and transferred to the SiO2/Si

wafer. Finally, the PMMA was removed with acetone for about 3 h.

|

Fig. 1 Schematic of RT-CVD furnace capable of synthesizing large-area graphene faster. |

The morphology of the synthesized graphene was measured

using a field emission scanning electron microscope (FE-SEM, JSM-700F, JEOL).

High purity (99.999%) commercial argon, hydrogen (MS DONGMIN SPECIALTY

GAS Ltd.), and methane (KOREA NOBLE GAS CO.) gas were used. The

absorbance spectrum of graphene was measured using a UV-visible spectro- photometer (Cary 60 UV-Vis, Agilent

Technologies). The electronic structure of graphene was evaluated using a Raman

spectroscopy (Confotec MR520, SOL instruments) with a 532 nm laser source, and

the electrical properties of graphene were measured using a four-point probe

instrument (Loresta-GP/MCP-T610, Mitsubishi Chemical Analytech Co.).

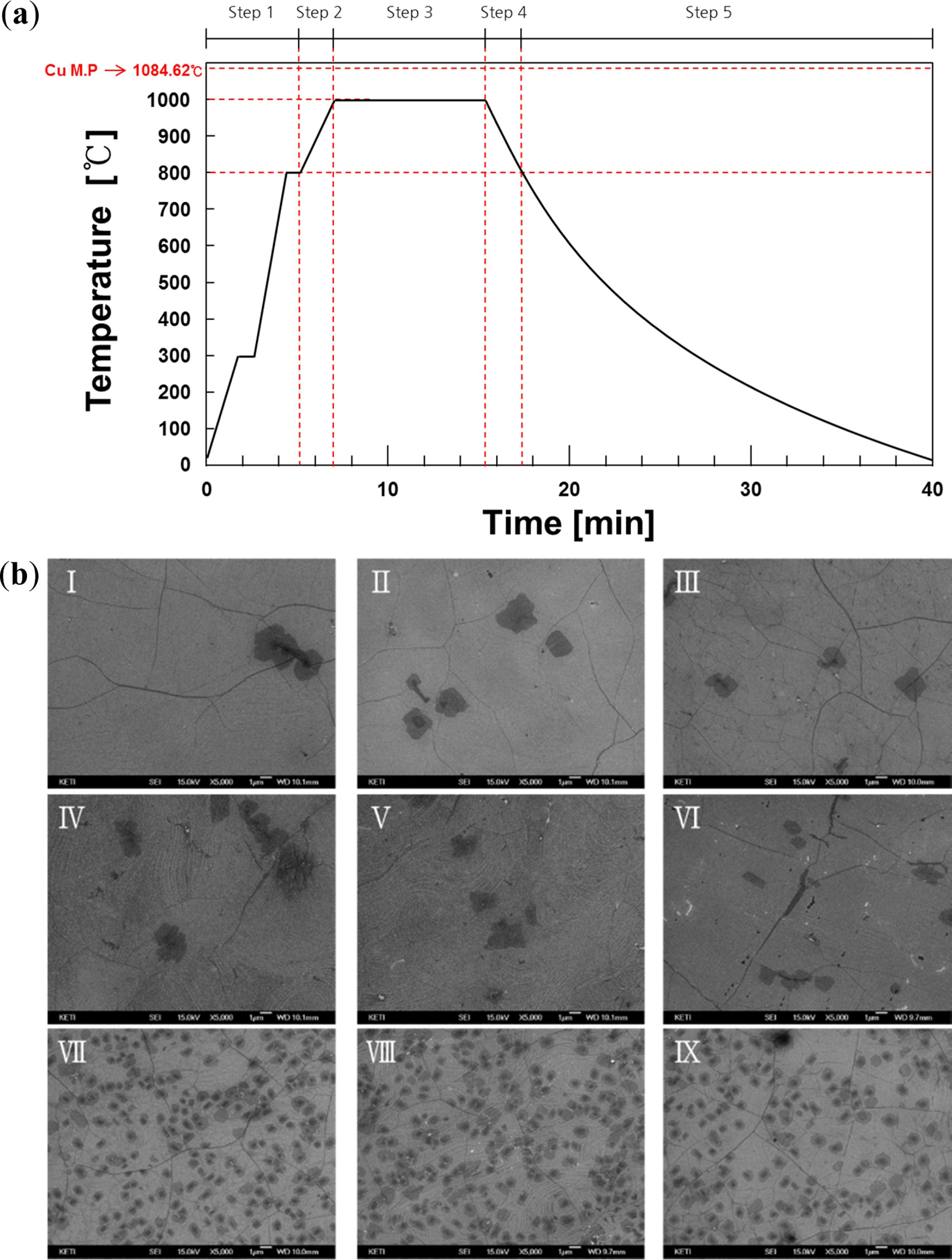

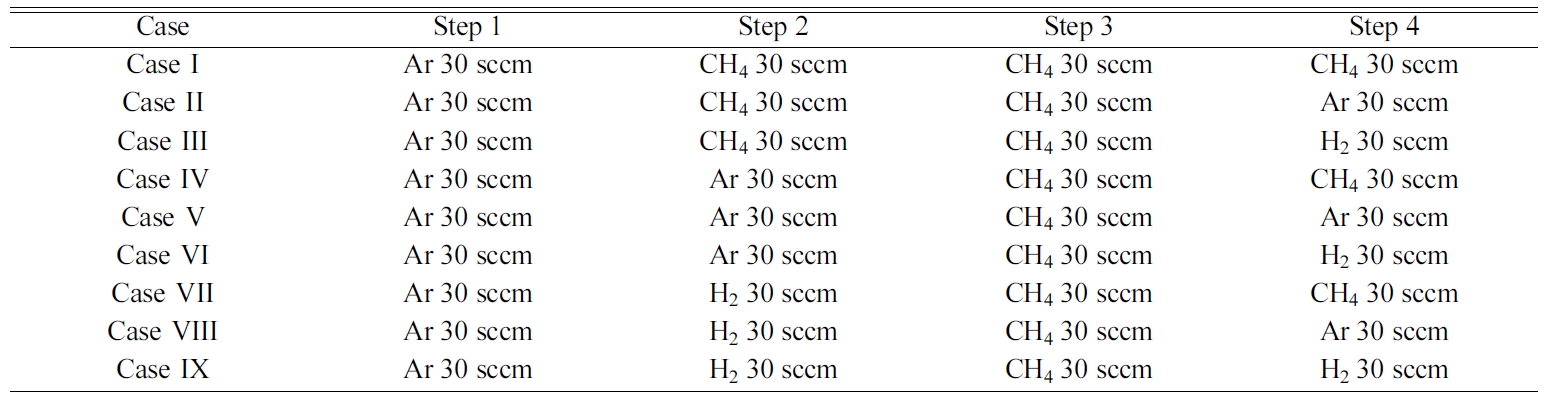

The synthesis process was separated into 5 steps to analyze

the impact of the different gas species on graphene properties at 800 oC

and 1,000 oC. In all the graphene synthesis processes, the

RT-CVD chamber was evacuated and maintained to 550 mTorr using a rotary vacuum

pump.

At the beginning of the process (Table. 1), It was heat up

to 800 oC from room temperature, at a heating rate of 140 oC/min

in an atmosphere of 30 sccm Ar flowing (Step1). Next, the copper foil was

thermally treated from 800 oC to 1,000 oC under

CH4, Ar, and H2 gases at an atmosphere of 30 sccm gas

flowing (Step2). Graphene was synthesized at 1,000 oC for 500

seconds in an atmosphere of 30 sccm CH4 flowing (Step3). After

the completion of graphene growth, an atmosphere of 30 sccm

of CH4, Ar, and H2 gases were flowed while lowering the

temperature of the copper foil from 1,000 oC to 800 oC

(Step4). Finally, the CVD chamber was cooled from 800 oC to

room temperature with continuous N2 flow at the rate of 1,0000 sccm.

