- Cu3Se2 counter electrode with rGO interlayer by pulsed electrodeposition for quantum dot-sensitized solar cells

Yong-Han Yun, In-Rok Jo, Young-Hoon Lee, Vu Hong Vinh Quy and Kwang-Soon Ahn*

School of Chemical Engineering, Yeungnam University, Gyeongsan 712-749, Republic of Korea

We synthesized a reduced

graphene oxide/copper selenide (rGO/Cu3Se2) cumulative

structure on a fluorine doped tin oxide (FTO) conducting glass substrate. The

pulsed electrodeposition method was used to construct the rGO and Cu3Se2

nanostructures. During rGO deposition, pulsed electrodeposition resulted in a

uniform film on the FTO. Deposited rGO with surface defects can act as an

active site for Cu3Se2 growth. In the case of Cu3Se2,

pulsed electrodeposition contributed to its uniform stoichiometry and porous

structure. This porosity affected the efficient diffusion of liquid

electrolytes toward the counter electrode surface and resulted in high power

conversion efficiency. In addition, the rGO interfacial layer served as

electron shuttle, directly prohibited the recombination path between the FTO

and electrolyte and enhanced the fill factor (FF). As a result, the FTO/rGO/Cu3Se2

electrodes with CdS/CdSe/ZnSe QD photoanodes achieved a power conversion

efficiency of 3.622%, which was a significant improvement over the 2.997%

efficiency of direct-deposited FTO/Cu3Se2 electrodes with

the same photoanodes.

Keywords: Quantum dot-sensitized solar cells, Reduced graphene oxide, Copper selenide, Pulsed electrodeposition, Counter electrode

Quantum Dot-sensitized Solar Cells (QDSSCs) are third

generation solar cells that have the potential to overcome the

Shockely-Queisser limit in the power conversion efficiency (PCE) of Si-based

solar cells [1]. They have a similar structure to dye-sensitized solar cells,

but the dyes are replaced with inorganic quantum dots (QDs). A

QD photosensitizer has more advantageous and unique

properties than organic dyes, including a size dependent band gap, hot carrier

injection, and multiple exciton generation. [2-4]. Most studies on QDSSCs have

focused on enhancing the performance of photoanodes to improve its

light absorbing efficiency and electron injection and

preventing recombination [5-7]. However, despite their importance, there

remains an insufficient number of studies on counter electrode materials. As

part of the QDSSC, the counter electrode plays an important role in the

reduction of electrolytes and maintenance of the polysulfide electrolyte

condition [3]. Even though the photoanode displays sufficient performance,

completion of QDSSC operations requires a stable and

efficient counter electrode [8, 9]. However, stable counter electrodes with

polysulfide are a con- tentious issue [10-12].

Most of the known materials used for counter electrodes exhibit

only limited stability against polysulfide electrolytes

[4]. It is for this reason that many researchers continue to

investigate stable counter electrode materials. Among them,

metal chalcogenides are a promising material for counter electrodes owing to

their good bulk conductivity and electrocatalytic properties [13]. To enhance

stability, some researchers have suggested that a combination with a carbon

based material is effective. [9] Reduced graphene oxide (rGO),

in particular, has arisen as the most prominent candidate

[14, 15]. The rGO has been investigated by many researchers

owing to its higher conductivity than graphene oxide and

surface area. Furthermore, it is proved that rGO interfacial layer has benefit

when adopted at photoanode and counter electrode both [16-18]. Wang et al

adopted rGO layer between FTO and TiO2 film as interfacial layer to

prevent direct contact with electrolyte from CdS QD [16]. This rGO layer also

supports transportation of electron, can be exploited in opposite side. In case

of counter electrode application, Jie Ma et al exploited graphene aerogel for

using its extreme surface area to support MoS2 [17]. Wei Lu’s group

has studied direct synthesis of copper sulfides on rGO sheets. During

hydrothermal synthesis, Cu2S is embedded in rGO as nano particle and

GO is reduced into rGO. They spin coated rGO-CuS paste with

ethanol and PEG on FTO for counter electrode,

achieved 4.76% in PCE [19]. However, binder may

limit efficient diffusion of

electrolyte along the porous structure. Binder-assisted adhesion

also may cause instable conduction and degradation.

However electrochemical process can grow rGO and

active materials onto substrate directly. Under precise

control of deposition condition, electrochemically grown

crystals exhibits robust contact with substrate. Additionally, it is well known

that electro pulse-deposition (EPD) can induce unique results [20] and give a

uniform composition to the resulting product, such as a thin film on the

substrate [21]. To the best of our knowledge, there are only a few studies that

have applied both pulse-deposited copper selenide (Cu3Se2)

and rGO in order to fabricate counter electrodes for QDSSCs. Zeng et al. (2016)

made a thin lead selenide film on FTO using pulsed voltage deposition [22]. Ahn

et al. (2019) used a similar approach for nickel selenides [23].

In this study, we introduce pulsed electro-deposited rGO and Cu3Se2

electrodes for the counter electrodes of QDSSCs.

GO

preparation

Synthesis of graphene oxide (GO) was followed by the

Hummer’s method from literature [24]. One gram of graphite powder was mixed

with 23 ml of H2SO4 (concentrated, 95%) under ice bath

and mild stirring conditions. One gram of NaNO3 was dissolved in the

mixture after adequate dissolution. Three grams of KMnO4 was slowly

added in portion. The temperature was kept under 20 oC during

the addition of the KMnO4. The color of mixture turned from a

graphite grey/black to a dark green. After two hours of stirring under ice bath

conditions, 46 ml of deionized (D.I.) water was introduced into the mixture.

Simultaneously, the temperature of the mixture was kept under 98 oC.

At that point, vigorous stirring was performed for two hours. To

complete the reaction and eliminate excessive elements in

the mixture, 140 ml of D.I. water and 2 ml of H2O2 (30%)

were added. The color immediately changed to a bright yellow. After 15 min of

stirring, 250 ml of diluted 1 M HCl aqueous solution was added to

the mixture to dissolve any metallic by-products. After washing

with DI water three times and centrifugation, brown

precipitates were formed. By dissolving and dispersing the proper amount of

this product in D.I. water, 1 mg/ml of a GO solution was synthesized for

further use.

GO

and Cu-EDTA solution for electrodeposition of an rGO layer

An ethylenediaminetetraacetic acid (EDTA) capped copper

(Cu-EDTA) solution was made by following literature [22, 25]. Simply,

0.5954 g of EDTA was dissolved in 20 ml of D.I. water. This was followed with

0.128 g of NaOH to adjust the pH beyond 12. Then, 0.1996 g of CuSO4

was added. One milliliter of the Cu-EDTA solution was mixed with 39 ml of GO

solution. The prepared solution was stable after being kept in the dark under

ambient air conditions for a few days. Using the prepared solution, an rGO

layer was electrodeposited onto FTO. Detailed conditions of the

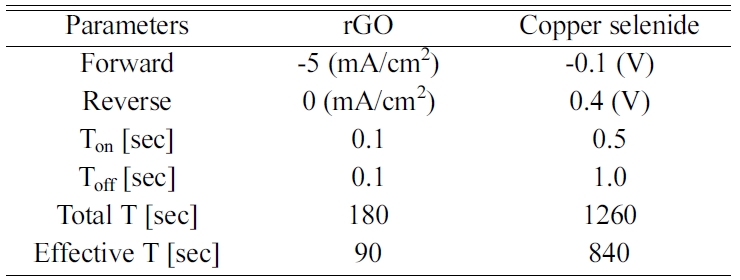

electrodeposition are described in Table 1.

