- Enhancement of surface roughness of zirconia substrate by slurry coating

Woo Chang Kim and Jong Kook Lee*

Department of Materials Science and Engineering, Chosun University, Gwangju 61452, Korea

In order to increase the bone

bonding-ability and biocompatibility of zirconia-based implants, the surface

roughness must be high. In this study, we tried to improve the surface

roughness of the zirconia substrates by surface modification using two types of

zirconia slurry and spin coating. We also investigated to the effect of

repeated coating times on the surface roughness of coating layer. Coating

layers fabricated by slurry and spin coating showed uniform thickness and dense

microstructure. As increasing the repeated coating times, the thickness of

coating layer gradually increased from 0.7 to 1.7 μm in case of small particles

or from 0.9 to 2.0 μm in case of large particles. Slurry containing small

particles (~ 40 nm) had low viscosity and good forming-ability of coating

films, but the improvement of surface roughness by slurry coating was not high.

Roughness enhancement on coated layer in zirconia slurry containing large

particles (~100nm) was higher than that of small particles at the same

processing condition. In this study, 4 times coating specimen showed maximum

surface roughness of Ra 0.36 μm in 3Y-TZP powder containing large particles, or

Ra 0.27 μm in that of small particles.

Keywords: Zirconia Slurry, Solid loading, Spin coating

Zirconia ceramics have promising mechanical properties,

including corrosion resistance, wear resistance and high stability and it is a

representative ceramic material in various industries [1, 2]. Excellent wear

resistance and high fracture toughness of the ceramic materials

applied to hip implant balls, bearings, grinding ball and various

wear resistant structural materials [3-6]. Additionally, zirconia is white with

high light transmittance, low sensitivity to plaque formation, and excellent

biocom- patibility, suggesting the utilization of

dental implant applications [7-10]. Zirconia materials are also used as oxygen

sensor and solid fuel cell material by utilizing ion

conductivity through oxygen vacancies and is suitable for

manufacturing various ceramic related components [11].

Recently, zirconia-based bioceramics are widely used as

implant materials because of their effective biological properties

such as biocompatibility, minimizing ion release, and low affinity to bacterial

colonization [12, 13]. Of the zirconia ceramics, 3mol% yttria stabilized

tetragonal ziconia polycrystals (3Y-TZP) is frequently used as a main material

for dental ceramic implants. It is also widely studied as a substitute material

for titanium implant due to its high refractive index, light transmittance and

aesthetics.

Enhanced mechanical and biological properties can be

improved by optimizing sintering processes and after surface treatment [14].

3Y-TZP ceramics has biological bioinertness and shows easy failure during implantation

due to the limit of direct bonding between implant and human bone [15-17]. In

order to further increase the bone bonding strength and

biocompatibility of such zirconia- based implants, surface

modification of implants is required [18-20]. The sol-gel and powder slurry

coating methods can be manufactured the surface coating of

zirconia implant through an inexpensive and simple process, enhancing the bone

cohesion and biocompatibility by improving surface roughness [21-22]. Slurry

coating provides a relatively thick coating layer and could be controlled the

thickness by repeated coating times, and is available to obtain the optimal

surface properties for the good induction of bone adhesion during the initial

period after implantation. Additionally, thick coating layer from slurry

coating process has an advantage to use for long periods due to the relatively

slower dissolution rate [23].

The preparation of aqueous slurry is most important in the

ceramic slurry coating process, and it should be controlled the slurry pH,

dispersant content and solid loading in order to produce a stable

and high production efficiency. Sometimes, to supplement the slurry dip

coating or sol-gel dip coating, spin coating is used to apply the coating

uniformity and dense coating layer. In general, the spin coating is thinly

spread on the substrate by the high-speed rotational movement on the substrate

to form a coating layer [24-26].

In this study, two types of 3Y-TZP powder with different

particle size were used to obtain the 3Y-TZP coating with high surface

roughness through the spin coating of aqueous slurry. We also have an

expectation to form a uniform and dense coating layer by this surface

modification, which improves the bone bonding strength

and biocompatibility of zirconia ceramics. In this process, we tried to control

the surface microstructure and roughness by change of slurry parameters,

i.e. particle type of 3Y-TZP and coating times, and investigated the dependence

of processing factors to coating surface and microstructural

evolution.

