- Enhanced optical output power of AlGaN/GaN ultraviolet light-emitting diodes fabricated with breakdown induced conductive channels

Seonghoon Jeonga, Sung-Nam Leeb, Chel-Jong Choia,* and Hyunsoo Kima,*

aSchool of Semiconductor and Chemical Engineering, Semiconductor Physics Research Center, Jeonbuk National University, Jeonju 54896, Korea

bDepartment of Nano-Optical Engineering, Korea Polytechnic University, Siheung 15073, Korea

The enhanced optical output

power of AlGaN/GaN deep ultraviolet light-emitting diodes (UV LEDs) were

demonstrated by using the breakdown-induced conductive channels (BICCs). The

BICCs could be made by electrical reverse biasing between two adjacent contact

pads formed on top p-type layers with a certain distance, causing an electrical

breakdown of pn junction and hence a generation of conductive channels.

Accordingly, the reflective Ni/Ag/Pt electrodes could be formed simultaneously

on the top p-type layer and the other p-type layer with the BICCs, acting as

the p- and n-contacts, respectively. The deep UV LEDs fabricated with the BICCs

produced the enhanced optical output power by 15% as compared to the reference

LEDs, which were fabricated with the conventional Ti/Al/Ti/Au layers formed on

mesa-etched n-type layer. This could be due to the reduced light absorption at

the n-contact pads, indicating that the use of BICCs will be very suitable for

obtaining better output performance of deep UV emitters.

Keywords: Ultraviolet, Light emitting diodes, Breakdown-induced conductive channels, AlGaN/GaN

GaN-based light-emitting diodes (LEDs) are being widely

used in a variety of applications such as displays, mobile

communications, automotive lighting and interior/exterior

lighting [1-3]. Recently, the deep ultraviolet light-emitting diodes (UV LEDs)

fabricated with the AlGaN/GaN-based materials have drawn considerable attention

owing to their potential applications with an extremely short emission

wavelength of ~260 nm such as sterilization, medical treatment, purification,

and bioindustry [4-7]. However, for faster commercialization,

it is still necessary to improve the external quantum efficiency or to increase

the optical output power of UV LEDs [1-7].

According to the literatures [8-14], the deep UV LEDs

were found to suffer from very poor light extraction efficiency. This was due

to the strong light absorption through the top p-GaN contact layer

[8-10], the anisotropic optical polarization nature of AlGaN-based

materials [8, 11, 12], and a significant total internal reflection

occurring as a result of a large difference in the refractive indices between

AlGaN-based semiconductors and substrate or air [8], [13-14].

Therefore, because the light experiences multiple internal reflections within a

chip, it is quite crucial to suppress the absorption of trapped light by

avoiding highly absorptive materials such as electrodes. The conventional metal

electrodes used in the deep UV LEDs are Ag- and Ti/Al-based schemes as a

reflective p-contact and a n-contact, respectively, because they are very

suitable for the formation of Ohmic contact upon thermal annealing. However,

the thermally annealed Ti/Al-based n-contacts are

generally known to have lower optical reflectivity against the Ag.

Very recently, our group showed that the reverse breakdown

mechanism of GaN-based LED, namely, the defect-assisted Zener breakdown. More

specifically, the reverse biasing of GaN p-n junction wan shown to induce a

local breakdown through the native crystal defects such as V-pits.

Interestingly, this phenomenon resulted in a formation of conductive channels,

which is so-called the breakdown-induced conductive channels

(BICCs). By using BICCs, AC-controllable light-emitting devices without any

AC–DC converter [15] or the flat-type InGaN-based LEDs without an n-contact

electrode [16] could be demonstrated.

In this study, based on the BICCs method, we attempted to

use the reflective Ni/Ag/Pt contact as the p- and n-electrodes for AlGaN/GaN deep

UV LEDs simultaneously. By using the BICCs, the Ni/Ag/Pt contact could be

served as the n-type electrodes as well as p-electrodes. The deep UV LEDs

fabricated with the BICCs produced the enhanced optical output power by 15% as

compared to the reference LEDs. This could be attributed to the reduced light

absorption at the n-contact by 65%. These results indicate that the use of

BICCs will be very suitable for obtaining better output performance

of deep UV emitters as well as for reducing the process

step of metal deposition.