Fig. 2(a) shows the temperature conditions of the RT-CVD synthesis process. The

gas conditions were as follows: Sample I: CH4 (step2)-CH4

(step4) flow, Sample II: CH4-Ar, Sample III: CH4-H2,

Sample IV: Ar-CH4, Sample V: Ar-Ar, Sample VI: Ar-H2,

Sample VII: H2-CH4, Sample VIII: H2-Ar, and

Sample IX: H2-H2, respectively. The FE-SEM surface images

of graphene transferred onto the silicon wafer were as shown in Fig. 2(b). The

FE-SEM images of samples VII, VIII, and IX show the

formation of numerous multilayer graphene domains when

hydrogen gas was introduced in Step2. Graphene was synthesized by

methane and the remaining hydrogen

promoted the formation of multilayer graphene on the

surface of the transition metal catalyst in Step3 [21].

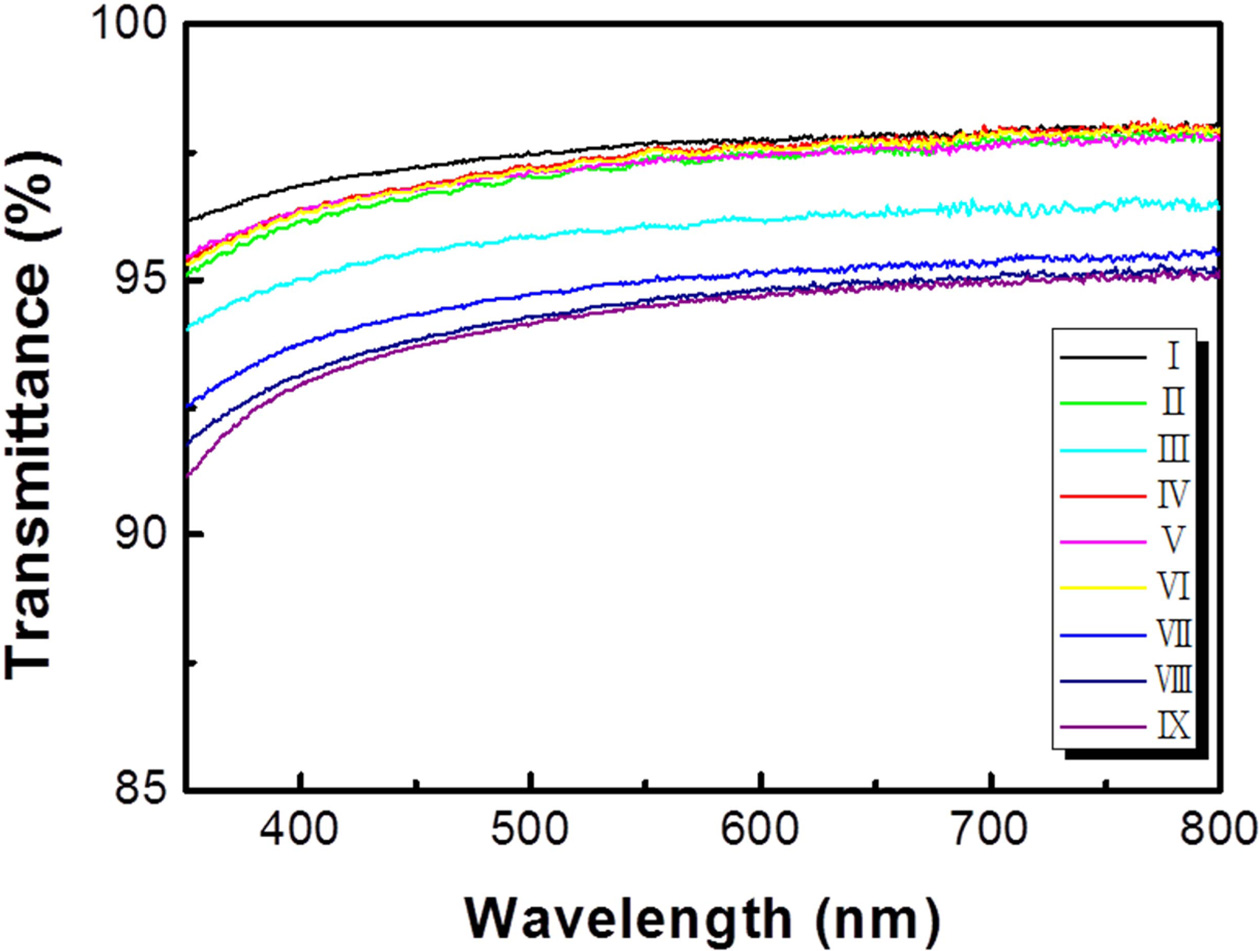

The optical properties of the synthesized graphene are

shown in Fig. 3. For samples VII, VIII, and IX, in which

multilayer domains were formed due to hydrogen

pretreatment, the measured transmittances were 94.97, 94.60, and

94.48%, respectively, and indicated an average absorption

rate of 5.32% (at 550 nm). In contrast, sample I exhibited the best transparency

(97.64%). Graphene was found to absorb approximately 2.3% of incident white

light [24, 25]. It was concluded that the graphene

domain islands with about 2~3 layers decreased the light

transmittance. Due to the effects of residual hydrogen and

methane on fast process rates, the domain density can

be increased. Lower nucleation barriers can increase graphene nucleation

density on the copper oxide compared with that ramped up and annealed on gas

conditions without hydrogen [21].