Cu and Se precursor solution for electrodeposition

of a Cu3Se2 layer

To begin, 4.9937 g of CuSO4 and 2.2192 g SeO2

were used to prepare 0.2 M of a Cu and Se precursor solution. The pH value of

both solutions was adjusted to a value of 2 using H2SO4.

Twenty milliliters of each solution were mixed together to produce a final

volume of 40 ml. A solution containing the precursors was prepared and mixed

just before deposition. Milli-Q pure water was used as the solvent for each

solution. This prepared solution was used to deposit Cu3Se2

onto FTO and rGO modified FTO. Detailed conditions of the electrodeposition are

described in Table 1.

Photoanode

for QDSSC sensitized with QDs

Preparation of the photoanodes followed the conventional

successive ion layer adsorption and reaction (SILAR) method with slight

modifications [6, 26]. First, the FTO was prepared using a typical

cleaning method that utilizes successive ultra-sonication through acetone,

ethanol, and D.I. water, respectively. A TiO2 film was prepared by

the doctor-blading method with a TiO2 paste (Ti-Nanoxide T/SP, 20 nm

diameter, Solaronix SA) on the FTO substrate. TiO2 films on the FTO

were dried at 70 oC over 30 min and sintered at 450 oC

for 30 min under ambient air conditions. After sintering, the CdS and CdSe QDs

were decorated onto the TiO2 film by the SILAR method. The

preparation of Cd and S precursor solutions followed literature [6]. To begin,

0.1 M of Cd(NO3)2 was dissolved in ethanol and 0.1 M of

Na2S was dissolved in methanol. Each dipping process took one

minute, and five cycles were done for CdS. A similar procedure was performed

for CdSe. The preparation of Cd and Se precursor solutions also followed the

literature referenced above. First, 0.03 M Cd(NO3)2 was

dissolved in ethanol, while 0.03 M SeO2 and 0.06 M

NaBH4 were dissolved in ethanol. Selenium dioxide

solution caused the color to change from an opaque red to transparent after

stirring under sealed conditions. Each dipping took one minute, and seven

cycles were done for CdSe. The deposition of CdSe was conducted under inert Ar

gas conditions. Next, ZnSe was deposited by the SILAR method, where it acted as

a passivation layer for CdS/CdSe QDs [6, 7]. Then, 0.1 M Zn(NO3)2,

0.1 M SeO2, and 0.2 M NaBH4 were dissolved in ethanol.

Each cycle took one minute, and five cycles were done for ZnSe. After the SILAR

process, every photoanode was washed with ethanol and kept in the dark under

inert gas conditions for further use.

Material

characterization

The surface morphology and cross section of each sample

was observed by high-resolution scanning electron microscopy (HR-SEM; S-4800,

Hitachi LTD). The structure and crystallinity were characterized

through X-ray diffraction (XRD; MPD for thin

film, DIATOME). To investigate the surface atomic state and

confirm the atomic ratio, X-ray photo-electron spectroscopy (XPS; K-alpha,

Thermo Fisher Scientific) was conducted.

Device

performance characterization

Symmetrical dummy cells for the Tafel analysis and

electrochemical impedance spectra (EIS) were prepared by two identical counter

electrodes. The polysulfide electrolytes used in the symmetrical cells had the

same composition (2 M Sulfur, 2 M Na2S, and 0.2 M KCl) as the full

cell with a solvent composed of methanol and water (7:3 by volume) [12, 37,

38]. The active area of the symmetrical cell was 1.2 cm2 for every

sample and experiment. The Tafel polarization (WBCS3000, WONATECH)

was recorded from -0.5 V to 0.5 V at a scan rate of 10 mV/s. An EIS (ZIVE,

WONATECH) analysis was carried out to understand the electrochemical

reaction around the surface of the electrodes. The PCE was measured

under 1-sun illumination by solar simulator (PEC-L12

Solar Simulator, Peccell technology, Inc.) and potentiostat (Iviumstat.h, Ivium

technologies).

|

Table 1 Overview of pulsed electrodeposition parameters for preparation of rGO and copper selenide. |

Structure

and morphology

Reduced graphene oxide (rGO) and umangite copper selenide

(Cu3Se2) layers were successively deposited onto an FTO

substrate. The rGO-modified FTO had many surface defects [29] that provided

active sites for copper selenide growth. These sites may also provide different

orientations compared with direct deposition onto FTO. The

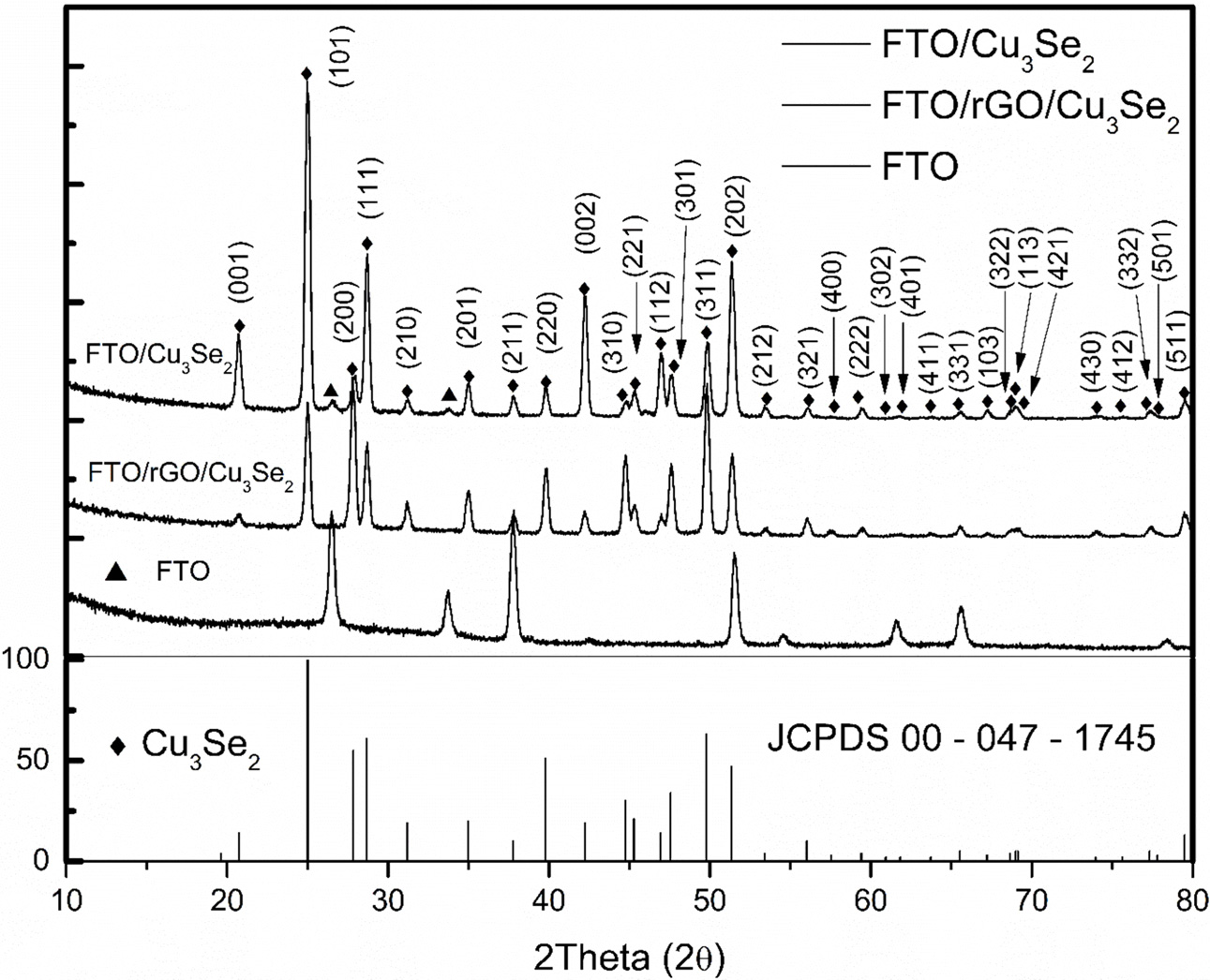

effect of rGO-modified FTO was confirmed via XRD.