To fabricate the deep UV LEDs, commercially available

AlGaN/GaN wafers (the peak emission wavelength of 273 nm) grown on c-plane

sapphire substrate by metalorganic chemical vapor deposition were

used. The structure of UV LEDs consisted of n-type AlGaN cladding layer, five

periods of AlGaN/AlGaN multiple quantum wells, p-type AlGaN cladding

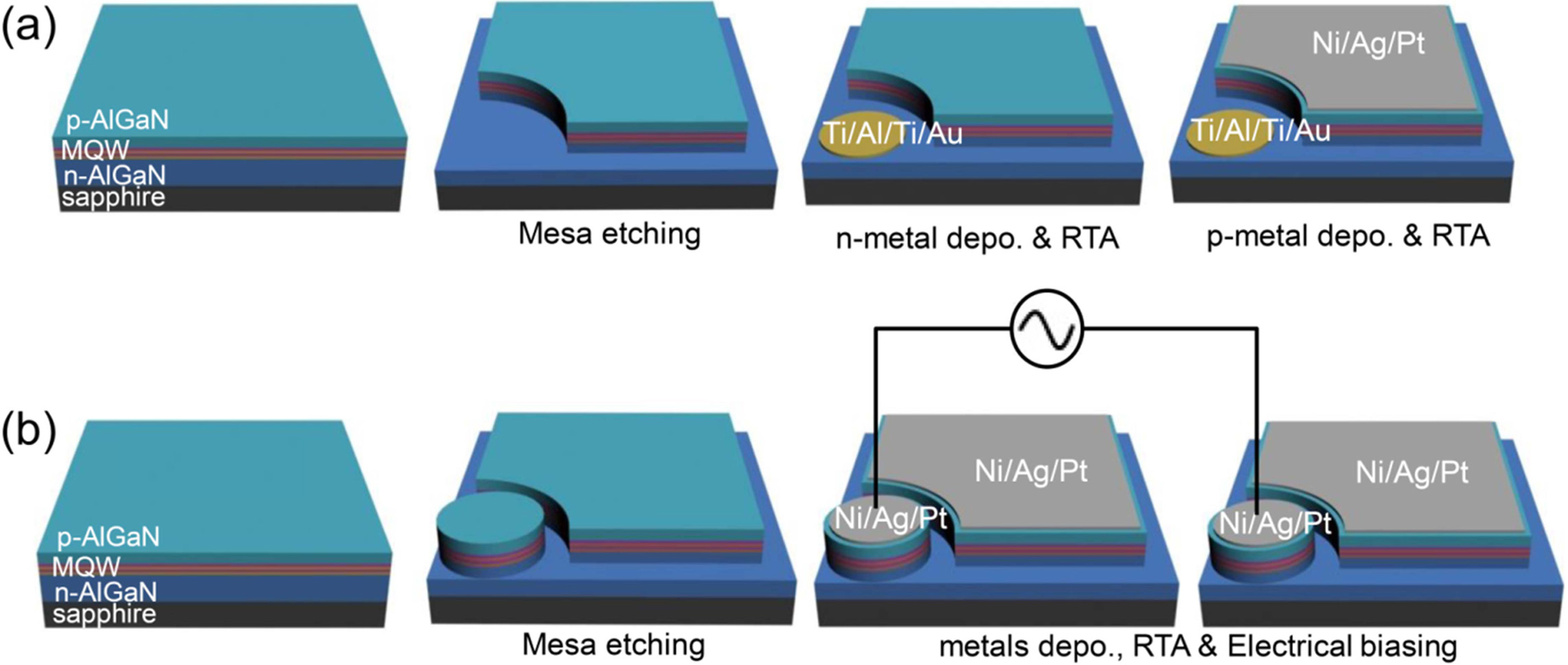

layer, and a p-type GaN contact layer. Fig. 1(a) shows the schematic

fabrication procedure of reference UV LEDs. For device fabrication, the mesa was defined

by conventional photolithography and dry

etching by inductively coupled plasma

reactive ion etching system. The etching depth was about 400 nm. As the

n-electrode, the 20/60/20/100

nm-thick Ti/Al/Ti/Au layers were then e-beam evaporated on the exposed n-AlGaN

layer, followed by rapid thermal annealing (RTA) at 950 oC for

1min in N2. As the p-electrodes, 2/200/30 nm-thick Ni/Ag/Pt layers

were deposited on p-AlGaN, followed by RTA at 550 oC for 1 min

in air. In addition, the schematic fabrication procedure of UV LEDs having

BICCs (referred hereto as ‘BICCs-LEDs’) is shown in Fig. 1(b). First, the mesa

was also defined by dry etching, while it should be noted that the small

circular mesa was additionally defined at the expected position of n-electrodes. Then, the Ni/Ag/Pt layers were

deposited on the top of each mesa simultaneously, followed by

RTA at 550 oC for 1 min in air. To generate the BICCs, the alternating electrical biasing

(± 15 V with a compliance current of 40 mA) was performed between

two adjacent contact pads, in which the electrical junction breakdown occurs.