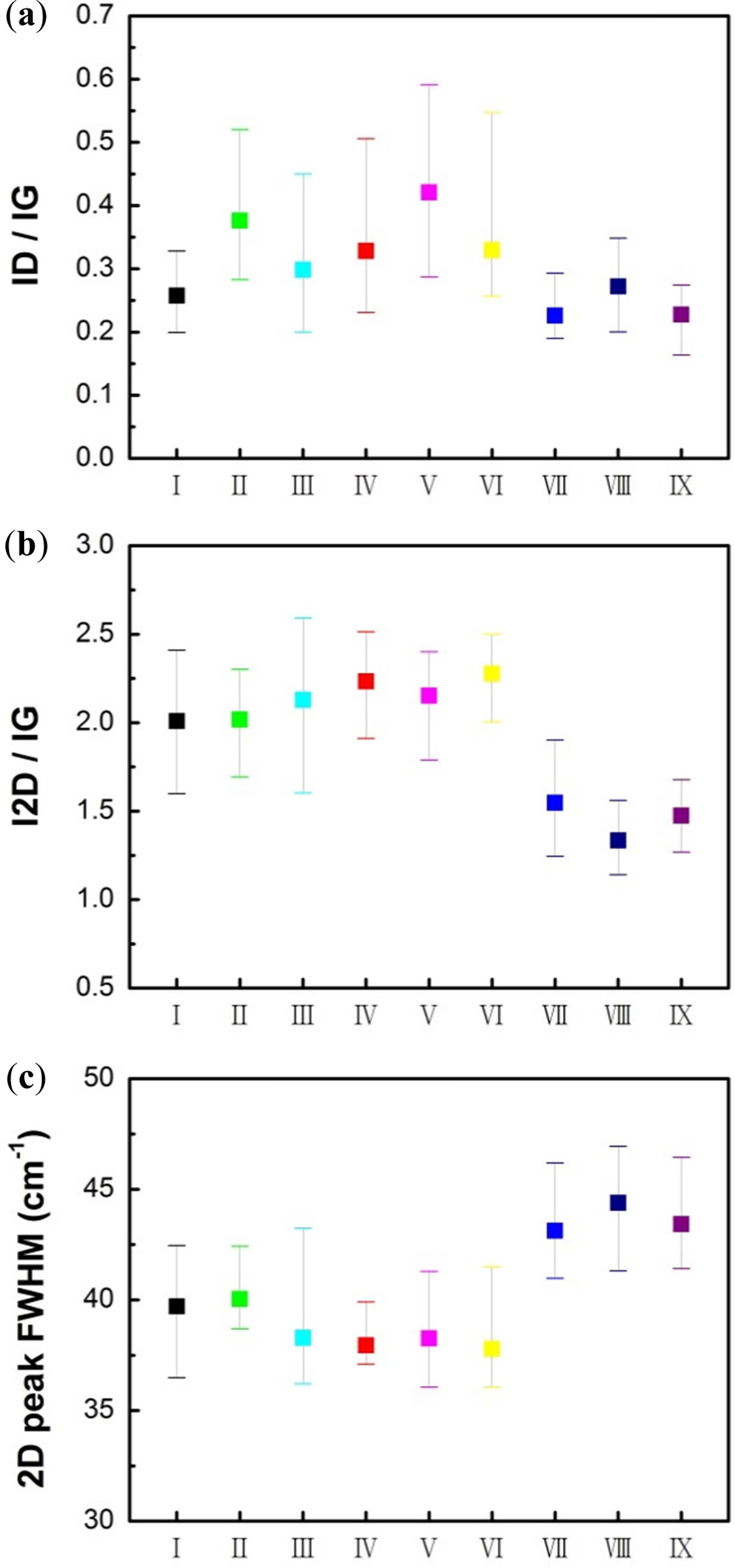

The statistical analyses of Raman spectral data of

graphene grown in nine different gas conditions were as presented in Fig. 4.

Raman spectroscopy can provide information about the lattice structure of the

target material using single frequency light such as a laser. The main features

in the Raman spectra of carbon were the D peaks (1,350 cm-1),

G peaks (1,580 cm-1)

and 2D peaks (2,700 cm-1),

respectively. The disorder-induced D peak is not apparent in pristine graphene

because of crystal symmetry, while the G peak, which is the primary in-plane

vibrational mode according to the bond stretching in both

rings and chains, was derived from all pairs of sp2-hybridized

carbon atoms. One way to characterize the disorder and defect levels of

graphene is to use Raman spectra for the intensity ratio (ID/IG)

of the D peak to G peak. Furthermore, the 2D peak is owing to double

resonance, which links the phonon wave vectors to the

electronic band structure. In addition, near the K point containing the phonon,

the 2D peak occurs as a result of the 2-phonon resonance process. The 2D peak

is very prominent in graphene than in bulk graphite.

Graphene can be deduced from the number of layers of

graphene using the intensity ratio of 2D peak to G peak (I2D/IG).

The I2D/IG ratio of pristine single-layer graphene was

3.4 [25-31]. In this study, Raman ratio was directly obtained from the

statistical analysis with 20 points. The ID/IG ratios of

samples I (0.258), VII (0.226), VIII (0.272), and IX (0.228) were lower than

that of the other samples. Formation of multi-layer graphene domains with

hydrogen pretreatment, and low ID/IG ratios were

calculated for samples VII, VIII, and IX. Among the samples synthesized under

the same gas conditions in Step2, the strongest D peak appeared for

the sample for which argon was introduced in Step4.

The absence of a reducing gas such as hydrogen and methane

to protect from oxidizing impurities promote defects [31].

The average value of I2D/IG ratio of

graphene and the full width at half maximum (FWHM) of the 2D peak distinguished

the graphene layer [27]. Samples VII, VIII, and IX exhibited lower I2D/IG

ratios and higher FWHM values than those of the samples prepared in

other conditions.