According to Fig. 1, the Cu3Se2 on FTO displayed a

typical peak known as umangite (JCPDS 00-047-1745). The Cu3Se2

on rGO-modified FTO displayed a similar peak, but a difference in the peak

intensity was observed. This difference came from the presence of different

orientations due to the active sites provided by the rGO-modified FTO. The Cu3Se2

on FTO, (101) displayed the dominant peak along the FTO. It should be noted

that the deposited selenium induced the reduction of copper ions to form copper

selenide [30, 31]. However, on the rGO-modified FTO,

copper was already deposited on the surface of the rGO

[20, 25]. The Cu-EDTA-GO solution was used to deposit the rGO

and facilitated the presence of copper on the rGO as a metallic cluster. According

to the electrodeposition mechanism of copper selenide,

selenium is first deposited on the substrate followed by the reduction of the

copper ions [30].

When selenium was deposited onto Cu, the presence of the

copper contributed to different preferential orientations of the copper

selenide. This is likely the reason for the reversed intensity between the Cu3Se2

(200) and (111) at the Cu3Se2 on the rGO modified sample.

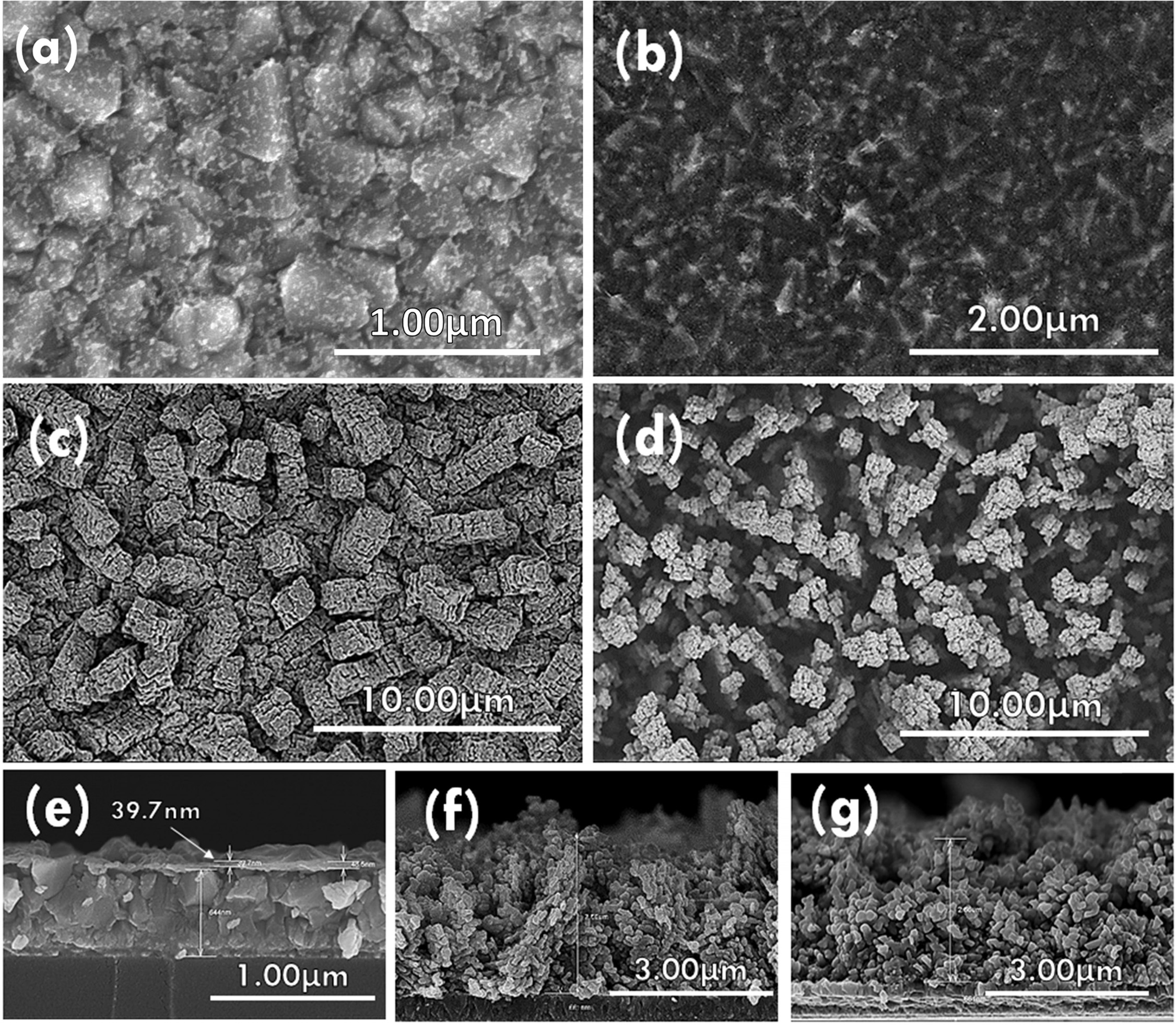

To understand the effect of surface modifications on the

morphology, SEM was conducted on each sample. Fig. 2 shows the top view and

cross-section of each sample. Fig. 2(a) shows a conventional Pt

electrode to compare with the other samples. Fig. 2(b) shows an

rGO-modified FTO. It is clear that the rGO uniformly covered the

FTO, and the copper clusters were regularly distributed

as well. From Fig. 2(c) and 2(d), the significant effects

of different substrates on the morphology can be seen. Fig.

2(c) shows a morphology that is vastly different from typical copper selenide

because of the pulsed electrodeposition technique [21]. During pulsed electrodeposition

in the forward condition, copper selenide was deposited onto FTO.