To investigate the contact properties, transmission line model (TLM) patterns

were also formed on the same wafer [17], in which the same method to generate

BICCs was carried out. The electrical and optical characteristics of the

fabricated devices were measured using a probestation system with parameter

analyzer (HP4156A), photodiode (883-UV),

and optical spectrometer (Ocean Optics USB2000).

|

Fig. 1 Schematic fabrication procedures for (a) reference LEDs and (b) BICCs-LEDs. |

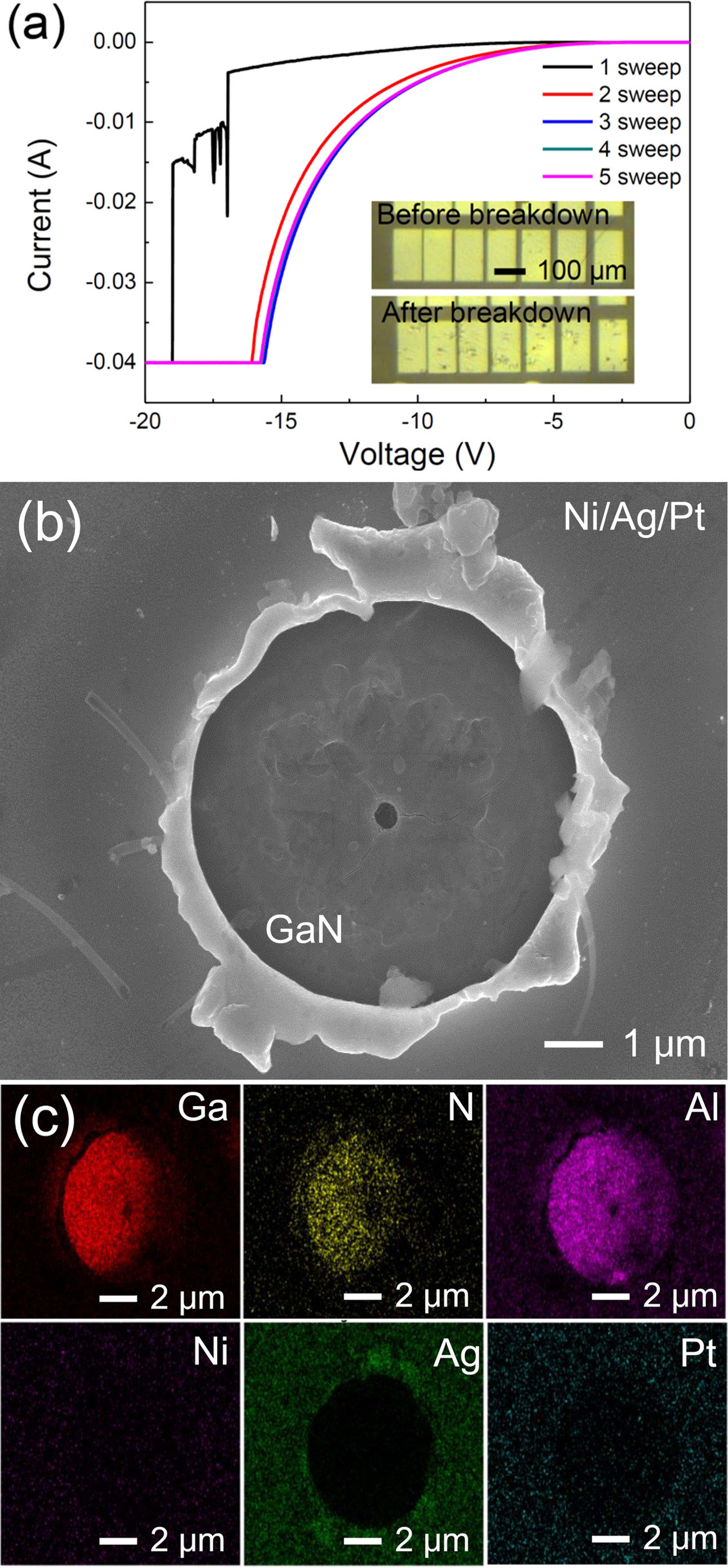

Fig. 2(a) shows the current-voltage (I-V) curves of

Ni/Ag/Pt contact formed on the top p-GaN layer as a function of reverse

biasing. For this study, the TLM patterns having the pattern size of

200 × 100 mm2 and a pad spacing of 5 μm was used (see the

inset of Fig. 2(a)). Note that the junction breakdown occurs at reverse

voltage lower than -15 V with the first I-V sweep.