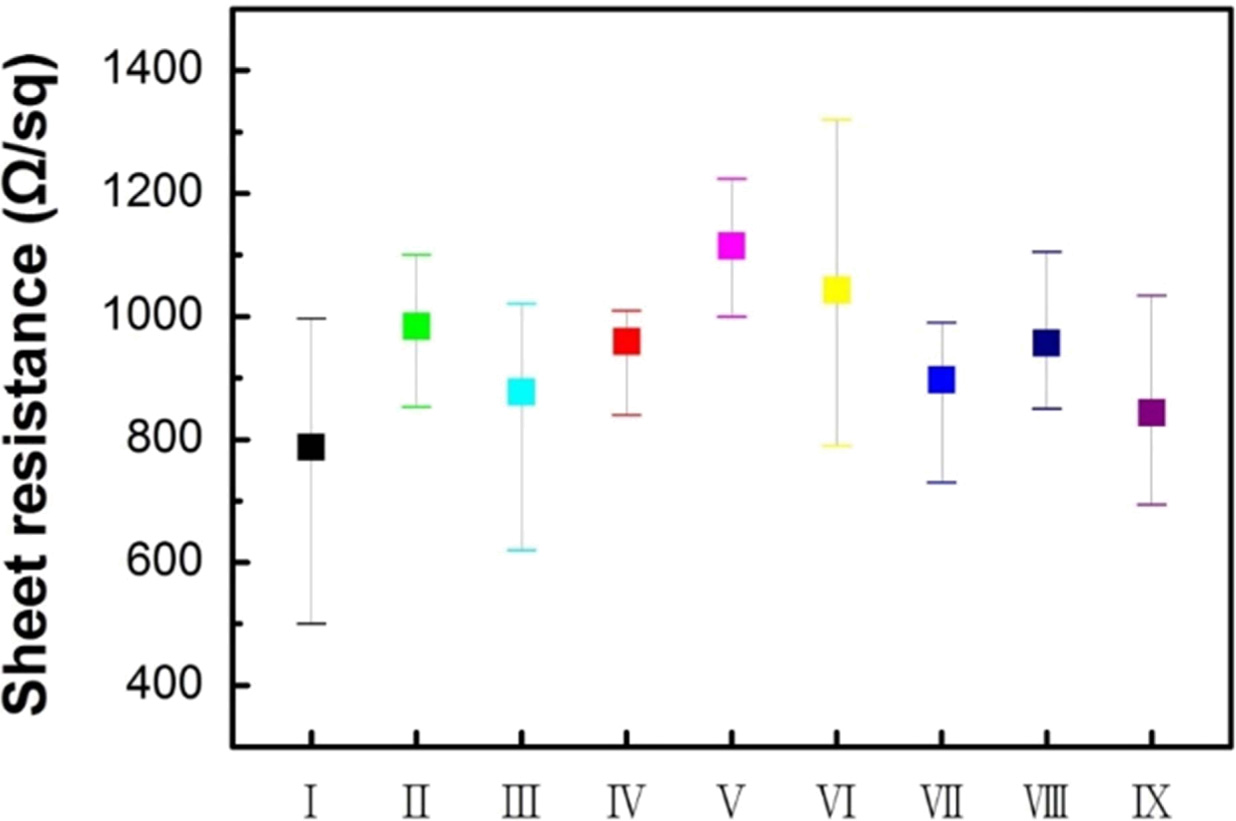

Fig. 5 shows the graphene sheet resistance to nine

graphene synthesis gas conditions. The lowest average sheet resistance of

787.49 Ω/sq was measured for sample 1. Among the samples

synthesized under the same gas conditions in Step2, the highest

sheet resistance was recorded for the sample for which argon was introduced in

Step4. The trend of sheet resistance (Fig. 5) is similar to that of ID/IG

ratio (Fig. 4 (a)). Further, the relatively poor electrical conductivity of

graphene is due to structural defects formed during the synthesis process [10].

Table 1

|

Fig. 2 (a) Process steps of graphene synthesis using RT-CVD. And (b) FE-SEM images of graphene synthesized in nine different gas conditions; Sample I: CH4-CH4, Sample II: CH4-Ar, Sample III: CH4-H2, Sample IV: Ar-CH4, Sample V: Ar-Ar, Sample VI: Ar-H2, Sample VII: H2-CH4, Sample VIII: H2-Ar, Sample IX: H2-H2. |

|

Fig. 3 Optical transmittance of graphene synthesized in nine different gas conditions. |

|

Fig. 4 Raman spectral data of graphene synthesized in nine different gas conditions. (a) ID/IG ratio, (b) I2D/IG ratio, and (c) 2D peak FWHM. |

|

Fig. 5 Sheet resistance of graphene synthesized in nine different gas conditions. |

Graphene synthesis using RT-CVD under various gas

conditions and hydrogen pre-treatment in Step2 led to the growth of multi-layer

graphene domains. On the other hand, the absence of a reducing gas promoted

defects, which led to the degradation of electrical characteristics.