During the reverse condition, the precursor concentration at the interface was

restored to near the initial condition by mass transfer and diffusion. By

iterating this cycle, tiny pillars that aggregated into square–like columns

were grown. In Fig. 2(d), the Cu on the rGO provided more active sites than the

FTO, which led to a more porous film. This enhanced porosity may help

to diversify the paths available for the active mass transfer of

electrolytes. However, observations from Fig. 2(f) and (g) may

indicate that the growth mechanisms of each film are similar to that of other

work [21]. The height of the films on

the different substrates were not significantly different

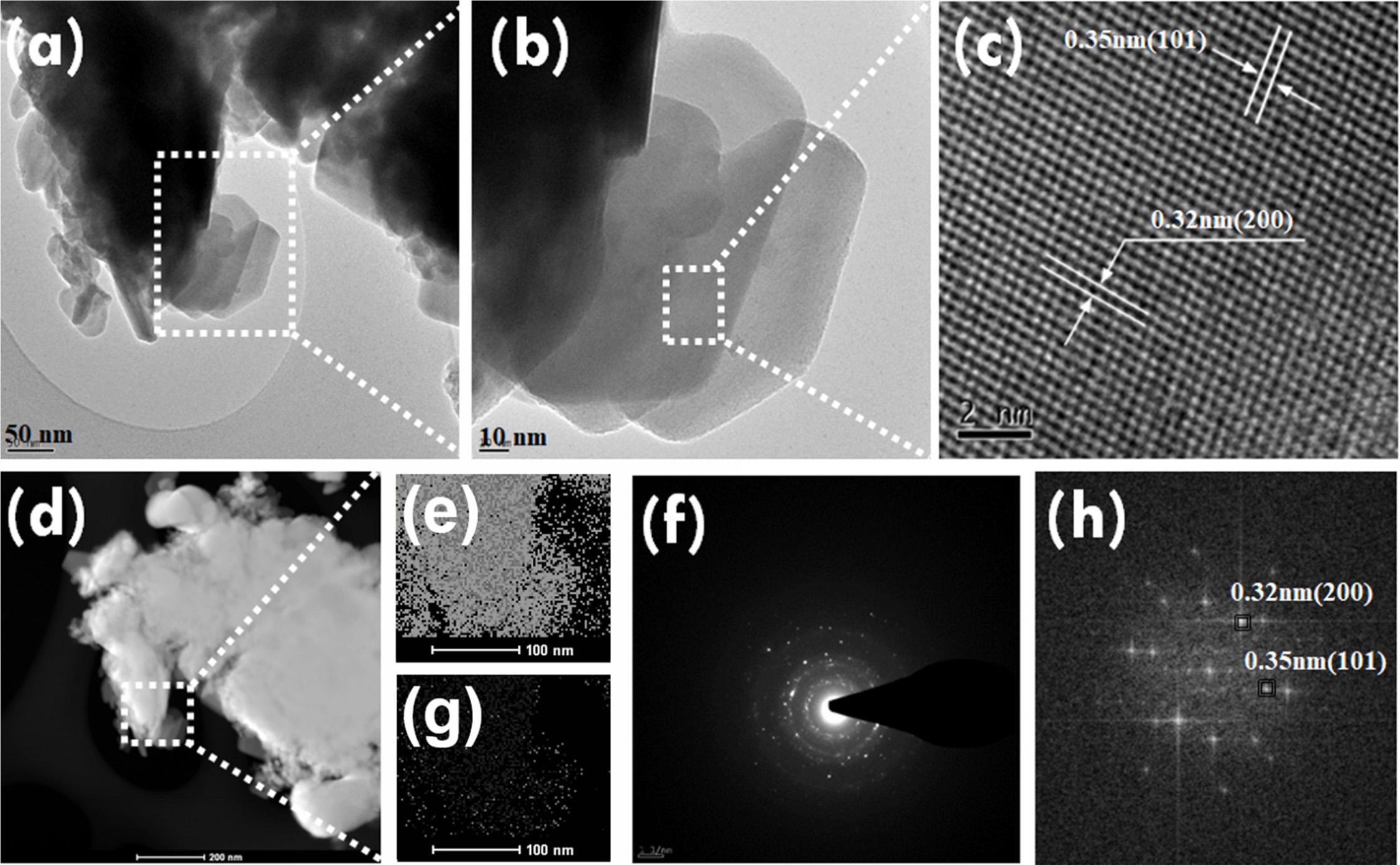

from each other. The microstructure of the rGO/Cu3Se2

sample was further investigated by transmission electron

microscopy (TEM). Fig. 3(a-c) show the crystalline

nature of Cu3Se2 on rGO. The results from Fig. 3(c)

confirmed (101) and (200) planes of umangite (JCPDS 00-047-1745), which

corresponded well to the results obtained via XRD. The loading densities of Cu3Se2

deposited on FTO and FTO/rGO were 0.3106 g/cm3 and 0.2938 g/cm3,

respectively.

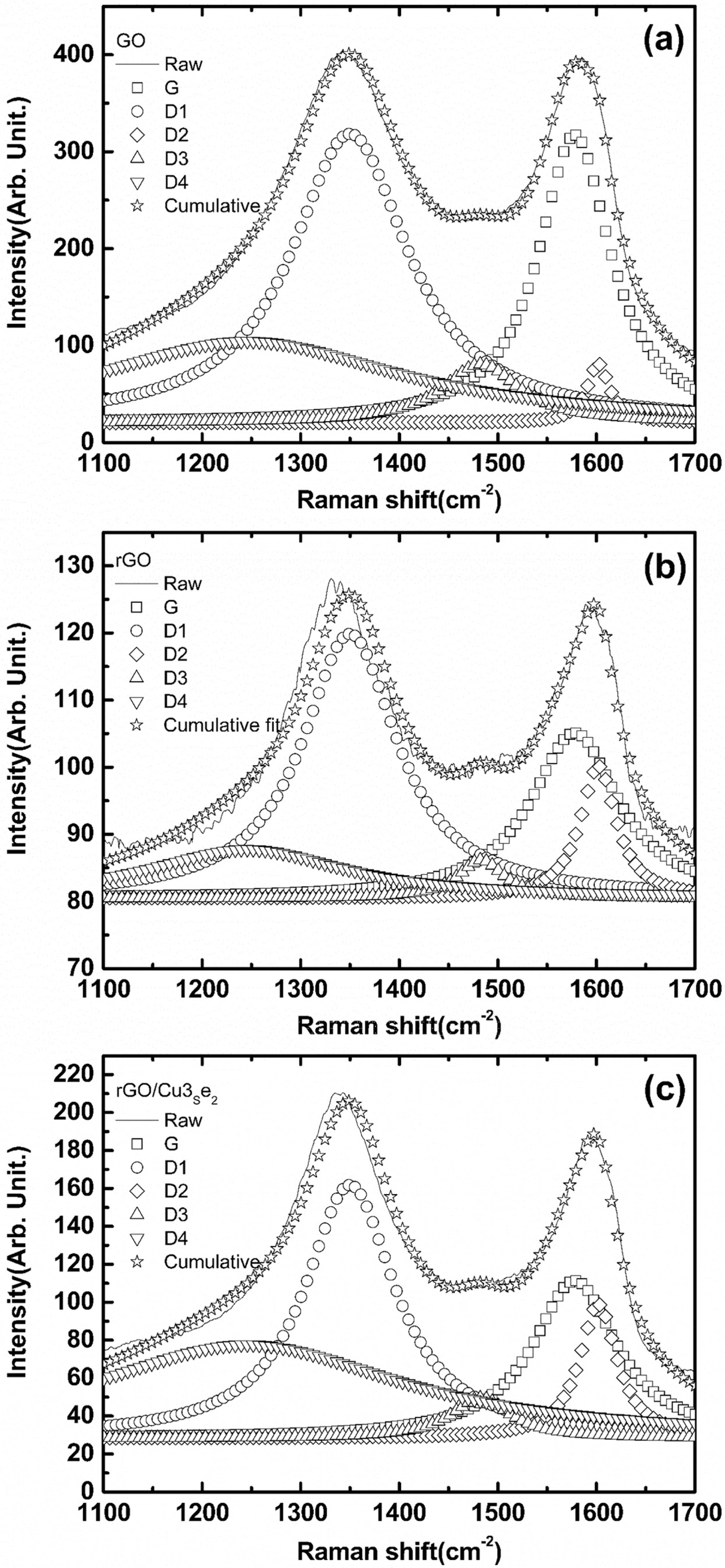

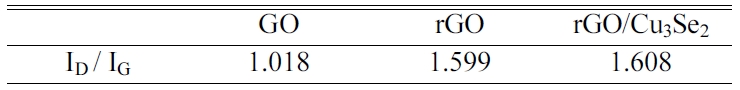

While Cu3Se2 has been well

characterized, there is still a lack of significant understanding of rGO. To

confirm the degree of reduction and existence of rGO on FTO, Raman spectroscopy

was used to measure each electrode. In Fig. 4(a), conventional D and G peaks

can be observed. This indicated that GO was successfully synthesized and well

oxidized [32, 33]. The deconvolution of Fig. 4(a) also corresponded to the

above prediction. Fig. 4(b) shows a diminished G peak, which indicated a

reduction of the oxygen containing group [39]. Fig. 4(c) shows similar results.