The additional I-V sweeps produced an insignificant change of I-V

curve, i.e., the generation of BICCs originating from the junction breakdown through the

V-defects were nearly saturated [15, 18, 19]. As shown in the inset of Fig.

2(a), a number of black spots were observed after electrical reverse biasing.

The measurements of SEM and EDX mapping on this black spot showed

that, first, the metal electrode is exploded and, second, the BICCs were formed

through the epitaxial V-defects [15] (Fig. 2(b)). The explosion and hence the peeling-off phenomenon of metal

electrode seems to be due to the

extremely large electrical resistivity of AlGaN epitaxial films [20].

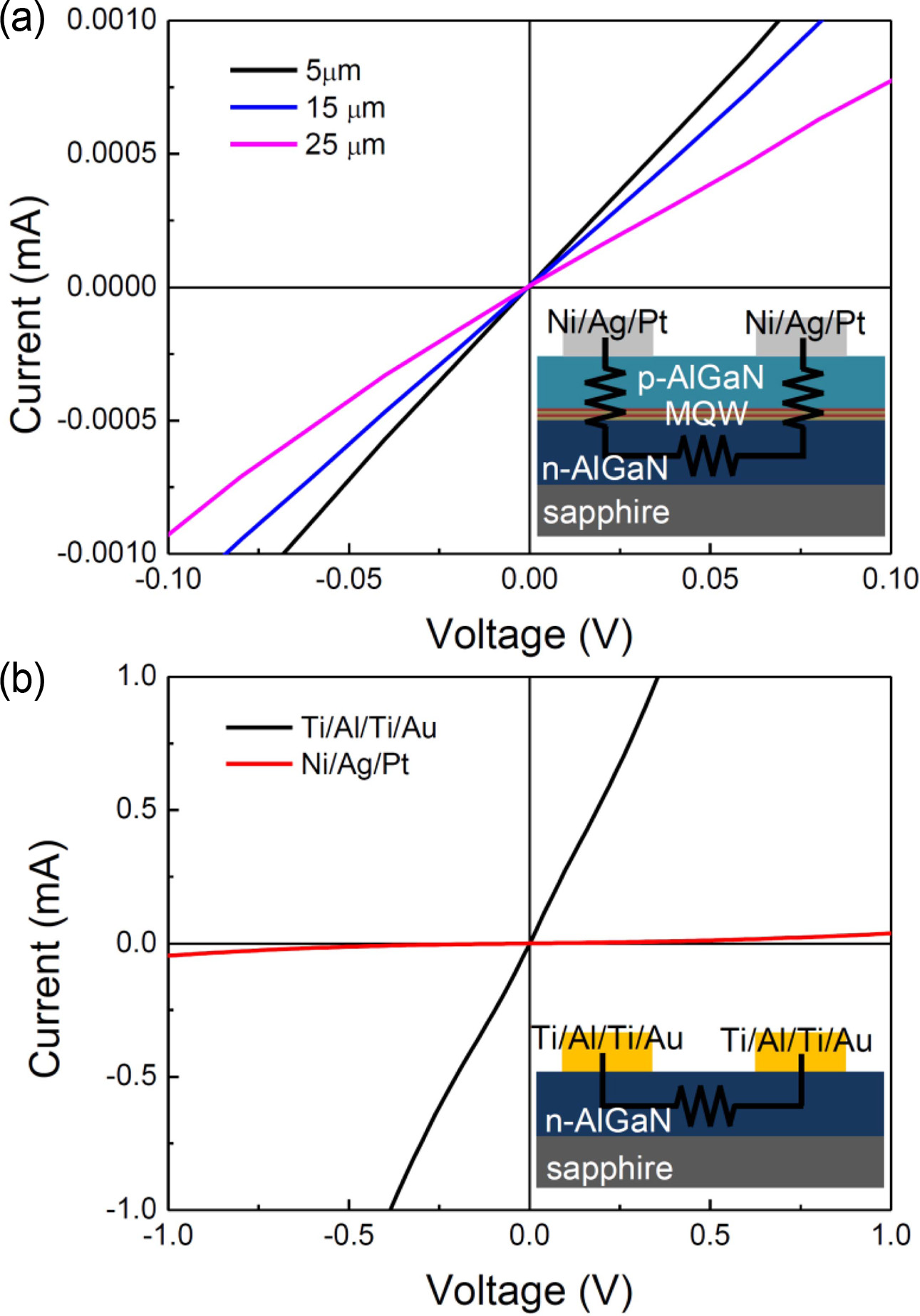

Fig. 3(a) shows I-V characteristics of the Ni/Ag/Pt

contact formed on BICCs as a function of the pad spacing. The I-V

curves showed a pad-spacing dependence, indicating that the TLM

method is valid [17]. However, the current level of contact was quite low,

resulted in the very high specific contact resistance (ρsc)