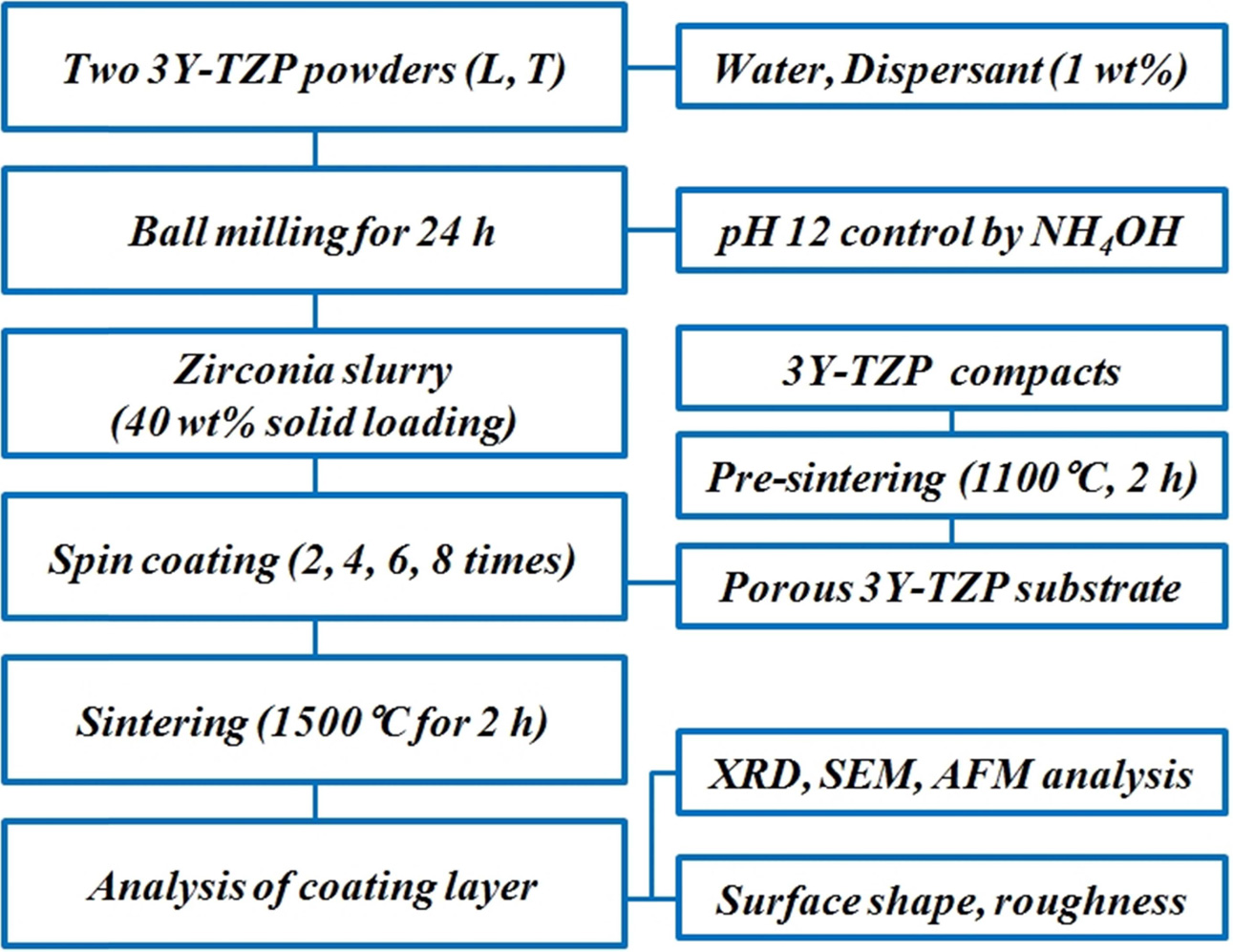

Two sizes of commercial 3Y-TZP powder were used for

zirconia slurry preparation. Powder properties about particle morphology, phase

composition and particle size distribution were characterized, and compared to

the influence on the slurry and coating properties. Slurry preparation

condition obtained from preliminary experiments was used, such as

pH 12, 1 wt.% dispersant (Darvan C), and 40 wt.% solid

loading. Two types of nanoscale 3Y-TZP powder (40 and 100 nm diameter) were

used to prepare the zirconia slurry through ball milling for 24 h as shown in

Fig. 1. Considering the slurry fluidity and coating thickness, the content of

solid loading of 3Y-TZP powder was fixed to 40 wt.%, determined from the

previous results [27].

The 3Y-TZP substrate for slurry coating was fabricated a

disc-type porous specimen by uniaxial pressing and pre-sintering at 1,100 °C

for 2 h. Using a spin coater, zirconia slurry was coated on the pre-sintered

3Y-TZP porous specimen, and repeated a spin coating after drying. Maximum

coating times at solid loading of 40 wt.% was limited to 8 on the

same substrate, considering the variation of surface roughness.

Final sintering after coating was carried out at 1,500 °C

for 2 h. Coated microstructure and surface morphology including surface

roughness were observed by Scanning Electron Microscope (SEM) and Atomic Force Microscope (AFM), and analyzed the

surface microstructure and coating thickness with powder type and coating

times. Of the surface parameter from AFM images, the value of Ra (center line average) was selected as a representative parameter of surface roughness.

Finally we investigated the influence of processing factors to the surface

properties of coated layer.