To verify the degree of reduction and other information, the D/G ratio was

calculated from the deconvoluted peaks [29, 33, 34]. Table 2 shows the D/G

ratios determined from the Raman spectroscopy of GO, rGO, and rGO/Cu3Se2

deposited FTO. The D/G ratio is an important index designating characteristic

for graphene and graphene-like materials. A larger D/G ratio indicates that a

smaller graphene oxide flake size was achieved [33]. It also indicates the

presence of more edge defect sites. An abundant number of defects can serve as

active sites for Cu3Se2 growth as mentioned previously. A

high D/G ratio can also indicate the removal of oxygen-containing groups

[35-37].

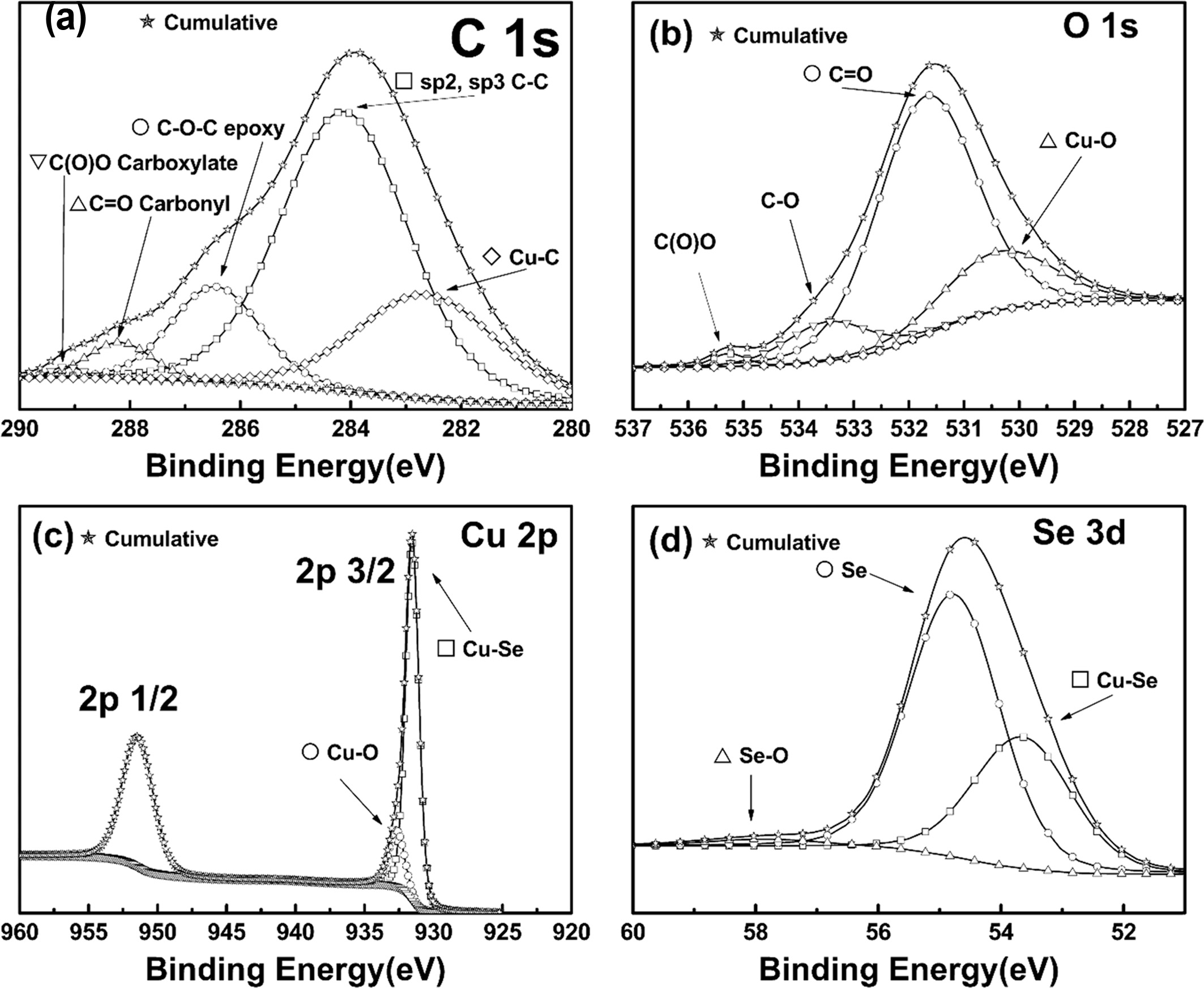

To support the above characterization, XPS was done on the

rGO/Cu3Se2 sample [38]. Fig. 5 shows the XPS spectra of

(a) C 1s, (b) O 1s, (c) Cu 2p, and (d) Se 3d from the

rGO/Cu3Se2 sample. Fig. 5(a) suggests that the

rGO was well reduced by the pulsed electrodeposition process. C-C strongly

remained at 284 eV. The peak value at 284 eV indicated C-C bonds relevant with

sp2 and sp3. There were slightly low residues for the C-O, C=O, O=C-O peaks.

This indicated that the reduction of GO was successful during

electrodeposition. It also corresponded well to the results obtained via Raman

spectroscopy. The broad peak around 283 eV was related to the metallic C [39],

and as Cu was adsorbed onto the rGO, that peak proved the existence of copper

clusters. The relatively small peaks at 286.5 eV, 287.8 eV, and 289.1 eV

corresponded to the results from the D/G ratio Raman spectroscopy, and

indicated the extinction of oxygen containing groups [38]. From the

deconvoluted XPS peak areas, the C/O ratio was calculated to be 8.944. This

indicated an adequate reduction of rGO on the FTO. This result corresponded to

the results from the Raman spectroscopy.