of 0.61 Ωcm2. This indicates that, although the BICCs resulted in a

current flow across junction from the top p-layer to bottom n-layer (see the

inset of Fig. 2(b)), the amount of current flow is insufficient, i.e., the

density of electrical conduction path is limited. Indeed, this is different

from our previous findings that the generation of BICCs led to a significant

current flow across the junction in the InGaN/GaN-based blue LEDs [15]. As

shown in Fig. 2(b), this is presumably due to the peeling-off of metal

electrode after BICCs formation, i.e., the although the BICCs is

generated, the conduction through BICCs would be very limited due

to the absence of metal contacts.

Fig. 3(b) shows the I-V curves of Ni/Ag/Pt formed

on BICCs and the conventional Ti/Al/Ti/Au formed on n-AlGaN layer (mesa etched

surface), where the pad spacing was 5 mm. The current flow of conventional

Ti/Al/Ti/Au contact is schematically drawn as shown in the inset of Fig. 3(b).

It is clear that the Ti/Al/Ti/Au formed on n-AlGaN layer has much steeper I-V

curve than the Ni/Ag/Pt formed on BICCs. Accordingly, the specific contact

resistance of Ti/Al/Ti/Au on n-AlGaN was measured to be

8.48 × 10-3 Ωcm2.

This result indicates that the contact properties of

Ni/Ag/Pt on BICCs still need to be further improved by optimizing the density

of BICCs.