|

Fig. 1 Schematic flowchart for the experimental procedure. |

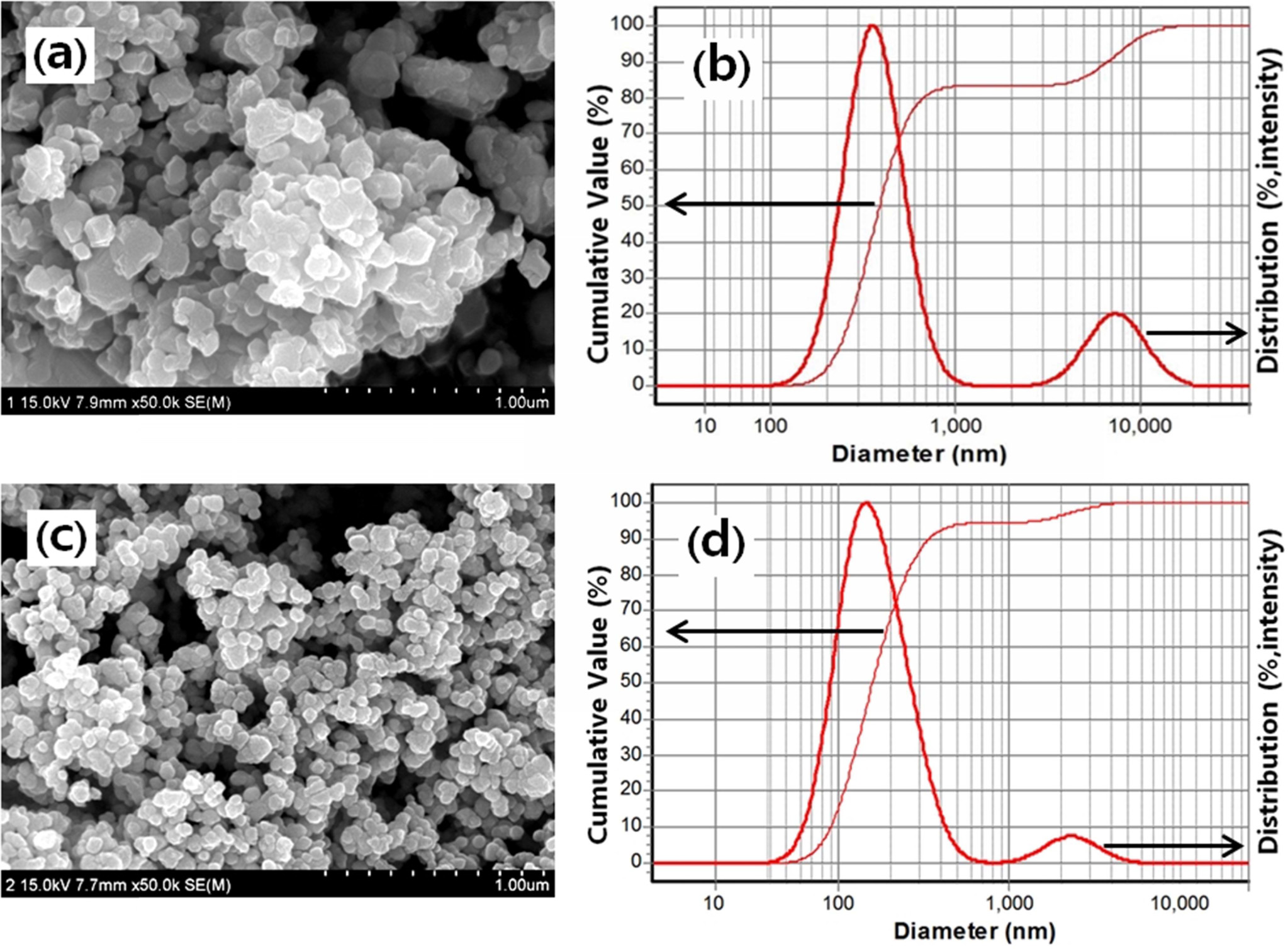

Two types of 3Y-TZP commercial powders with different

particle size were used as raw materials for the slurry preparation and their

microstructural morphology and agglomeration characterization

via particle size distribution analysis were shown in Fig. 2. The

first powder containing large scale particles (noted to L powder) showed a

severe agglomeration (larger agglomerate size and more secondary

agglomerate) and large primary particle size (about 100 nm). The second powder

containing small scale particles (note to T powder) is small primary particle

size (about 40 nm) and weak agglomeration characteristics. From the analysis of

particle size distribution as shown in Fig. 2(a), L powder

consists of 83% primary aggregates of 232 nm and 17% secondary aggregates of

2.5 μm. Comparatively, T powder is composed of 94% primary aggregates of 197 nm

and 6% secondary aggregates of 1.6 μm.