The flow of methane in Step2 and Step4 during graphene synthesis by

RT-CVD caused less degradation of electrical properties and provided

optical properties similar to that of pristine graphene.

This work was supported by the “World Class 300 Project

(R&D) (S2561932)” of the MOTIE, MSS (Korea). This work

was supported by the Ministry of Trade, Industry and Energy through Technology

Innovation Program (Grant No. 10067449). This work was partly supported

by the GRRC program of Gyeonggi province [GRRC

Sungkyunkwan 2017-B03, Development of chemical sensor based on metal oxide

materials]. This work was supported by the Korea Basic Science

Institute (KBSI) National Research Facilities

& Equipment Center (NFEC) grant

funded by the Korea government (Ministry of

Education) (No. 2019R1A6C1010031).

†Y.S. Lee, †D.I.

Jeong, and †Y. Yoon contributed equally to

this work. †Y.S. Lee, †D.I. Jeong, and †Y.

Yoon designed and wrote this study.

- 1. K.S. Novoselov, V. Fal, L. Colombo, P. Gellert, M. Schwab, and K. Kim, Nature 490[7419] (2012) 192-200.

-

- 2. O.C. Compton and S.T. Nguyen, Small 6[6] (2010) 711-723.

-

- 3. C. Lee, X. Wei, J.W. Kysar, and J. Hone, Science 321[5887] (2008) 385-388.

-

- 4. M. Pumera, Energy Environ. Sci. 4[3] (2011) 668-674.

-

- 5. X. Wang, L. Zhi, and K. Müllen, Nano Lett. 8[1] (2008) 323-327.

-

- 6. X. Yang, J. Zhu, L. Qiu, and D. Li, Adv. Mater. 23[25] (2011) 2833-2838.

-

- 7. V. Goyal and A.A. Balandin, Appl. Phys. Lett. 100[7] (2012) 073113.

-

- 8. M.I. Katsnelson, Mater. Today 10[1-2] (2007) 20-27.

-

- 9. A.C. Neto, F. Guinea, N.M. Peres, K.S. Novoselov, and A.K. Geim, Rev. Mod. Phys. 81[1] (2009) 109-162.

-

- 10. K.S. Kim, Y. Zhao, H. Jang, S.Y. Lee, J.M. Kim, K.S. Kim, J.-H. Ahn, P. Kim, J.-Y. Choi, and B.H. Hong, Nature 457[7230] (2009) 706-710.

-

- 11. A. Reina, X. Jia, J. Ho, D. Nezich, H. Son, V. Bulovic, M.S. Dresselhaus, and J. Kong, Nano Lett. 9[1] (2008) 30-35.

-

- 12. M. Losurdo, M.M. Giangregorio, P. Capezzuto, and G. Bruno, Phys. Chem. Chem. Phys., 13[46] (2011) 20836-20843.

-

- 13. C. Mattevi, H. Kim, and M. Chhowalla, J. Mater. Chem. 21[10] (2011) 3324-3334.

-

- 14. X. Li, Y. Zhu, W. Cai, M. Borysiak, B. Han, D. Chen, R.D. Piner, L. Colombo, and R.S. Ruoff, Nano Lett. 9[12] (2009) 4359-4363.

-

- 15. J. Ryu, Y. Kim, D. Won, N. Kim, J.S. Park, E.-K. Lee, D. Cho, S.-P. Cho, S.J. Kim, and G.H. Ryu, ACS Nano 8[1] (2014) 950-956.

-

- 16. F. Banhart, J. Kotakoski, and A.V. Krasheninnikov, ACS Nano 5[1] (2010) 26-41.

-

- 17. A. Hashimoto, K. Suenaga, A. Gloter, K. Urita, and S. Iijima, Nature 430[7002] (2004) 870-873.

-

- 18. S. Bhaviripudi, X. Jia, M.S. Dresselhaus, and J. Kong, Nano Lett. 10[10] (2010) 4128-4133.