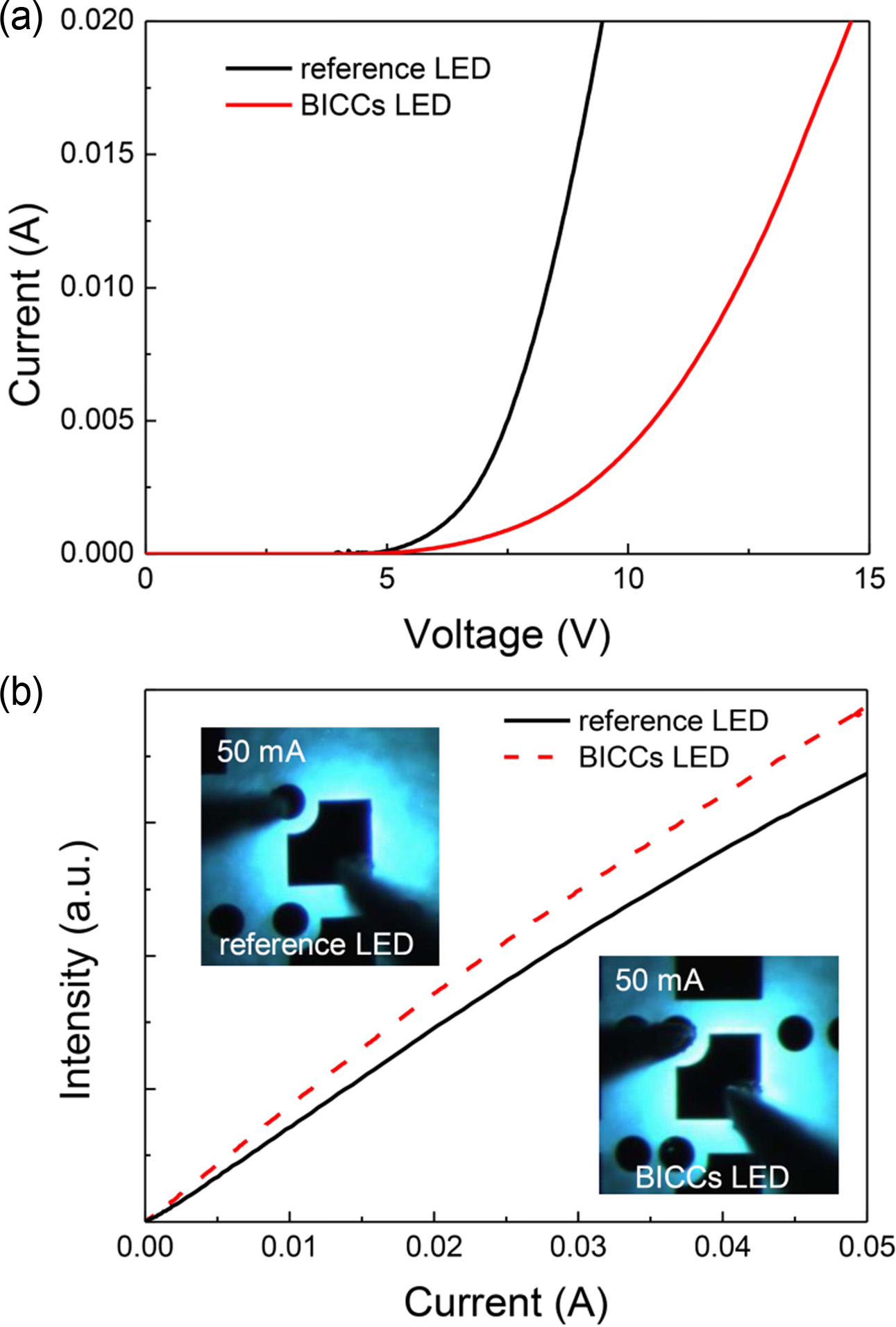

Fig. 4(a) shows the I-V curves of the reference

LEDs and the BICCs-LEDs. Consistently, the reference LEDs showed superior I-V

curves against the BICCs-LEDs. For example, the forward voltages

measured at injection current of 20 mA were 9.4 V and 14.6

V for the reference LEDs and BICCs-LEDs, respectively. This is essentially due

to the worse contact properties of Ni/Ag/Pt on BICCs over the Ti/Al/Ti/Au on

n-AlGaN.

Nevertheless, the optical output properties of the

BICCs-LEDs were significantly improved as compared to the reference LED (Fig.

4(b)). For example, the optical output power of BICCs-LEDs was about 15% higher

than that of the reference LEDs when measured at injection current 50 mA. Here,

the optical output power was measured using the photodiodes, which were placed

bottom side of LED wafers. A noticeable output enhancement is attributed to the

higher optical reflectivity of thermally annealed Ni/Ag/Pt contact than that of

annealed Ti/Al/Ti/Au.