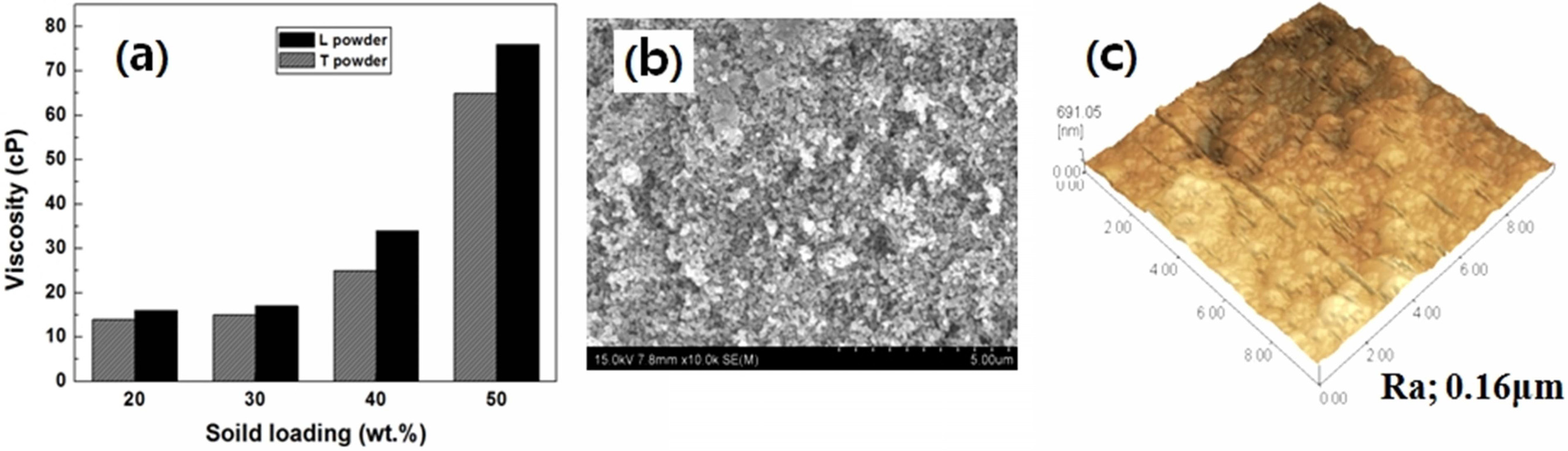

Fig. 3(a) shows the slurry viscosity at pH 12 as a

function of solid loading prepared by mixing and milling of 3Y-TZP powder,

distilled water, dispersant and pH control agent. With increasing the solid

loading of 3Y-TZP powder, slurry viscosity was gradually increased regardless

of powder type. But the slurry including 50wt.% solid loading had high

viscosity over 60 cP, which was limited to carry out the spin coating due to

the less fluidity of slurry. So, solid loading was fixed to 40 wt.% in this

experiment, considering a coating efficiency for a

forming-ability of 3Y-TZP thick film. Slurry viscosity for L or T

powder containing 40 wt.% solid loading indicated the proper range (about 36

and 27 cP, respectively) for spin coating, and L powder slurry had higher

viscosity than that of T powder due to the large particle size and severe

agglomeration.

Fig. 3(b) and (c) show the surface microstructure and

morphology for zirconia substrate observed by SEM and AFM. Pre-sintered 3Y-TZP

substrate at 1,100 °C for 2 h

shows porous microstructure with grain size of 175 nm and apparent density of 90%.

Porous structure of substrate surface enhances the slurry coating by the

capillary force of open pores. From the analysis of AFM images, porous 3Y-TZP

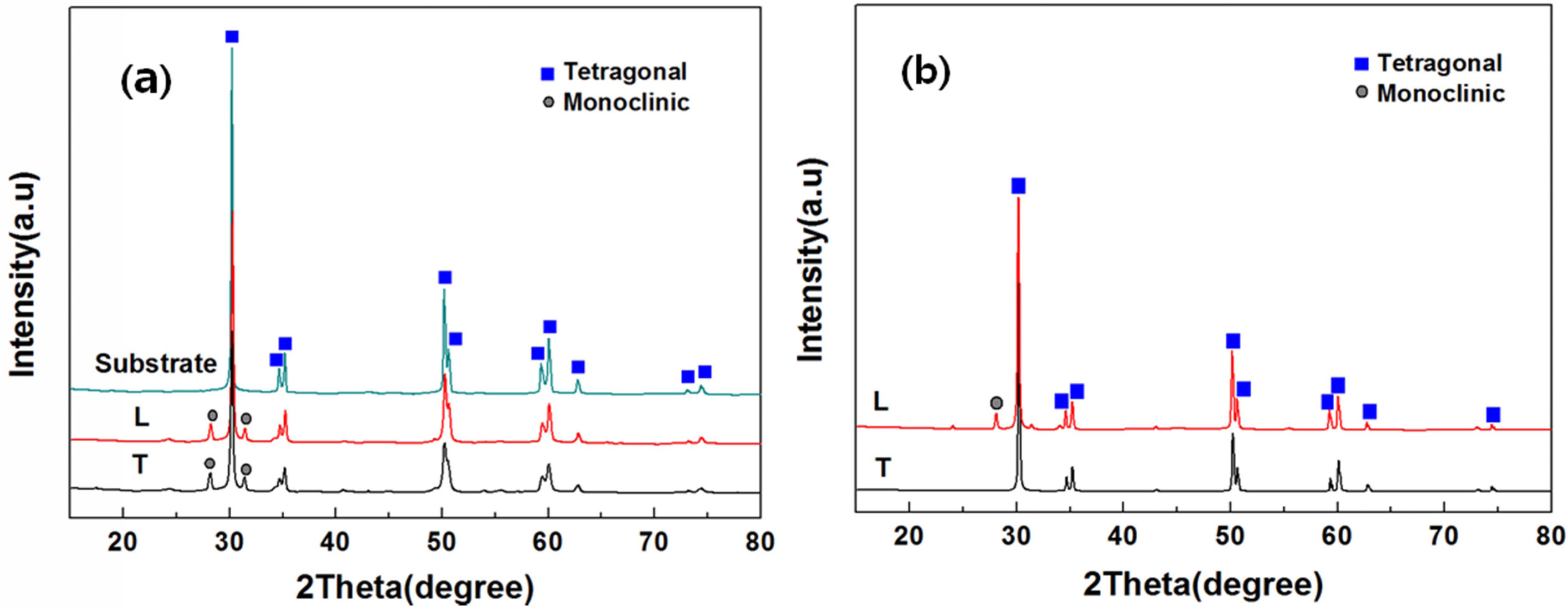

substrate had roughened surface (Ra; 0.16 μm). Phase composition of two types

of 3Y-TZP powder and pre-sintered substrate presents in Fig. 4(a), indicating a

main tetragonal phase and a little minor monoclinic phase in commercial two

powders. Phase composition of coated layer after a spin coating and sintering

at 1,500 °C for 2 h was slightly different from each other as shown in

Fig. 4(b). Coated layer fabricated from L powder indicates a main tetragonal

phase and a small quantity of monoclinic phase. The partial existence of

monoclinic phase on coating surface is due to the severe agglomeration and the growth

of a few large grains during sintering. On the other hand, coated zirconia

layer by T powder composed of all tetragonal grains, because of small particles

and densification due to the sintering at high temperature.