Morphology-dependent

device performance

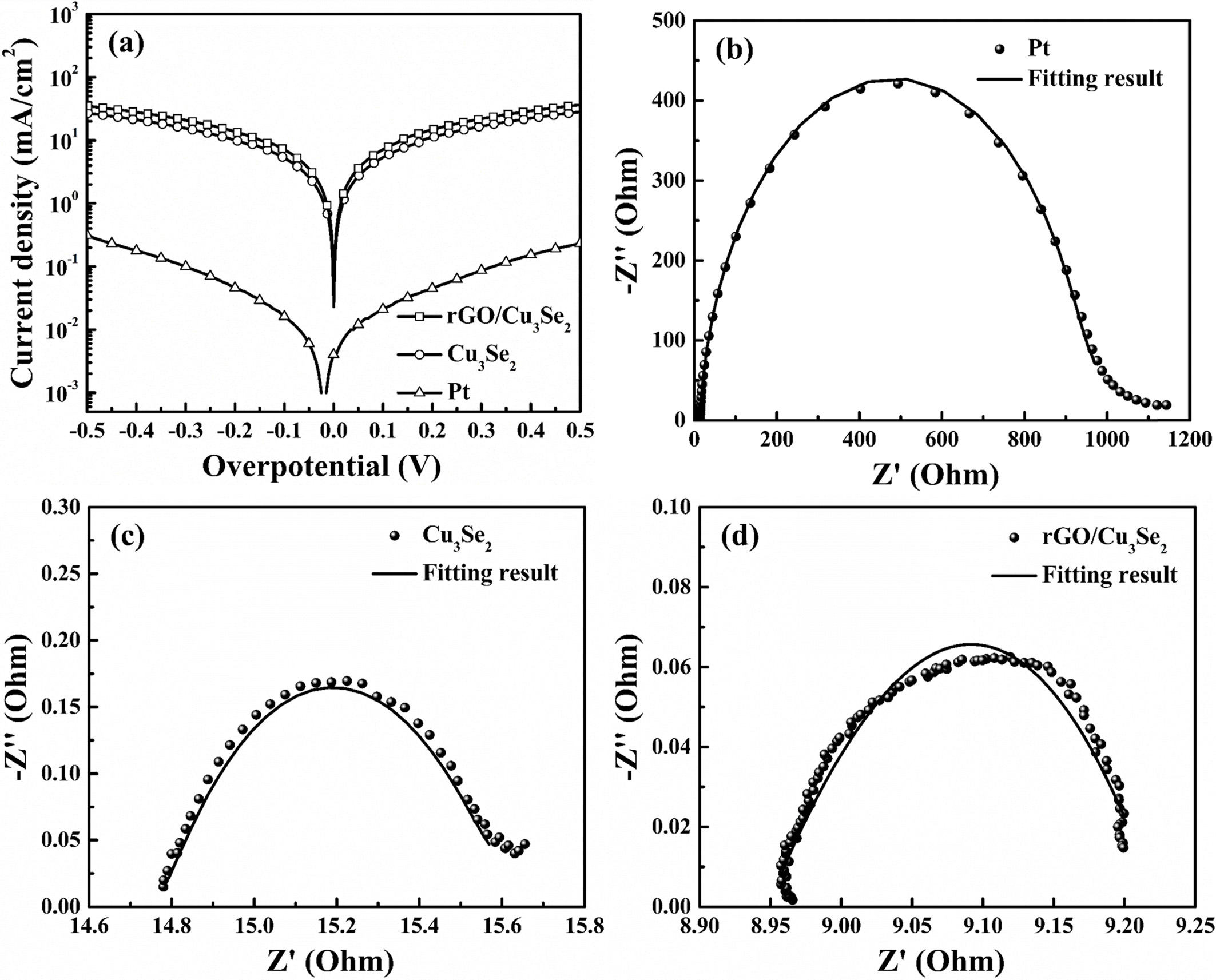

The electrochemical activity of the prepared CEs was

analyzed by Tafel analysis EIS. Fig 6(a) shows the Tafel polarization curves of

the Pt, Cu3Se2 and rGO/Cu3Se2 CEs.

Among these CEs, rGO/Cu3Se2 exhibited the highest

limiting current density (Jlim). The porous structure of the Cu3Se2

grown on rGO provided more electrocatalytic active sites, which lead the

superior mass transfer. Fig. 6(b-d) show the Nyquist plots of different

symmetrical cells and the fitting parameters are listed in Table 3, where RS

the series resistance and Rct is the charge transfer resistance

between the CE and electrolyte. The Rct values of Pt, Cu3Se2

and rGO/Cu3Se2 CEs were 844.9, 1.15 and

0.292 Ω, respectively. This result shows the rGO/Cu3Se2

CE has superior charge transfer kinetics which can affect in FF.

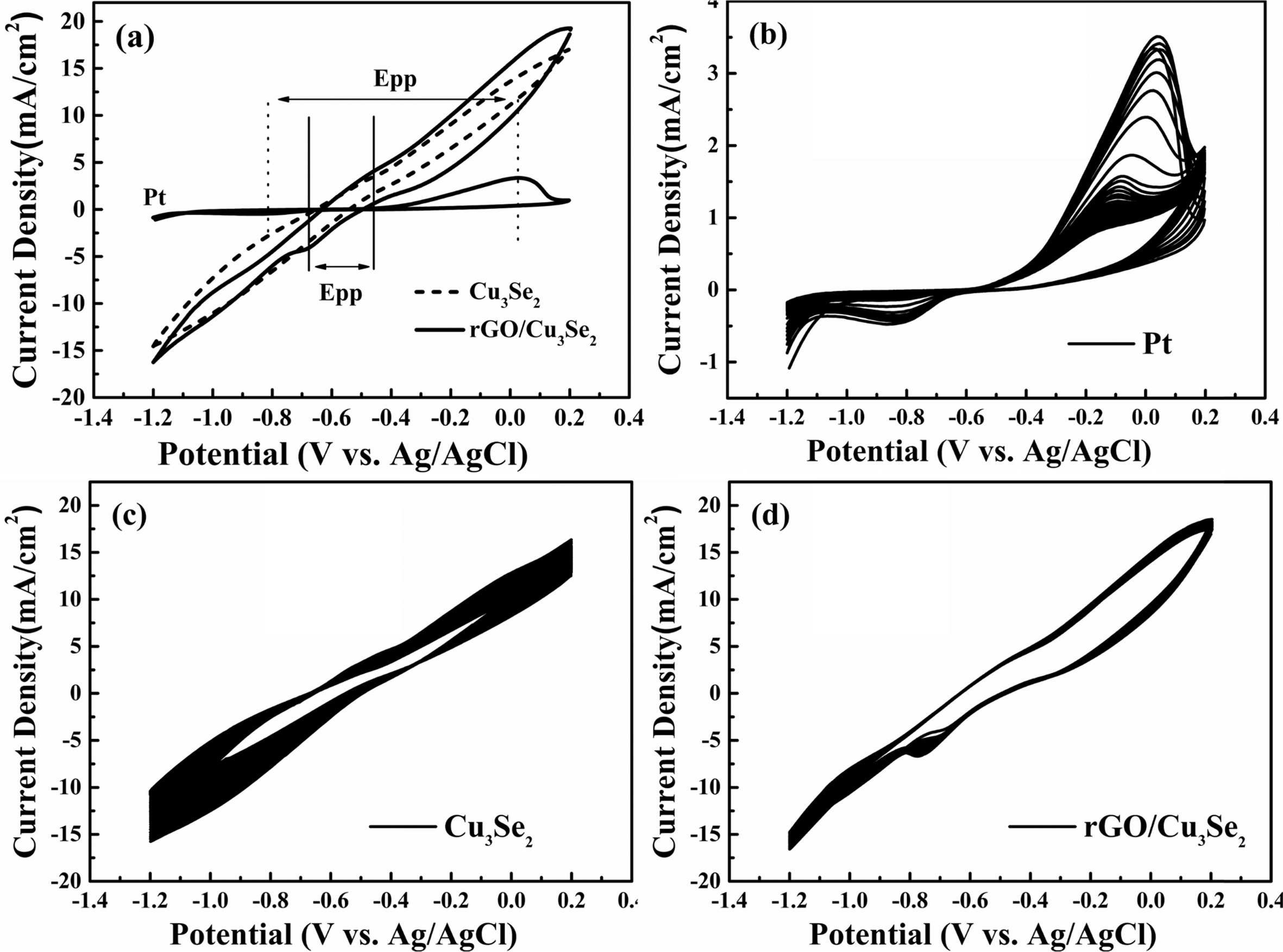

Cyclic voltammetry (CV) was performed to evaluate the

electrocatalytic activity and electrochemical stability. The oxidation

and reduction peak current and peak-to-peak

potential difference (Epp) are simple and powerful tool for

estimate the electrocatalytic activity [40, 41]. Both Cu3Se2

and rGO/Cu3Se2 electrodes with high electrocatalytic

activity showed the lower Epp value than Pt as shown in Fig. 7(a). Meanwhile

the oxidation and reduction peak positions of Cu3Se2 and

rGO/Cu3Se2 electrodes are very similar, the current

densities of the oxidation and reduction peaks of rGO/Cu3Se2

electrode is greater than that of the unmodified Cu3Se2 electrode.

It shows that the Cu3Se2, which grown on rGO, has a

higher surface area due to the porous morphology as observed in SEM. Fig.