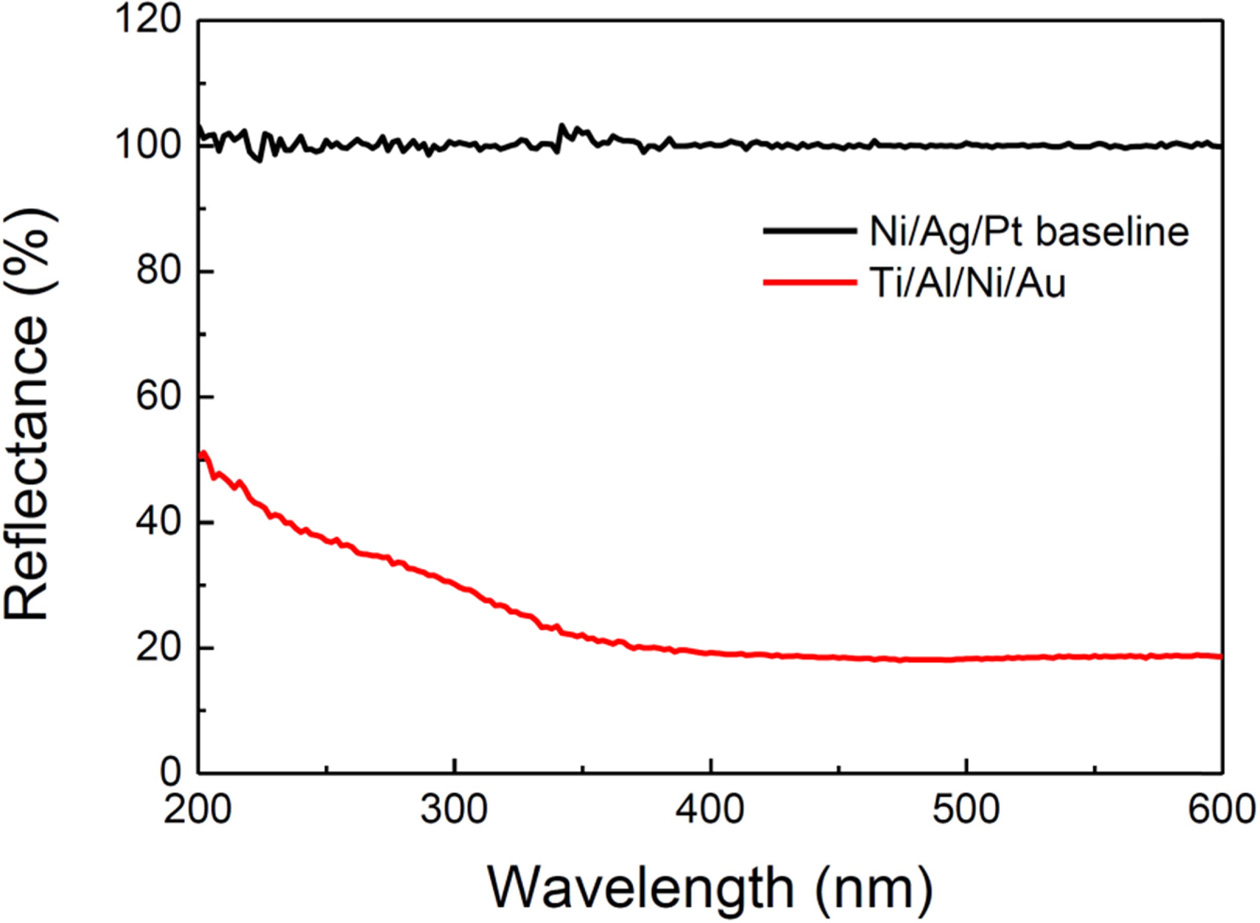

Indeed, it is generally known that the optical

reflectivity of Ag is highest among metals in the

visible wavelength range (> 400 nm) [21].

However, the optical reflectivity of Ag drops significantly at the

wavelength below 400 nm. On the one hand, the Al metal is known to show the

highest optical reflectivity at the deep UV wavelength range

(< 300 nm), while the Ti has poor reflectivity. However, it should be

noted that the metal electrodes are thermally annealed for the formation of

Ohmic contact. During the annealing process, each metal can interdiffuse

depending on their thermodynamic tendency. In

other words, this indicates that the optical reflectivity of

electrodes should be compared after thermal annealing. Fig.

5 shows the relative optical reflectance spectra of thermally annealed Ni/Ag/Pt

and Ti/Al/Ti/Au prepared on both-side polished sapphire

substrates. For this measurements, the optical reflectance spectra of annealed

Ni/Ag/Pt were set as the base line of 100%. Note that, at the wavelength of 273

nm, the optical reflectance of annealed Ni/Ag/Pt was ~65% higher

than that of annealed Ti/Al/Ti/Au. Therefore, the enhanced

optical output power of BICCs-LEDs is explained.

|

Fig. 2 (a) I-V curves of Ni/Ag/Pt contact formed on the top p-GaN layer as a function of reverse biasing. The inset shows the optical microscopic image of the TLM patterns before and after breakdown. (b) SEM image and (c) EDX mapping images of TLM patterns after breakdown by reverse biasing. |

|

Fig. 3 (a) I-V characteristics of the Ni/Ag/Pt contact formed on BICCs-generated conduction layer as a function of the pad spacing. The inset shows the schematic cross-sectional diagram of current flow across BICCs. (b) I-V curves of Ni/Ag/Pt formed on BICCs and the conventional Ti/Al/Ti/Au formed on n-AlGaN layer. The inset shows the schematic current flow of conventional n-contact. |

|

Fig. 4 (a) Typical I-V curves of reference LEDs and BICCs-LEDs. (b) The optical output power verse current curve of reference LEDs and BICCs-LEDs. The inset show the EL image of both LEDs taken at injection current of 50 mA. |

|

Fig. 5 The relative optical reflectance spectra of thermally annealed Ni/Ag/Pt and Ti/Al/Ti/Au electrodes. |

In summary, the optical output power of AlGaN/GaN deep UV

LEDs could be improved by using reflective Ni/Ag/Pt contact and BICCs. By using

BICCs, the Ni/Ag/Pt contacts could be used as the p- and n-type electrodes

simultaneously. Besides the simpler and cost-comparative

process step, the Ni/Ag/Pt contact showed much higher optical reflectivity than

the reference Ti/Al/Ti/Au contact. Accordingly, the UV LEDs

fabricated with the Ni/Ag/Pt and BICCs produced 15% higher optical

output power than the reference LEDs. This indicates that, if the electrical

contact properties are further improved, the BICCs method combined with the use

of reflective metal contact would be promising for improving the output

efficiency of deep UV LEDs.

This work was supported by Samsung Research Funding Center

of Samsung Electronics under Project Number SRFC-IT1501-06, and by the

Technology Innovation Program (Leading design of future environment

products using advanced photocatalytic purification sterilization

technology) (Project No. 20006767) funded by the

Ministry of Trade, Industry & Energy, Republic of Korea.