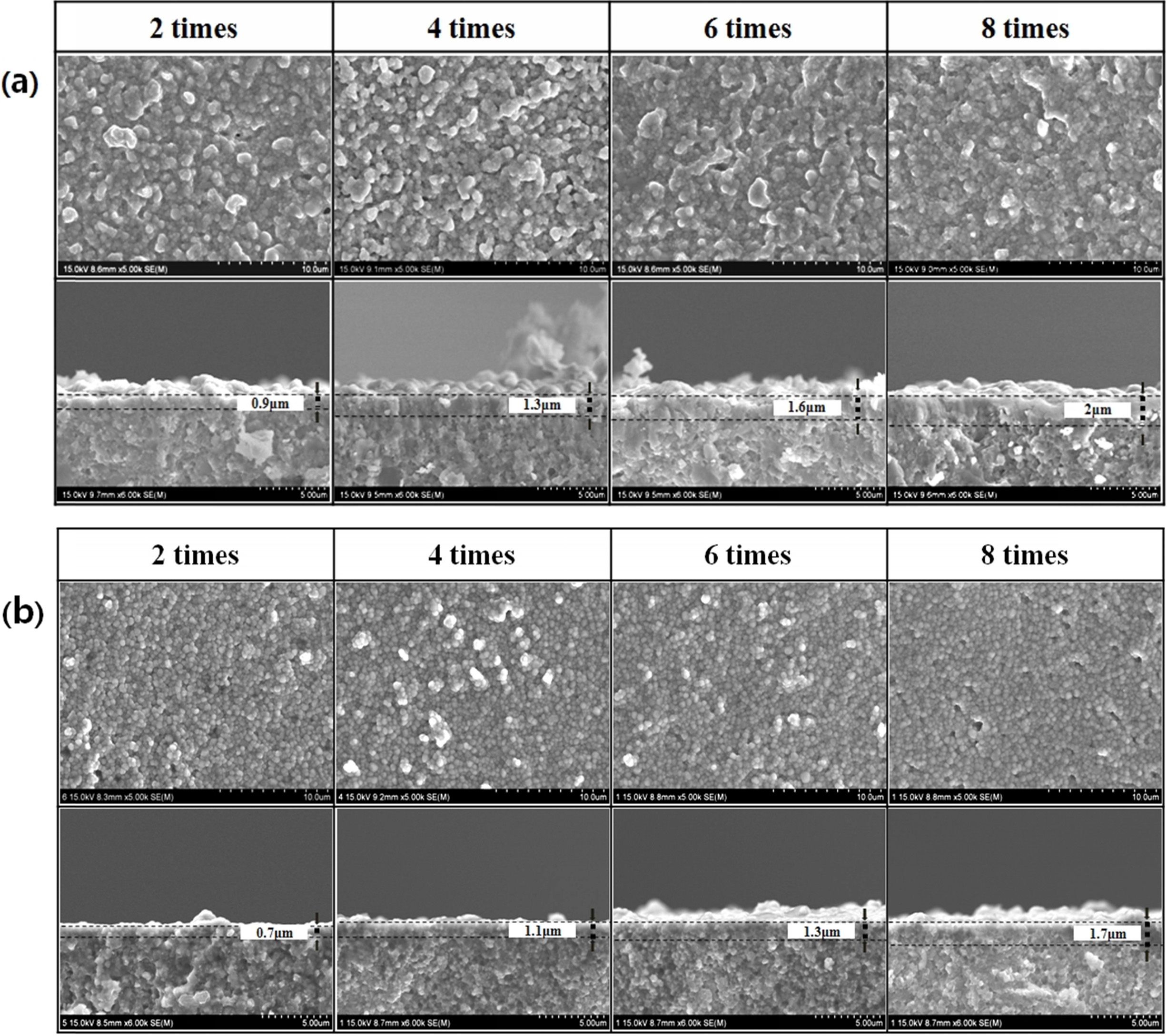

Fig. 5 shows the surface microstructure and perpen- dicular fractured surface of coated layer

after the post-sintering at 1500°C for 2 h. 3Y-TZP coated films are homogeneous

surface microstructure and uniform thickness, but it depends on

the powder type and coating times. In 3Y-TZP coated surface

layer fabricated from L powder, the growth of large scale grains was evident

and resulted to large average grain size of 650 nm, irrespective of coating

times, and the thickness of coating layer was gradually increased from 0.9 to

2.0 μm with increasing coating times. In contrast, coated surface layer

fabricated from T powder, small scale grains were mainly observed on surface

microstructure, indicating the grain growth inhibition during sintering by soft

agglomerates, and resulted to small average grain size of 300 nm. The thickness

of coating layer in this powder was also gradually increased from 0.7 to 1.7 μm

with increasing coating times.