-

- 19. Y. Hao, M. Bharathi, L. Wang, Y. Liu, H. Chen, S. Nie, X. Wang, H. Chou, C. Tan, B. Fallahazad, H. Ramanarayan, C. W. Magnuson, E. Tutuc, B. I. Yakobson, K. F. McCarty, Y.-W. Zhang, P. Kim, J. Hone, L. Colombo, and R. S. Ruoff, Science 342[6159] (2013) 720-723.

-

- 20. X. Li, W. Cai, J. An, S. Kim, J. Nah, D. Yang, R. Piner, A. Velamakanni, I. Jung, E. Tutuc, E. Tutuc, S. K. Banerjee, L. Colombo, and R. S. Ruoff, Science 324[5932] (2009) 1312-1314.

-

- 21. I. Vlassiouk, M. Regmi, P. Fulvio, S. Dai, P. Datskos, G. Eres, and S. Smirnov, ACS Nano 5[7] (2011) 6069-6076.

-

- 22. X. Li, C.W. Magnuson, A. Venugopal, R.M. Tromp, J.B. Hannon, E.M. Vogel, L. Colombo, and R.S. Ruoff, J. Am. Chem. Soc. 133[9] (2011) 2816-2819.

-

- 23. L. Tao, J. Lee, H. Chou, M. Holt, R.S. Ruoff, and D. Akinwande, ACS Nano 6[3] (2012) 2319-2325.

-

- 24. R.R. Nair, P. Blake, A.N. Grigorenko, K.S. Novoselov, T.J. Booth, T. Stauber, N.M. Peres, and A.K. Geim, Science 320[5881] (2008) 1308-1308.

-

- 25. D. Yoon, Y.-W. Son, and H. Cheong, Phys. Rev. Lett. 106[15] (2011) 155502.

-

- 26. Z. Ni, Y. Wang, T. Yu, and Z. Shen, Nano Res. 1[4] (2008) 273-291.

-

- 27. Y. Hao, Y. Wang, L. Wang, Z. Ni, Z. Wang, R. Wang, C.K. Koo, Z. Shen, and J.T. Thong, Small 6[2] (2010) 195-200.

-

- 28. D.R. Cooper, B. D’Anjou, N. Ghattamaneni, B. Harack, M. Hilke, A. Horth, N. Majlis, M. Massicotte, L. Vandsburger, and E. Whiteway, ISRN Condens. Matter Phys. 2012 (2012) 1-56.

-

- 29. I. Childres, L.A. Jauregui, J. Tian, W. Park, H. Cao, and Y.P. Chen, New Developments in Photon and Materials Research 1. 13[2] (2013) 025008.

-

- 30. C. Casiraghi, S. Pisana, K. Novoselov, A. Geim, and A. Ferrari, Appl. Phys. Lett. 91[23] (2007) 233108.

-

- 31. S. Choubak, P.L. Levesque, E. Gaufres, M. Biron, P. Desjardins, and R. Martel, J. Phys. Chem. C 118[37] (2014) 21532-21540.

-

This Article

This Article

-

2020; 21(S1): 47-52

Published on May 31, 2020

- 10.36410/jcpr.2020.21.S1.s47

- Received on Dec 16, 2019

- Revised on Apr 21, 2020

- Accepted on May 4, 2020

Services

Services

- Abstract

introduction

experimental

characterization

results and discussion

conclusion

- Acknowledgements

- References

- Full Text PDF

Shared

Correspondence to

Correspondence to

- Dae Ho Yoon a and Woo Seok Yang c

-

aSchool of Advanced Materials Science and Engineering, Sungkyunkwan University, Suwon 440-746, Republic of Korea

cNano Materials and Components Research Center, Korea Electronics Technology Institute, Seongnam-si, Gyeonggi-do 13509, Republic of Korea

Tel./Fax: +82-31-290-7388 (D. Yoon), +82-31-789-7057 (W. Yang)

E - E-mail: dhyoon@skku.edu, wsyang@keti.re.kr

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.