7(b-d) show the CV curves of different CEs for 50 cycles. Pt CE has very low

current density owing to their poor electrocatalytic activity and

stability. Cu3Se2 CE has a higher current compared

to Pt but shows apparent current decay which means low

stability. rGO/Cu3Se2 CE has an excellent electrochemical

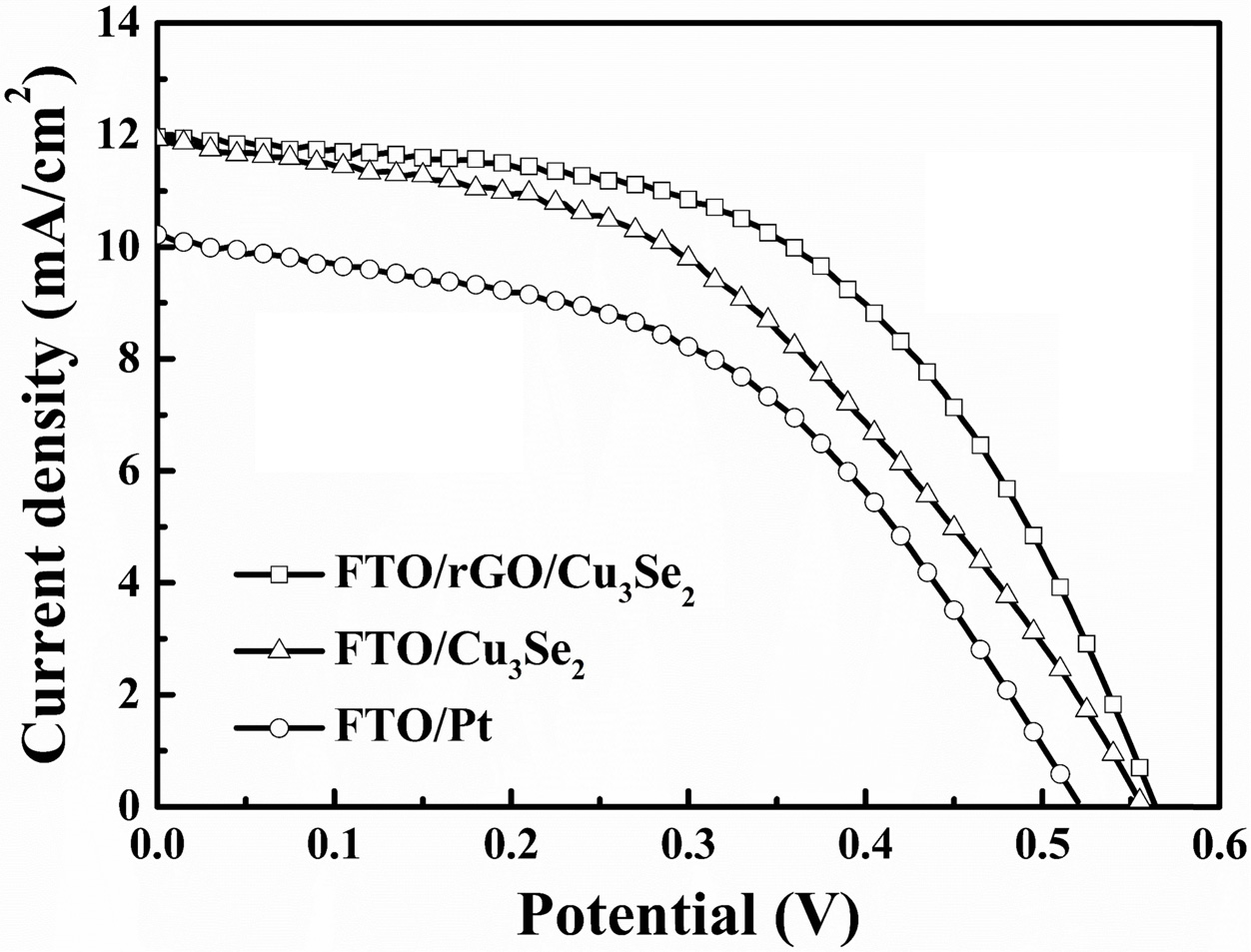

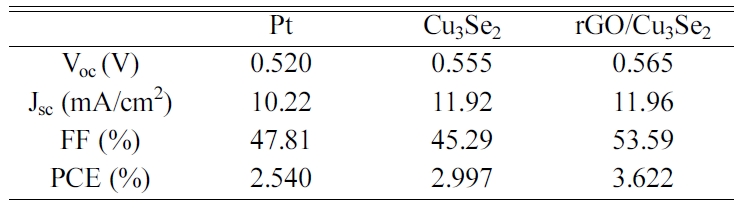

stability in polysulfide electrolyte. Fig. 8 and Table 4 show the J-V curves

and parameters of the QDSSCs with different CEs. QDSSC with rGO/Cu3Se2

CE has the significantly improved FF of 53.59% and PCE of 3.622% compared to Cu3Se2

CE.

|

Fig. 1 XRD results of FTO/Cu3Se2, FTO/rGO/Cu3Se2 and FTO. |

|

Fig. 2 SEM images of electrode surface, (a) FTO/Pt, (b) FTO/rGO, (c) FTO/Cu3Se2 (d) FTO/rGO/Cu3Se2 and (e-g) are cross section of (bd) respectively. |

|

Fig. 3 (a-c) TEM and HRTEM images of Cu3Se2, (d) EDAX objective area, (e, f) Cu and Se elemental mapping in scan area, (g) SAED pattern of sample and (h) FFT from (c). |

|

Fig. 4 Raman spectra of (a) GO, (b) rGO, (c) rGO/Cu3Se2. |

|

Fig. 5 XPS spectra of (a) C 1s, (b) O 1s, (c) Cu 2p and (d) Se 3d from FTO/ rGO/Cu3Se2. |

|

Fig. 6 (a) Tafel polarization curves from symmetrical cells of Pt, Cu3Se2 and rGO/Cu3Se2. Nyquist plots of (b) Pt, (c) Cu3Se2 and (d) rGO/Cu3Se2. |

|

Fig. 7 (a) Cyclic voltammetry curves of CEs. Cycling stability tests for 50 cycles of (a) Pt, (b) Cu3Se2 and (c) rGO/Cu3Se2. |

|

Fig. 8 J-V curves of Pt, Cu3Se2 and rGO/Cu3Se2 electrodes. |

An rGO/Cu3Se2 layered structure was

successfully synthesized onto an FTO substrate through the facile

electrodeposition process. A GO solution composed of Cu-EDTA provided a uniform

rGO film on the FTO substrate. The rGO layer provided active sites for Cu3Se2

growth and also prevented direct contact of the electrolyte with the FTO

substrate, which suppressed recombination. Pulsed electrodeposition resulted in

the stoichiometric formation of Cu3Se2 on rGO-modified

FTO. The deposition of Cu3Se2 on rGO modified FTO

achieved stability under ambient air conditions and a much more porous

structure than the direct formation of Cu3Se2 on FTO. A

strong dependence between the morphology and mass transfer of electrolytes was

observed. The porous structure induced the rGO layer to Cu3Se2

and led to the enhanced performance of the QDSSC from the increased FF and Jlim.

This work was supported by the 2019 Yeungnam University

Research Grant. This study was also supported by

the “Human Resources Program in Energy Technology” of

the Korea Institute of Energy Technology Evaluation and

Planning (KETEP), supported by the Ministry of Trade, Industry & Energy,

Republic of Korea (No. 20174030201760).

- 1. M.C. Beard, J.M. Luther, O.E. Semonin and A.J. Nozik, Acc. Chem. Res. 46[6] (2013) 1252-1260.

-

- 2. D.M. Chapin, C.S. Fuller and G.L. Pearson, J. Appl. Phys. 25[5] (1954) 676-677.

-

- 3. S. Kumar, M. Nehra, A. Deep, D. Kedia, N. Dilbaghi and K.-H. Kim, Renew. Sustain. Energy Rev. 73 (2017) 821-839.