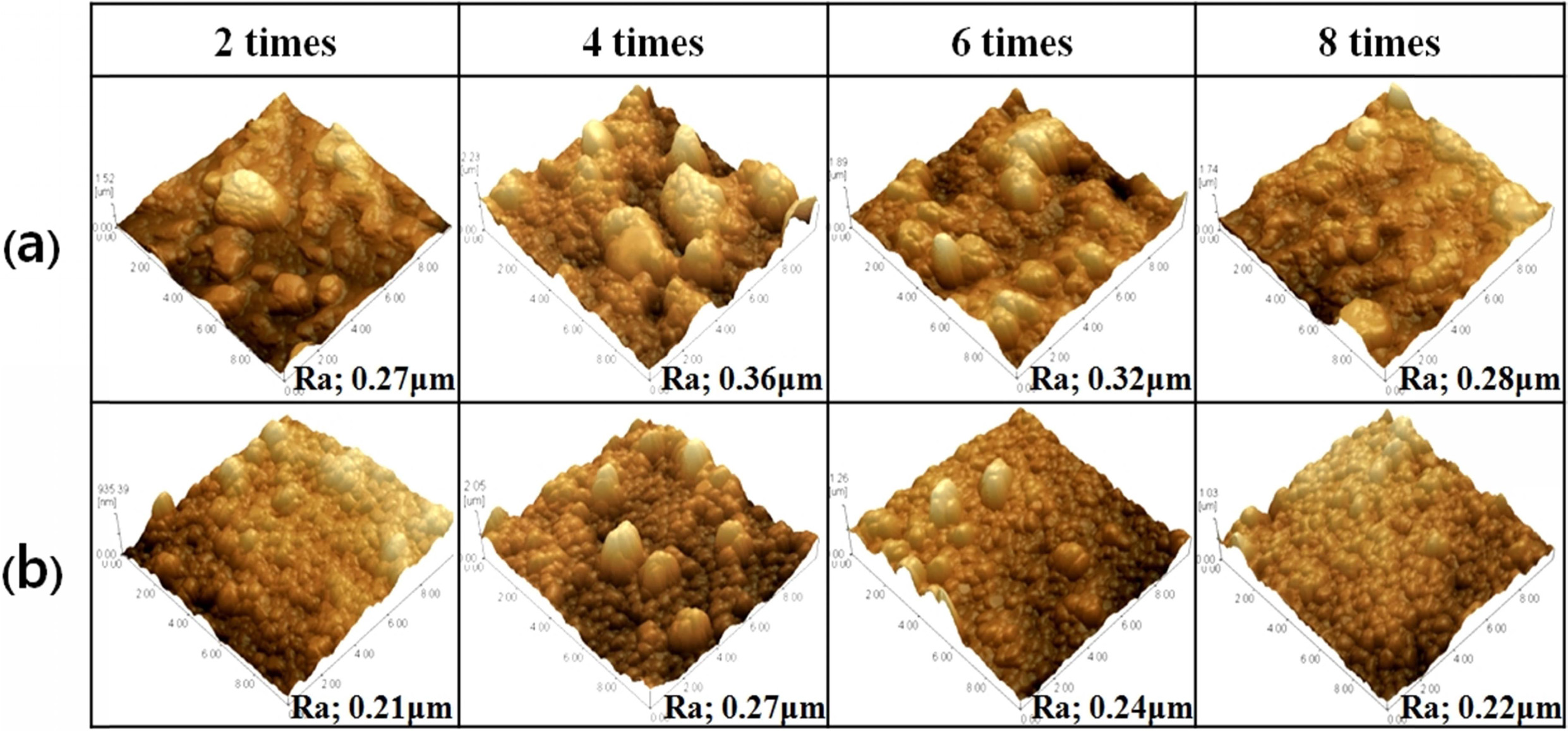

Surface morphology and roughness analyzed from AFM images

were dependent on the powder type and coating times. In comparison

with substrate morphology, some protruding particles as like a

mountain-like shape were observed on coated surface, which number and size were

dependent on the type of powder and coating times. Protruding particles formed

from L powder in Fig. 6 are larger than that of T powder, meaning that it

related with the particle size of starting powder. The number of

protruding particles on coated surface showed the maximum

value in 4 times coating specimen, compared with less protruding particles in 2

or 8 times coating specimen. It suggested that the formation and surface

appearance of protruding particles were related with the particle deposition

during spin coating, that is, particle compaction and arrangement

at repeated coating. As shown in AFM images, the number of protruding

particles was increased to 4 time coatings in both types of 3Y-TZP powder, but

they partially disappeared from the coated surface in 6 or 8 coatings

specimen. It means that the formation and surface appearance of protruding

particles were related with particle adhesion, dispersed arrangement and

filling up on planar substrate surface during repeated coating. So it resulted

that the size and number of protruding particles were directly affected to the

surface roughness of coated surface.