- 1. M. R. Krames, O. B. Shchekin, R. Mueller-Mach, G. O.Mueller, L. Zhou, G. Harbers, and M. G. Craford, J. Disp. Technol. 3 (2007) 160-175.

-

- 2. S. Nakamura, T. Mukai, and M. Senoh, Jpn. J. Appl. Phys. 30 (1991) L1708-L1711.

-

- 3. J. J. Wierer, D. A. Steigerwald, M. R. Krames, J. J. O’Shea, M. J. Ludowise, G. Christenson, Y. C. Shen, C. Lowery, P. S. Martin, S. Subramanya, W. G. W. Götz, N. F. Gardner, R. S. Kern, and S. A. Stockman, Appl. Phys. Lett. 78[22] (2001) 3379-3381.

-

- 4. H. Kudo, M. Sawai, Y. Suzuki, X. Wang, T. Gessei, D. Takahasho, T. Arakawa, and K. Mitsubayashi, Sens. Actuator B-chem. 147 (2010) 676-680.

-

- 5. J. Close, J. Ip, K. H. Lam, Renew. Energy 31 (2006) 1657-1664.

-

- 6. J. L. Shie, C. H. Lee, C. S. Chiou, C. T. Chang, C. C. Chang, C. Y. Chang, J. Hazard. Mater. 155 (2008) 164-172.

-

- 7. M. Kneissl, T. Seong, J. Han, and H. Amano, Nat. Photonics 13 (2019) 233-244.

-

- 8. Y. Cuo, J. Yan, Y. Zhang, J. Wang, and J. Li, J. Nano- photonics 12[4] (2018) 043510.

-

- 9. H. Ryu, I. Choi, H. Choi, and J. Shim, Appl. Phys. Express 6 (2013) 062101.

-

- 10. M. Akiba, H. Hirayama, Y. Tomita, Y. Tsukada, N. Maeda, and N. Kamata, Phys. Status Solidi C. 9[3/4] (2012) 806-809.

-

- 11. P. Dong, J. Yan, Y. Zhang, J. Wang, C. Geng, H. Zheng, X. Wei, Q. Yan, and J. Opt. Express 22[S2] (2014) A320-A327.

-

- 12. S. Zhao, M. Djavid, and Z. Mi, Nano Lett. 15[10] (2015) 7006-7009.

-

- 13. N. Maeda and H. Hirayama, Phys. Status Solidi C 10[11] (2013) 1521-1524.

-

- 14. M. Shatalov, W. Sun, A. Lunev, X. Hu, A. Dobrinsky, Y. Bilenko, J. Yang, M. Shur, R. Gaska, and C. Moe, Appl. Phys. Express 5[8] (2012) 082101.

-

- 15. S. Han, S. Baek, H. Lee, H. Kim, and S. Lee, Sci. Rep. 8 (2018) 16547.

-

- 16. S. Baek, H. Lee, and S. Lee, Sci. Rep. 9 (2019) 13654.

-

- 17. G. K. Reeves and H. B. Harrison, IEEE Electron. Device Lett. 3(1982) 111-113.

-

- 18. X. H. Wu, C. R. Elsass, A. Abare, M. Mack, S. Keller, P. M. Petroff, S. P. DenBaars, and J. S. Speck, Appl. Phys. Lett. 72 (1998) 692-694.

-

- 19. H. K. Cho and J. Y. Lee, Appl. Phys. Lett. 79 (2001) 215-217.

-

- 20. S. Jeong, M. S. Kim, S. Lee, and H. Kim, Mat. Sci. Semicon. Proc. 90 (2019) 72.

-

- 21. H. Kim, K. H. Baik, J. Cho, J. W. Lee, S. Yoon, H. Kim, S. Lee, C. Sone, Y. Park, and T. Seong, IEEE Photonics Technol. Lett. 19 (2007) 336-338.

-

This Article

This Article

-

2020; 21(S1): 23-27

Published on May 31, 2020

- 10.36410/jcpr.2020.21.S1.s23

- Received on Dec 13, 2019

- Revised on Apr 24, 2020

- Accepted on May 4, 2020

Services

Services

- Abstract

introduction

experimental

results and discussion

conclusions

- Acknowledgements

- References

- Full Text PDF

Shared

Correspondence to

Correspondence to

- Chel-Jong Choi and Hyunsoo Kim

-

School of Semiconductor and Chemical Engineering, Semiconductor Physics Research Center, Jeonbuk National University, Jeonju 54896, Korea

Tel : +82-63-270-3974

Fax: +82-63-270-3585 - E-mail: cjchoi@jbnu.ac.kr, hskim7@jbnu.ac.kr

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.