-

- 4. P.V. Kamat, J. Phys. Chem. C. 112[48] (2008) 18737-18753.

-

- 5. F. Huang, J. Hou, H. Wang, H. Tang, Z. Liu, L. Zhang, Q. Zhang, S. Peng, J. Liu, and G. Cao, Nano Energy. 32 (2017) 433-440.

-

- 6. J. Tian, R. Gao, Q. Zhang, S. Zhang, Y. Li, J. Lan, X. Qu, and G. Cao, J. Phys. Chem. C. 116[35] (2012) 18655-18662.

-

- 7. F. Huang, J. Hou, Q. Zhang, Y. Wang, R. Massé, S. Peng, H. Wang, J. Liu, and G. Cao, Nano Energy. 26 (2016) 114-122.

-

- 8. I. Rauf and P. Rezai, Renew. Sustain. Energy Rev. 73 (2017) 408-422.

-

- 9. P.N. Kumar, A. Kolay, S.K. Kumar, P. Patra, A. Aphale, A.K. Srivastava and M. Deepa, ACS Appl. Mater. Interfaces. 8[41] (2016) 27688-27700.

-

- 10. B. Zhang, H. Yuan, X. Zhang, D. Huang, S. Li, M. Wang and Y. Shen, ACS Appl. Mater. Interfaces. 6[23] (2014) 20913-20918.

-

- 11. Y.-L Lee and C.-H. Chang, J. Power Sources. 185[1] (2008) 584-588.

-

- 12. H.K. Jun, M.A. Careem and A.K Arof, Int. J. Photoenergy. 2013 (2013) 1-10.

-

- 13. H.M. Choi, I.A. Ji and J.H. Bang, ACS Appl. Mater. Interfaces. 6[4] (2014) 2335-2343.

-

- 14. V.T. Chebrolu and H.-J. Kim, J. Mater. Chem. C. 7[17] (2019) 4911-4933.

-

- 15. Y. Zhu, S. Murali, W. Cai, X. Li, J.W. Suk, J.R. Potts and R.S. Ruoff, Adv. Mater. 22[35] (2010) 3906-3924.

-

- 16. L. Wang, J. Feng, Y. Tong and J. Liang, Int. J. Hydrog. Energy. 44[1] (2019) 128-135.

-

- 17. J. Ma, W. Shen and F. Yu, J. Power Sources. 351 (2017) 58-66.

-

- 18. S. Li, H. Min, F. Xu, L. Tong, J. Chen, C. Zhu and L. Sun, RSC Adv. 6[41] (2016) 34546-34552.

-

- 19. B. Yuan, Q. Gao, X. Zhang, L. Duan, L. Chen, Z. Mao, X. Li and W. Lü, Electrochim. Acta. 277 (2018) 50-58.

-

- 20. C.L.P. Pavithra, B.V. Sarada, K.V. Rajulapati, T.N. Rao and G. Sundararajan, Sci. Rep. 4[1] (2015) 4049.

-

- 21. A. Moysiadou, R. Koutsikou and M. Bouroushian, Mater. Lett. 139 (2015) 112-115.

-

- 22. B.B. Jin, Y.F. Wang, X.Q. Wang, and J.H. Zeng, Appl. Surf. Sci. 369 (2016) 436-442.

-

- 23. Y.-H. Lee, Y.-H. Yun, VHV. Quy, S.-H. Kang, H.S. Kim, E. Vijayakumar and K.-S. Ahn, Electrochim. Acta. 296 (2019) 364-371.

-

- 24. N.I. Kovtyukhova, P.J. Ollivier, B.R. Martin, T.E. Mallouk, S.A. Chizhik, E.V. Buzaneva, and A.D. Gorchinskiy, Chem. Mater. 11[3] (1999) 771-778.

-

- 25. Y. Mai, M. Zhou, H. Ling, F. Chen, W. Lian, and X. Jie, Surf. Sci. 433 (2018) 232-239.

-

- 26. V. Gonzalez-Pedro, X. Xu, I. Mora-Ser and J. Bisquert, ACS Nano. 4[10] (2010) 5783-5790.

-

- 27. H.J. Lee, M. Wang, P. Chen, D.R. Gamelin, S.M. Zakeeruddin, M. Grátzel, and M.K. Nazeeruddin, Nano Lett. 9[12] (2009) 4221-4227.

-

- 28. J. Yu, W. Wang, Z. Pan, J. Du, Z. Ren, W. Xuea and X. Zhong, J. Mater. Chem. A. 5[27] (2017) 14124-14133.

-

- 29. S. Pei and H.-M. Cheng, Carbon. 50[9] (2012) 3210-3228.

-

- 30. L. Li, J. Gong and W. Zhu, IOP Conf Ser Earth Environ Sci. 59[1] (2017) 012060.

-

- 31. D. Lippkow and H.H. Strehblow, Electrochim. Acta. 43[14-15] (1998) 2131-2140.

-

- 32. J. Sourice, A. Quinsac, Y. Leconte, O. Sublemontier, W. Porcher, C. Haon, A. Bordes, E.D. Vito, A. Boulineau, S.J. Larbi, N. Herlin-Boime, and C. Reynaud, ACS Appl. Mater. Interfaces. 7[12] (2015) 6637-6644.

-

- 33. A. Wang, W. Yu, Y. Fang, Y. Song, D. Jia, L. Long, M.P. Cifuentes, M.G. Humphrey and C. Zhang, Carbon. 89 (2015) 130-141.

-

- 34. S.H. Huh and S. Mikhailov, in “Physics and Applications of Graphene – Experiments” (IntechOpen, 2011) p. 73.

-

- 35. L. Zhou, X. Yang, B. Yang, X. Zuo, G. Li, A. Feng, H. Tang, H. Zhang, M. Wu, Y. Ma, S. Jin, Z. Sun and X. Chen, J. Power Sources. 272 (2014) 639-646.

-

- 36. A. Wei, L. Xiong, L. Sun, Y. Liu, W. Li, W. Lai, X. Liu, L. Wang, W. Huang and X. Dong, Mater. Res. 48[8] (2013) 2855-2860.

-

- 37. M.A. Pimenta, G. Dresselhaus, M.S. Dresselhaus, L.G. Cancado, A. Jorio and R. Saito, Phys. Chem. Chem. Phys. 9[11] (2007) 1276-1290.

-

- 38. A.G. Marrani, R. Zanoni, R. Schrebler, and E.A. Dalchiele, J. Phys. Chem. C. 121[10] (2017) 5675-5683.

-

- 39. N. Dukstiene, L. Tatariskinaite, M. Andrulevicius, Mater Sci-Poland. 28[1] (2010) 93.

- 40. R. Riaz, M. Ali, I.A. Sahito, A.A. Arbab, T. Maiyalagan, A.S. Anjum, M.J. Ko, S.H. Jeong, Appl. Sur. Sci. 480 (2019) 1035-1046.

-

- 41. R. Riaz, M. Ali, H. Anwer, M.J. Ko, S.H. Jeong, J. Colloid Interface Sci. 557 (2019) 174-184.

-

This Article

This Article

-

2020; 21(S1): 33-40

Published on May 31, 2020

- 10.36410/jcpr.2020.21.S1.s33

- Received on Dec 19, 2019

- Revised on Mar 31, 2020

- Accepted on Apr 14, 2020

Services

Services

- Abstract

introduction

experimental section

results and discussion

conclusion

- Acknowledgements

- References

- Full Text PDF

Shared

Correspondence to

Correspondence to

- Kwang-Soon Ahn

-

School of Chemical Engineering, Yeungnam University, Gyeongsan 712-749, Republic of Korea

Tel : +82-53-810-2524

Fax: +82-53-810-4631 - E-mail: kstheory@ynu.ac.kr

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.