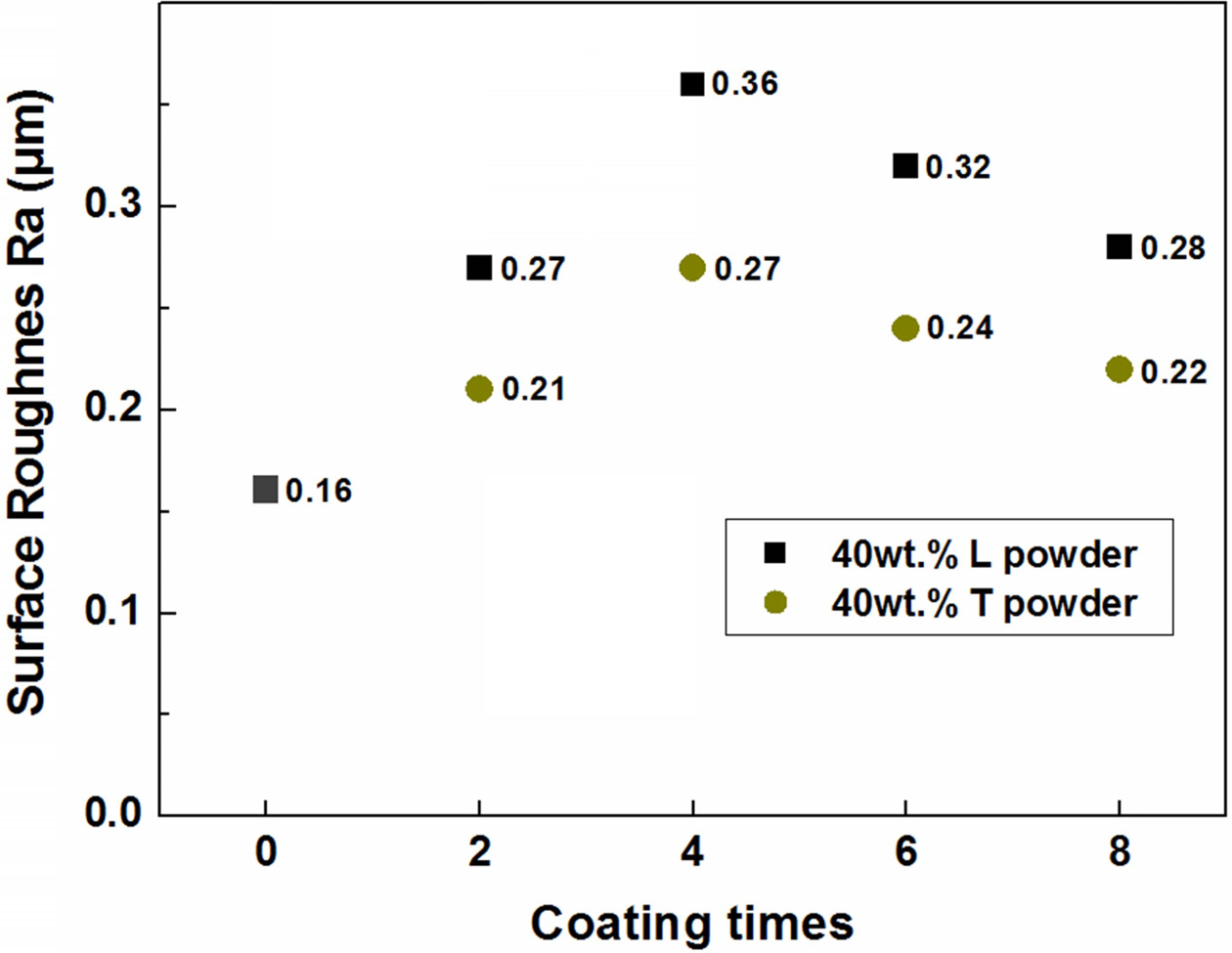

From the investigation of the relation with coating times

and surface roughness on coated surface, 4 times coating specimen showed

maximum surface roughness (Ra 0.36 μm in L powder, Ra 0.27 μm in T powder) in

both types of 3Y-TZP powder as shown in Fig. 7. Also, surface roughness of

coated layer from L powder was higher than that of T powder due to the rough

surface by large protruding particles, regardless of coating times.

|

Fig. 2 Particle morphology and particle size distribution analysis of two types of 3Y-TZP commercial powder; (a), (b) L powder, and (c), (d) T powder. |

|

Fig. 3 Characteristics of slurry viscosity and surface morphology of 3Y-TZP substrate; (a) viscosity variation with solid loading of two types of 3Y-TZP powders, (b) porous microstructure of 3Y-TZP substrate and (c) surface morphology by AFM observation. |

|

Fig. 4 Phase composition of (a) two types of starting 3Y-TZP powder and pre-sintered substrate, and (b) coated surface after slurry coating. |

|

Fig. 5 Variation of surface microstructure and film thickness on coated layer with powder type and coating times; (a) L powder, (b) T powder. |

|

Fig. 6 Variation of surface morphology and roughness on coated layer with powder type and coating times; (a) L powder, (b) T powder. |

|

Fig. 7 Dependence of surface roughness (Ra) on the powder type and coating times. |

Zirconia slurry coatings were fabricated by spin coating

using two sizes of commercial powder to enhance the surface roughness of 3Y-TZP

substrate. Sintered coating layer with homogeneous microstructure,

uniform thickness and high compactness could be obtained from

spin coating of slurry, but physical properties of coated layer were dependent

on the particle size in slurry and coating times. The coating

thickness gradually increases with repeated coating times, but surface roughness

of coated surface is dependent on the powder type

and repeated coating times. Slurry coating containing large

particles is more effective to improve the substrate roughness

than that of small particles. We also confirmed that repeated slurry coating is

available to increase the surface roughness of 3Y-TZP substrate, but limits the

maximum roughness by the coating time due to the appearance condition of

protruding particles on substrate surface. In this experiment, 4 times coating

specimen showed maximum surface roughness (Ra 0.36 μm in L powder, Ra 0.27 μm

in T powder) in both types of 3Y-TZP powder.

This work was supported by the National Research

Foundation of Korea (NRF) grant funded by the Korean government (MEST) (No.

2018-019041).

- 1. P. F. Manicone, I. P. Rossi, and L. Raffaelli, J. Dent. 35[11] (2007) 819-826.

-

- 2. R. B. Osman, and M. V. Swain, Mater. 8[3] (2015) 932-958.

-

- 3. J. Chevalier, and L. Gremillard, J. Am. Ceram. Soc. 92[9] (2009) 1901-1920.

-

- 4. M. Hisbergues, S. Vendeville, and P. Vendeville, J. Biomed. Mater. Res. Part B: Appl. Biomater. 88B[2] (2009) 519-529.

-

- 5. V. Lughi, and V. Sergo, Dent. Mater. 26[8] (2010) 807-820.

-

- 6. M. Stimmelmayr, S. Sagerer, K. Erdelt, and F. Beuer, Int. J. Oral. Maxillofac. Implants. 28[2] (2013) 488-493.

-

- 7. I. Denry, and J.R. Kelly, Dent. Mater. 24[3] (2008) 299-307.

-

- 8. S. Zinelis, A. Thomas, K. Syres, N. Silikasand, and G. Eliades, Dent. Mater. 26[4] (2010) 295-305.

-

- 9. L. Rimondini, L. Cerroni, A. Carrassi, and P. Torricelli, Int. J. Oral. Maxillofac. 17[6] (2002) 793-798.

- 10. I. Denry, Dent. Mater. 29[1] (2013) 85–96.

-

- 11. L. D. Liu, Y.H. Cheng, and W.C.J. Weic, J. Ceram. Process. Res. 20[4] (2019) 347-356.

- 12. A. Scarano, F.D. Carlo, M. Quaranta, and A. Piattelli, J. Oral. Implantol. 29[1] (2003) 8-12.

-

- 13. L. Sennerby, A. Dasmah, B. Larsson, and M. Iverhed, Clin. Implant. Dent. Relat. Res. 7[1] (2005) 13-20.

-

- 14. Y. I. Kim, S. H. Sung, S. M. Lee, S. H. Lee, B. S. Lim, J. S. Byun, C. Y. Hyun, Y. Hwang, and J. W. Byeon. J. Ceram. Process. Res. 13[1] (2012) s31-s36.

- 15. A. Afzal, Mater. Express. 4[1] (2014) 1-12.

-

- 16. J. Chevalier, Biomater. 27[4] (2006) 535-543.

-

- 17. H. J. Wenz, J. Bartsch, S. Wolfart, and M. Kern, Int. J. Prosthodont. 21[1] (2008) 27-36.

- 18. M. Gahlert, T. Gudehus, S. Eichhorn, E. Steinhauser, H. Kniha, and W.Erhardt, Clin. Oral. Implants. Res. 18[5] (2007) 662-668.

-

- 19. G. Soon, B. Pingguan-Murphy, K.W. Lai, and S.A. Akbar, Ceram. Int. 42[11] (2016) 12543-12555.

-

- 20. S. Roedel, J. C. M. Souza, F. S. Silva, J. Mesquita-Guimarães, M. C. Fredel, and B. Henriques, Ceram. Int. 44[11] (2018) 12496-12503.

-

- 21. D. Yamashita, M. Machigashira, M. Miyamoto, H. Takeuchi, K. Noguchi, Y. Izumi, and S. Ban, Dent. Mater. J. 28[4] (2009) 461-470.

-

- 22. R. Mai, C. Kunert-Keil, A. Grafe, T. Gedrange, G. Lauer, M. Dominiak, and T. Gredes, Ann. Anat. 196[6] (2012) 561-566.

-

- 23. H. W. Kim. H. E. Kim, and J. C. Knowles, J. Biomed. Mater. Res. B: Appl. Biomater. 70[2] (2004) 270-277.

-

- 24. C. Agrafiotis, A. Tsetsekou, and I. Leon, J. Am. Ceram. Soc. 83[5] (2000) 1033-1038.

-

- 25. J. C. Kim, D. Y. Lee, H. R. Kim, H. W. Lee, J. H. Lee, and J. W. Son, Thin. Solid. Films. 519[8] (2011) 2534-2539.

-

- 26. M. Norouzi, and A. A. Garekani, Ceram. Int. 40[2] (2014) 2857-2861.

-

- 27. D. S. Kim, and J. K. Lee, J. Nanosci. Nanotechnol. 19[2] (2019) 1118-1121.

-

This Article

This Article

-

2020; 21(S1): 41-46

Published on May 31, 2020

- 10.36410/jcpr.2020.21.S1.s41

- Received on Dec 16, 2019

- Revised on Apr 16, 2020

- Accepted on May 4, 2020

Services

Services

- Abstract

introduction

experimental details

results and discussion

conclusions

- Acknowledgements

- References

- Full Text PDF

Shared

Correspondence to

Correspondence to

- Jong Kook Lee

-

Department of Materials Science and Engineering, Chosun University, Gwangju 61452, Korea

Tel : +82 62-230-7202

Fax: +82 62-608-5402 - E-mail: jklee@chosun.ac.kr

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.